Patents

Literature

344results about How to "Realize mechanized production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coarse cereal instant rice and preparation method thereof

ActiveCN103564344ABlocking stickingPrevent too softFood ingredient functionsFood preparationPearl barleyGram

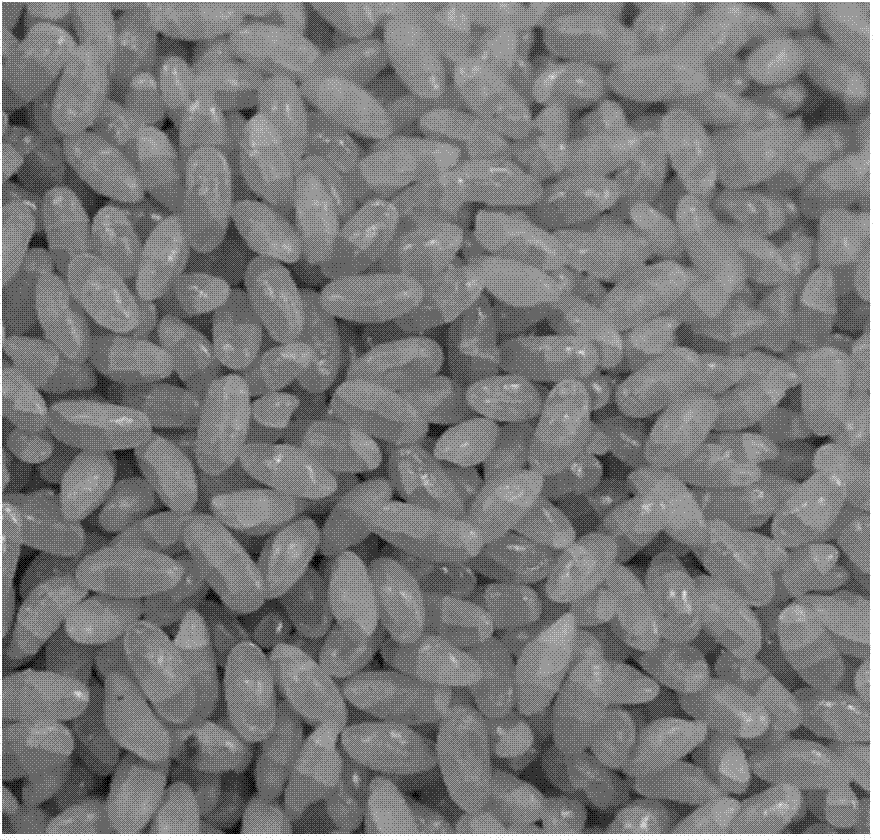

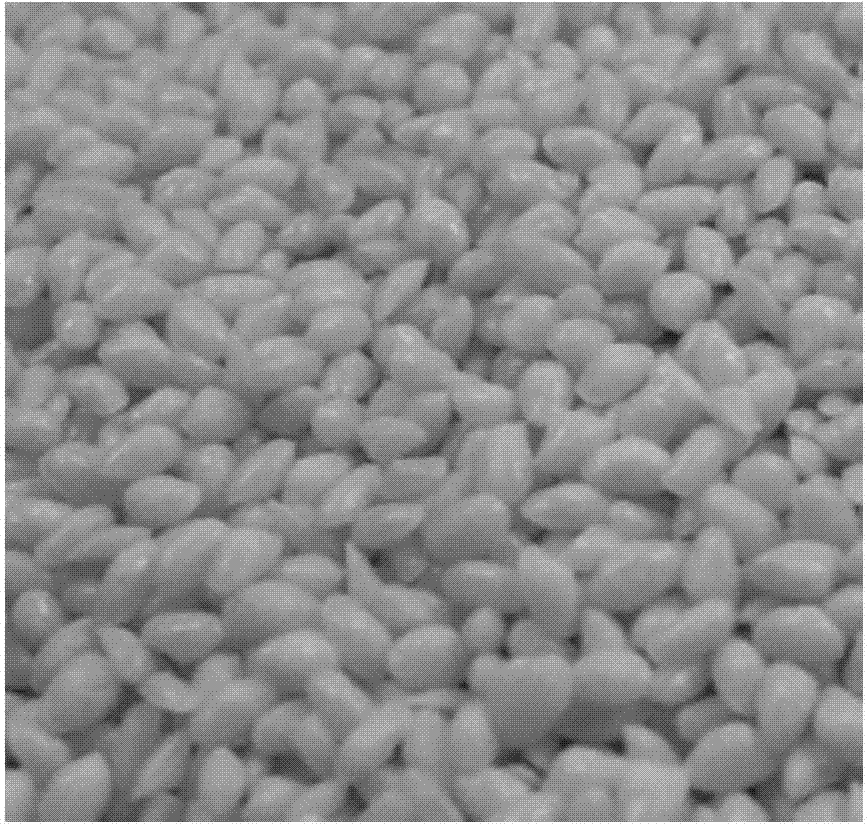

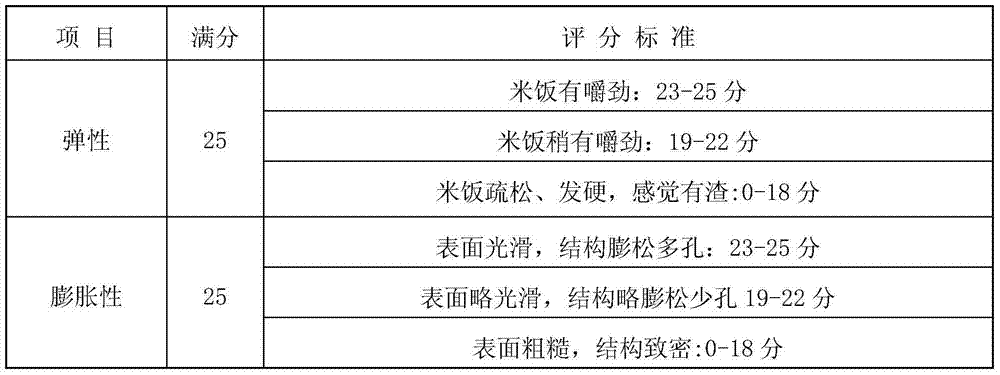

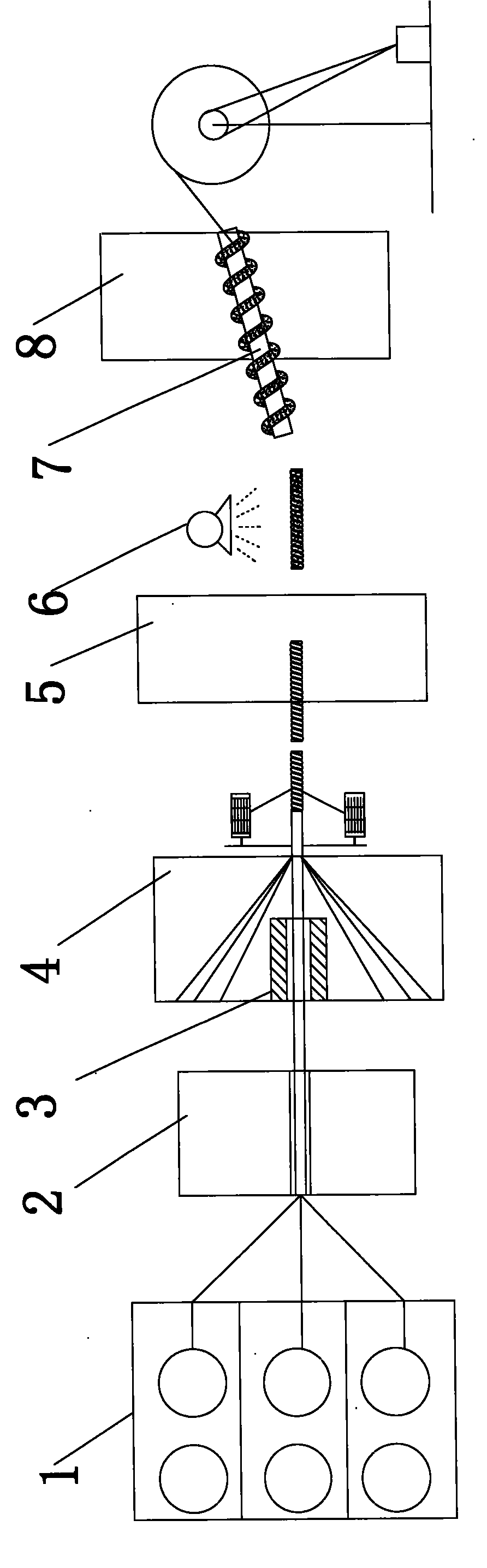

The invention discloses a coarse cereal instant rice and a preparation method of the coarse cereal instant rice. The coarse cereal instant rice is mainly prepared by conducting extrusion curing, cutting, pelletizing, drying, then baking and puffing on coarse cereal powder, starch and solid vegetable oil, wherein the coarse cereal is selected from one or combination of corn flour, rice flour, sorghum flour, buckwheat, pearl barley flour, black rice four, sweet potato flour, millet flour, coarse rice powder, glutinous rice flour, red rice flour, soybean flour, red bean flour, green gram starch, black bean flour, oat powder and wheat flour. The coarse cereal instant rice provided by the invention adopts a loose porous structure inside, so that the coarse cereal instant rice is good for digesting and absorbing and is excellent in rehydration property, the rehydration time is relatively short, the rehydrated rice is in full grain, and the coarse cereal instant rice is chewy and not hard or sticky when being eaten.

Owner:王金玺

Method for processing composite fiber material spiral stirrup

The invention discloses a method for processing composite fiber material spiral stirrup. The method comprises the following steps of: gumming, premolding, semi-solidifying and drying, molding spiral stirrup, sizing and drying, and cutting and packaging. In the multiturn continuous closed-type composite material spiral stirrup of the invention, the continuous spiral composite material stirrup replaces the single-ring composite material stirrup, so that the spiral stirrup can save materials and man-hours in the same member, resists corrosion, and can also improve the bearing capacity of a girder or a column under the condition of constant section and equal spacing; the tensile strength of the composite material stirrup is three times that of steel bar; the weight is only one-fourth that of the steel bar; and the composite material stirrup has the advantages of no magnetism, water resistance, freeze resistance, strong chemical corrosive resistance and the like; and due to the adoption of a process for molding the composite fiber material spiral stirrup, the disadvantage that a conventional composite material is difficult to bend into the stirrups with different shapes after solidification and sizing is overcome, and the shape of the composite material steel bar can be changed so as to manufacture the spiral stirrup according to the requirements of people.

