Patents

Literature

71results about How to "Guaranteed tight fit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

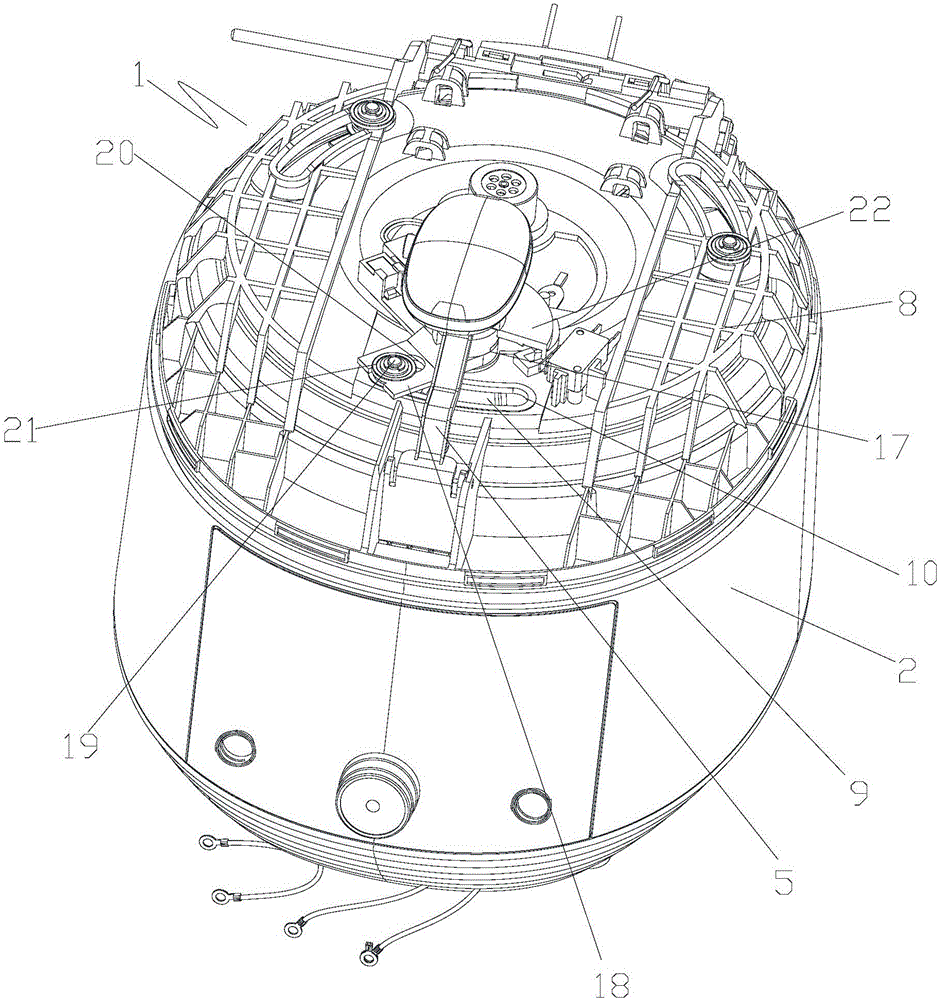

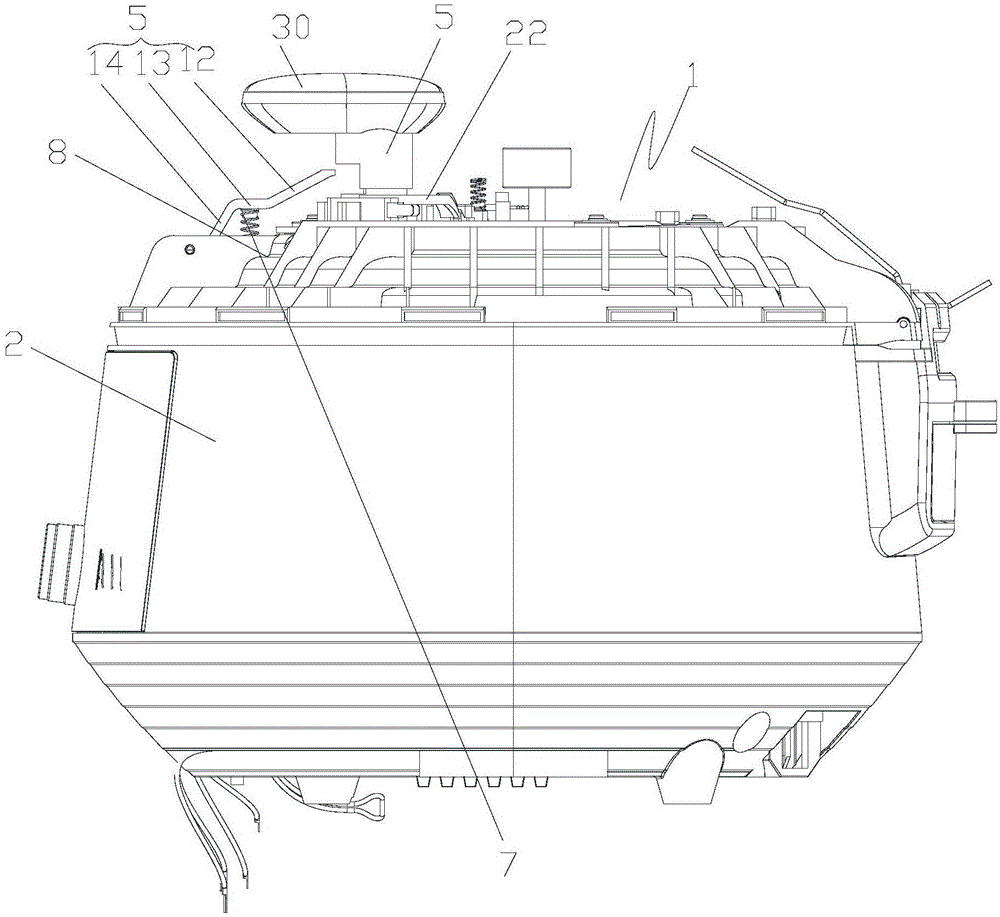

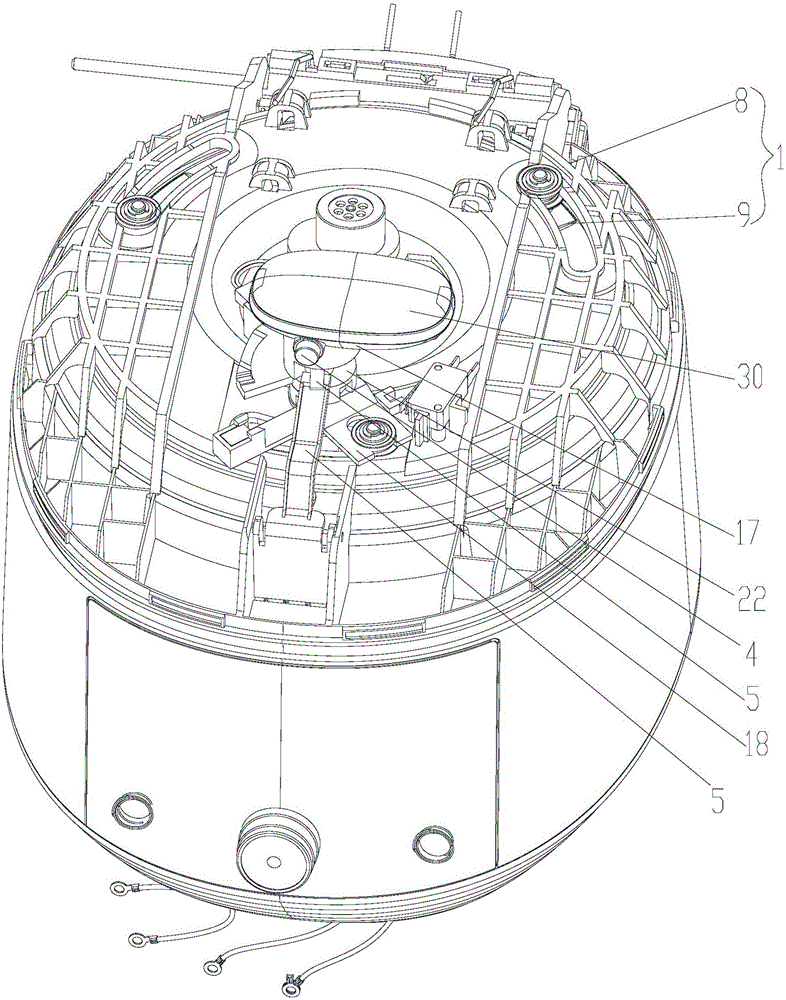

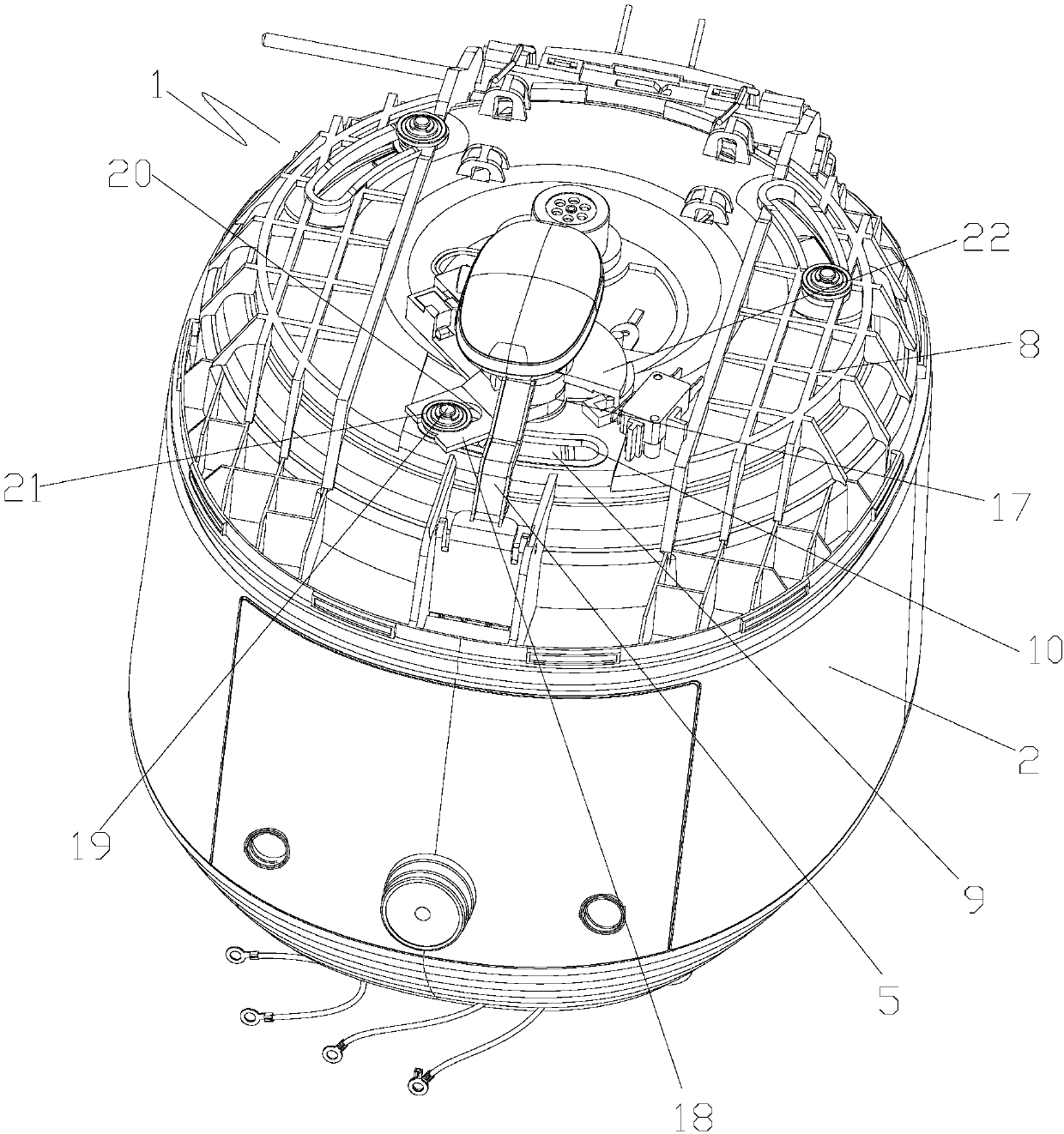

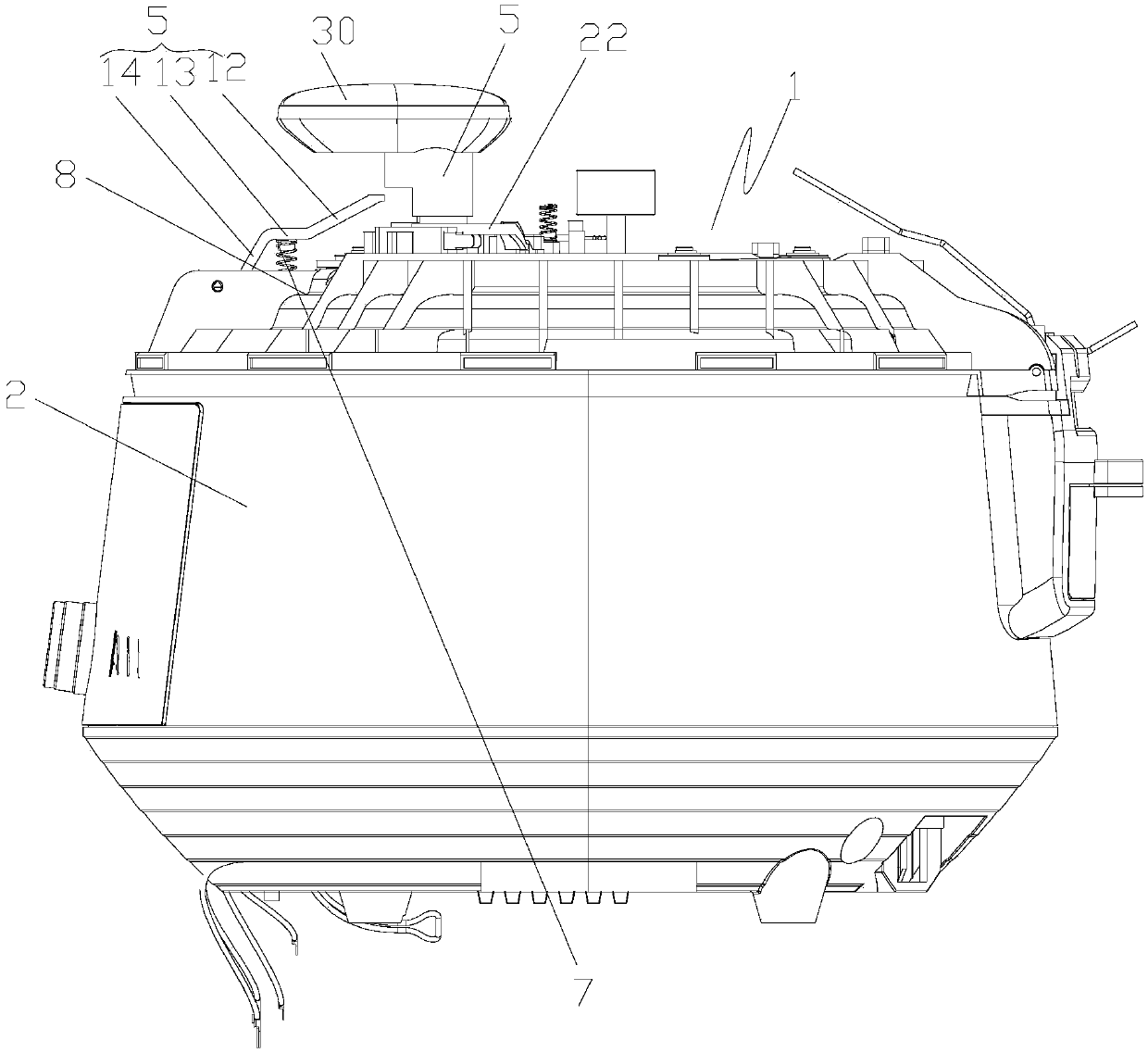

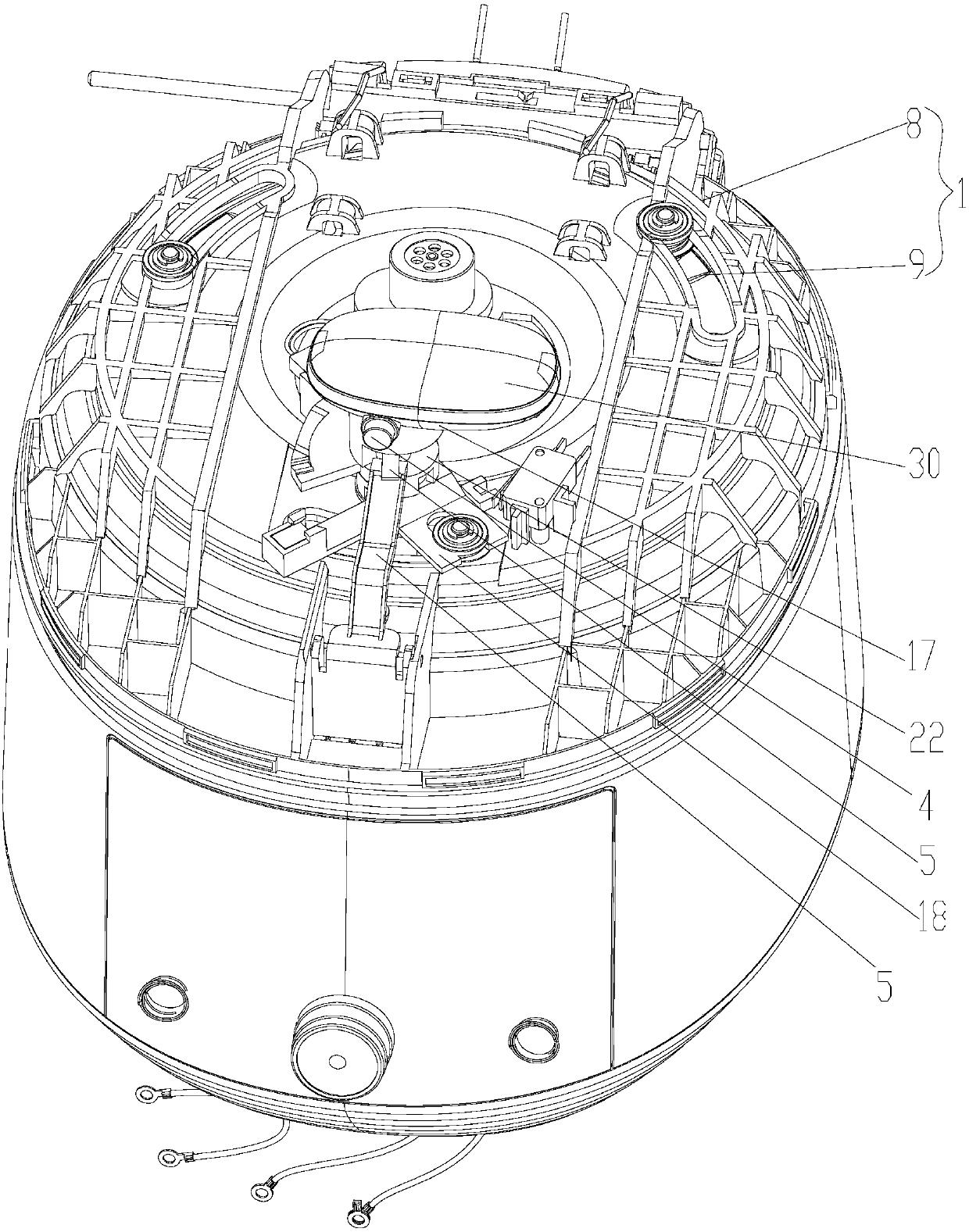

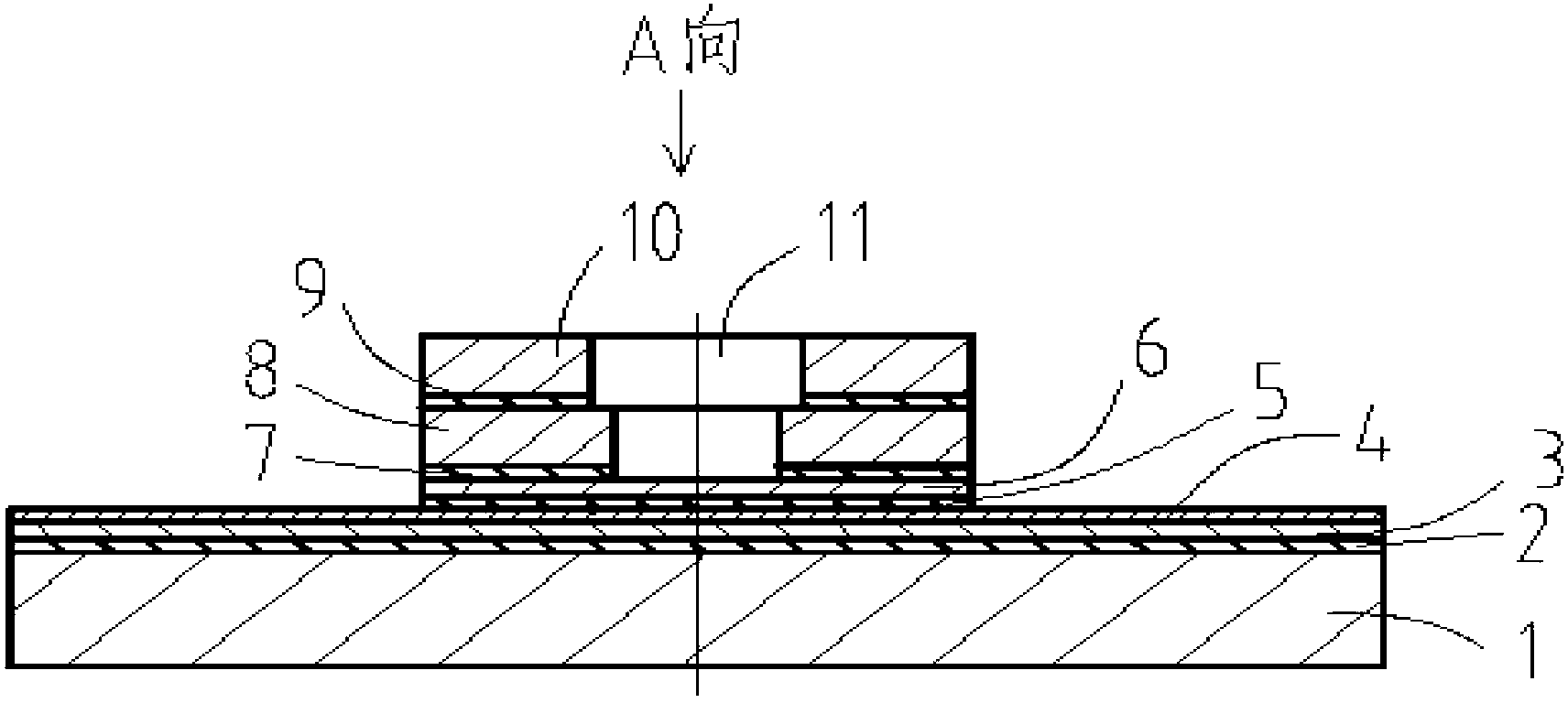

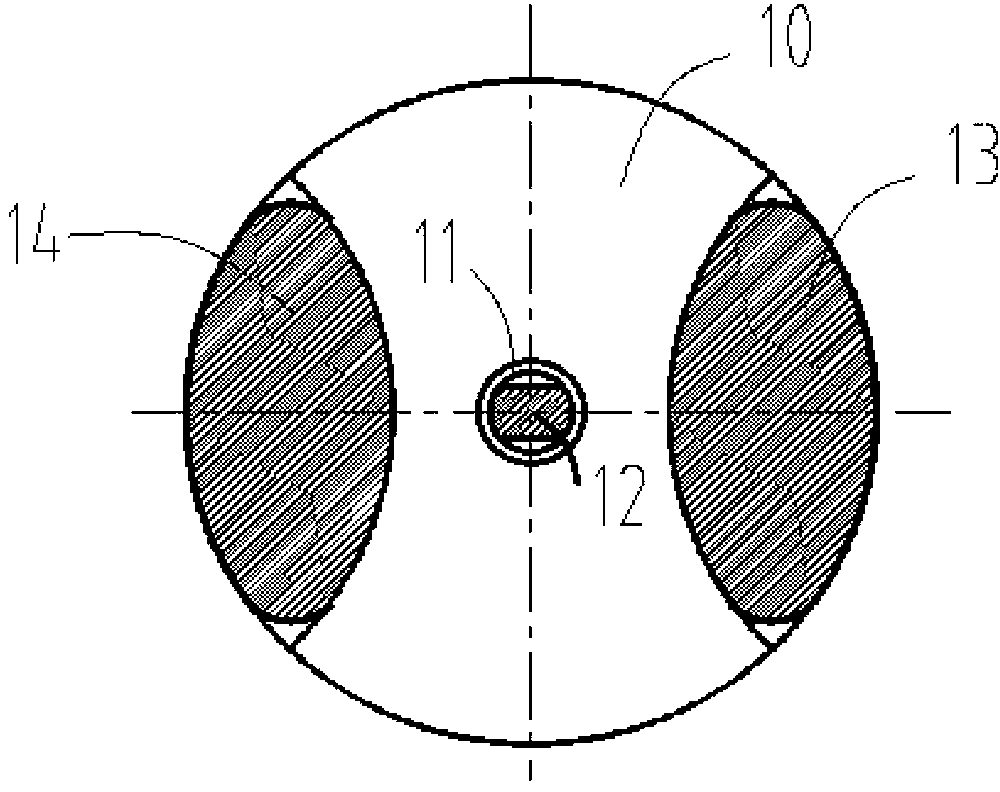

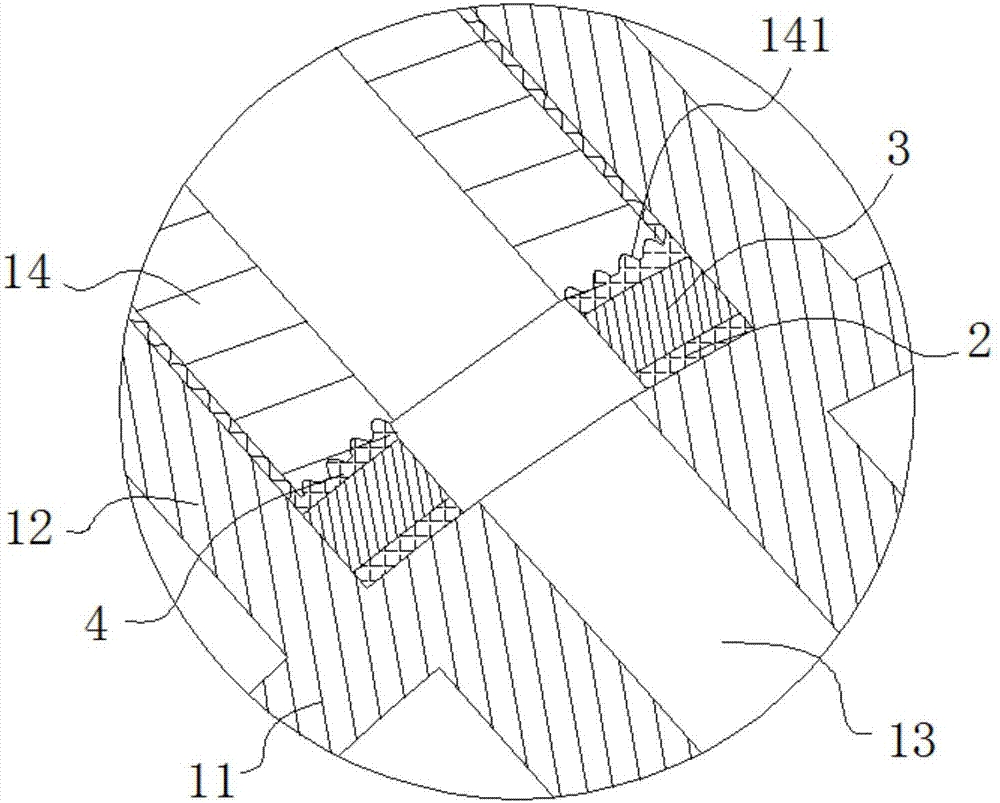

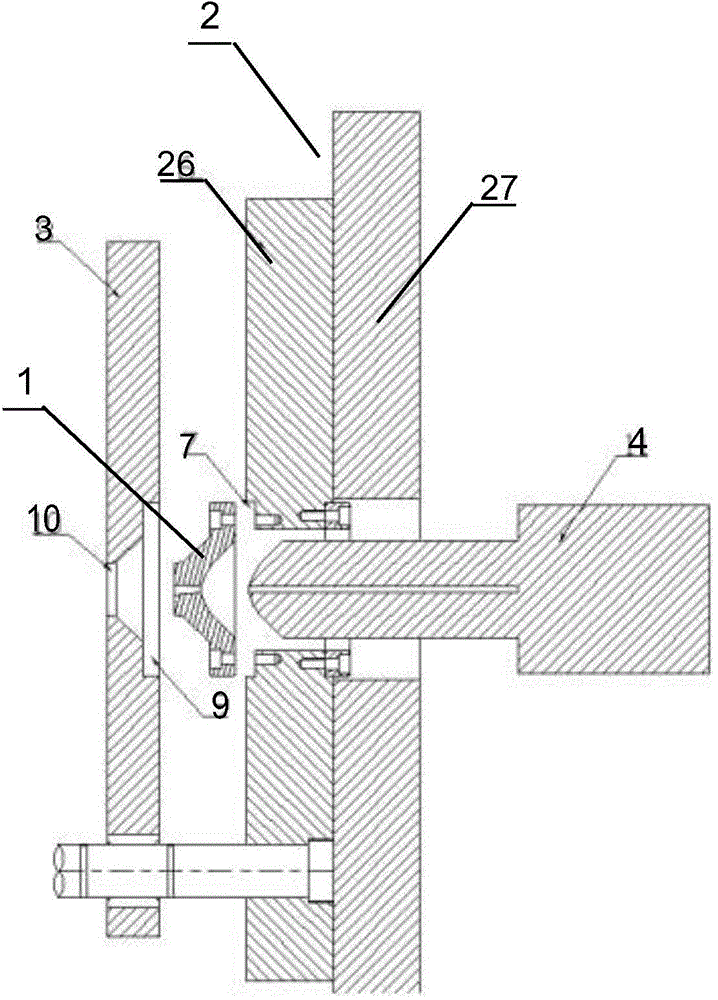

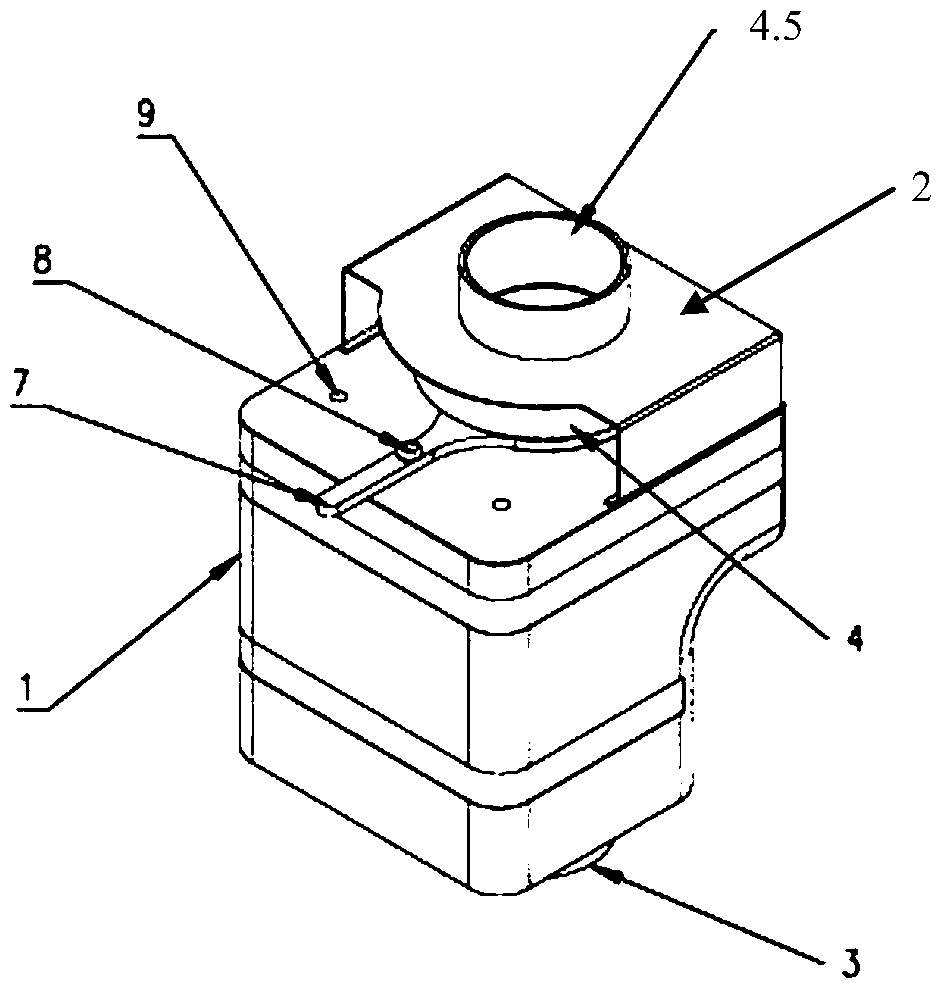

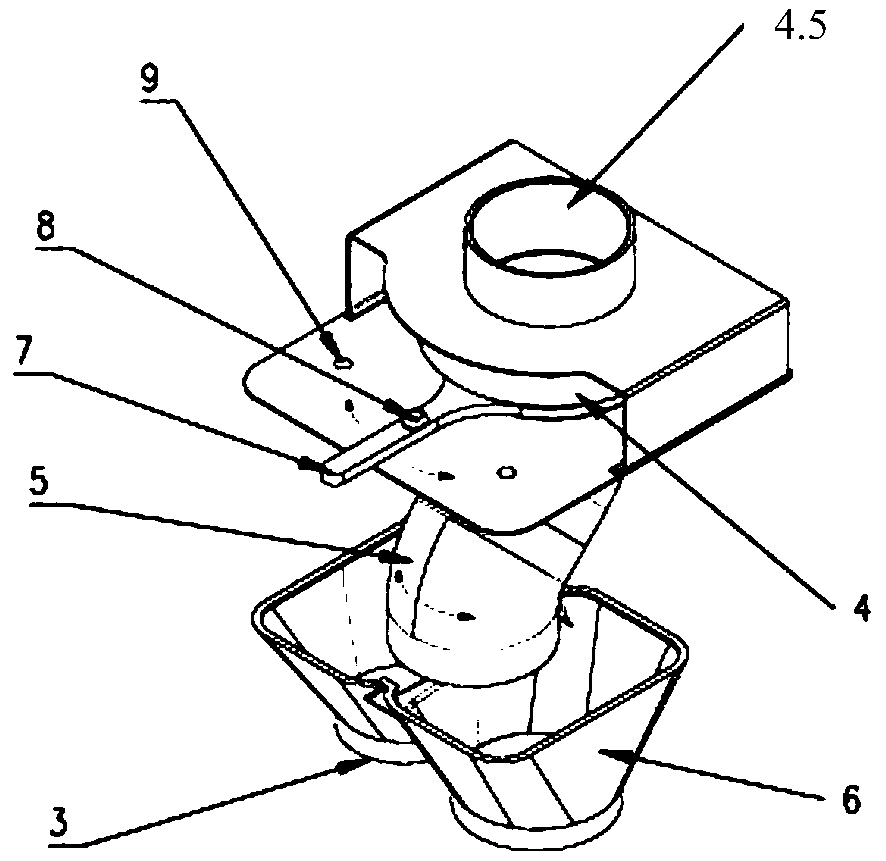

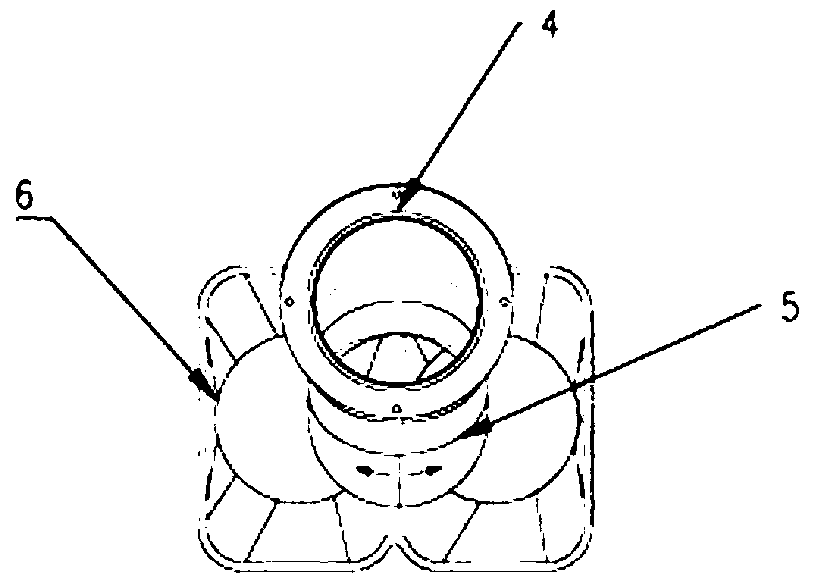

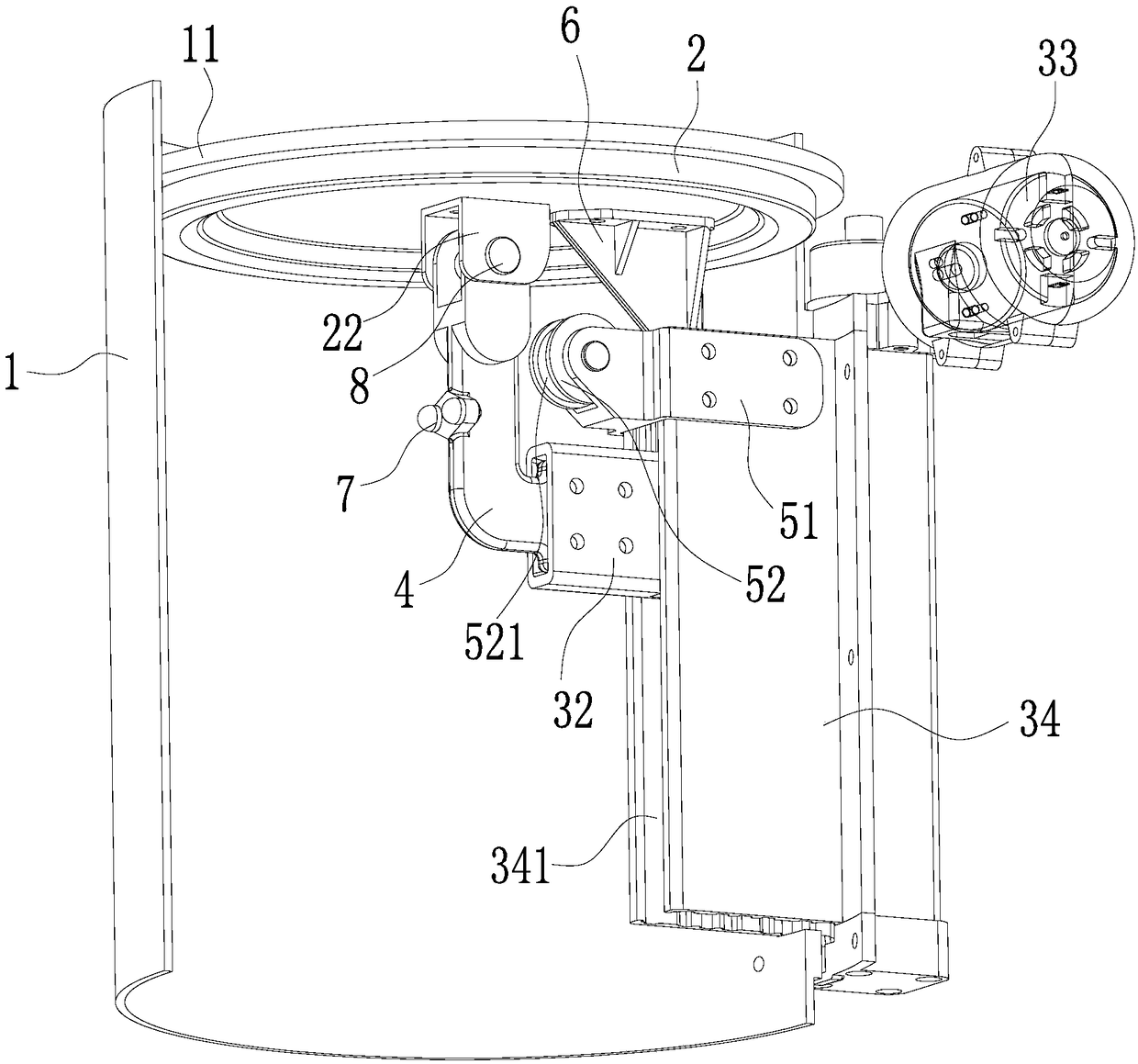

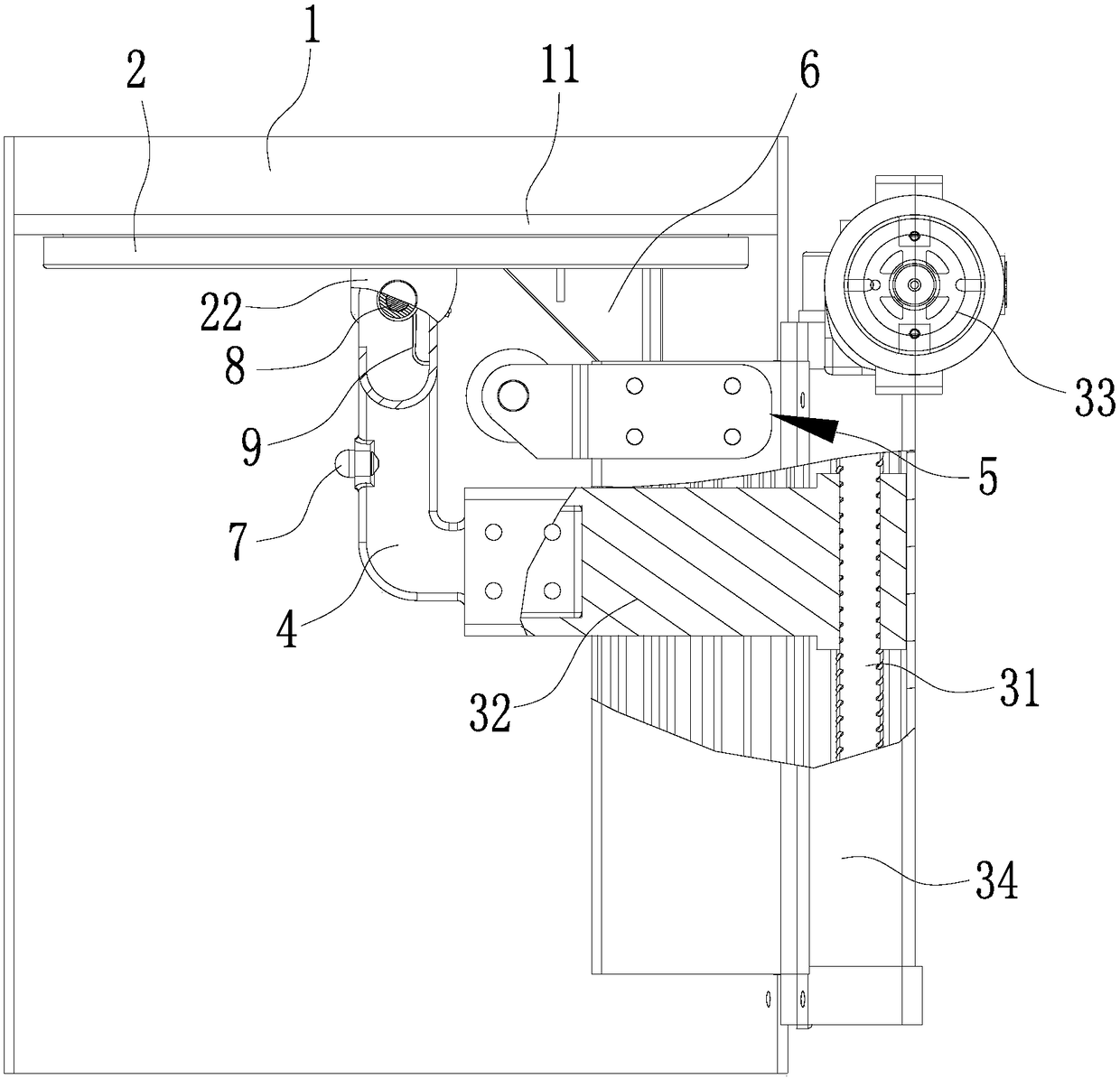

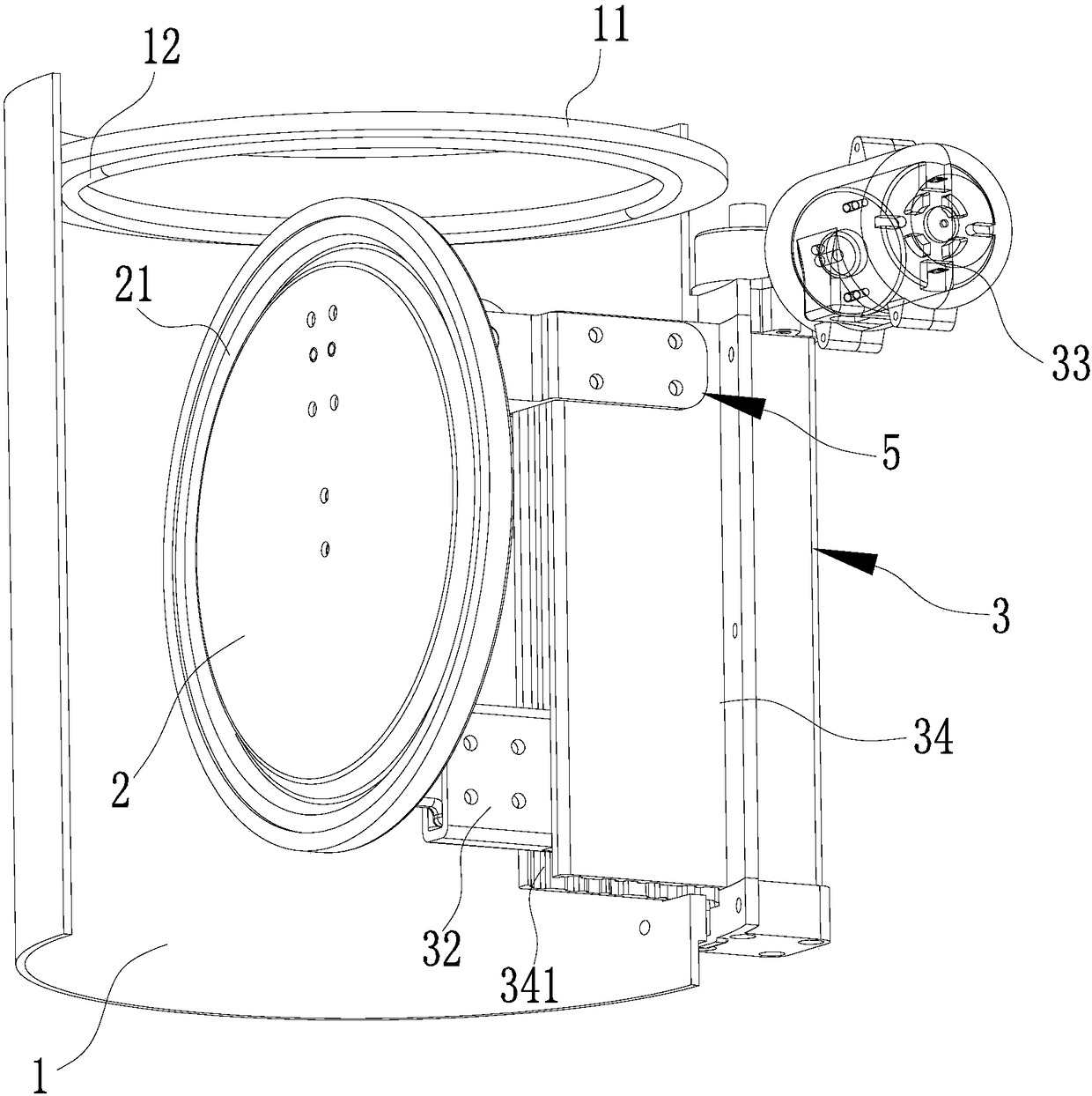

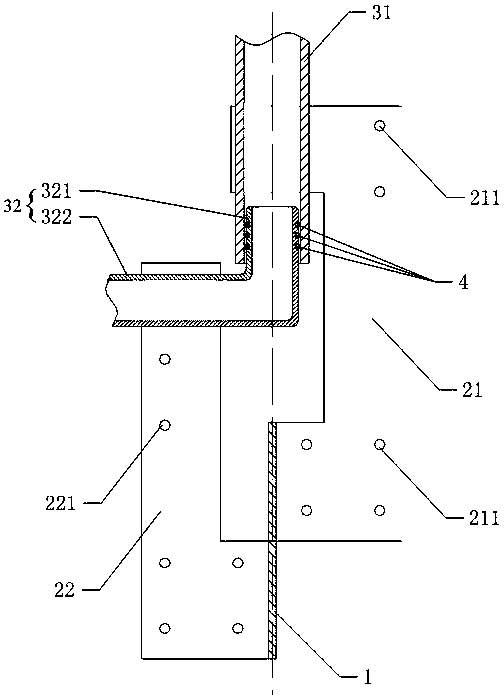

Electric pressure cooker

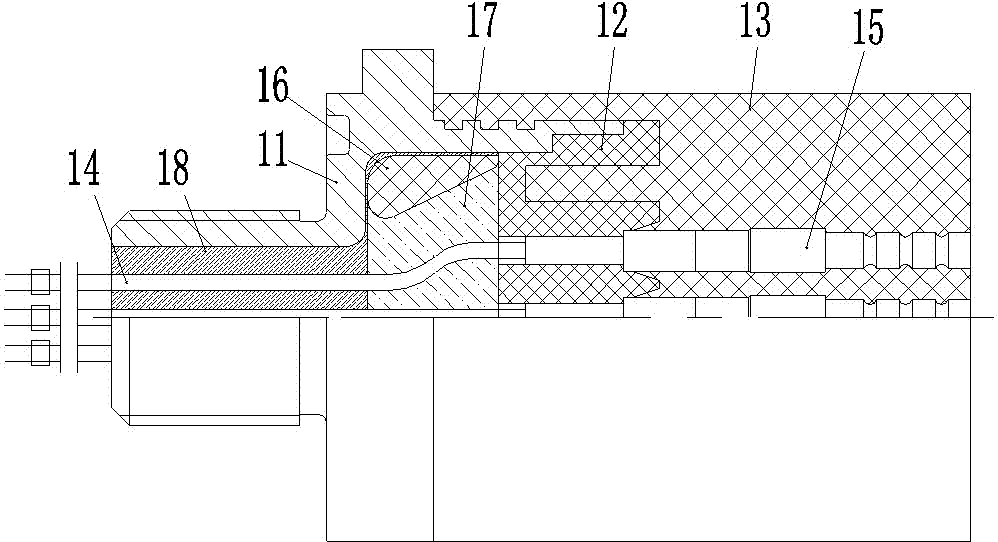

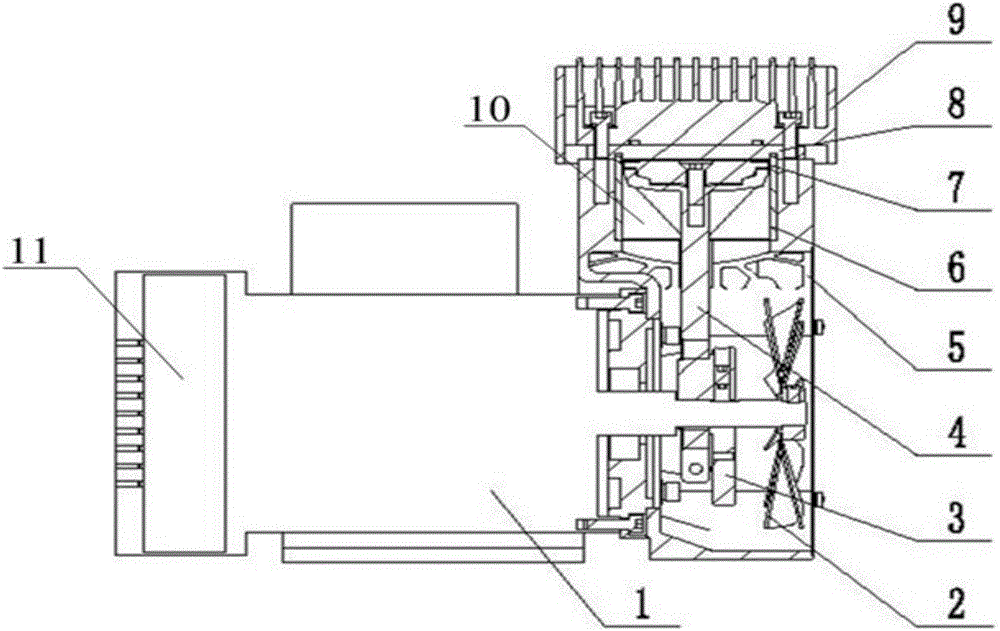

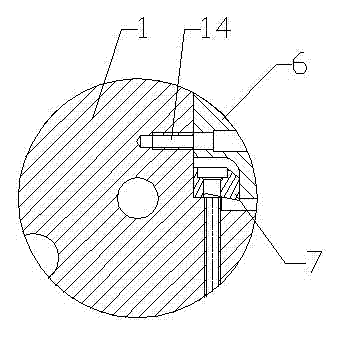

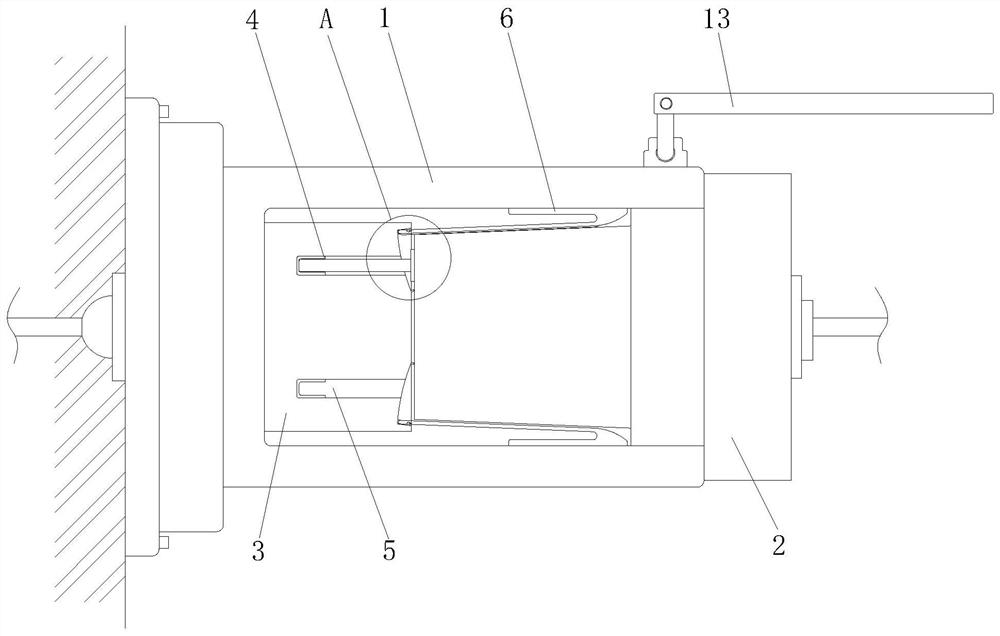

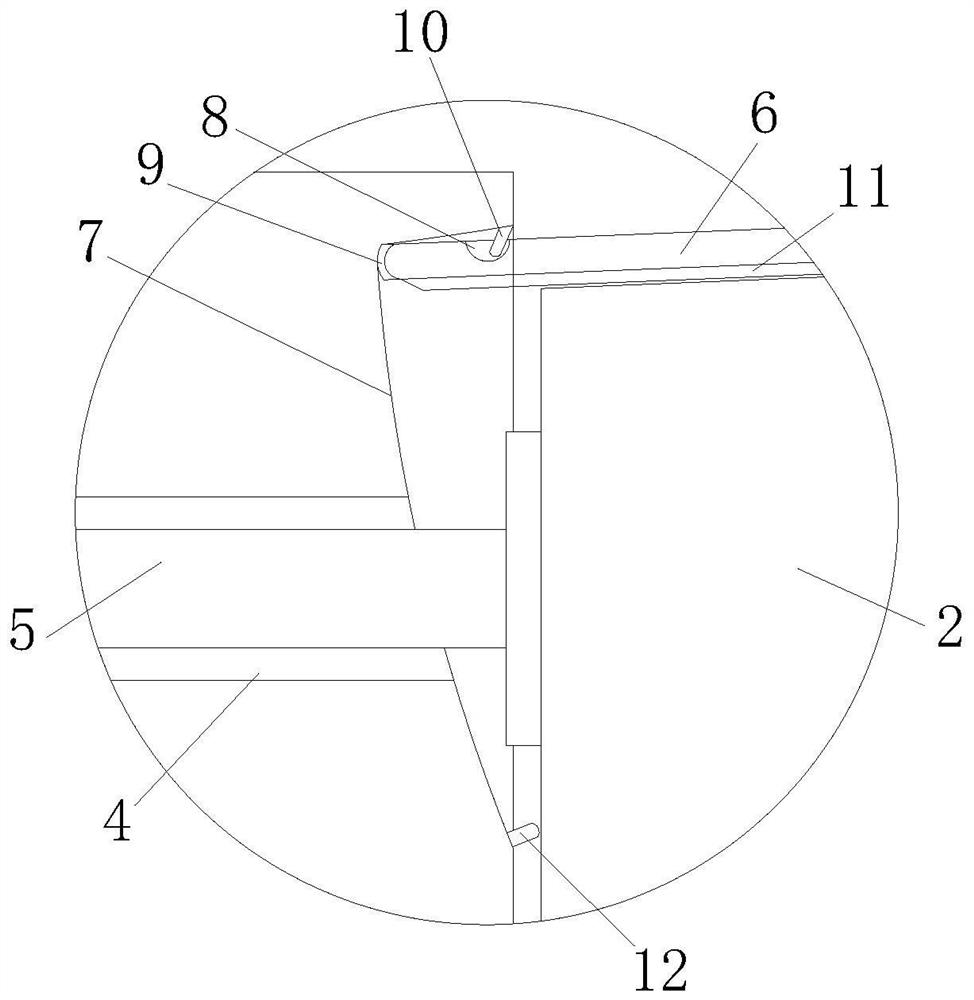

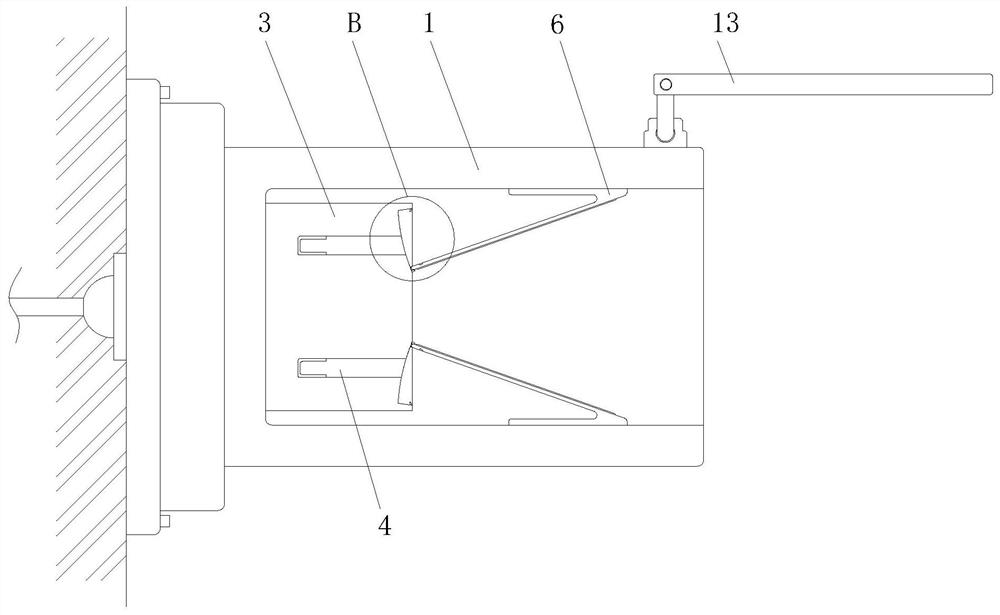

The invention provides an electric pressure cooker which comprises a cooker cover (1) and a cooker body (2). The cooker body (2) comprises a first buckle (3). The cooker cover (1) comprises a pressing part (4) and a lock catch part (5) linked with the pressing part (4). The lock catch part (5) comprises a trigger end and a lock catch end. The lock catch end is provided with a second buckle (6) buckled with the first buckle (3), and the pressing part (4) is in driving connection with the trigger end, and the pressing part (4) drives the second buckle (6) at the lock catch end and the first buckle (3) to be unlocked in a pressing state. A first elastic part (7) is arranged on the cooker cover (1), and the first elastic part (7) is connected with the lock catch part (5) and provides elastic locking force for locking the first buckle (3) for the lock catch part (5). The electric pressure cooker is simple in structure and convenient to operate, and can achieve a good sealing effect, and the use experience of a user is improved.

