Brick pile packaging method and brick pile packaging production line

A packaging production line and packaging method technology, applied in packaging, building materials packaging, transportation and packaging, etc., can solve the problems of backward packaging process methods, high labor intensity of workers, and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

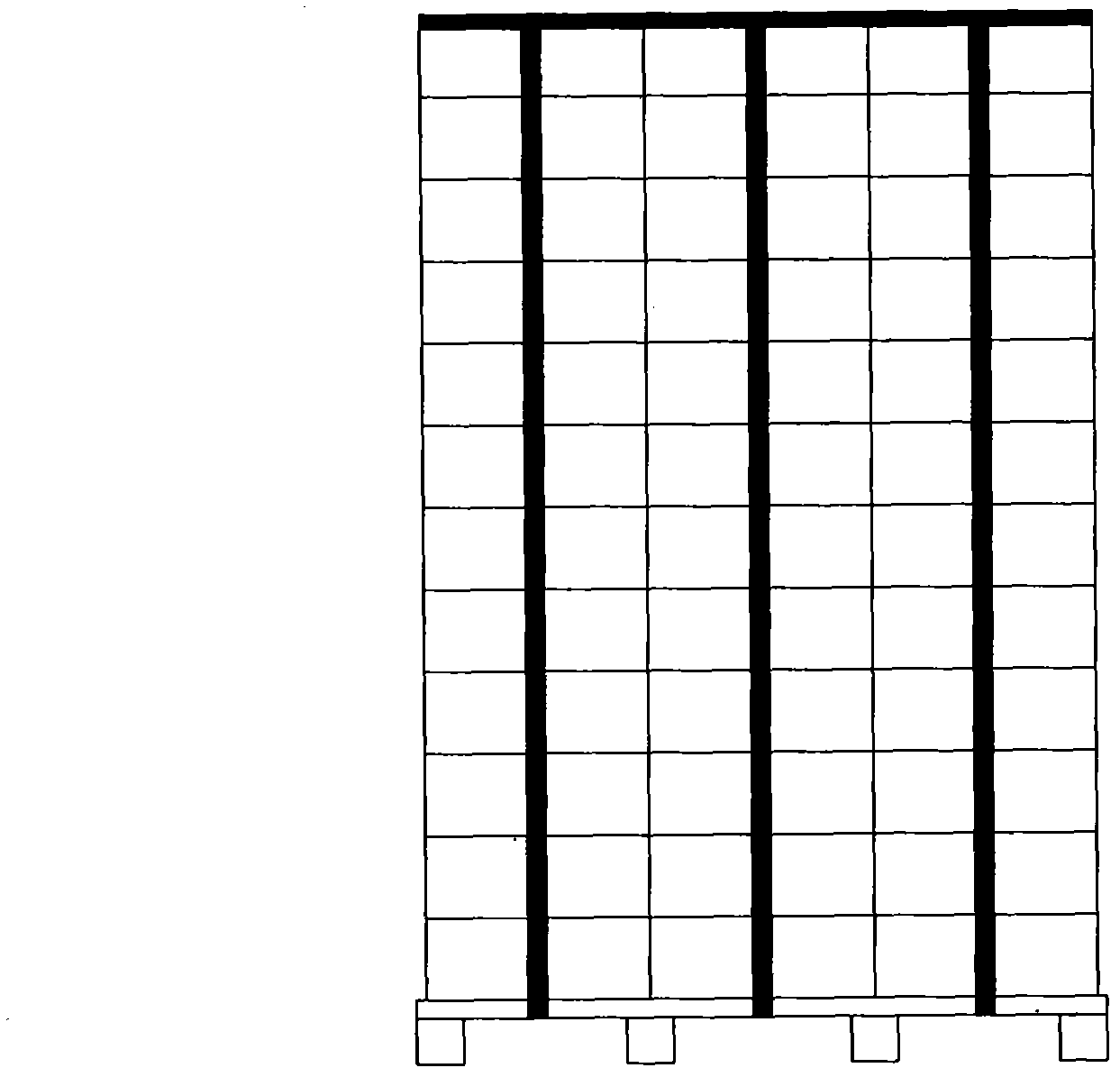

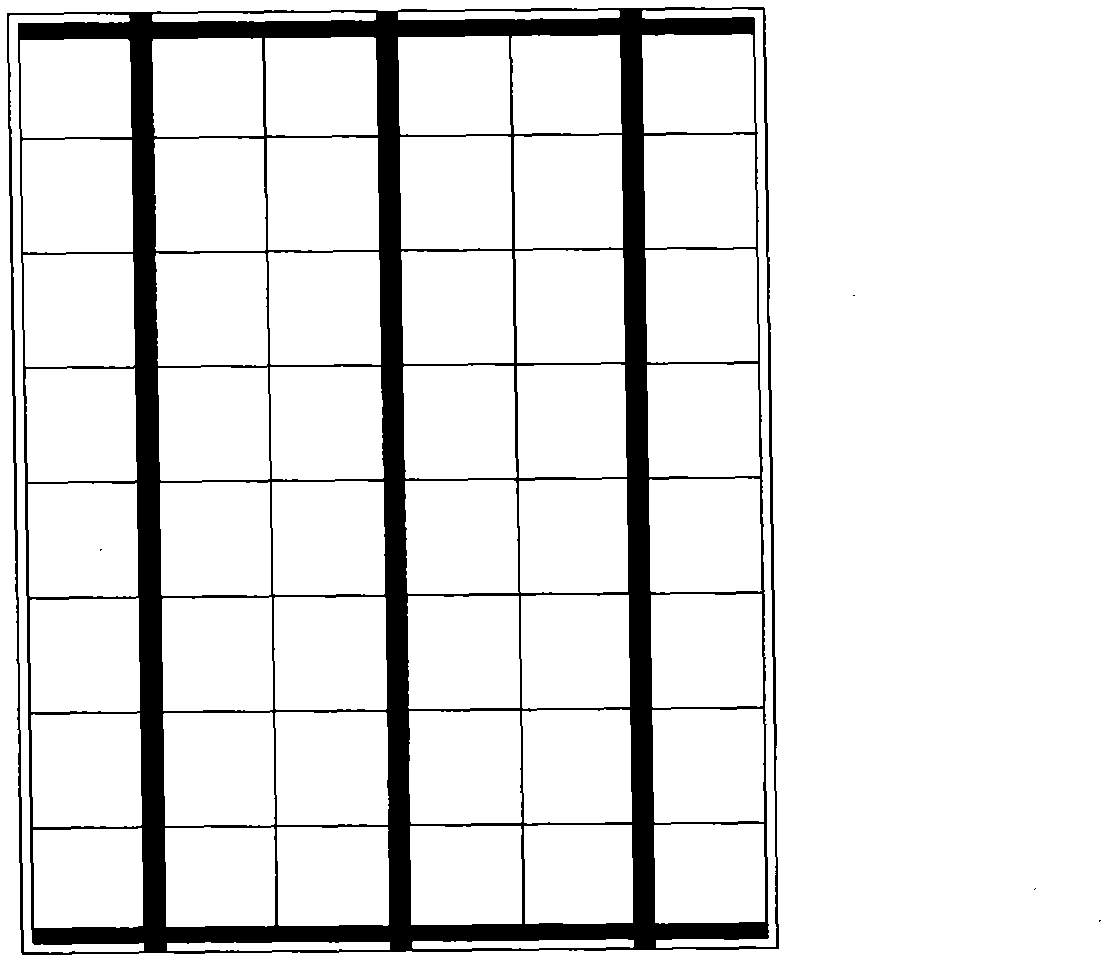

[0024] see figure 1 and figure 2 , a packaging method of brick stamping is that the finished brick stamping on the steaming car is processed by mechanical equipment and divided into 4 packaging stampings. There are 3 rows in the direction, 8 rows in the direction of the brick width of 115mm, and 12 layers in the direction of the brick height of 90mm. The external dimensions of the packaging stamp are 920mm long x 720mm wide x 1080mm high, and stamp the 4 packages on the steaming car. Carry them to the pallets respectively, and cover the two brick stomping corner lines along the length of the bricks on the uppermost layer of the bricks with corner guards. The strapping tape, the strapping tape is a kind of plastic tape, and the corner beading strip is a plastic strip, which makes the 288 bricks into a solid whole through the brick stomping of the pallet, the corner beading strip and the strapping tape.