Owner:沈锋

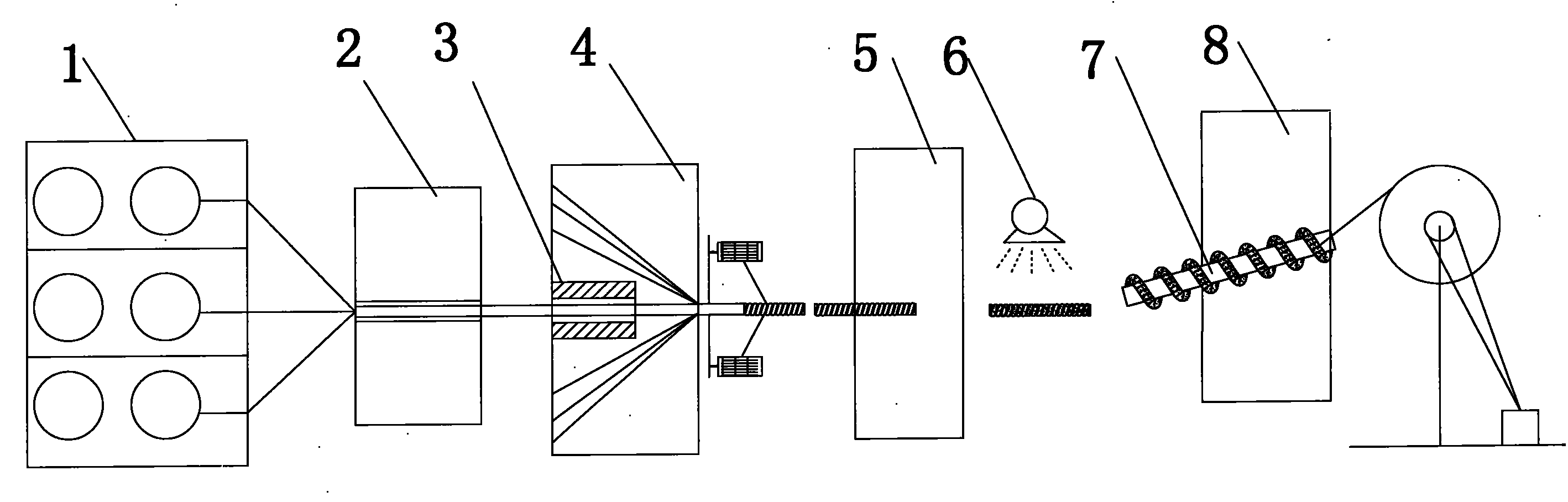

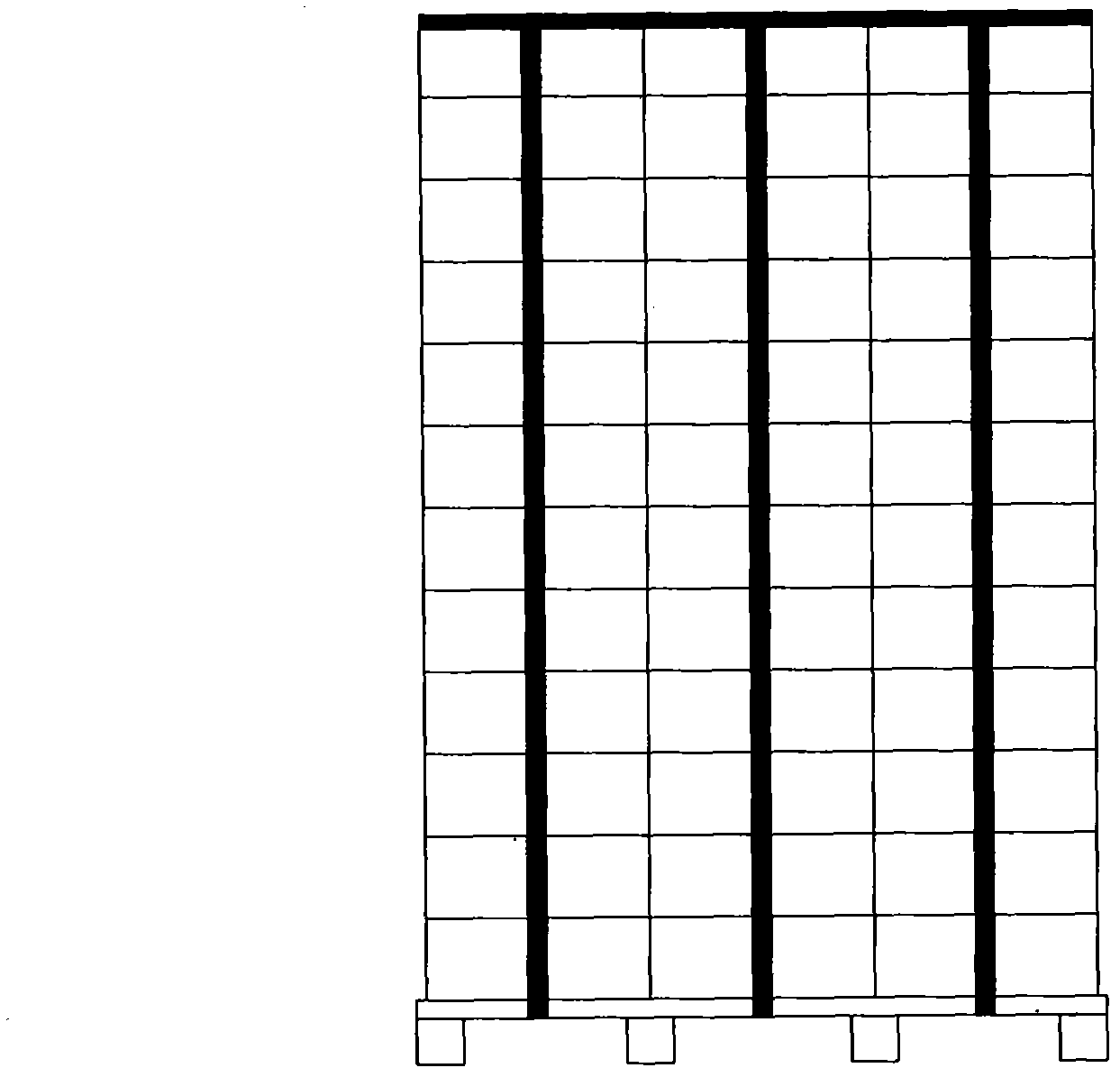

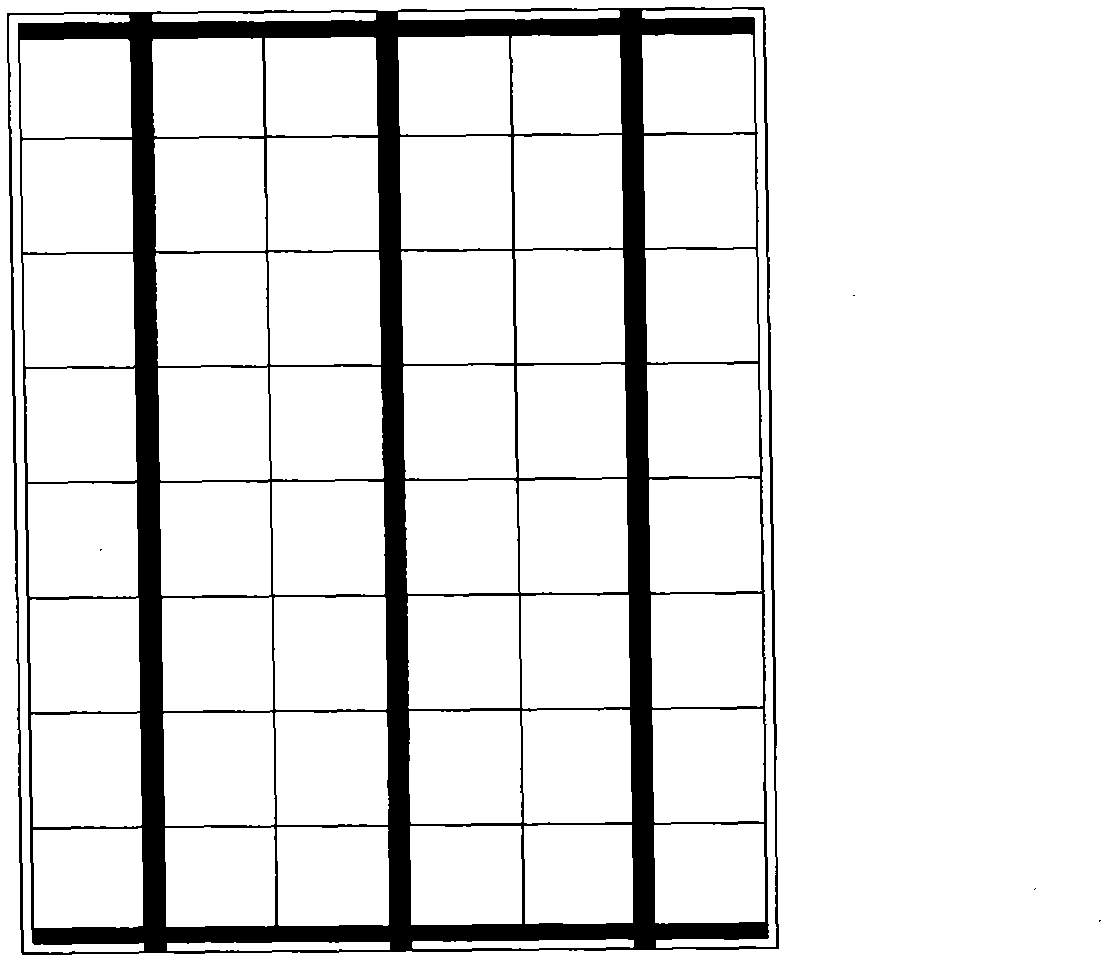

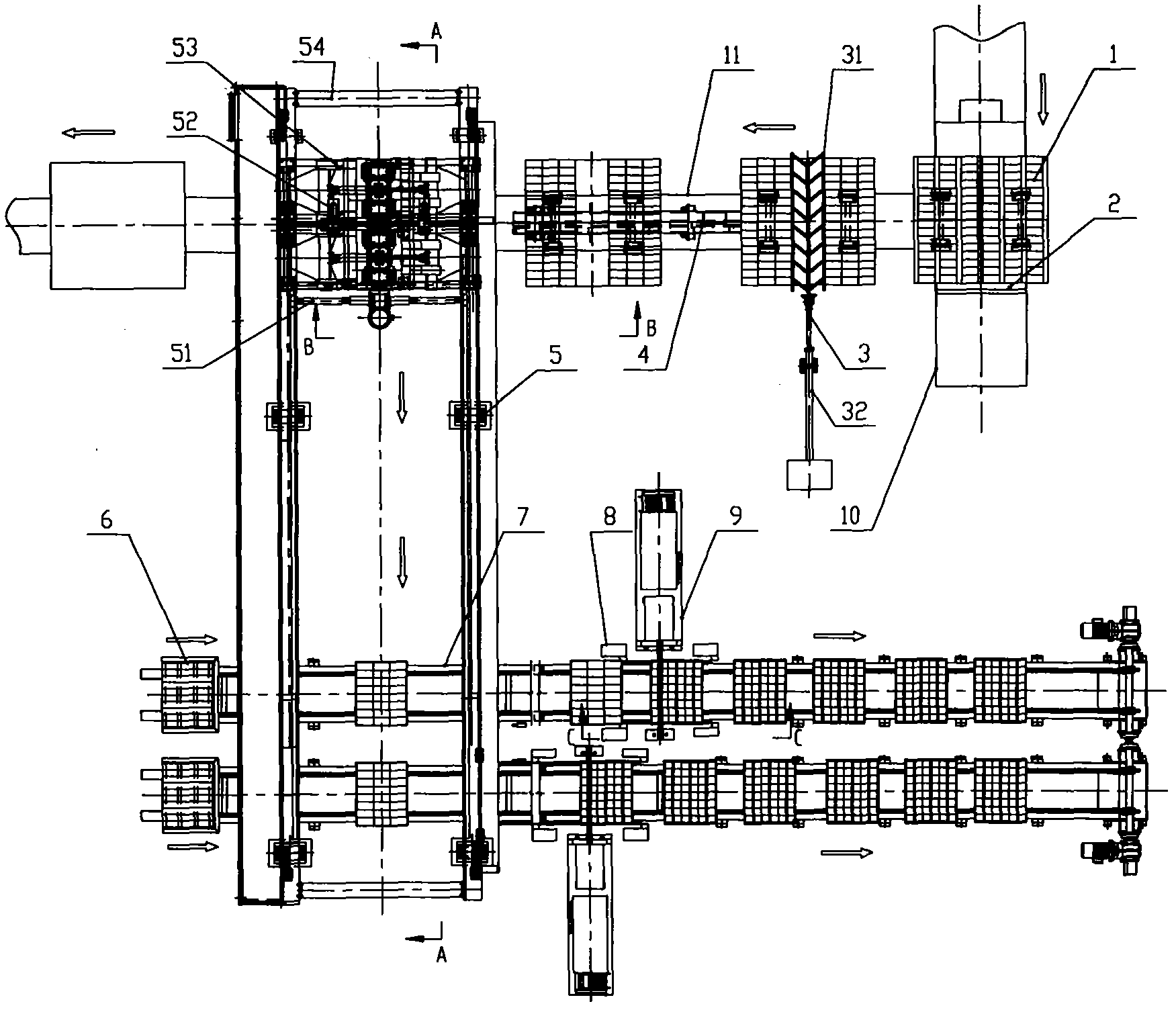

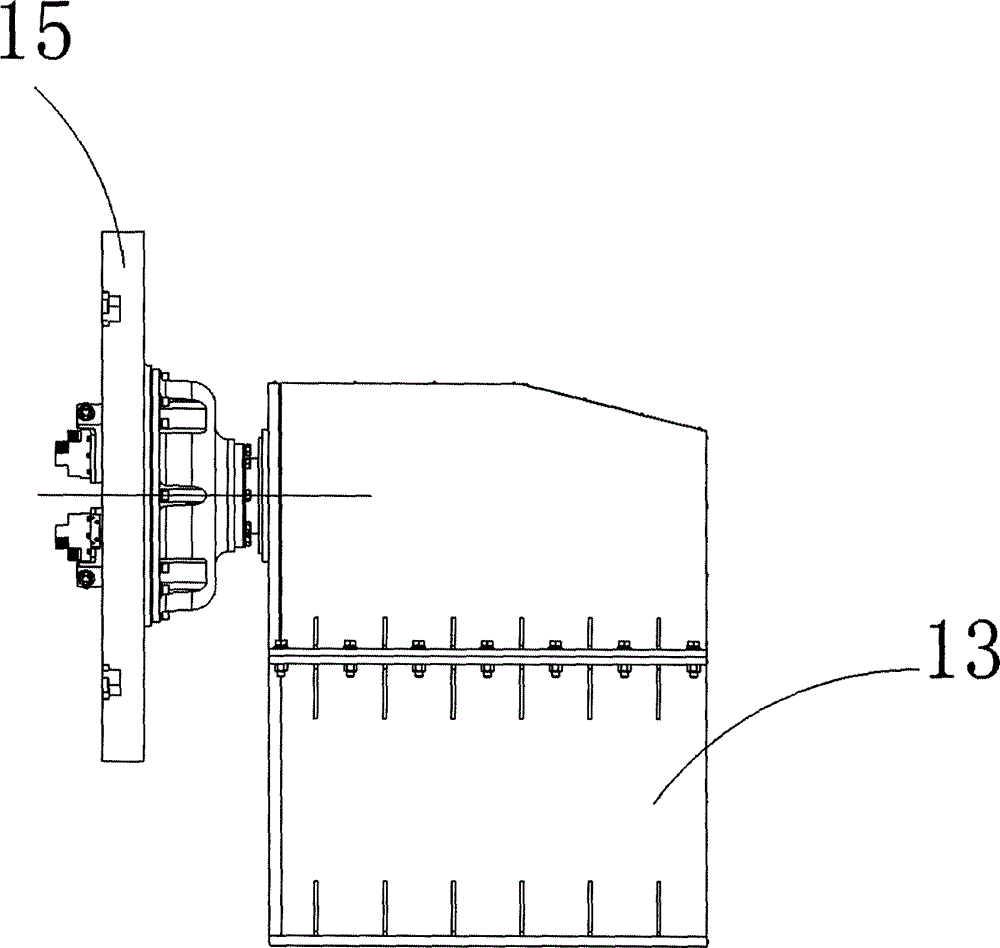

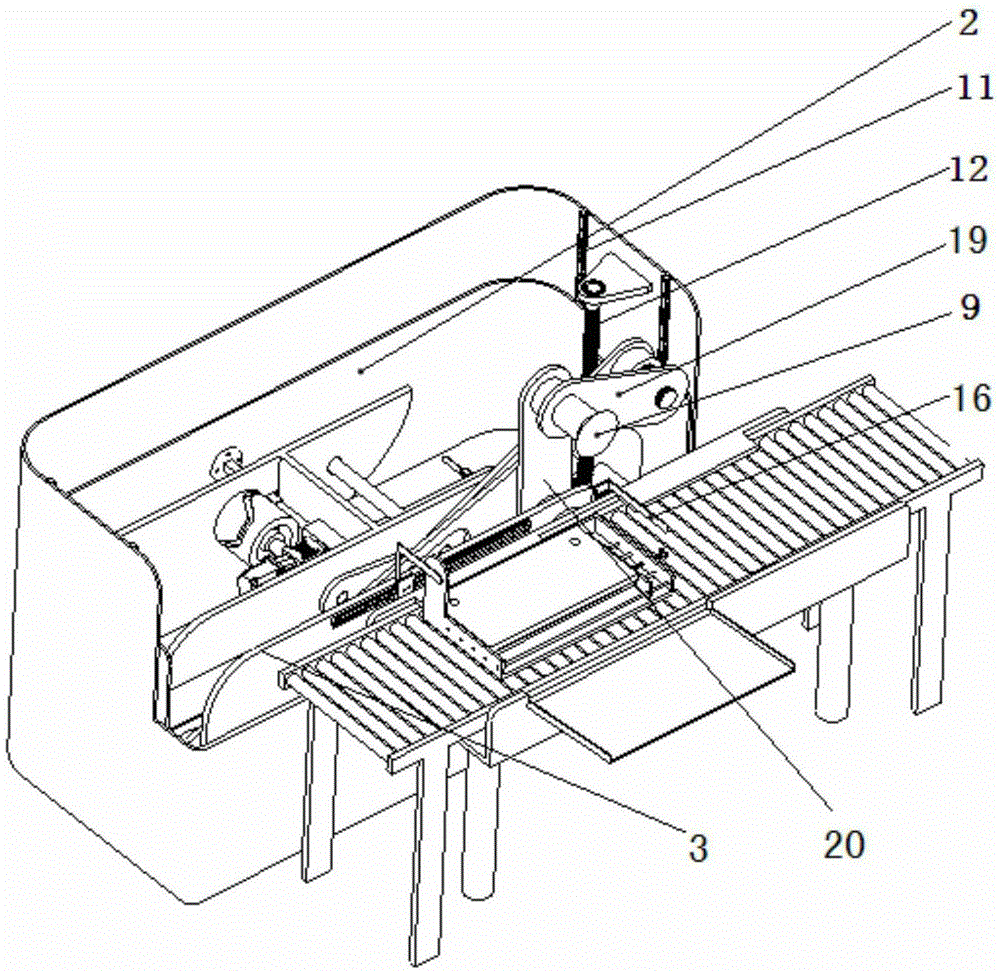

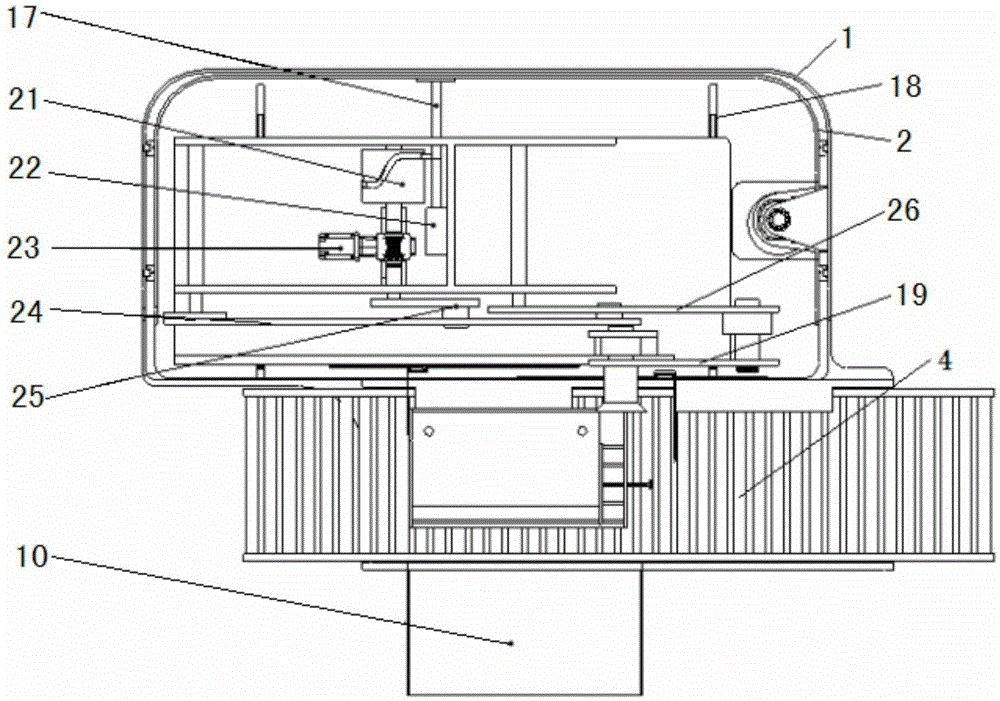

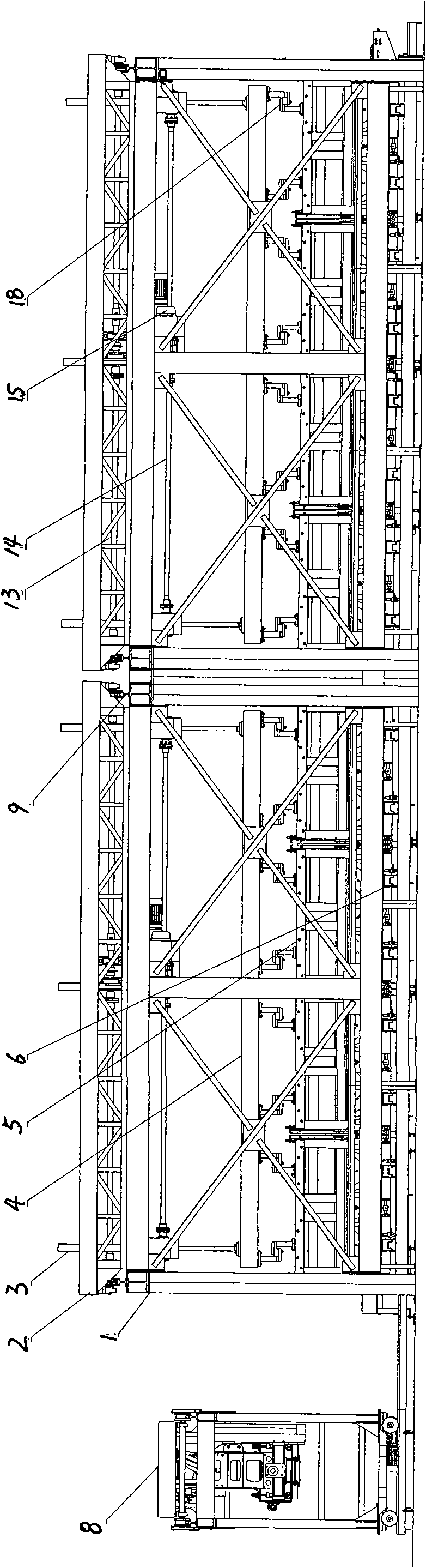

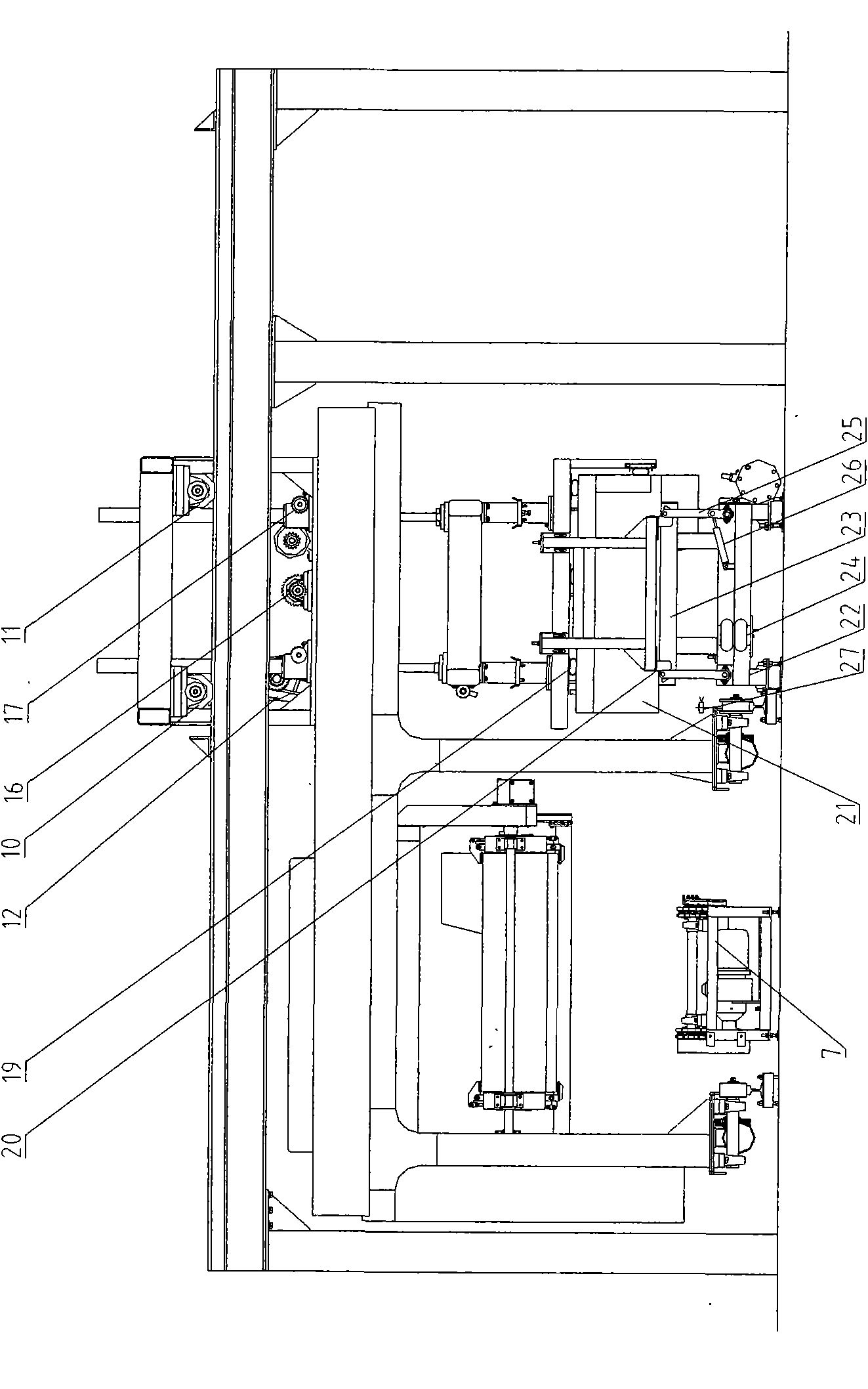

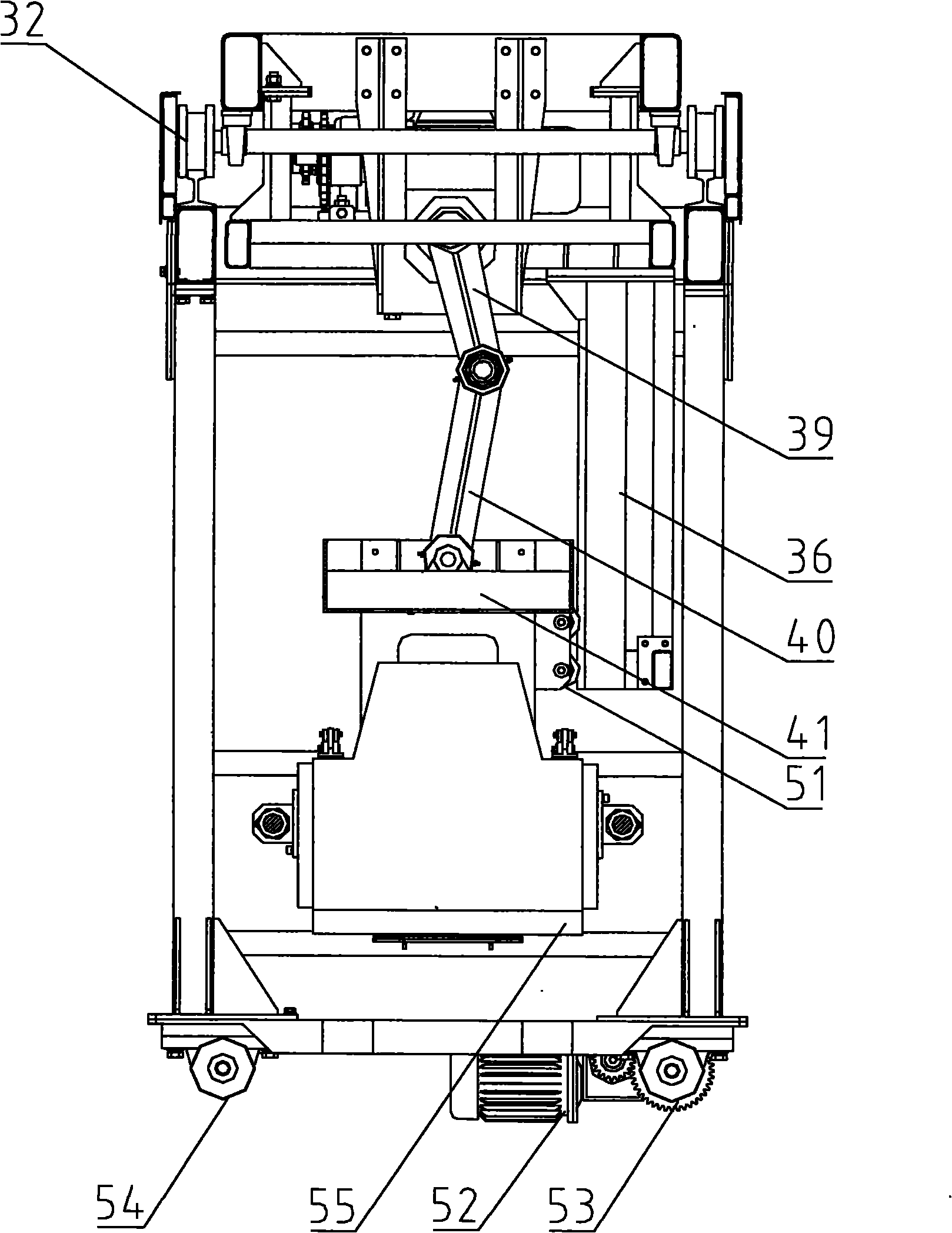

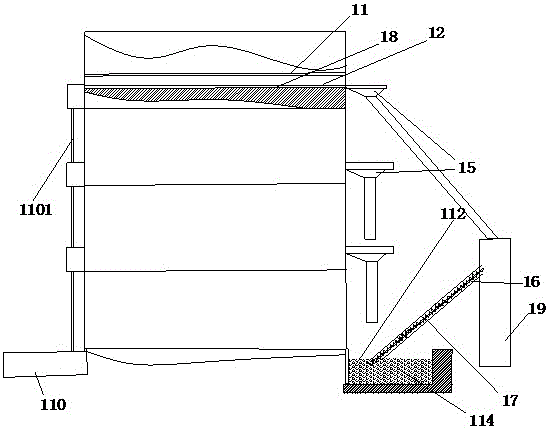

Brick pile packaging method and brick pile packaging production line

InactiveCN102556399ACompact and stable structureSimple structureBuilding material packagingAuxillary shaping apparatusProduction lineBrick

The invention belongs to the technical field of packaging machinery, and particularly relates to a brick pile packaging method and a brick pile packaging production line. A brick pile on a steam-curing car is mechanically divided into a plurality of packaging piles, the packaging piles are placed on pallets, two corner beads are covered on two diagonal lines of each packaging pile respectively, and bricks in each of a plurality of brick rows along with the corresponding pallet and the diagonal lines are bundled by a bundling strap, so that the bricks form a firm whole by bundling each packaging pile. The packaging production line comprises a pile dividing device, a brick holding device, two vertical bundling machines, four bead clamping and cutting devices, two pallet bins and two packaging conveying devices, wherein the pile dividing device is used for dividing the pile, the brick holding device is used for holding the bricks to place each two packaging piles onto the pallets of the packaging conveying devices respectively by means of pile division, the bead clamping and cutting devices are used for covering and cutting the corner beads, and the vertical bundling machines are used for vertically bundling the packaging piles. The bundled brick piles are compact and firm in structure, the whole packaging production line realizes mechanized production, production efficiency is greatly improved, and labor intensity of workers is relieved.

