Patents

Literature

120results about How to "The method is simple and flexible" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Certificate management system and method

InactiveUS20050120205A1The method is simple and flexibleKey distribution for secure communicationData processing applicationsService provisionSmart card

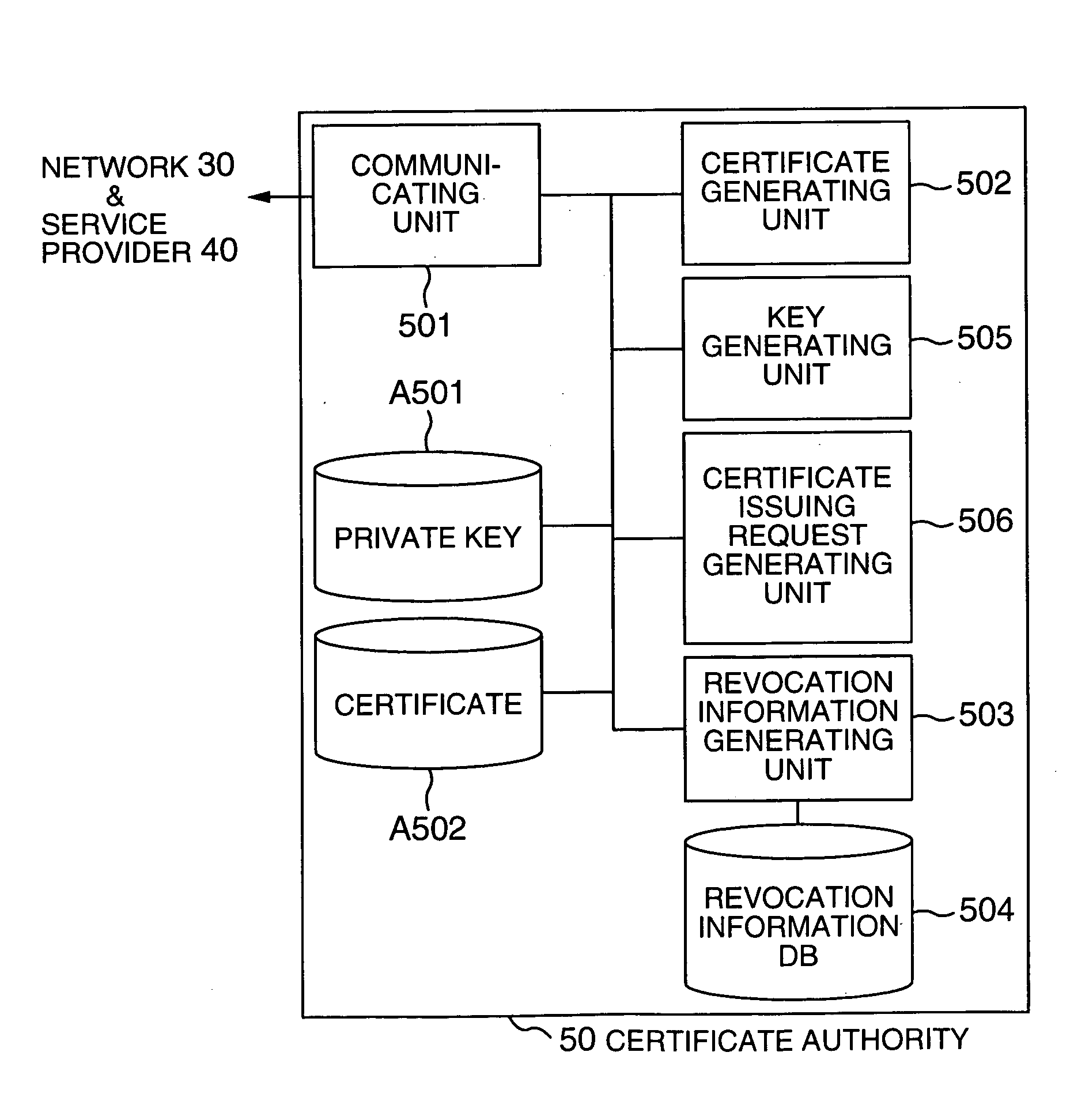

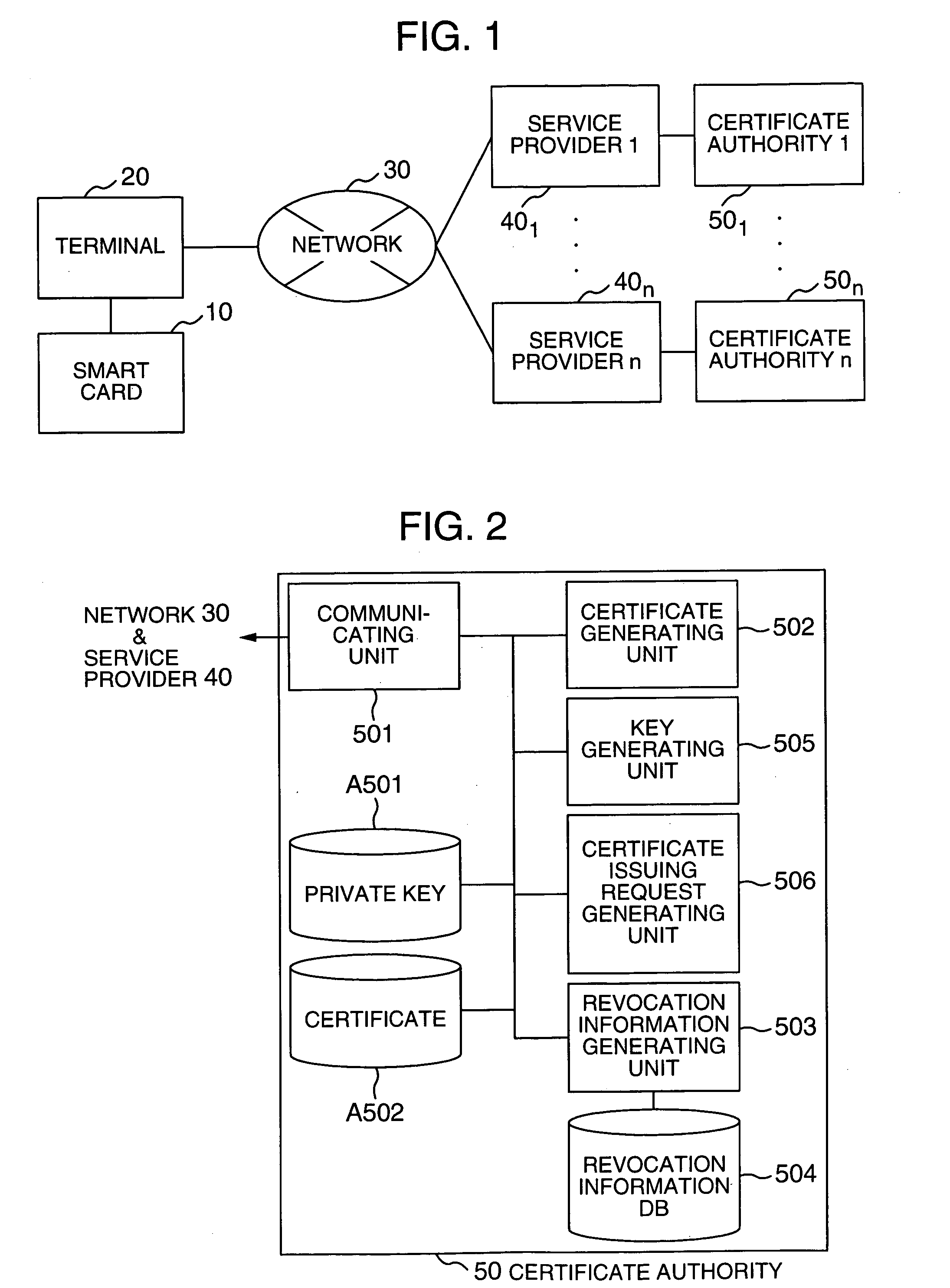

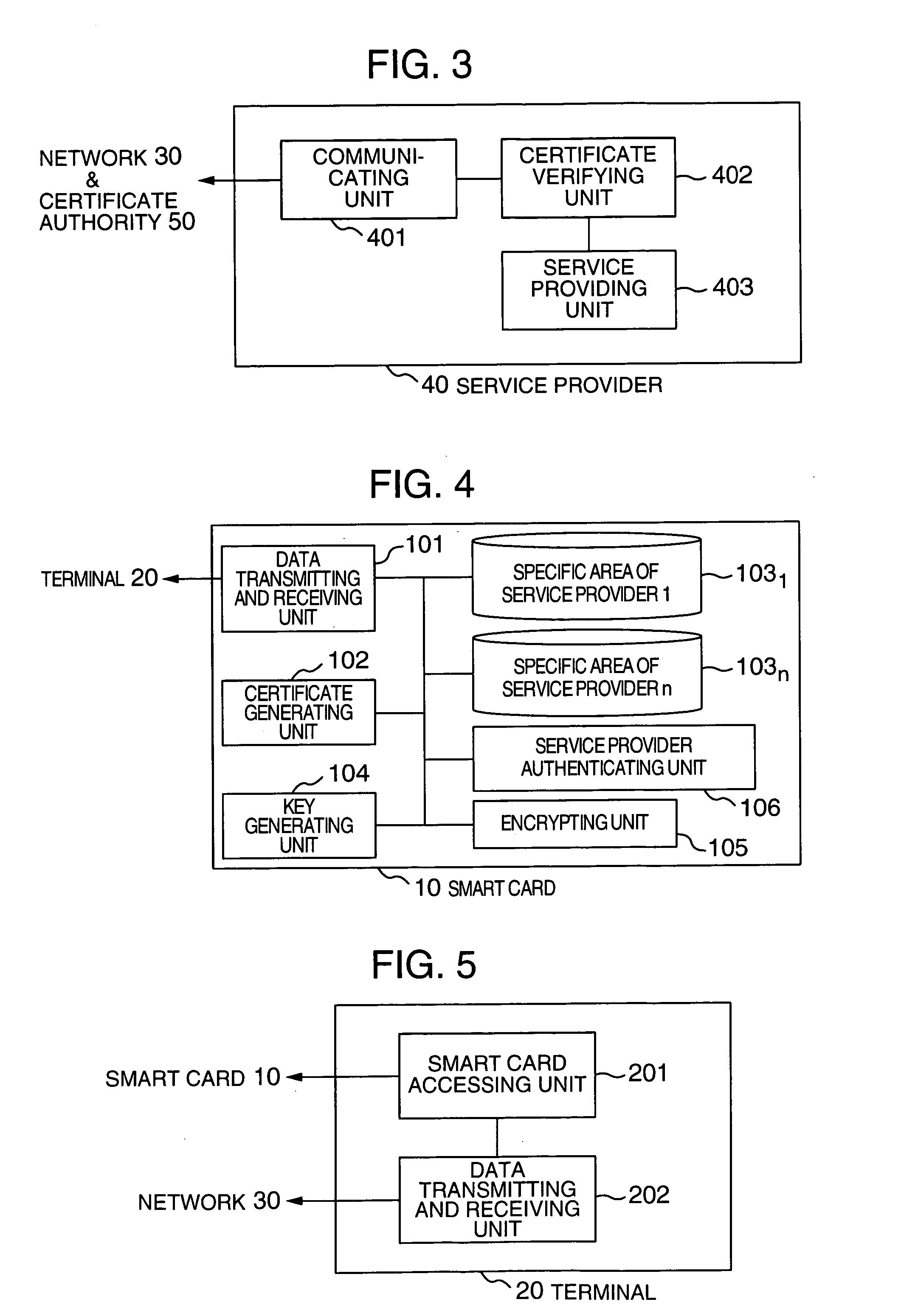

A certificate management method is provided whereby a plurality of service providers have different reliable certificate authorities and, when certificates issued from the certificate authorities are implemented into a smart card, merely by revoking the certificate issued from the certificate authority on which the first service provider relies, all other implemented certificates can be revoked, and the certificates can be individually revoked. A system for implementing the method is provided. The certificate authorities n (n≧2) issue a certificate n by using a private key n′ corresponding to certificate n′ generated by using a certificate 1 issued from a certificate authority 1 which has previously been installed in the smart card and a corresponding private key 1. Thus, the issued certificates have a hierarchical chain relation. When the user wants to revoke all certificates, the certificate 1 issued from the certificate authority 1 is revoked.

Owner:HITACHI LTD

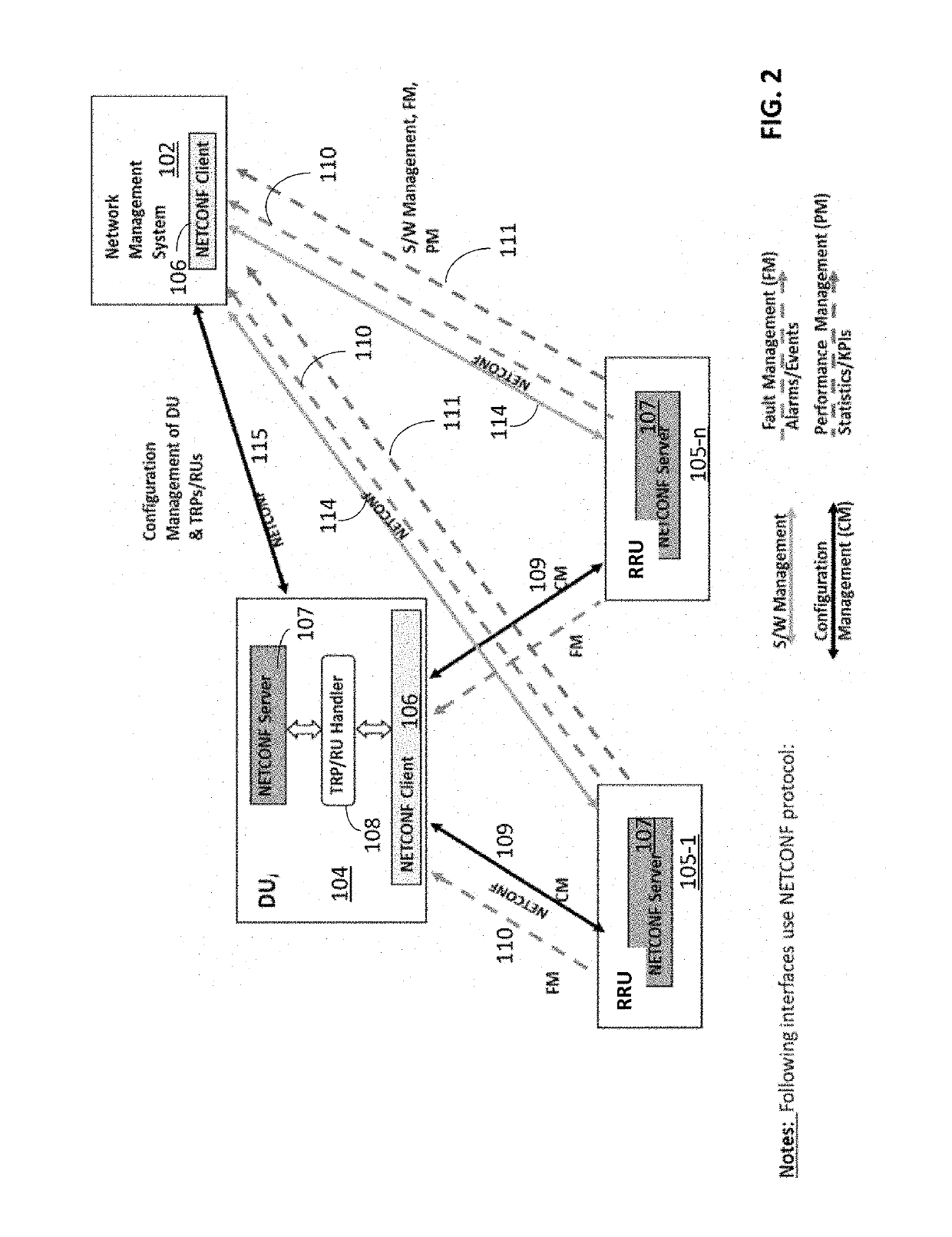

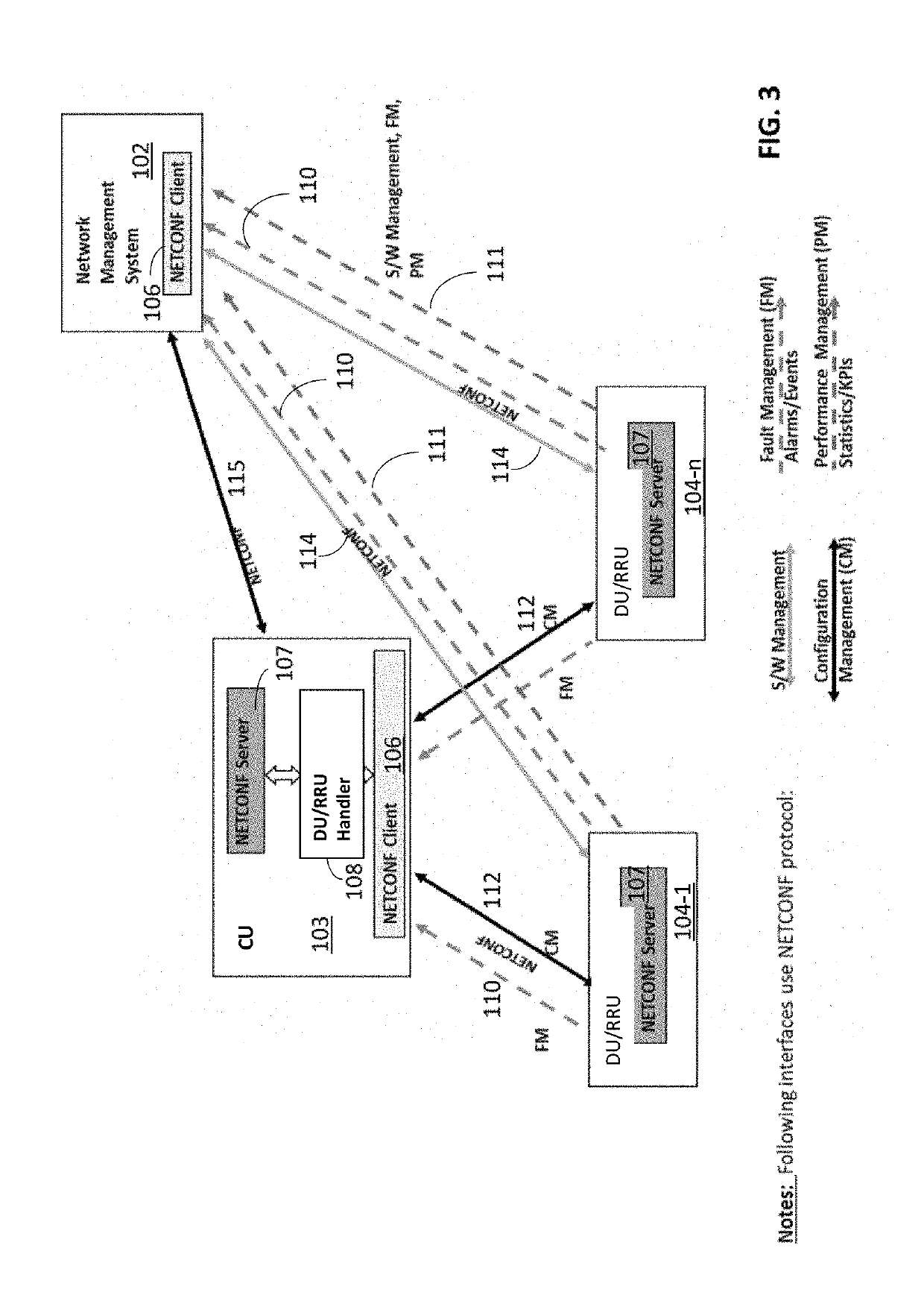

Management of radio units in cloud radio access networks

ActiveUS20190245740A1Provide flexibilityThe method is simple and flexibleData switching networksSoftware deploymentTelecommunicationsRadio access network

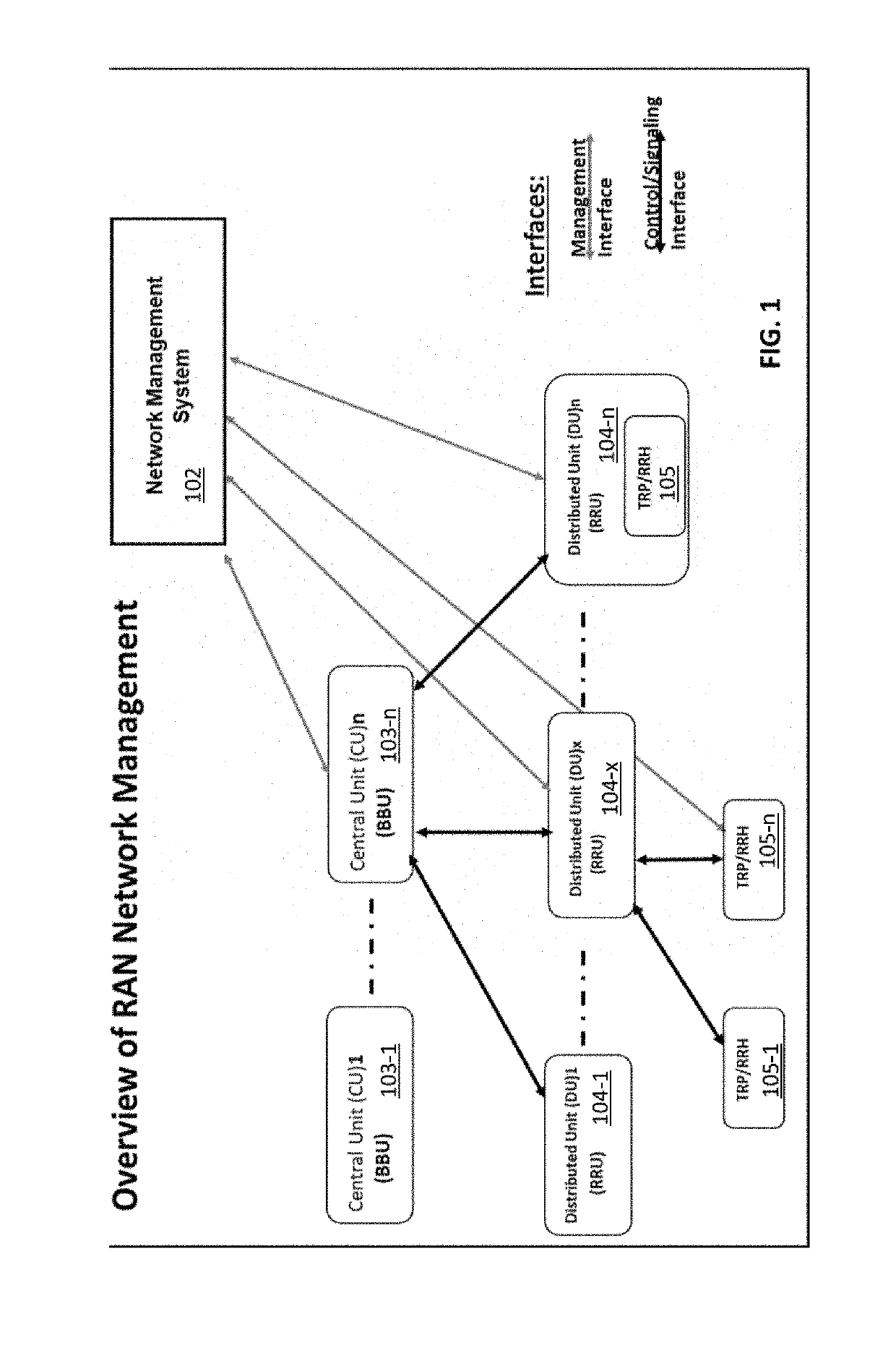

There is provided a system, method, and interfaces for Radio Access Networks and Cloud Radio Access Networks.

Owner:MAVENIR NETWORKS INC

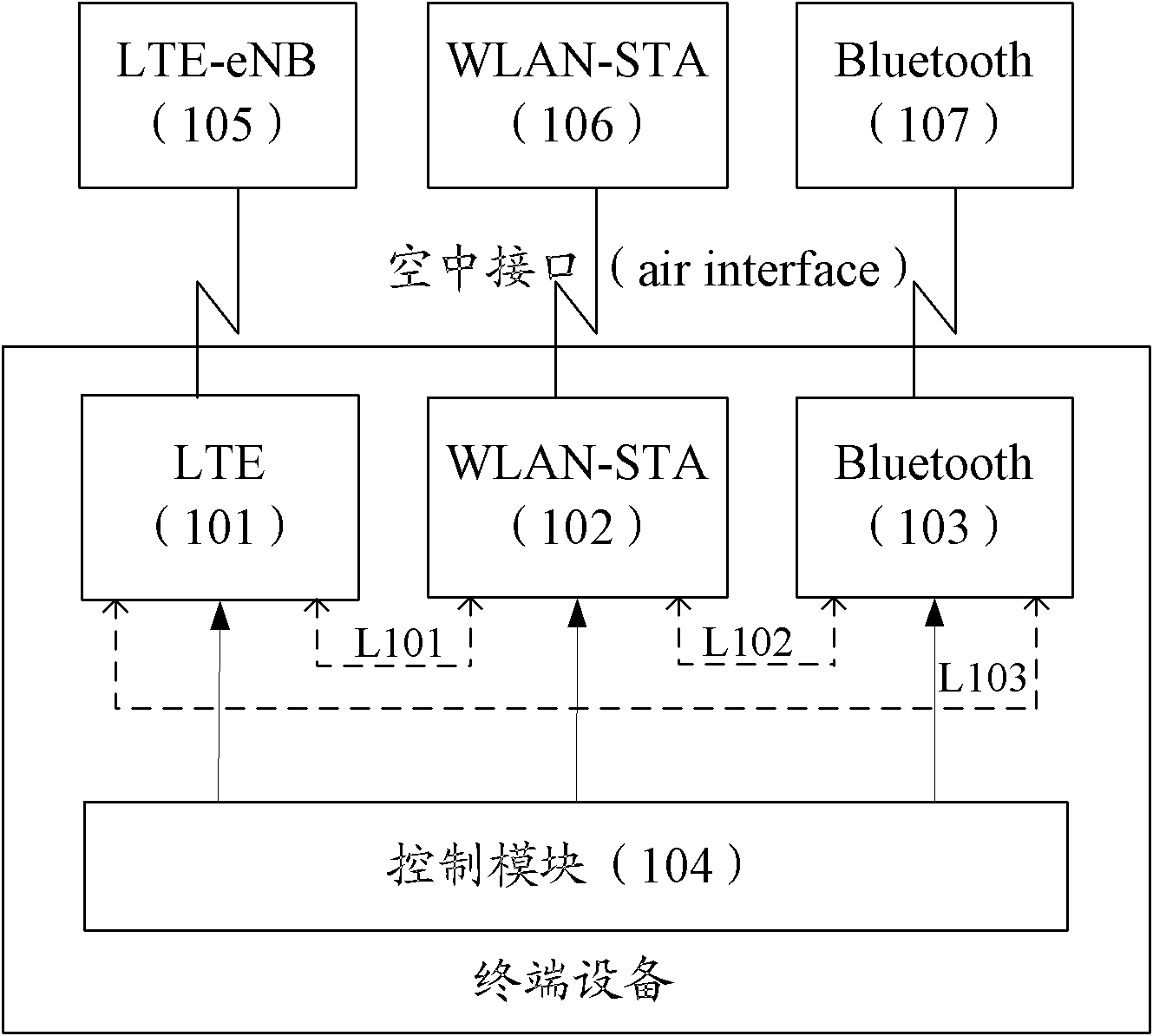

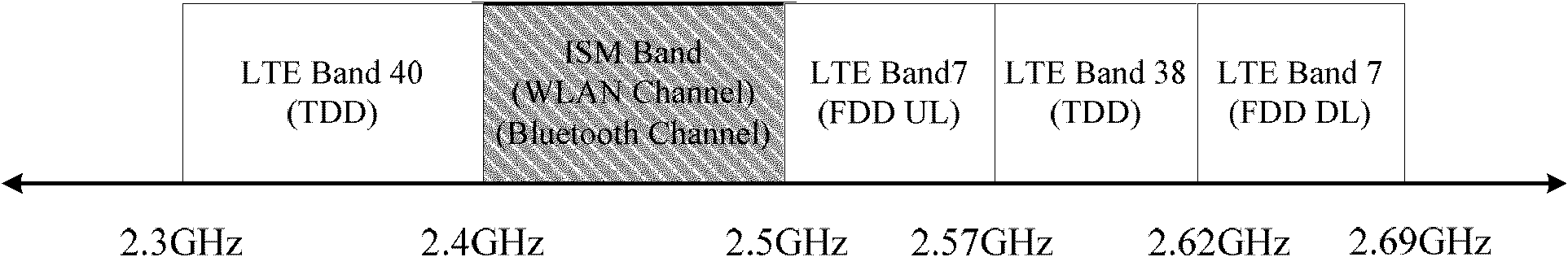

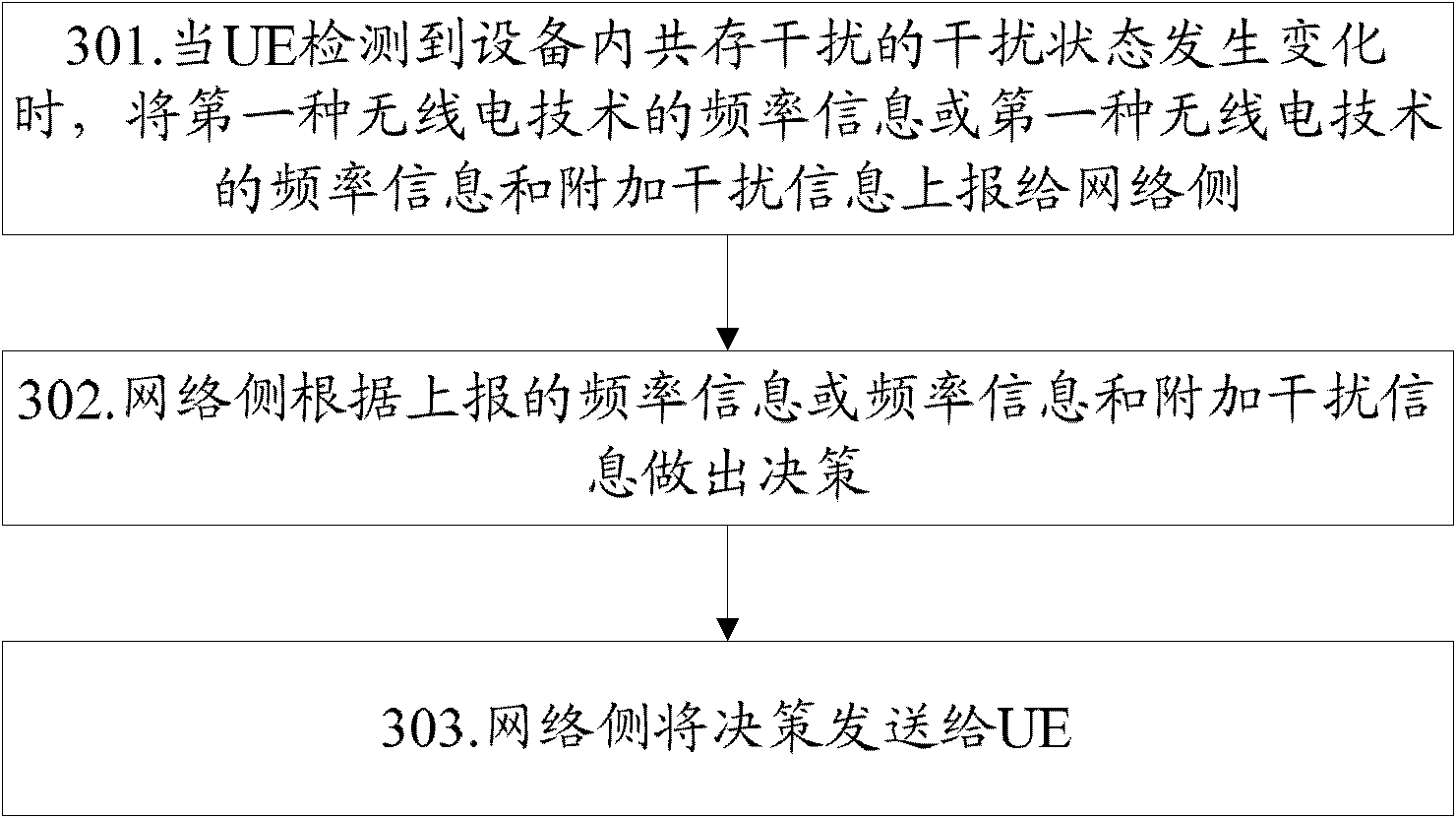

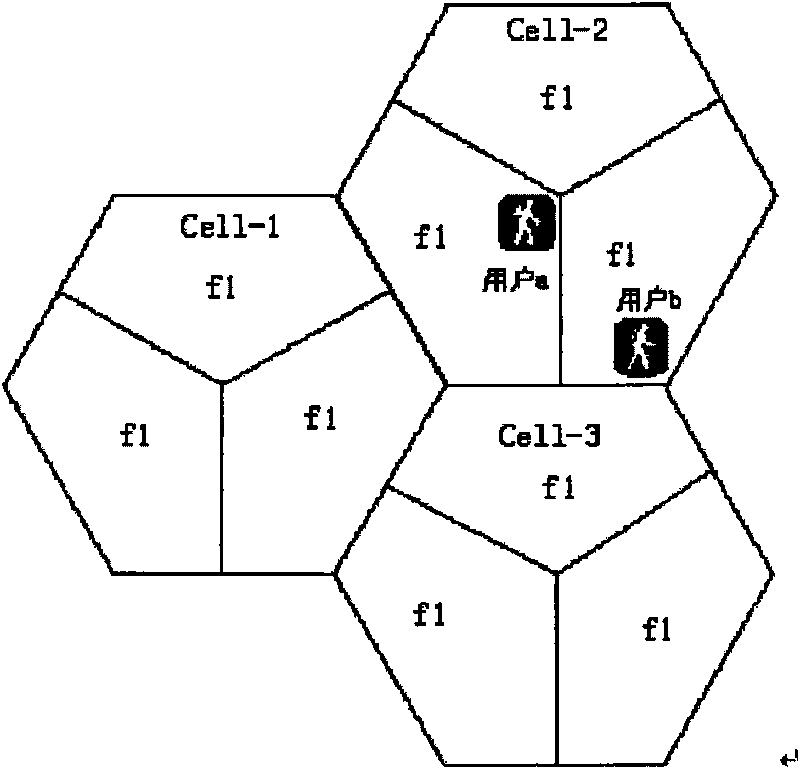

Method and system realizing interference information reporting, and UE

ActiveCN102595465AThe method is simple and flexibleImprove efficiencyError preventionNetwork traffic/resource managementTelecommunicationsUser equipment