Owner:GREE ELECTRIC APPLIANCES INC

Electric pressure cooker

The invention provides an electric pressure cooker which comprises a cooker cover (1) and a cooker body (2). The cooker body (2) comprises a first buckle (3). The cooker cover (1) comprises a pressing part (4) and a lock catch part (5) linked with the pressing part (4). The lock catch part (5) comprises a trigger end and a lock catch end. The lock catch end is provided with a second buckle (6) buckled with the first buckle (3), and the pressing part (4) is in driving connection with the trigger end, and the pressing part (4) drives the second buckle (6) at the lock catch end and the first buckle (3) to be unlocked in a pressing state. A first elastic part (7) is arranged on the cooker cover (1), and the first elastic part (7) is connected with the lock catch part (5) and provides elastic locking force for locking the first buckle (3) for the lock catch part (5). The electric pressure cooker is simple in structure and convenient to operate, and can achieve a good sealing effect, and the use experience of a user is improved.

Owner:GREE ELECTRIC APPLIANCES INC

Impact piece exploder and manufacture method thereof

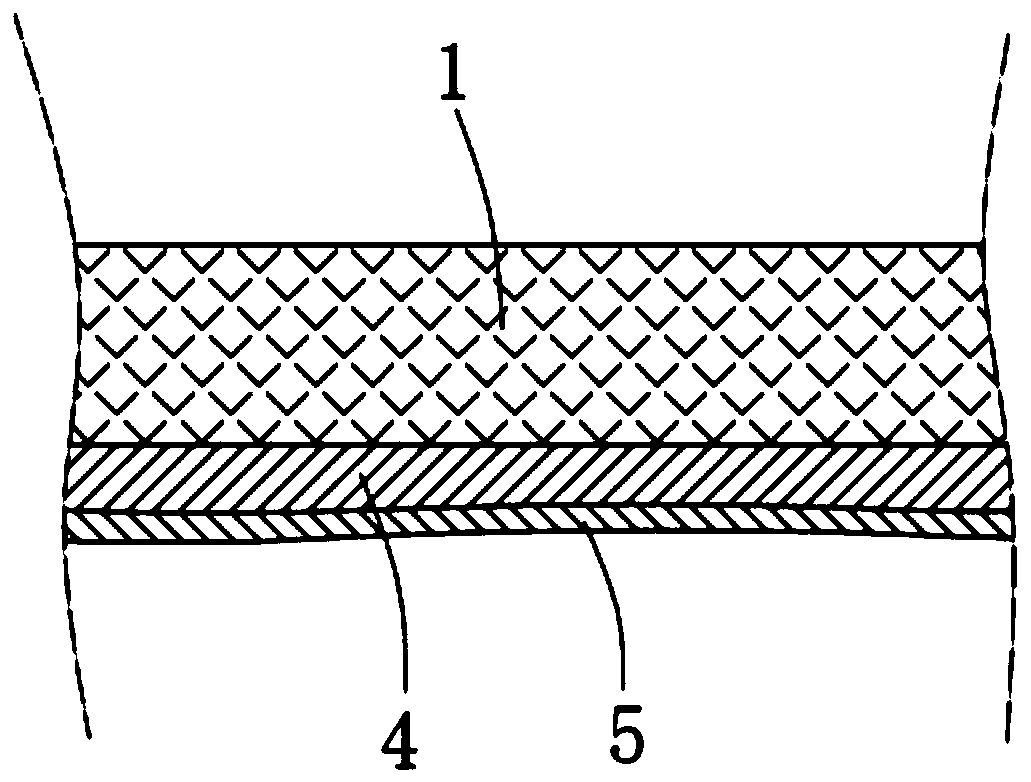

The invention discloses an impact piece exploder and a manufacture method thereof. The manufacture method comprises the following steps: using half curing adhesive to axially couple together a reflective sheet, a bridge foil, a flyer and an accelerating chamber in sequence, wherein the reflective sheet, the flyer and the accelerating chamber are made of polyimide; using a first polyimide layer to form a reflective sheet layer; pressurizing and bonding the reflective sheet layer; using a second polyimide layer and a copper foil layer to form a composite film; then, exposing, developing and etching the copper foil layer of the composite film to acquire the bridge foil; using bonding glue to glue a polyimide film on the surface of the bridge foil to serve as the flyer layer; then, processing the accelerating chamber on a third polyimide layer and a fourth polyimide layer; using the half