Owner:LUOYANG ZHONGYE HEAVY IND GRP CO LTD

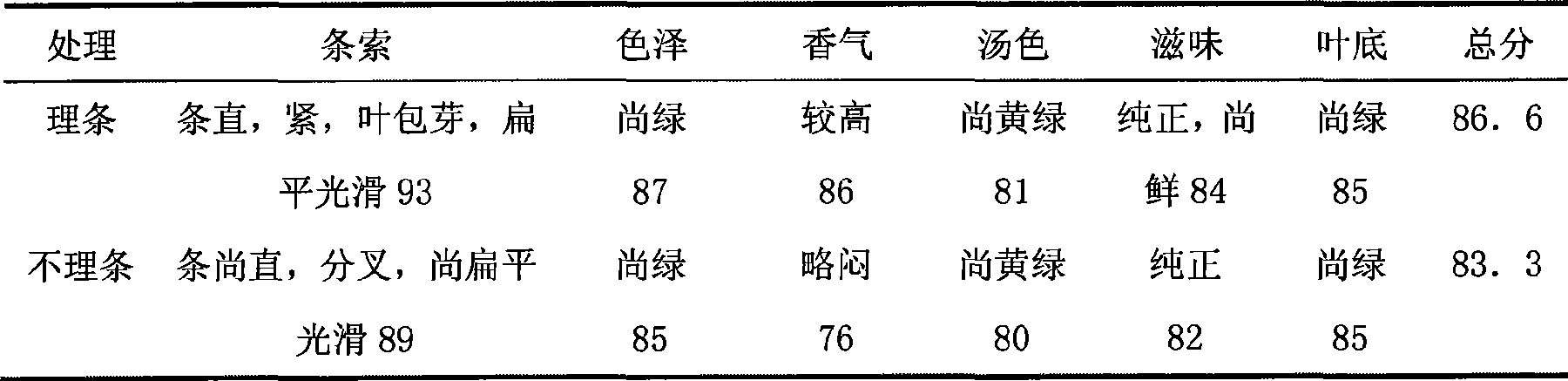

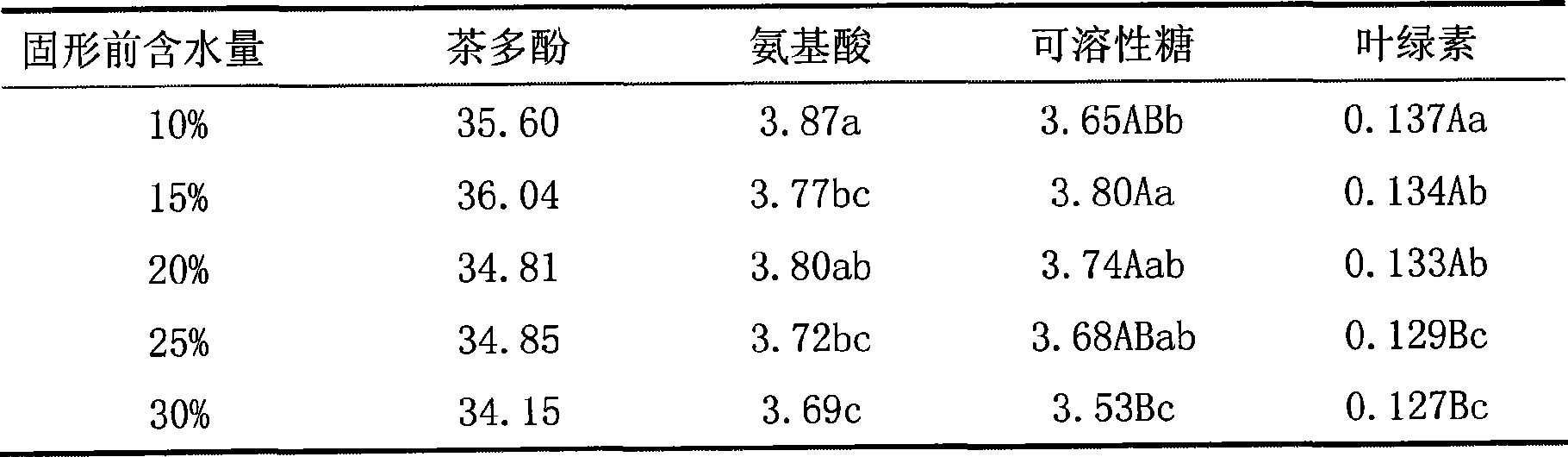

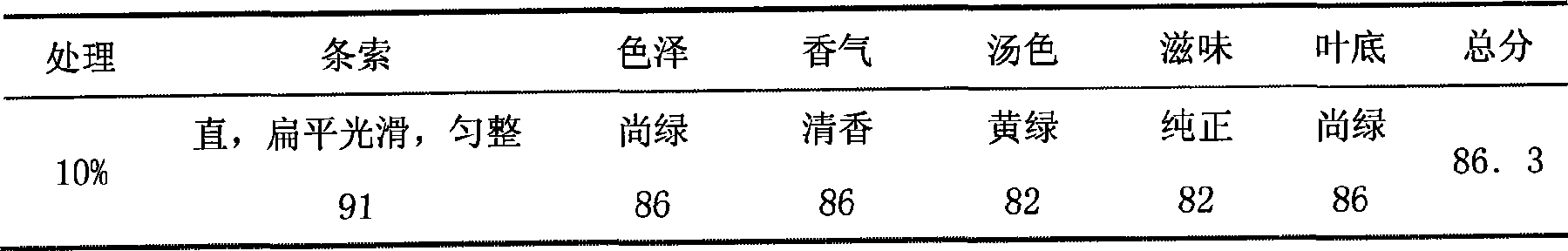

Mechanized method for processing flat green tea

The invention belongs to the technical field of tea manufacture, in particular to a method for mechanically processing flat green tea. The method is characterized in that fresh green tea leaves are prepared into well-known tea with a flat shape through spreading, enzyme deactivating, sorting, pressing, solidifying, flavoring and other steps. The flat well-know tea has the characteristics of flat and smooth strips, no fragment, unpolished rice like color and luster, constant chestnut fragrance, green and bright color of liquor color, fresh and pure taste, tender, uniform, green and bright leaves and the like. The tea quality can completely reach the level of manually processing, and the method is applicable to mechanical processing production.

Owner:HUAZHONG AGRI UNIV

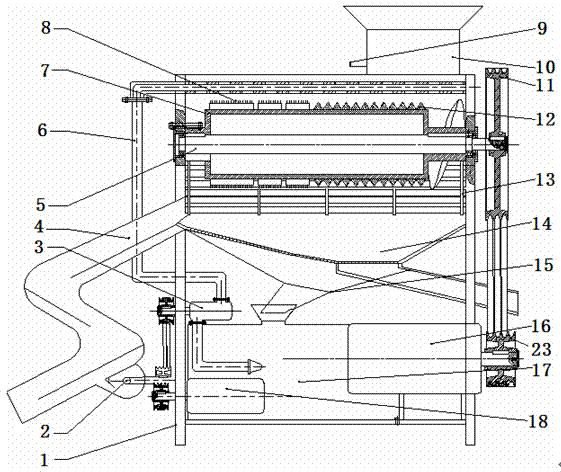

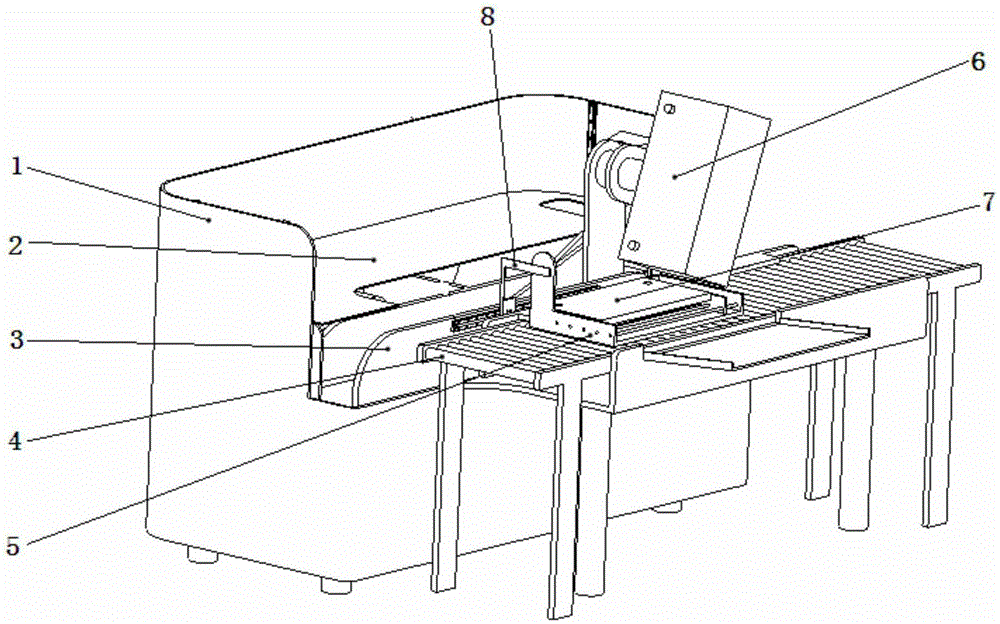

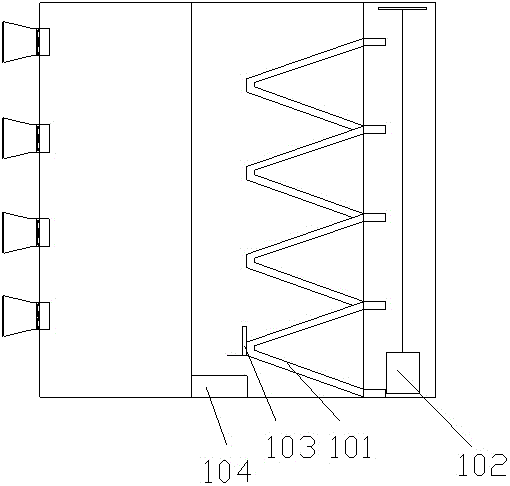

Peeling-cleaning all-in-one machine for green walnuts

InactiveCN104256858ARealize mechanized productionShorten the timeClimate change adaptationHuskingWalnut NutWater storage

The invention relates to a peeling-cleaning all-in-one machine for green walnuts, and belongs to the technical field of processing mechanical equipment for agriculture products. The peeling-cleaning all-in-one machine for green walnuts disclosed by the invention comprises a peeling device, an impurity removal and cleaning device, and a drying device, wherein the peeling device comprises a rack, a central main shaft, a peeling rotary drum, a charge port, a concave-plate sieve and a first motor; the impurity removal and cleaning device comprises a water pump, an S-shaped discharge tube, a water tube, a residue collection device, a water collection bucket, a water storage box and a second motor; the drying device comprises a hot-air device and the S-shaped discharge tube. The peeling-cleaning all-in-one machine for green walnuts disclosed by the invention is capable of meeting peeling and cleaning requirements on green walnuts, and ensuring the quality of peeling, thorough in peeling, complete in cleaning, high in automation degree, capable of realizing the cyclic utilization of water resources and primary drying for walnuts, low in cost, stable in running, and wide in market prospect.

Owner:KUNMING UNIV OF SCI & TECH

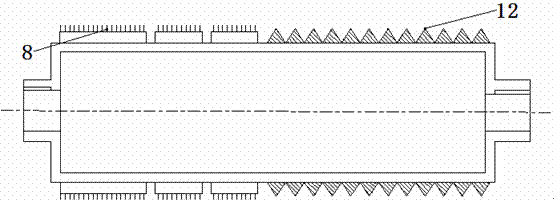

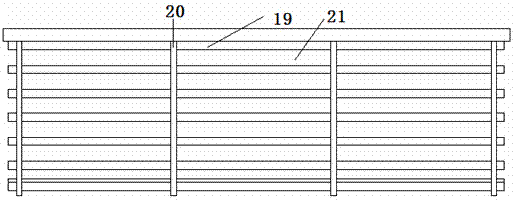

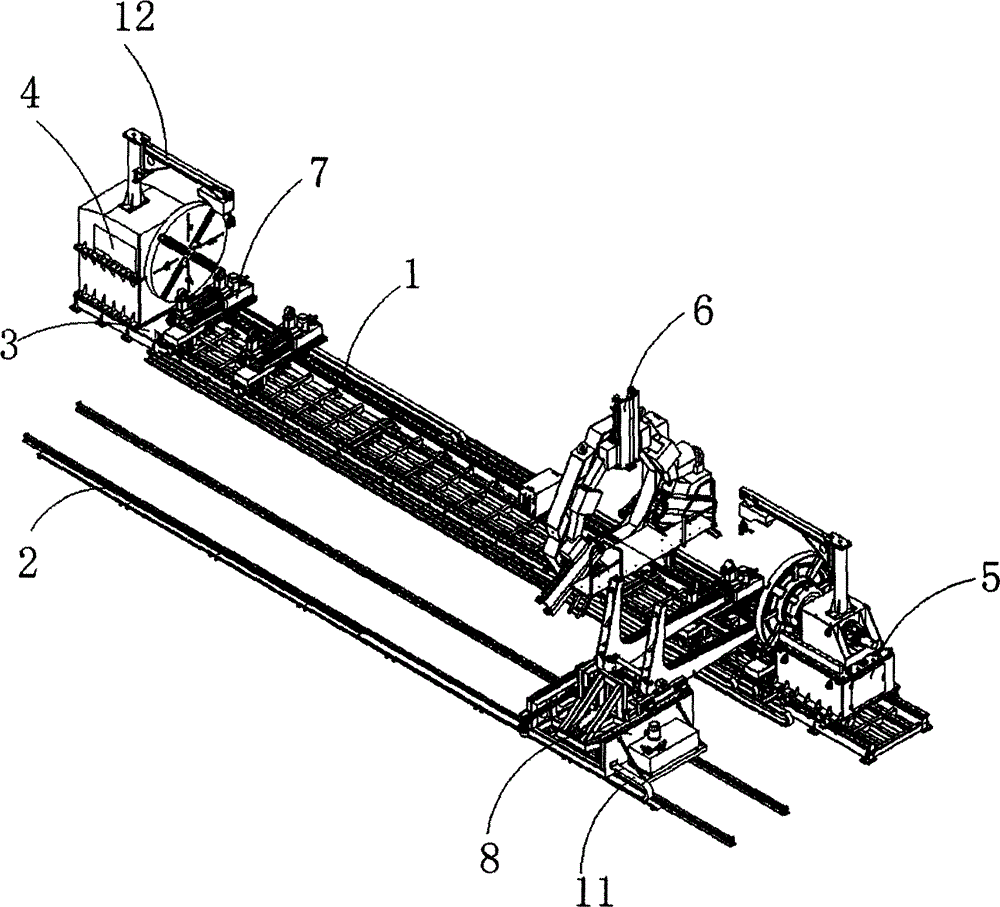

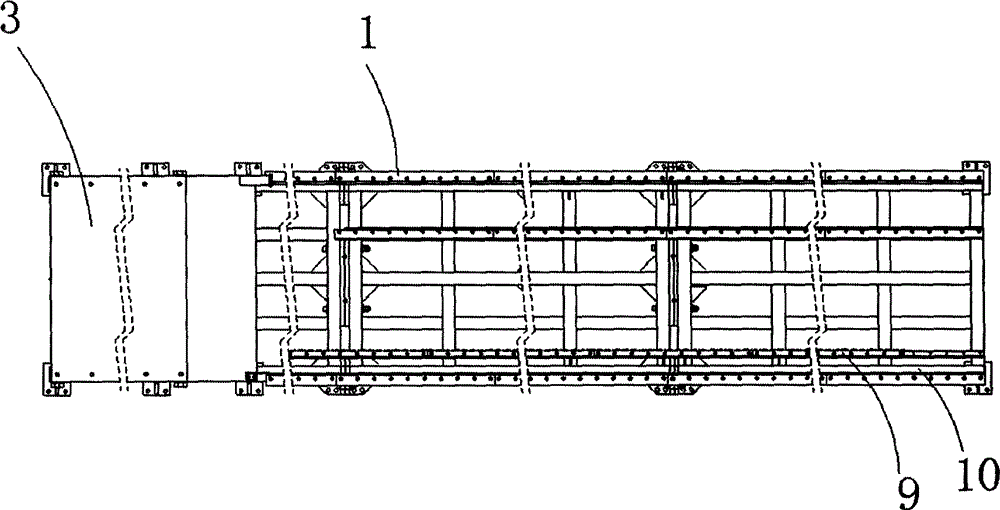

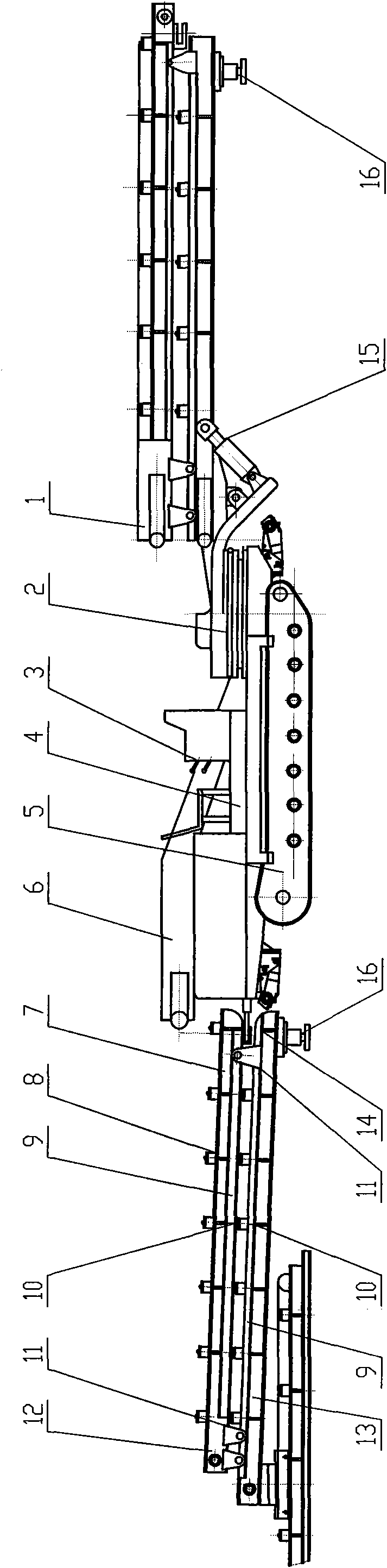

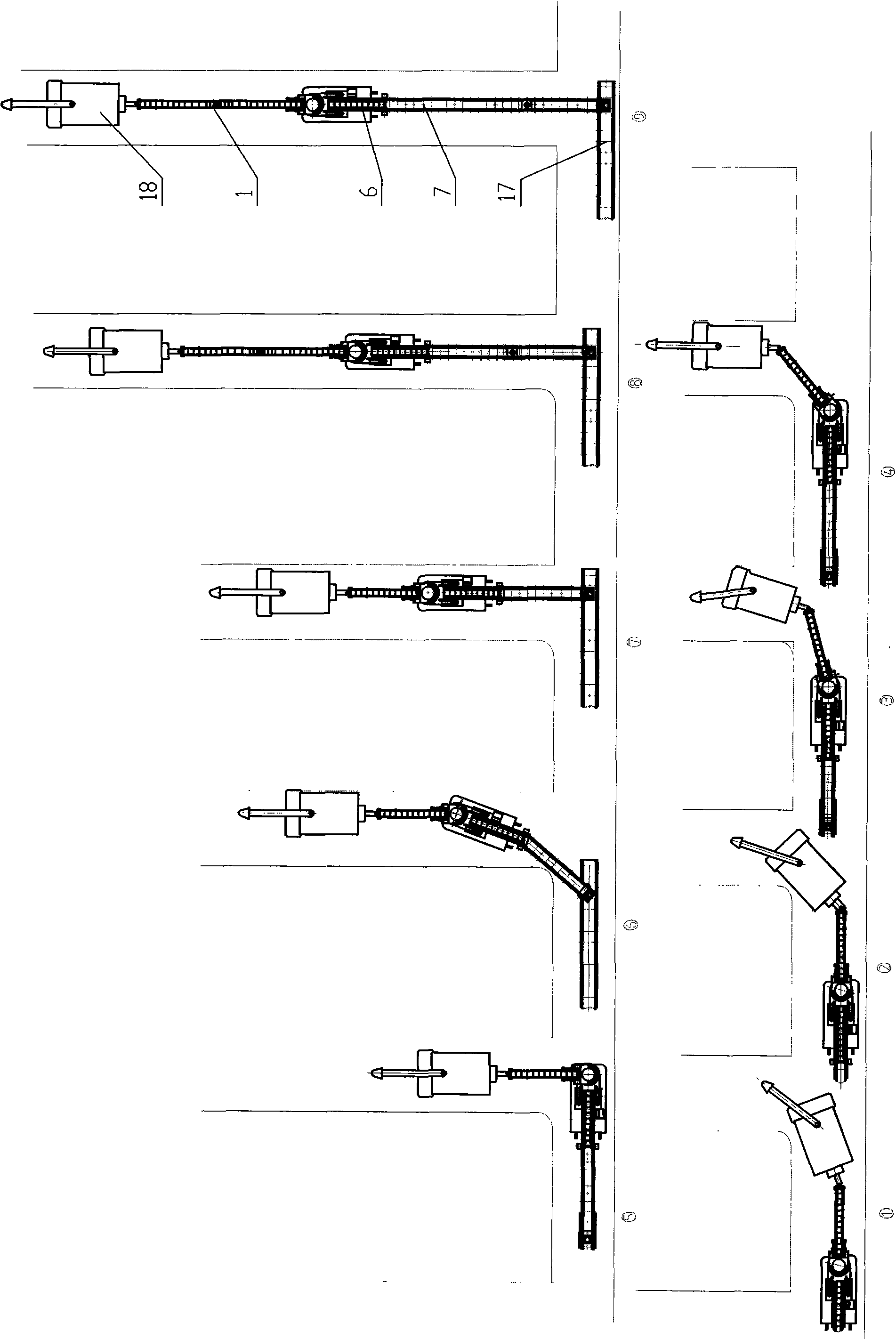

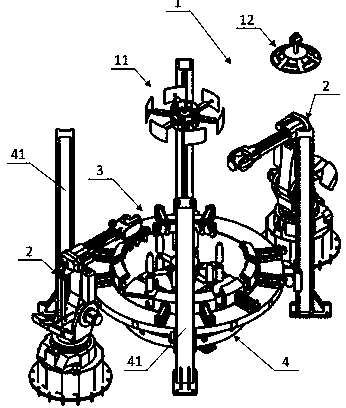

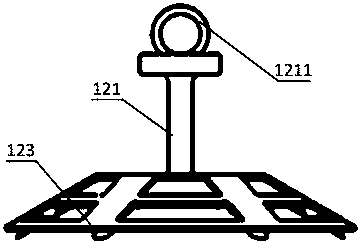

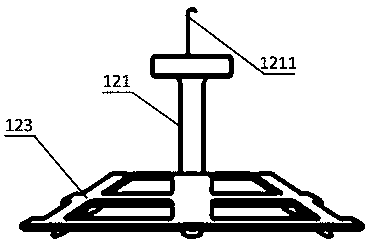

Assembly welding system for cone-shaped pipe circumferential weld

InactiveCN105397345ACompact structureRealize mechanized productionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringTailstock

The invention discloses a welding system, in particular to an assembly welding system for cone-shaped pipe circumferential welds. A headstock locking machine is arranged on a headstock installing plate. The right end of a base is provided with a tailstock locking machine, a gantry external pressure tool is arranged on the base, and the two ends of the gantry external pressure tool are provided with rolling wheel bracket machines respectively. An overturn railway is provided with an overturn feeding machine. The tailstock locking machine, the gantry external pressure tool, the rolling wheel bracket machines and the overturn feeding machine are connected with a drag chain. The upper portions of the headstock locking machine and the tailstock locking machine are provided with flange hoisting systems respectively, and the flange hoisting systems are distributed correspondingly to the rolling wheel bracket machines. The assembly welding system for the cone-shaped pipe circumferential welds is compact in structure, manual press-button operating is achieved, and feeding and centering are completed electrically; mechanized production is achieved, efficiency is greatly improved, labor intensity is reduced, production quality is ensured, and human factors are decreased; the assembly welding system is convenient to operate, high in speed, stable and high in efficiency.

Owner:HANGZHOU XINCHENGXIANG ELECTROMECHANICAL TECH

Magnetic shoe grinding device

The present invention relates to a special grinding equipment, in particular to a magnetic tile grinding equipment which is applied to the grinding of the inner concave surface, the outer convex surface, two side surfaces and two end surfaces of a tile to overcome the problem that all processing procedures of the tile grinding process can not be completed by one machine in prior art and to solve the deficiencies such as a great labor intensity and environment pollution in prior grinding method. The equipment has a body, which is equipped with a guiding rail that is in the same direction with the tile axis. The tile is allowed to slide on the guiding trail. The body at the side of the guiding rail is separately provided with an inner concave, an outer convex grinding head, two side grinding heads and two end grinding heads with each of the grinding heads equipped with a forming grinding wheel which fits into the shape of the grinding surface. The body is also equipped with a feeding device to drive the tile to slide on the guiding rail.