The invention discloses a method for realizing interference information reporting, which comprises the following steps of: when user equipment (UE) detects that the interference state of memory interference in the UE changes, reporting frequency information of a first radio technology or the frequency information and additional interference information of the first radio technology to a network side; or when the UE detects that the interference state of the memory interference in the UE changes, reporting the frequency information of the first radio technology to the network side; and when the UE receives an instruction of demanding to report the additional information from the network side, reporting the additional interference information to the network side. The invention further provides a system for realizing the interference information reporting, and the UE. According to the technical scheme of the invention, the UE can report the frequency information and the additional information to the network side.

Owner:ZTE CORP

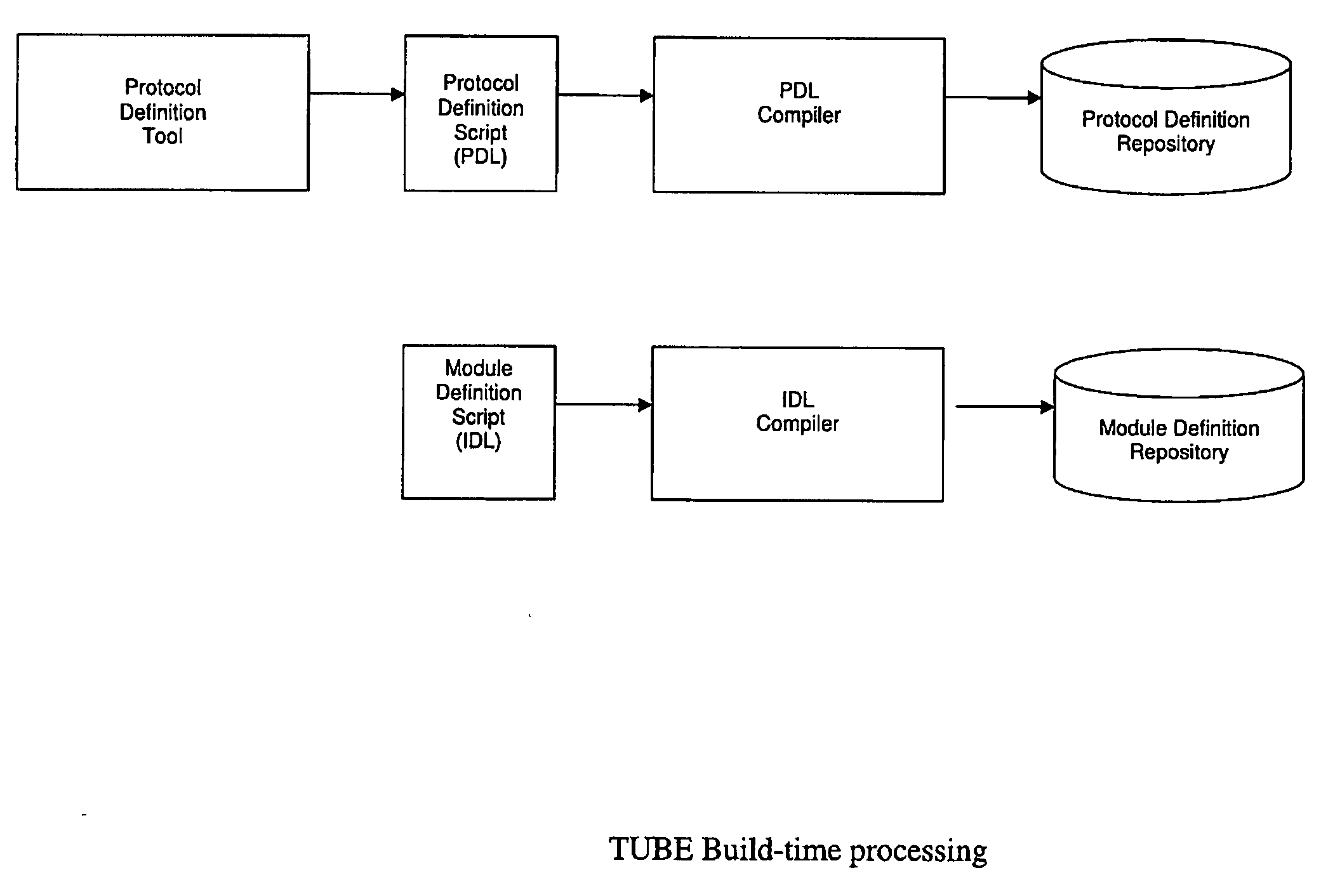

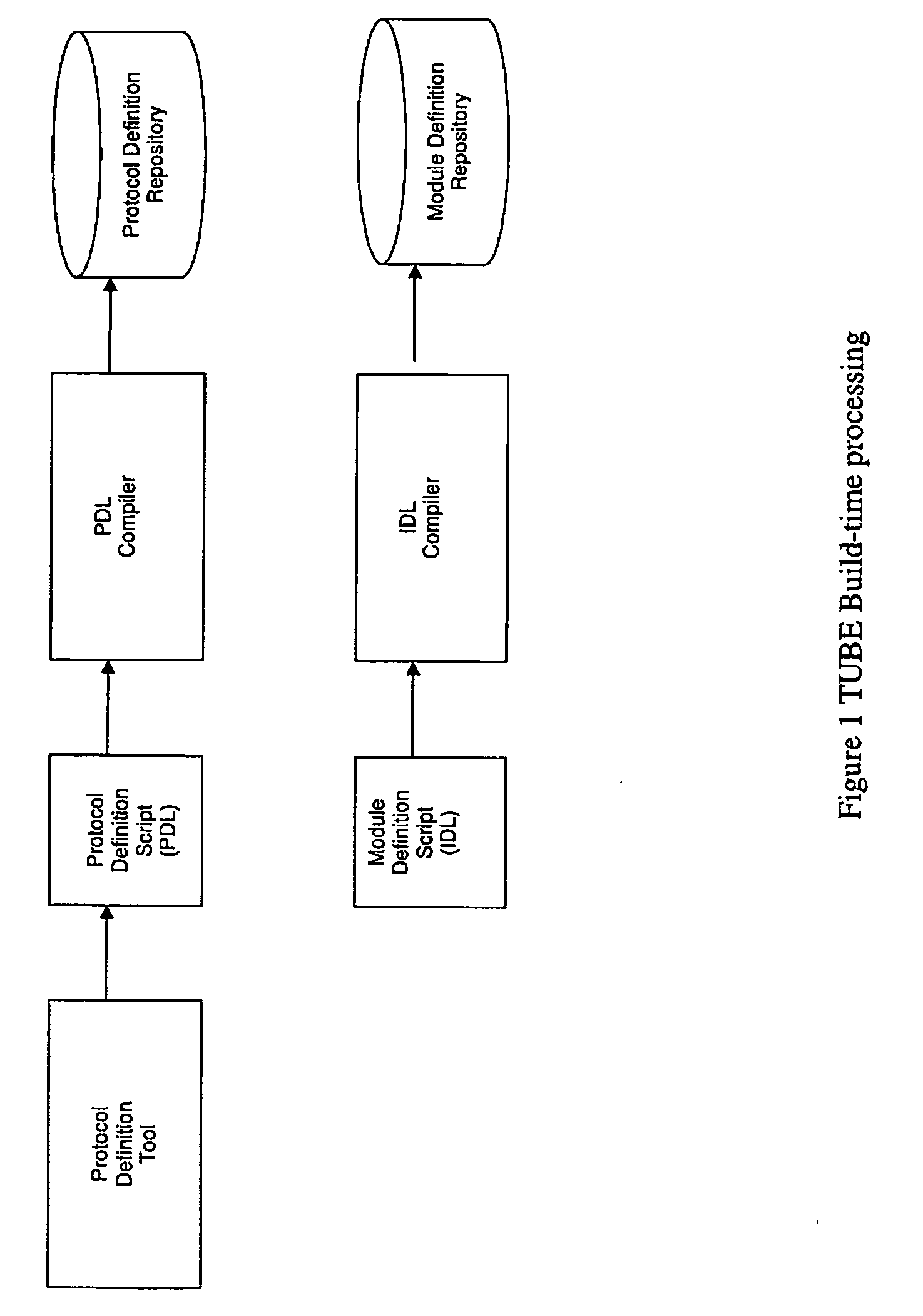

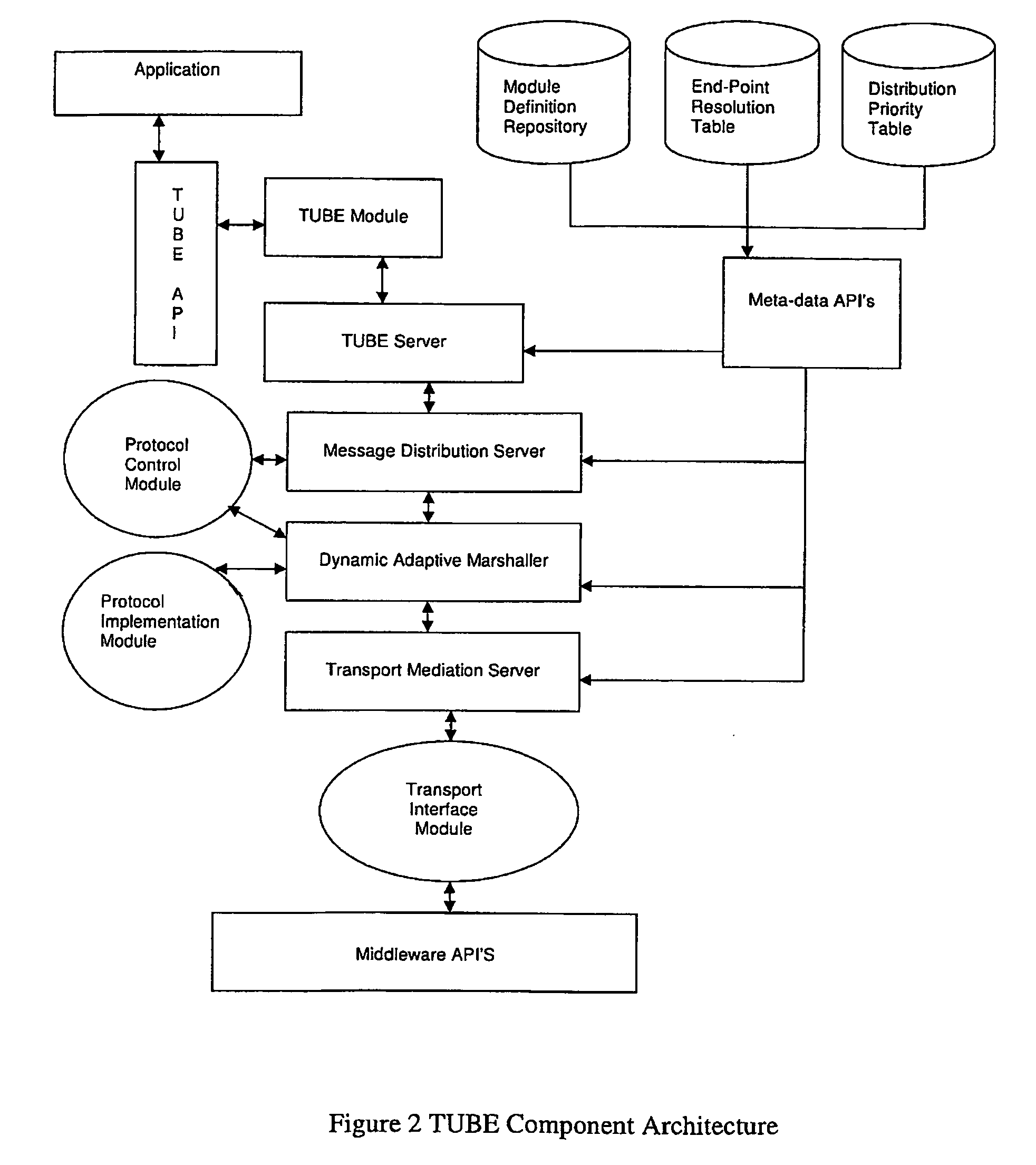

Midleware broker

InactiveUS20100161821A1The method is simple and flexibleEasy and flexibleInterprogram communicationMultiple digital computer combinationsSearch data structureOutbound communication

A method of flow of an outbound communication to another module with interface using a broker which is able to review all data structures, regardless of complexity, as being comprised of a finite set of primitive data types (e.g. integer, float etc.) and with reference to the repository determine a mechanism for reading and writing these types to enable processing of structures of arbitrary complexity, wherein the rules and mechanisms for reading these basic types are defined by the protocol and once the rules are captured allow processing of any message over this protocol

Owner:SLAMKOVIC RICHARD D

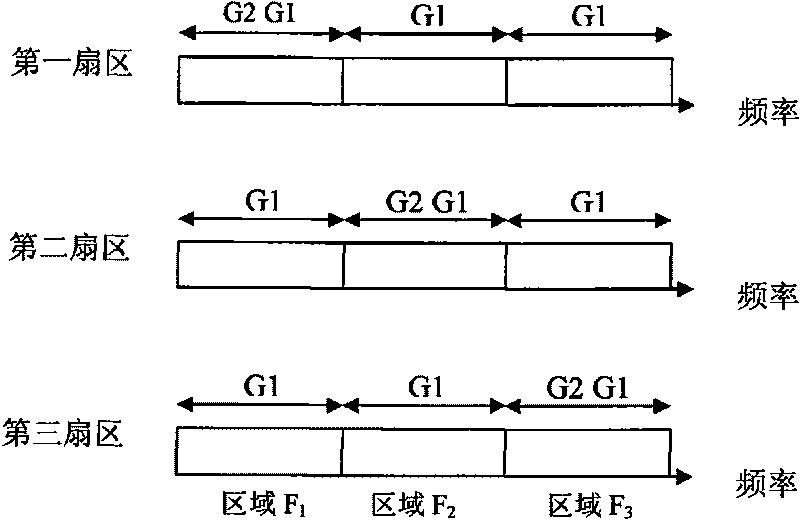

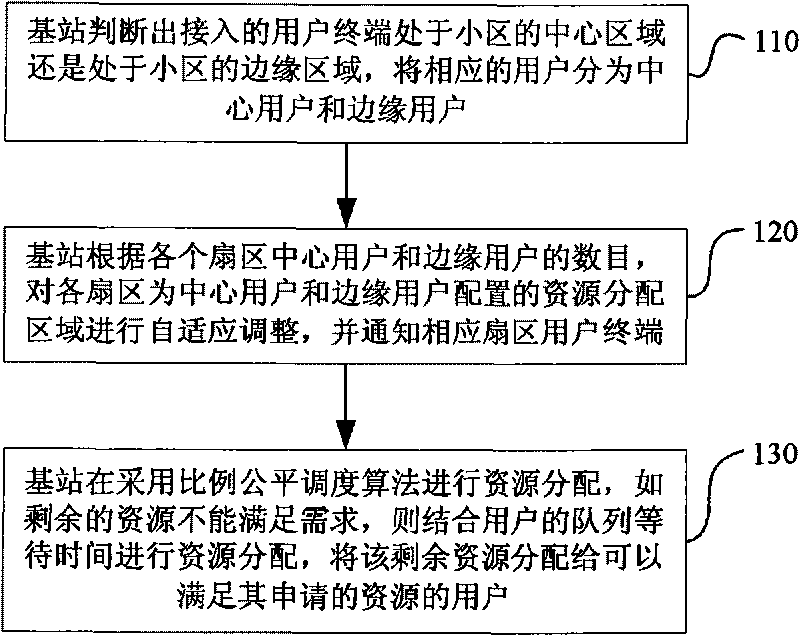

Resource allocation method with partial frequency multiplexing

ActiveCN101730231AImprove communication qualityAvoid interferenceRadio transmission for post communicationWireless communicationMultiplexingPartial frequency reuse

The invention discloses a resource allocation method with partial frequency multiplexing, which comprises the following steps of: dividing users of accessed user terminals in a cell into central users and edge users by a base station; and carrying out self-adaptive adjustment on resource allocation regions allocated to the central users and the edge users in a sector by the base station, for each sector in the cell, according to quantity information of the central users and the edge users in the sector, and notifying the user terminals in the sector. Therefore, the resource allocation method can allocate the resources more reliably and avoid interference as much as possible.

Owner:ZTE CORP

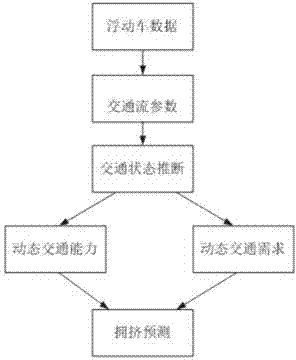

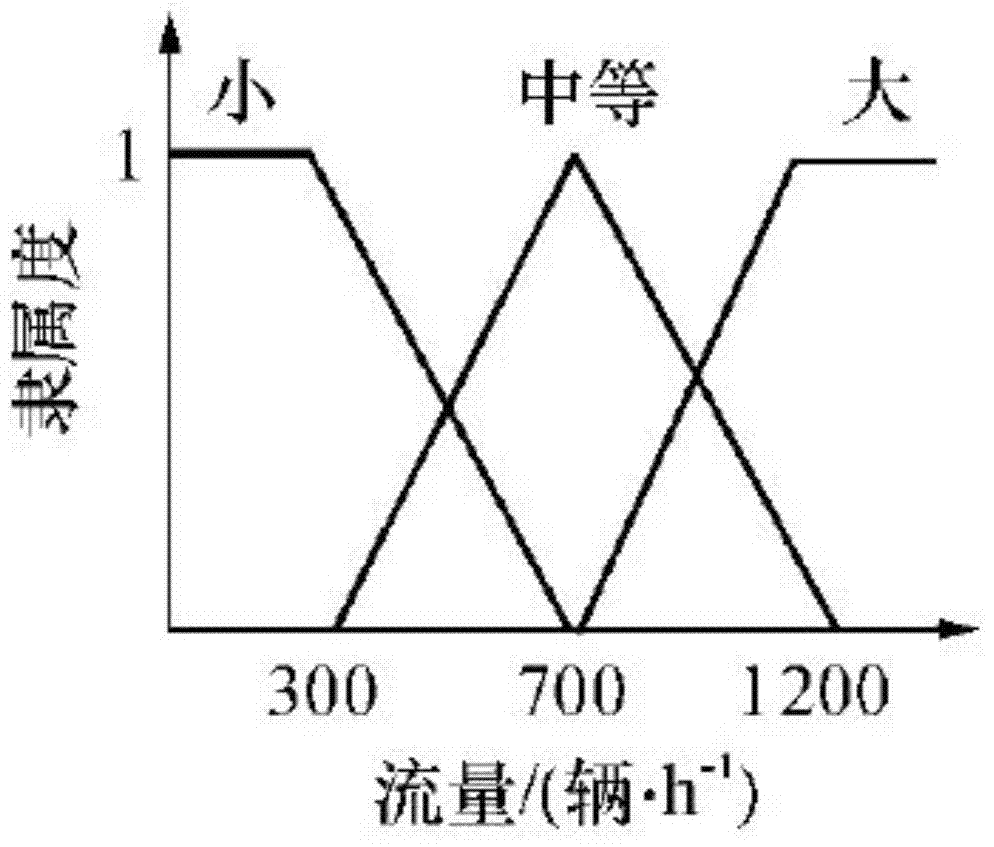

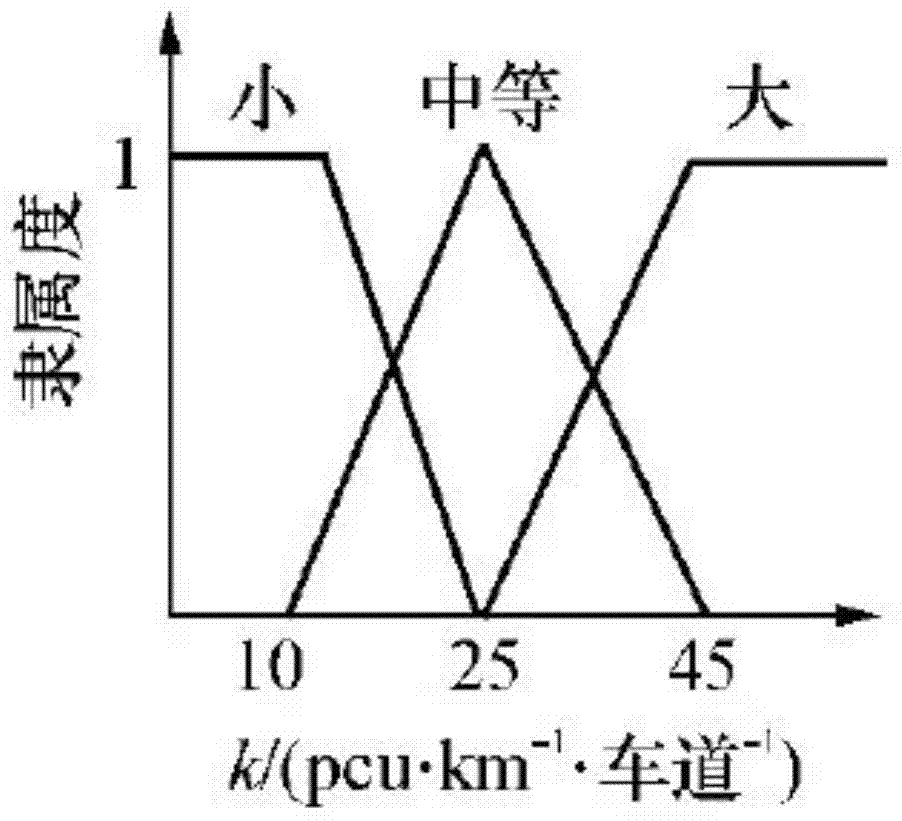

Urban road network dynamic traffic jam prediction method based on floating vehicle data

InactiveCN103942953ATake advantage ofThe method is simple and flexibleDetection of traffic movementTraffic capacityEngineering

The invention discloses an urban road network dynamic traffic jam prediction method based on floating vehicle data. The urban road network dynamic traffic jam prediction method based on the floating vehicle data includes the following steps that first, a road section jam state discrimination index is determined; second, the floating vehicle data are converted into traffic flow parameters; third, the road section traffic flow state is judged; fourth, the dynamic traffic capacity C1 of a target road section 1 is predicted; fifth, the dynamic traffic demand D1 of the target road section 1 is predicted; sixth, the jam probability, the jam (if happening) degree LOC and the jam formation time of the target road section 1 are predicted. The urban road network dynamic traffic jam prediction method based on the floating vehicle data is a method for predicting dynamic traffic jams of an urban road network, provides a decision making basis for urban traffic management and control measures and has practical promotional value.

