Detection device for knife point dynamic characteristics of numerical control machine tool and method of detection device

A technology of CNC machine tools and dynamic characteristics, applied in the direction of measuring/indicating equipment, metal processing mechanical parts, metal processing equipment, etc., can solve the cost, convenience and ease of use. High-precision calculation, inability to realize the process recording of tool tip temperature information and data, etc., to achieve the effect of reducing machine tool installation, debugging and subsequent maintenance costs, shortening auxiliary time, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing. Embodiments of the present invention include, but are not limited to, the following examples.

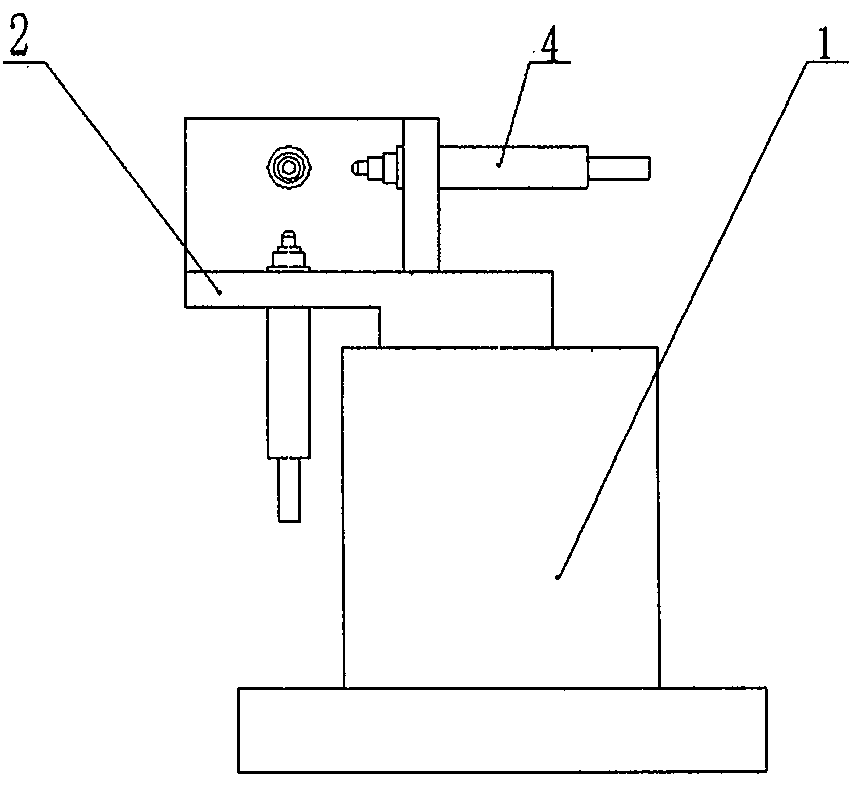

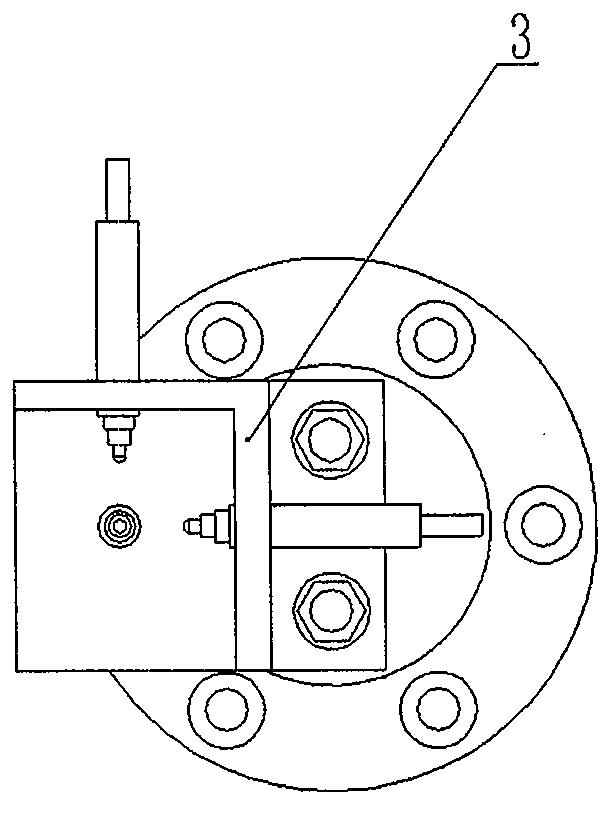

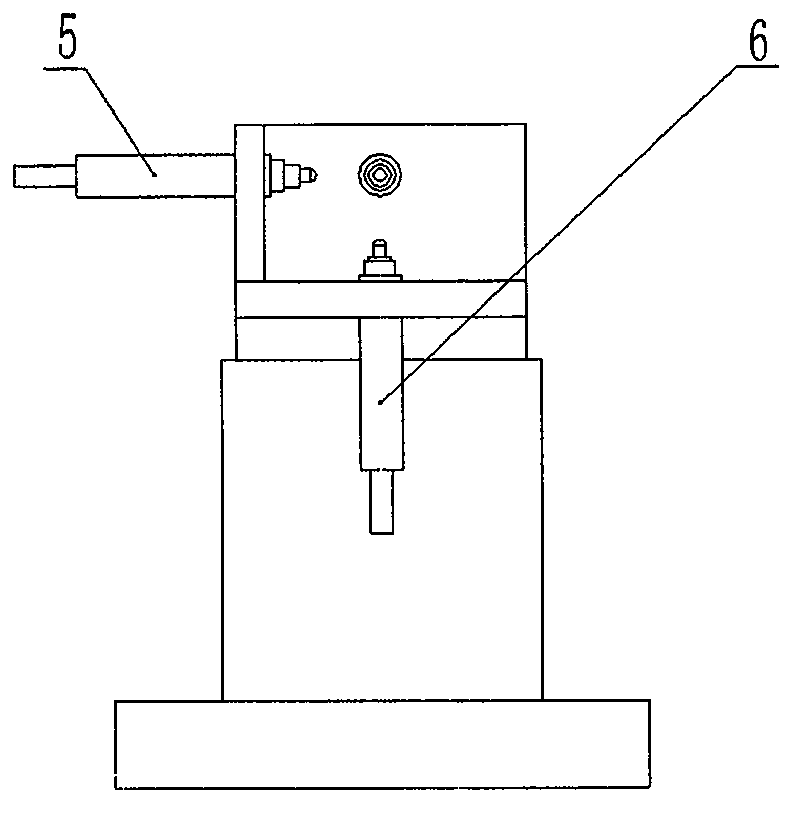

[0036] Such as figure 1 , figure 2 , image 3 As shown, it is a front view, a top view and a side view of a preferred example of the structure of the detection device for the precision of the dynamic characteristics of the CNC machine tool tip of the present invention. It mainly includes a support 1 installed on the workbench of the CNC machine tool, including a support 1 installed on the work platform of the CNC machine tool, a connecting plate 2 arranged on the top of the support, and a threaded through hole is arranged inside the connecting plate 2 so that the third displacement sensor 6 can move along Through-type installation in the vertical direction, the L-shaped support wall plate 3 installed on the connecting plate, the two walls of the L-shaped support wall plate 3 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com