Measuring method of section profile and shape in cold-formed steel figuration process

A cross-sectional profile and forming process technology, applied in the field of measurement, can solve complex and cumbersome problems, do not support online measurement, etc., achieve high safety, easy operation, and improve the effect of forming quality

Inactive Publication Date: 2008-02-20

无锡凯博易机电科技有限公司

View PDF1 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The present invention aims at the above-mentioned deficiencies existing in the prior art, and provides a method for measuring the profile shape of the cross-section during the forming process of cold-formed steel, which overcomes the shortcomings of various previous methods for measuring the profile shape of the cross-section that are too complicated and cumbersome, and do not support online measurement. It is suitable for online continuous measurement of cross-sectional shape of cold-formed steel products of various specifications. It is a fast, simple, flexible, safe, economical and practical cross-sectional shape measurement method

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0028] In this specific embodiment, the quick-setting material is gypsum, and the porous flexible strip is a filter sponge strip.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

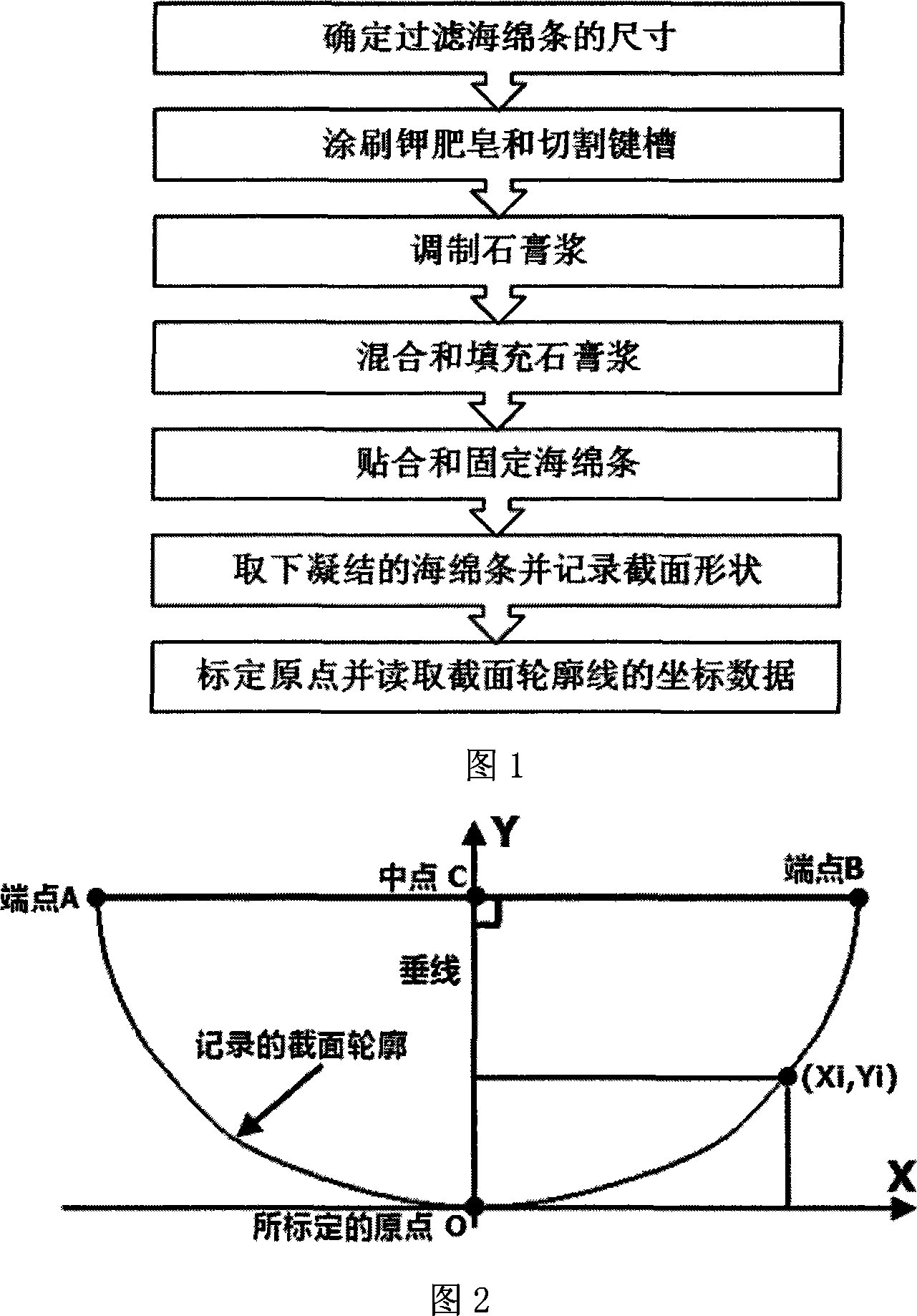

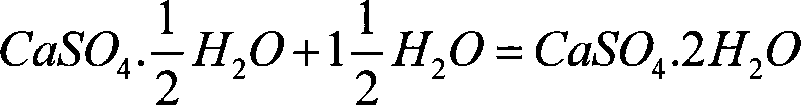

The utility model provides a measurement method for cross-section contour shape of cold-rolled forming section during forming process in measurement technical field. The utility model is characterized in that the length of a flexible strip with a hole-shaped structure is determined at first, then a keyway and potash soap are arranged on the flexible strip; fast gelatination material is prepared, mixed and filled; the flexible strip is tightly adhered and fixed; he condensed flexible strip is then removed and the cross-section shape is recorded. A transparent plastic sheet with the cross-section shape is spread on a piece of coordinate paper and the location is adjusted well so that the coordinate value of any point of the successive contour line can be read. The utility model can overcome the disadvantages in prior art that on-line measurement is not supported and the workpiece needs to be removed. The utility model is suitable for the shape measurement of on-line cross-section contour of various specifications of roll forming product as a fast, simple, flexible, safe, economic and practical method for measuring cross-section.

Description

technical field [0001] The invention relates to a method in the technical field of measurement, in particular to a method for measuring the profile shape of a section in the forming process of cold-formed steel. Background technique [0002] Cold-formed steel products mainly include welded pipes and special-shaped pipes. Because cold-formed steel has the advantages of light weight, metal saving, energy saving, and high geometric precision, its application fields are very wide, and it can be used as pipelines for gas, coal slurry, ore powder, etc., high and low pressure boiler tubes, and chemical heat exchanger tubes. , Oil well casing, pipe structural steel beams, structural steel grids, etc. With the rapid development of my country's economic construction, cold-formed steel will play an extremely important role in industry, agriculture, national defense and daily life. The shape and size of the cross-sectional contours of welded pipes and special-shaped pipes in the cold-...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01B21/00G01B21/04G01B21/20

Inventor 彭颖红蒋劲茂李大永谷中莹史文超尹忠慰

Owner 无锡凯博易机电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com