Owner:吕景文

Method for massively planting apocynum venetum on saline-alkali desert lands

ActiveCN101965777AOvercoming sowing seedlingsFast growthPlantingCultivating equipmentsApocynum venetumGreenhouse

The invention relates to a method for massively planting apocynum venetum on saline-alkali desert lands. The method is implemented by the steps of seed screening, nutrition cup preparation, room-temperature facility arrangement, seeding in time, seeding amount control, management during seedling time, nursery garden transplanting, nursery garden field management and large-field transplanting. In the method, massive and productive apocynum venetum planting experiments are carried out under specific weather conditions in the Altay region of Xinjiang, and the experiments prove that when the method is used, the survival rate of the apocynum venetum large-field strains planted on the gobi desert lands reaches 95.8 to 96.4 percent, a service life is shortened, and an application prospect is wide. Particularly, the seedling plants for the gobi desert lands can be cultivated in one year, so that the shortcoming that the conventional large field or nursery garden seedlings raised by direct seeding are transplanted to the gobi desert lands after 2 to 3 years generally is overcome and the massive planting and mechanical field management are realized.

Owner:XINJIANG ALTAY PREFECTURE GAUBAO KENDER CO LTD

Corner-crossing transfer conveyer

InactiveCN101624138AReduce labor intensityImprove shipping speedControl devices for conveyorsEarth drilling and miningMechanical engineeringEngineering

The invention relates to a conveyer, in particular to a corner-crossing transfer conveyer which comprises a left walking part, a right walking part, a front conveyer, a middle conveyer, a tail conveyer and a hydraulic system, wherein a stand is arranged on the left walking part and the right walking part, a rotary table which can be rotated for 90 degrees left and right is arranged at the front part of the conveyer, the front conveyer is arranged on the rotary table, the middle conveyer is arranged between the left walking part and the right walking part, and the tail conveyer is hung at the tail part of the conveyer. The front conveyer and the tail conveyer are both of telescopic belt conveyers, and conveying distances of the front conveyer and the tail conveyer can be regulated. The invention changes the lagging production mode that coals at the corners need to be shoveled by manpower in the original drifting process, realizes the mechanical production, greatly improves the conveying speed of coals, lightens the labor intensity of workers, saves the manpower, and can be used at both corners and straight tunnels.

Owner:SHANXI DONGHUA MACHINERY

Health thorn tea, processing technique of health thorn tea and processing equipment for health thorn tea

ActiveCN102599307AImprove beauty effectImprove antioxidant capacityTea substituesAcute hyperglycaemiaCooking & baking

The invention discloses a processing technique of health thorn tea and processing equipment for health thorn tea, which relate to the technical field of processing of agricultural products. The health thorn tea is made of fresh thorn tea leaves. The processing technique includes cutting, primary fixation, primary spreading and cooling, secondary fixation, secondary spreading and cooling, primary rolling, tertiary spreading and cooling, primary baking, secondary rolling, fourth spreading and cooling, secondary baking, grading and packaging. The processed health thorn tea has the advantages of blood glucose lowering, blood lipid lowering, blood pressure lowering, immunity enhancement, heart rate slowing, coronary flow increasing, anticoagulation, antithrombosis, hypoxia tolerance, mononuclear macrophage functional promotion, radio resistance and the like, and is suitable for middle-aged and aged people and people with hyperlipidemia, hypertension and hyperglycemia. The processing technique and the processing equipment for the health thorn tea can also be used for processing common tea and other types of health tea.

Owner:HUNAN ZHONGKE AGRI

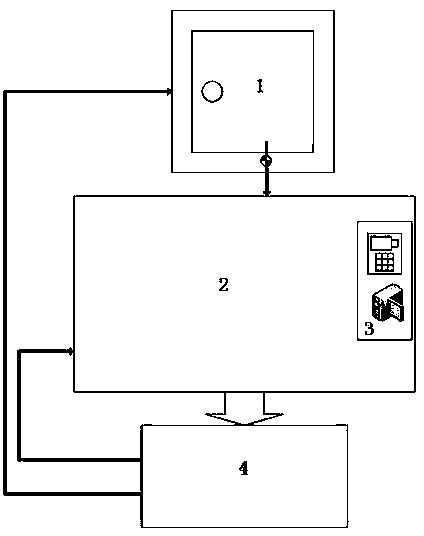

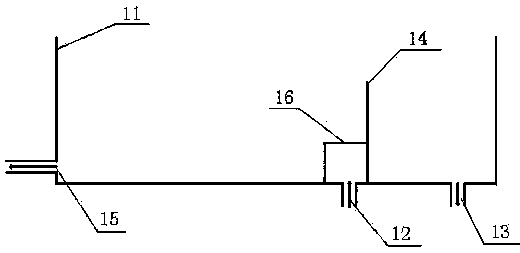

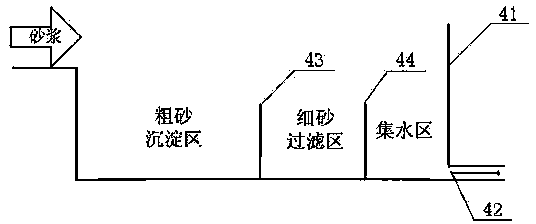

Tailing pond model test simulation system

The invention discloses a tailing pond model test simulation system. The tailing pond model test simulation system comprises a water supply system, a terrain simulation system, a measuring system and a water and sand recovery system. The water supply system is communicated with the upstream of the terrain simulation system through a water conveying pipeline. The downstream of the terrain simulation system is communicated with the water and sand recovery system through a mortar channel. The water and sand recovery system is provided with a sand filter device and a water return port. The measuring system is used for measuring parameters of dam-break debris flow in the terrain simulation system. The terrain simulation system comprises a terrain simulation support. A rib mesh layer, a felt layer and a waterproof layer are installed at the top end of the terrain simulation support in sequence from bottom to top. The terrain simulation support comprises a plurality of adjustable supporting bases. The lower portions of every two adjacent adjustable supporting bases are connected through a cross beam. The rib mesh is installed at the top ends of the adjustable supporting bases. The tailing pond model test simulation system solves the problems that the terrain manufacturing process is complex and water and sand are difficult to recover during tests, the model test efficiency is improved, and the test system can be recycled.

Owner:SHIJIAZHUANG TIEDAO UNIV

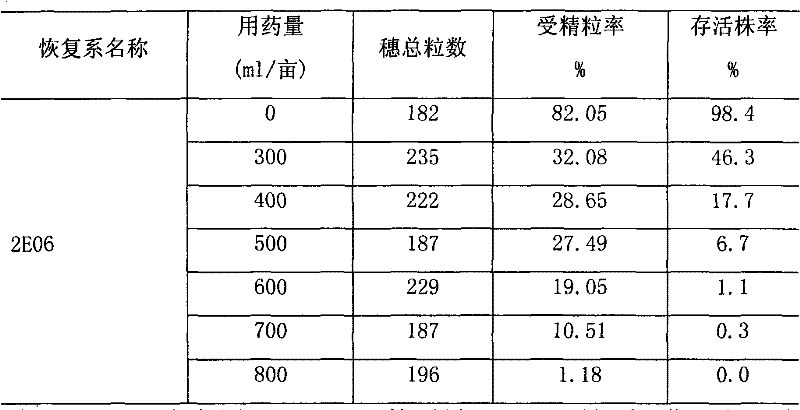

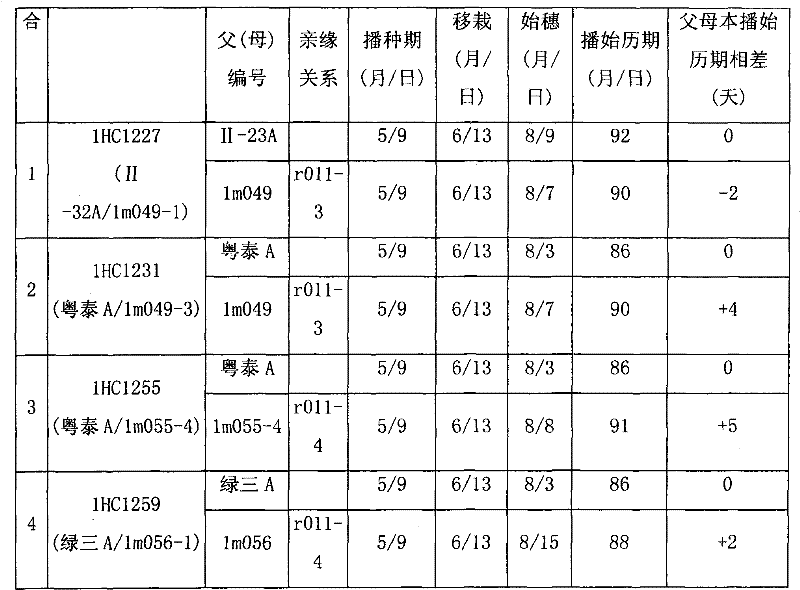

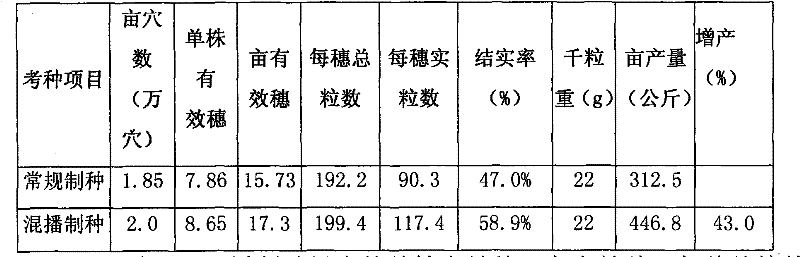

Production method for mechanized production of rice seed

InactiveCN102342243ARealize mechanized productionExpand production scalePlant genotype modificationAgricultural scienceTechnological system

The invention discloses a production method for mechanized production of rice seeds, which comprises the following steps: firstly cultivating a good sterile line and a restorer line with a close growth period, breeding a strong heterotic hybrid rice combination which is suitable for mechanized seed production, with parents of the hybrid combination as test carriers and through systemic research, implanting related genes into the sterile line or the restorer line, after pollination, constructing a brand new hybrid rice seed production technology system which is suitable for mechanized operations by a method of killing the male parent and harvesting the female parent; the invention solves the bottleneck problem for seed production of hybrid rice, realizes mechanized production, enlarges the production to be with a large scale and be intensive, increases the production efficiency, and reduces labor cost.

Owner:RICE RES ISTITUTE ANHUI ACAD OF AGRI SCI

Cake type mooncake and preparation method thereof

ActiveCN104222241AExtended shelf lifeSolve the defect that can not be stuffedDough treatmentBakery productsYolkPreservative

The invention discloses cake type mooncake and a preparation method of the cake type mooncake. The cake type mooncake comprises soft stuffing and cake type mooncake skin covering the soft stuffing. The cake type mooncake skin comprises, by weight, 24% to 26% of weak strength flour, 4% to 6% of high gluten flour, 20% to 22% of egg pulp, 2% to 3% of yolk, 20% to 22% of castor sugar, 20% to 22% of shortening, 1% to 2% of milk powder, 0.2% to 0.3% of salt, 0.4% to 0.5 % of baking powder, 0.1% to 0.2% of cake emulsifier, 0.05% to 0.08% of thickener and 0.1% of corrosion remover. Before the cake type mooncake is baked, encrusting is conducted through a universal encrusting machine, the cake type mooncake is directly baked after encrusting, the stuffing does not fall to the bottom or deform, the taste of fragrant, sweet and soft of cake is kept, the defect that traditional cake is short in shelf life is overcome, and the shelf life of the cake type mooncake can reach six to twelve months under the condition of normal temperature and sealed package.

Owner:GUANGZHOU RESTAURANT GRP LIKOUFU FOOD

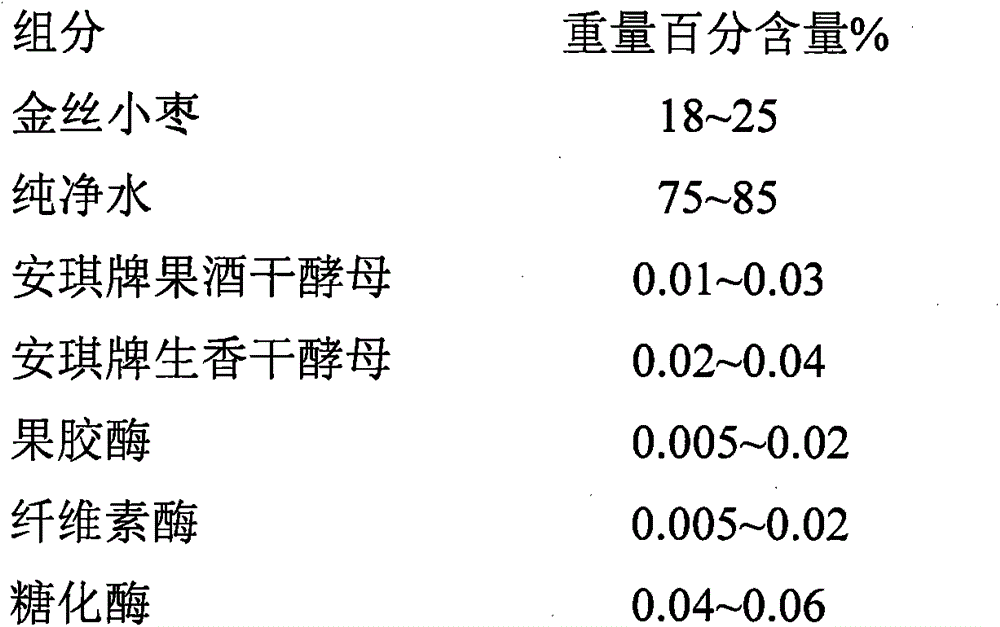

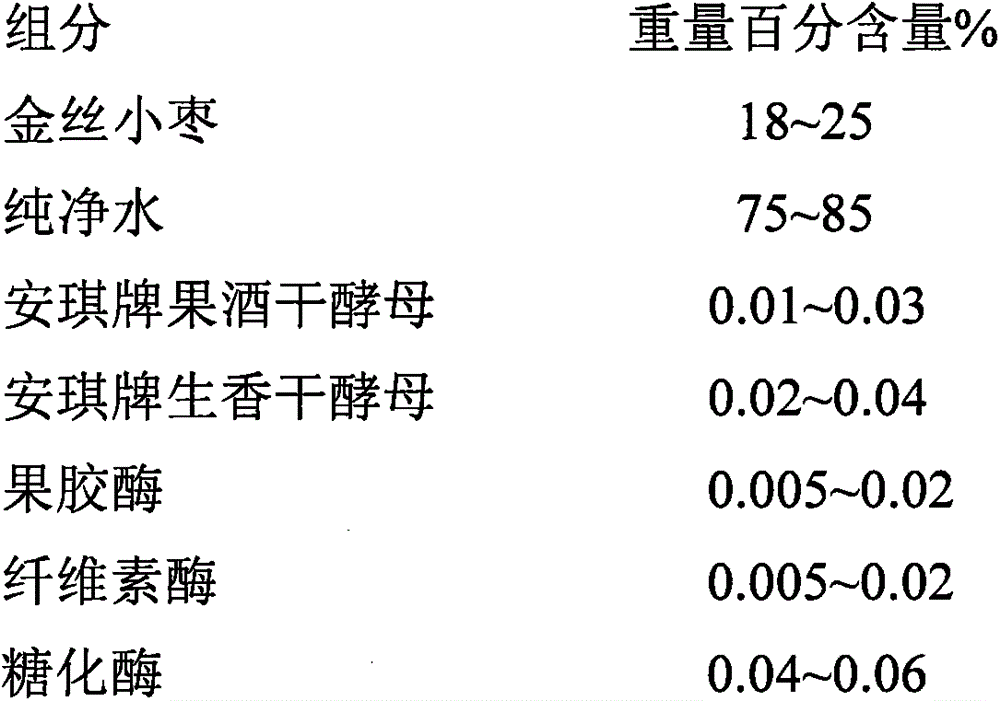

Production process of jujube-flavored white spirit

ActiveCN103555512ASolve efficiency problemsSolve UtilizationAlcoholic beverage preparationYeastDistillation

The invention relates to a production process of jujube-flavored white spirit, which relates to the technical field of brewing. The production process is characterized in that jujubes are boiled after being baked, different corresponding enzymic preparations, fermenting agents and ester-producing yeast are added in the production process, and the white spirit is prepared by processing the jujubes in the liquid-state distillation, storage and blending after the liquid-state fermentation. By adopting the production process, the defects that the jujube-flavored white spirit produced by solids is low in production efficiency, low in utilization rate of raw materials, relatively high in cost and impure in flavor can be overcome, raw materials can be saved, the labor production efficiency can be improved, the taste of the produced spirit is pure, and the mechanical production can be realized.

Owner:SHANDONG SHUANGLINGCHUN BIOLOGICAL TECH

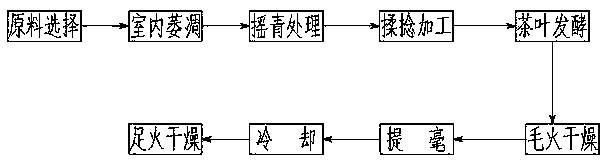

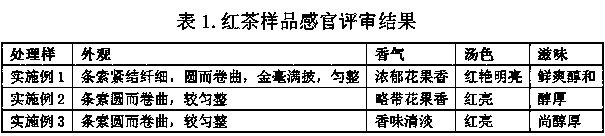

Processing method of floral organic black tea

ActiveCN103947777AIncrease the extraction processNice appearancePre-extraction tea treatmentTea flavoringCell buddingBud

The invention discloses a processing method of floral organic black tea. The method comprises the following steps: selecting raw materials, withering indoors, rocking green leaves, rolling, fermenting the tea leaves, drying with a gross fire, extracting pekoe, cooling and drying with a complete fire. According to the method, a three-time green leaf rocking technology is adopted after the withering process, so that the bud head black tea has the unique fragrances of flowers and fruits and substances in bud heads can be fully converted; a conventional black tea fermentation process is improved, and the black tea is continuously fermented in a fermentation machine, so that the mechanical production of the tea leaves is realized; a pekoe extraction process is added, so that the appearance is relatively attractive; the black tea is produced from single buds as raw materials, the blank of a production process of the bud head black tea is filled, the floral organic black tea is prepared by adopting a creative process of rocking the green leaves, fermenting, extracting the pekoe and drying step by step; tea strips are tight, slender, round and curly, the golden pekoe is fully distributed on the tea strips, the fragrance of dry tea is like the combined fragrance of fruits, honey, flowers, potatoes and the like, and the tea is red and bright in color of tea soup, mellow and fresh in taste, lingering in taste in the throat, and refreshing.

Owner:SICHUAN HANYUAN ORGANIC TEA CO LTD

Heavy type lead-acid storage battery turnover device

InactiveCN105329647ARealize mechanized productionReduce manufacturing costConveyor partsPush pullAssembly line

The invention discloses a heavy type lead-acid storage battery turnover device which comprises an outer rack, an inner rack, a sliding rack, a lifting device, a push-pull device, a turnover device body, a sucking disc and an assembly line raceway, wherein the inner rack is mounted on a plurality of slideways on the inner side walls of the outer rack through a sliding table and is connected with the outer rack through the lifting device; the slideways are arranged at the bottom of the inner rack; the sliding rack is arranged on the slideways at the bottom of the inner rack through the sliding table; the push-pull device is arranged between the inner rack and the sliding rack; the turnover device body is arranged on the sliding rack; the sucking disc is mounted on a first connecting rod in the turnover device body and is close to the hinge end of the first connecting rod and a second connecting rod; the assembly line raceway is arranged on the outer side of the outer rack in a manner of corresponding to the sucking disc. The heavy type lead-acid storage battery turnover device has the advantages of being simple and stable in structure, low in manufacturing cost, automatic and efficient in turnover process, and suitable for storage batteries of different models.