Owner:SOUTH CHINA UNIV OF TECH

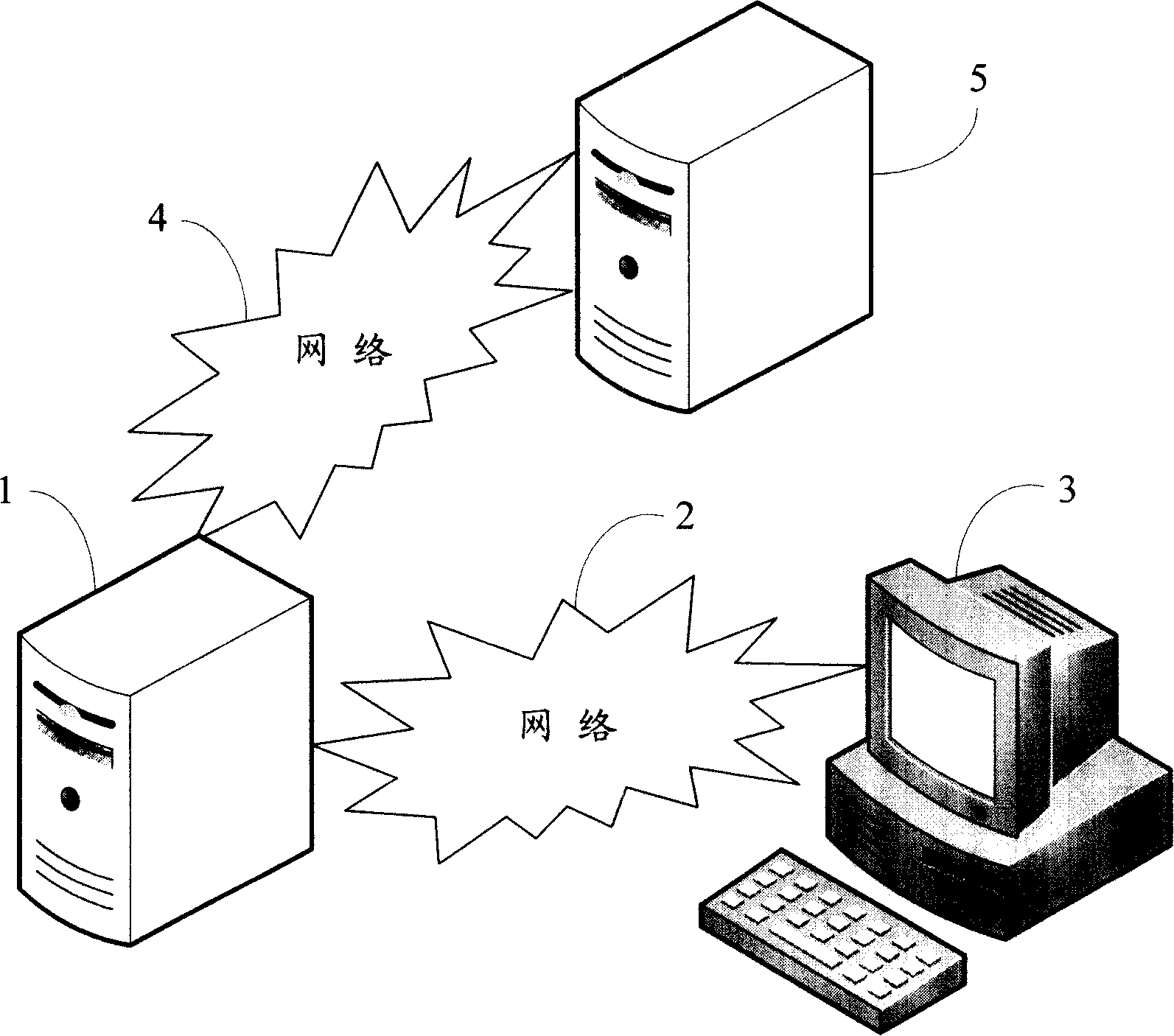

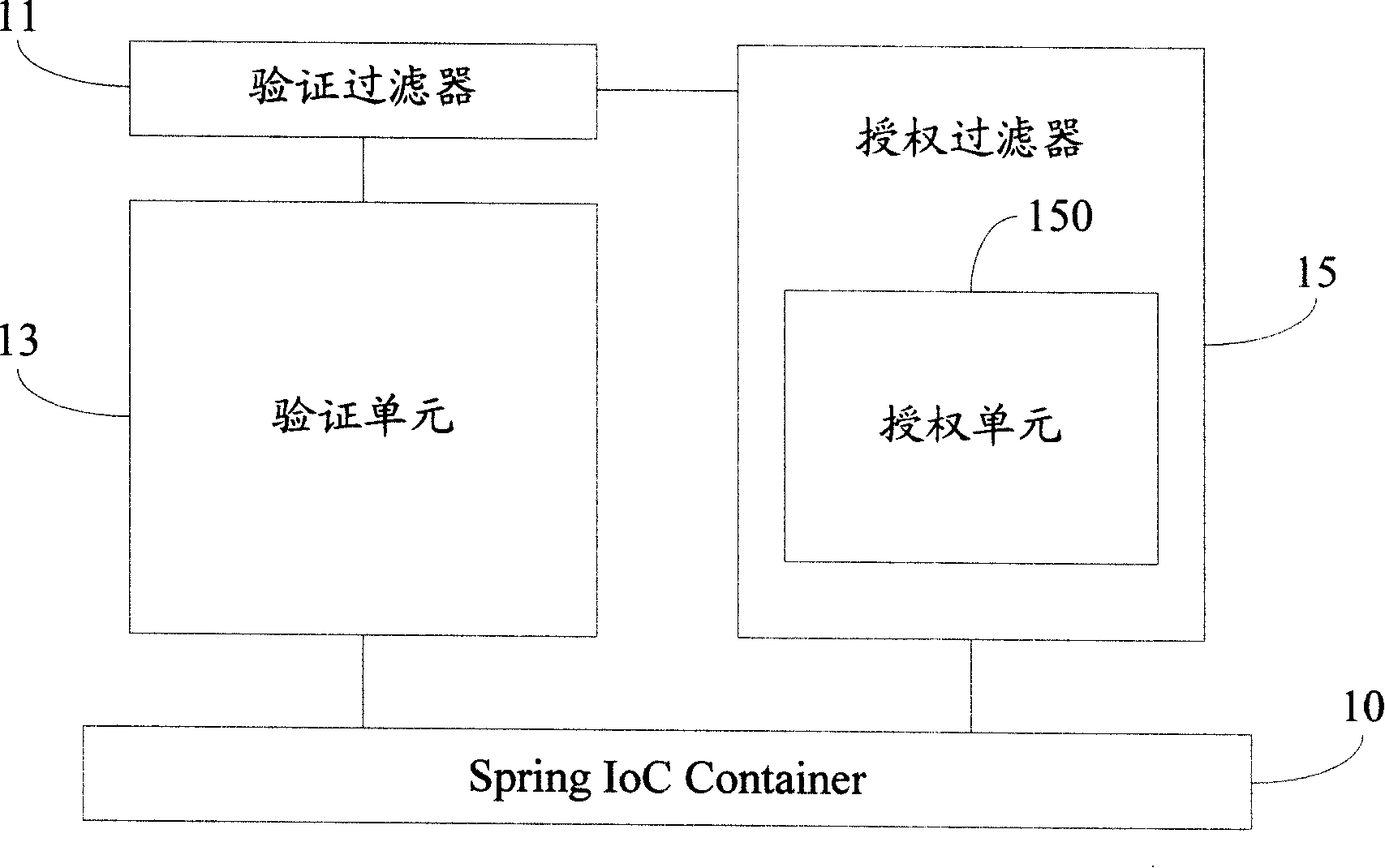

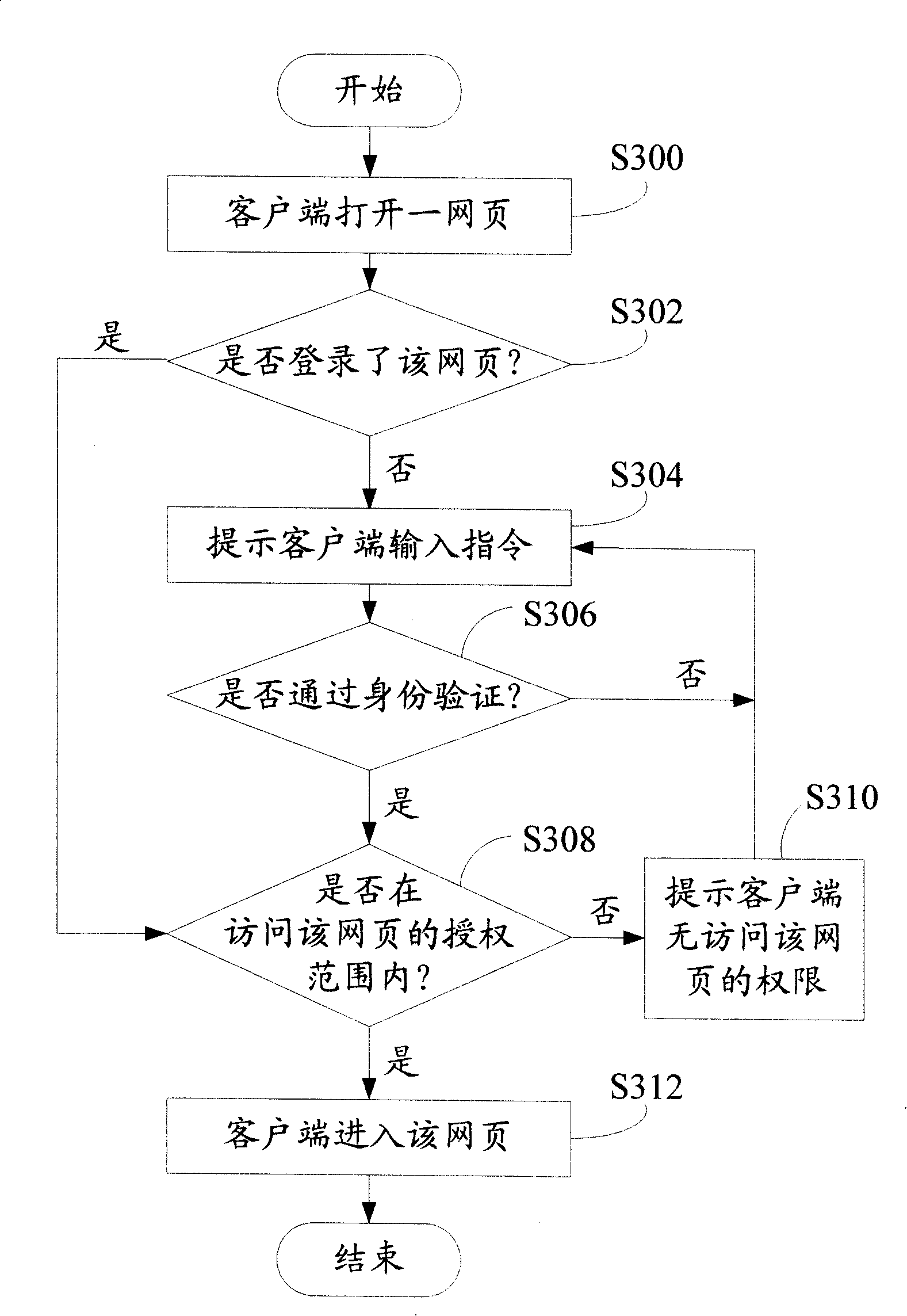

Webpage privilege control system and method

InactiveCN101212457AAuthority control reachesThe method is simple and flexibleDigital data authenticationTransmissionApplication serverControl system

The invention provides a method for managing and controlling webpage rights. The method verifies and manages the rights of accessing the webpage by a user end through an amounted configuration file in an application server. The method comprises the following steps: whether the user end log in the webpage is detected; if the user end dose not log in the webpage, a login dialogue frame is introduced; when the inputted instruction in the user end is received, an identity code and an identification code matching with the instruction are looked for in a database server for determining whether the user end passes through the identity verification; if the user end passes through the identity verification, the webpage access rights corresponding to the user end identity code is read out from the database server so as to determine whether the access rights of the user end is in the webpage authorization range. Besides, the invention also provides a system for managing and controlling the webpage rights.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Hybrid spread spectrum communication system based on low density parity code (LDPC) encoding and method thereof

ActiveCN103701490ASolve the delay problemEasy to implementError preventionBurst errorFrequency offset

The invention discloses a hybrid spread spectrum communication system based on low density parity code (LDPC) encoding and a method thereof. The problems of leakage capture, high leakage capture probability, slow convergence of a phase-locked loop and low decoding performance of the existing synchronous capture method are mainly solved. The system comprises a transmitting part and a receiving part, wherein the transmitting part is used for carrying out pretreatment on original information; the pretreatment data are subjected to frequency hopping treatment and transmitted after being modulated and filtered by a base band; the receiving part is used for obtaining a synchronization point position and a frequency offset value in the received signal through synchronous capture, and intercepting useful data to carry out de-hopping according to the synchronization point position; the base band demodulates and filters; the filtering data are subjected to frequency offset compensation according to the frequency offset value; the data after frequency offset compensation are subjected to dispreading and frequency offset rectification; the frequency offset rectification data are decoded and the decoding result is output. The hybrid spread spectrum communication system has the advantages of being strong in burst error resisting ability, high in real-time synchronization capture speed, high in capture accuracy, high in convergence speed of the phase-locked loop, and good in decoding performance, and can be applied to reliable communication under the condition of very low powder spectral density.

Owner:XIDIAN UNIV

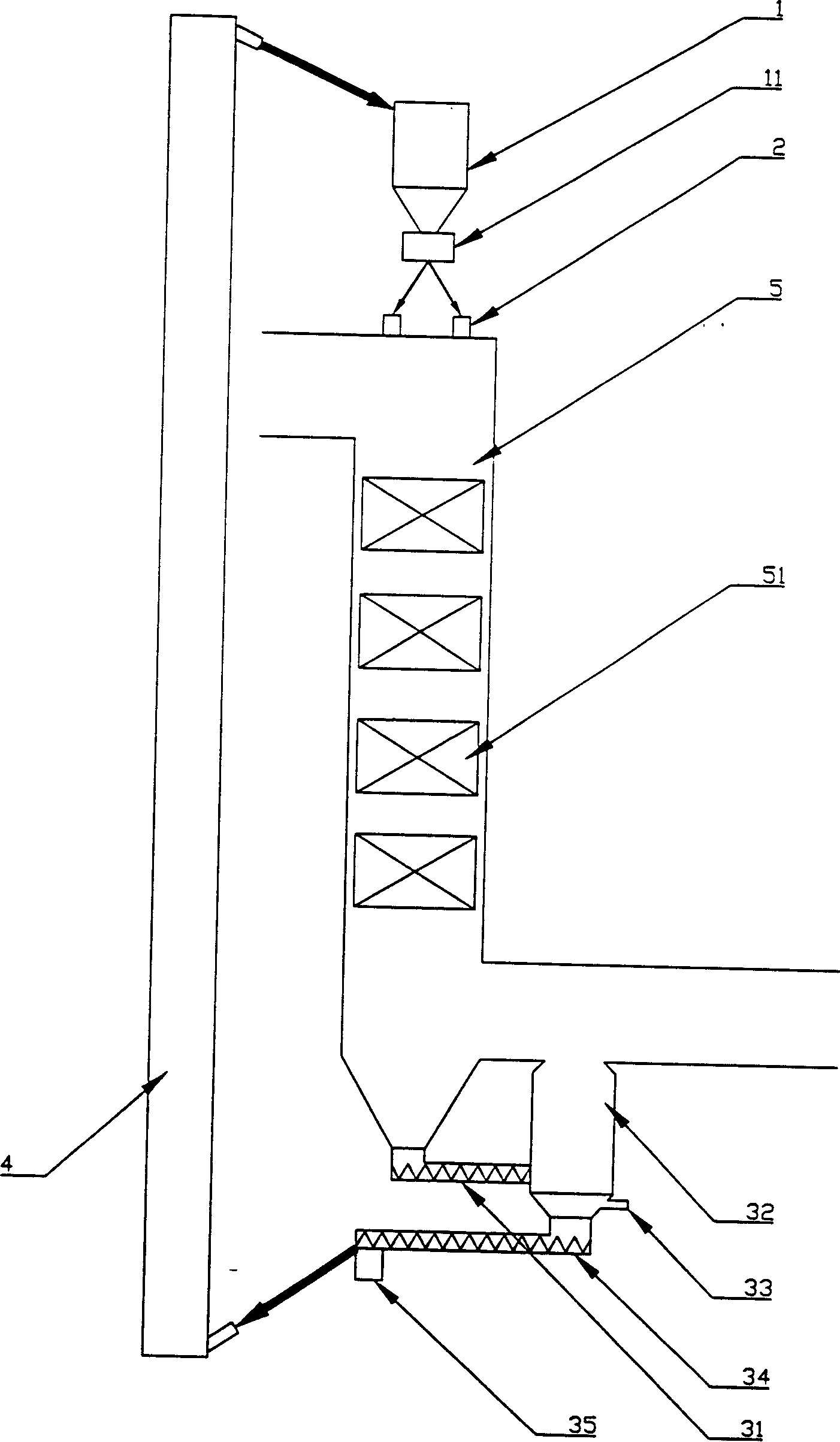

Method and apparatus for removing viscous ash deposit in boiler

InactiveCN1789814AEfficient removal of sticky dustSticky Soot RemovalSolid removalFluidized bedSurface dust

This invention relates to one method and device to remove adhesive dust in oven, wherein the method comprises the following steps: Joining the particles from oven tail smoke channel or remaining oven top along with smoke to tube beam to take off its surface dust; depositing the dust and particles one the smoke channel bottom to enter flow bed filtering device; the air outside smoke channel entering flow chamber to flow the particle and dust from flow chamber top to smoke channel back section; the particle are sent to the feed back device through the flow chamber bottom discharge screw through gas force transmission system or lift machine to send to materials bin; if the particle and dust are severely stuck, then from bin screw to re-fill particle from the side exhaust system by the bin.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

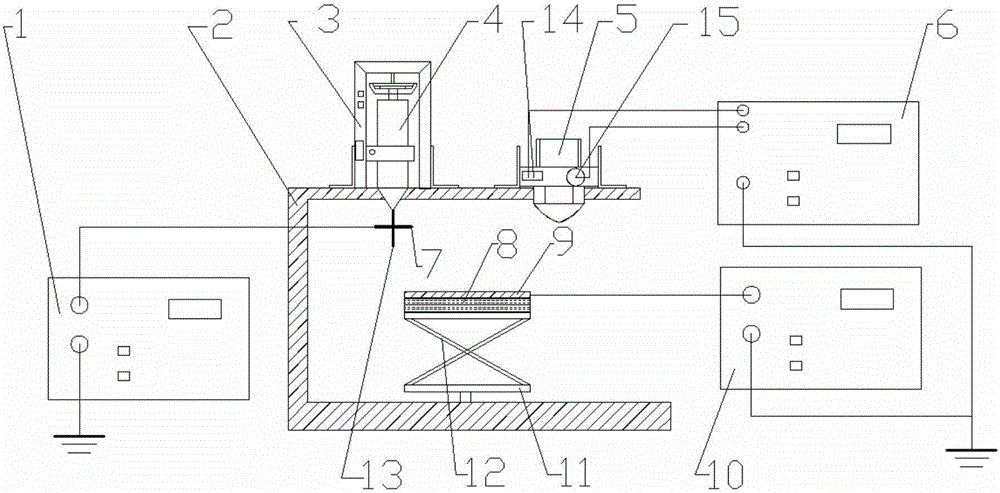

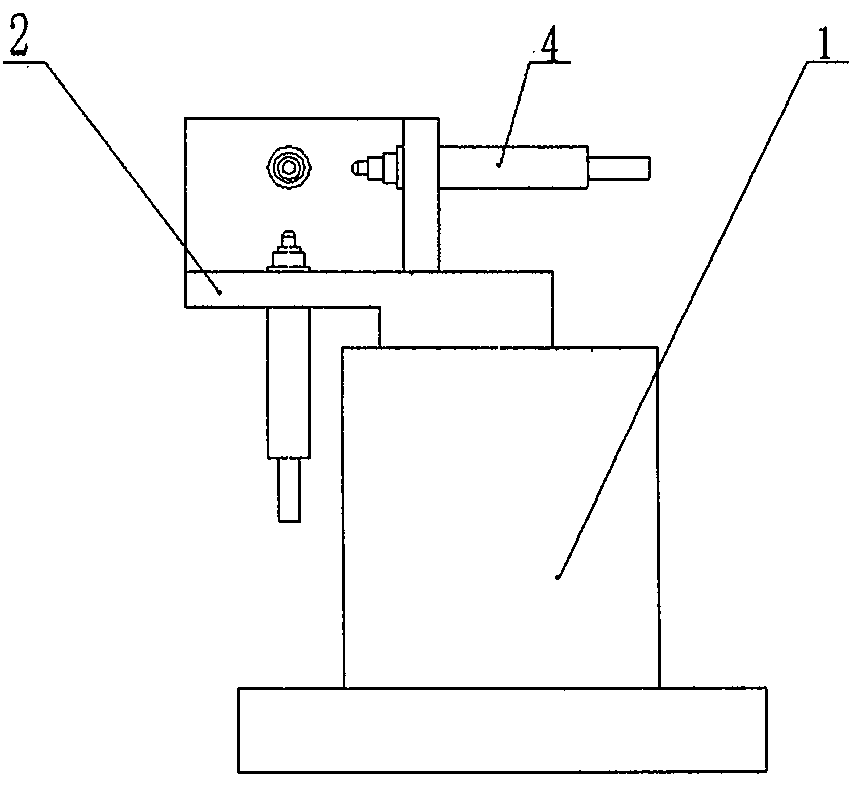

3D printing method and device for manufacturing micro-fluidic chip by utilizing nanometer fiber paper base laminate

InactiveCN106732840AReduce manufacturing costImprove hydrophobicityAdditive manufacturing apparatusLaboratory glasswaresMolten stateFiber

The invention provides a 3D printing method and device for manufacturing a micro-fluidic chip by utilizing a nanometer fiber paper base laminate, relating to micro-fluidic chips. The 3D printing method comprises the following steps: 1) depositing a nanometer fiber paper base on a collecting plate; 2) moving the collecting plate into a hydrophobic material jet printing area, heating for maintaining the hydrophobic material in a sprayer to be in a molten state, adding into an electric field, and downward jetting the hydrophobic material fiber, thereby forming a hydrophobic material fiber pattern; 3) designing each layer of hydrophobic material fiber pattern, and constructing the structure of the micro-fluidic chip in a 3D printing manner of continuously overlapping the nanometer fiber paper base and the hydrophobic material fiber pattern; and 4) heating the collecting plate, permeating each layer of hydrophobic material into the nanometer fiber paper base, constructing a micro-fluidic control structure, and finally forming the micro-fluidic chip with the 3D structure on the nanometer fiber paper base. The printing device is provided with a direct current power supply, a two-dimension jet printing motion platform, a feeding pump, a spinning needle, a liquid storage needle drum, a jet, an auxiliary power supply, a temperature control device, a conductive substrate, an insulating plate, the collecting plate and a lifting platform.

Owner:XIAMEN UNIV

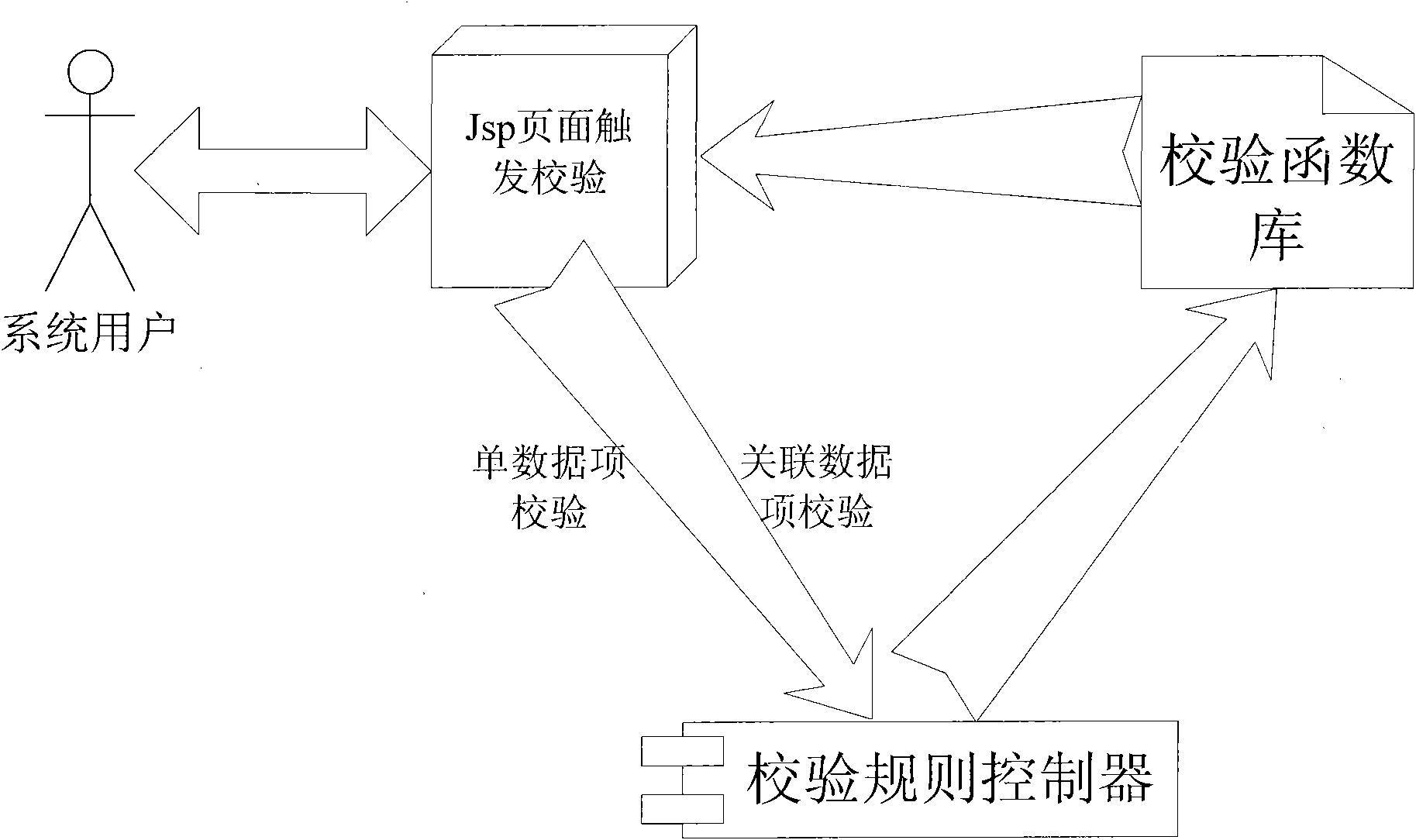

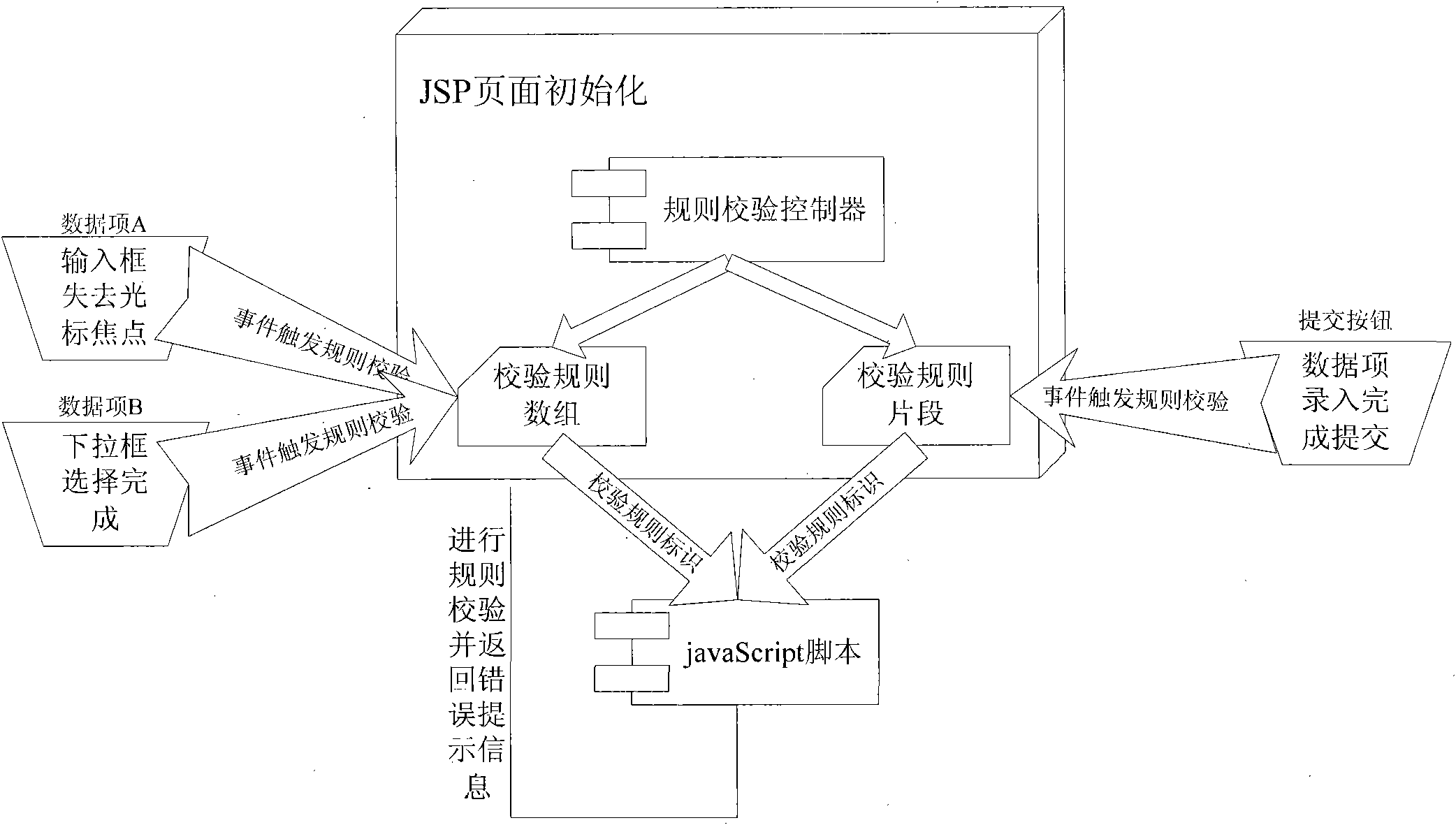

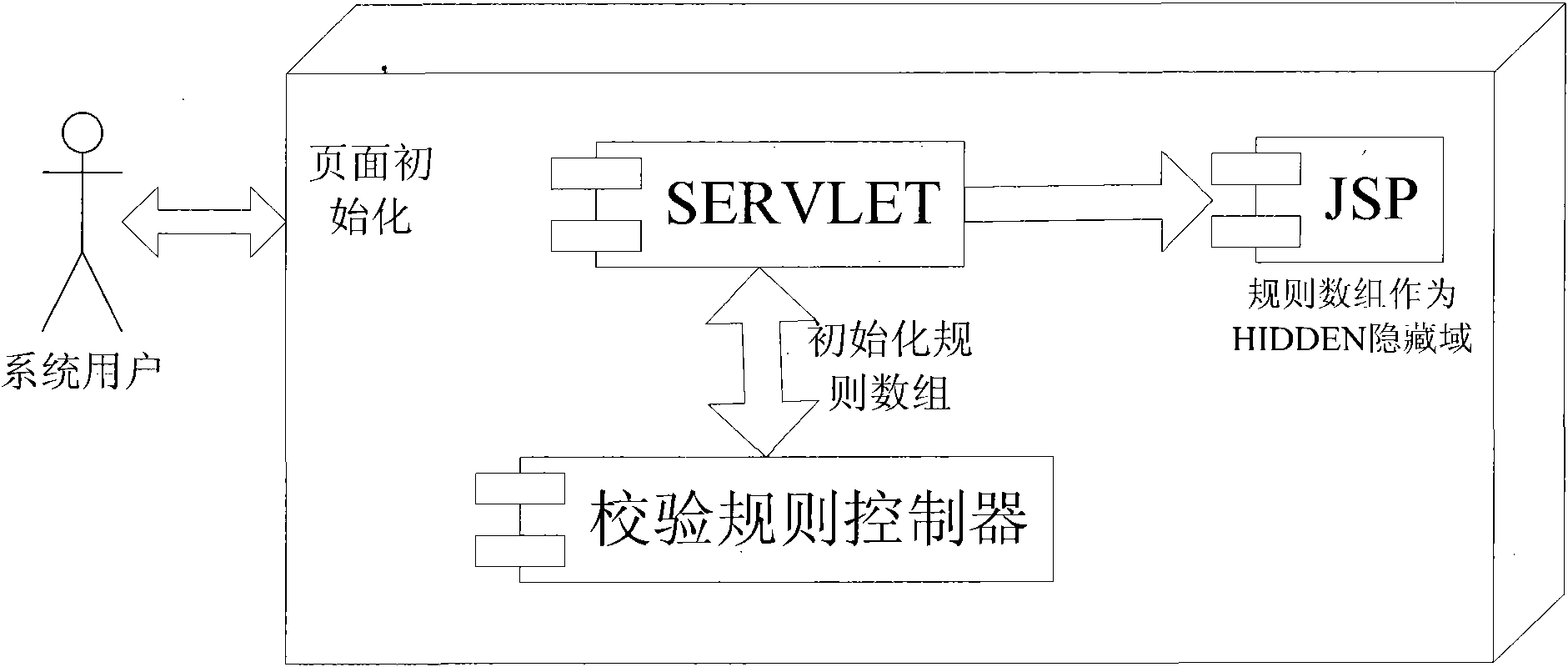

Data item calibration method based on JSP page

InactiveCN101788950AReduce development difficultyReduce development riskSoftware testing/debuggingSystem developmentComputer science

The invention discloses a data item calibration method based on a JSP page, belonging to a data item calibration method. A javaScript script file is written in JSP and is calibrated. The invention comprises (1) JSP, data item description, other page display contents, write-in data item and page submitting triggering; (2) a calibrating rule controller, an data item and route configuration of the calibrating rule, wherein the calibrating rule controller serves as a configuration file to store the corresponding relation of the data item and calibrating rule identification, is in an XML form and can realize rule route by simple configuration; and (3) a calibration database, comprising a public function, an arithmometer and a user-defined function library. Compared with the prior art, the data item calibration method based on a JSP page of the invention is simple and flexible, has low cost, can improve system development efficiency and can lower the technical requirements of on-site implementing maintenance personnel.