curing adhesive to pressurize and bond the reflective sheet, the bridge foil, the flyer and the accelerating chamber in a counterpoint manner; and finally, blanking the impact piece exploder on a punch. The impact piece exploder is high in reliability, low in material cost, and convenient for automatic mass production.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

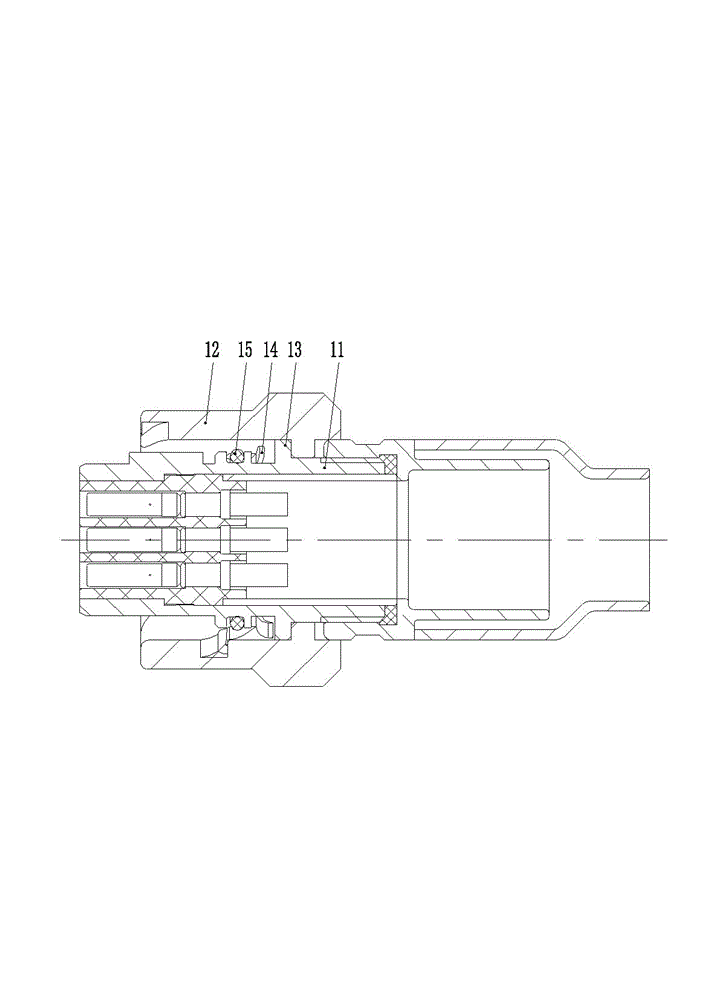

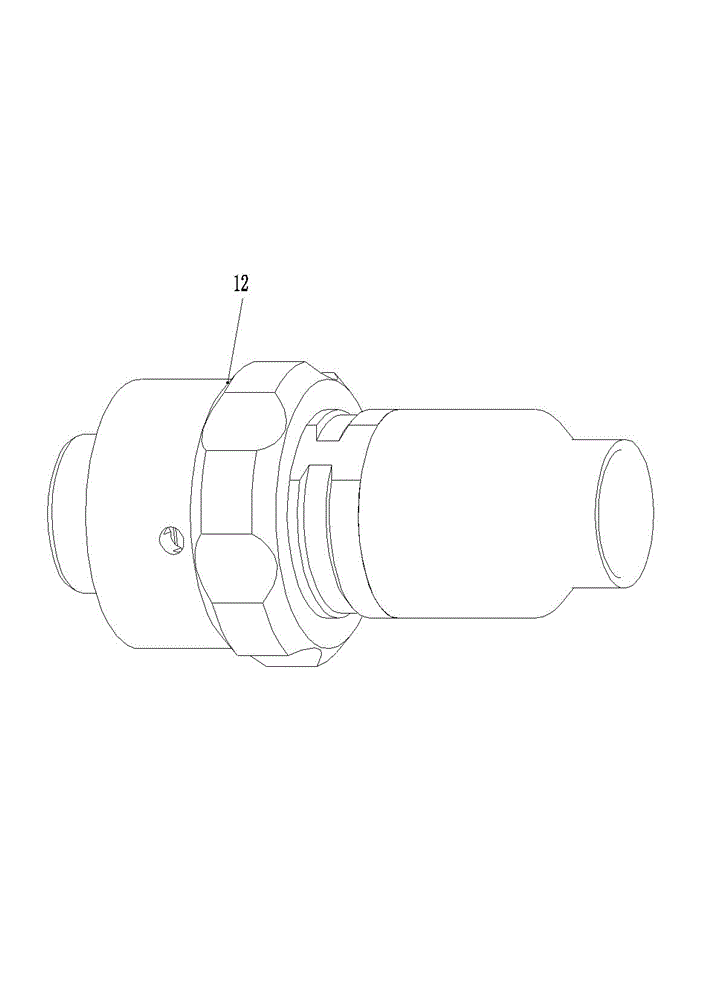

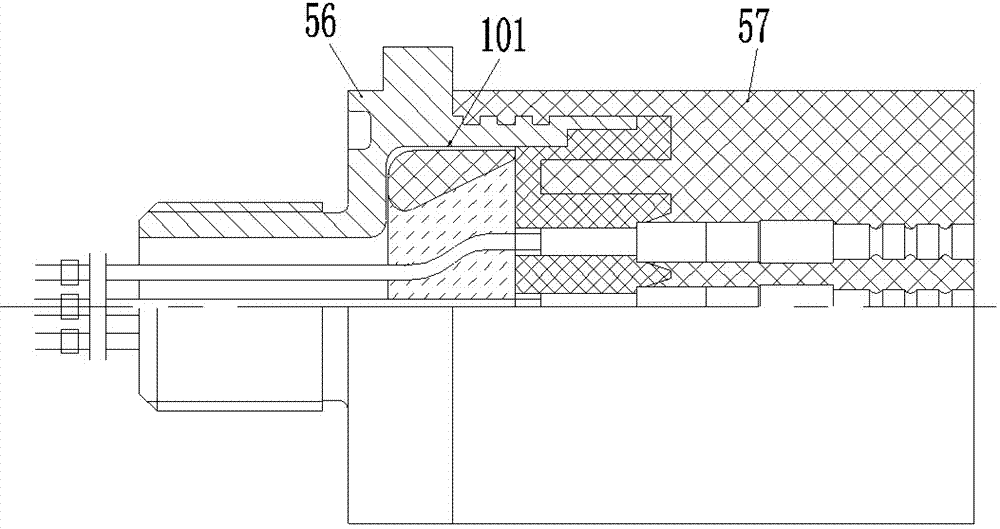

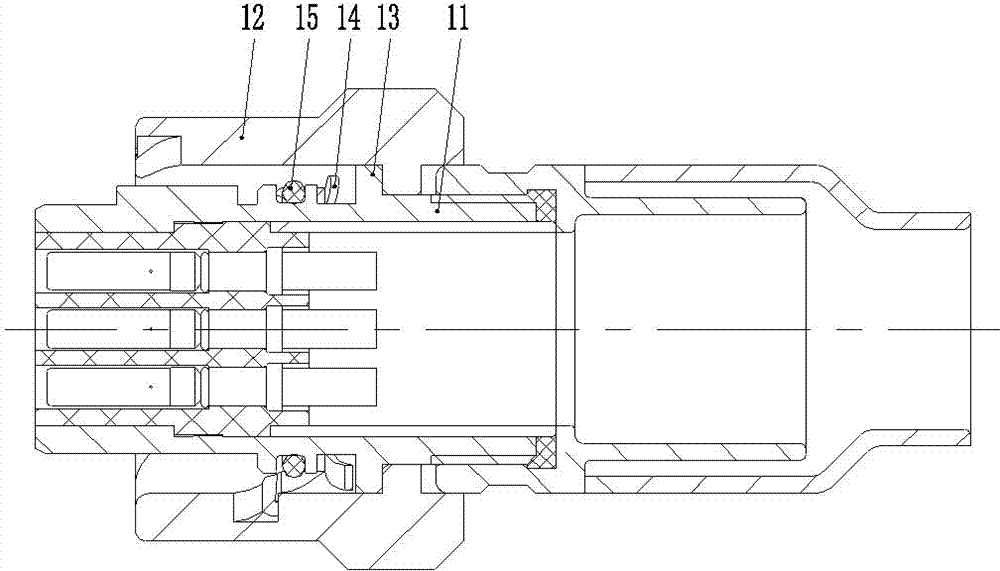

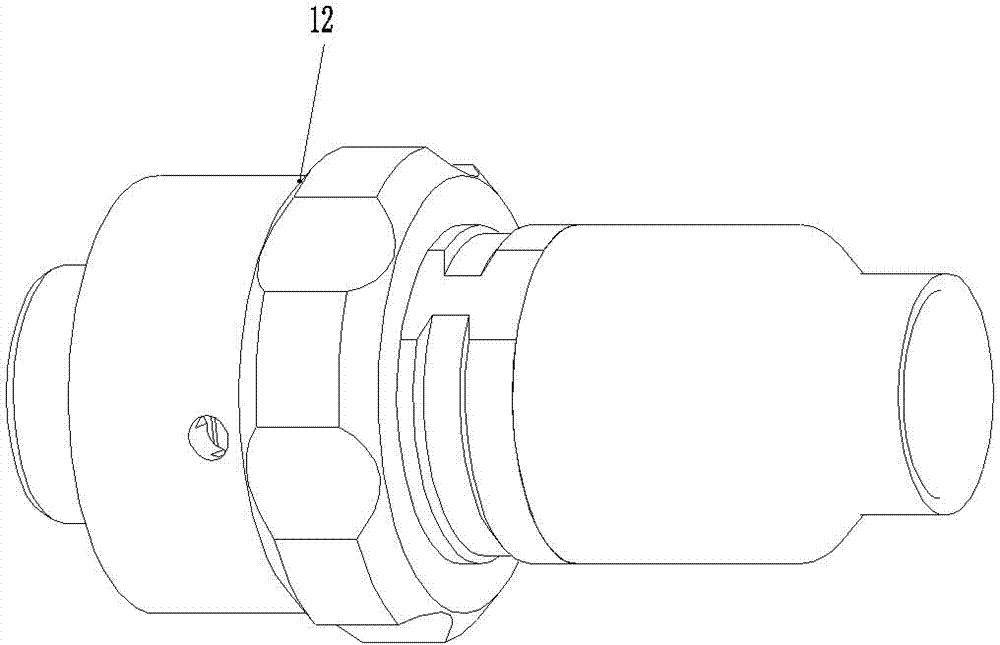

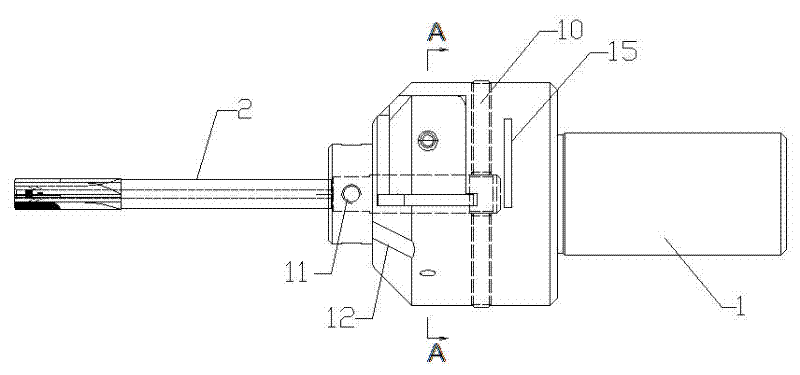

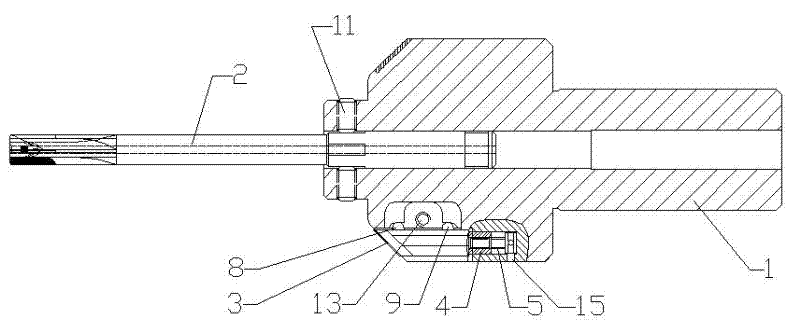

Locking threaded connector and assembly thereof

ActiveCN102751617APrevent looseningSolve the problem of displacement in the direction of separationEngagement/disengagement of coupling partsCouplings bases/casesEngineeringShock resistance

The invention relates to a locking threaded connector and an assembly thereof. The locking threaded connector comprises a shell with the front end being a plugging end and a connection screw cap which is assembled forwards on the shell in a locking way, wherein the front part of the shell is provided with a plugging part for being plugged into an adaptive connector, a corrugated spring is sleeved on the plugging part, the front side of the corrugated spring is provided with a jacking surface which is in jacking fit with the end surface of the plugging end of the shell of the adaptive connector, the outer wall of the shell is provided with a pressure-bearing wall which is used for preventing the backward movement of the corrugated spring when the adaptive connector jacks the corrugated spring, and the pressure-bearing wall is nested inside the connection screw cap; and the problems that an electric connector which realizes the shock resistance and loosening prevention through the corrugated spring moves in the direction to be separated from the adaptive connector when the electric connector is subjected to the force in the separation direction can be solved.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