Owner:XIANGTAN UNIV

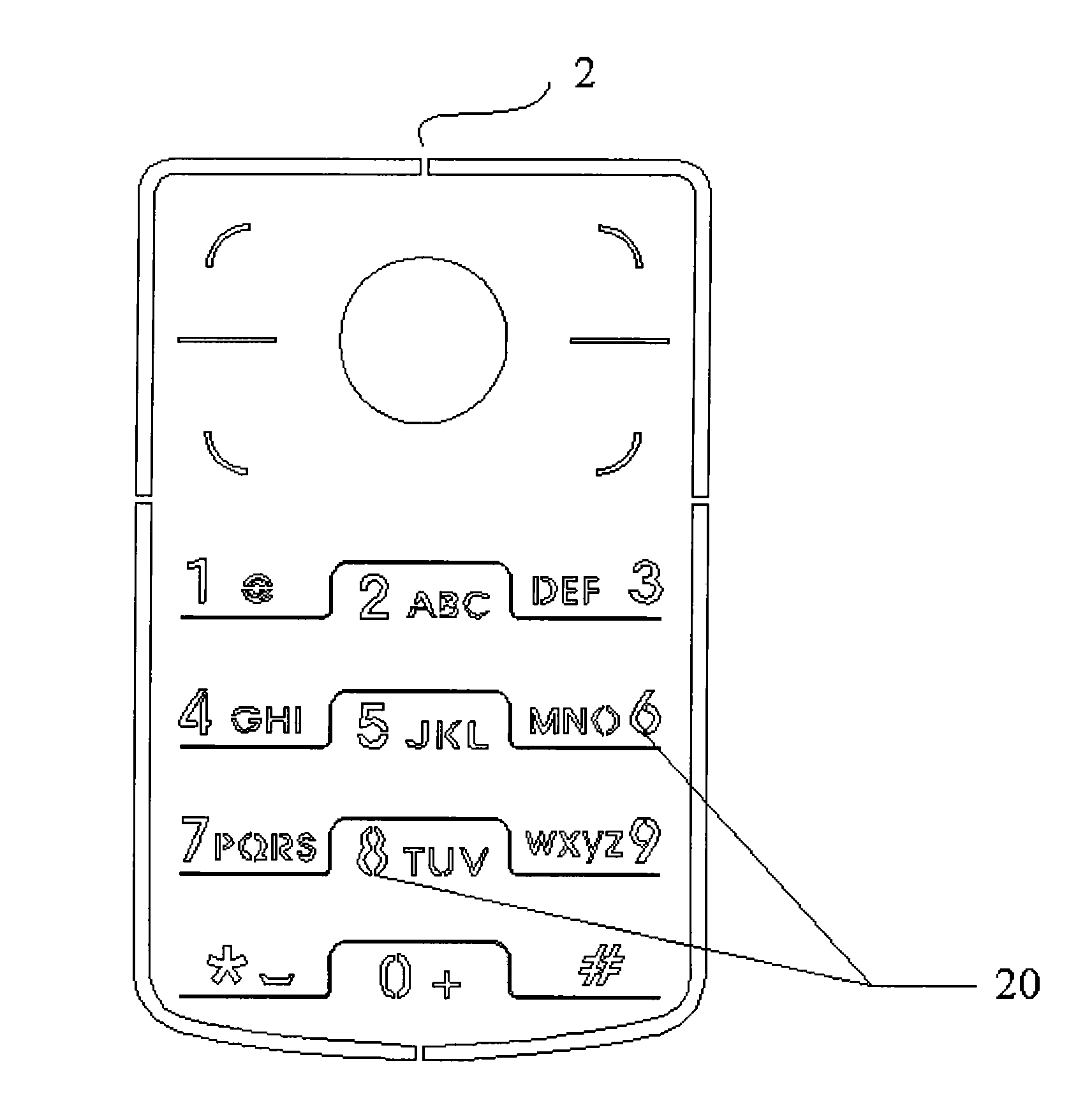

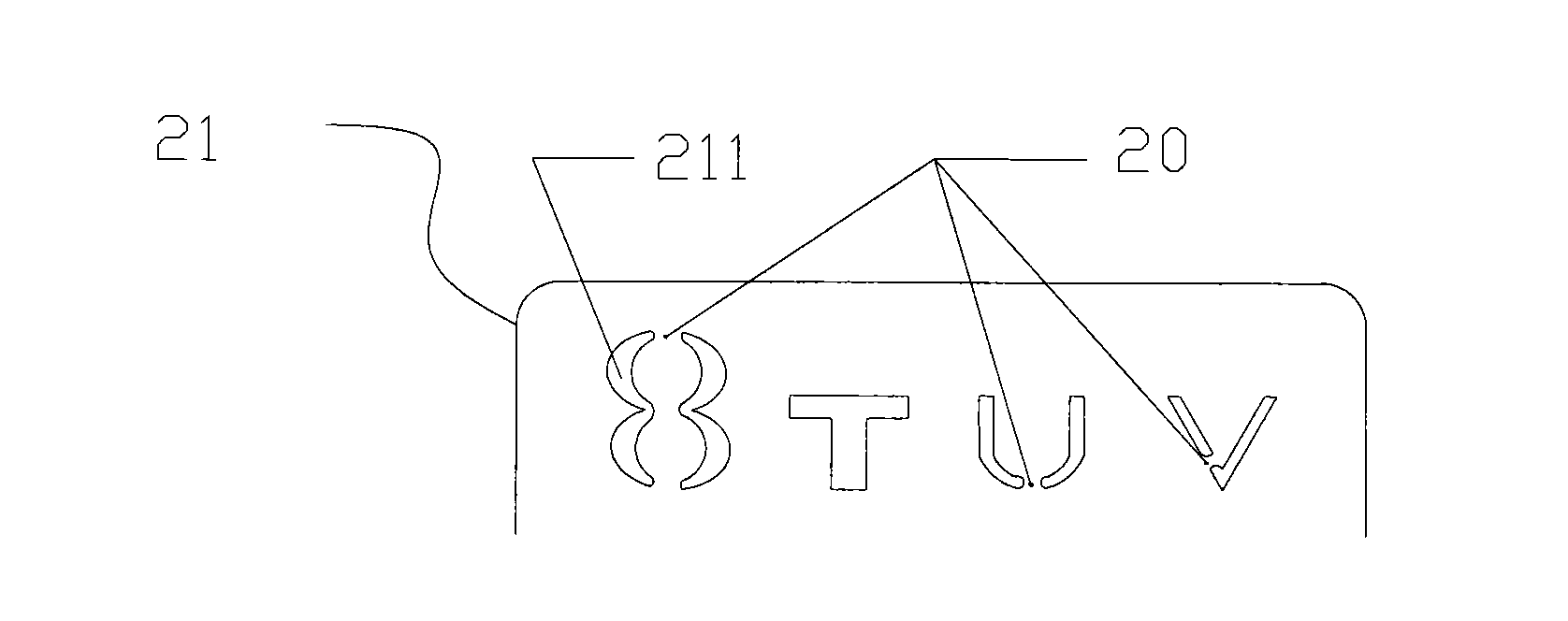

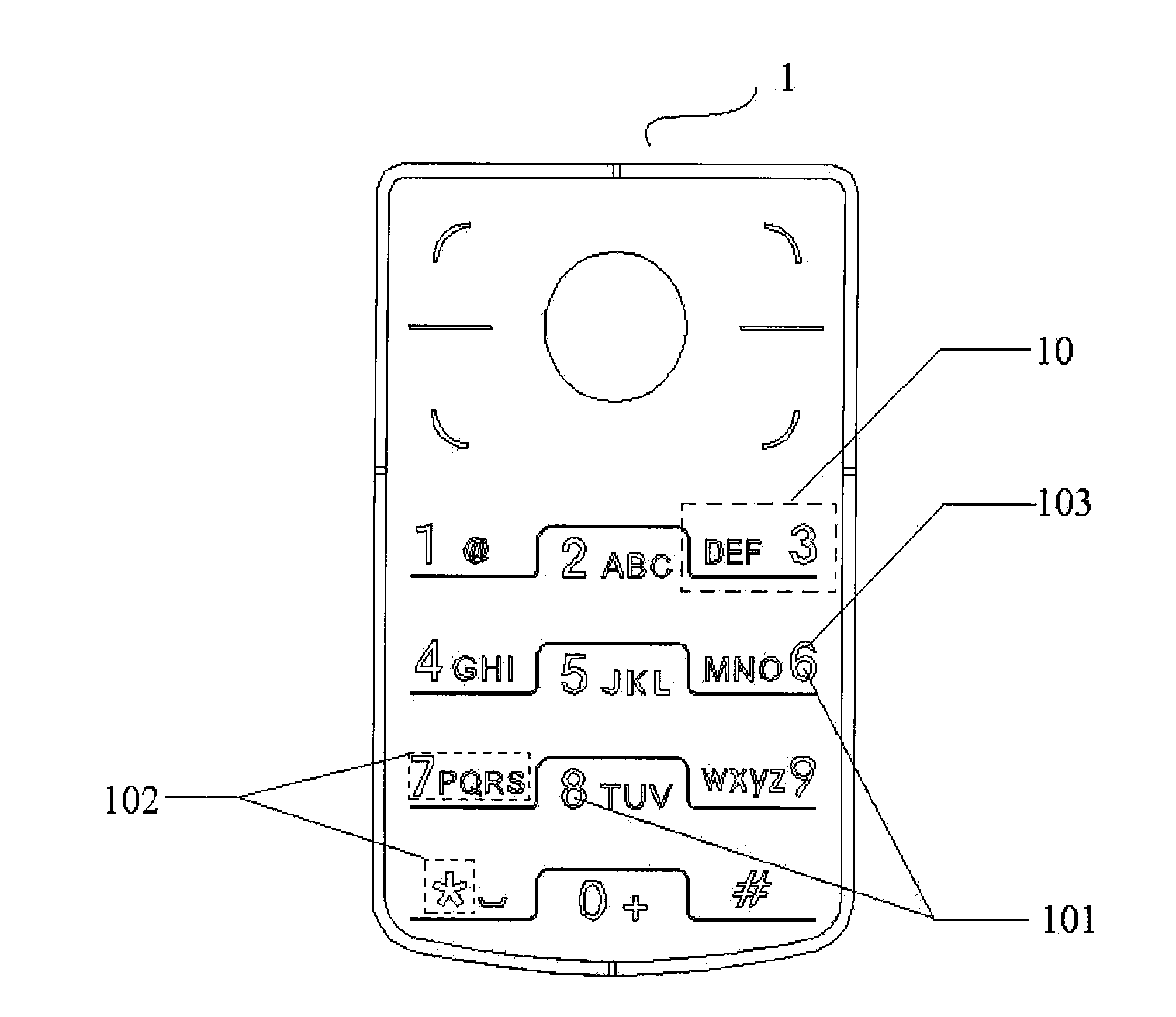

Key, keyboard, manufacturing method for keyboard and mobile phone with keyboard

InactiveCN101635212AKeep shapeIncreased sensitivityElectric switchesTelephone set constructionsEngineeringMobile phone

The invention provides a key with patterns. The key comprises a base material layer, two opposite surfaces of the base material layer are an appearance surface and a bottom surface respectively, the base material layer of the key is provided with at least one gap penetrating the thickness of the base material layer, and the gap forms the patterns, wherein the key also comprises an elastic body layer which is attached to the bottom surface of the base material layer, at least one of the patterns comprises a closed ring, and gaps for forming the closed ring are continuous. An isolated part isolated by the patterns with the closed ring on the key can be stably kept on the key without adding a connecting point according to the key with the patterns, and the sensitivity of the key is not influenced. The invention also provides a keyboard with the key, a manufacturing method for the keyboard and a mobile phone comprising the keyboard. The method of the invention is convenient to operate, can realize mechanized production, and reduces the cost.

Owner:BYD CO LTD

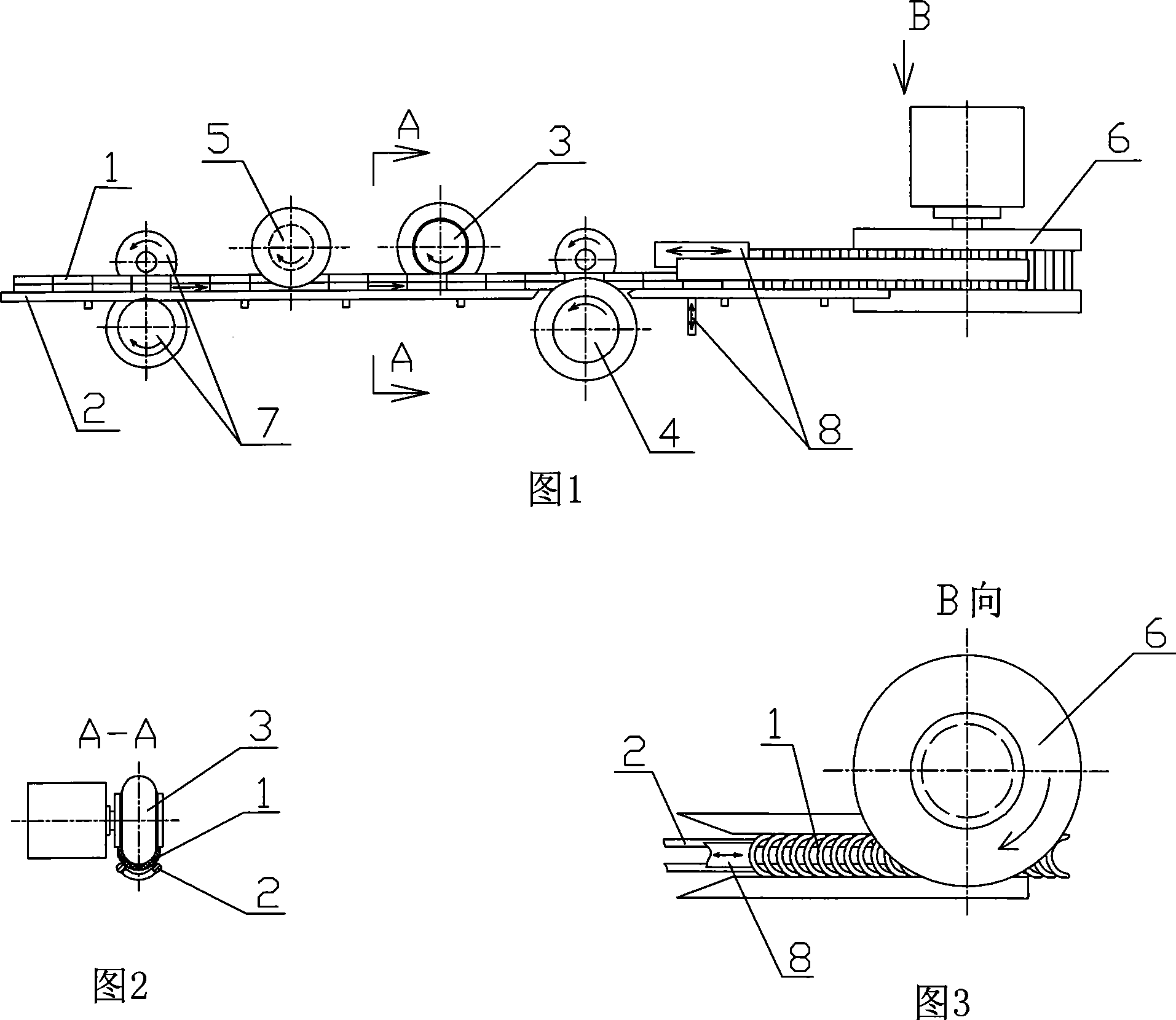

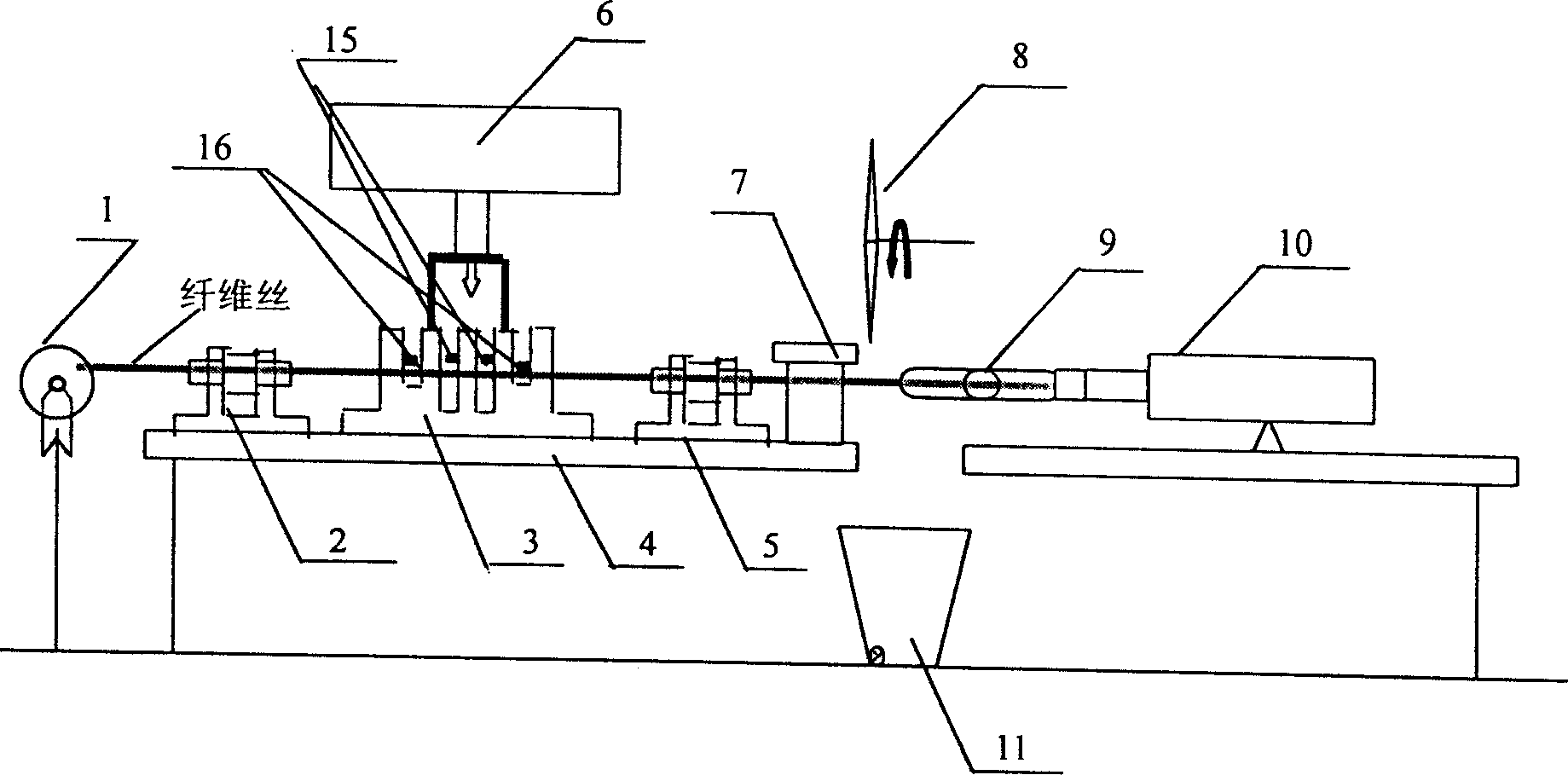

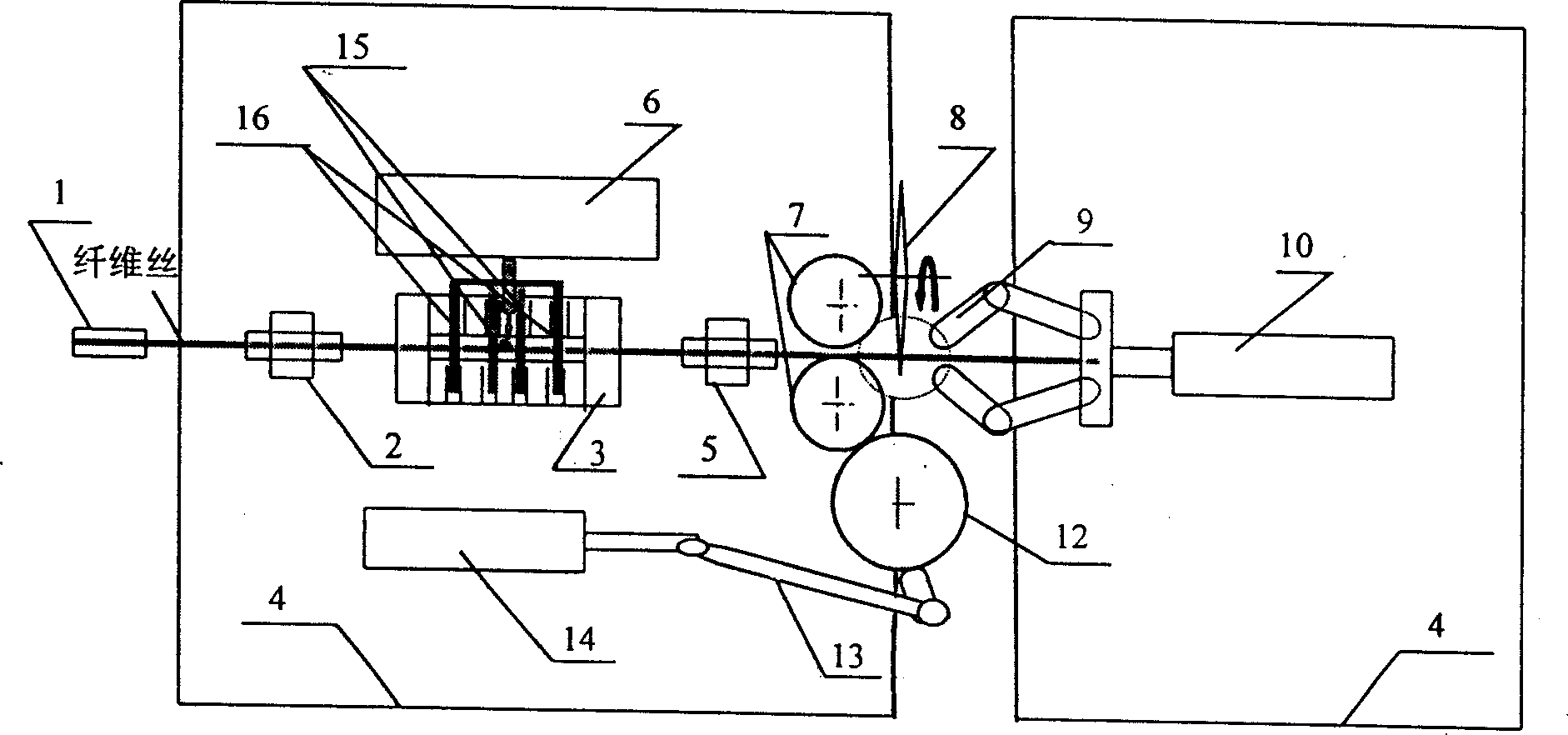

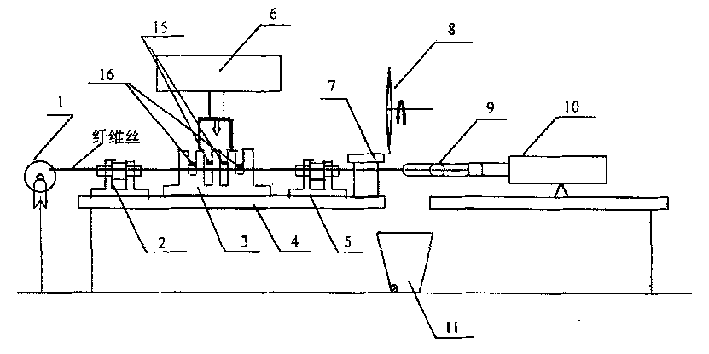

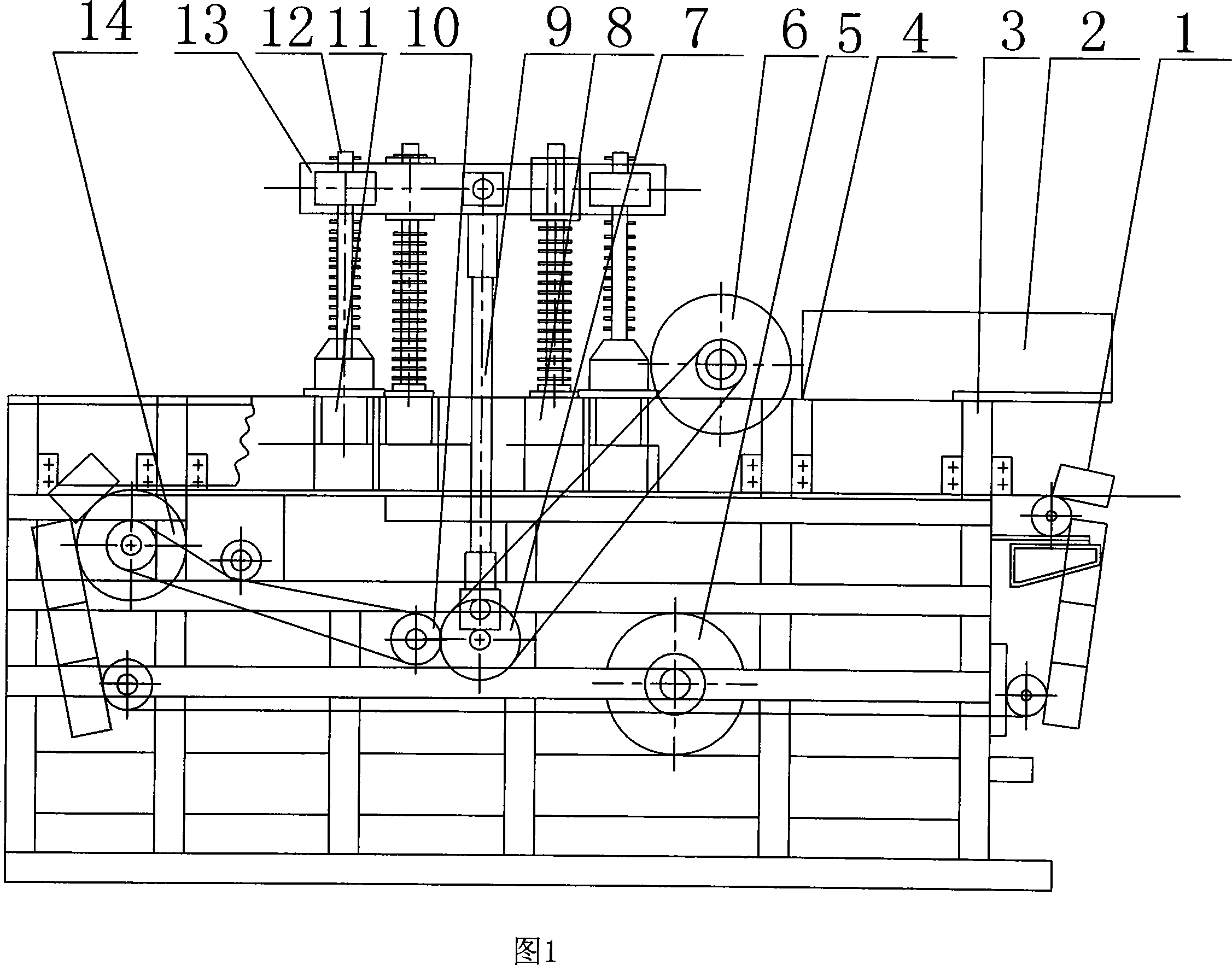

Manufacturing method of fiber ball filtering material and its device

InactiveCN1475293ARealize mechanized productionReduce manufacturing costFiltration separationFiberWastewater

A process for preparing fibrous balls as filter material from fibres includes binding fibres together, clamping both ends and straightening it, fusing the fibre bundle at intervals by ultrasonic welder, cutting at the points except fused points, and loosening the fibres to form fibrous balls. Its apparatus is composed of machine base, two perforators, holder for fusing fibres, clamping rollers for delivering fibre bundle, clamper, ultrasonic welder, cutting blades and cylinder.