Owner:浪潮(山东)电子信息有限公司

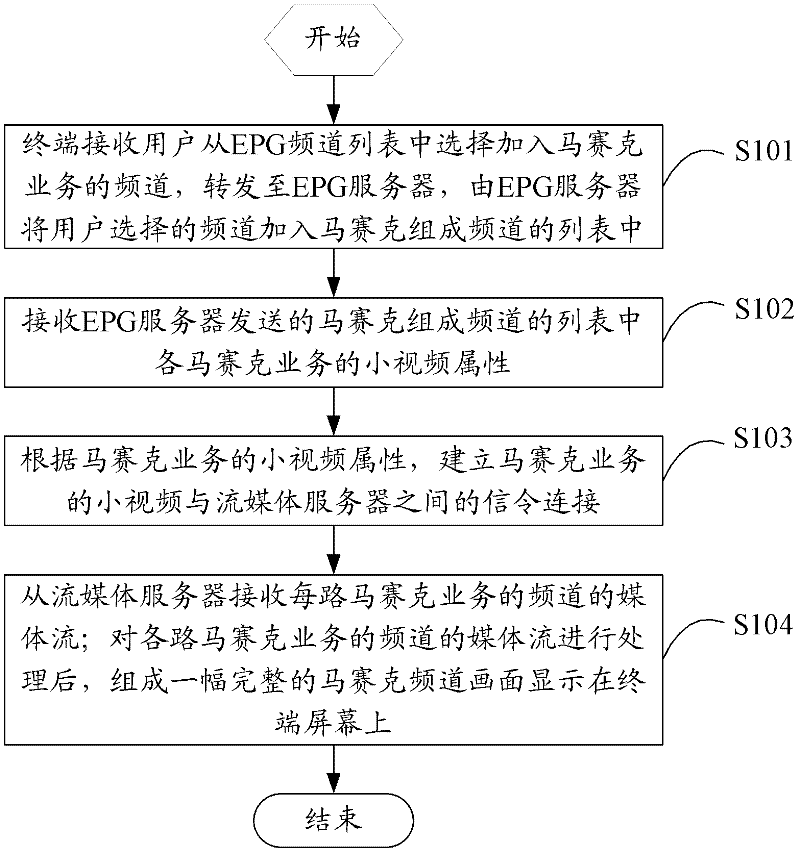

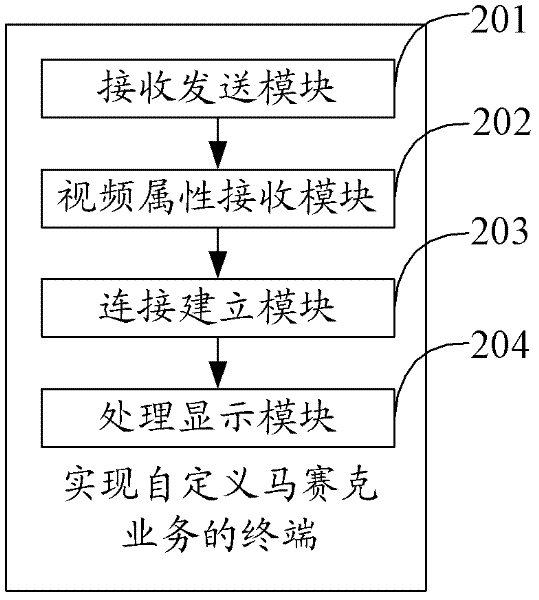

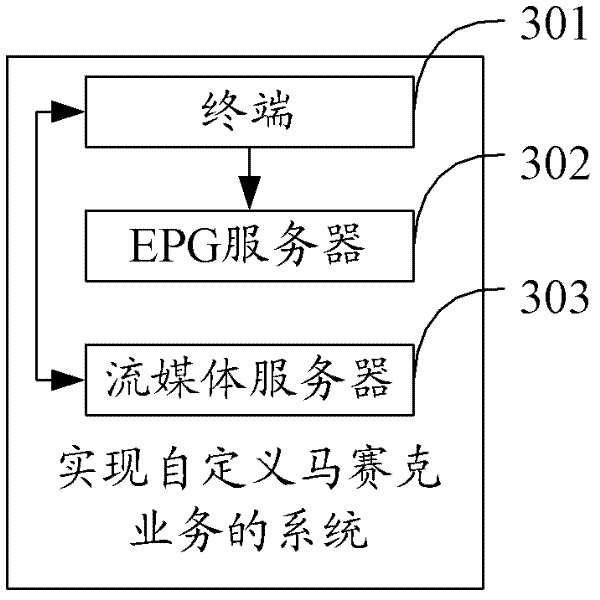

Method, terminal and system for realizing customized mosaic services

InactiveCN102421014AImprove interactivityImprove friendlinessSelective content distributionTelecommunicationsComputer terminal

The invention relates to a method, terminal and system for realizing a customized mosaic services. The method comprises the steps of: receiving a frequency channel, to be added into the pixelization service, selected by a user from an EPG (Electron Program Guide) frequency channel list and forwarding the selected frequency channel to an EPG server by a terminal, and adding the frequency selected by the user into a frequency channel list constituted by mosaic by the EPG server; receiving small video attributes, sent by the EPG server, of each mosaic service; establishing a signalling connection between a small video and a stream media server for the mosaic services according to the small video attributes of the mosaic services; receiving the media stream of the frequency channel of each path of mosaic service from the stream media server; processing the media stream of each path of mosaic service to constitute a piece of complete mosaic frequency channel picture to be displayed on a terminal screen. In the invention, a user can select a small mosaic video to be displayed in a customized manner without limits from head-end encoders and other equipment, thus, favorable user interactivity and friendliness are achieved, and the method is simple and flexible to implement and is strong in expandability.

Owner:ZTE CORP

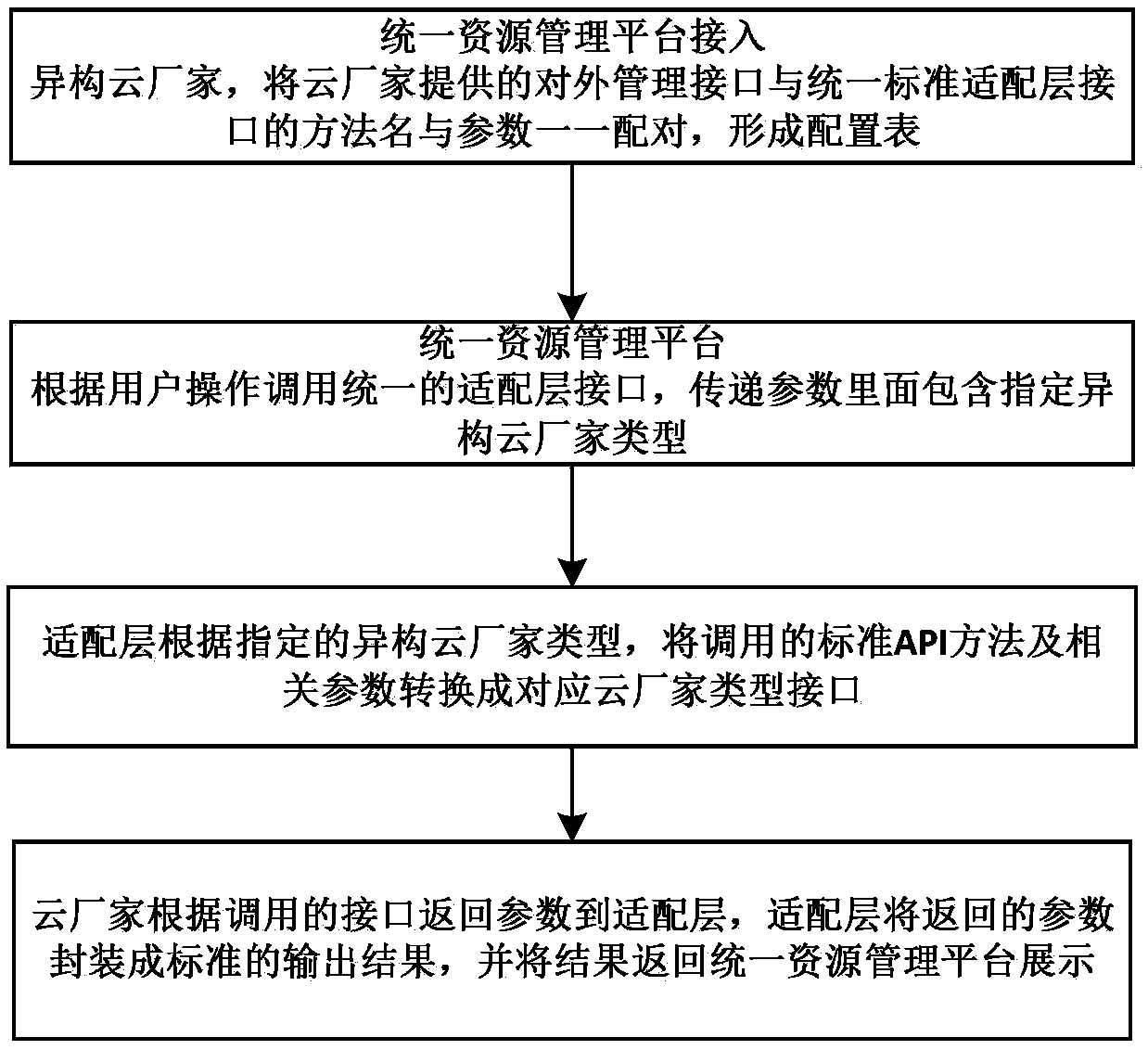

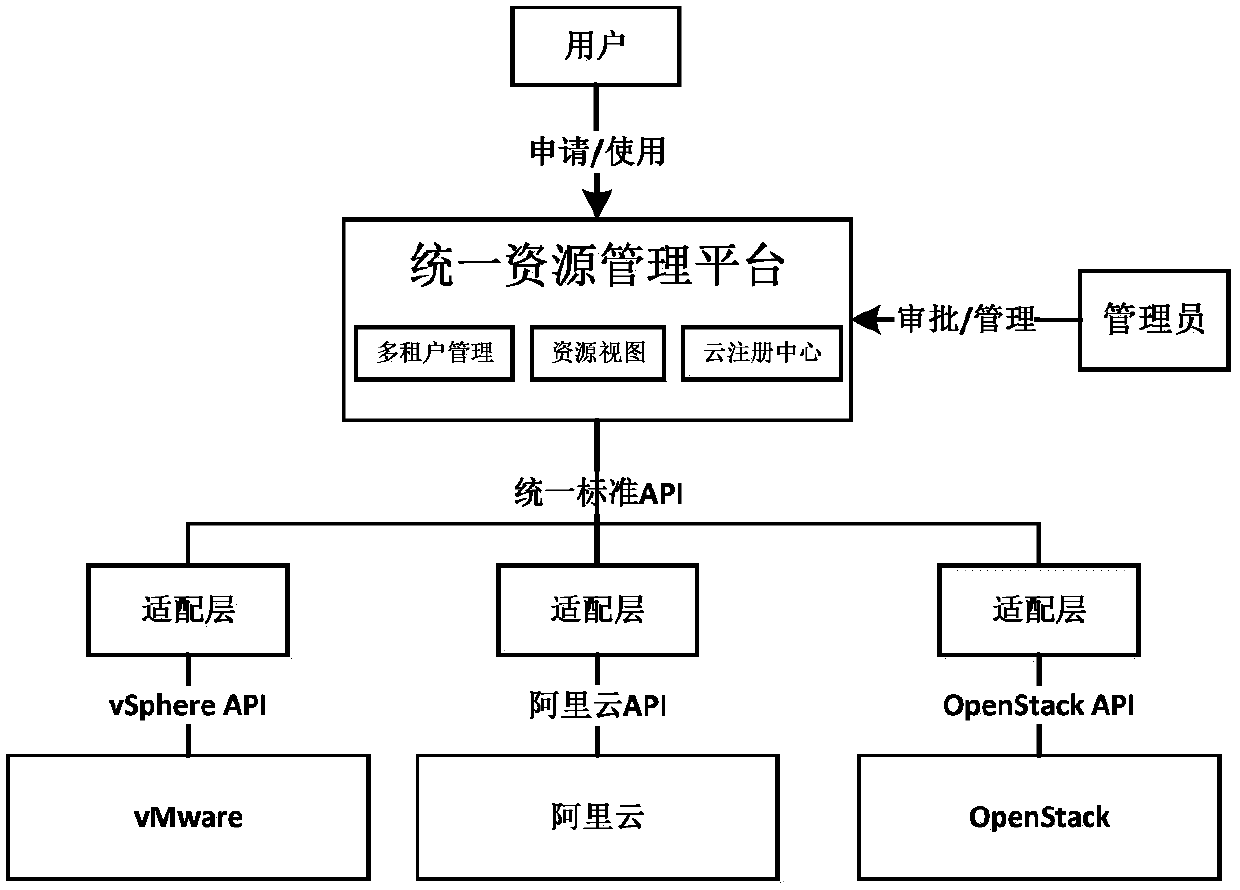

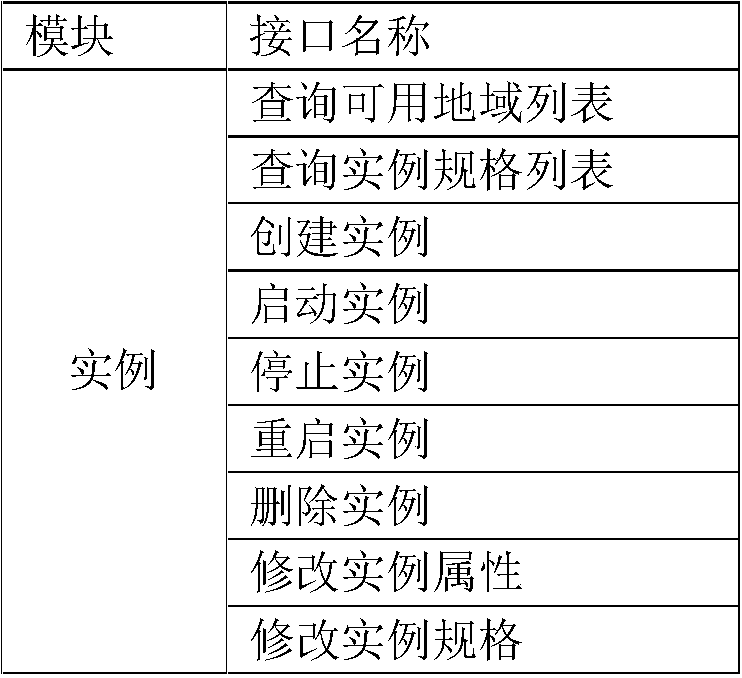

Heterogeneous cloud management system and method suitable for cloud computing

InactiveCN107659624AReduce development complexityRetain propertiesTransmissionLayer interfaceCloud management

The invention relates to the technical field of cloud computing, and particularly relates to a heterogeneous cloud management system and method suitable for cloud computing. The method comprises the steps of first, accessing a heterogeneous cloud manufacture, and matching method names and parameters of external management interfaces provided by the cloud manufacture and uniform standard adapter layer interfaces correspondingly, so as to form a configuration table; then, invoking a uniform adapter layer interface by a platform according to a user operation, wherein a transmission parameter comprises a designated heterogeneous cloud manufacture type; then, converting the invoked standard API method and related parameter into an interface of a corresponding cloud manufacture by an adapter layer according to the designated heterogeneous cloud manufacture type; and finally, returning the parameter to the adapter layer by the cloud manufacture according to the invoked interface, packaging the returned parameter into a standard output result by the adapter layer, and returning the result to the platform to display. The method solves the management problem of the heterogeneous cloud platform, and can be applied to unified management of the heterogeneous cloud platform.

Owner:G CLOUD TECH

Preparation method of functional regenerated cellulose fiber

ActiveCN106435817AEvenly dispersedStable in natureFlame-proof filament manufactureArtificial thread manufacturing machinesProduction lineCellulose fiber

The invention relates to a preparation method of a functional regenerated cellulose fiber. The method comprises the steps that cellulose with low polymerization degree is dissolved with a cellulose solvent, and a carrier solution of functional powder is obtained; the functional powder is mixed with the carrier solution under the intense shear effects provided by a stirring device, and a functional mother solution is obtained; the functional mother solution is injected into a cellulose spinning solution in a mode of online addition, and the spinning solution is subjected to extrusion and solidification to form the functional regenerated cellulose fiber. According to the preparation method, the problems that by means of a traditional method, the functional powder and the spinning solution are difficult to mix and dispersion is nonuniform are overcome, the used mother solution is solidified and formed with fibers and enters the solvent and the coagulating bath system without any additional auxiliaries. The forming method is simple, flexible and efficient, the production of the functional regenerated cellulose fiber can be achieved based on a conventional production line.

Owner:DONGHUA UNIV

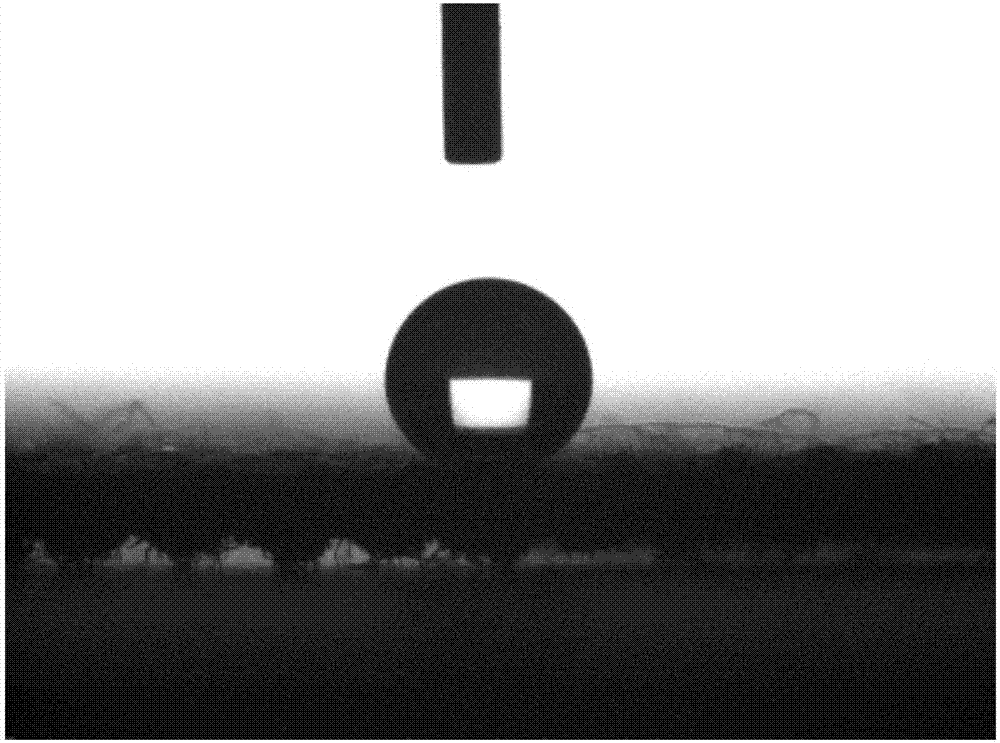

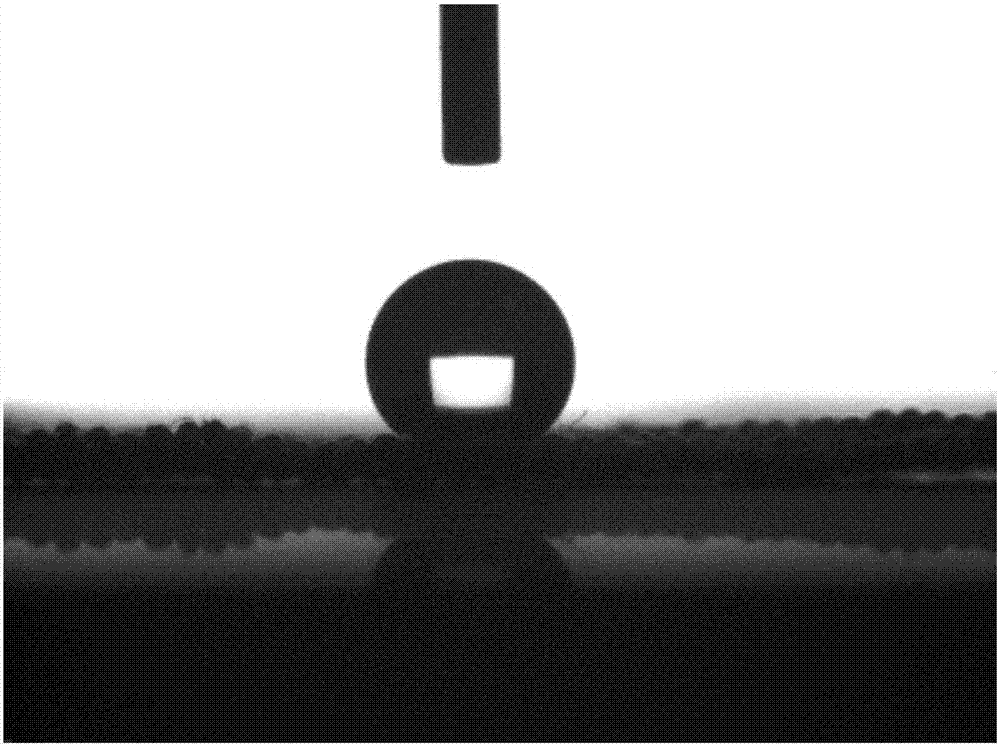

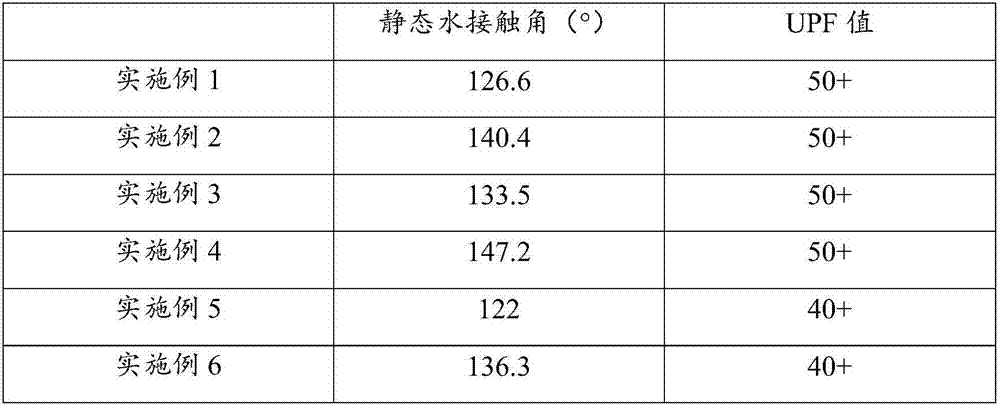

Hydrophobic anti-ultraviolet fabric and preparation method thereof

ActiveCN107503120AThe method is simple and flexibleSuitable for mass productionLight resistant fibresLiquid repellent fibresHigh volume manufacturingUltraviolet

The invention discloses a hydrophobic anti-ultraviolet fabric and a preparation method thereof. A base material of the fabric has a hydrophilic surface, and the fabric is loaded with graphene oxide and aminopropyl isobutyl silsesquioxane. In the preparation method disclosed by the invention, the graphene oxide and the aminopropyl isobutyl silsesquioxane are jointly used for preparing a functional fabric for the first time, thereby endowing the hydrophilic base material of the fabric with hydrophobic and anti-ultraviolet properties, and improving the application value of the fabric; and preparation method disclosed by the invention only adopts a two-step finishing process to obtain a fluorine-free hydrophobic fabric with excellent performance. The preparation method is easy and flexible, green and environmentally friendly, and suitable for mass production.

Owner:江苏华佳控股集团有限公司 +1

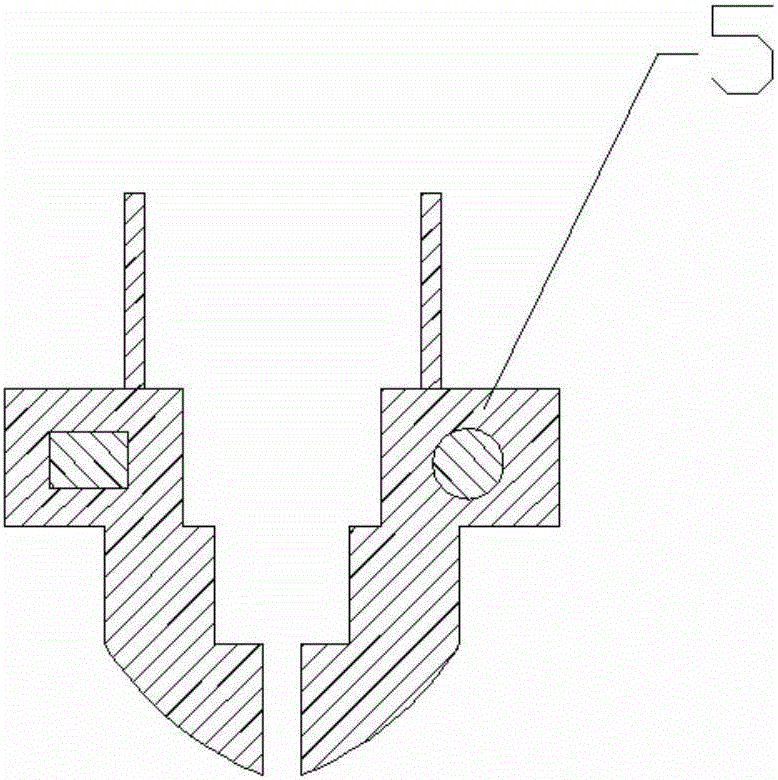

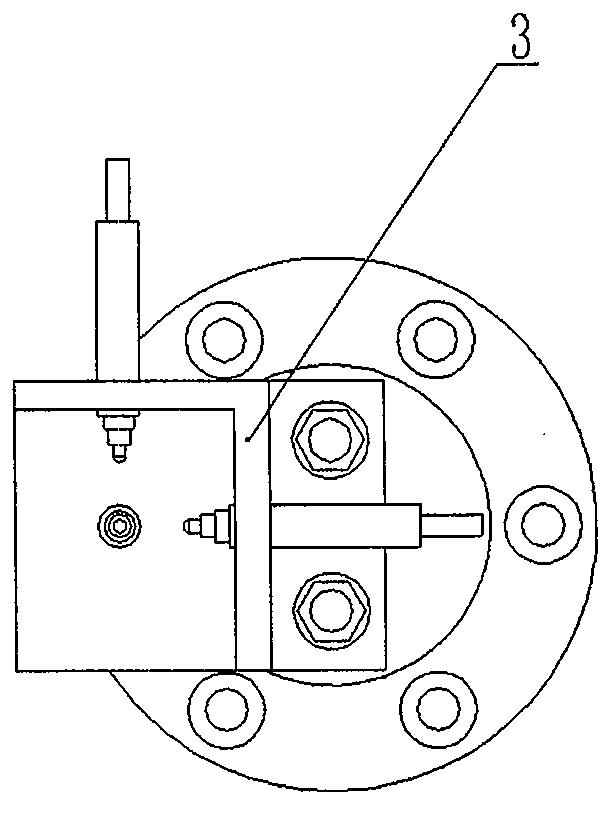

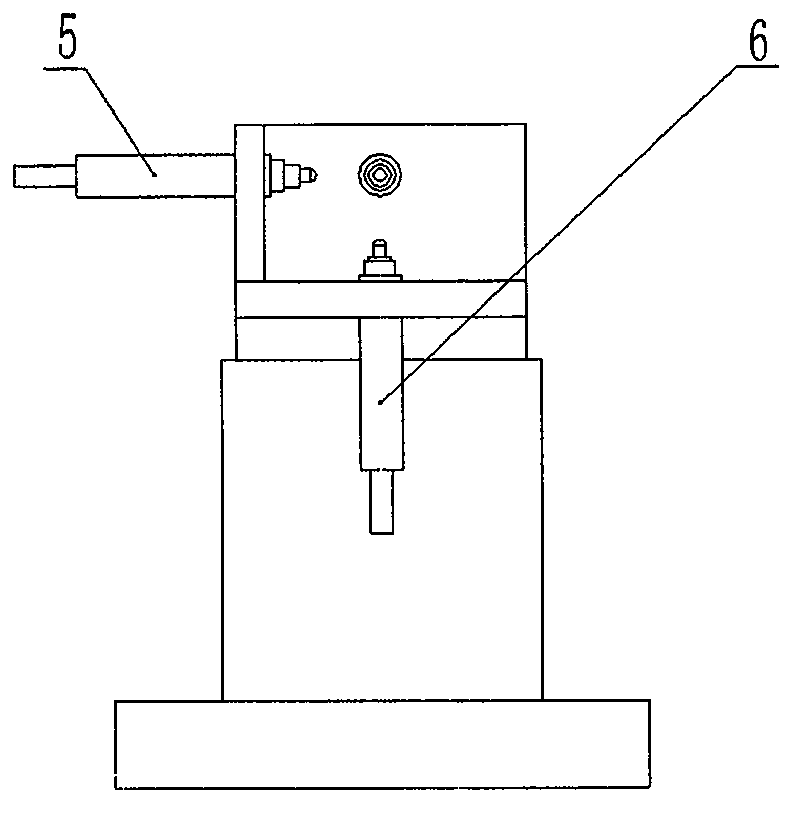

Detection device for knife point dynamic characteristics of numerical control machine tool and method of detection device

ActiveCN105269404ALow costSimple structureMeasurement/indication equipmentsNumerical controlData information