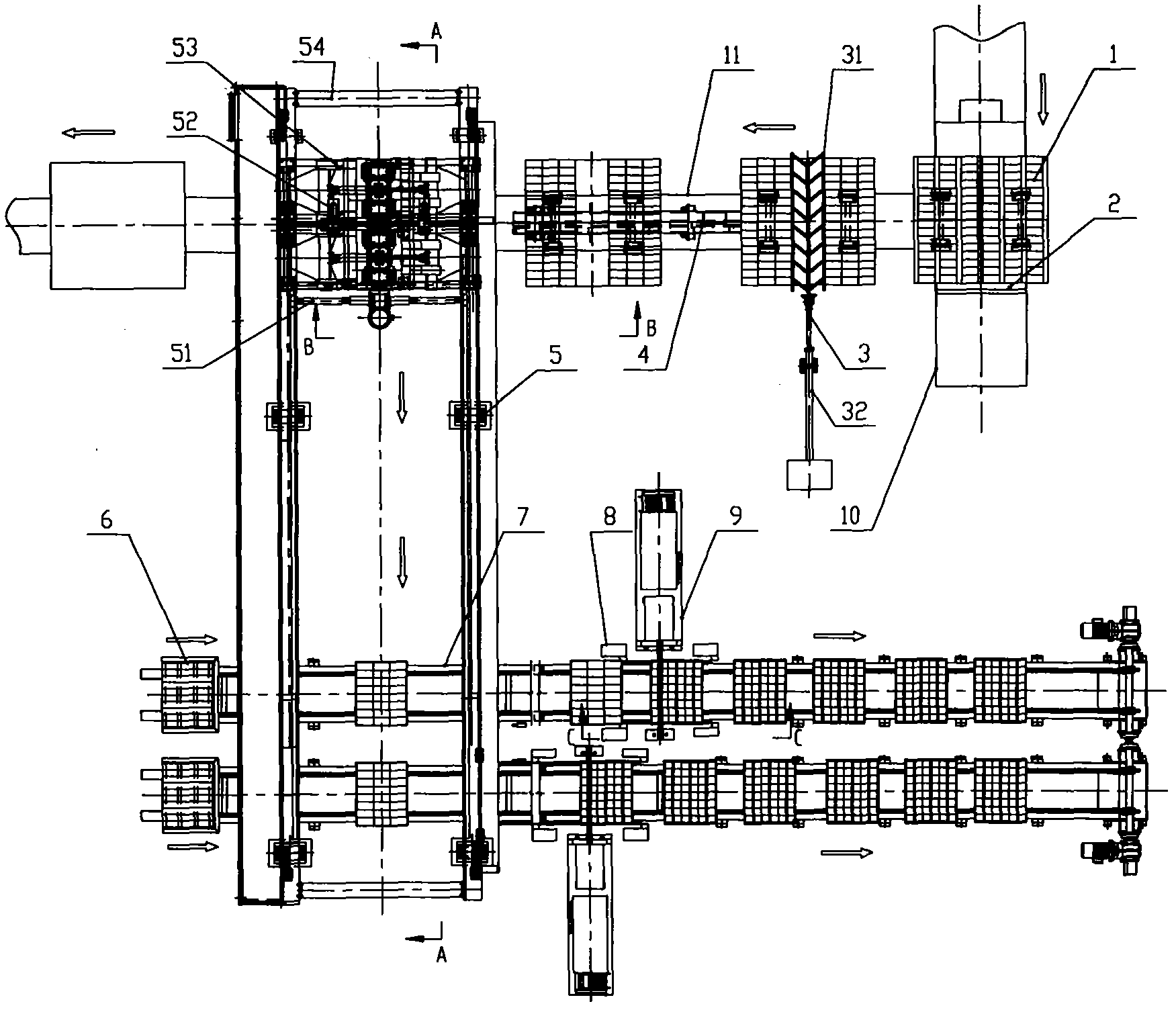

[0025] see Figure 3 to Figure 7 , a packaging production line for bri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com