Owner:TONGFANG ENVIRONMENT

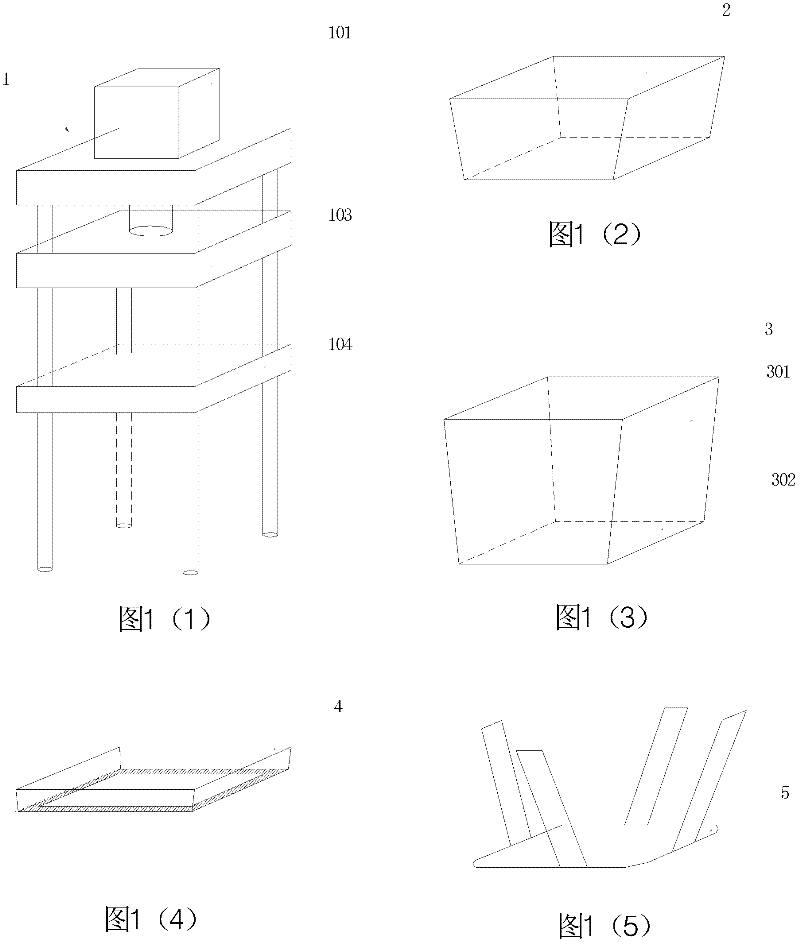

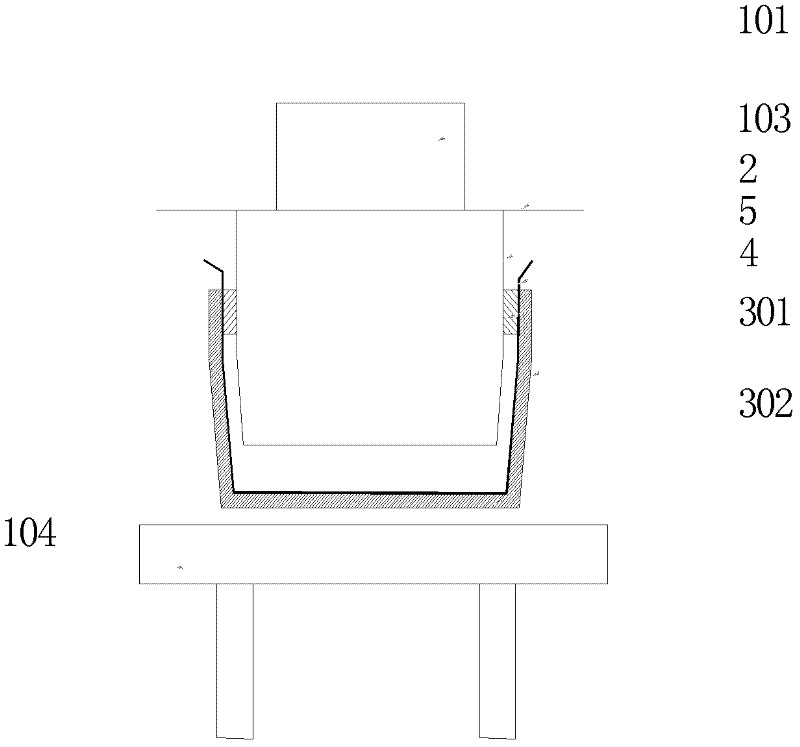

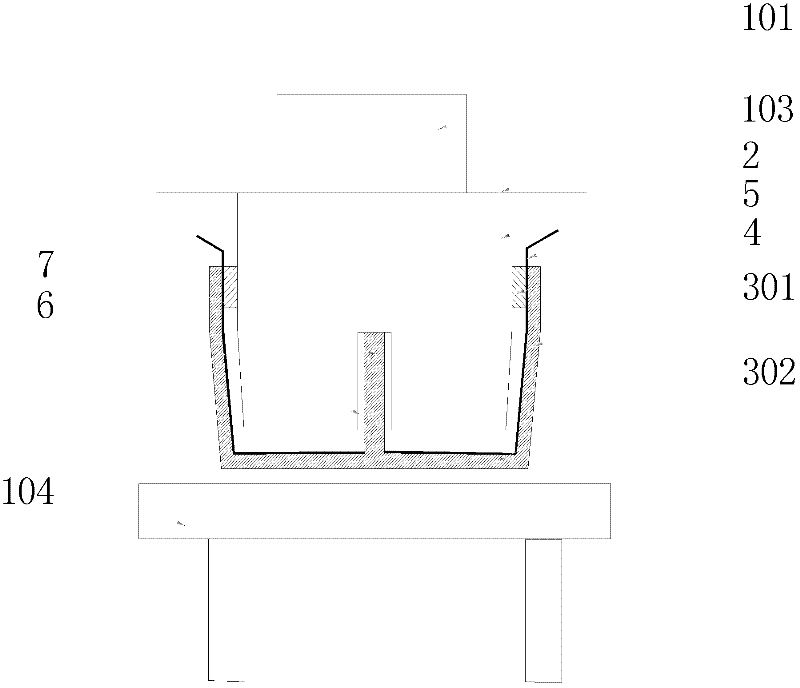

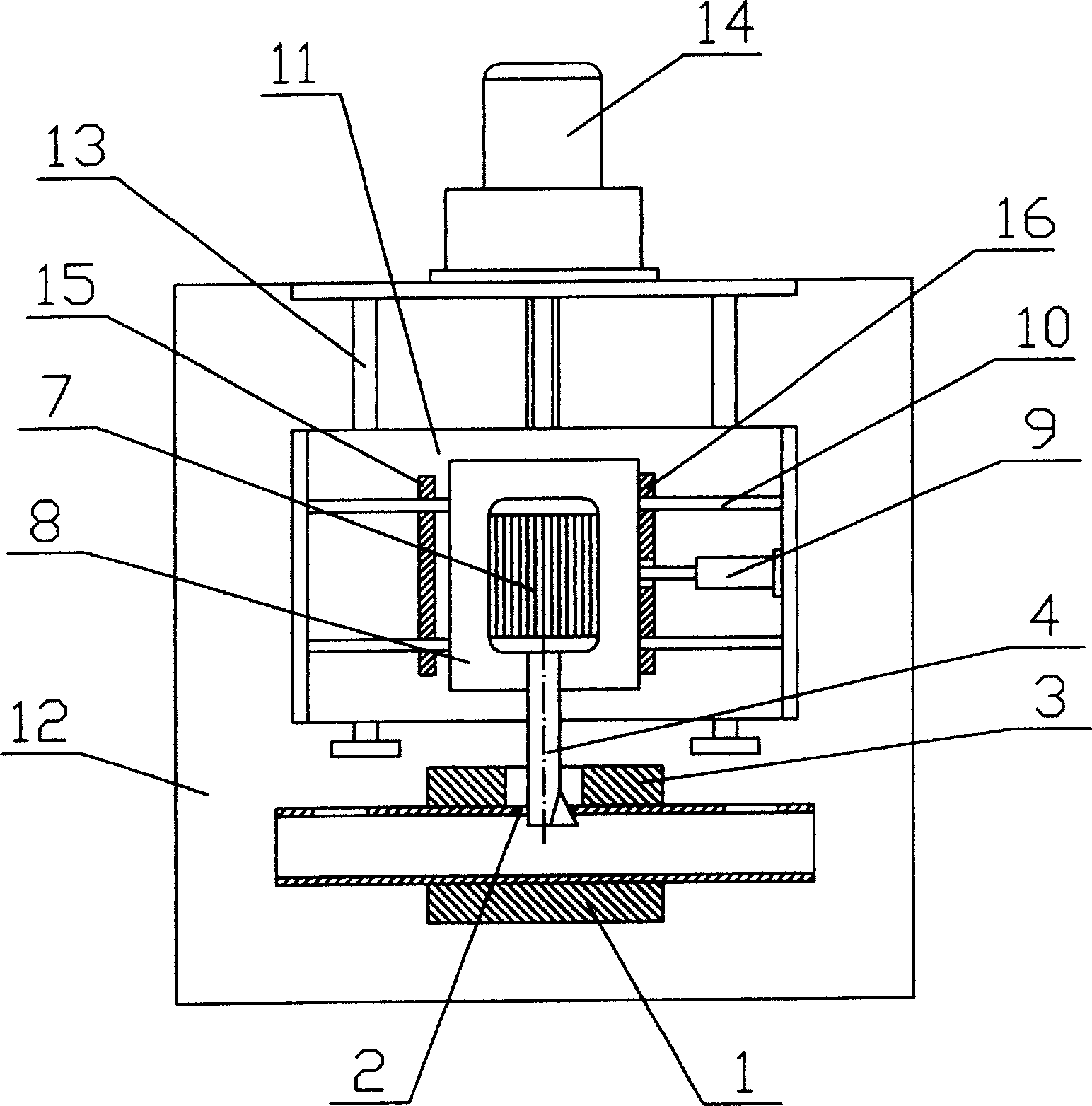

Machine manufactured mould system for manufacturing combined open-web member

The invention relates to a machine manufactured mould system for manufacturing a combined open-web member. The system comprises a pressure machine, an internal mould, an external mould, a seal plate and a demoulding device, wherein the seal plate is arranged on the upper part of the side of the internal mould and is a ring-shaped block to block off the gap between the internal mould and the external mould; the demoulding device is put at the internal side of the external mould; partial parts of the demoulding device extend from the external mould; and the partial parts or the whole part, which is arranged in the external mould, of the demoulding device is matched with the contact part on the inside surface of the external mould. The system has the following beneficial effects: the hydraulic machinery is utilized to press the dry cementing materials; after being formed, the open-web member is timely taken out of the mould system by utilizing the demoulding device; machining of the member can be completed in a shorter time; industrialized production of the open-web member is realized; and the manufactured open-web member has high density, uniform thickness and high production efficiency and is convenient to transport and simple to construct when being applied to the cast-in-situ open-web floor systems.

Owner:王本淼

Flanging arrangement for wall hole of thin metal pipe

The invention discloses flanging device for thin metal pipe wall hole, which comprises clamp used to hold thin metal pipe, corresponding flanging mould, flanging cutter that can insert from flanging mould and wall hole to hole inside, power driver for flanging cutter; set flanging blade on one side of knife handle with eccentric of cross section larger along handle axis, and the distance from promote end of out margin of the maximum section to handle axis is larger than the radius of wall hole, the circumcircles of the maximum section and handle section are less than diameter of wall hole. This invention cancels inner mould, with simple technique, and improves greatly the work efficiency.

Owner:夏纪运

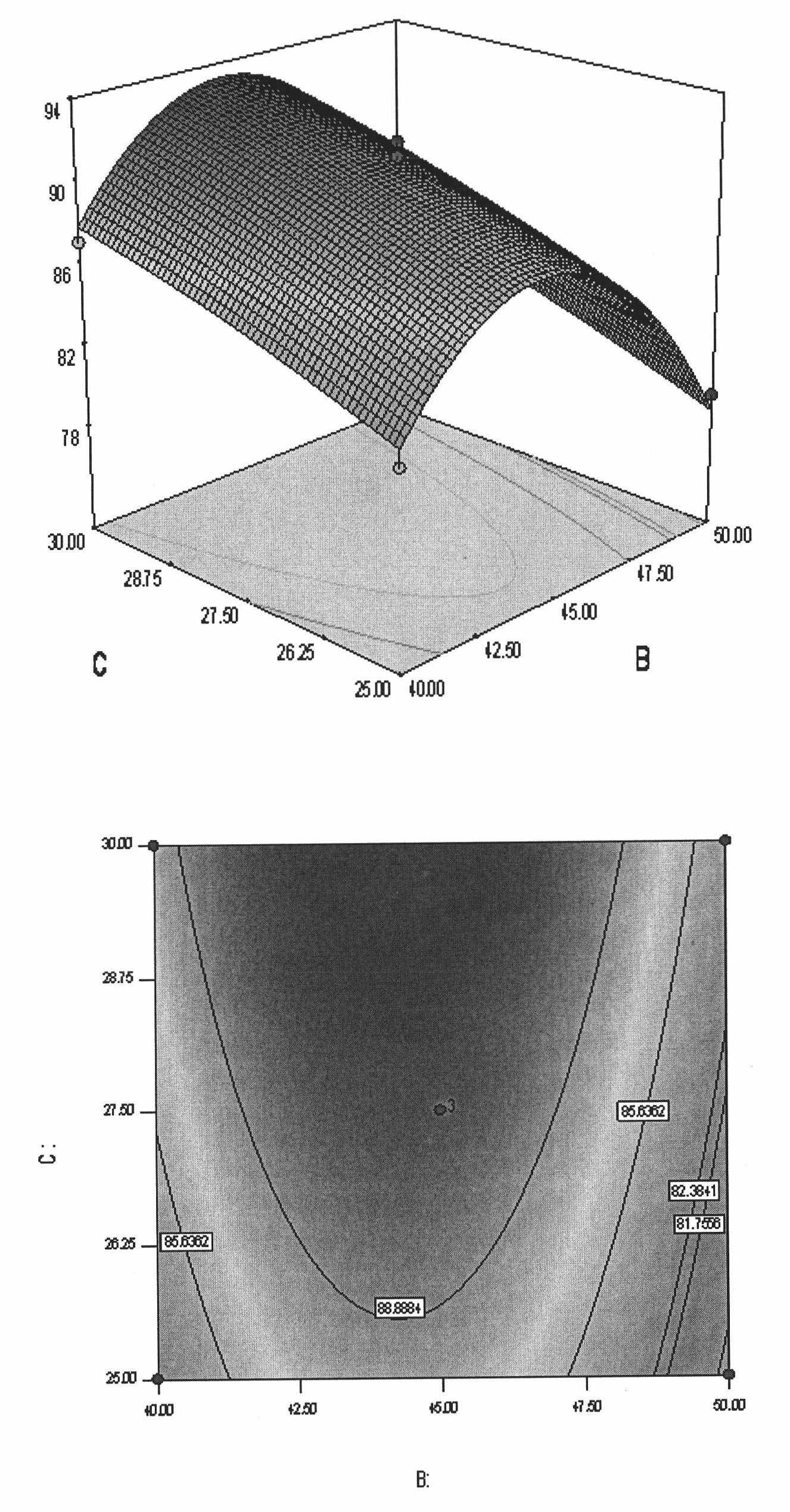

Supercritical CO2 method for extracting barbadosnut seed oil and product thereof

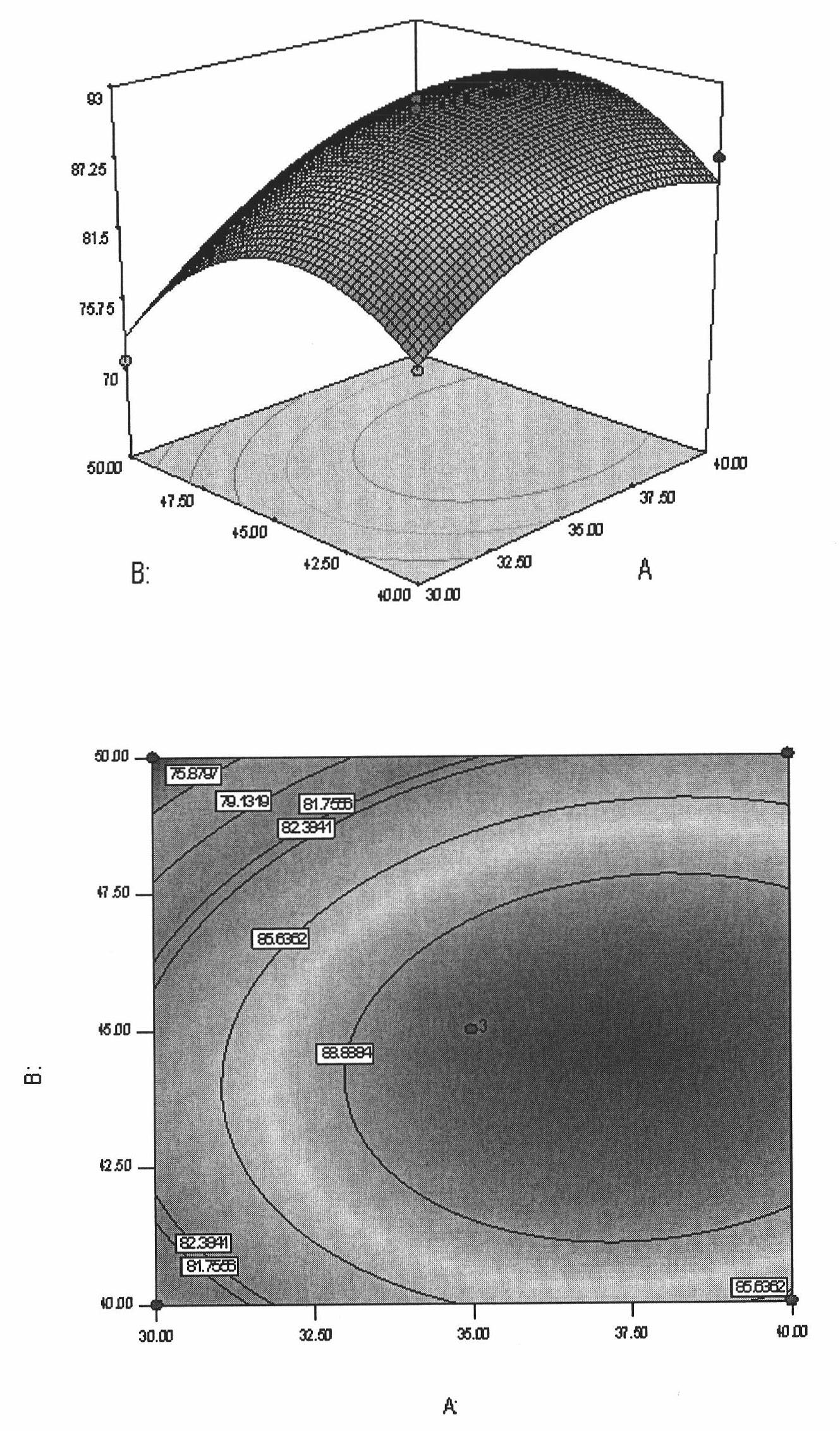

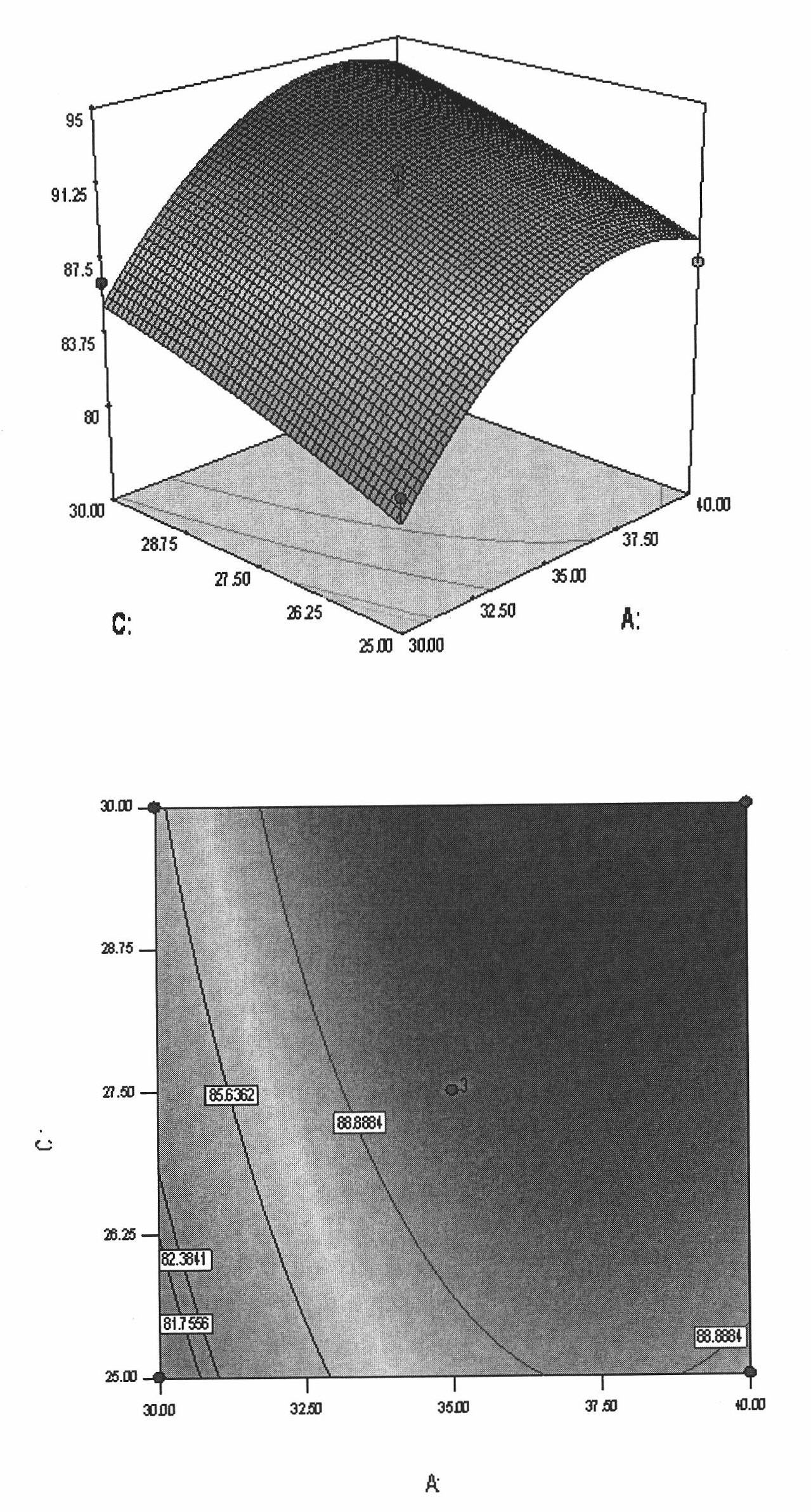

InactiveCN101775333ASimple extraction methodEasy to operateFatty-oils/fats productionOperabilityDeep processing

The invention discloses a method for extracting barbadosnut seed oil by supercritical CO2 extraction technology. The method comprises the following raw materials and processes: decladding barbadosnut seed, grinding and sieving, wherein the extraction ratio of barbadosnut seed oil is 93.13-94.41% under the condition that the particle size of raw materials is 20 mesh, the extracting pressure is 37.73 MPa, the extracting temperature is 44.53 DEG C, the CO2 flow rate is 30 L / h, the extraction time is 120min, the usage of entrainer is 40%, the separation pressure is 6.5-7.0 MPa, and the separation temperature is 50 DEG C. By adopting the supercritical CO2 technology for extracting barbadosnut seed oil, a new method for the deep processing of the barbadosnut seed is provided, thereby being capable of effectively developing the research on supercritical CO2 extraction of extracting the barbadosnut seed oil. The invention has the advantages of strong operability, good safety, high oil extraction ratio, good repeatability, simple process, no pollution and the like, and can be used for extracting the barbadosnut seed oil during production.

