Method for processing composite fiber material spiral stirrup

A composite fiber and spiral stirrup technology is applied in the processing field of composite fiber material spiral stirrups, which can solve the problems of difficult to grasp the size, increase the overall weight of the building, consume a lot of manpower and time, and achieve obvious energy saving effect and material saving. , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

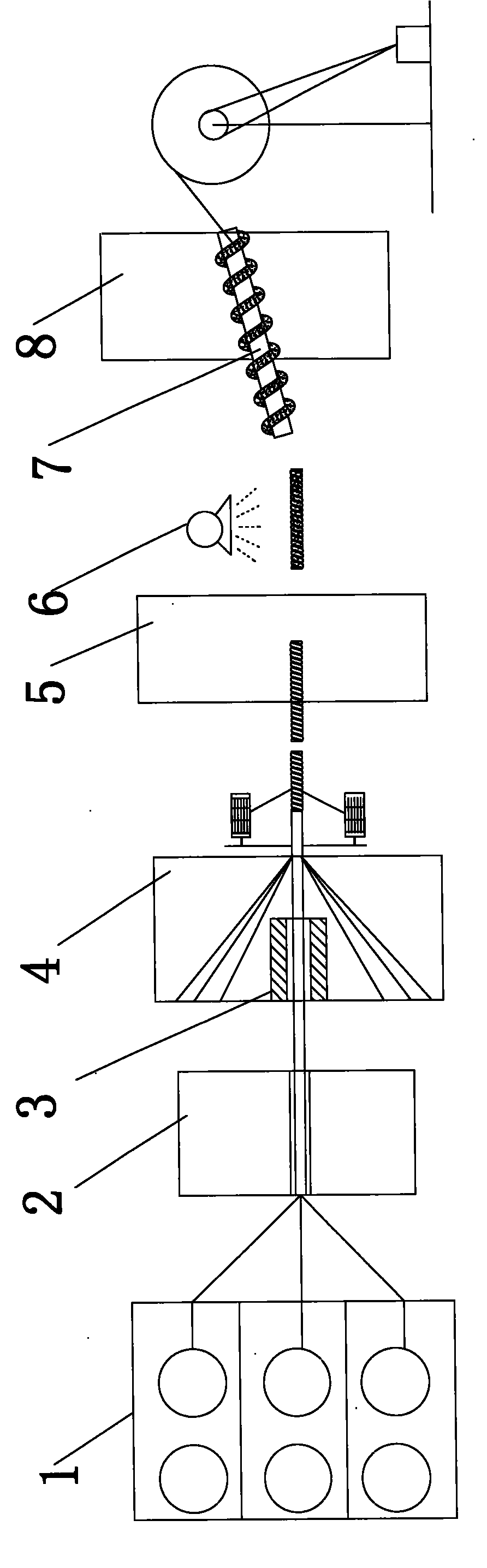

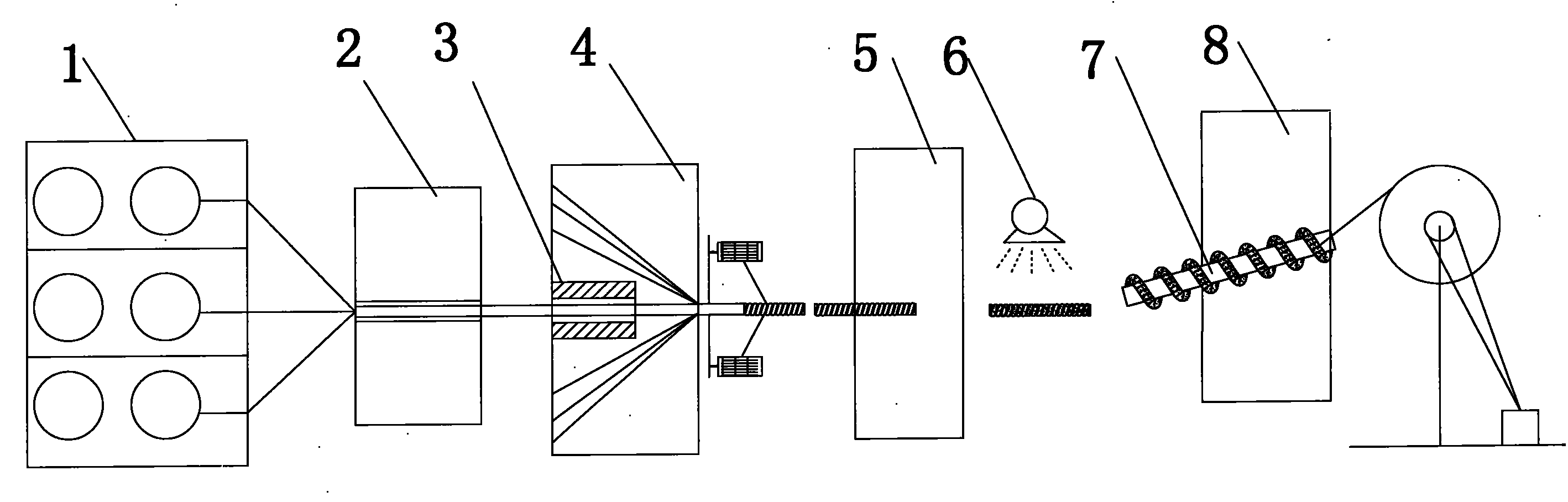

[0020] The present invention will be further explained below in conjunction with the accompanying drawings.

[0021] Manufacture a glass fiber spiral stirrup with a diameter of 20 mm and a weight of 570 g, wherein the glass fiber content is 427.5 g, accounting for 75% of the total weight, and the resin content is 25%, which is 142.5 g.

[0022] (1) Dipping: take 89 pieces of 4800tex pultruded glass fiber yarn, arrange the glass fiber yarn on the creel 1 according to its length direction; lead the glass fiber material yarn from the creel 1, and use pultrusion The process organizes all the fiberglass yarns into a large bundle and then impregnates them in the resin binder tank 2. The resin used is epoxy resin, and the model produced by Baling Petrochemical Co., Ltd. is 128. During deployment, the curing agent and accelerator provided by the company are used, and the consumption is respectively 5% of the total weight of epoxy resin.

[0023] If it needs to be used in flame-retard...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com