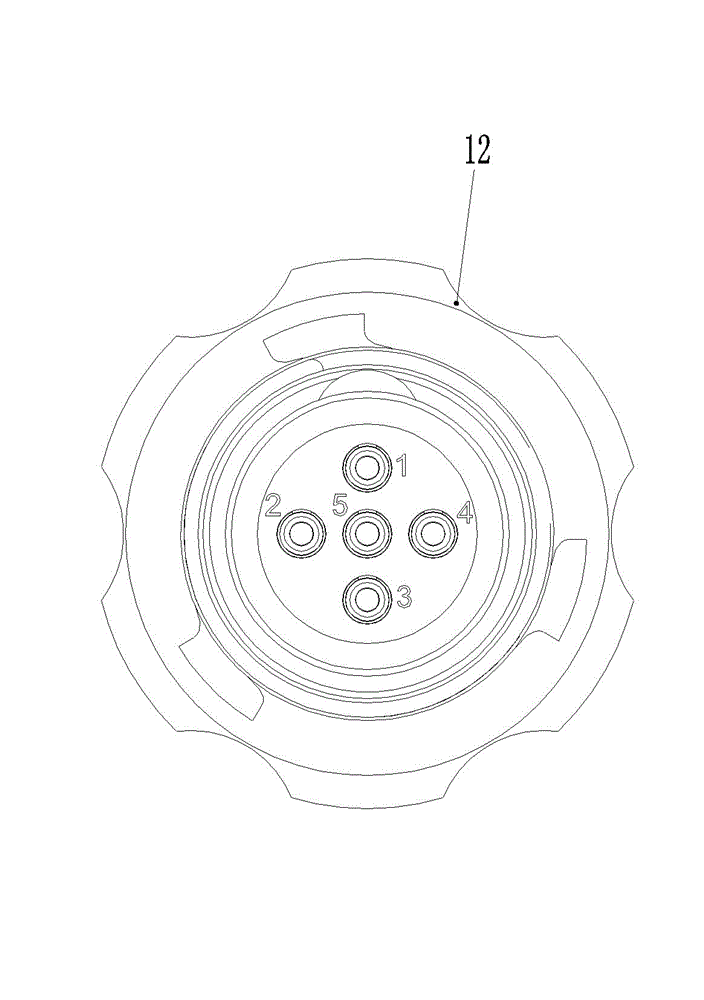

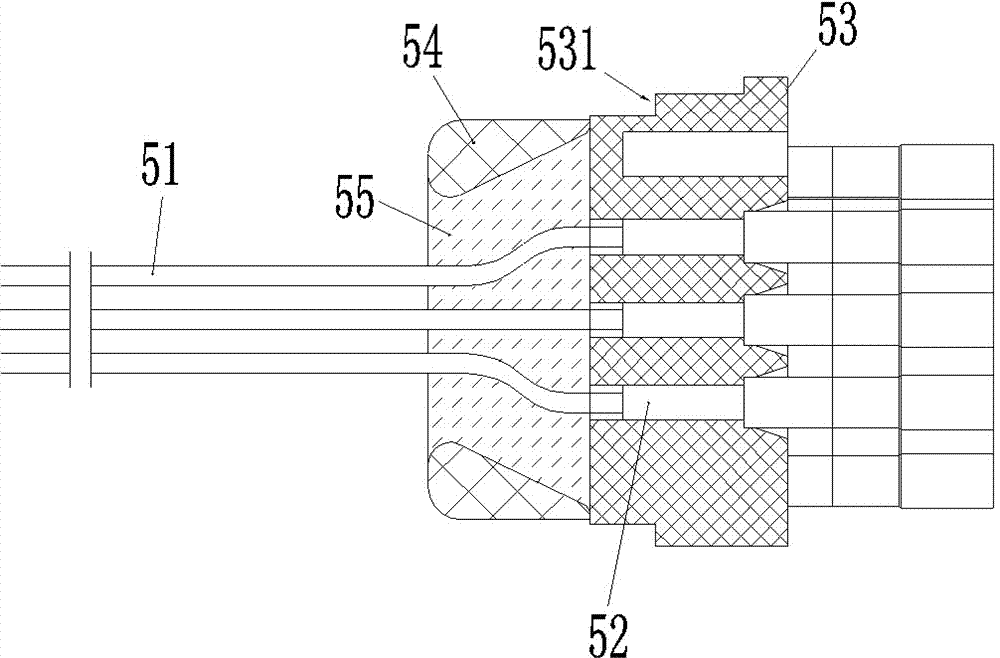

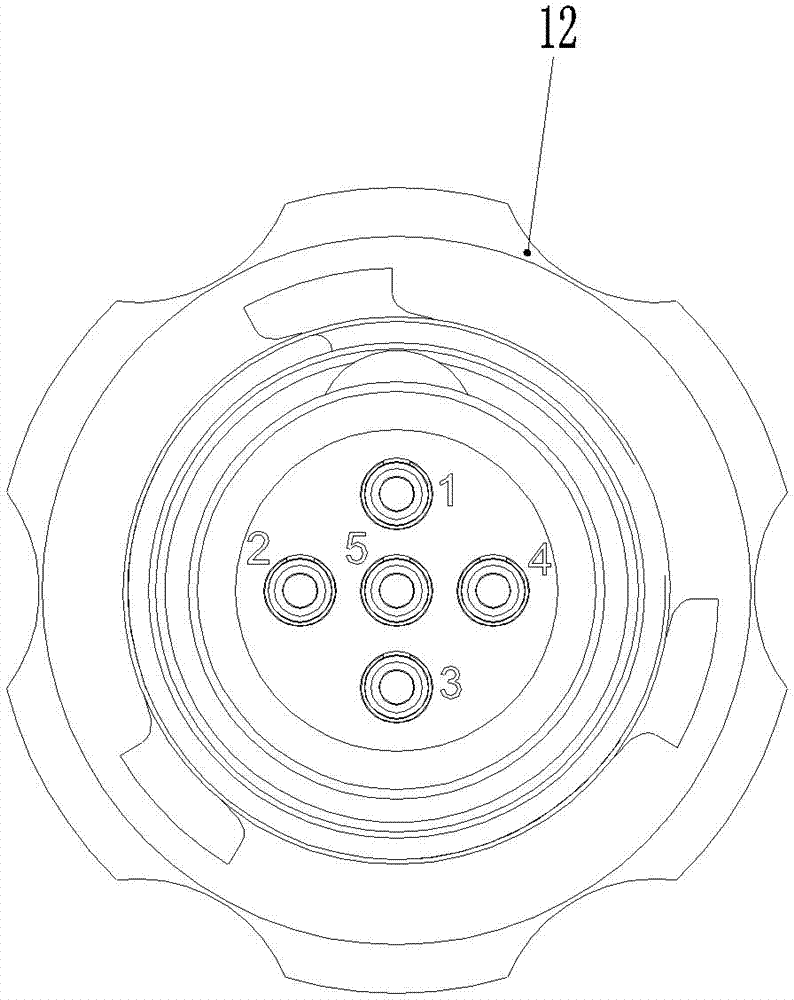

Underwater plug-pull connector and preparation method thereof

InactiveCN103036101ASolve the unreliable sealingStrong enoughContact member assembly/disassemblyCouplings bases/casesVulcanizationEngineering

The invention relates to the field of electric connectors, in particular to an underwater plug-pull connector and a preparation method thereof, wherein the underwater plug-pull connector can be applied to the seafloor and other deepwater environments. The front end of the connector serves as a plug end, the connector comprises a shell, an insulator, a sulfide body and a contact piece connected with a conducting wire, and the contact piece, the insulator and the shell are fixed together in a vulcanization mode through the sulfide body. A locating step surface facing the front is installed inside the shell, a matching step surface which is in check fit with the locating step surface is installed on the outer circumferential surface of the insulator, the contact piece is installed inside an installation hole of the insulator in a plug-in mode, the rear side of the insulator is fixedly connected with a supporting piece, and an air exhaust gap is formed between the supporting piece and the inner wall surface of the shell. The fact that the insulator has enough strength to bear vulcanization injection force can be guaranteed through the supporting piece, and meanwhile, the air exhaust gap is formed between the supporting piece and the inner wall surface of the shell, so that during a vulcanization process, air inside the shell can be exhausted from the rear end of the shell through the air exhaust gap, and therefore, the problem that seal of an existing underwater plug-pull connector is not reliable is solved.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

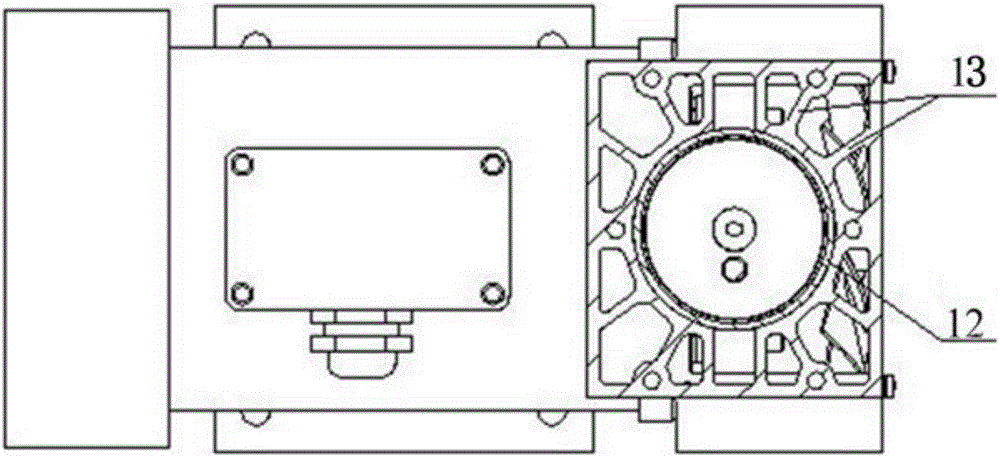

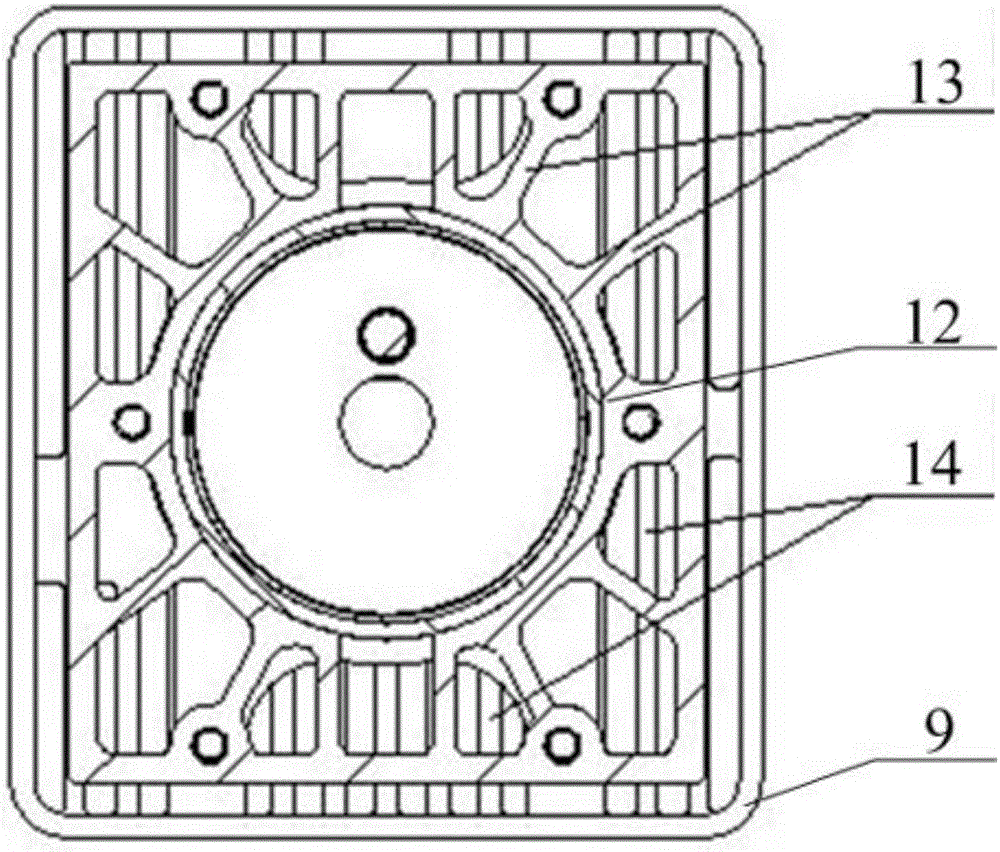

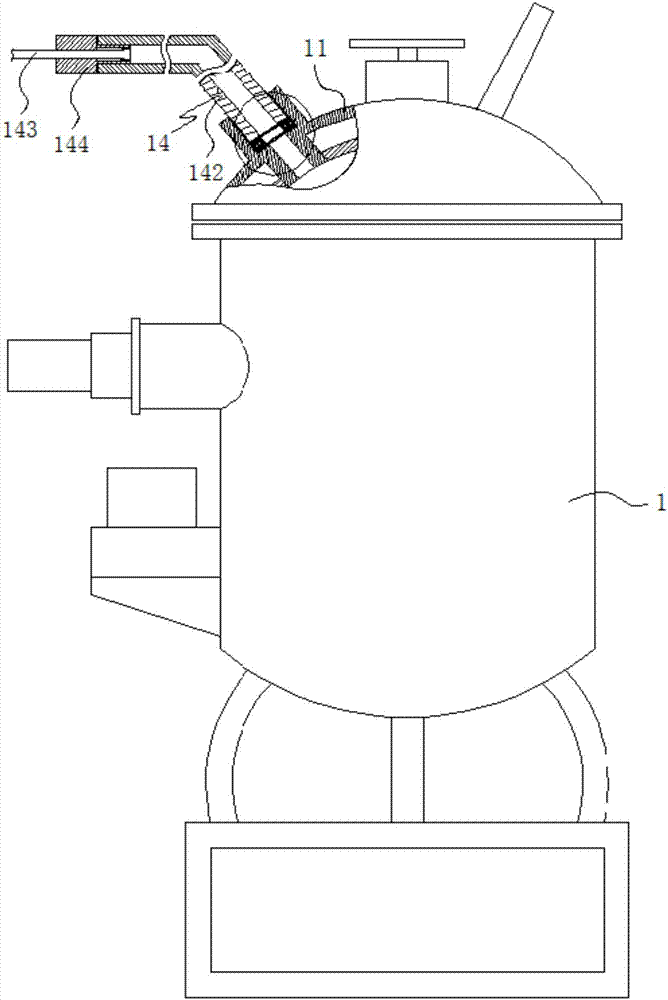

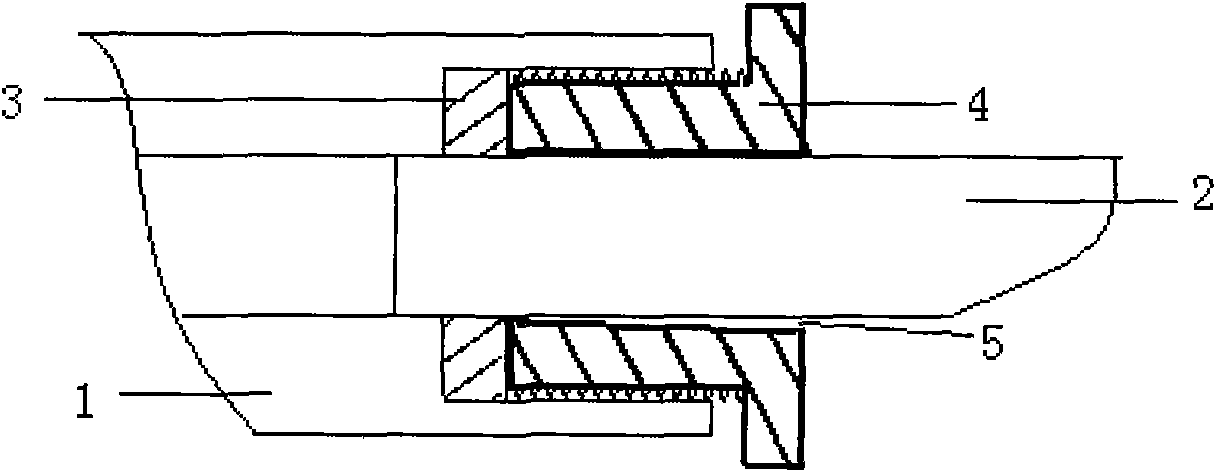

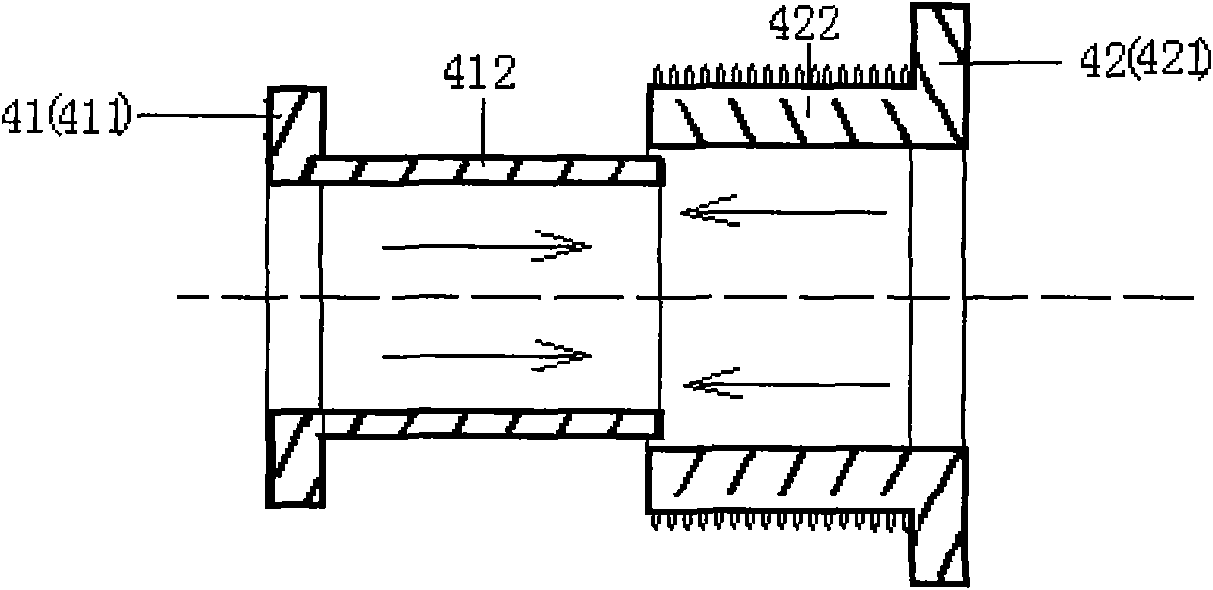

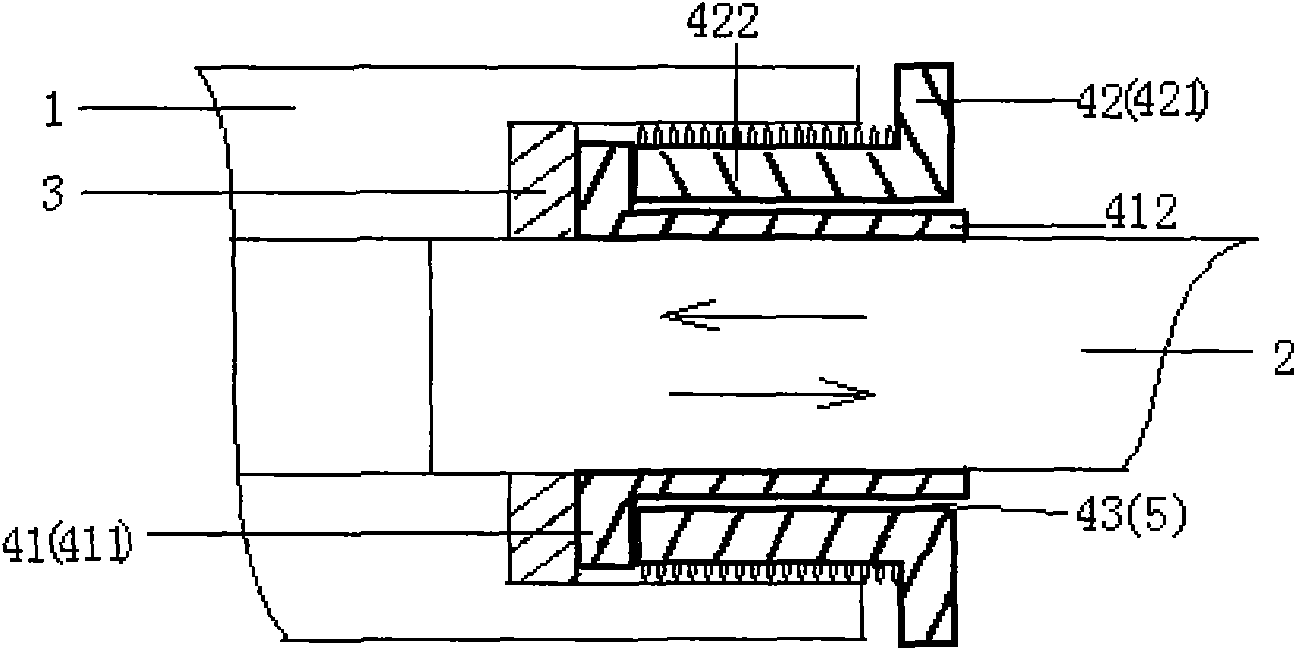

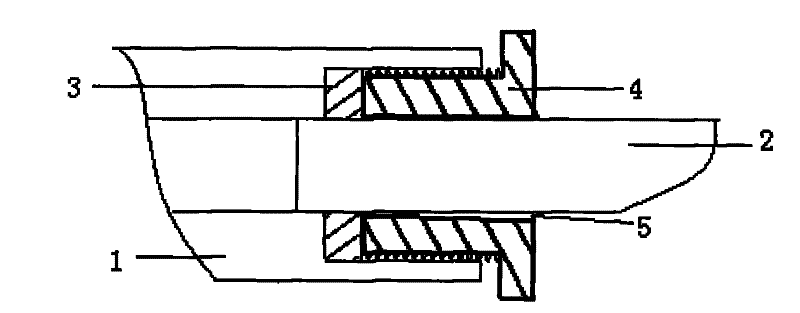

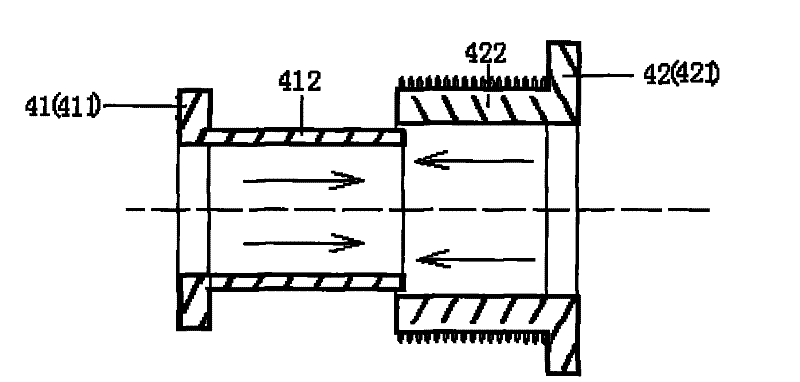

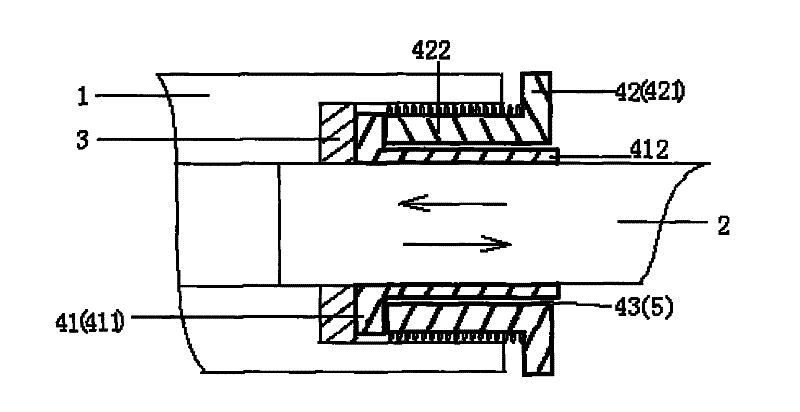

Oilless compressor and auxiliary compressor set

InactiveCN105927507AIncrease working temperatureImprove cooling effectPositive displacement pump componentsPiston pumpsWorking temperatureEngineering

The invention discloses an oilless compressor, and belongs to the field of electric locomotive equipment. The oilless compressor comprises a driving motor, a box body, a crankshaft, a cylinder and a piston module; the driving motor is connected with the box body; the cylinder is mounted in the box body; the crankshaft is connected with the driving motor, and is positioned in the box body of the compressor; the piston module is arranged in the cylinder, and is connected with the crankshaft; the oilless compressor is a single-cylinder structure; a cooling blade is mounted on the driving motor; a cylinder mounting ring base is arranged in the box body of the compressor, and is connected with the box body of the compressor through multiple cooling ribs; and a cylinder cover is arranged at the top of the box body of the compressor, and is provided with multiple first cooling fins. The oilless compressor realizes quick heat transfer of the cylinder, prevents excessive working temperature of the cylinder, guarantees the matching tightness between the cylinder and the piston module, and increases the displacement of the compressor to 0.08 m3 / min. The invention further discloses an auxiliary compressor set.