The invention discloses a detection device for knife point dynamic characteristics of a numerical control machine tool and a method of the detection device. Mainly the problems that detection performance indexes of knife point dynamic characteristics of an existing numerical control machine tool are not comprehensive or accurate, and detection cost of instruments and cutting test pieces is high are solved. The detection device for the knife point dynamic characteristics of the numerical control machine tool comprises a supporting base, a connecting plate and an L-shaped supporting wall plate. The top of the supporting base is provided with displacement sensors in a penetrating manner through holes, wherein the displacement sensors are arranged in the manner that every two displacement sensors are perpendicular to each other; meanwhile, acquired temperature data of main heat sources of the machine tool are integrated so that a main shaft can acquire real-time location and posture information of a point of a knife point in the swinging or rotating process, and correlation calculation of accuracy and generation of compensating data are completed by automatically obtaining fused data information through a data collector and transmitting the fused data information to a computer at high speed to be recorded and analyzed. The detection device is ingenious in structural design, the knife point characteristic testing functions are comprehensive, universality is high, numerical control machining precision testing cost is greatly reduced, and good practical and popularization value is achieved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

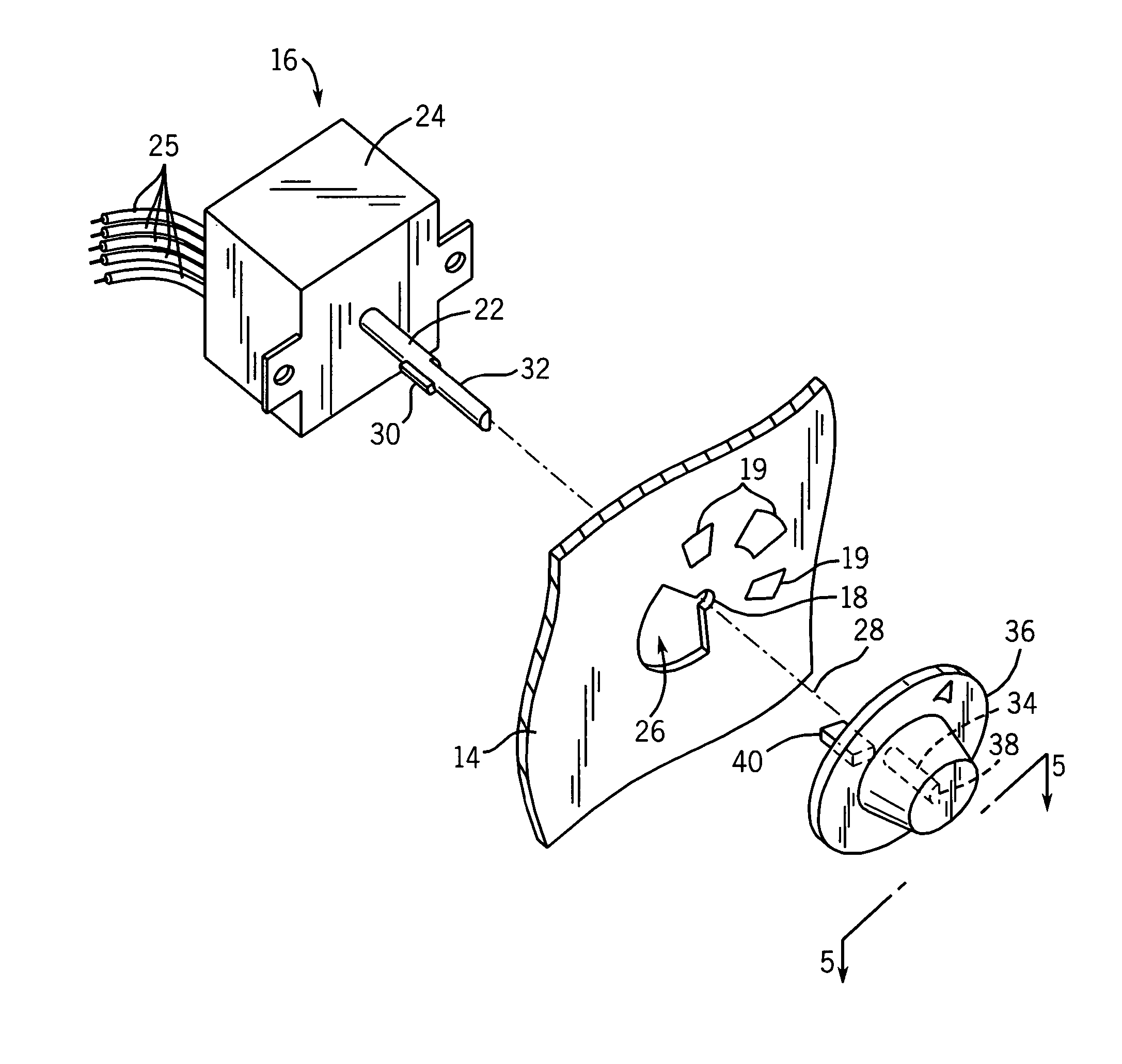

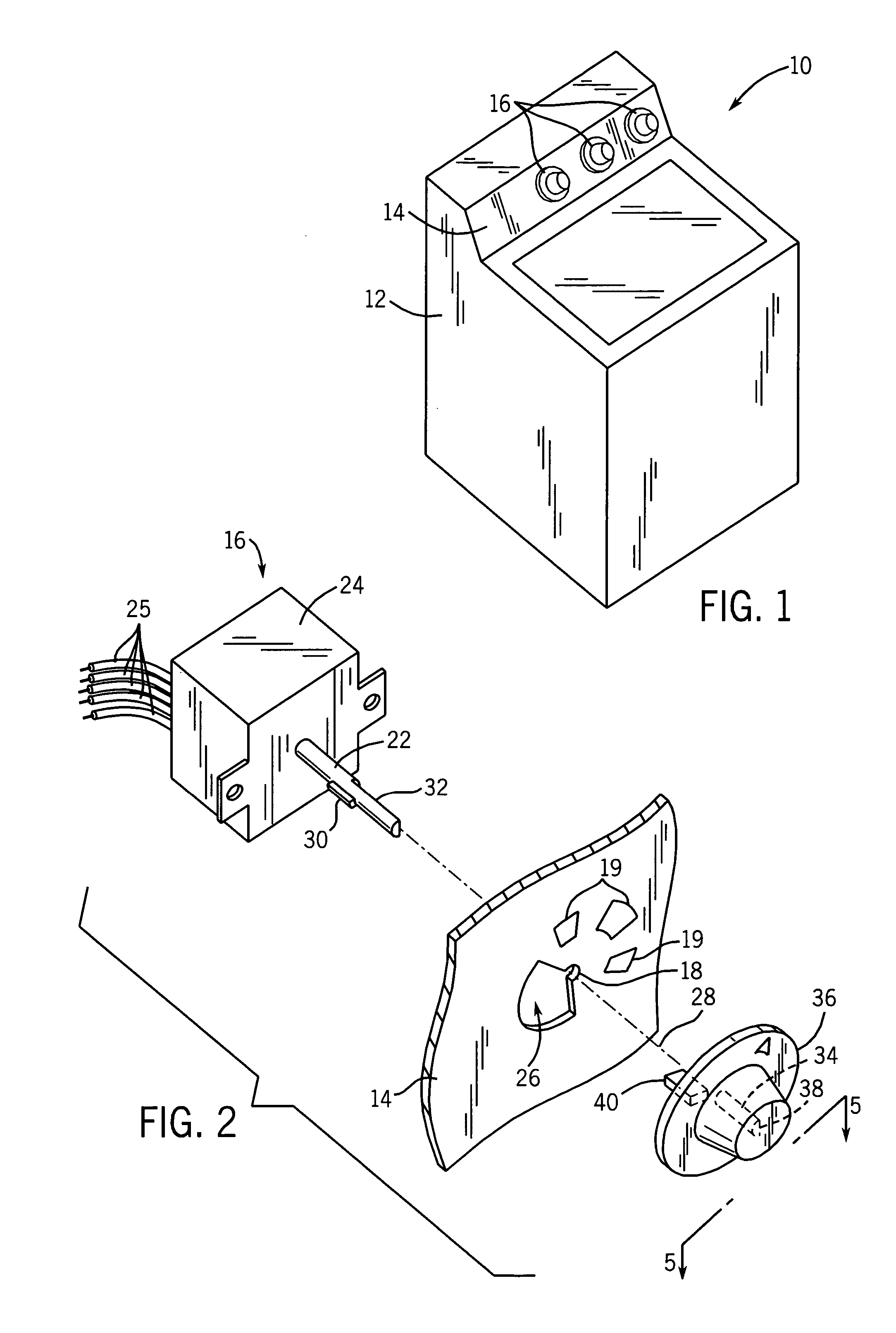

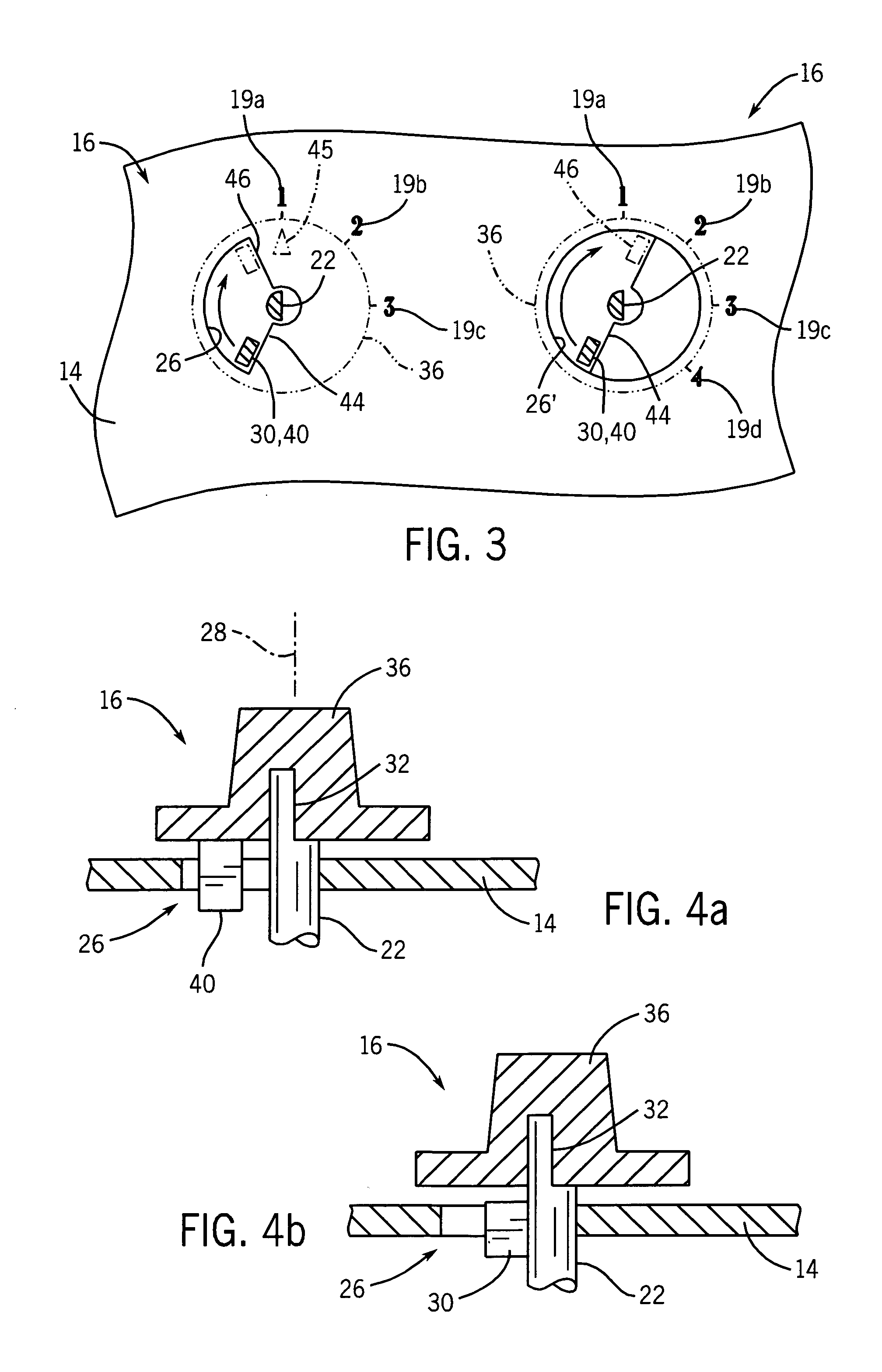

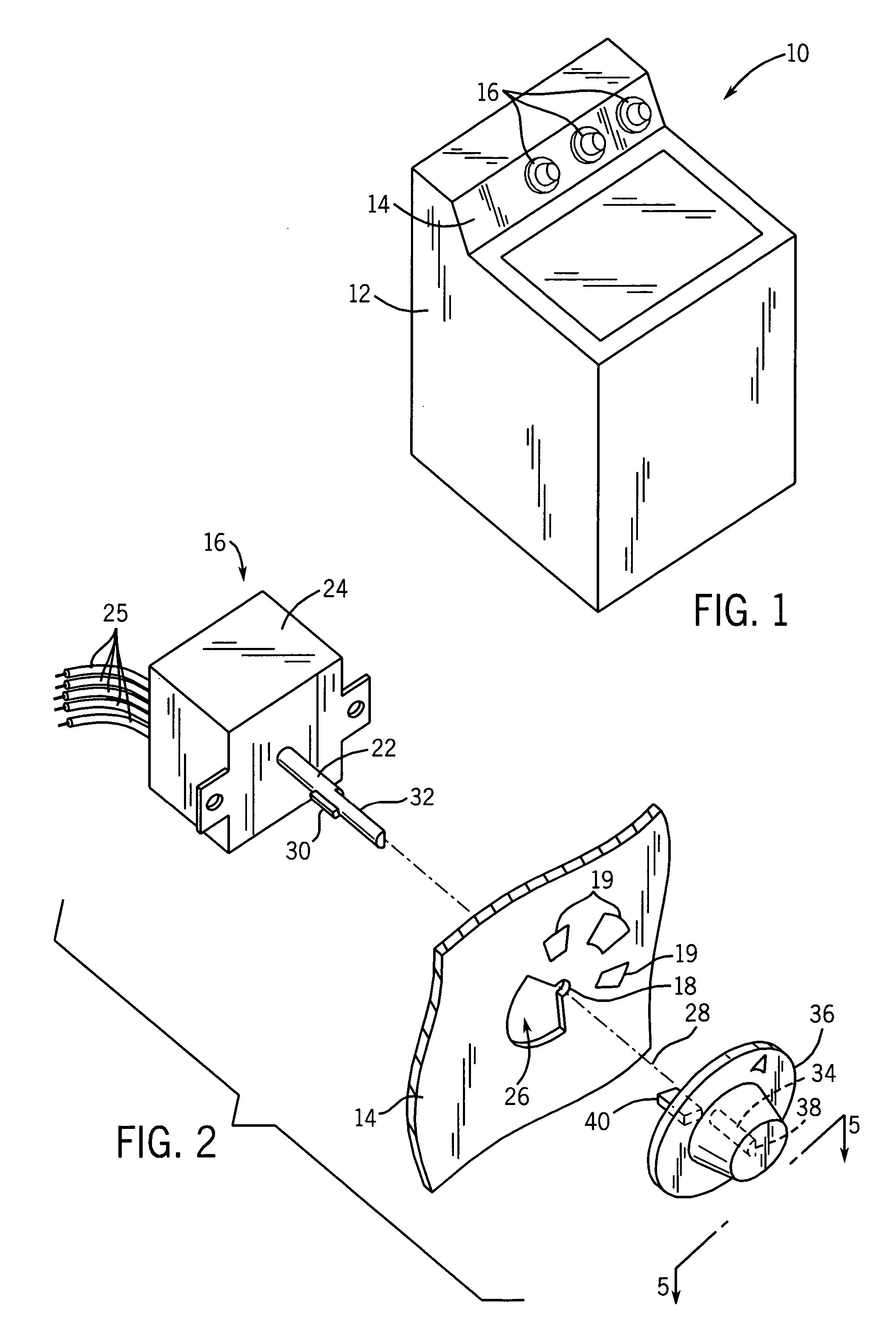

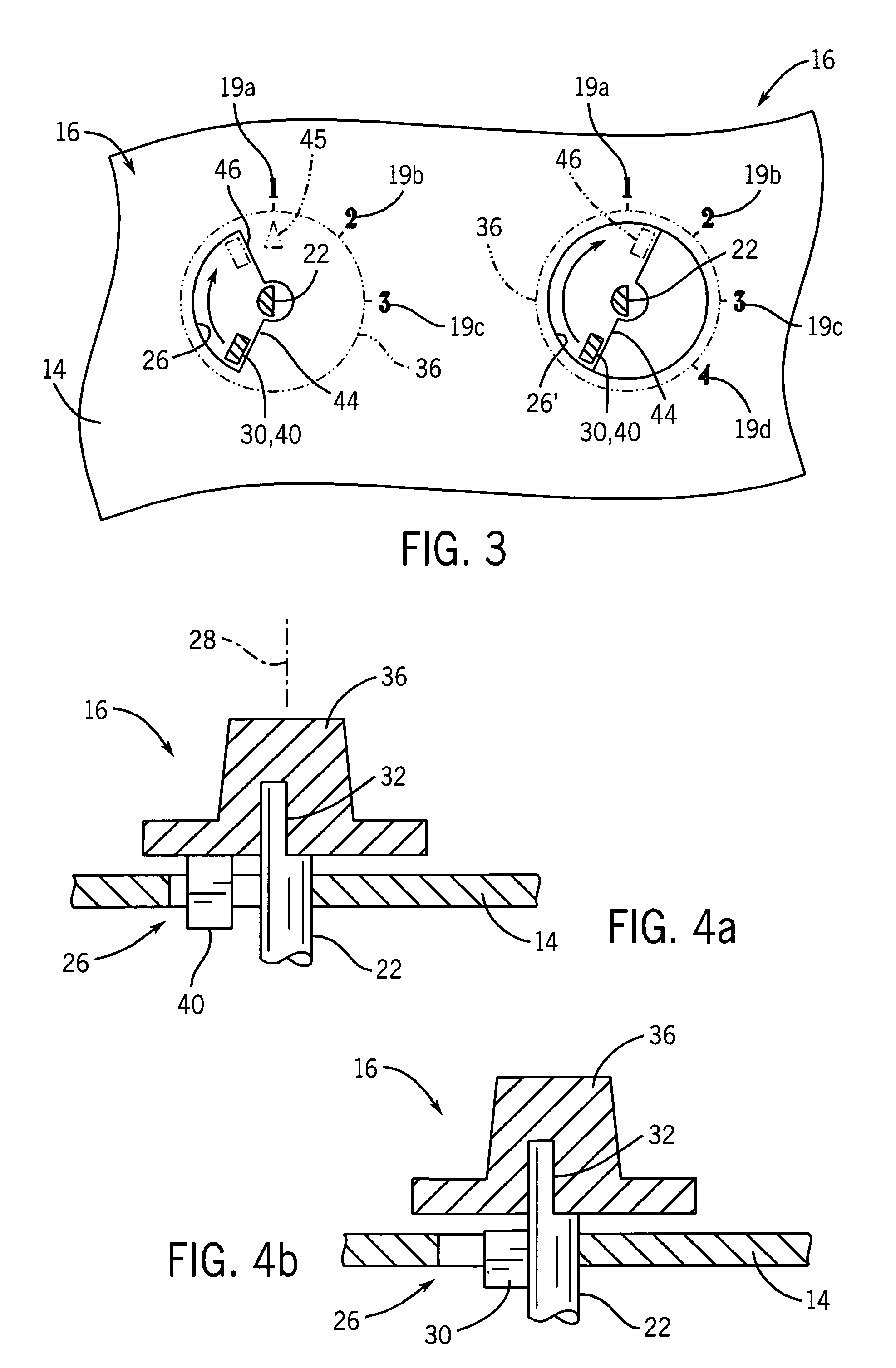

Appliance selector switch programmed by console cutout

InactiveUS20050167255A1Rule out the possibilityThe method is simple and flexibleContact operating partsEmergency protective devicesElectronic switchElectrical and Electronics engineering

A console switch assembly for appliances provides a rotatable electronic switch having a rotational range constrained by a cutout in the control panel to which the switch is mounted. The cutout most simply may be a sector of a circle having a different angular range which constrains a projecting tooth on the shaft of the switch or knob attached to the shaft of the switch.

Owner:ILLINOIS TOOL WORKS INC

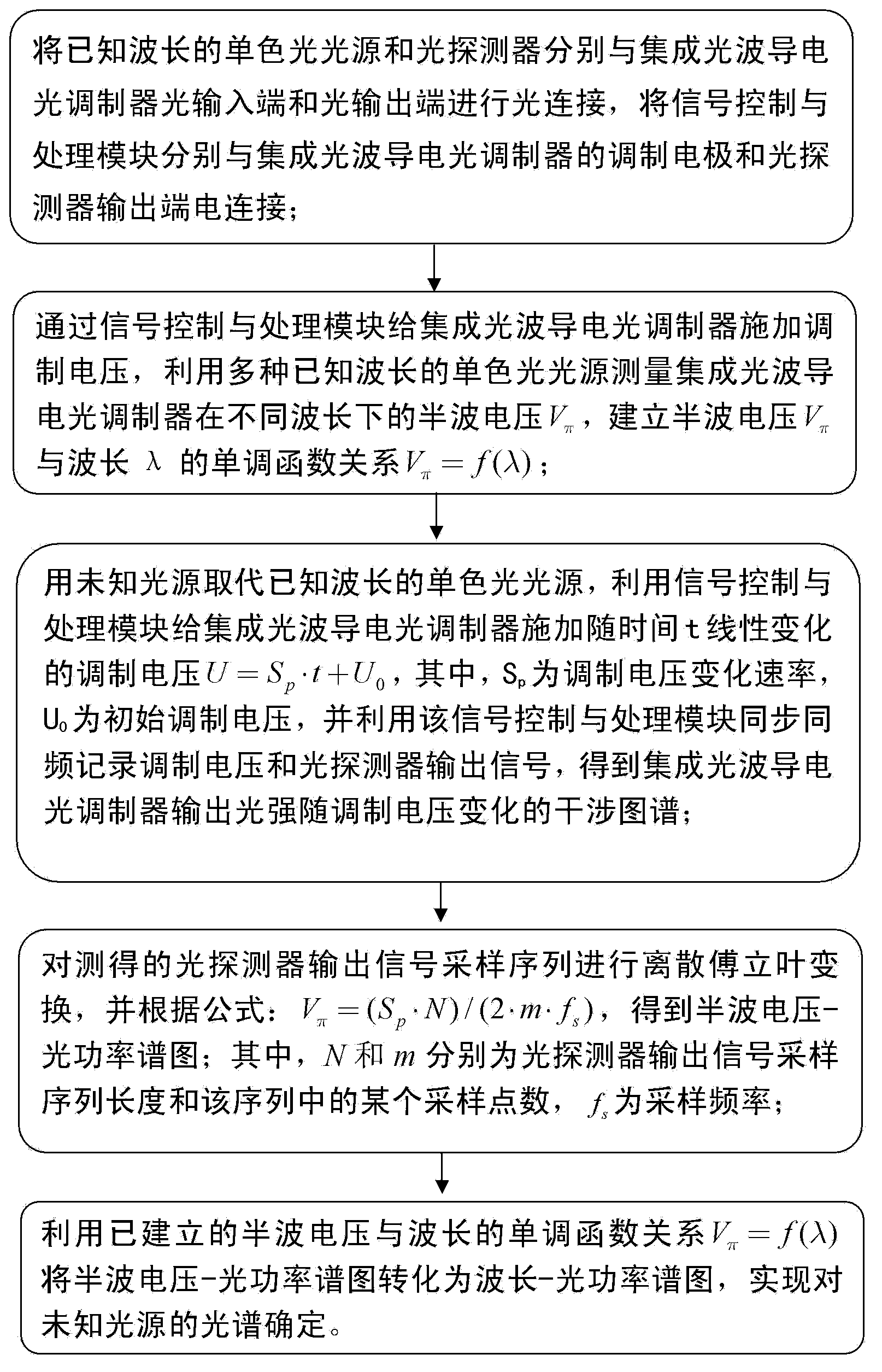

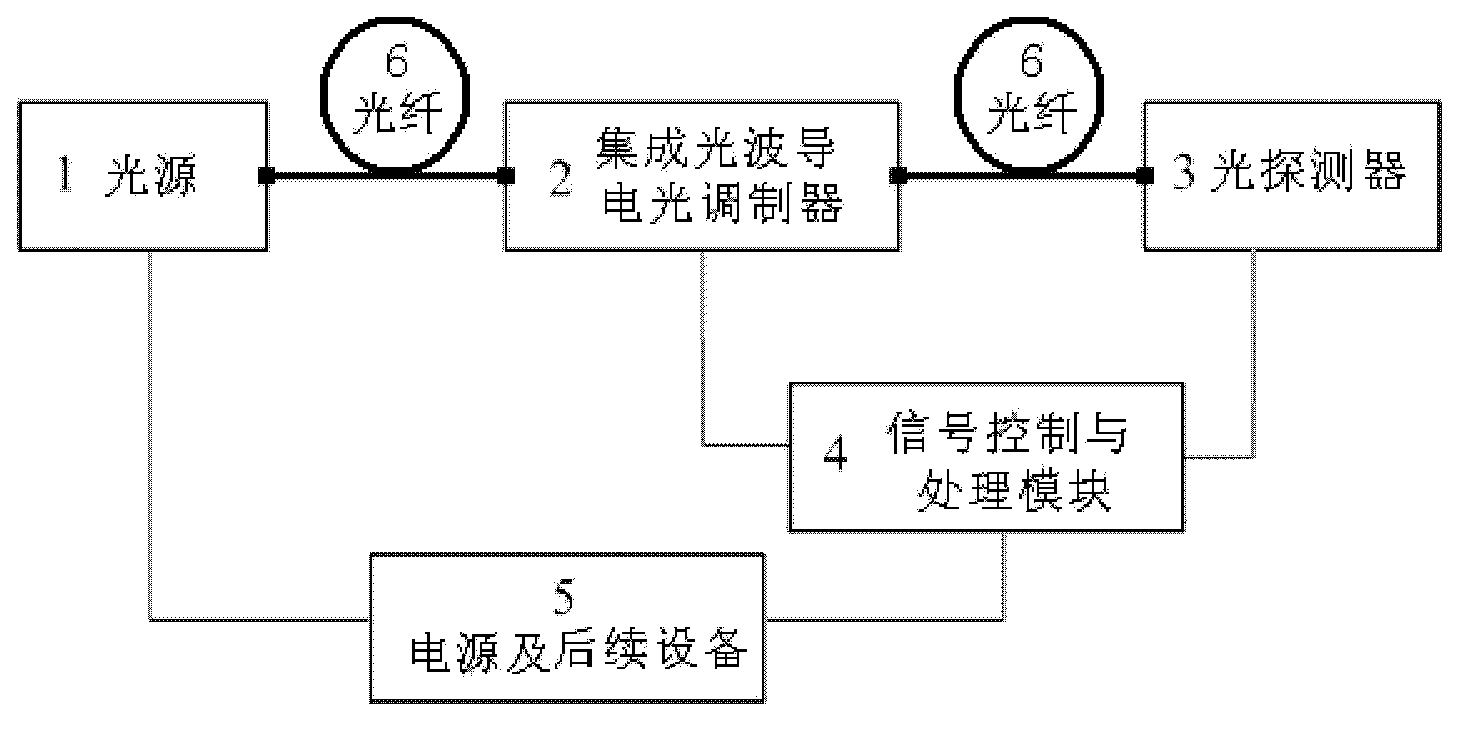

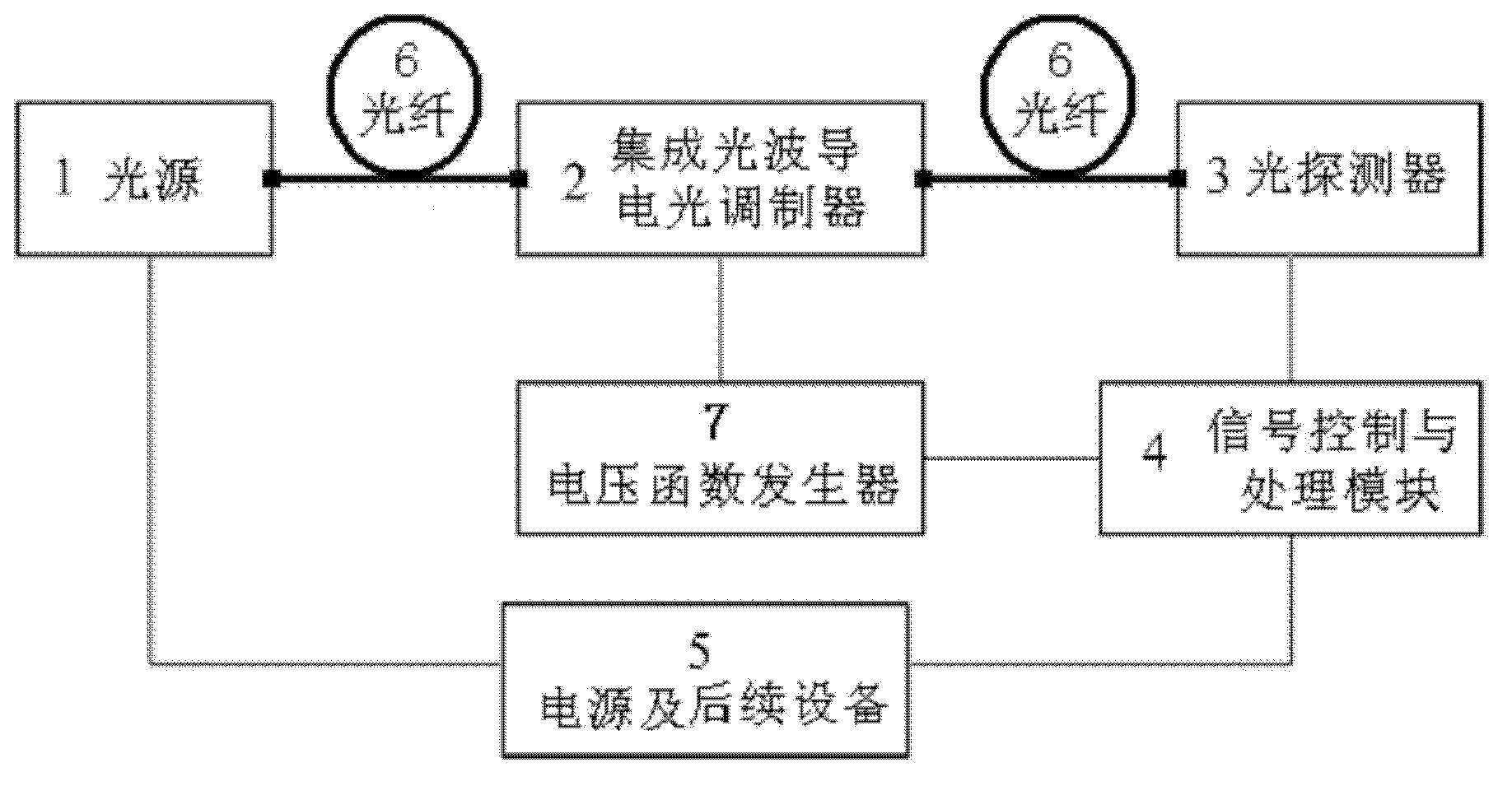

Method for obtaining light source spectra

ActiveCN103852164ASimple and fast operationHigh precisionEmission spectroscopyAbsorption/flicker/reflection spectroscopyFluorescence spectrometryLength wave

