MgF2/oxide composite membrane used for anti-reflection of glass surface

A glass surface and oxide technology, used in ion implantation plating, coating, instruments, etc., can solve problems such as no better solutions, improve work efficiency and service life, expand selection range, and improve scratch resistance. rubbing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

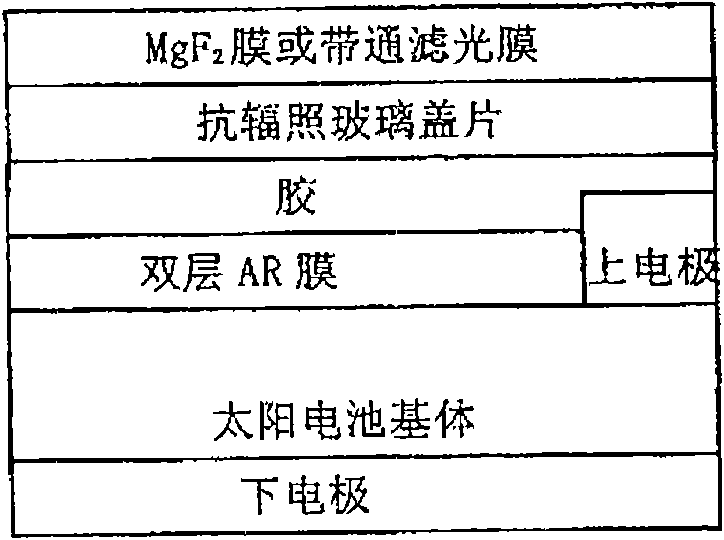

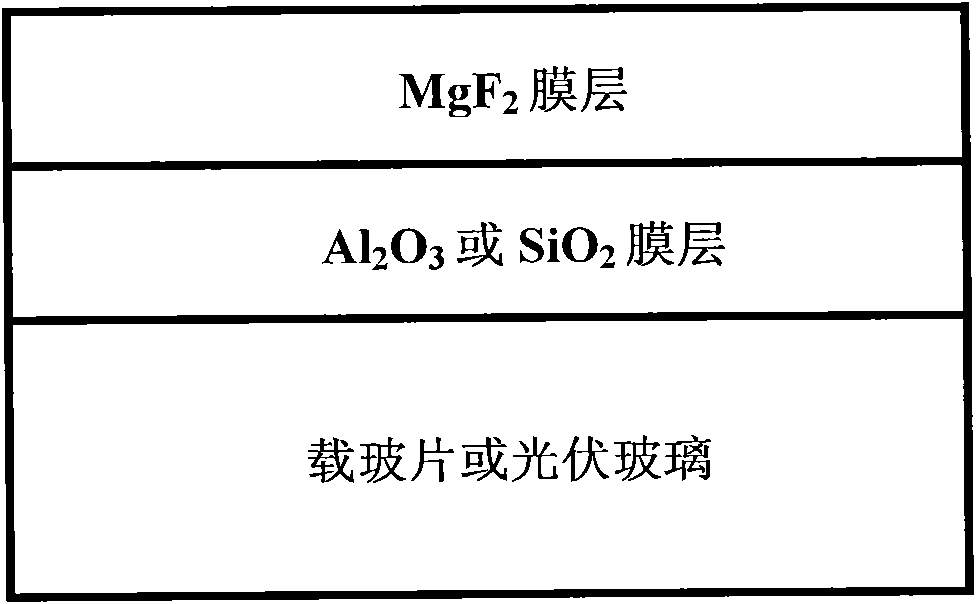

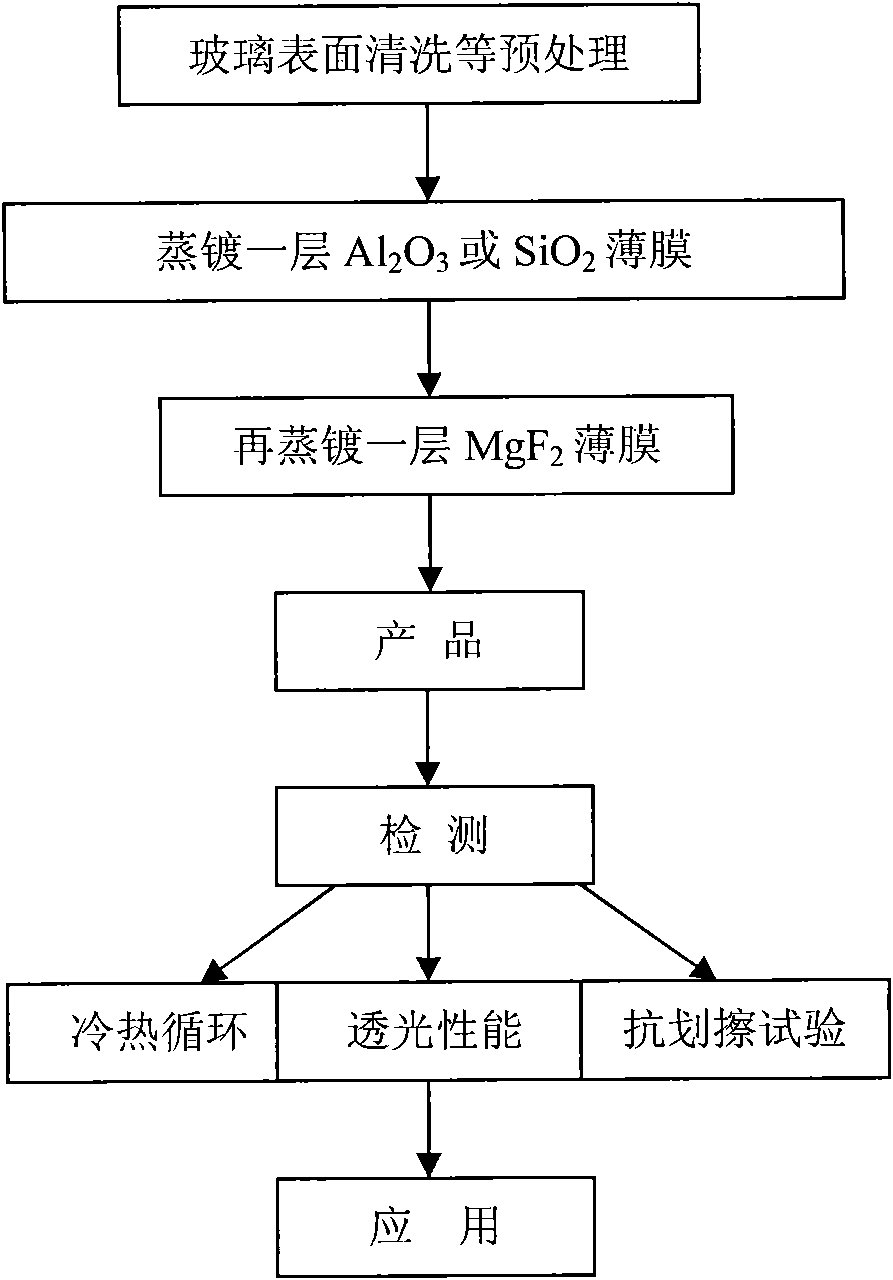

[0031] Embodiment 1: prepare MgF on glass substrate 2 / Al 2 o 3 Double layer anti-reflection composite film

[0032] Deposition of MgF on glass slide and photovoltaic glass surface by electron beam vacuum evaporation coating process 2 / Al 2 o 3 Double-layer anti-reflection composite film, the main structure and performance of the test are as follows:

[0033] (1) The surface of the film layer is smooth and bright, and the total thickness of the film layer is about 180nm;

[0034] (2) After coating, the maximum transmittance of the glass slide increases from 90.8% to 95.3%, and the average reflectance of 350nm-1000nm decreases from 10.53% to 7.64%. The transmission spectrum curve is as follows Figure 4 Shown; the maximum transmittance of photovoltaic glass is increased from 92.4% to 95.5%, and the average reflectance of 350nm-1000nm is reduced from 9.14% to 6.51%. The transmission spectrum curve is as follows Figure 5 shown;

[0035] (3) The overall thermal shock resi...

Embodiment 2

[0037] Embodiment 2: prepare MgF on glass substrate 2 / SiO 2 Double layer anti-reflection composite film

[0038] Deposition of MgF on glass slide and photovoltaic glass surface by electron beam vacuum evaporation coating process 2 / SiO 2 Double-layer anti-reflection composite film, the main structure and performance of the test are as follows:

[0039] (1) The surface of the film layer is smooth and bright, and the total thickness of the film layer is about 200nm;

[0040] (2) After coating, the maximum transmittance of the glass slide increases from 90.8% to 94.1%, and the average reflectance of 350nm-1000nm decreases from 10.53% to 7.21%. The transmission spectrum curve is as follows Figure 6 Shown; the maximum transmittance of photovoltaic glass is increased from 92.4% to 96.6%, and the average reflectance of 350nm-1000nm is reduced from 9.14% to 6.02%. The transmission spectrum curve is as follows Figure 7 shown;

[0041] (3) The overall thermal shock resistance o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com