Owner:江苏德厚机电有限公司

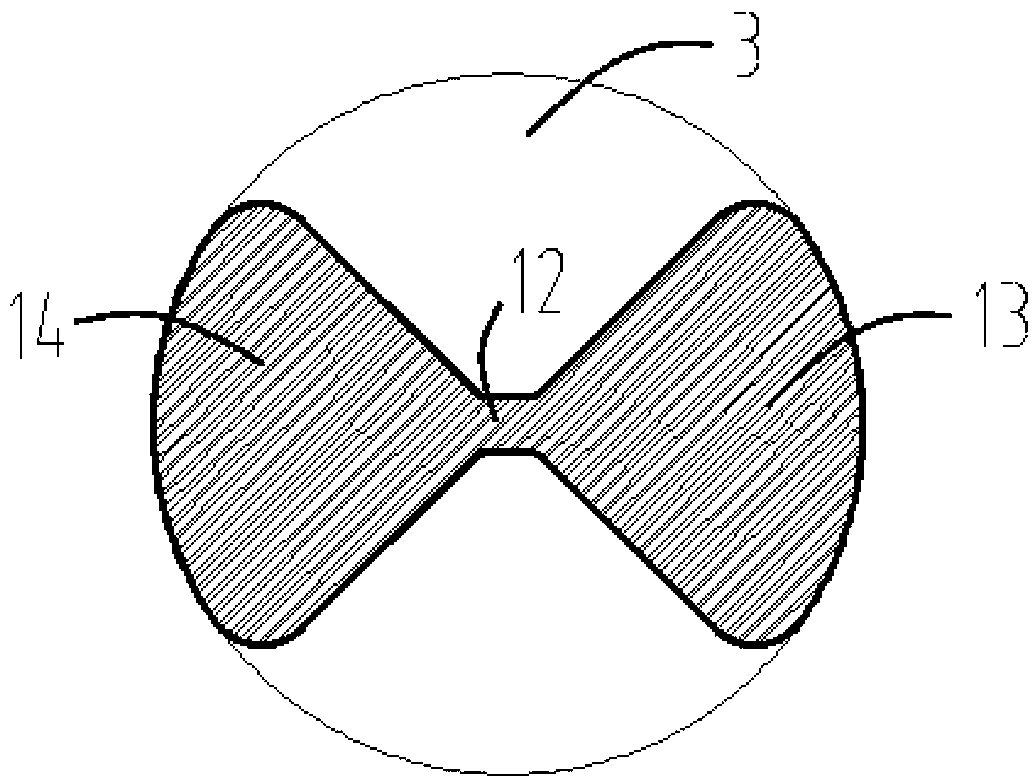

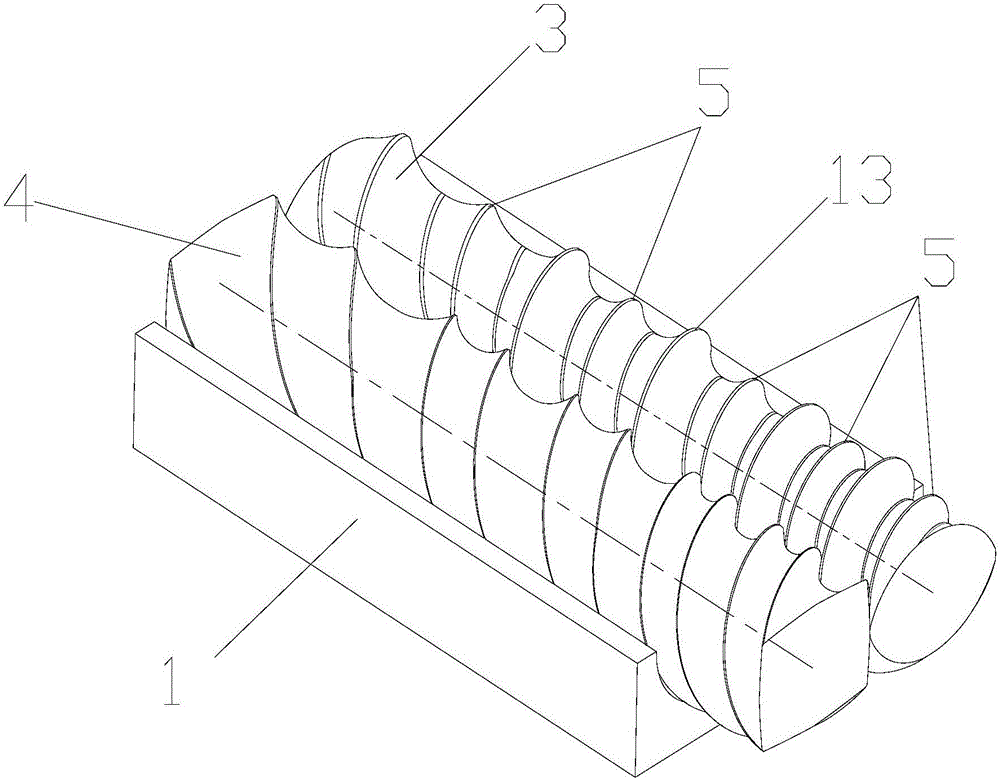

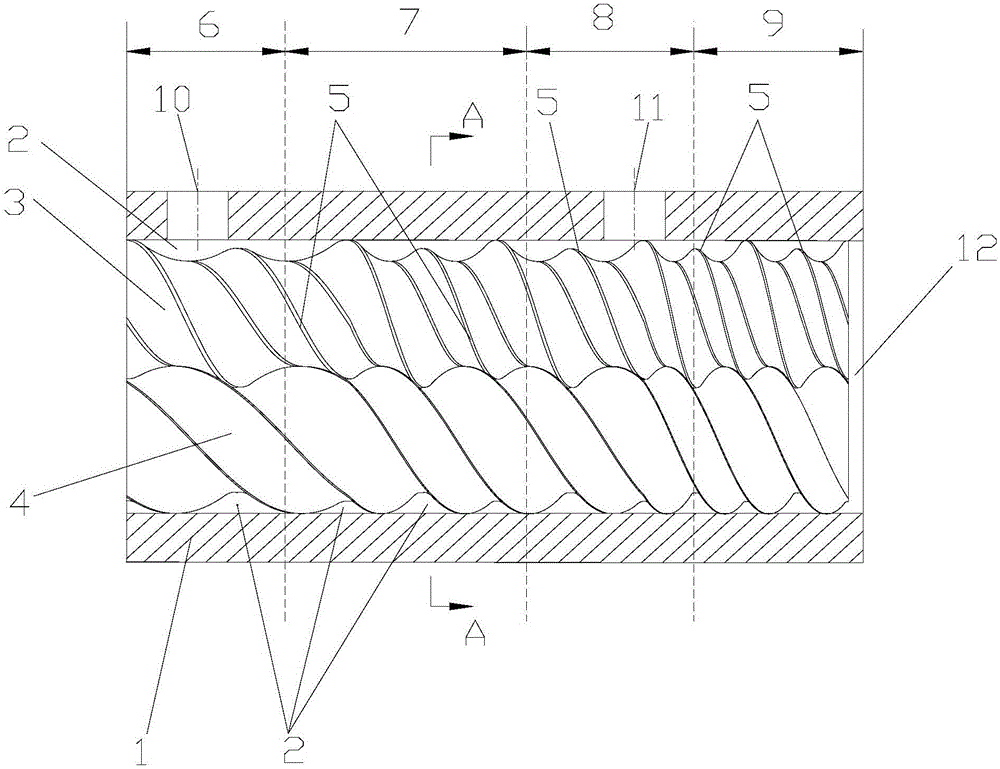

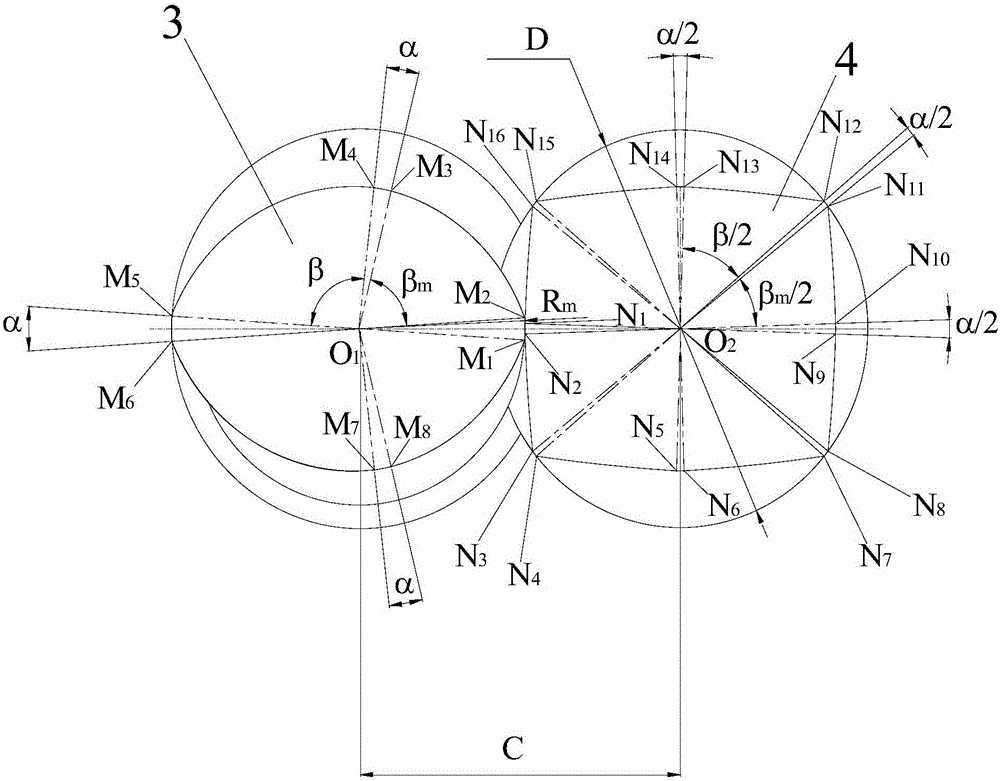

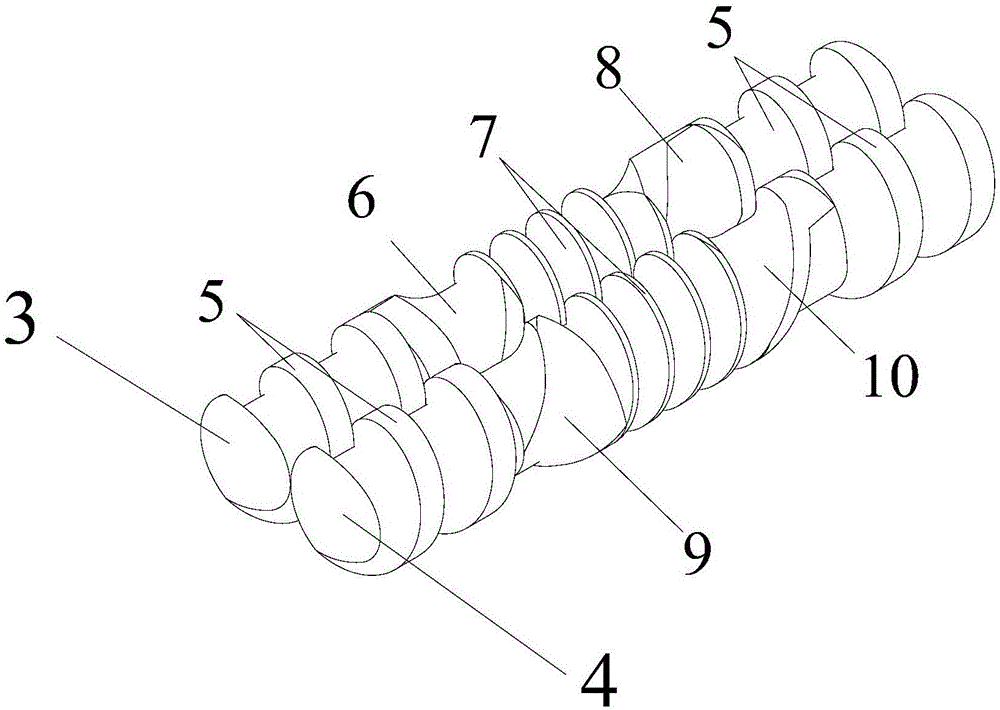

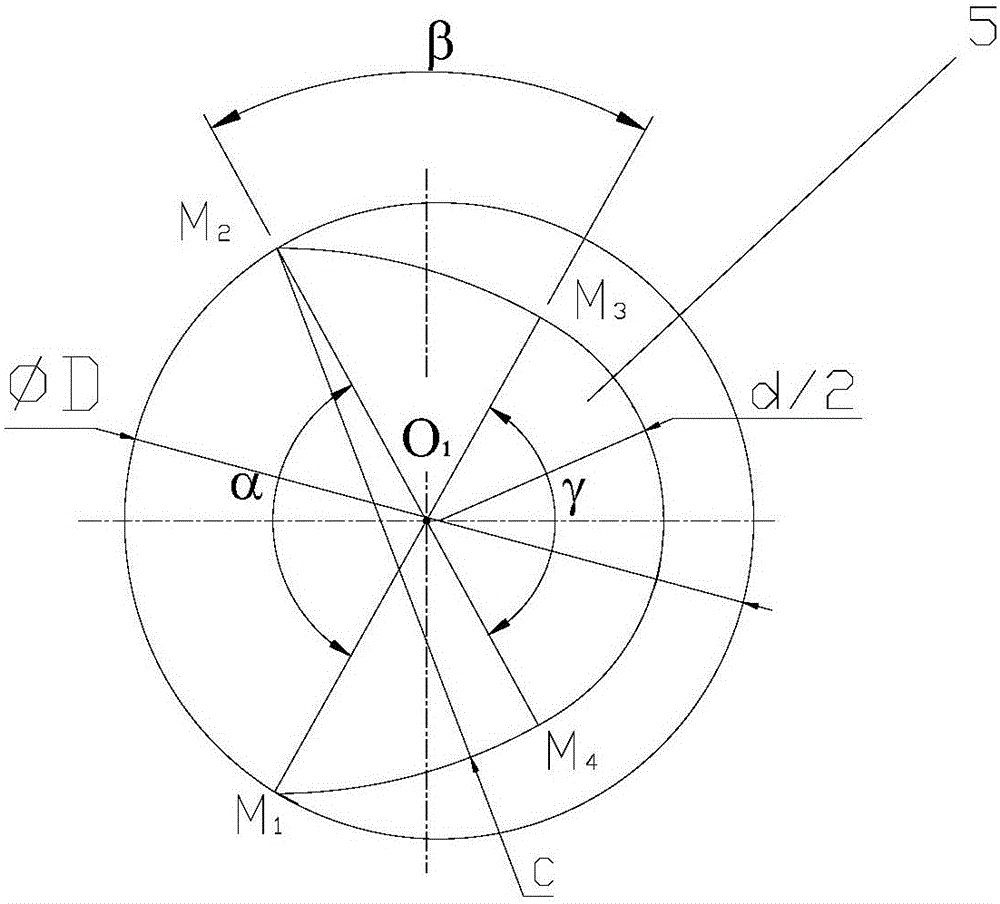

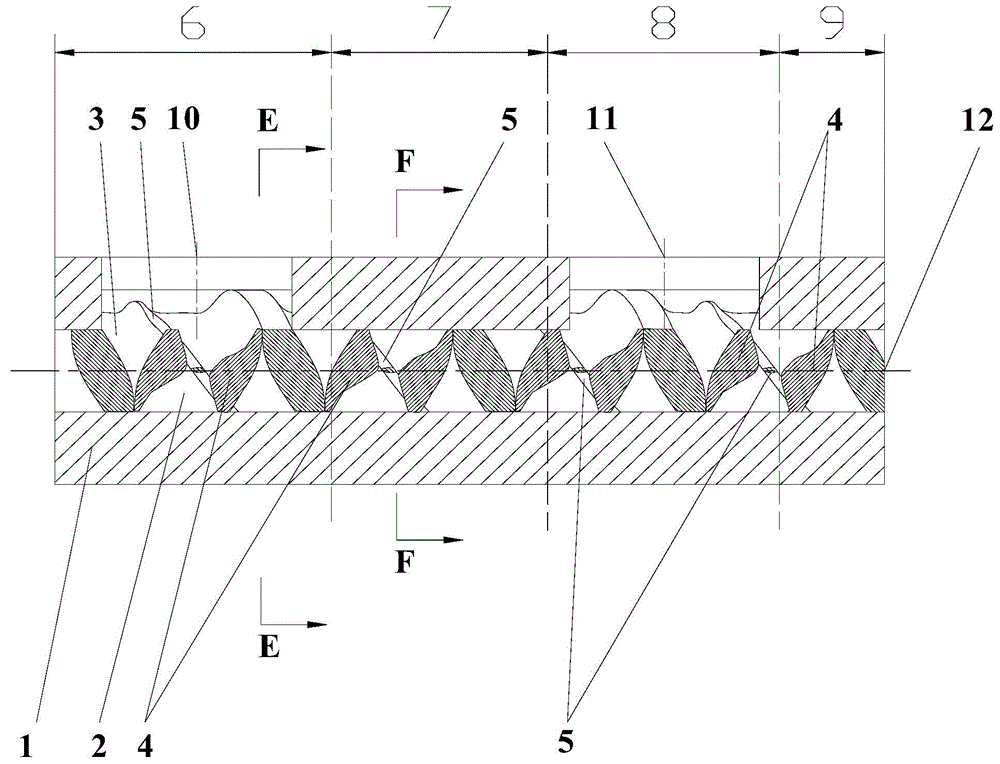

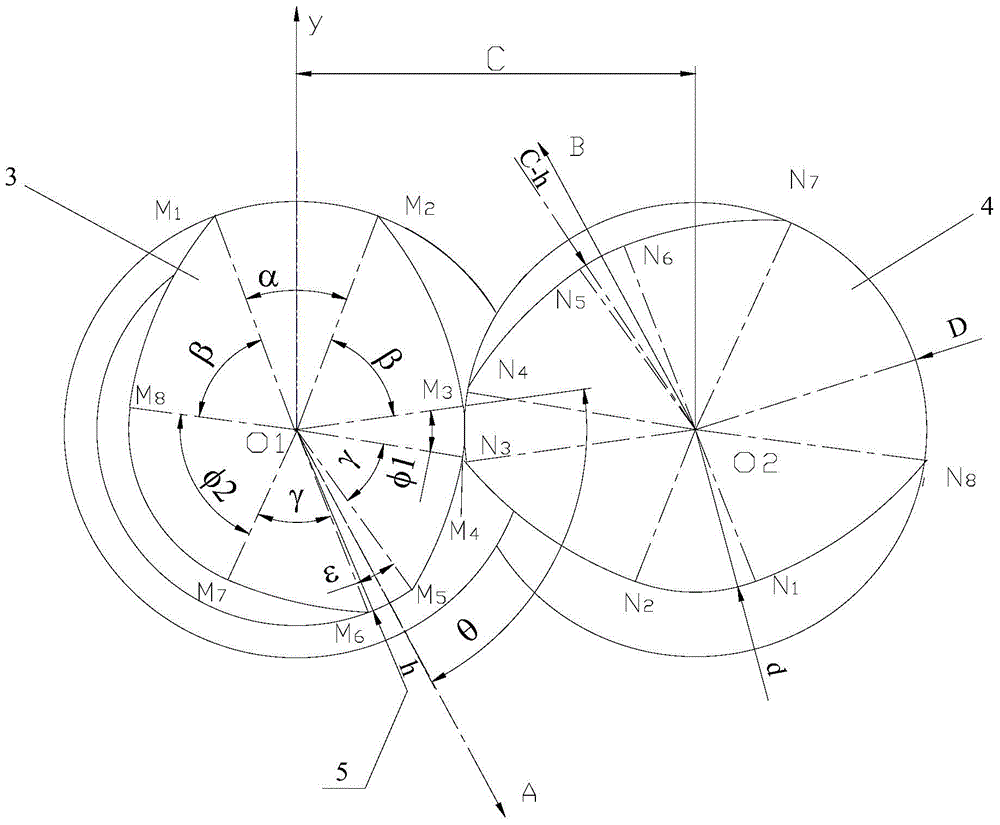

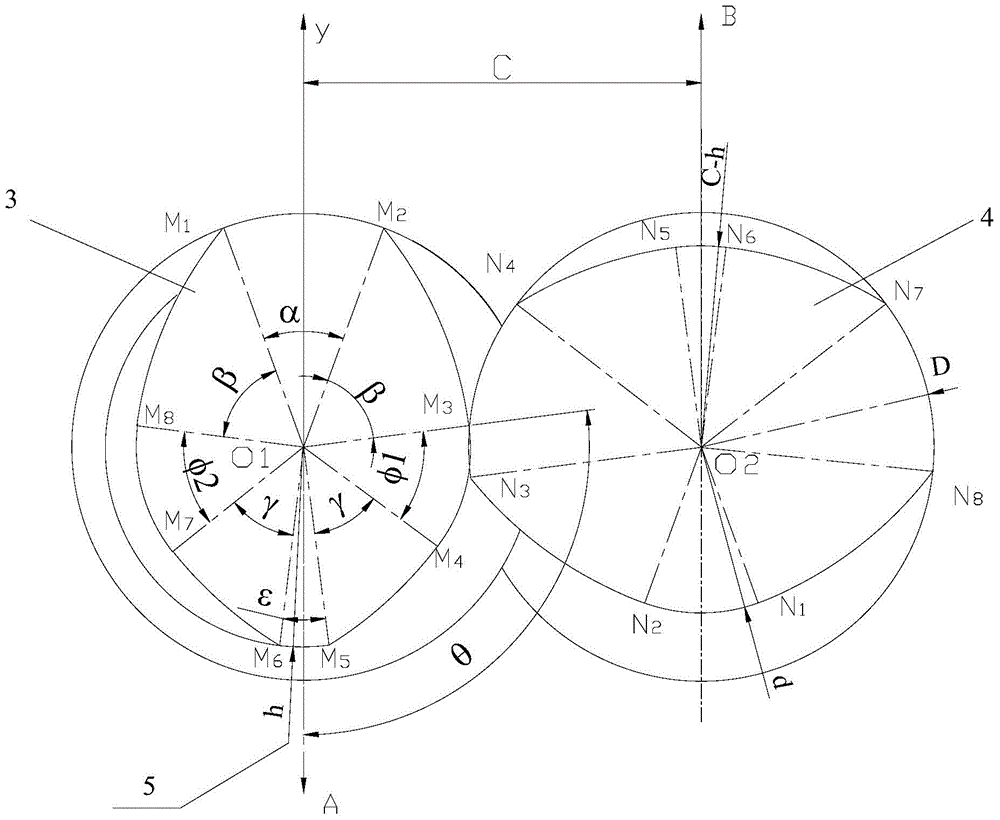

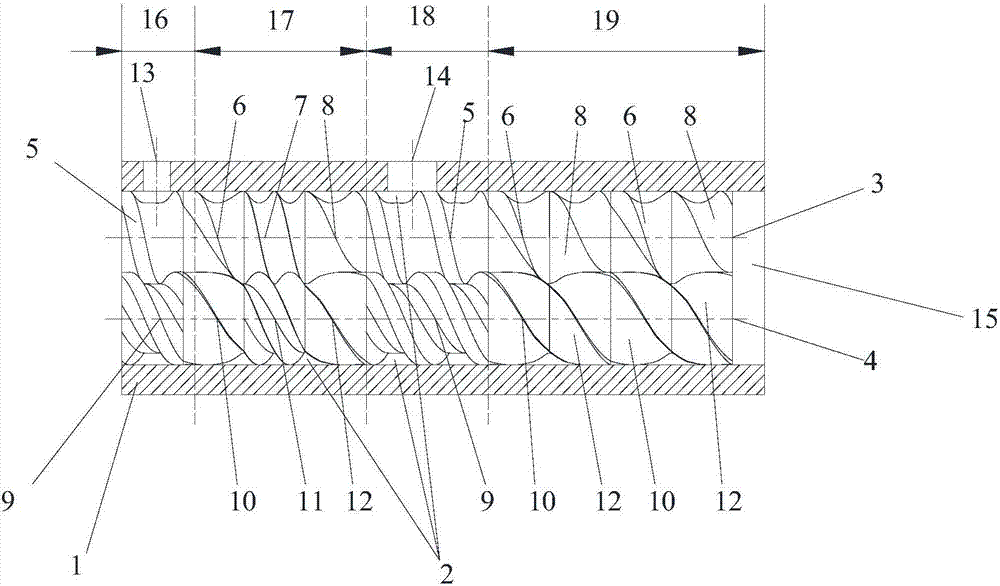

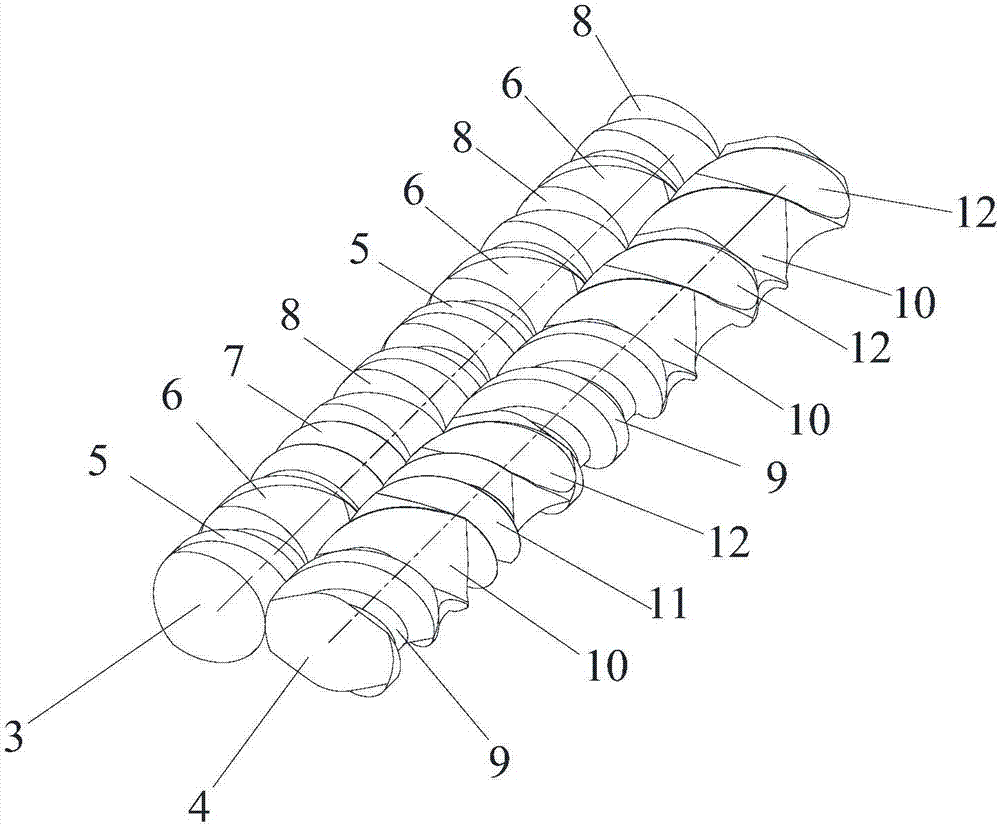

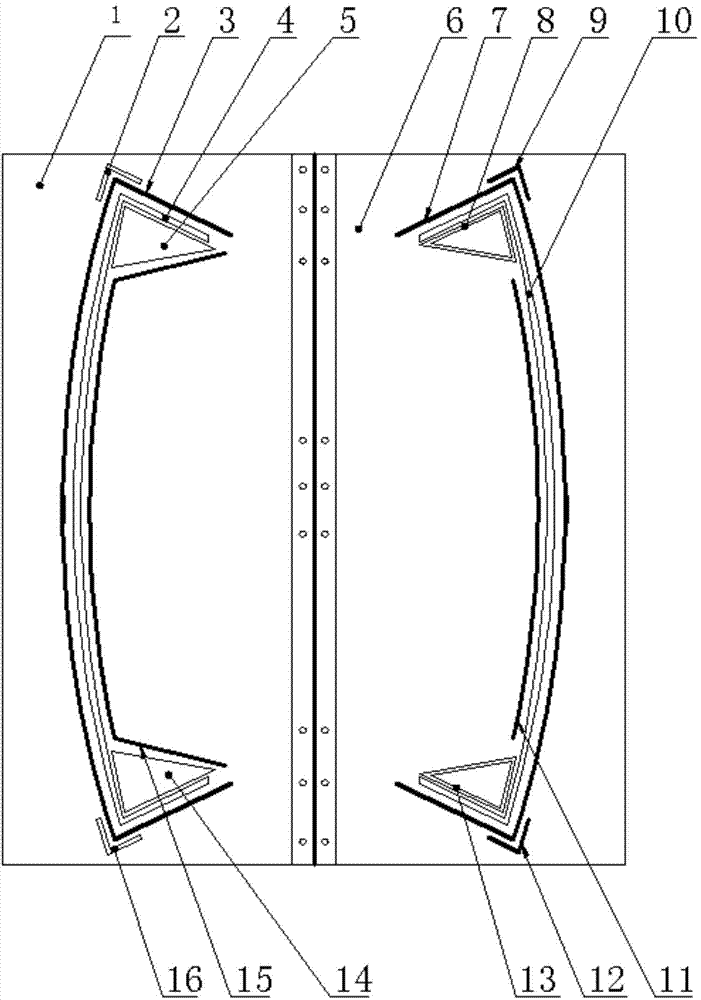

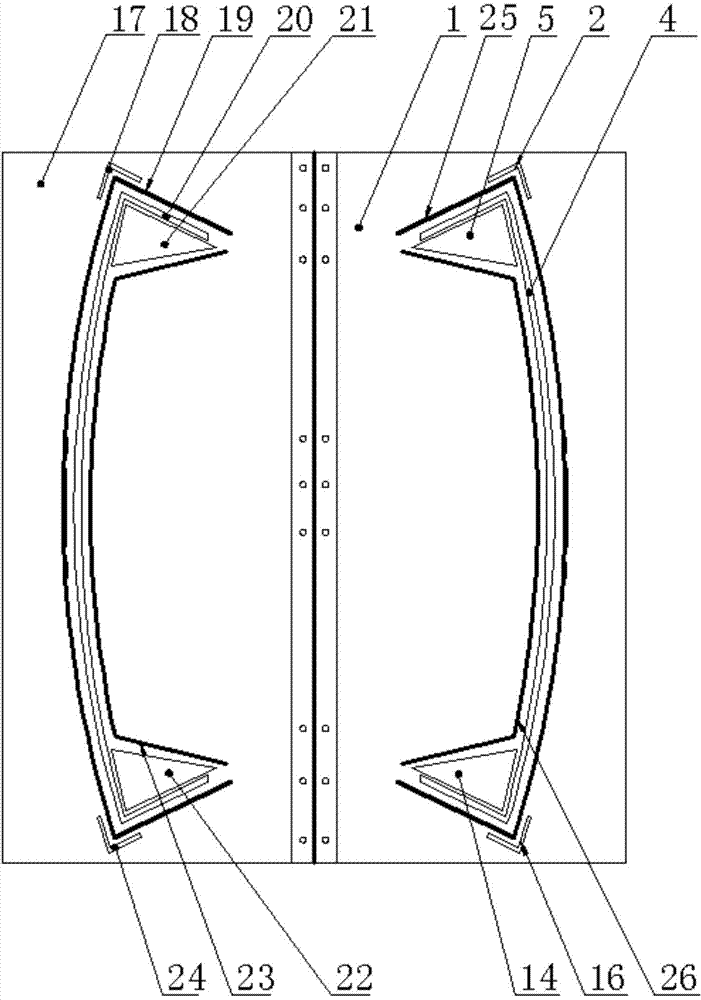

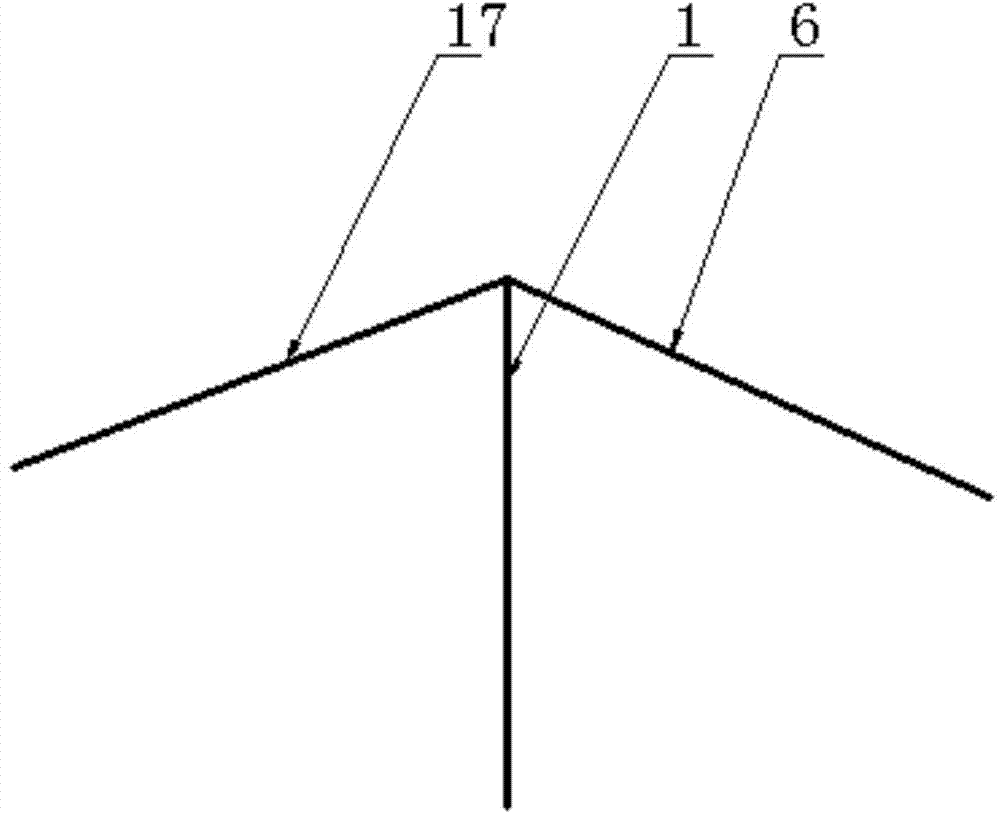

Embedded type short-screw-flight same-direction asymmetric multi-screw extruder and machining method thereof

ActiveCN106476242AImprove delivery efficiencyAvoid unstable product qualityHomoclinic orbitEngineering

The invention discloses an embedded type short-screw-flight same-direction asymmetric multi-screw extruder and a machining method thereof. A screw mechanism in the extruder comprises a first screw and a second screw which are engaged with each other. The first screw is of a single-start thread structure, and the second screw is of a four-start thread structure. Embedded type short screw flights used as auxiliary screw flights are arranged in screw channel passageways each formed between two adjacent main screw flights in the first screw. The height of the auxiliary screw flights is smaller than or equal to the height of the main screw flights. According to the machining method of the embedded type short-screw-flight same-direction asymmetric multi-screw extruder, material conveying is achieved under the common effect of the axial positive displacement conveying force of the screw mechanism and the friction force between the first screw and the second screw. By means of the homoclinic orbit flow disturbance which is introduced through the embedded type short screw flights and shaped like the Arabic number '8', the whole-journey chaotic mixing in the screw channel passageways, the one-to-two topological chaotic effect formed by a passageway composed of the first screw and the second screw, the periodic compression and expansion effect generated by the passageways of the screw mechanism and the differential-speed rotation effect of the two screws are triggered, and the materials are sufficiently mixed, molten, mixed and plastified.