Owner:SICHUAN AGRI UNIV

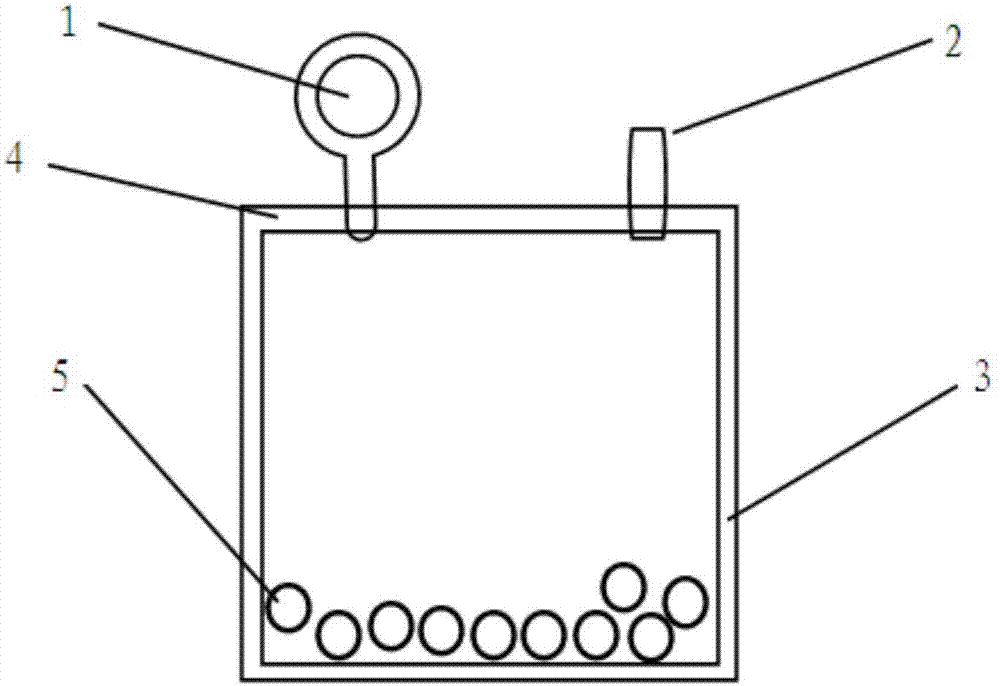

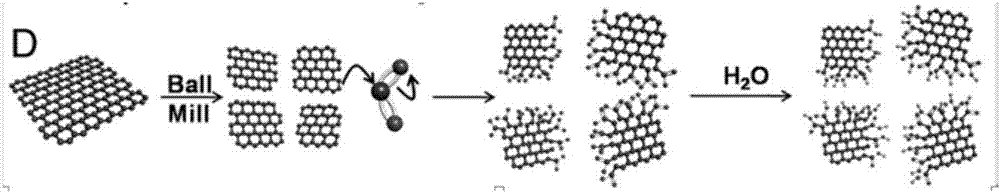

Method for preparing single-layer graphene through mechanical method

InactiveCN107089655AHigh degree of carboxylationIncrease success rateSingle layer grapheneExhaust valveSteel ball

The invention belongs to the technical field of graphene preparation and relates to a method for preparing single-layer graphene through a mechanical method. A specific technological process of the method comprises three steps of a hydroxylation process, a decontaminating process and a reduction process. The edge of natural flake graphite is processed in a carboxylation mode through a ball milling method to obtain initial carboxylation graphene powder, then pure carboxylation graphene powder with small iron content is obtained through the decontaminating process, and high-quality single-layer graphene is obtained through the thermal reduction process. The method avoids any strong oxidant and has high carboxylation degree, short ball milling time and high success rate; the decontaminating process is simple and effective; the reduction process avoids using reducing agents and is environmentally friendly; a main structure of a ball milling tank related to the hydroxylation process comprises a pressure meter, a gas exhaust valve, a tank body, a sealing cover and a stainless steel ball. The method has high preparation success rate, large yield, no pollution and low energy consumption and can achieve large-scale mechanical production through amplifying ball milling equipment.

Owner:QINGDAO UNIV

Forming machine of standing toilet pan

ActiveCN101844368ARealize mechanized productionIncrease profitUrinalsCeramic shaping apparatusEngineeringLight rail

The invention relates to a forming machine of a standing toilet pan, which belongs to the technical field of the ceramic production equipment. The invention is used for realizing the mechanized mold matching, tight locking, mold opening and automatic demolding in the standing toilet pan production. The invention has the technical scheme that the forming machine consists of a main frame, a mold opening traveling crane, a spiral hoisting machine, a main beam, a mold locking hoisting frame, a forming line, a side arrangement rolling wheel conveying line and an automatic blank remover, wherein the mold opening traveling crane is positioned on a light rail at the top of the main frame, the upper end of the spiral hoisting machine is arranged on the mold opening traveling crane, the lower end of the spiral hoisting machine is connected with the main beam, a plurality of groups of hoisting hooks are arranged above the mold locking hoisting frame and mutually correspond to hoisting hooks arranged on the main beam, mold locking latch hooks are symmetrically arranged at both sides of the mold locking hoisting frame, the lower end of the mold locking hoisting frame is provided with molds, the forming line is arranged under the mold locking hoisting frame, the positions of the molds on the forming line correspond to molds under the mold locking hoisting frame, and the side arrangement rolling wheel conveying line and the automatic blank remover are positioned at one side of the forming line. The invention realizes the mechanized production of the standing toilet pan products, greatly improves the work efficiency, improves the utilization rate of the shop area, and reduces the work intensity of workers.

Owner:HUIDA SANITARY WARE

Mechanized production method of yellow rice wine wheat starter

InactiveCN101157891ARealize mechanized productionQuality improvementBioreactor/fermenter combinationsBiological substance pretreatmentsBrickRhizopus

A mechanical production method for wheat starter (a kind of rhizopus) of yellow rice wine relates to the fermentation technical field. The invention uses a making and pressing rhizopus brick machine assisted by some mechanical devices such as a machine for grinding wheat, a machine for mixing, and a rhizopus brick conveyer in place of the traditional rhizopus- producing process such as grinding wheat, mixing, piling up, mixing the rhizopus, raising the rhizopus, treading the rhizopus, and cutting the rhizopus etc. The production method of the invention is arranged reasonably and is also easy and convenient to operate. The quality of the rhizopus product can be comparable with that of the traditional rhizopus product. Besides, the quality is stable and reliable. The invention can decrease the intensity of labor while improving the work efficiency greatly. The social economy efficiency is remarkable. The invention can replace the traditional rhizopus-producing technique.

Owner:吴善好

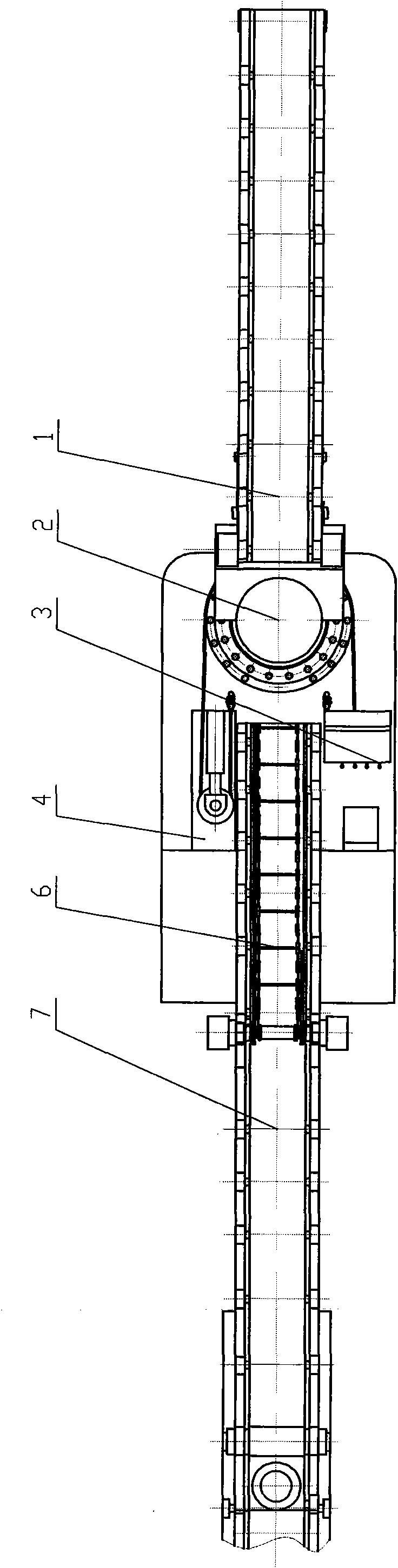

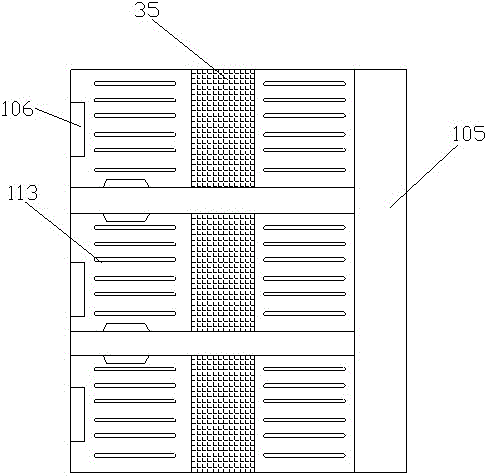

Assembling device for assembling cylinder bodies and assembling cylinder body and seal head

ActiveCN109623186AReduce misalignmentReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesWeldingRobot

The invention provides a assembling device for assembling cylinder bodies and assembling a cylinder body and a seal head. The assembling device comprises a lifting appliance mechanism, welding robots,an internal-shoring tool and an external-clamping tool, wherein the lifting appliance mechanism is arranged above the internal-shoring tool so as to hoist a lower cylinder body or a to-be-assembled component; the internal-shoring tool is used for fixing the lower cylinder body and the to-be-assembled component and driving the lower cylinder body and the to-be-assembled component to rotate, and lifting type guide mechanisms are arranged on the internal-shoring tool and extend upwards from the inner part of the lower cylinder body so as to guide falling of an upper cylinder body and carry out rounding on the upper cylinder body and the lower cylinder body; the external-clamping tool is arranged outside the internal-shoring tool in a sleeved mode so as to guide falling of the seal head, andthe outer wall of the lower cylinder body and the outer wall of the seal head are clamped; and each welding robot is arranged on one side of the internal-shoring tool to weld a girth weld between thelower cylinder body and the to-be-assembled component. According to the assembling device for assembling the cylinder bodies and assembling the cylinder body and the seal head, the mechanization is realized, workers can find the girth weld without climbing on a working table, the labor intensity of workers is reduced and the production efficiency is improved.

Owner:JIANGSU NEW TIANBAO MACHINERY

Multi-storey building type livestock breeding system and breeding method

ActiveCN106172022AIntensifyRealize mechanized productionAnimal housingAnimal scienceLivestock breeding

The invention relates to a multi-storey building type livestock breeding system and breeding method. The multi-storey building type livestock breeding system comprises a building with multiple groups of breeding layers, each group comprises at least two breeding layers, each breeding layer is provided with closed breeding houses, the house mutilayer breeding layers are each internally provided with automatic excrement and urine cleaning and collecting devices and automatic feeding devices, and each breeding layer is provided with a feeding bin used for providing feed for all the breeding houses of each breeding layer; each breeding layer is provided with an environment control system for regulating the breeding environment of each breeding layer, the building is internally provided with livestock ramps located between adjacent breeding layers, and a conveying device allowing people and livestock to come in and go out is arranged on the side of the building. The multi-storey building type livestock breeding system achieves automatic feeding of the feed and excrement and urine cleaning and collecting in a multi-storey building, and temperature and humidity control is achieved by means of regulation of the environment control system; according to the multi-storey building type livestock breeding system and breeding method, a good effect of separating dry space from moist space can be achieved, intensive and mechanized production of livestock breeding is achieved, control of the internet of things is promoted, the land is effectively saved, fine management is achieved, and the economic benefit is increased.

Owner:FUJIAN GHBEST ECOLOGICAL FARMING DEV

Organic fertilizer special for ginseng and preparation method for organic fertilizer

ActiveCN102249757ASlow and long-lasting nutrient supplyIncrease enzyme activityBio-organic fraction processingOrganic fertiliser preparationNutrientChemistry

The invention relates to a fertilizer, in particular to an organic fertilizer special for ginseng and a preparation method for the organic fertilizer. The organic fertilizer is more suitable for non-forestland growth of the ginseng. The organic fertilizer is prepared from the following raw materials in percentage by weight: 20 to 40 percent of sawdust, 10 to 20 percent of chicken manure, 10 to 20percent of soybean curb residue, 10 to 20 percent of bark and 10 to 20 percent of corn flour. The preparation method comprises the following steps of: (1) fermenting and composting materials; (2) fermenting and composting the chicken manure; and (3) mixing, namely mixing the composted materials and the composted chicken manure in a ratio that the chicken manure accounts for 10 to 15 percent of the total weight, crushing and screening to obtain the organic fertilizer. The organic fertilizer increases organic matters of soil, provides massive nutrient components required by plants, and has the characteristics of balanced nutrients, reliable fertilizer efficiency and advanced process.

