Ship flange integration propulsion device

A propeller and rim technology, applied in the field of ship rim integrated propulsion, can solve the problems of poor sealing performance, prone to water leakage, loud noise and wake vortex, etc., and achieves low operating noise, good sealing effect and high propulsion efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

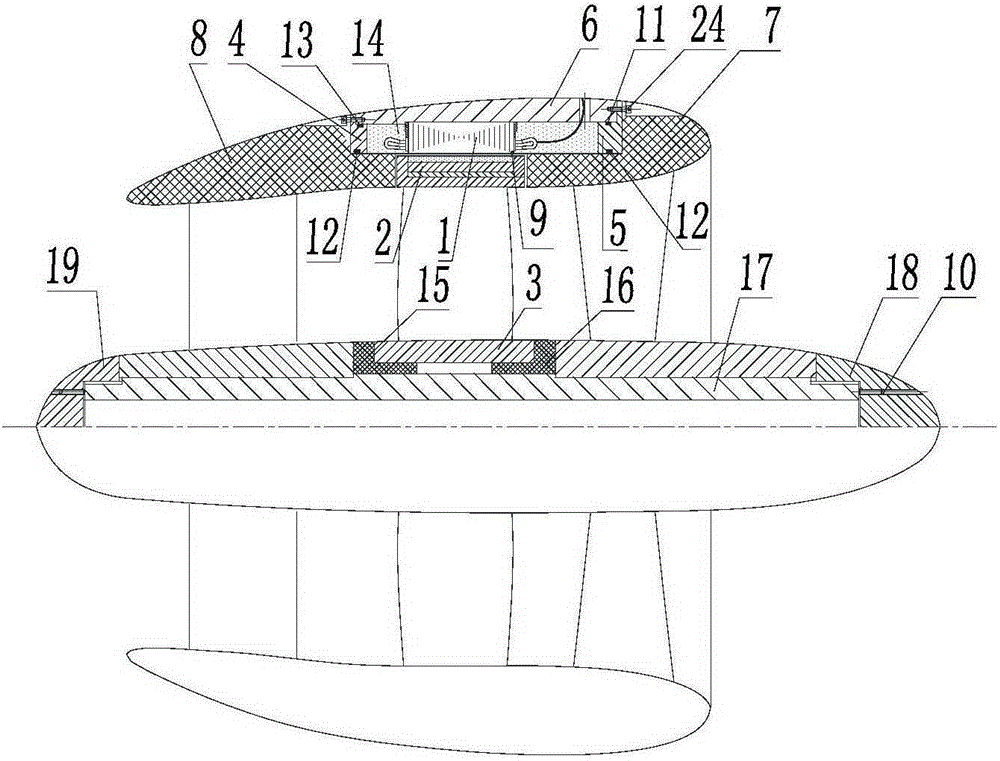

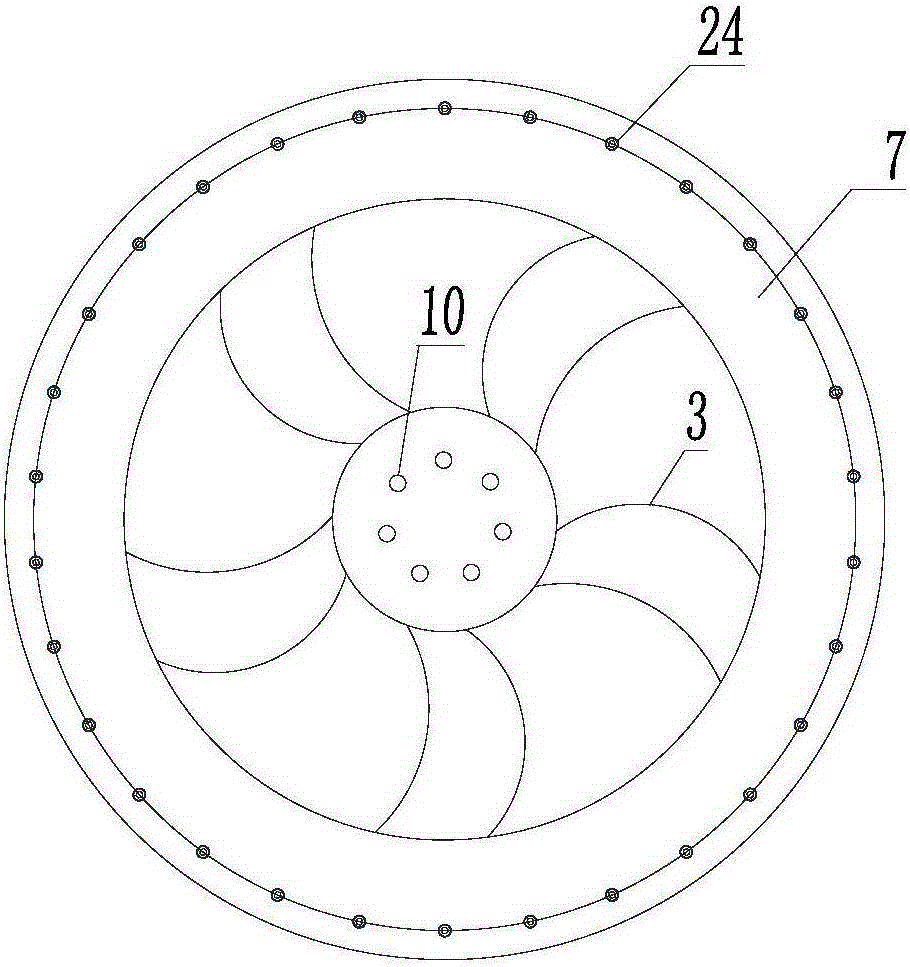

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings. Such as figure 1 , figure 2 As shown, the ship rim integrated propeller of the present invention includes a motor stator assembly 1, a motor rotor assembly 2, a propeller assembly 3, a conduit 6, a rear shroud 8, a front shroud 7, a first water Lubricated bearing 16, the second water-lubricated bearing 15, shaft 17, rear propeller hub cap 19, front propeller hub cap 18, front shroud connecting plate, rear shroud connecting plate, front end cover 5, rear end cover 4 and glass fiber reinforced plastics sleeve 9;

[0042] The above-mentioned motor stator assembly 1 is in the shape of a ring as a whole, and its outer peripheral surface forms an interference fit with the inner wall surface of the above-mentioned conduit 6, and is installed at the inner axial middle position of the above-mentioned conduit;

[0043] The above-mentioned propeller assembly 3, the front wind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com