Owner:GUANGDONG IND TECHN COLLEGE

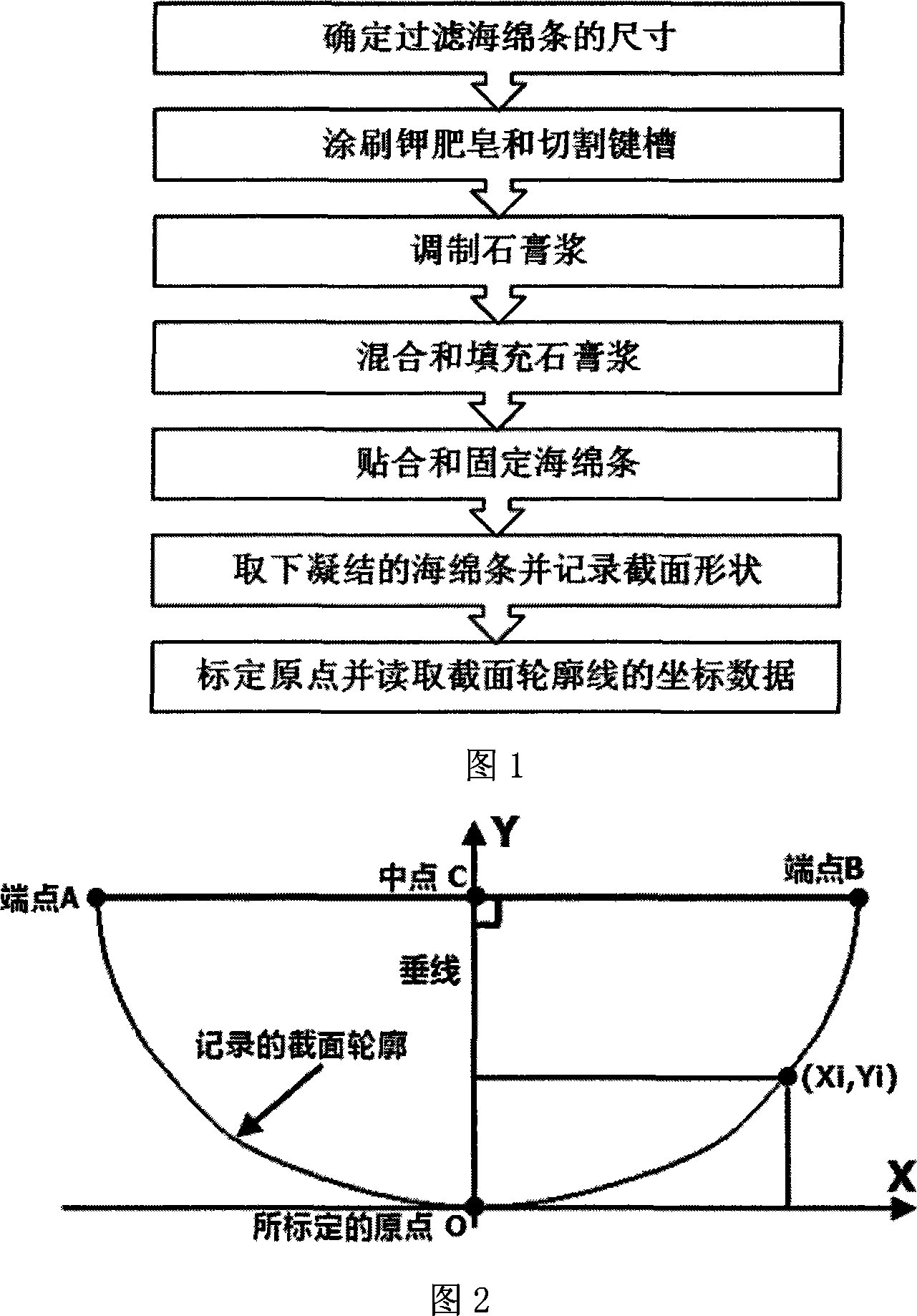

Measuring method of section profile and shape in cold-formed steel figuration process

The utility model provides a measurement method for cross-section contour shape of cold-rolled forming section during forming process in measurement technical field. The utility model is characterized in that the length of a flexible strip with a hole-shaped structure is determined at first, then a keyway and potash soap are arranged on the flexible strip; fast gelatination material is prepared, mixed and filled; the flexible strip is tightly adhered and fixed; he condensed flexible strip is then removed and the cross-section shape is recorded. A transparent plastic sheet with the cross-section shape is spread on a piece of coordinate paper and the location is adjusted well so that the coordinate value of any point of the successive contour line can be read. The utility model can overcome the disadvantages in prior art that on-line measurement is not supported and the workpiece needs to be removed. The utility model is suitable for the shape measurement of on-line cross-section contour of various specifications of roll forming product as a fast, simple, flexible, safe, economic and practical method for measuring cross-section.

Owner:无锡凯博易机电科技有限公司

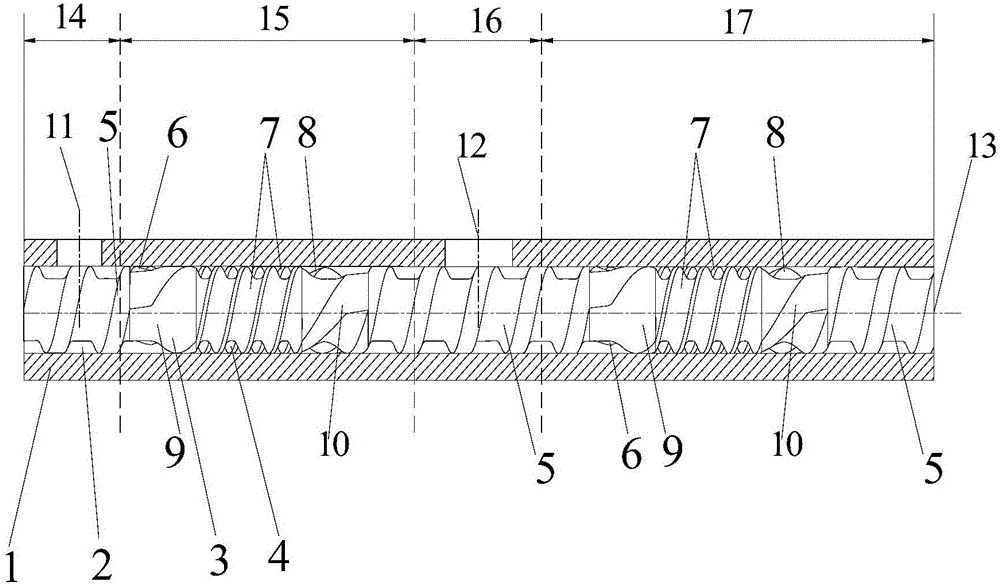

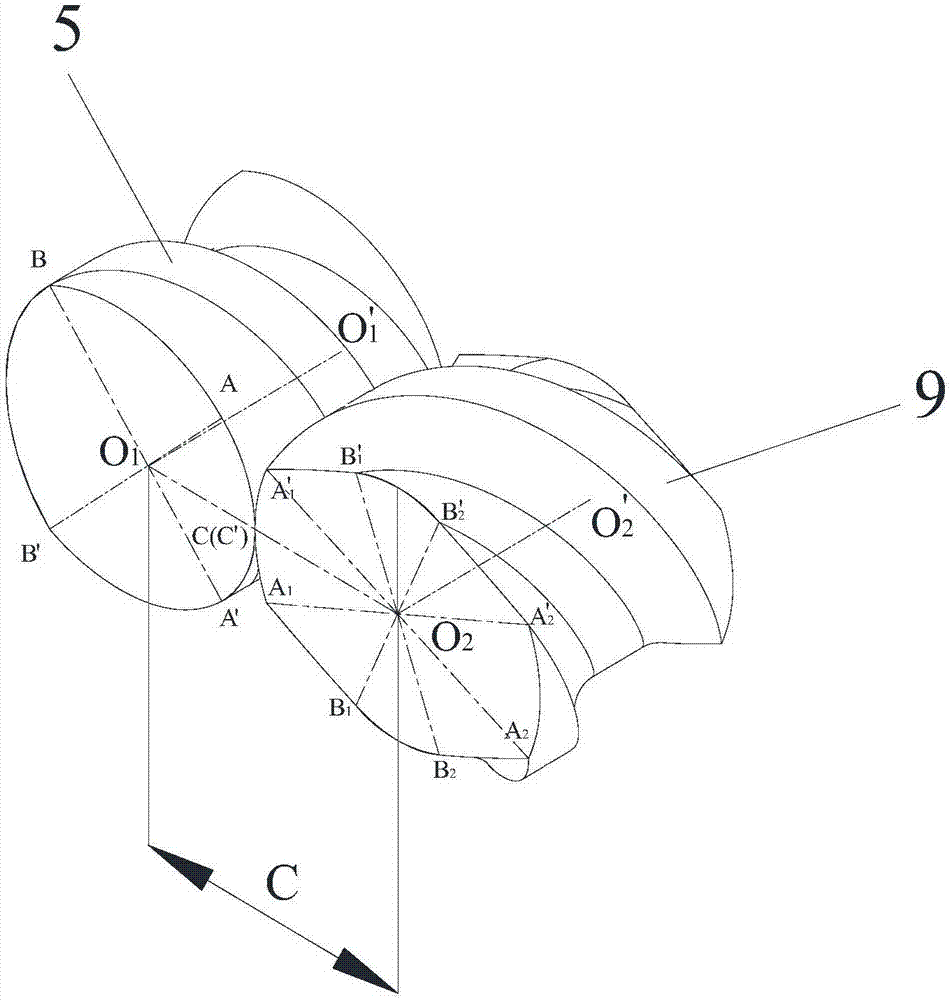

Homodromous self-cleaning double-screw extrusion machine with number of starts gradually changing and with whole-process self-cleaning function and machining method thereof

The invention discloses a homodromous self-cleaning double-screw extrusion machine with the number of starts gradually changing and with a whole-process self-cleaning function and a machining method thereof. A screw assembly of the extrusion machine comprises a first screw and a second screw, wherein the first screw and the second screw rotate at equal speed and in the same direction and are kept engaged. The first screw comprises a first single-start thread element, a first transitional element, a multi-start thread element, a second transitional element and a second single-start thread element which are connected in sequence. The second screw comprises a first single-start thread element, a third transitional element, a multi-start thread element, a fourth transitional element and a second single-start thread element which are connected in sequence. The machining method includes the steps that materials are conveyed through rotation of the first screw and the second screw, and constituents in the materials are promoted to be mixed through a structure of gradually changing numbers of starts of threads; a runner expands, contracts and expands again in sequence, so that the materials are divided, combined and divided again in the runner for chaotic mixing; self-cleaning is achieved through mutual wiping of the first screw and the second screw.

Owner:GUANGDONG IND TECHN COLLEGE

Same-direction self-cleaned twin-screw extruder with baffle plates and processing method thereof

ActiveCN104527025AImprove delivery efficiencyAvoid unstable product qualityTransportation and packagingRotary stirring mixersFistEngineering

Owner:GUANGDONG IND TECHN COLLEGE

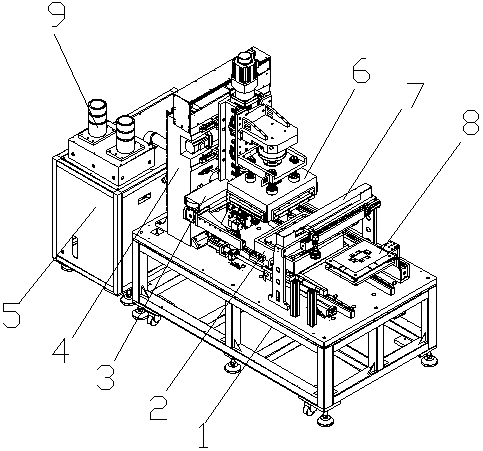

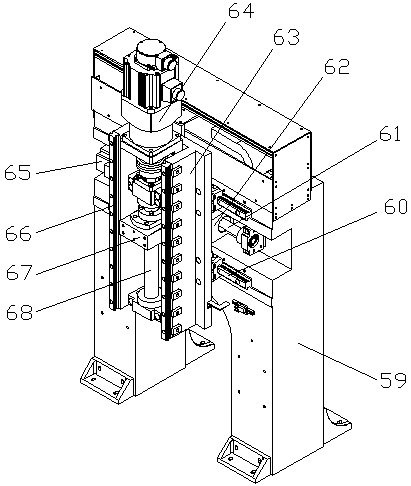

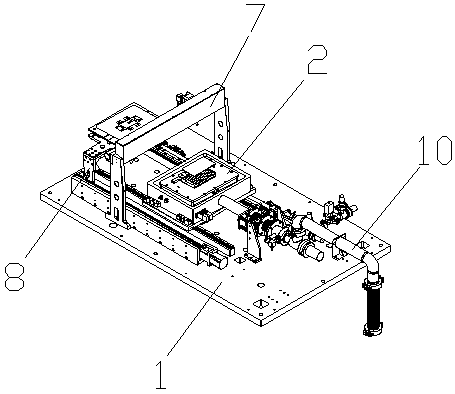

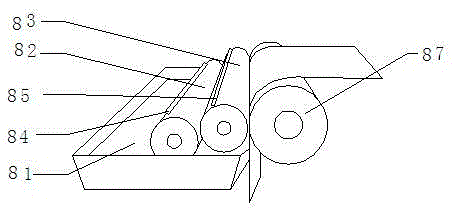

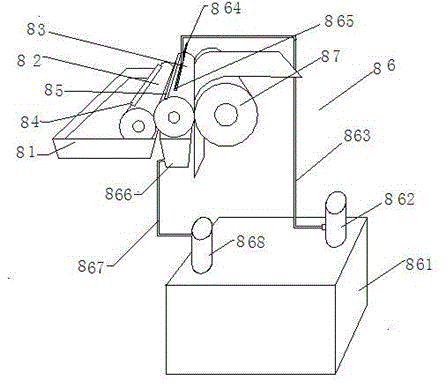

Automatic-alignment high-precision vacuum laminating machine

InactiveCN108327379AAvoid it happening againQuality improvementLaminationLamination apparatusDistribution controlGlass sheet

The invention relates to an automatic-alignment high-precision vacuum laminating machine. The automatic-alignment high-precision vacuum laminating machine comprises a frame, a power distribution control cabinet, a laminating mechanism and an air pumping mechanism and is characterized in that the laminating mechanism comprises an upper box feeding mechanism, an upper box jig component, a lower boxfeeding device, a lower box jig component and a glass sheet conveying device, the upper box jig component is slidably arranged on the right of the upper box feeding device along a Z-axis direction, the lower box jig component coordinated with the upper box jig component is arranged on the lower box feeding device along an X-axis direction, the left side of the lower box jig component is sequentially communicated with the air pumping mechanism and an exhaust component through a vacuum pipe component, and the glass sheet conveying device is arranged on the frame along the X-axis direction and located between the upper box jig component. The automatic-alignment high-precision vacuum laminating machine has the advantages that the upper box jig component and the lower box jig component are coordinated to form a sealed space, the air pumping mechanism is used to vacuumize the sealed space, workpiece lamination under a vacuum state can be achieved, bubbles between workpieces can be avoided, and the quality of finished products are increased greatly.

Owner:DONGGUAN UNIV OF TECH

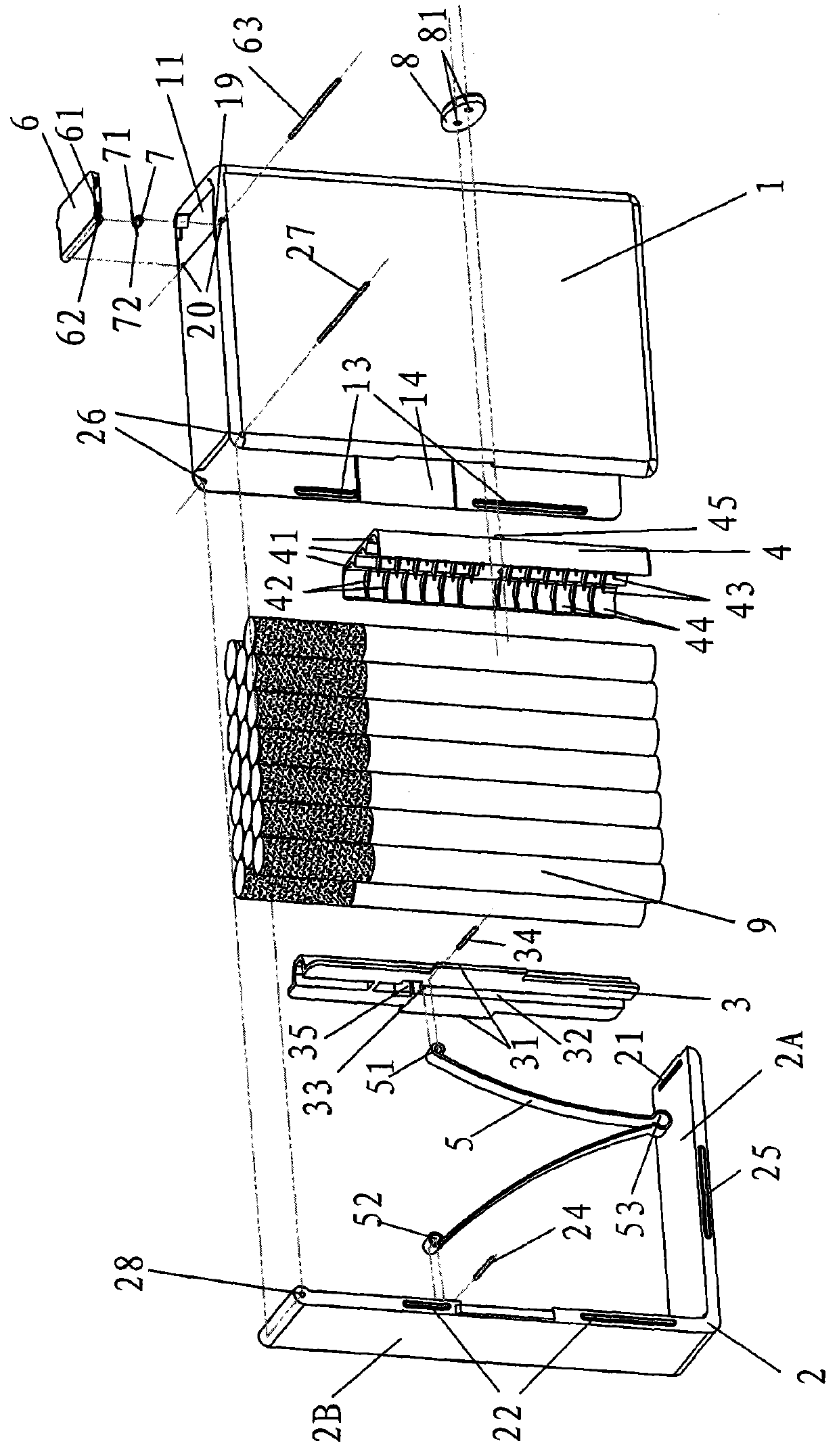

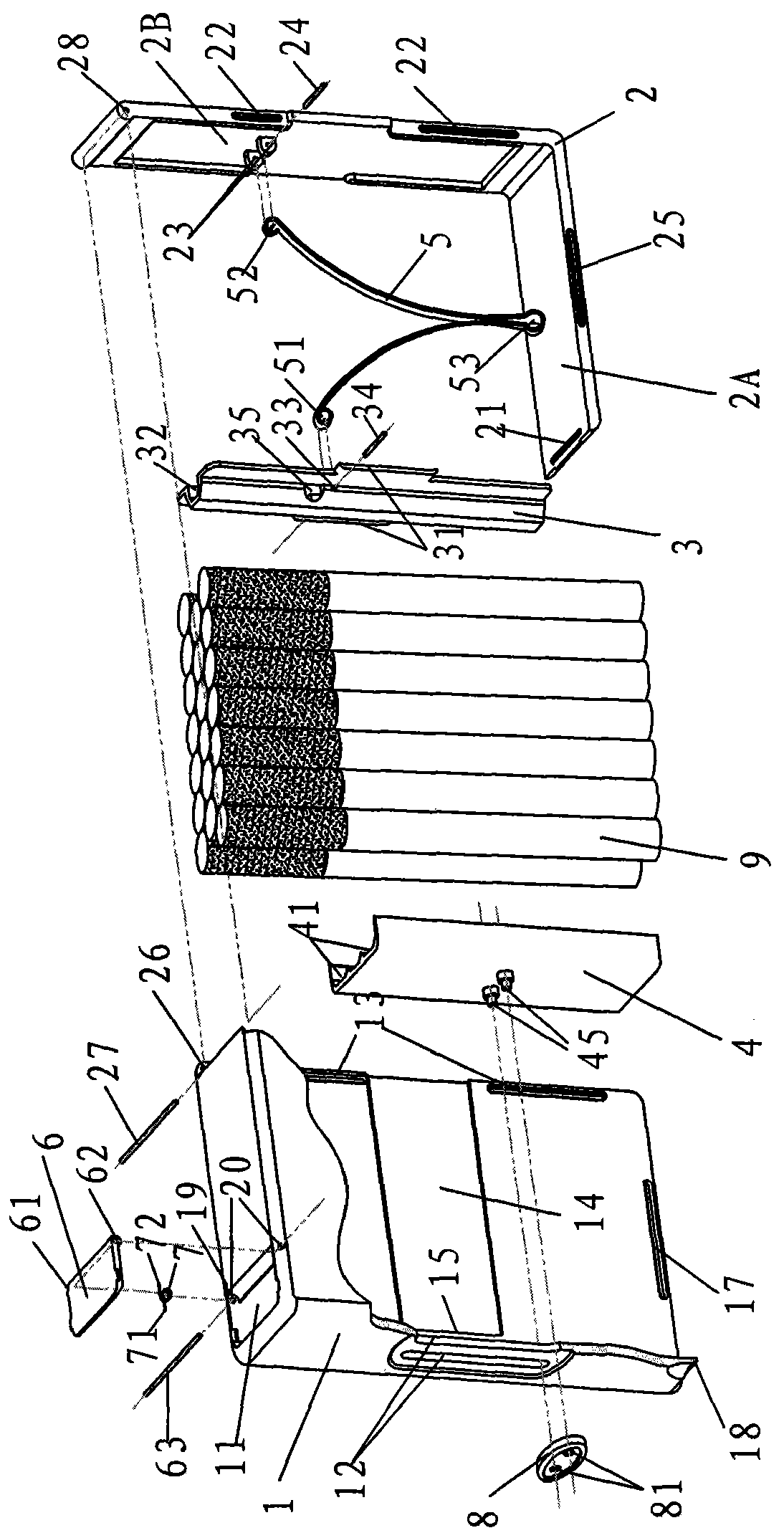

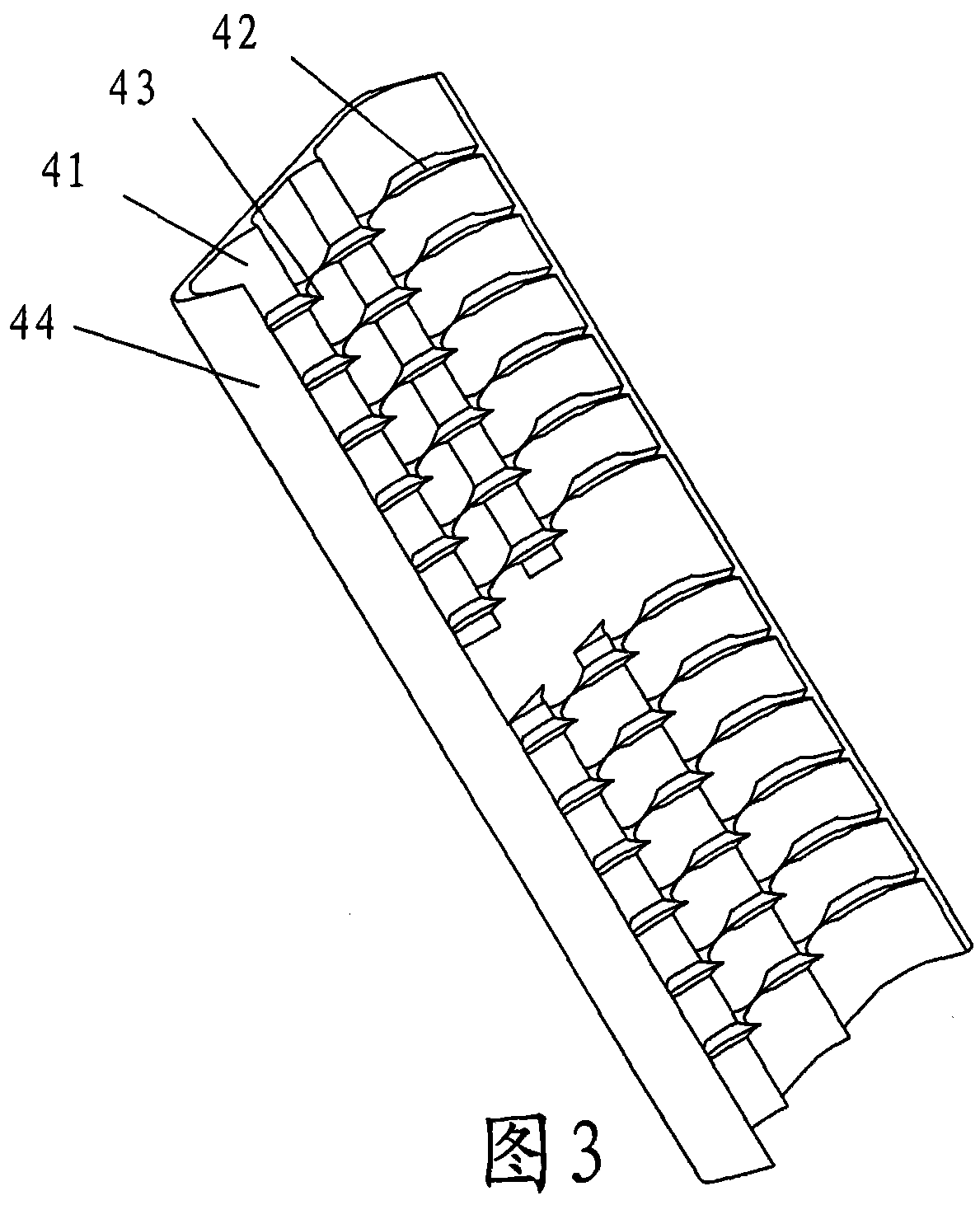

Controllable telescopic cigarette case

InactiveCN101028139AAvoid misalignmentReduce volumeContainers for flexible articlesPackaging cigaretteMovement controlPush pull

Owner:DONGGUAN TIANXIN METAL PROD

Co-rotating differential multi-screw extruding machine with gradually changing type thread number and machining method thereof

InactiveCN107031015AFacilitate interface updatesIncrease the exhaust areaDifferential equationEngineering

The invention discloses a co-rotating differential multi-screw extruding machine with the gradually changing type thread number and a machining method thereof. A first threaded rod in the extruding machine comprises two single-start thread elements, three single-start-gradually-changed-to-double-start transition thread elements, a double-start thread element and three double-start-gradually-changed-to-single-start transition thread elements; and a second threaded rod comprises two double-start thread elements, three double-start-gradually-changed-to-four-start transition thread elements, a four-start thread element and three four-start-gradually-changed-to-double-start transition thread elements. According to the machining method, a threaded rod mechanism achieves five enhancement mixing mechanisms by adopting the structure of the threaded rod mechanism, and conducts all-sided enhancement mixing on materials.

