Flat copper wire bending forming device

A technology for bending and forming flat copper wires, which is applied in the field of bending and forming devices for flat copper wires for motor stators, can solve problems such as difficulty in ensuring product consistency, high labor intensity of workers, and large manual participation, and achieve reduction Human participation, improved product quality and production efficiency, adaptable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

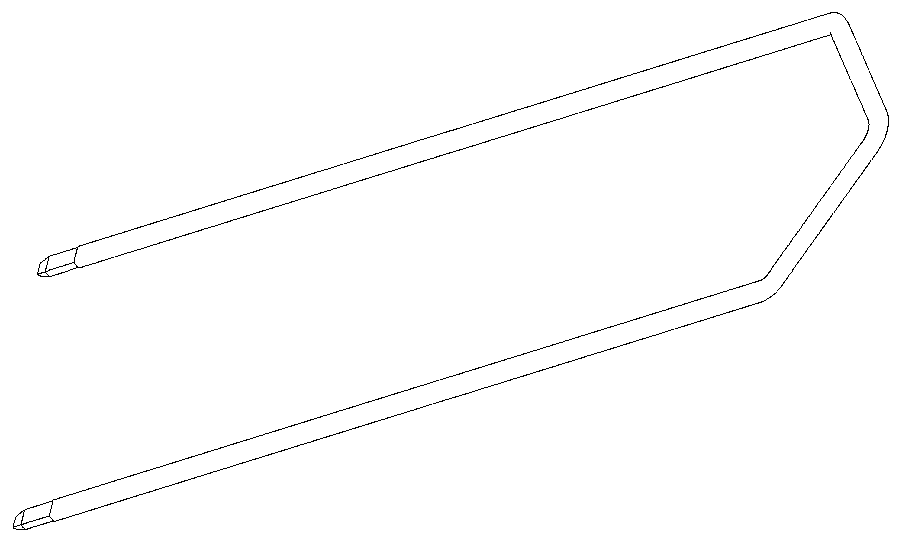

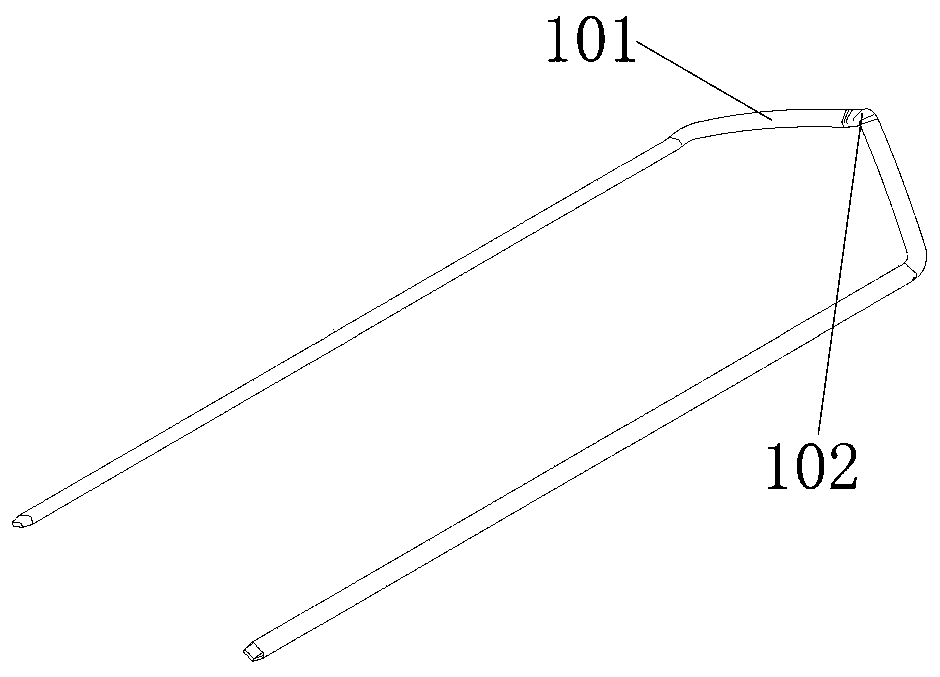

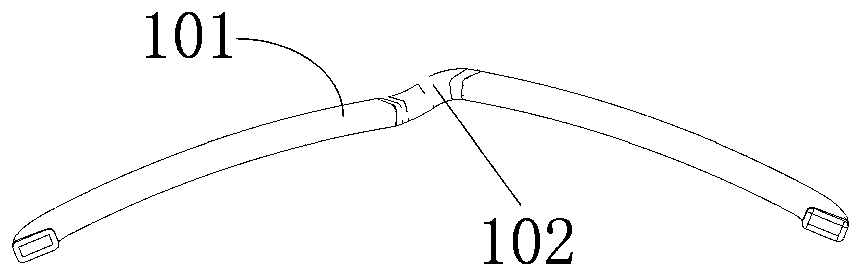

[0053] Such as Figures 3 to 6 As shown, the flat copper wire bending and forming device of the present invention includes a pressing die 1 for pressing a flat hairpin-shaped flat copper wire into a space-shaped hairpin-shaped flat copper wire, a base 3, and a base 3 arranged on the base 3 on the drive unit.

[0054] Wherein, the pressing die 1 is provided with at least one set, and each set of pressing dies 1 includes two pairs of pressing heads consisting of a first pair of pressing heads and a second pair of pressing heads, and the first pair of pressing heads is formed by the first pair of pressing heads. The upper half indenter 11 and the first lower half indenter 13 constitute, the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com