The invention discloses a method for obtaining light source spectra. The method includes the following steps that: a plurality of monochromatic light sources of which the wavelength is known are utilized to measure half-wave voltage of an integrated optical waveguide electro-optic modulator under different wavelengths, and the monotonic function relationship between the half-wave voltage and the wavelengths is established; and after an unknown light source is connected with the same integrated optical waveguide electro-optic modulator, an interference pattern of linear change with modulation voltage of the integrated optical waveguide electro-optic modulator is measured, and the measured interference pattern is subjected to Fourier transform, such that a distribution curve of incident light power with the half-wave voltage is obtained, and a distribution curve of the incident light power with the wavelengths can be obtained through utilizing the established monotonic function relationship between the half-wave voltage and the wavelengths, and then, the spectra of the unknown light source can be obtained. With the method of the invention adopted, the determination of various kinds of parameters of the integrated optical waveguide electro-optic modulator is not required. The method is advantageous in simple operation, high precision and strong anti-interference ability, and can be used for determining the spectra of light sources and measuring visible-infrared absorption spectra and fluorescence spectra of substances.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

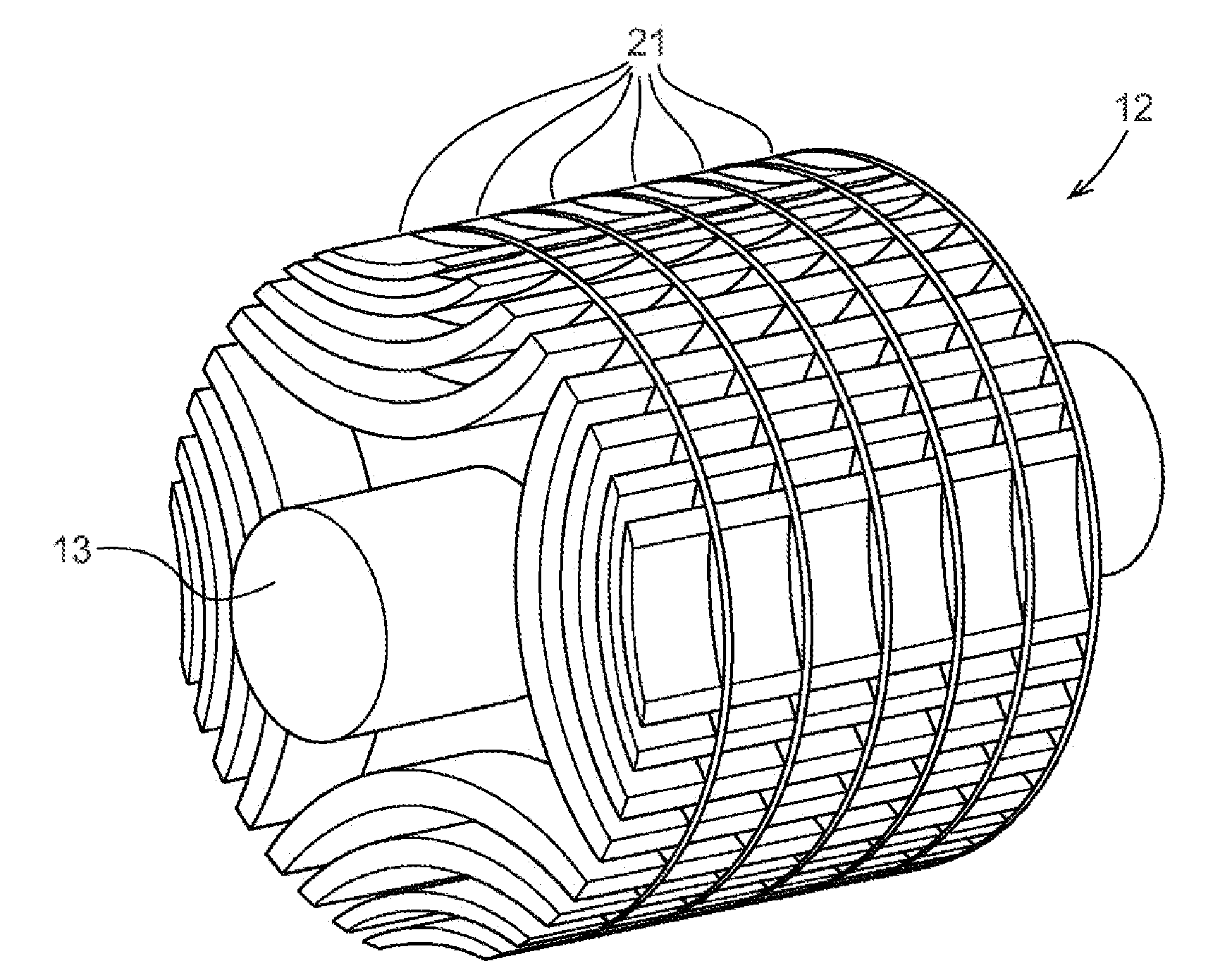

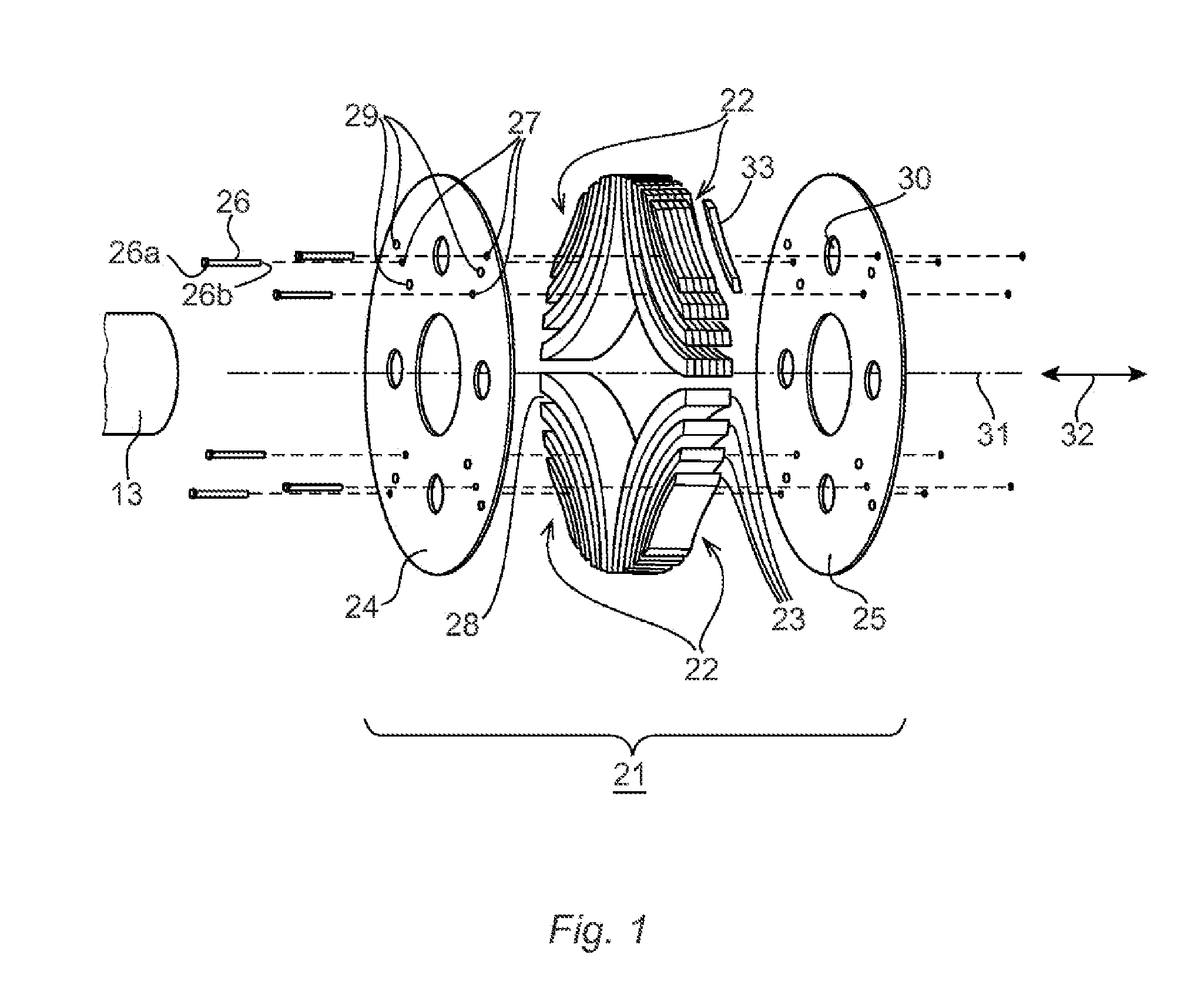

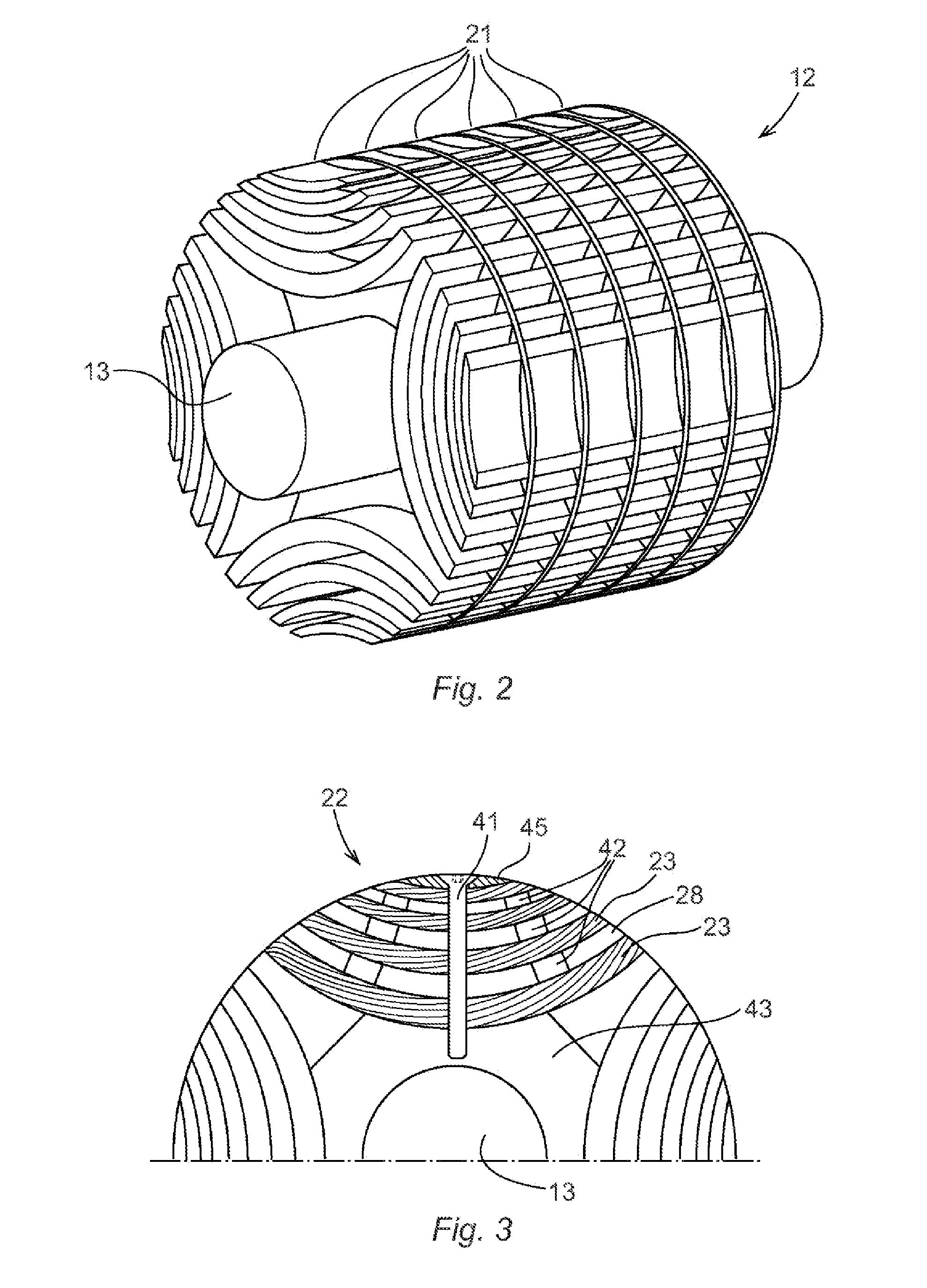

Modular Rotor For Synchronous Reluctance Machine

InactiveUS20120146448A1Improve electrical performanceThe method is simple and flexibleMagnetic circuit rotating partsSynchronous reluctance motorAdhesive

A rotor for a synchronous reluctance machine includes a plurality of rotor modules disposed in an axial sequence along a common axis. Each rotor module includes a plurality of poles disposed in adjacent sectors about the common axis, each pole including a plurality of magnetic segments spaced apart from one another in radial direction, a support plate, provided on an axial side of the plurality of poles, and fastening means for fastening the plurality of poles to the support plate. The fastening means, preferably a plurality of axially arranged bolts or an adhesive, bonds the plurality of poles to the support plate.

Owner:ABB RES LTD

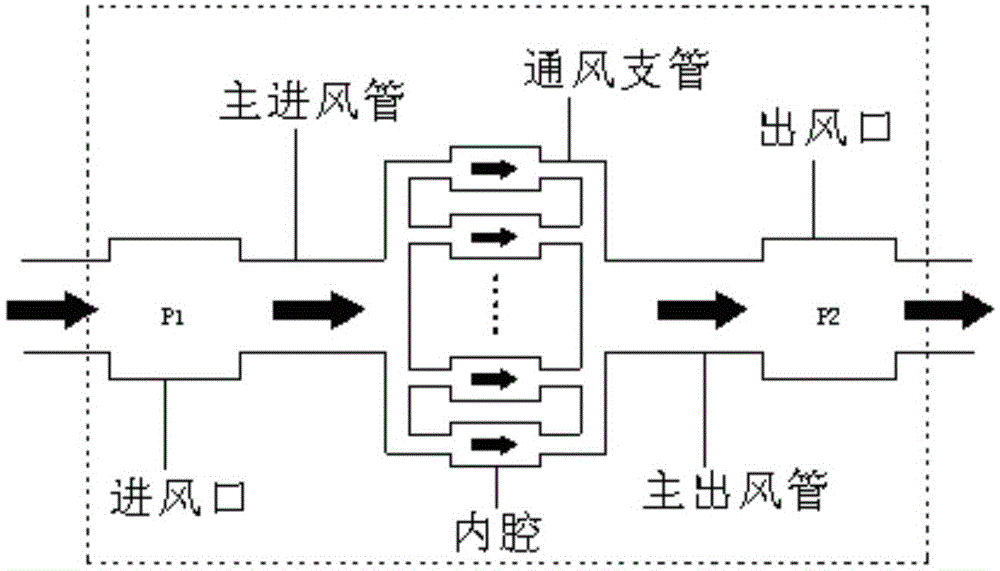

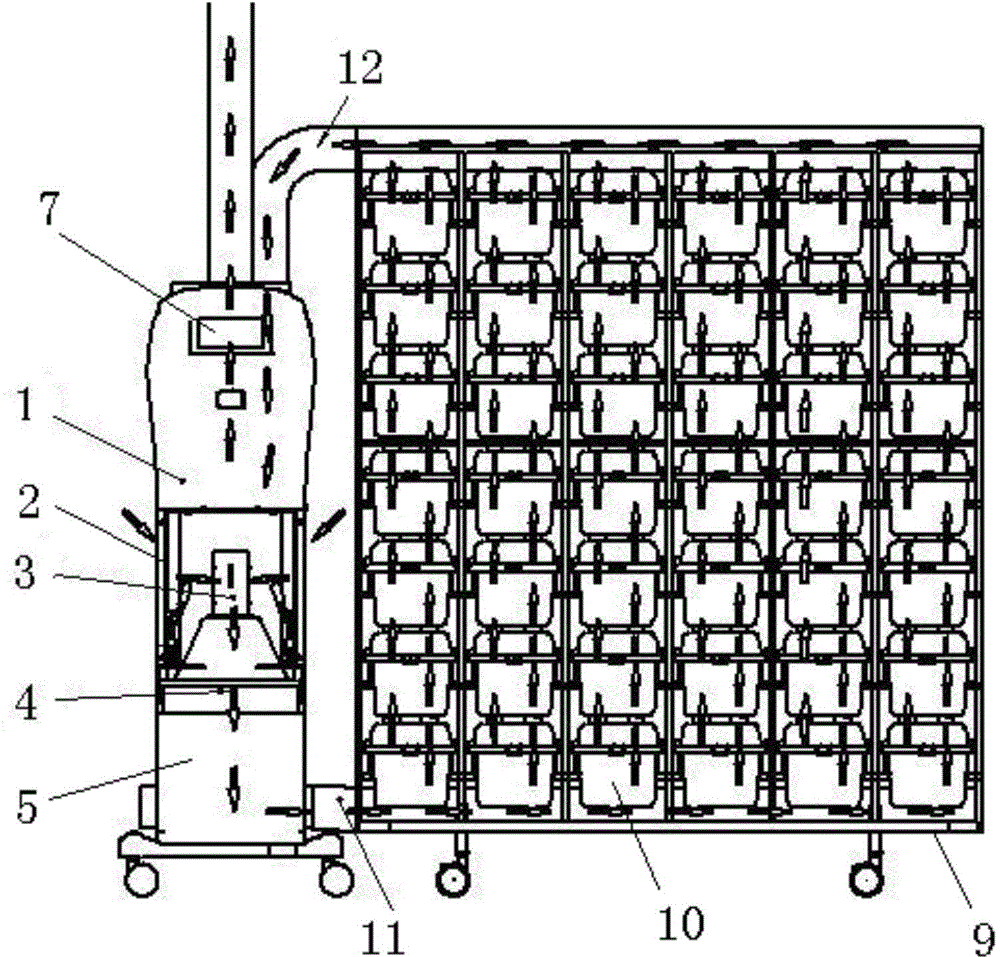

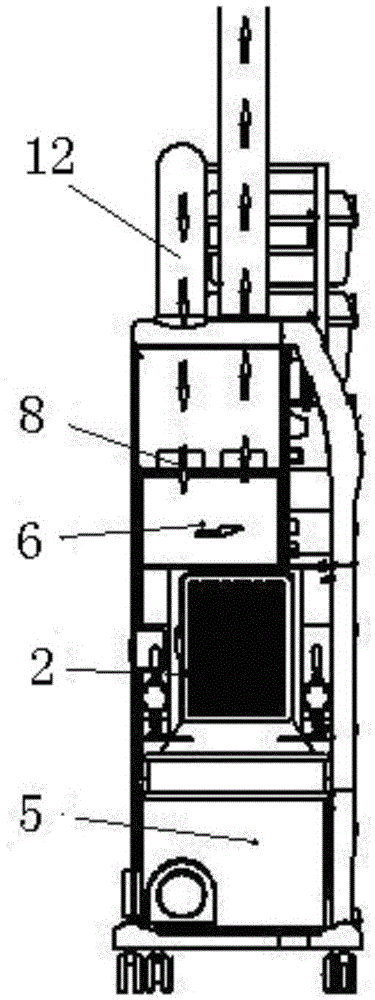

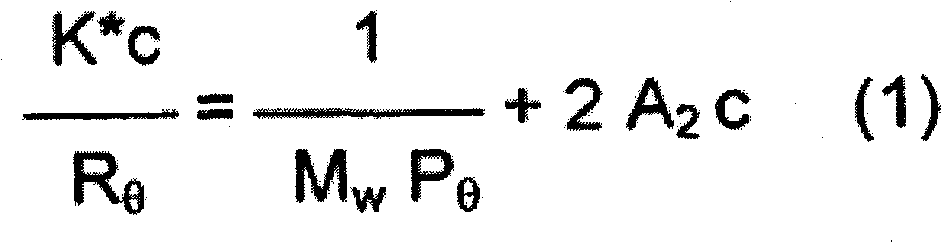

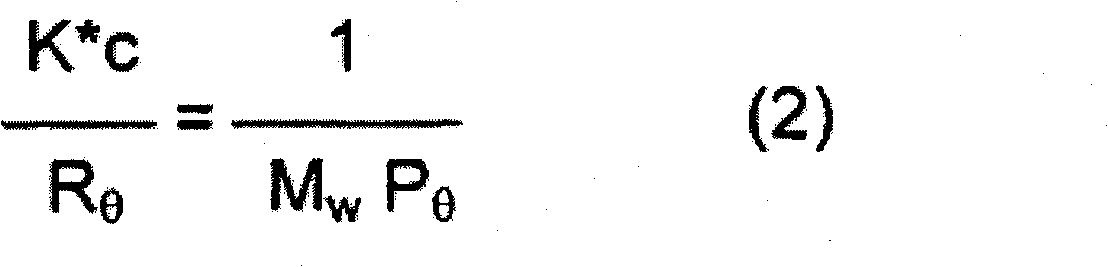

Independent ventilation cage flow measurement method, cage box external pressure difference measurement method, control system and control method

InactiveCN103548700AAccurate measurementThe method is simple and flexibleAnimal housingVolume/mass flow by differential pressureRegression analysisDifferential pressure

The invention discloses an independent ventilation cage flow measurement method which comprises the following steps of (1) dividing the voltage of an air inlet fan motor into N sampling points and dividing the voltage of an air outlet fan motor into M sampling points; (2) controlling the air inlet fan motor to work on a first sampling point, controlling the air outlet fan motor to work on a 0 sampling point and an M sampling point, collecting pressure difference between an air inlet box and an air outlet box through a pressure difference sensor, and utilizing a standard flow measurement instrument to demarcate flow in an independent ventilation cage of the air outlet fan motor on each of the sampling points; (3) repeating the step (1) and the step (2) when the air inlet fan motor works on other sampling points; (4) performing regression analysis on M+1 groups of pressure difference-flow data to obtain N pressure difference-flow curves meeting the following formula: deltaP+ K1 (v+ K2) 2= C, demarcating N groups of weight factors K1 and K2 when the air inlet fan motor works on different sampling points, and storing the N groups of weight factors K1 and K2 into a controller; (5) during actual operation, selecting the nearest voltage sampling point of an air inlet fan according to the voltage of the air inlet fan motor through the controller, and calculating the flow v by means of the weight factors of the nearest voltage sampling point and the measured pressure difference. The invention further discloses a cage box external pressure difference measurement method and a control method based on the independent ventilation cage flow measurement method and the cage box external pressure difference measurement method.

Owner:上海鸣励实验室科技发展有限公司

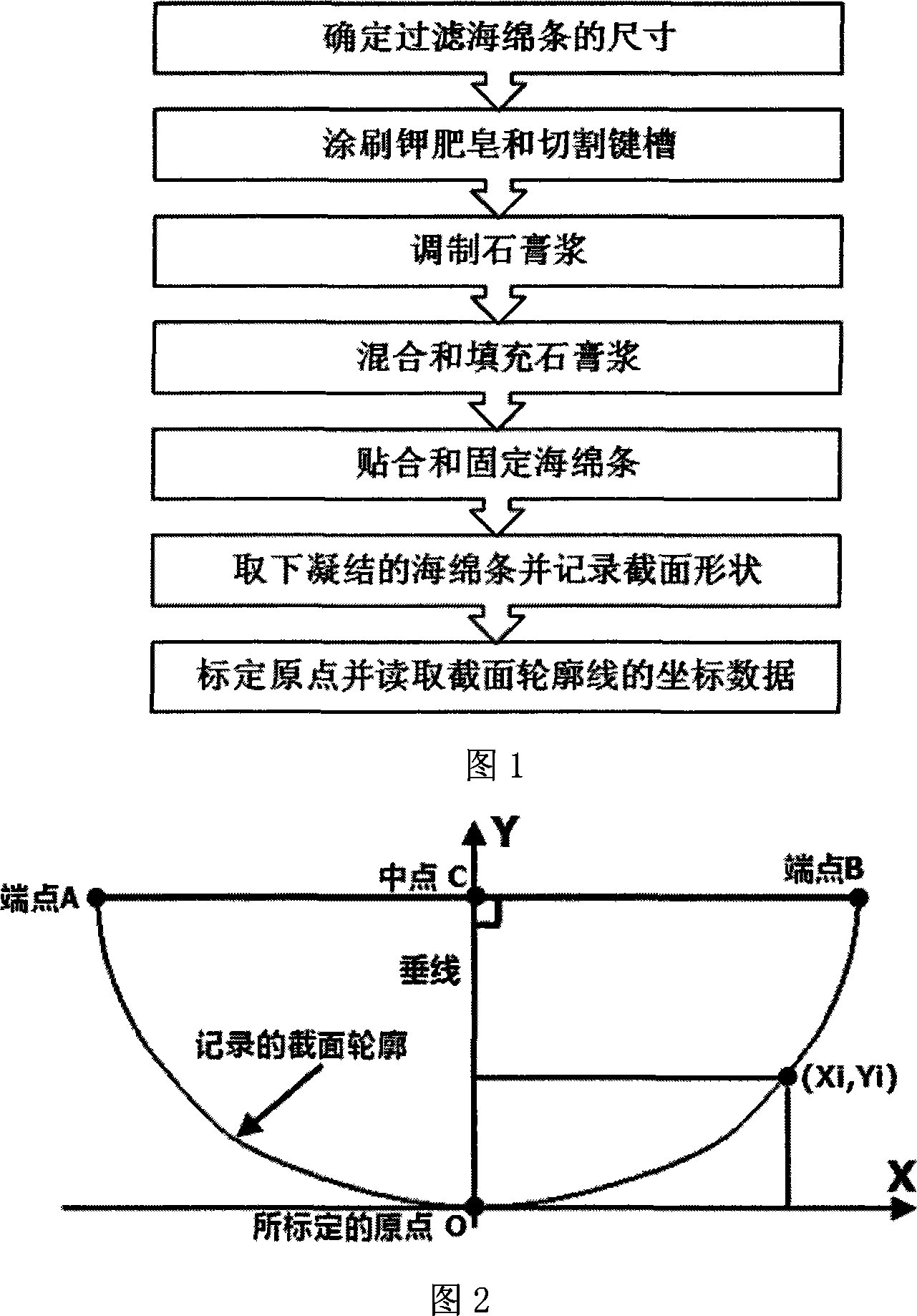

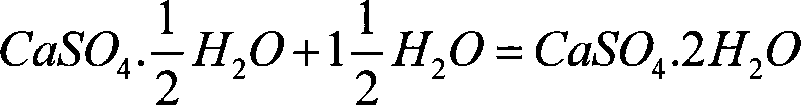

Measuring method of section profile and shape in cold-formed steel figuration process

The utility model provides a measurement method for cross-section contour shape of cold-rolled forming section during forming process in measurement technical field. The utility model is characterized in that the length of a flexible strip with a hole-shaped structure is determined at first, then a keyway and potash soap are arranged on the flexible strip; fast gelatination material is prepared, mixed and filled; the flexible strip is tightly adhered and fixed; he condensed flexible strip is then removed and the cross-section shape is recorded. A transparent plastic sheet with the cross-section shape is spread on a piece of coordinate paper and the location is adjusted well so that the coordinate value of any point of the successive contour line can be read. The utility model can overcome the disadvantages in prior art that on-line measurement is not supported and the workpiece needs to be removed. The utility model is suitable for the shape measurement of on-line cross-section contour of various specifications of roll forming product as a fast, simple, flexible, safe, economic and practical method for measuring cross-section.