Owner:徐百平

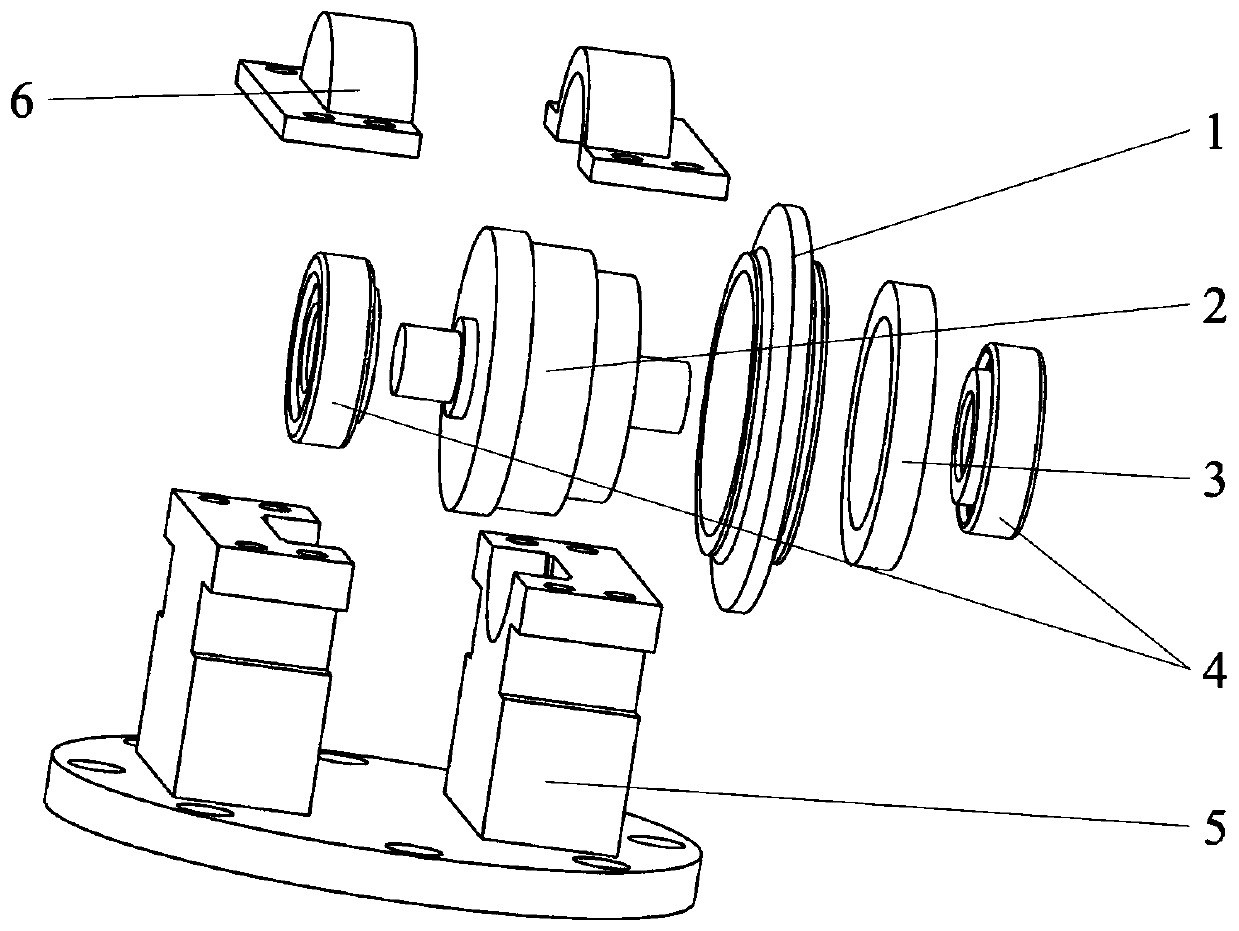

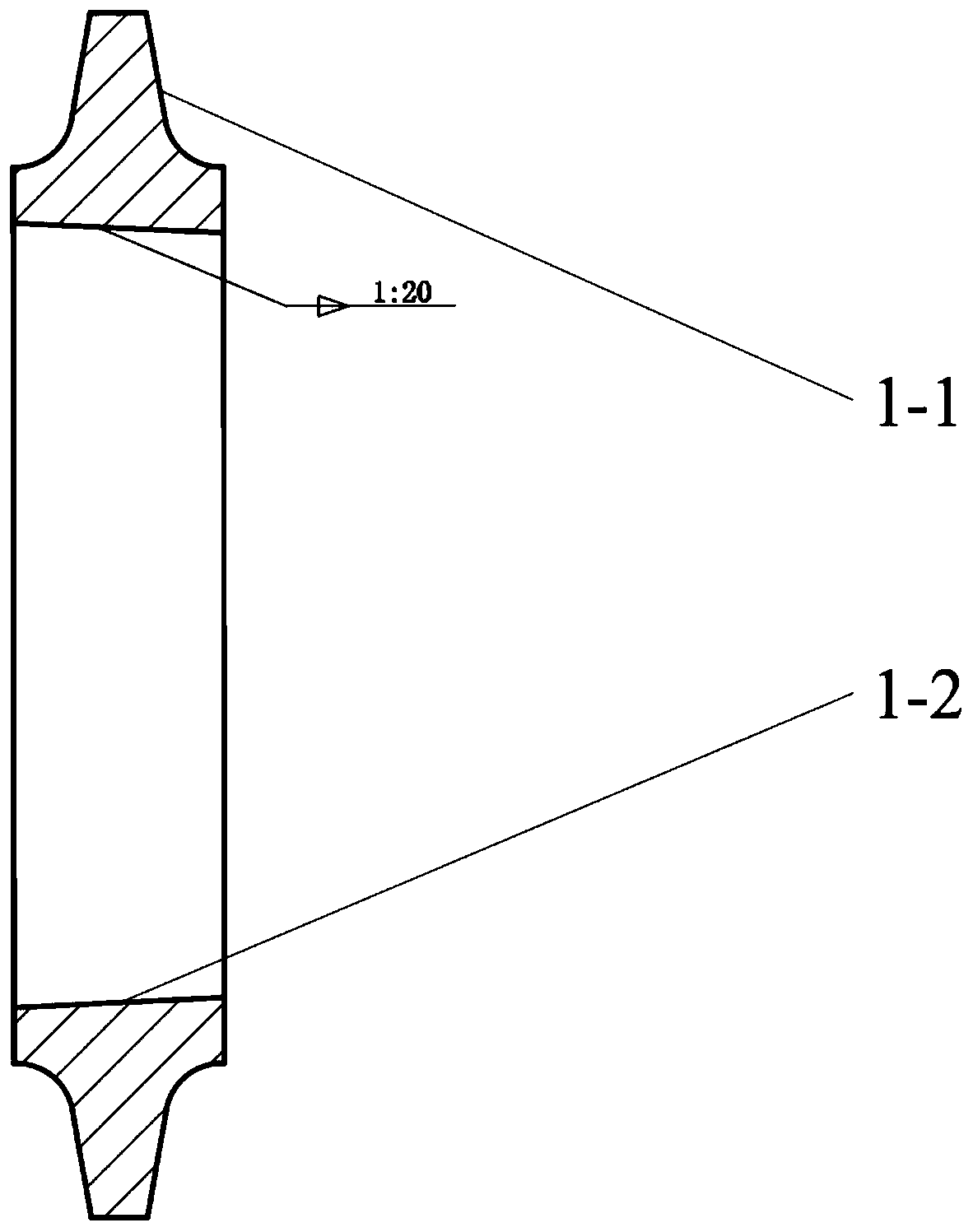

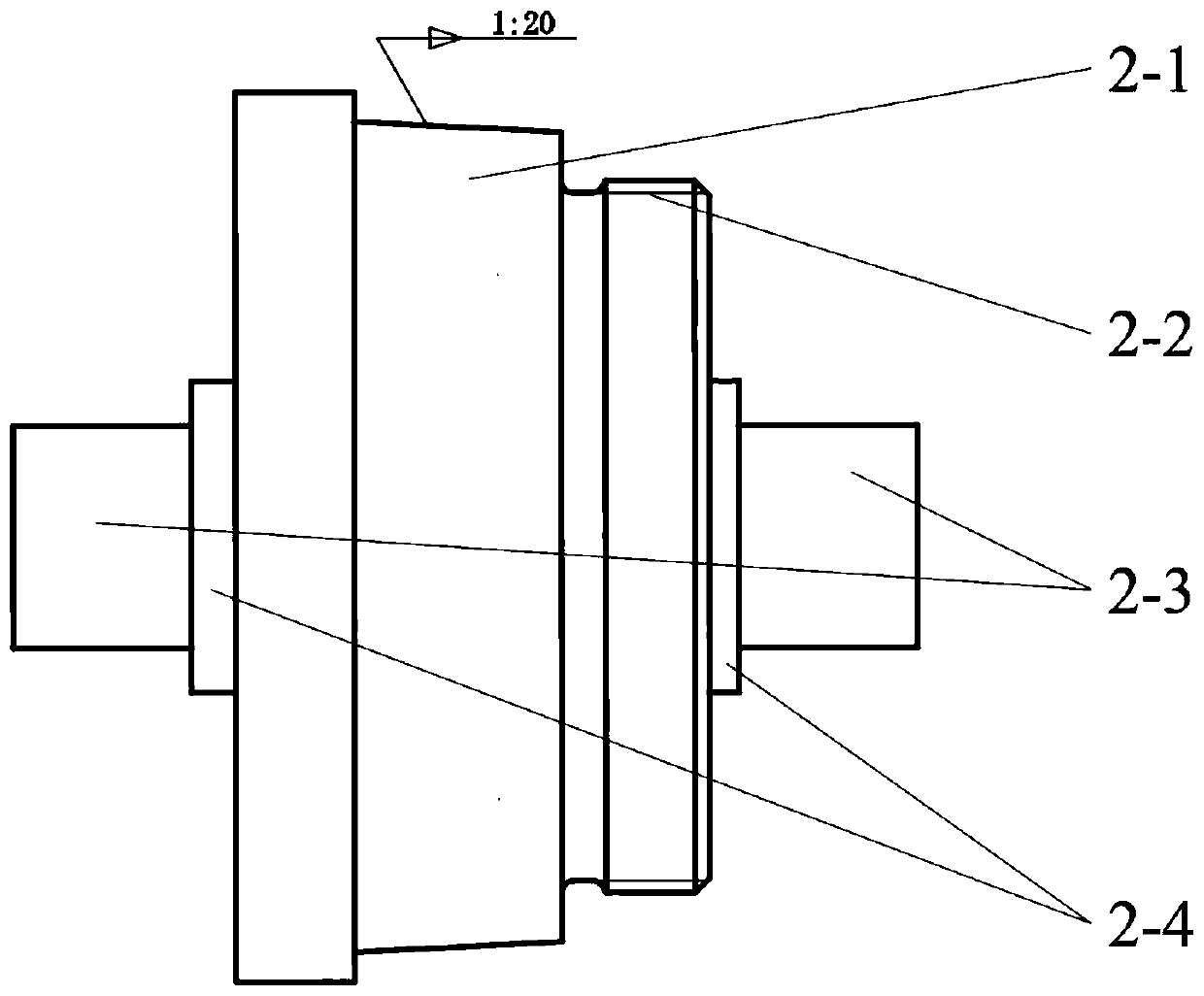

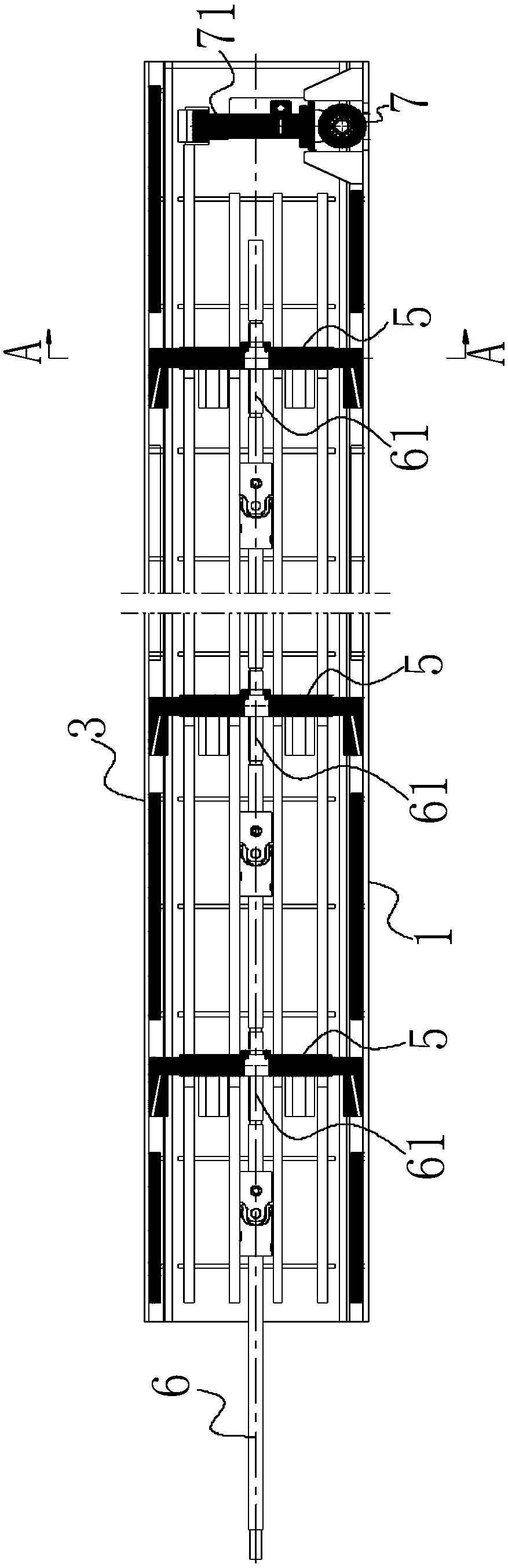

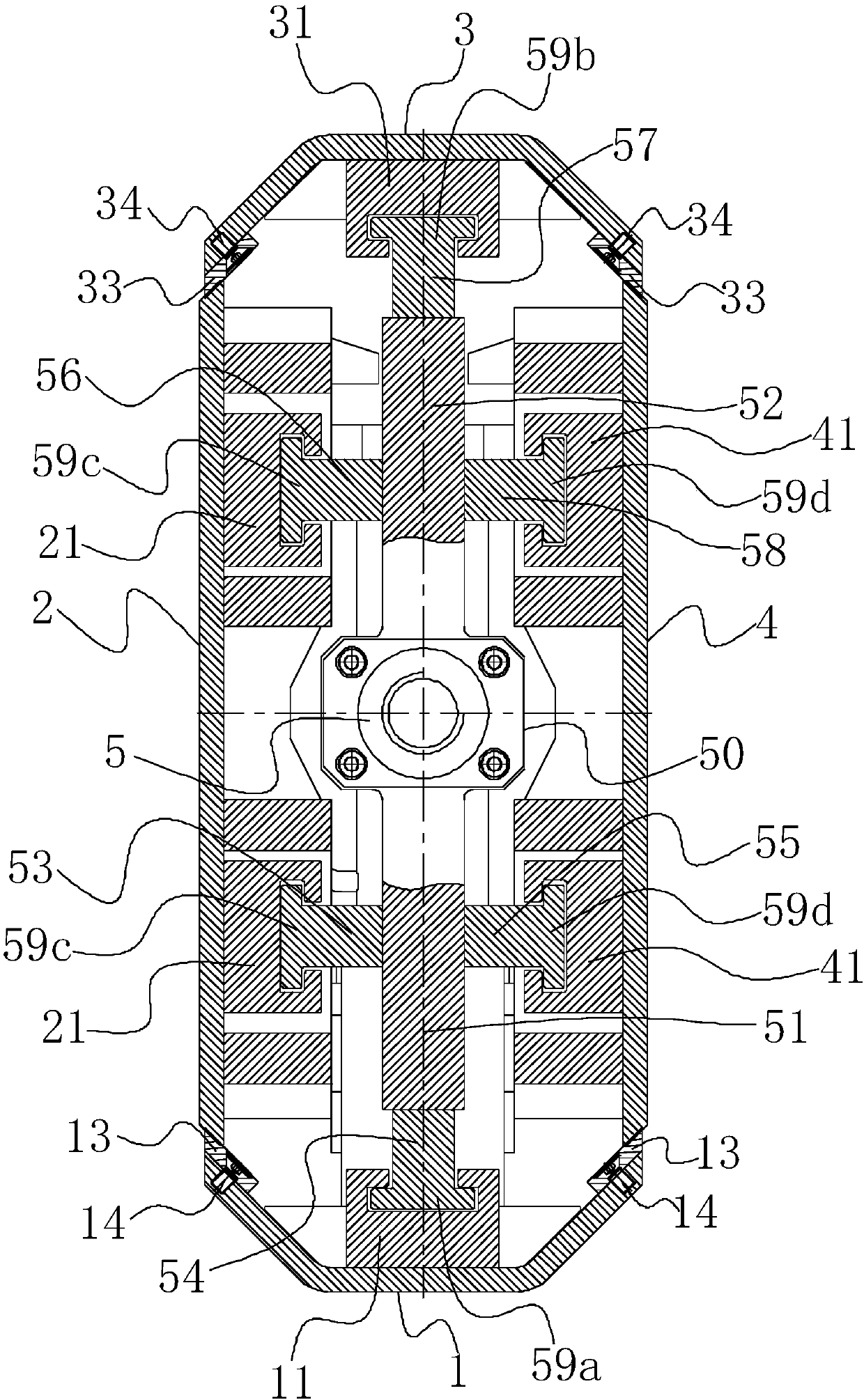

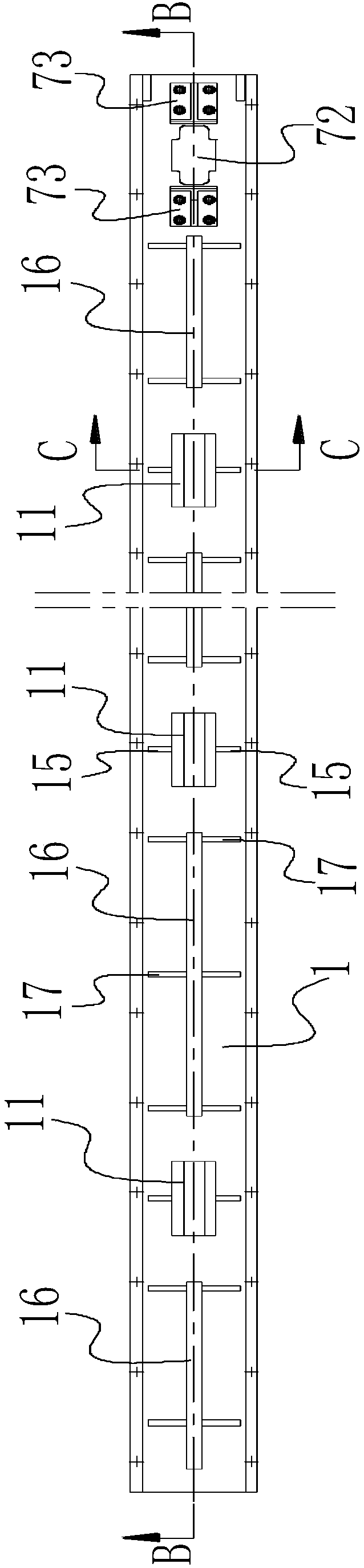

Scaling hob and cutter holder for TBM test bed

InactiveCN111091748AEasy detection and analysisImprove experimental efficiencyEducational modelsStructural engineeringMechanical engineering

The invention discloses a scaling hob and a cutter holder for a TBM test bed. The invention belongs to the field of TBM test beds, and particularly relates to a scaling hob and a cutter holder for a TBM test bed. The problems of high cost, large mass and size, long experiment time and inconvenience in disassembly and assembly due to the fact that a hob used by a test bed is generally a hob actually used on a TBM are solved. The scheme of the invention comprises that the scaling hob comprises the cutter holder, two supports are arranged on the cutter holder, the two supports are adjacently arranged, grooves I are formed in the supports, the grooves I in the two supports are oppositely formed, bearings are arranged in the grooves I, bearing covers are arranged around the grooves I, the two bearings are connected with a same cutter shaft, the cutter shaft is sleeved with a cutter ring, and the cutter shaft is sleeved with a baffle. The device is simple in structure, the cutter ring can bedisassembled and assembled under the condition that the bearing is not taken down, follow-up analysis and detection of the cutter ring are facilitated, the experiment efficiency can be remarkably improved, and the cost is saved.

Owner:CHINA RAILWEY ENG SERVICE CO LTD +1

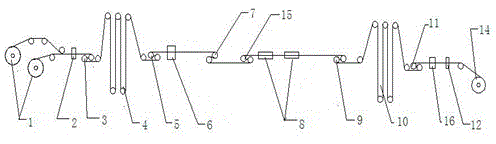

Production line for roller-coated color steel plate

InactiveCN102975019AGuaranteed uptimeGood molding effectOther manufacturing equipments/toolsRotary pressesProduction lineSurface roughness

The invention provides a production line for roller-coated color steel plates. Steel bands at all process sections are flattened through a plurality of tension rollers and stable and constant tension is particularly provided for a roller coating section. Moreover, since corona treatment is conducted to the surfaces of the steel bands before the steel bands enter the roller coating section to form a plurality of pits on the surfaces of the steel bands, the surface roughness of the steel bands is improved, the adhering force between the surfaces of the steel bands and color pattern layers is improved, the color pattern layers are not apt to peel off and the formability of the steel bands is improved.

Owner:LIAONING CHAOSHUO TOMA TECH STEEL PLATE PRINTING

Eye washing device

The invention discloses an eye washing device. The eye washing device comprises a housing. The housing comprises an eyewash containing chamber, an eyewash discharging chamber and an eye cleaning chamber. A chamber opening is formed in the eye cleaning chamber, a sealing ring is arranged at the chamber opening, a strip-shaped protrusion is arranged on the sealing ring, and a first communication hole communicated with the eyewash containing chamber and a second communication hole communicated with the eyewash discharging chamber are also formed in the eye cleaning chamber. The eyewash containingchamber is of a closed cavity structure with a liquid injection port. A first adjustment component is arranged in the eyewash containing chamber. The eyewash discharging chamber is a closed cavity with a liquid outlet. A second adjustment component is arranged in the eyewash discharging chamber. The eye washing device is provided with chambers with different functions to separate an eyewash to ensure the eye washing environment. At the same time, the eyewash is prevented from being dropped and wasted when the eye washing device is matched with the eyes, and meanwhile, the eye washing device is more convenient to use.

Owner:枣庄瑞衡建筑工程有限公司

Stainless steel pipe machining method

InactiveCN107881326AThere will be no deformationGuaranteed tight fitRare-earth elementHigh intensity

The invention discloses a stainless steel pipe machining method. The stainless steel pipe machining method comprises the following steps that (1) liquid steel is smelted, specifically, a, sintering isconducted, b, smelting is conducted, and c, nitrogen is introduced; (2) continuous casting is conducted, specifically, a raw material treated through the step (1) is subjected to continuous steel casting through a continuous casting machine, and a round pipe blank is obtained; and (3) fixed cutting and acid pickling are conducted, specifically, the pipe plank is cut into blanks being 4-6 m long through a cutting machine, then the blanks are subjected to acid pickling and passivating through stainless steel acid pickling and passivating solution, and heating is conducted. The nitrogen contentof the stainless steel is up to 3.5-5 wt%, and the effect that a stainless steel pipe has good corrosion resistant, tensile strength and high strength is ensured; meanwhile, rare earth elements and copper elements are added for synergistic effect, killed bacterial microbial species in stainless steel is effectively increased, time is greatly shortened, the efficiency is improved, and the corrosionresistance of stainless steel is improved.