Owner:吉林省集安益盛药业股份有限公司

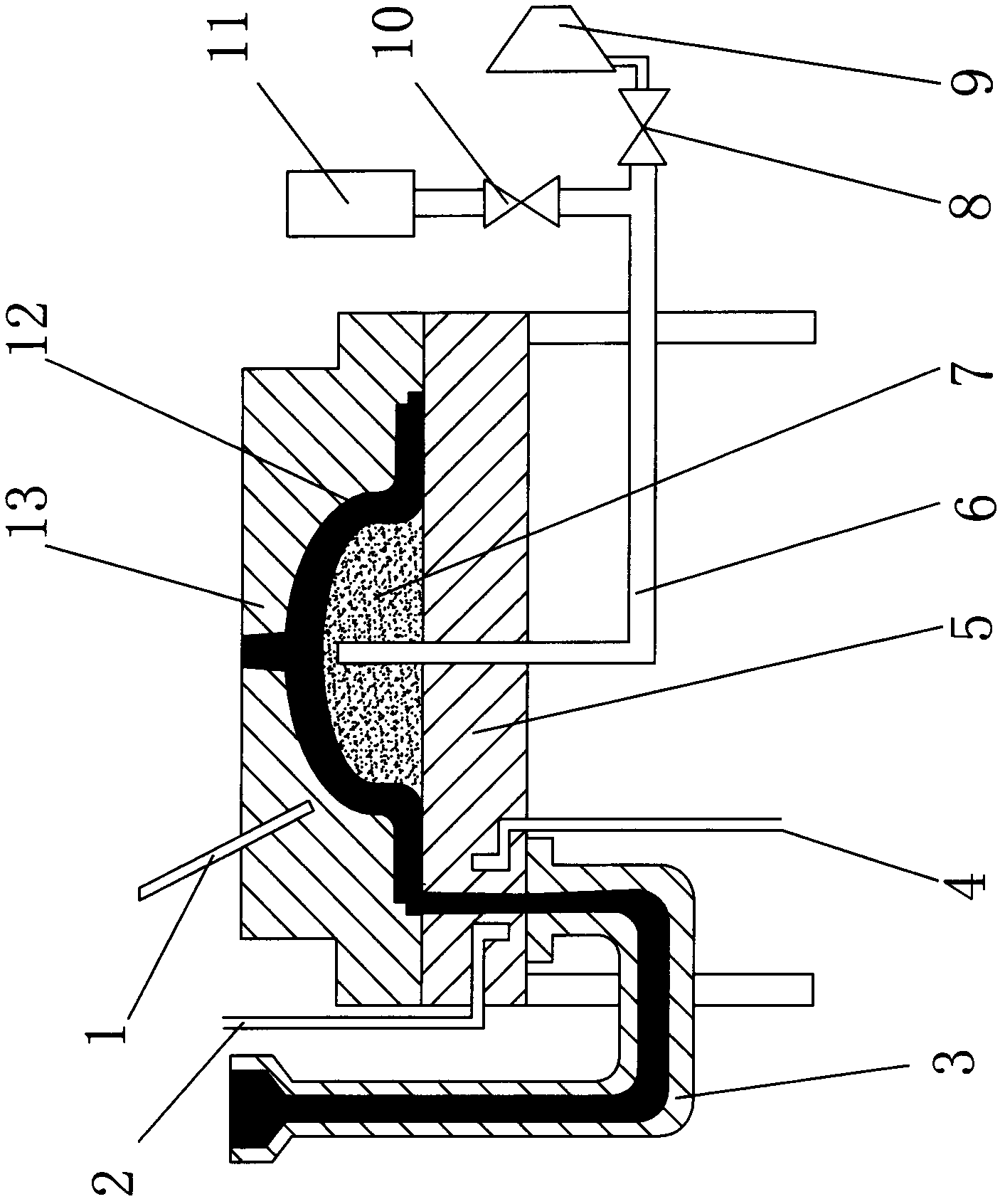

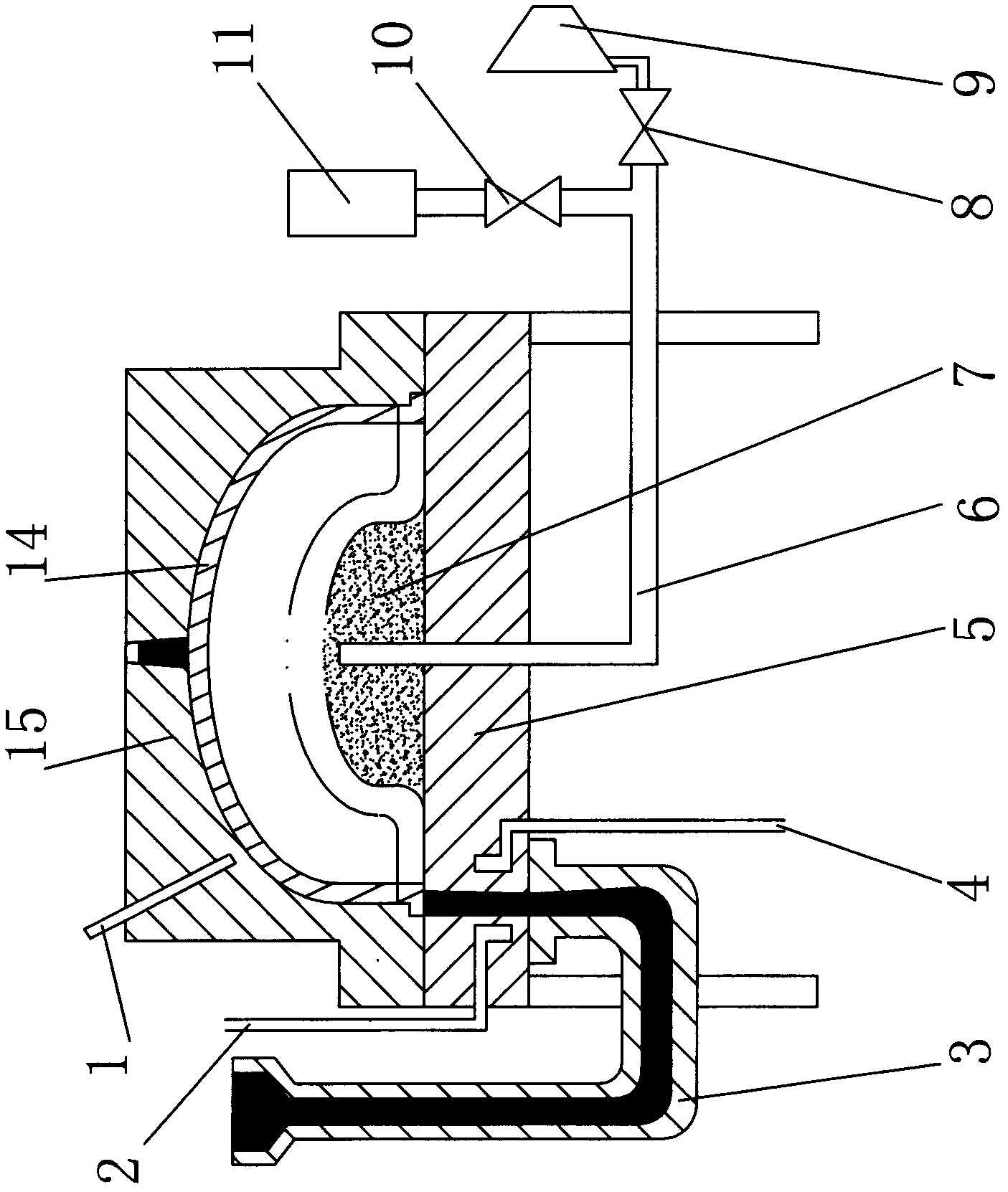

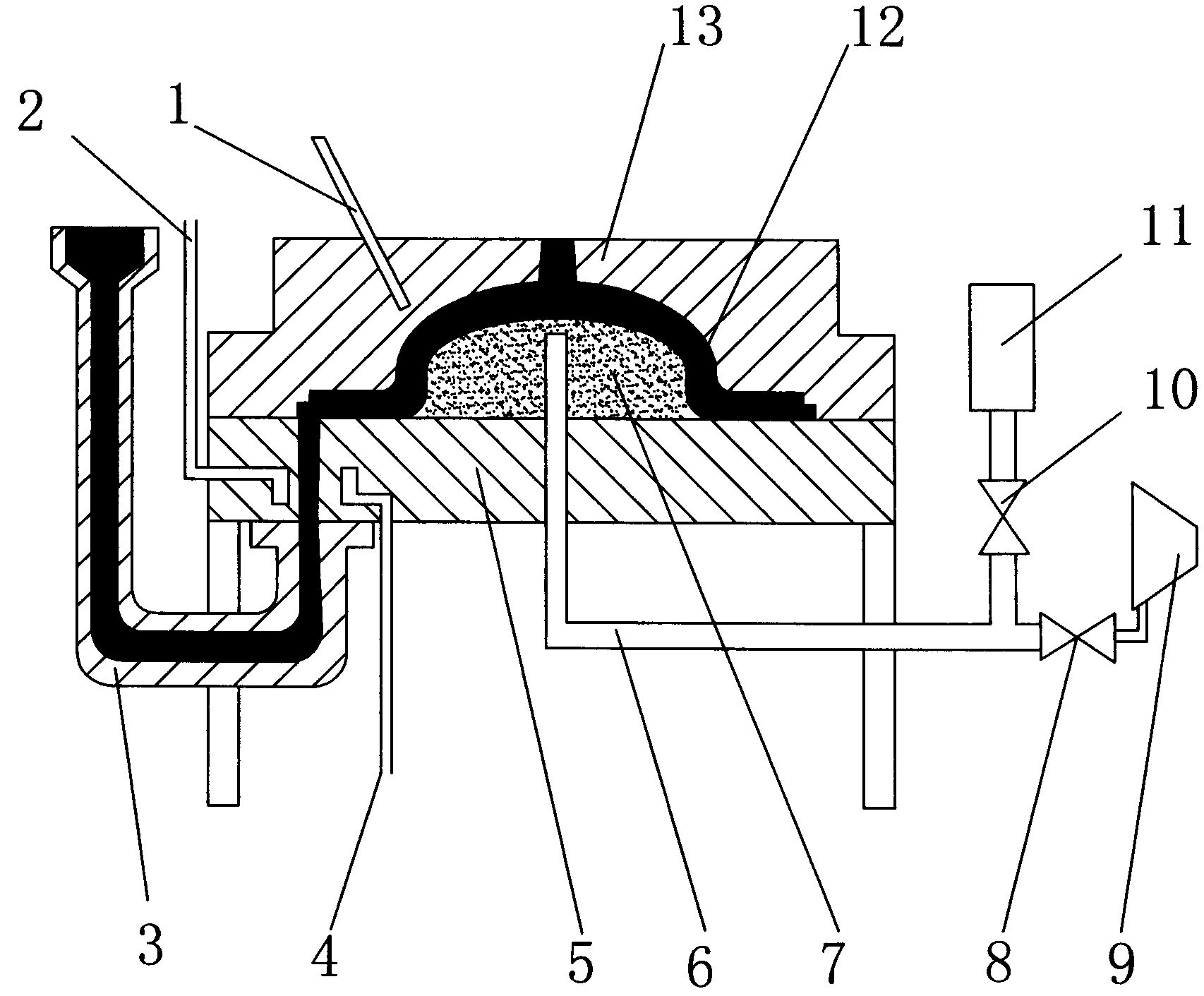

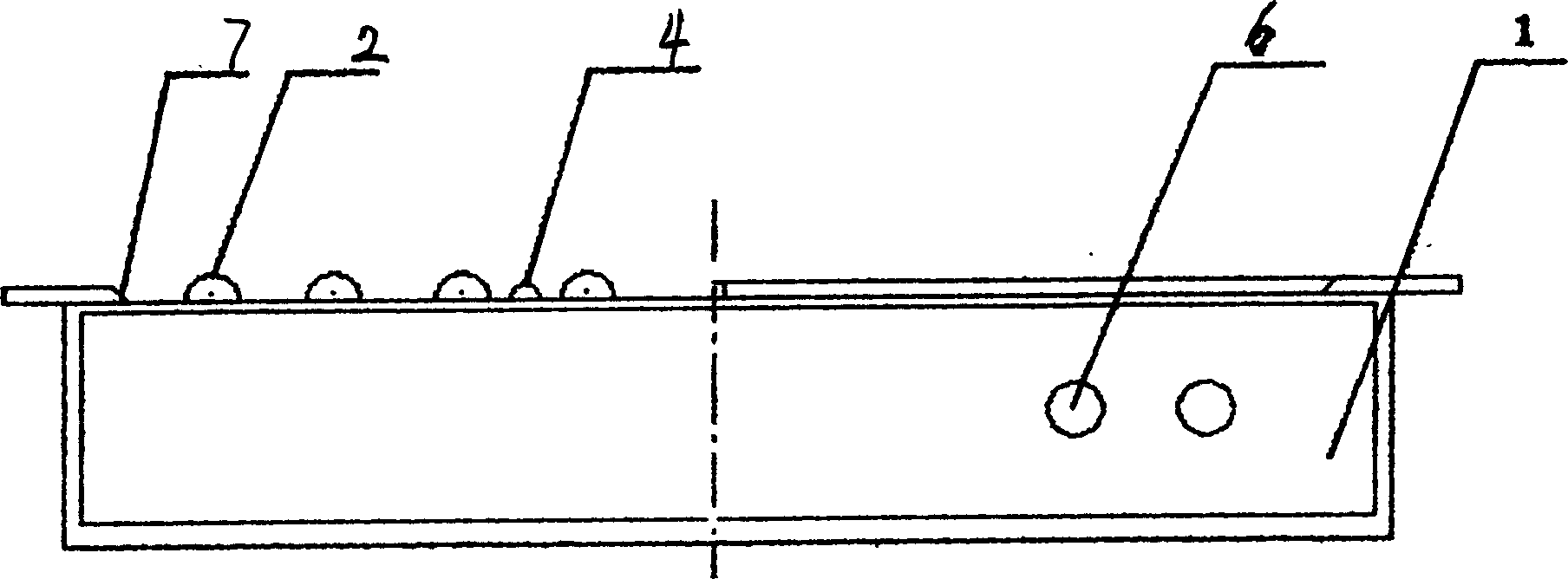

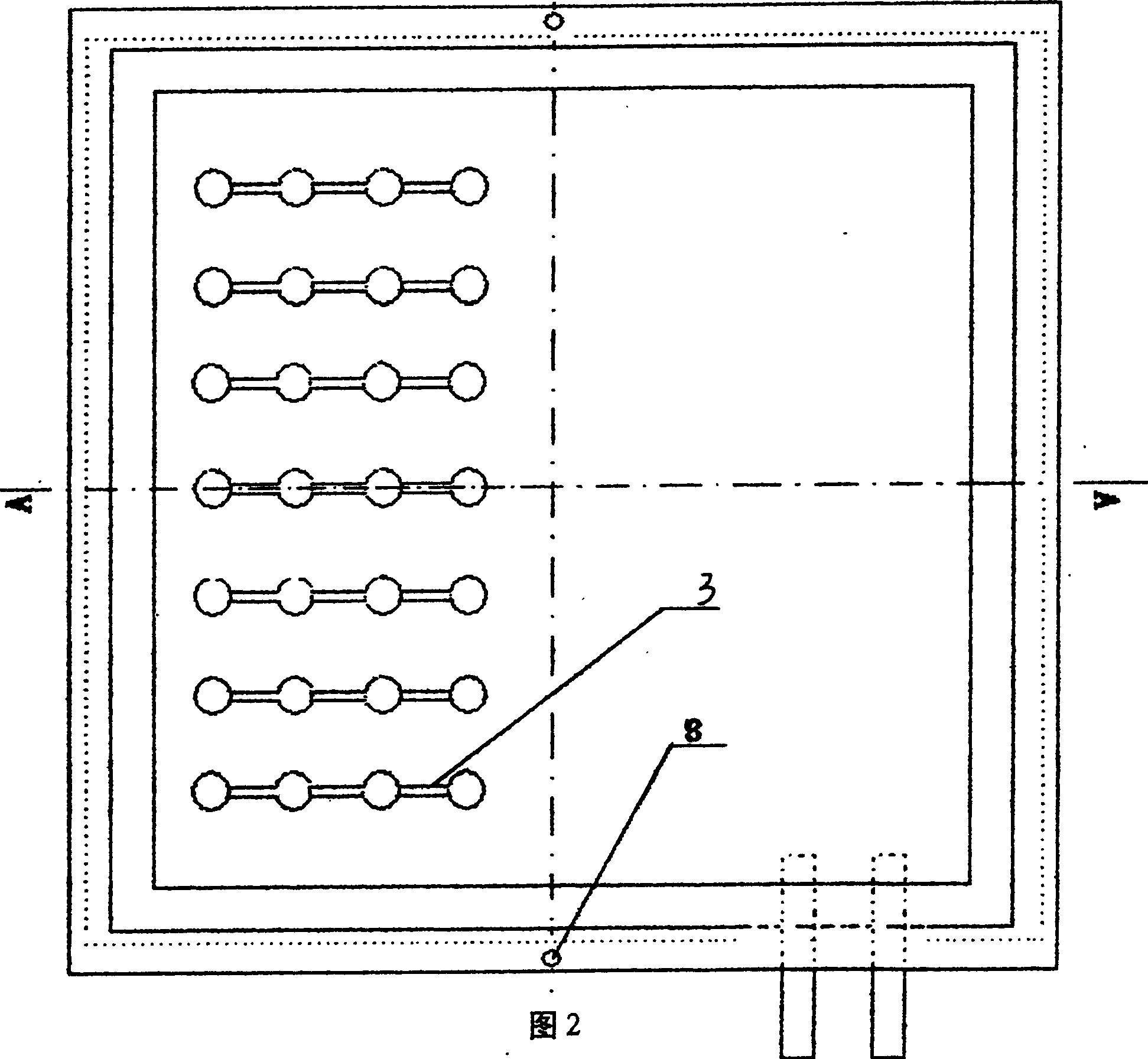

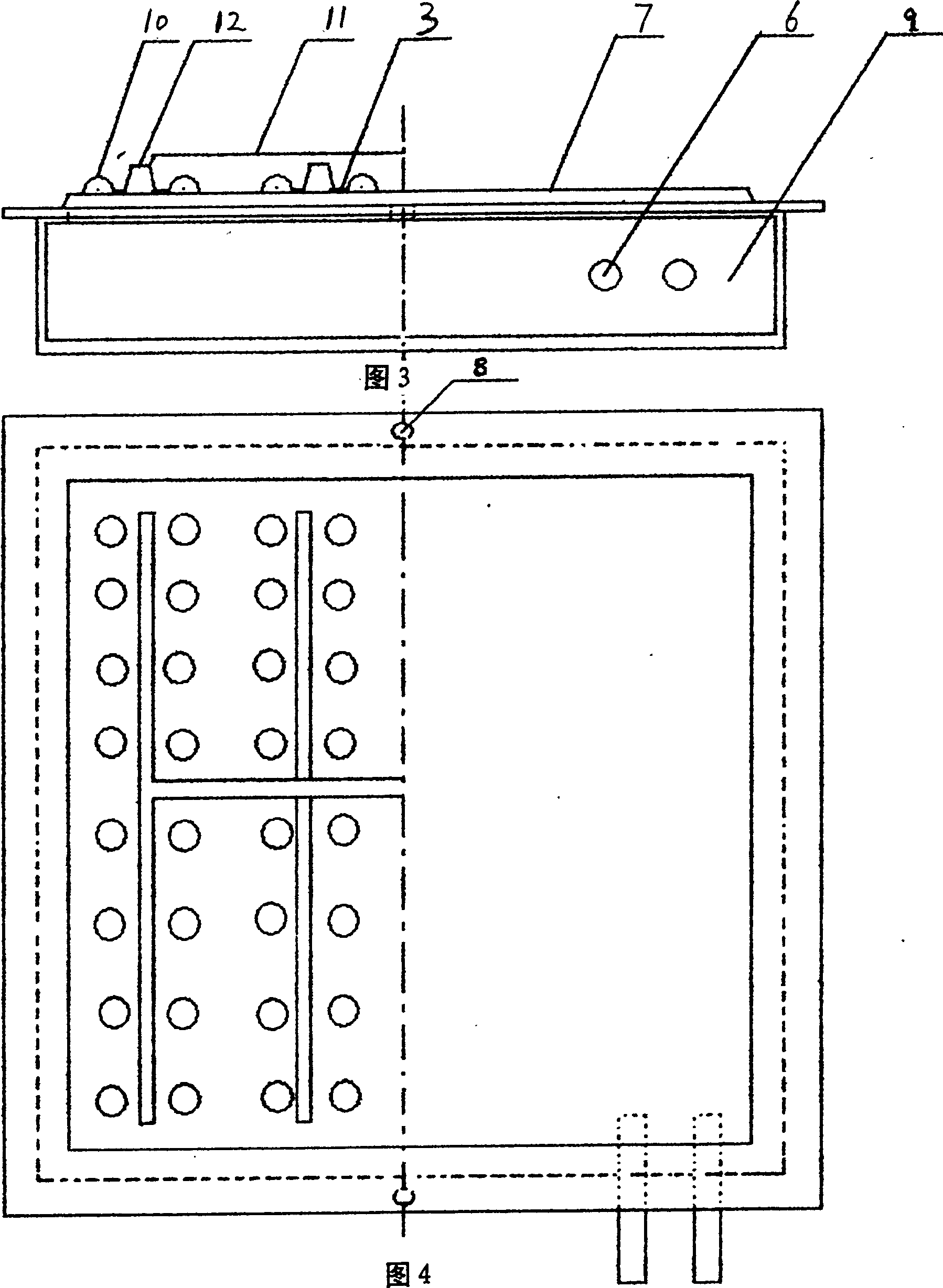

Method and device for pneumatic bulging after head casting

InactiveCN102615505AReduce consumptionSimple manufacturing processOther manufacturing equipments/toolsCrystal structureCrystallization temperature

The invention relates to a method and a device for pneumatic bulging after head casting, in particular to a method and a device for refining crystal structure of a casting by pneumatic bulging to improve strength, which belong to the technical field of pressure container manufacturing. Alloys are prepared and melted according to a required proportion, metal melt heated to pouring temperature is poured into a mould composed of an upper casting mould, a base and a core, gas in the mould is exhausted through a man gas pipe disposed inside the core during pouring, and accordingly interior pressure of a cavity is smaller than atmospheric pressure. When the temperature of the metal melt in contact with the upper casting mould is lower than 10-360 DEG C of crystallization temperature, the upper casting mould is quickly replaced with an upper bulging mould. The surface of a cavity of the replacement upper bulging mould is the same as a final shape of a head in size. A cavity of a head blank is gradually filled with pressure gas through the main gas pipe disposed inside the core. Under the bulging action of the pressure gas, the head blank deforms in a thermoplastic way and finally in the same shape as the inner cavity of the upper bulging mould.

Owner:SHAANXI UNIV OF SCI & TECH

Method for producing milling-ball by vacuum sealing and its shaped mould

InactiveCN1579670AIncrease productivityHigh yieldFoundry mouldsFoundry coresEngineeringMechanical engineering

The invention shows a method of producing grinding pencil wheel in vacuo and its mould. It pumps the air, covers top sheet, fills sand, tamp it, covers backing film, pumps the air and gets the moulds, lower model and upper model of the grinding pencil wheel. Then it closes the mould and forms the cavity of the mould. Finally, it pours it into shape, cools it and gets the intact mould. The invention's advantages lie in: the method of producing grinding pencil wheel in vacuo can increases the work efficiency greatly; the work efficiency of the single cargo is increased by scores of times; the manufacturing rate reaches 95%; the defective index is decreased greatly and can realize the mechanized production. The mould of the grinding pencil wheel is featured by reasonable construction and simple operation.

Owner:XINJIANG UYGUR AUTONOMOUS REGION NO 3 MACHINE TOOL WORKS

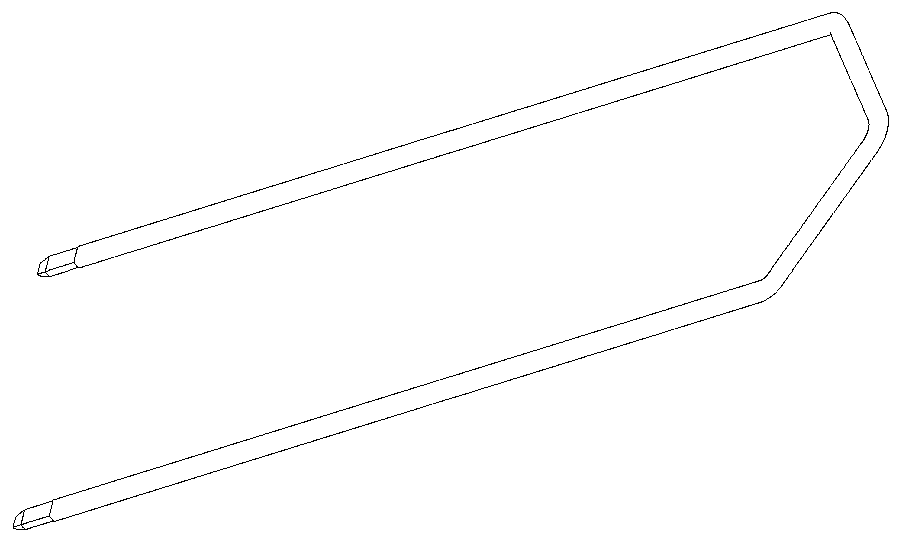

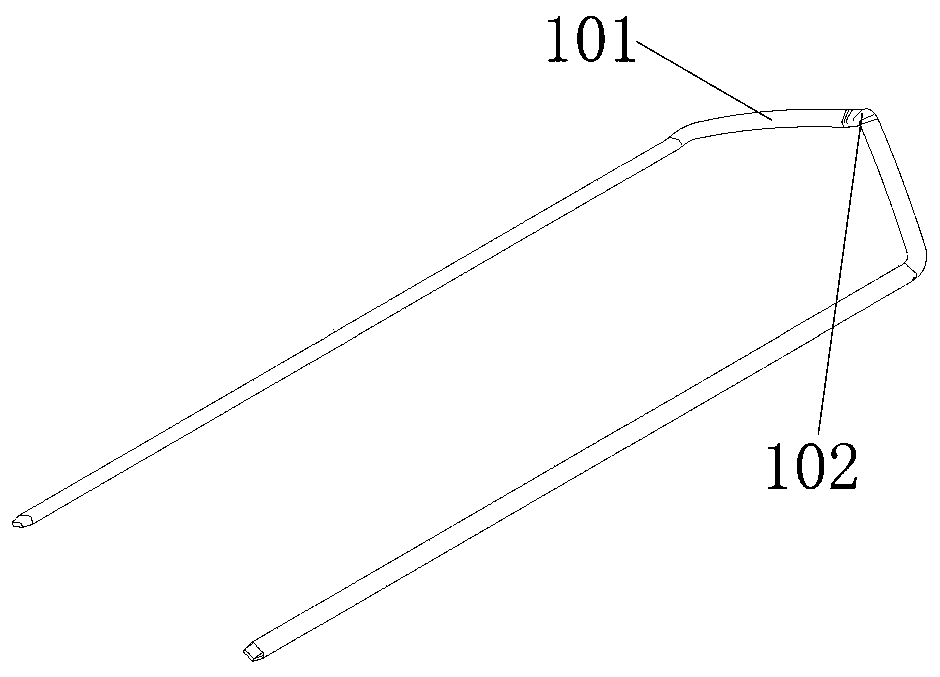

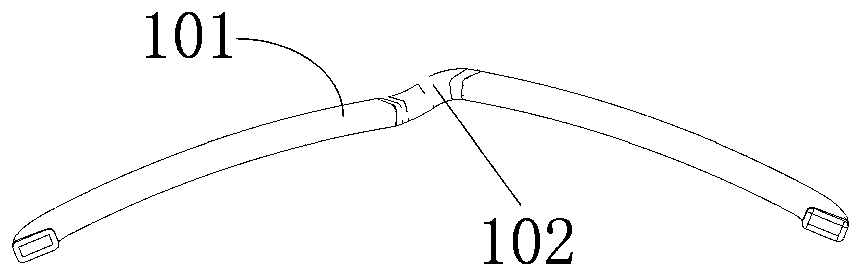

Flat copper wire bending forming device

ActiveCN110640050ARealize mechanized productionReduce human involvementManufacturing dynamo-electric machinesCopper wireEngineering

The invention discloses a flat copper wire bending forming device. The flat copper wire bending forming device comprises a compression die and a driving unit, wherein the compression die comprises twopairs of pressing heads consisting of a first upper half pressing head, a first lower half pressing head, a second upper half pressing head and a second lower half pressing head; the two upper half pressing heads are combined to form an upper forming surface, and the two lower half pressing heads are combined to form a lower forming surface; the driving unit comprises a first actuator, a second actuator, a third actuator, a fourth actuator and a fifth actuator, wherein the first actuator, the second actuator, the third actuator and the fourth actuator are used for respectively controlling theup and down movement of each pressing head, and the fifth actuator is used for adjusting the horizontal transverse distance between the two pairs of pressing heads; and the moving amount of each actuator is set according to the forming condition of the shape of bent part transition section of a space-type hairpin-shaped flat copper wire, so that a flat hairpin-shaped flat copper wire in the compression die is pressed into the space-type hairpin-shaped flat copper wire with the bent part transition section. According to the flat copper wire bending forming device, the mechanical production ofthe space-type hairpin-shaped flat copper wire can be achieved, the manual involvement is reduced, and the product quality and the production efficiency are improved.

Owner:ANHUI JEE AUTOMATION EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com