Owner:无锡凯博易机电科技有限公司

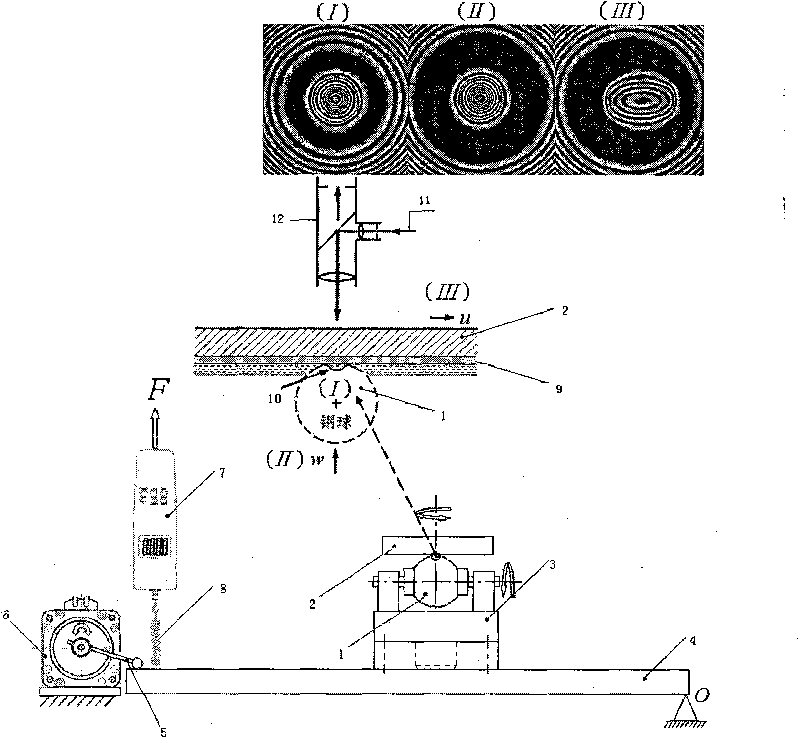

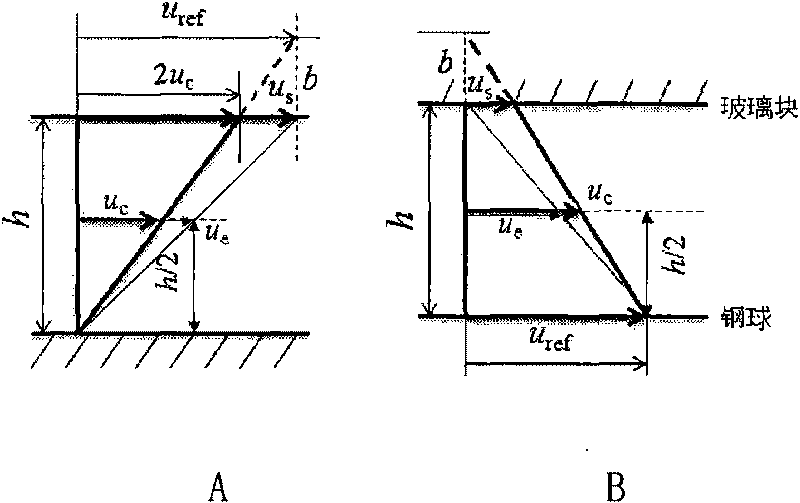

Method for measuring sliding length of high-pressure lubricant interface

InactiveCN101738166AThe principle of composition is reliableSimple structureSurface/boundary effectUsing optical meansClassical mechanicsImage processing software

The invention relates to a method for measuring sliding length of a high-pressure lubricant interface, and belongs to the technical field of sliding length measurement of the high-pressure lubricant interface. The method comprises the following steps of: firstly, selecting and determining lubricant, initial oil-sealing depth and applied load; secondly, measuring the sliding length of the high-pressure lubricant interface based on a light interference technique and applying the predetermined load to a steel ball by a digital-readout puller; thirdly, according to different requirements on the initial oil-sealing depth, setting the parameter of a motor through the initial depth for impacting; fourthly, according to the requirement on the measurement of the sliding length of the interface of an elastic flow contact region based on an impacting technique, sliding a glass block or the steel ball and recording the motion process of the sealed lubricant in the contact region; and finally, analyzing the motion speed of an oil-sealing core and calculating the sliding speed and the sliding length. A device for measuring the sliding length of the high-pressure lubricant interface has the advantages of reliable principle, simple structure, convenient operation, high measurement and calculation accuracy, nimble method and high practicability.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

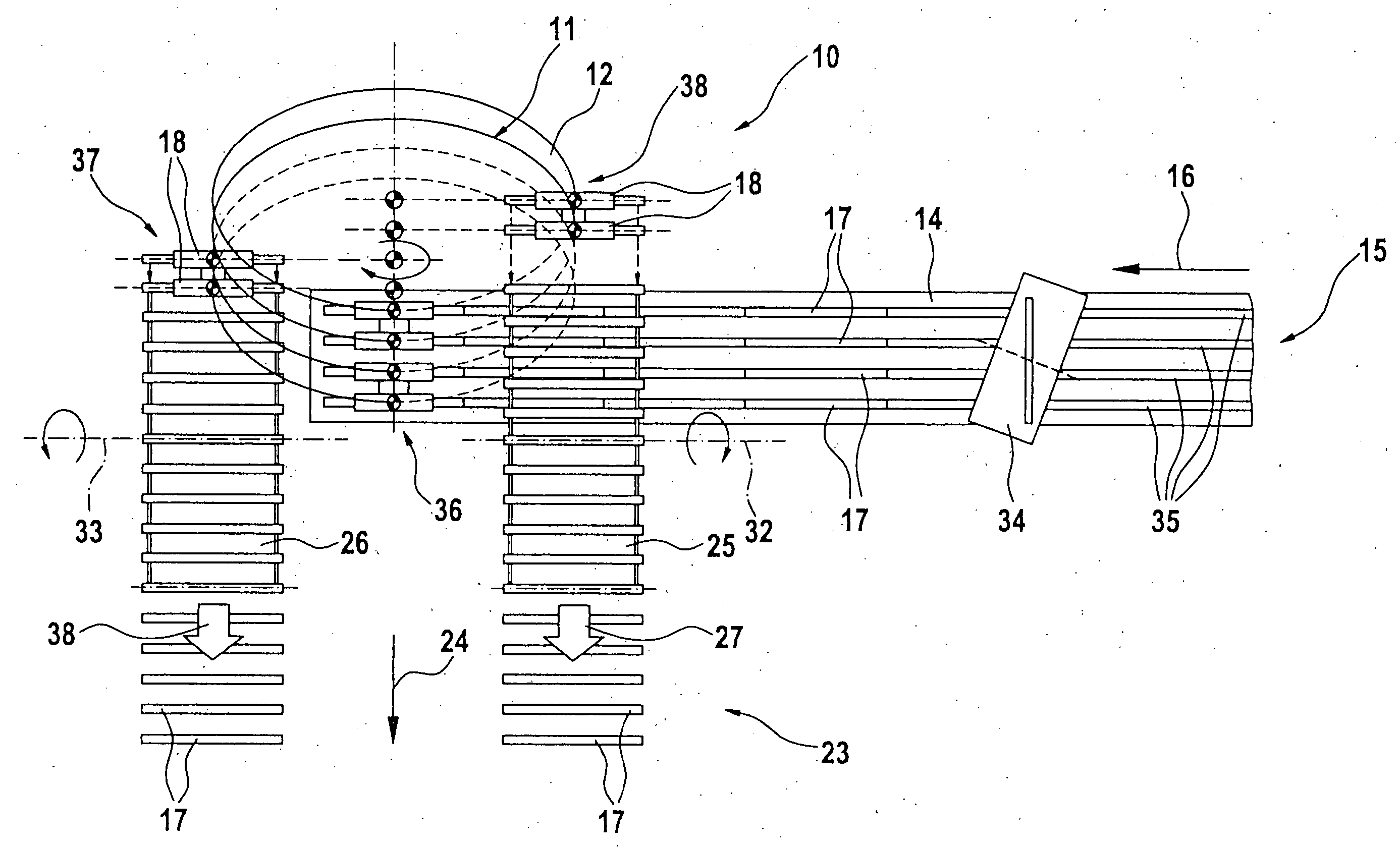

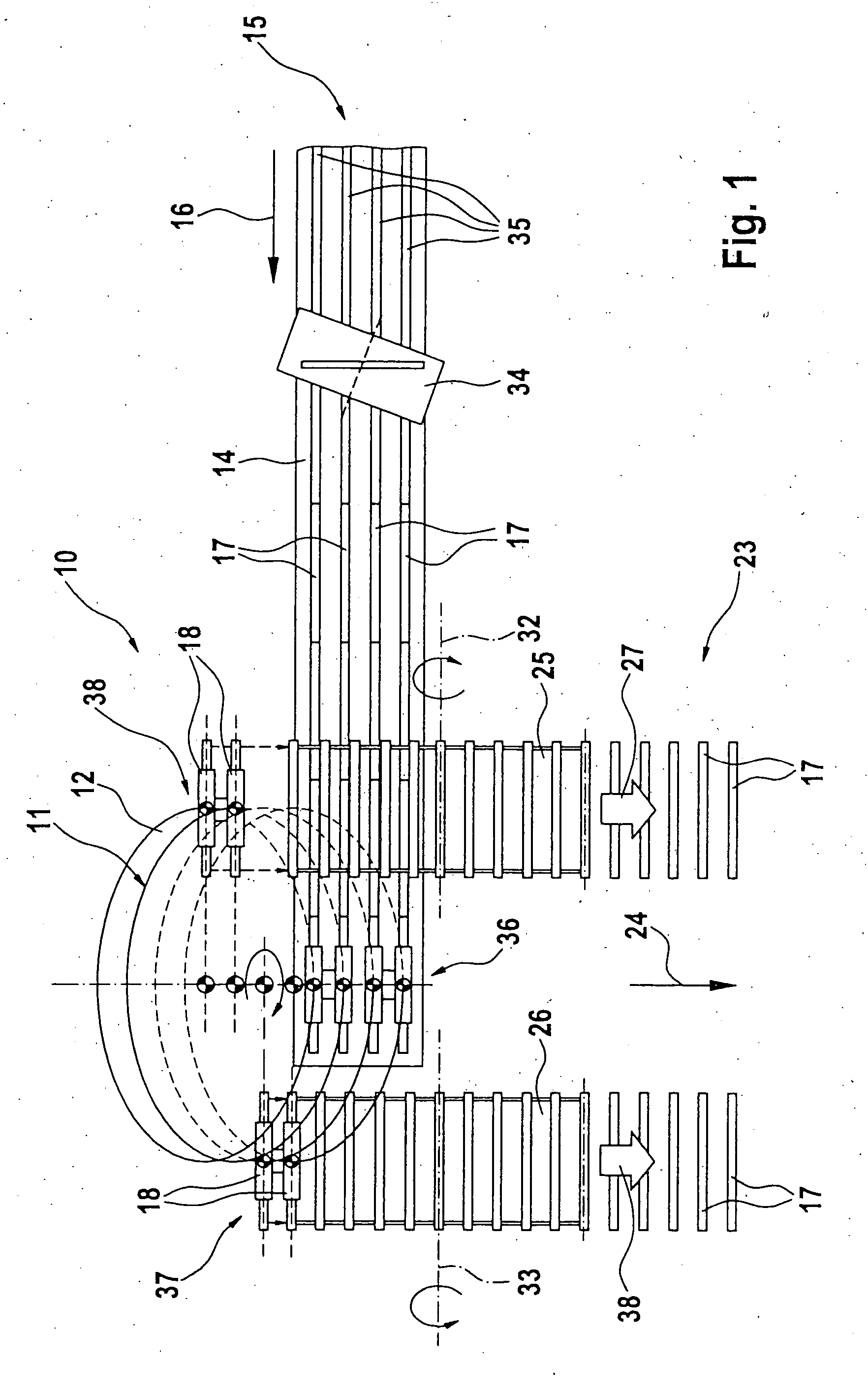

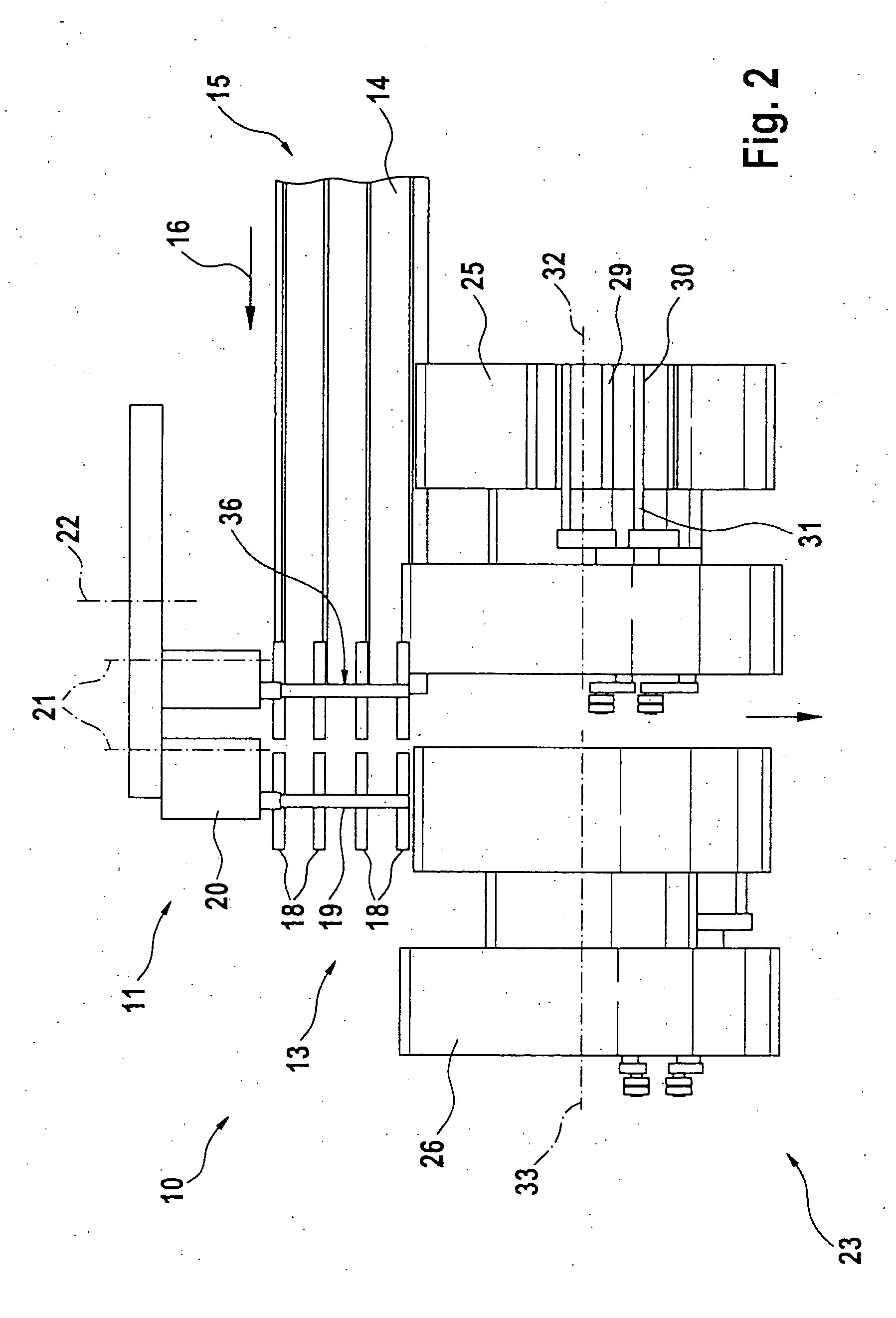

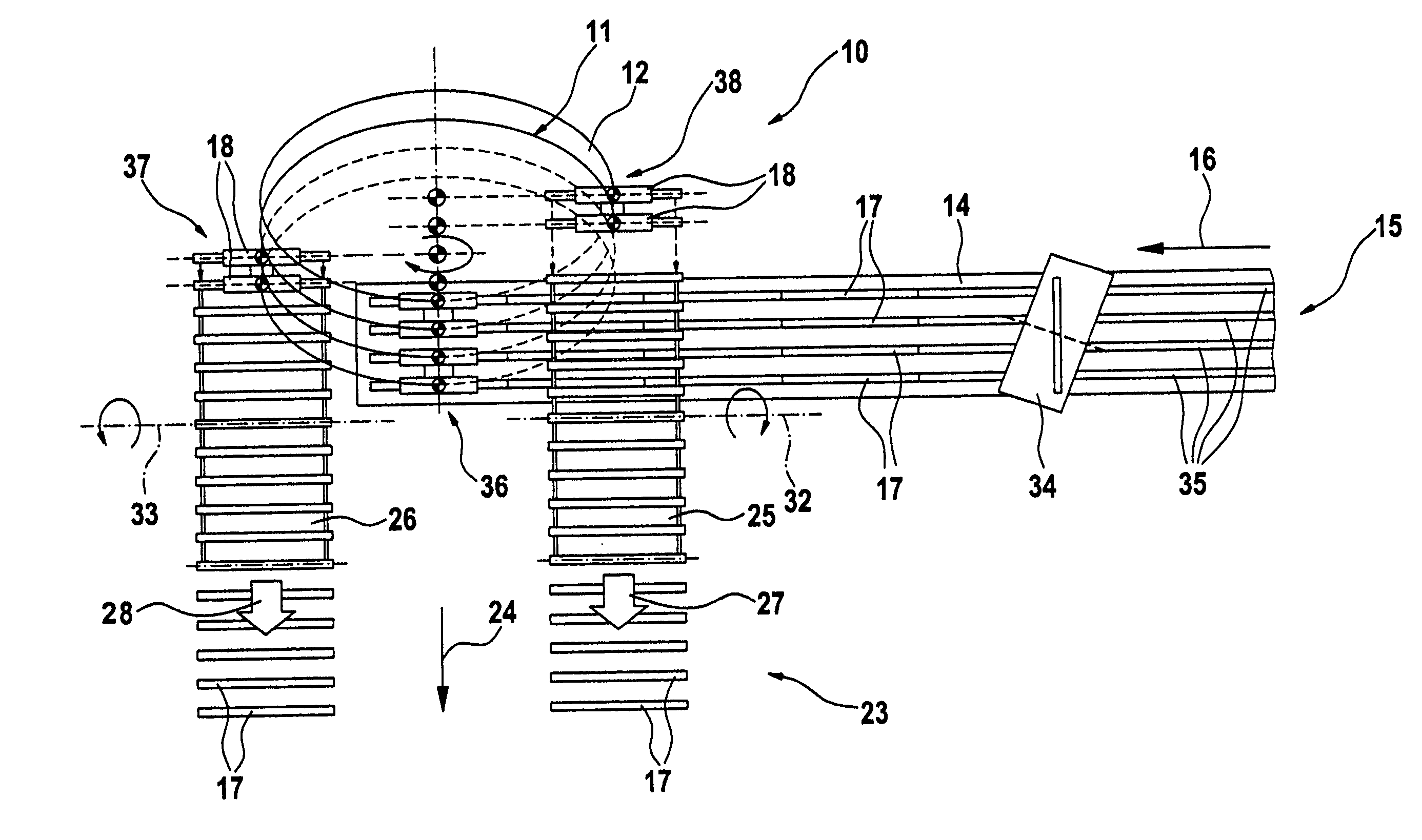

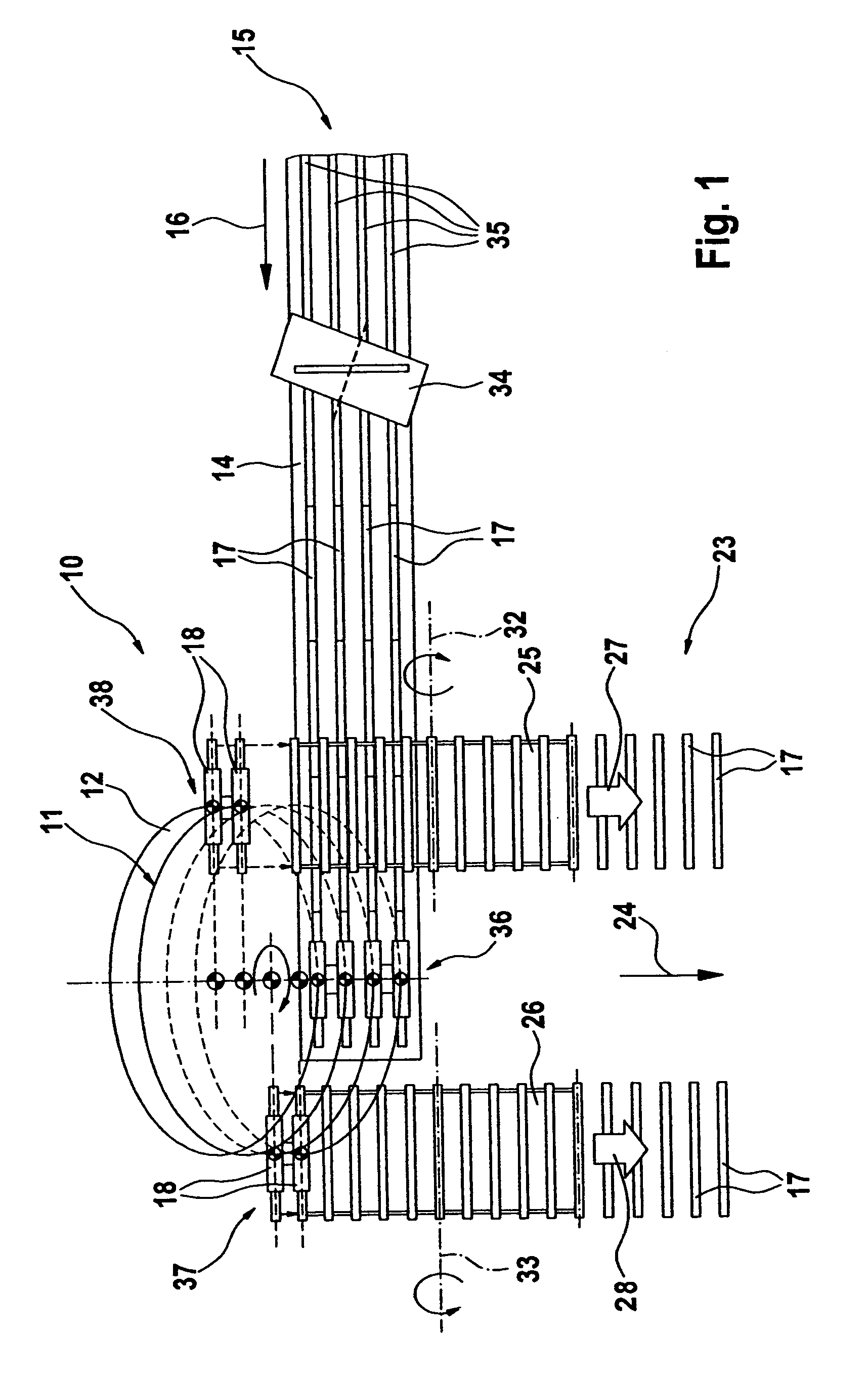

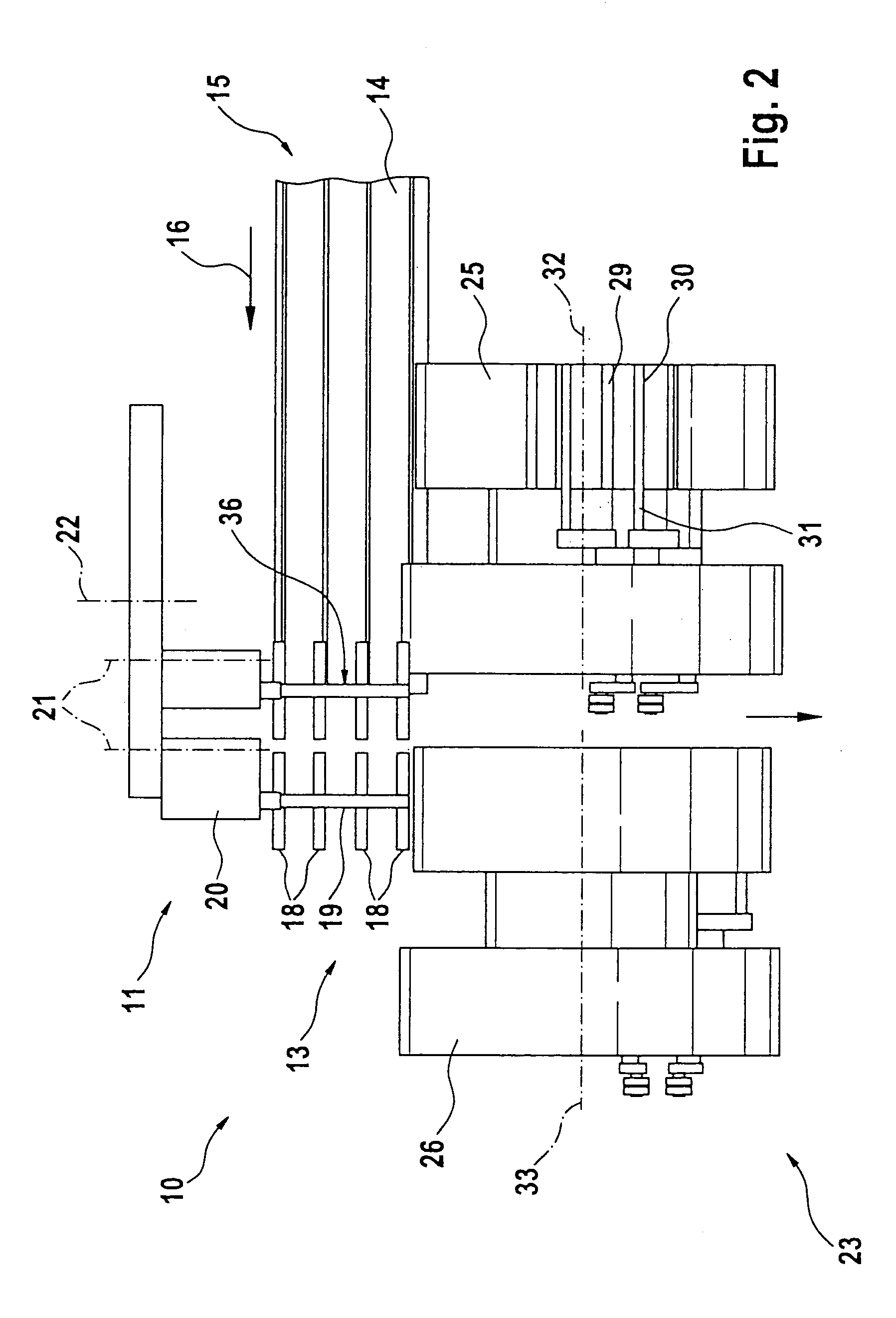

Apparatus and method for the transfer of rod-shaped articles

InactiveUS20050077149A1High throughput capacitySimple and flexible methodCigarette manufactureConveyor partsMechanical engineeringEngineering

The present invention is directed to an apparatus for transferring rod-shaped articles from a longitudinal conveyor transporting the articles in a longitudinal axial direction onto a transverse conveyor transporting the articles in a transverse axial direction, in which the directions of transport of the longitudinal conveyor and the transverse conveyor are oriented transversely to each other. The apparatus includes a conveying device having receptacles, and the receptacles are structured and arranged to receive a plurality of articles transported adjacent each other on a track of the longitudinal conveyor and to discharge the articles as a plurality of groups of articles onto different tracks of the transverse conveyor. The instant abstract is neither intended to define the invention disclosed in this specification nor intended to limit the scope of the invention in any way.

Owner:HAUNI MASCHINENBAU AG

Appliance selector switch programmed by console cutout

InactiveUS7202433B2Rule out the possibilityThe method is simple and flexibleContact operating partsEmergency protective devicesElectronic switchEngineering

A console switch assembly for appliances provides a rotatable electronic switch having a rotational range constrained by a cutout in the control panel to which the switch is mounted. The cutout most simply may be a sector of a circle having a different angular range which constrains a projecting tooth on the shaft of the switch or knob attached to the shaft of the switch.

Owner:ILLINOIS TOOL WORKS INC

Apparatus and method for the transfer of rod-shaped articles

InactiveUS7131524B2Improve throughputThe method is simple and flexibleCigarette manufactureConveyor partsMechanical engineering

An apparatus for transferring rod-shaped articles from a longitudinal conveyor transporting the articles in a longitudinal axial direction onto a transverse conveyor transporting the articles in a transverse axial direction, in which the directions of transport of the longitudinal conveyor and the transverse conveyor are oriented transversely to each other. The apparatus includes a conveying device having receptacles, and the receptacles are structured and arranged to receive a plurality of articles transported adjacent each other on a track of the longitudinal conveyor and to discharge the articles as a plurality of groups of articles onto different tracks of the transverse conveyor.

