Tailing pond model test simulation system

A simulation system and model test technology, applied to hydraulic models, etc., can solve problems such as complex terrain production process and difficult water and sand recovery, so as to improve modeling speed, reduce human error, and achieve zero pollution discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

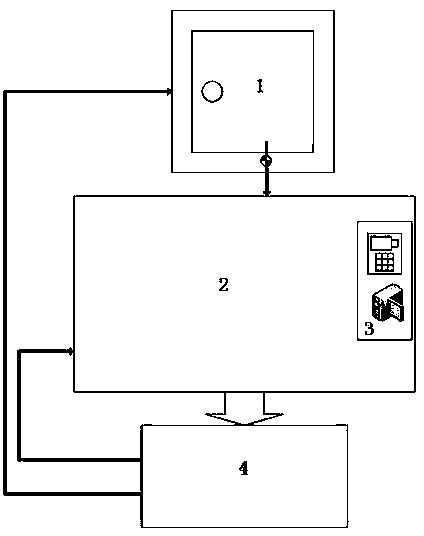

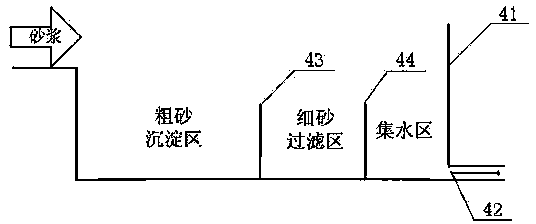

[0030] A tailings pond model test simulation system, its structure is as follows figure 1 As shown, it includes a water supply system 1, a terrain simulation system 2, a measurement system 3, and a water and sand recovery system 4. The water supply system 1 is connected to the upstream of the terrain simulation system 2 through a water pipeline, and the downstream of the terrain simulation system 2 is connected to it through a mortar channel. Water and sand recovery system 4, water and sand recovery system 4 is provided with filter sand device and return water port 42, and return water port 42 is communicated with water supply system 1 through return water pipeline; Described measuring system 3 is used for the dam-break debris flow in terrain simulation system parameters to measure.

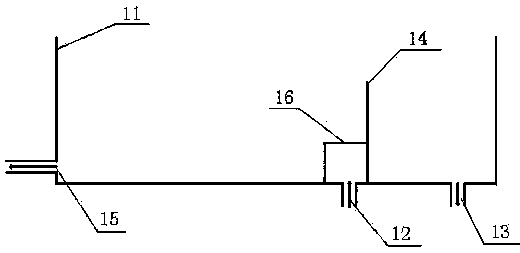

[0031] The terrain simulation system described in the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com