Owner:HAUNI MASCHINENBAU AG

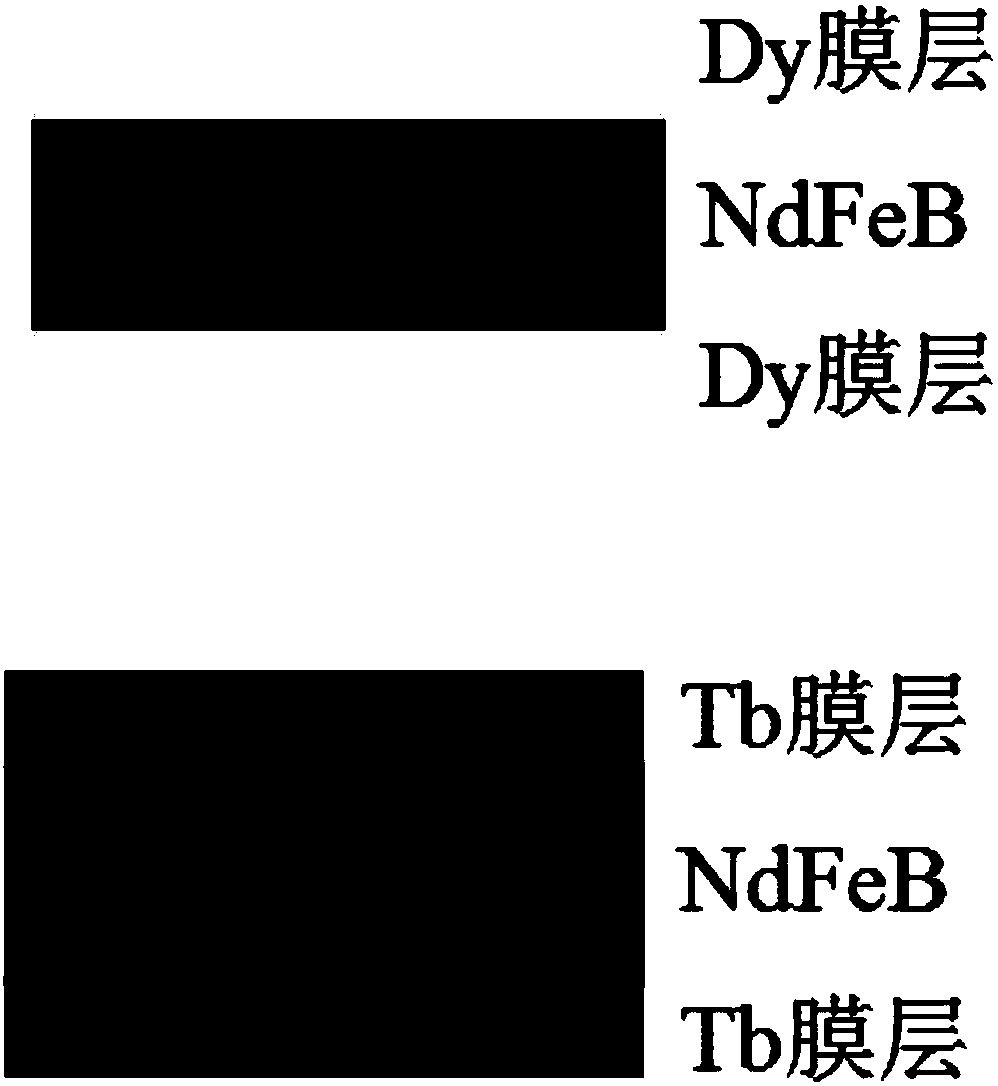

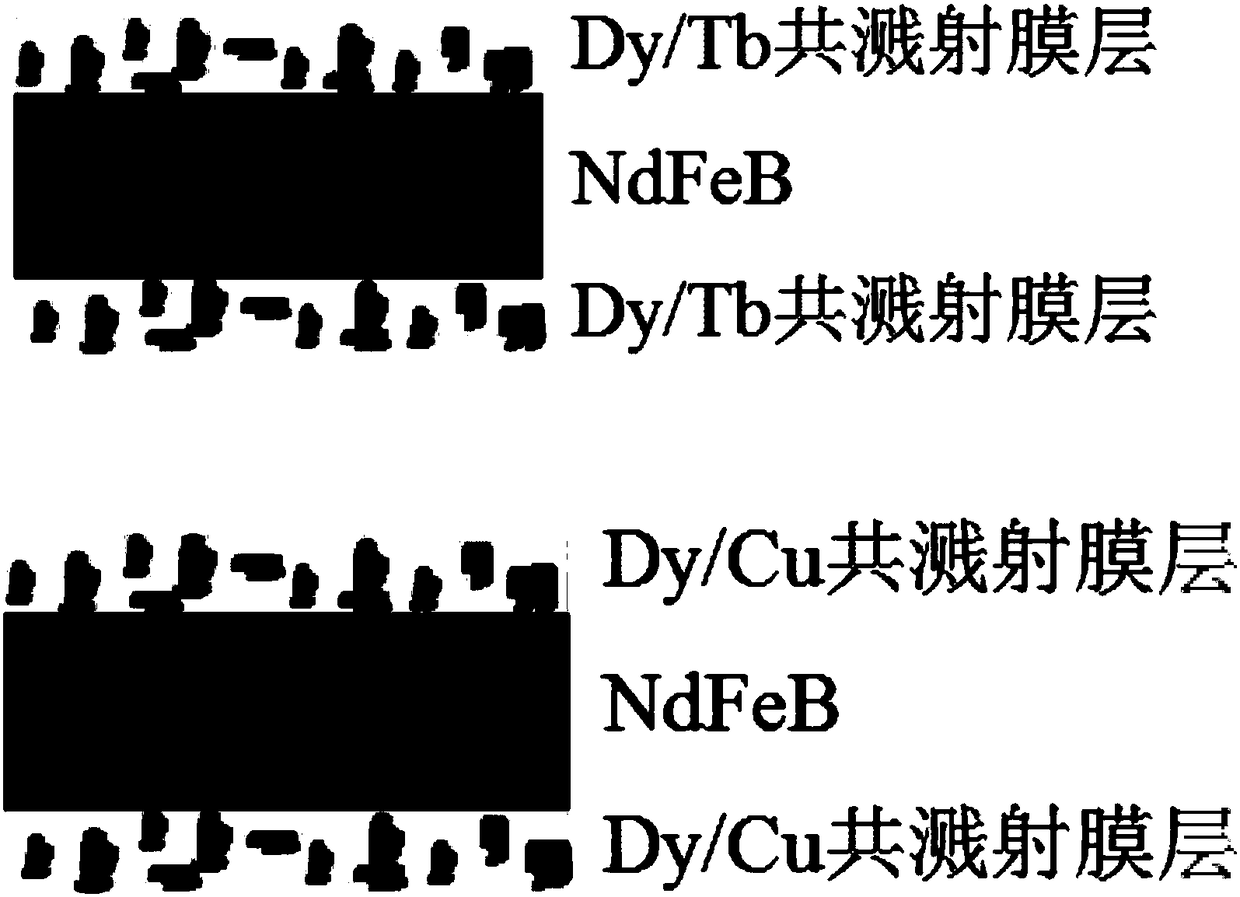

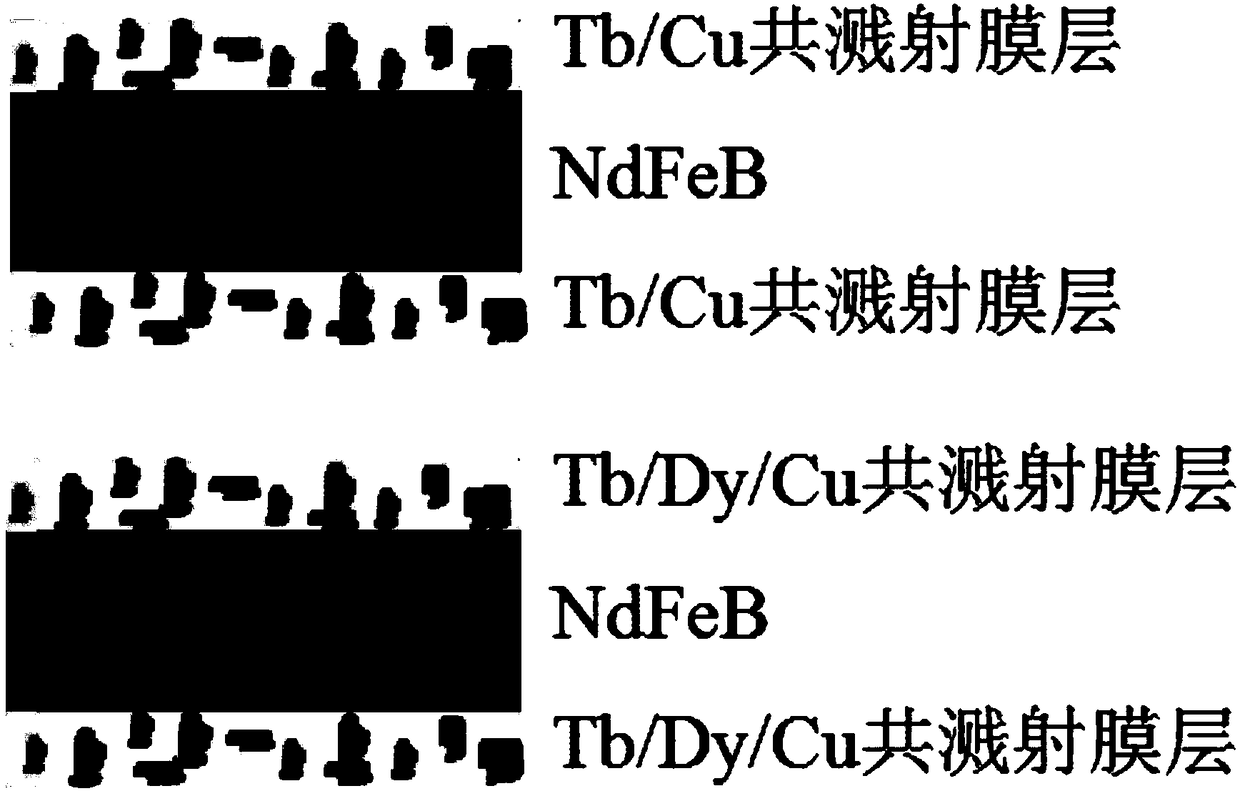

Sintered neodymium-iron-boron magnet deposited with compound film and preparing method thereof

ActiveCN108231322AThin-film methods are flexible and simpleEasy to controlVacuum evaporation coatingSputtering coatingNeodymium iron boronMetallurgy

The invention discloses a sintered neodymium-iron-boron magnet deposited with compound film. The sintered neodymium-iron-boron magnet comprises a sintered neodymium-iron-boron magnet body and the compound film which is deposited on the outer surface of the sintered neodymium-iron-boron magnet body through a magnetron sputtering method; the elementary composition of the compound film comprise the essential element of Tb and / or Dy and the optional element of Cu, and the compound film is co-sputtering mixed film or alternating mixed film. By means of the sintered neodymium-iron-boron magnet deposited with the compound film, the coercive force of the sintered neodymium-iron-boron magnet is obviously improved, and the product cost is obviously lowered.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +1

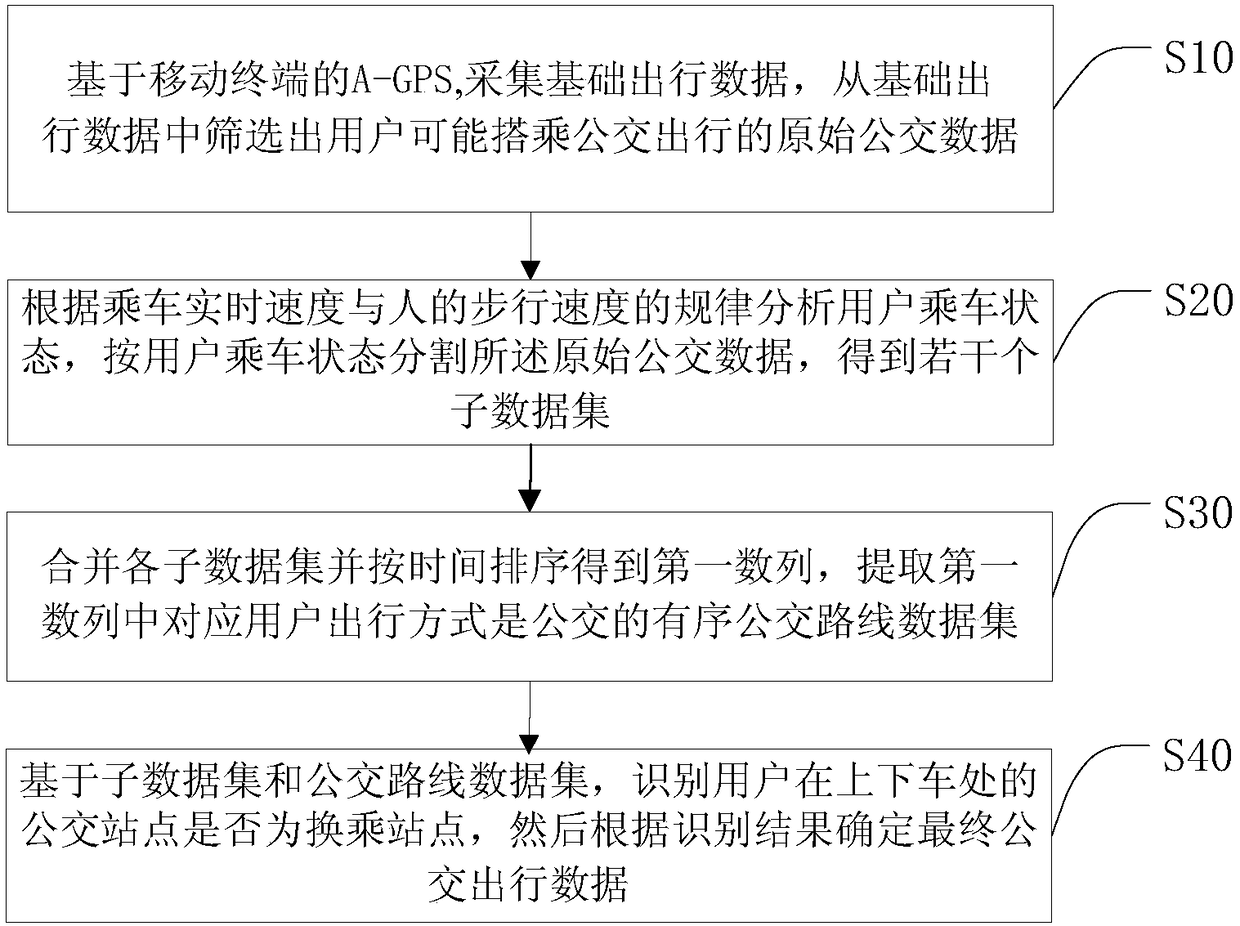

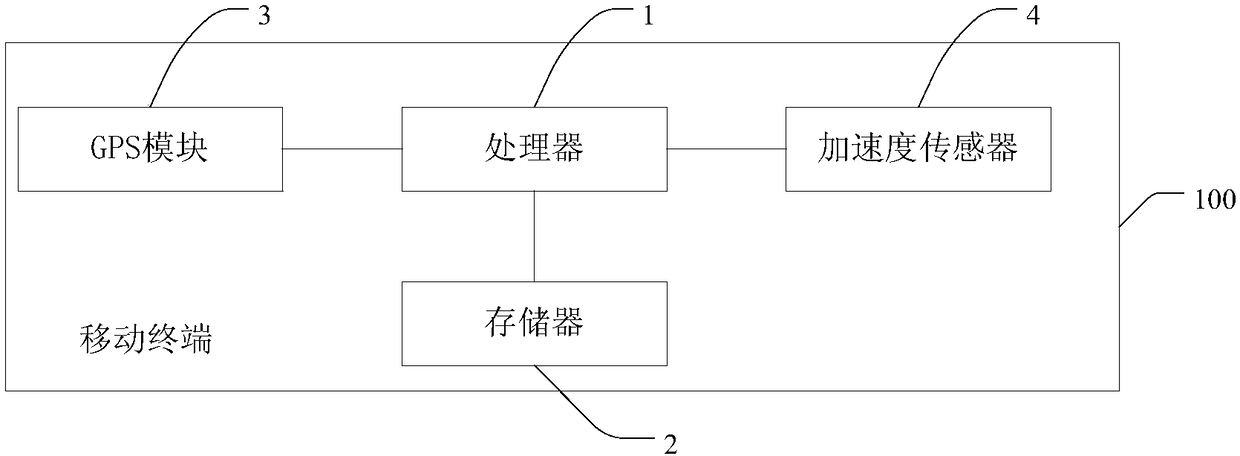

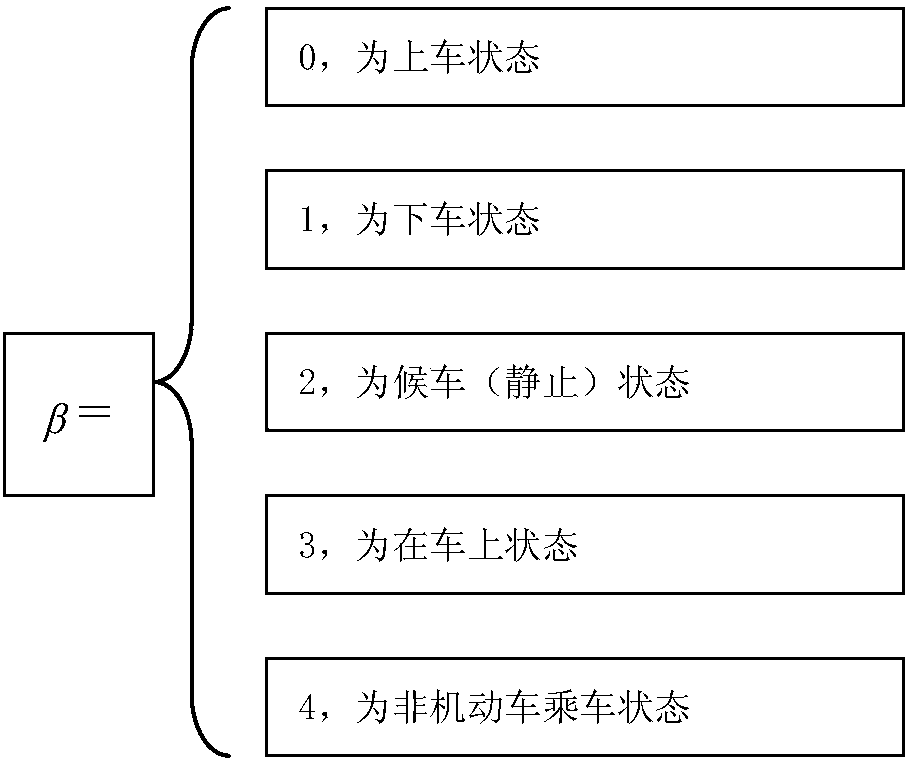

Mobile terminal positioning-based bus OD data acquisition method and storage medium

InactiveCN108573604AHigh transfer recognition accuracyReduce misjudgmentDetection of traffic movementSatellite radio beaconingData setComputation complexity

The invention discloses a mobile terminal positioning-based bus OD data acquisition method and a storage medium. The method comprises steps: based on A-GPS of the mobile terminal, basic trip data areacquired, and original bus data with a user possibly taking a bus for the trip are screened from the basic trip data; according to the rule of a real-time vehicle taking speed and a walking speed of aperson, the vehicle taking state of the user is analyzed, the original bus data are segmented according to the vehicle taking state of the user, and a plurality of sub data sets are obtained; the plurality of sub data sets are combined and ordered according to the time to obtain a first sequence, and a bus route data set with the user trip mode to be the bus in the first sequence is extracted; and based on the sub data sets and the bus route data set, data of getting-on and getting-off bus stops to be transfer stops are removed, and final bus trip data are determined. According to the characteristics of transfer time and a fixed bus route, high-accuracy bus OD data are acquired, the calculation complexity is reduced, errors are reduced, and the bus service level is improved.

Owner:深圳市交投科技有限公司

Preparation method of cellulose/carbon nanotube composite fiber

ActiveCN106435797AEvenly dispersedStable in natureMonocomponent cellulose artificial filamentArtifical filament manufactureCelluloseFiber

The invention relates to a preparation method of a cellulose / carbon nanotube composite fiber. The preparation method comprises the steps that a cellulose solvent is adopted to dissolve a low-polymerization-degree cellulose, and a carrier solution for carbon nanotubes is prepared; under the strong shear effect provided by a stirring device, the carbon nanotubes is mixed with the carrier solution to prepare a carbon nanotube mother solution; the carbon nanotube mother solution is injected into a cellulose spinning solution in an online adding mode, the spinning solution is subjected to extrusion, solidification and drawing to prepare the cellulose / carbon nanotube composite fiber. For solving the problem that the carbon nanotubes are difficultly and uniformly mixed with a high-viscosity spinning solution, the carbon nanotube mother solution is injected into the cellulose spinning solution, and further the cellulose / carbon nanotube composite fiber is prepared in a spin-forming mode. The mother solution carrier used by the method solidifies and is formed with the fiber without the operation of feeding an additional additive into a solvent and coagulation bath system. The preparation method is simple, flexible and efficient, and production of the cellulose / carbon nanotube composite fiber can be achieved based on a conventional production line.

Owner:DONGHUA UNIV

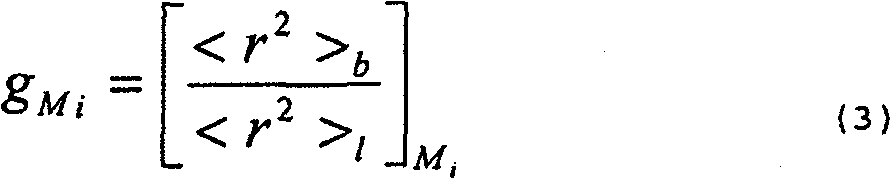

Process for the preparation of branched polybutadiene with a high content of 1,4-cis units

ActiveCN102037027AThe method is simple and flexibleOrganic-compounds/hydrides/coordination-complexes catalystsCarboxylic saltSolvent

Process for the preparation of polybutadiene effected by the polymerization of butadiene in an aliphatic and / or cyclo-aliphatic solvent in the presence of a catalytic system prepared in situ which comprises: (i) a carboxylate of neodymium soluble in the process solvent containing a variable quantity of water, the H2O / Nd molar ratio ranging from 0.001 / 1 to 0.50 / 1; (ii) an alkyl compound of aluminum; (iii) an alkyl compound of aluminum in which at least one bond of Al consists of an Al-Cl bond; The total Al / Nd molar ratio ranging from 4 / 1 to 12 / 1, and the Cl / Nd molar ratio ranging from 2 / 1 to 6 / 1.

Owner:POLIMERI EUROPA SPA

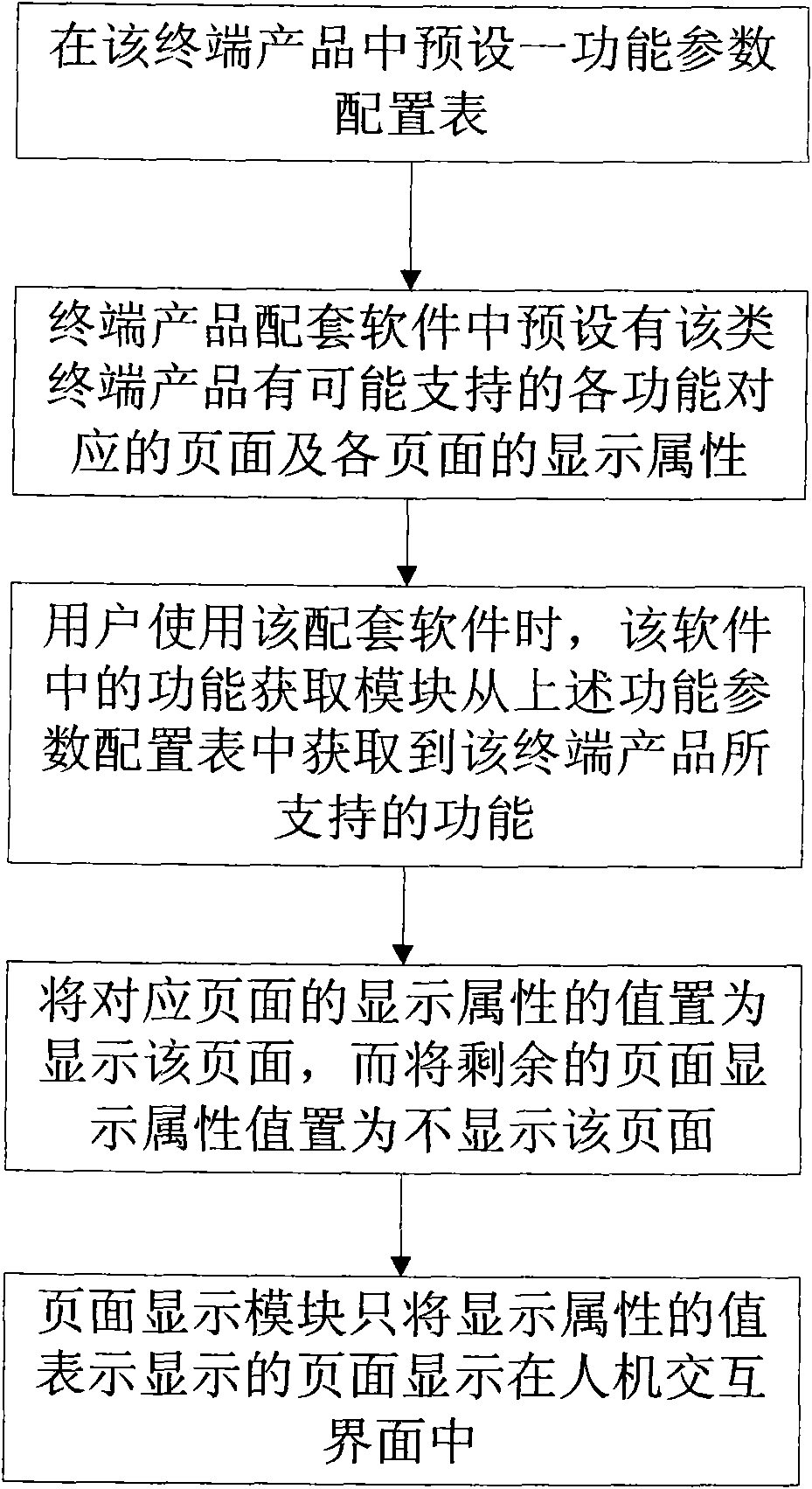

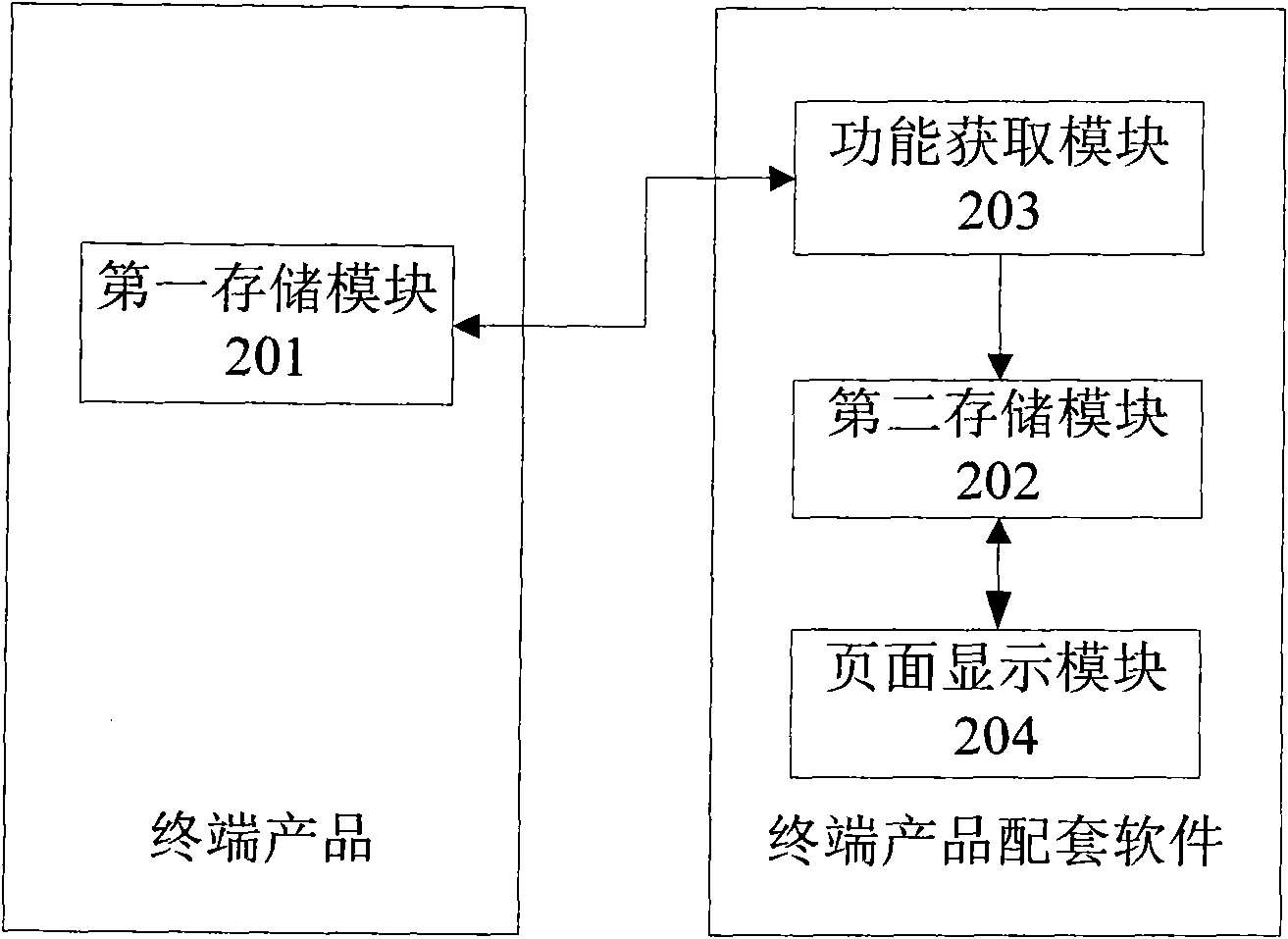

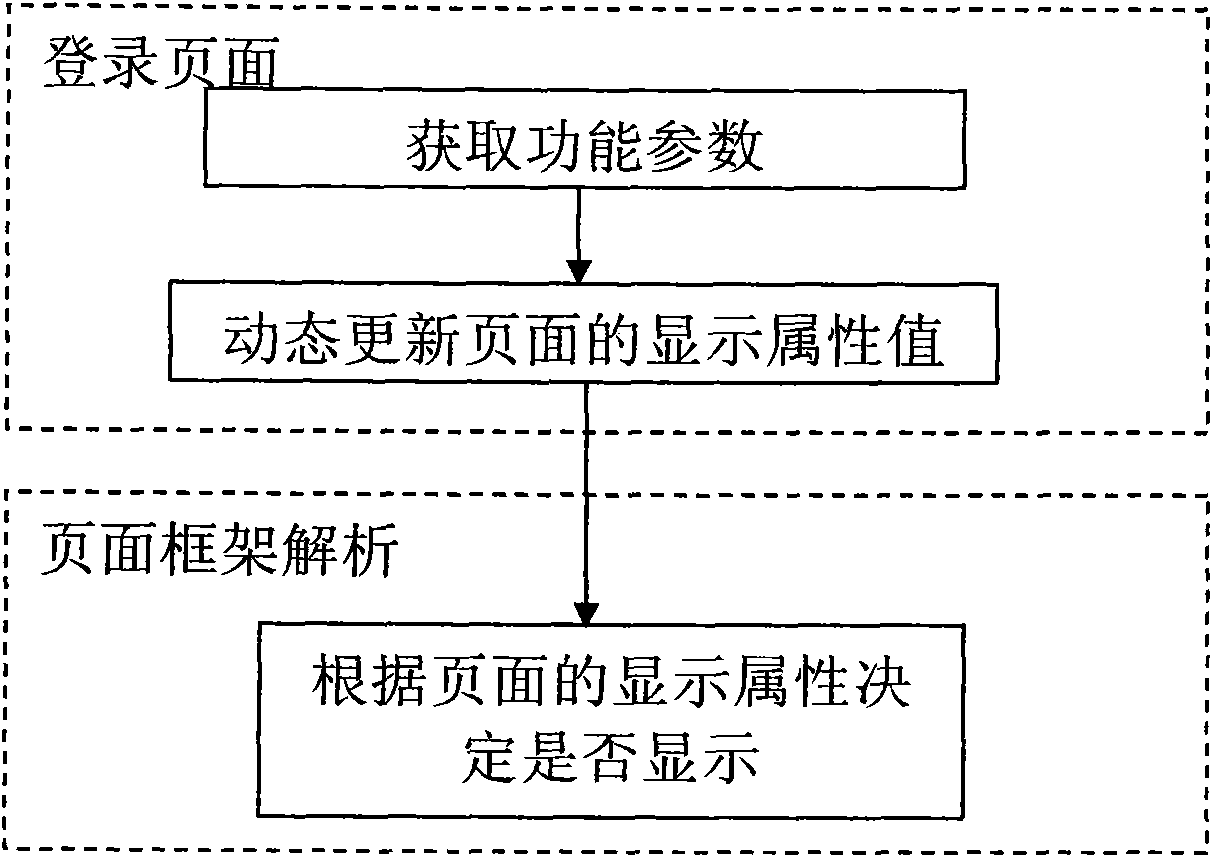

Method and system for self-adaptively displaying terminal product complete software web pages

ActiveCN101593112AImplement Adaptive DisplayMeet individual needsSpecific program execution arrangementsInput/output processes for data processingSelf adaptiveWeb page

The invention discloses a method and a system for self-adaptively displaying terminal product complete software web pages. The method comprises that: a functional parameter configuration table is preset in a terminal product and at least contains all functions supported by the terminal product; web pages corresponding to the functions possibly supported by the terminal product and the display attributes of the web pages are preset in complete software of the terminal product, wherein the values of the display attributes shows if the web page is required to be displayed; and when the complete software is to be used, a function acquisition module in the software acquires the functions supported by the terminal product from the functional parameter configuration table and then sets the values of the display attributes of the corresponding web pages as display and the values of the display attributes of the rest web pages as not display, and a web page display module only displays the web pages of which the values of the display attributes are display on a human-computer interface. The method and the system realize the self-adaptive display of the web pages. The method is flexible and simple.

Owner:ZTE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com