Owner:吴文君

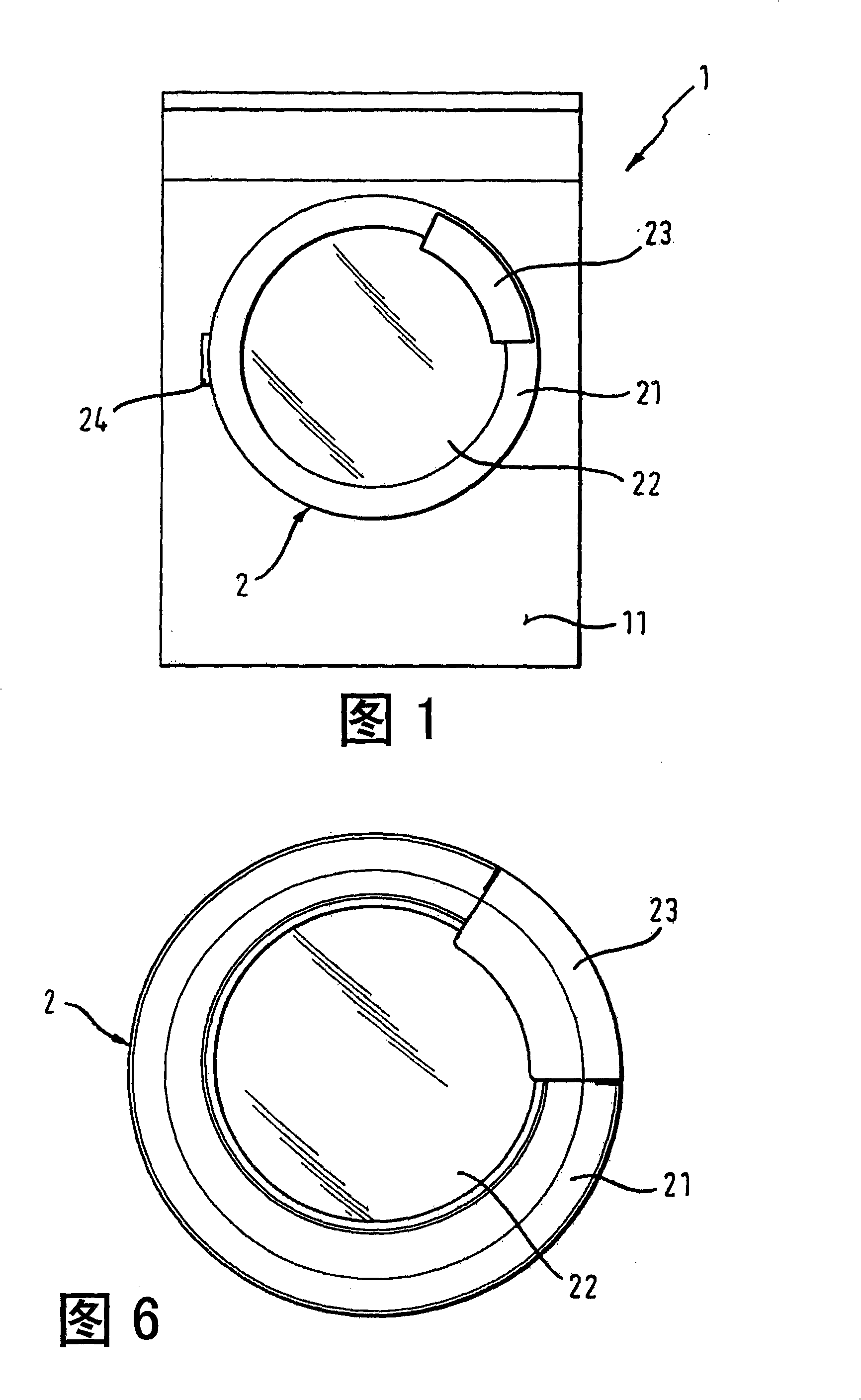

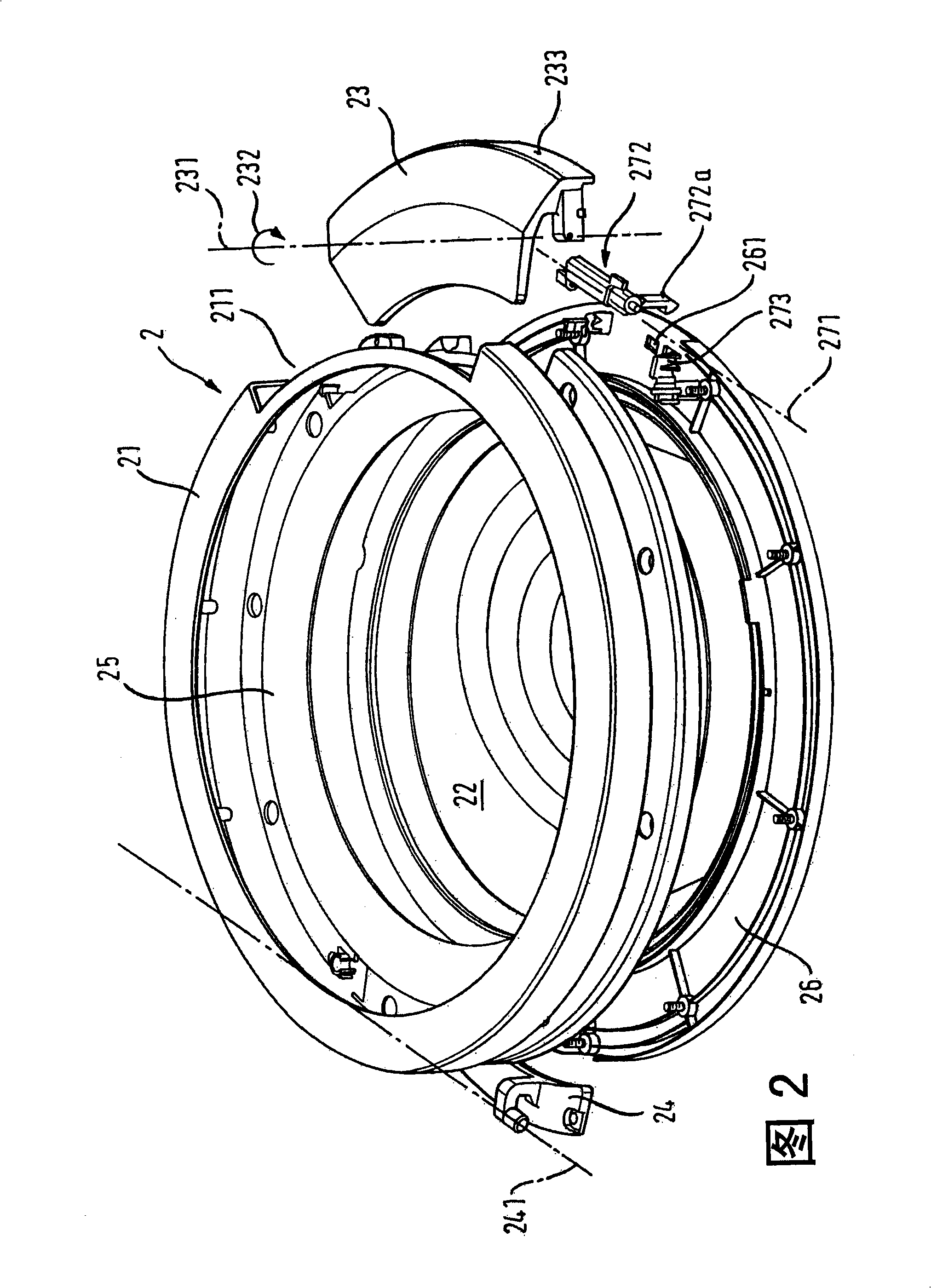

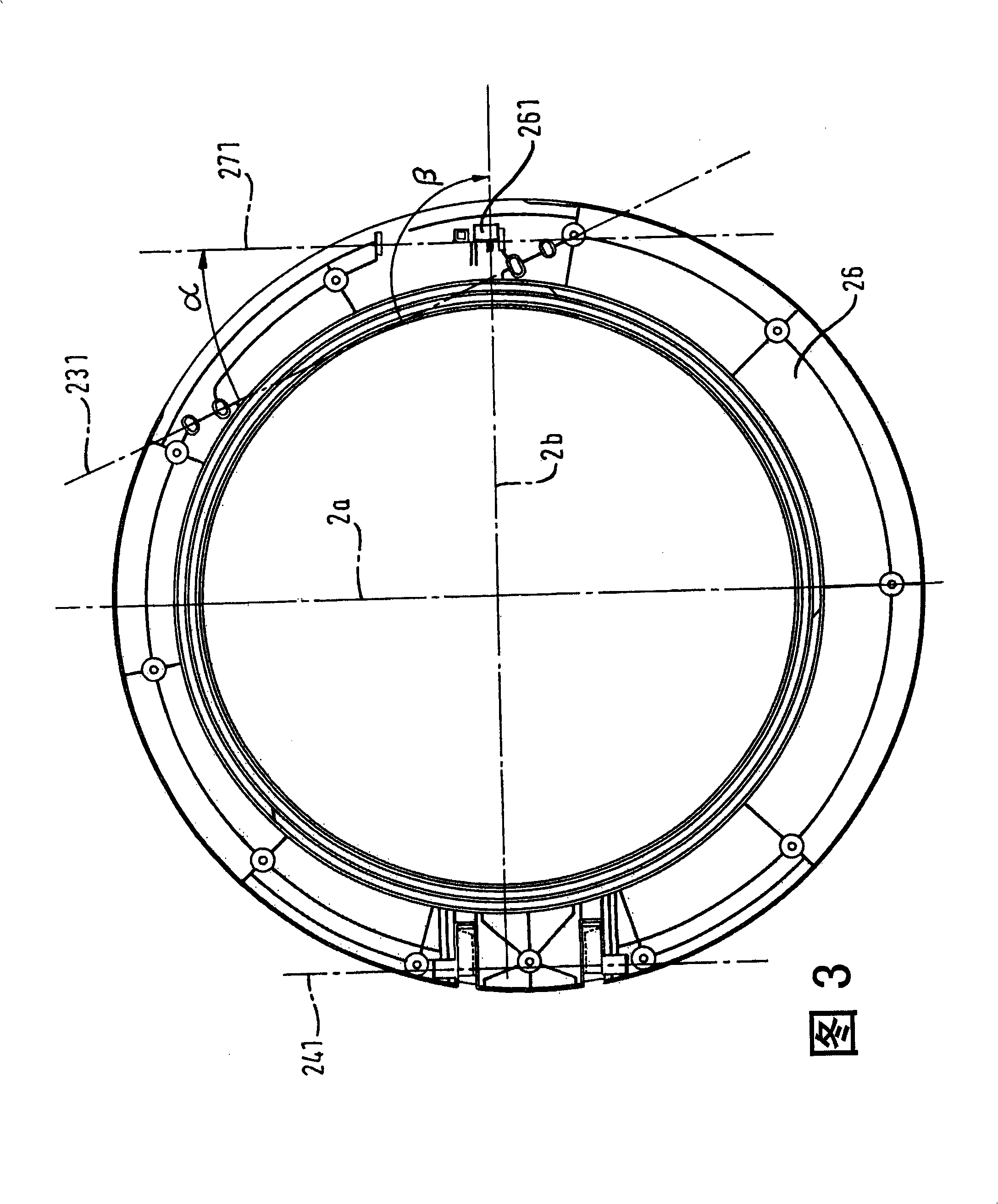

Door for a domestic appliance

InactiveCN101495696AGuaranteed tight fitOther washing machinesTextiles and paperLaundryMechanical engineering

The invention relates to a door for a domestic appliance (1), comprising a displaceable handle element (23) that is mounted essentially above the horizontal centre line of the door (2), a hinge device (24) that can rotate about an essentially vertical hinge axis (241) and that is used to couple the door (2) to the domestic appliance (1) and a latch device (27), that has a displaceable latch bolt (272a) and that can be mechanically coupled to the handle element (23) in such a way that the actuation of the handle element (23) allows the latch device (27) to be actuated. The latch device (27) is mounted on the door (2) in such a way that when said door (2) is closed, the latch bolt (272a) lies on an essentially horizontal centre line of the opening of the domestic appliance (1) that may be closed by the door (2). The invention also relates to a laundry care appliance comprising a door of this type.

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

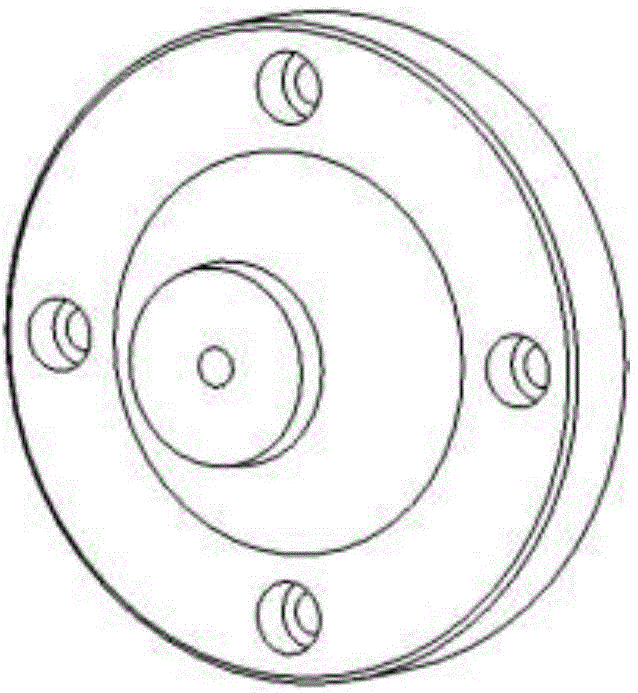

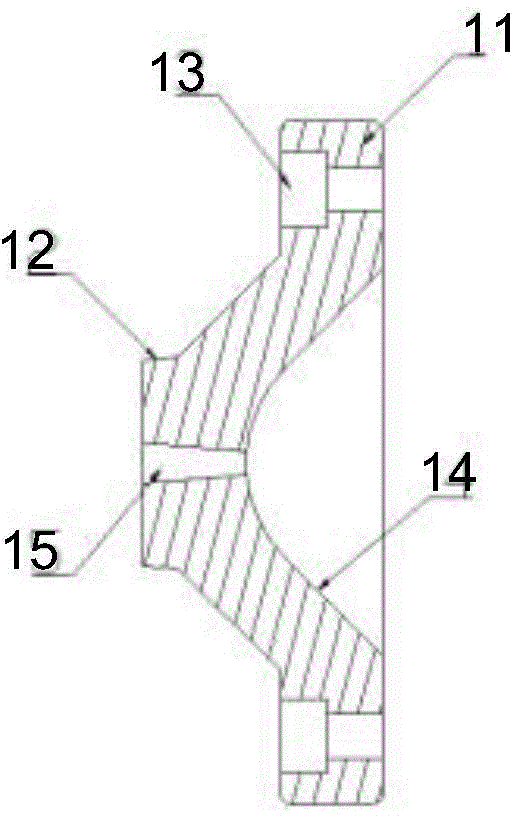

Point-type plastic filling device of injection mold

The invention provides a point-type plastic filling device of an injection mold. The point-type plastic filling device comprises a sprue bush, a mechanical plate part, a pushing plate and a lengthened injection head. The sprue bush is machined by virtue of a turning lathe. The sprue bush comprises a sprue bush fixing seat which is arranged at the bottom, a conical sealing compound which is arranged at the front end, a fixed screw, and an arc contact surface and a plastic feeding opening which are formed at the bottom of the sprue bush fixing seat. The point-type plastic filling device is integrally designed and machined, and the sprue bush is arranged between a mold mechanical plate and the pushing plate, so that the service life of the mold can be prolonged, and the machining efficiency of the injection molding procedure can be effectively improved.

Owner:北京世东凌云科技有限公司

An anti-loosening threaded connector and its components

ActiveCN102751617BPrevent looseningSolve the problem of displacement in the direction of separationEngagement/disengagement of coupling partsCouplings bases/casesShock resistanceScrew cap

The invention relates to a locking threaded connector and an assembly thereof. The locking threaded connector comprises a shell with the front end being a plugging end and a connection screw cap which is assembled forwards on the shell in a locking way, wherein the front part of the shell is provided with a plugging part for being plugged into an adaptive connector, a corrugated spring is sleeved on the plugging part, the front side of the corrugated spring is provided with a jacking surface which is in jacking fit with the end surface of the plugging end of the shell of the adaptive connector, the outer wall of the shell is provided with a pressure-bearing wall which is used for preventing the backward movement of the corrugated spring when the adaptive connector jacks the corrugated spring, and the pressure-bearing wall is nested inside the connection screw cap; and the problems that an electric connector which realizes the shock resistance and loosening prevention through the corrugated spring moves in the direction to be separated from the adaptive connector when the electric connector is subjected to the force in the separation direction can be solved.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

Compound tool for processing guide pipe hole of cylinder cover and conical surface of valve seat

InactiveCN102189297AEliminate repetitive positioning errorsGuaranteed runout accuracyReaming toolsReamerKnife handles

The invention discloses a compound tool for processing the guide pipe hole of a cylinder cover and the conical surface of a valve seat. The compound tool comprises a tool handle, a reamer, and a blade; a reamer clamping mechanism is movably clamped in the tool handle; and the blade is movably arranged on the conical surface of the tool handle through a compressing mechanism. The compound tool is a split compound tool; the reamer and the blade can be replaced unlimitedly, the disadvantages brought by unbalanced service lifer of the reamer and the blade are avoided, the tool handle is recycled, the raw materials are saved and processing cost is reduced, and simultaneously, the processing quality and the production efficiency are effectively improved.

Owner:ZHENGZHOU DIAMOND PRECISION MFG

Novel charging matching mechanism for electric vehicle

ActiveCN112134066AGuaranteed tightnessGuarantee the safety of useCouplings bases/casesTwo-part coupling devicesElectrical connectionElectric cars

The invention relates to the technical field of related structures of electric vehicle accessories, and discloses a novel charging matching mechanism for an electric vehicle, which comprises a socketshell and a plug seat. The socket shell is mounted on a vehicle body through screws. A sealing cover is movably mounted at a port of the socket shell. A jack electric connector is mounted on the innerside of the socket shell. The jack electric connector penetrates through the socket shell through a wire to be electrically connected with a power source. Conductive heads are installed on the end face of the plug seat, jacks are formed in the jack electric connector, and the conductive heads are matched with the jacks of the jack electric connector. Sealing elastic pieces are symmetrically installed at the top and the bottom of the inner side of the socket shell. Arc-shaped limiting grooves matched with the sealing elastic pieces are formed in the ports of the jack electric connector, and longitudinal clamping grooves are formed in the bent inner side faces of the sealing elastic pieces. According to the novel charging matching mechanism for an electric vehicle, the sealing performance of the jack electric connector in the socket shell is effectively guaranteed, the jack electric connector is subjected to double sealing, and the use safety of an electric vehicle charging structure isguaranteed.

Owner:无锡铃派科技有限公司

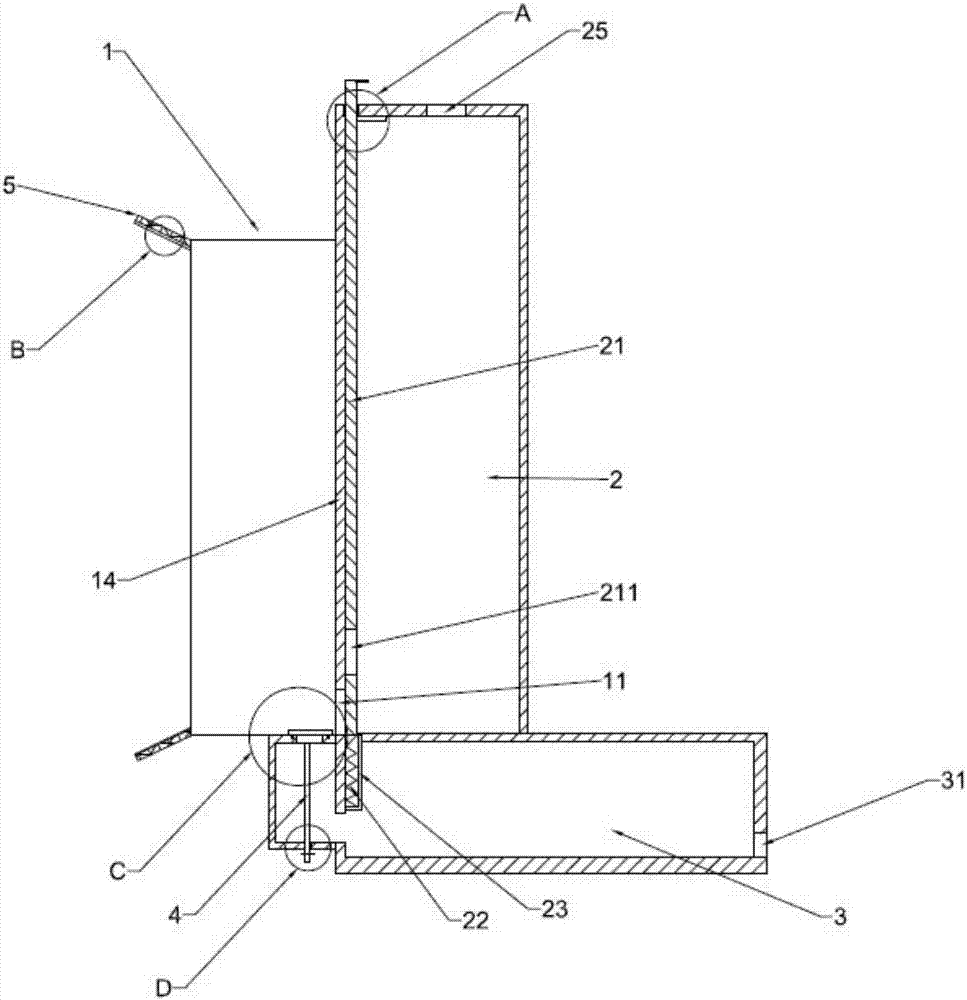

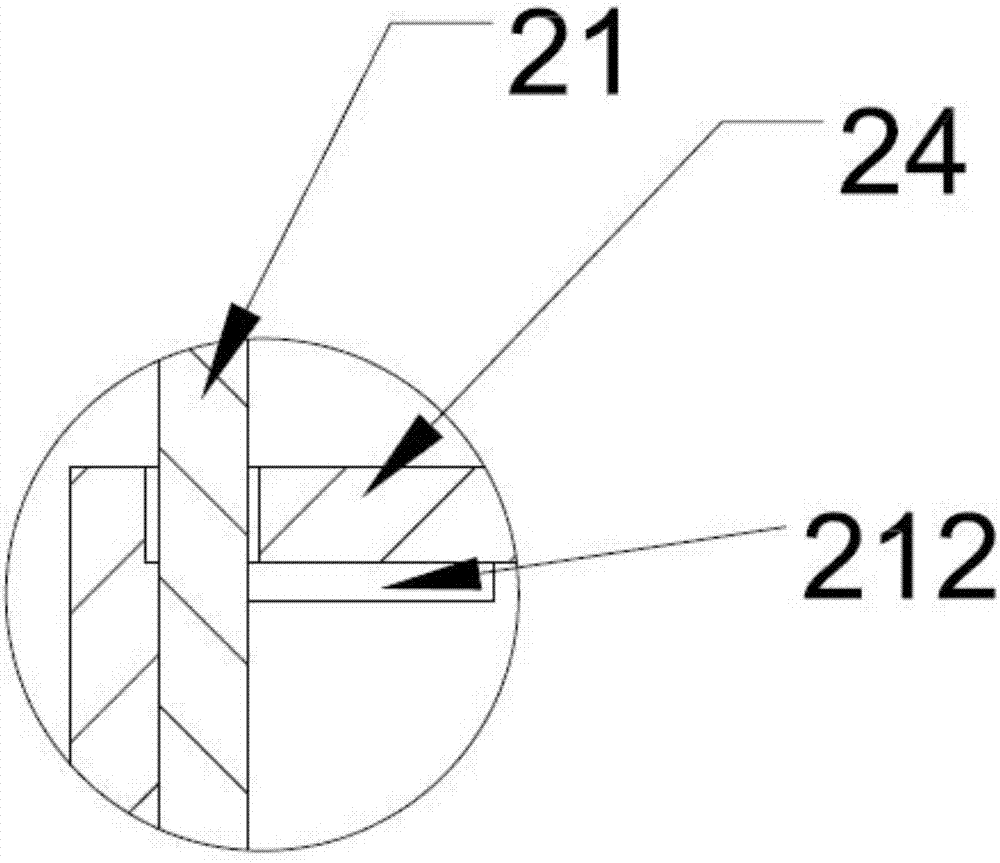

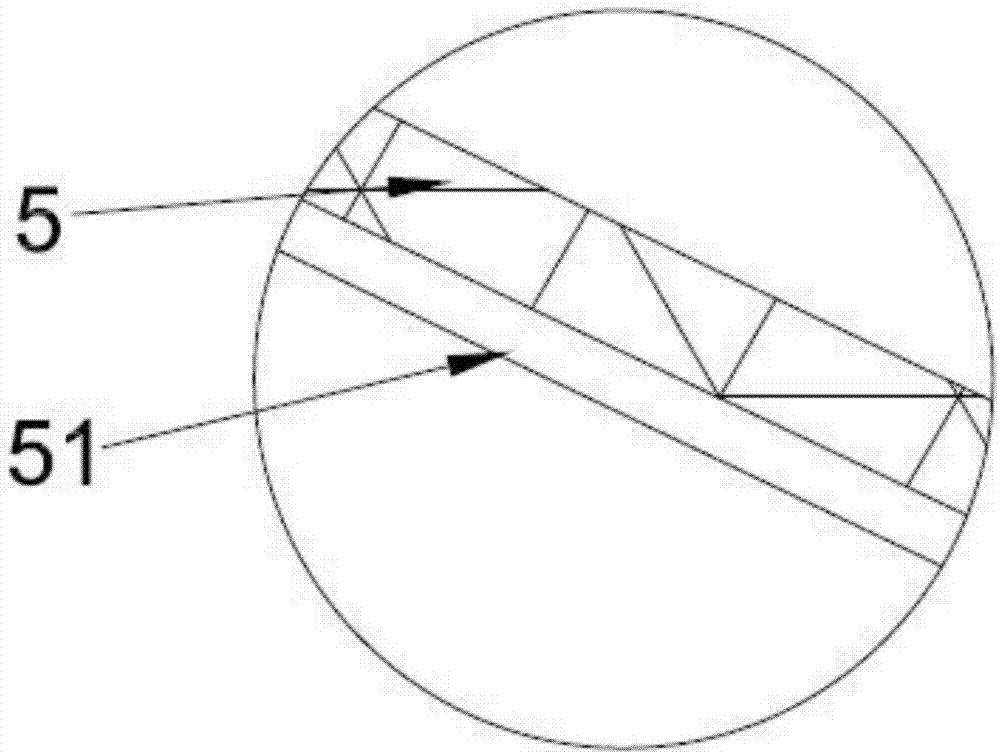

Gravity flow water quality current divider

PendingCN109356258ASimple structureEasy to installGeneral water supply conservationSewage drainingWater qualityCurrent divider

The invention discloses a gravity flow water quality current divider. The gravity flow water quality current divider comprises a current divider body, wherein the current divider body comprises an upper cover plate, a rotating apparatus, an elbow, a water receiving hopper, and a shell, wherein the rotating apparatus is fixed on the upper cover plate, and the rotating apparatus comprises an upper rotating body, a lower rotating body and a ring-shaped component; the upper part of the elbow is communicated with the lower end of the lower rotating body, and the elbow can be driven by the rotatingapparatus to rotate by adopting the center axis of the rotating apparatus as an axis; the water receiving hopper is arranged below the elbow, the lower part of the water receiving hopper is communicated with a water outlet pipe, and when the rotating apparatus rotates to a predetermined angle, the lower part of the elbow is communicated with the water receiving hopper; and a water inlet pipe is fixed on the top of the shell, the elbow, the rotating apparatus and the water receiving hopper are arranged in the shell, and a water outlet pipe extends out of the lower end of the shell. The gravityflow water quality current divider has the characteristics of simple structure, convenience in installation, flexibility in operation, stability in operation and the like, the pollution can be effectively prevented, and the rainy water utilization efficiency can increased. Since the gravity flow water quality current divider has no structure such as a valve, a tee joint and the like, the loss of water head can be reduced, the discontinuous rainy water division can be realized, and the blockage problem can be avoided.

Owner:BEIJING TIDELION S&I RAINWATER HARVESTING TECH CO LTD

Telescopic inner die and T-shaped pile die provided with same

InactiveCN110722667AEasy to put inEasy to take outCeramic shaping mandrelsCeramic shaping coresStructural engineeringMechanical engineering

The invention discloses a telescopic inner die. The telescopic inner die comprises a frame body sequentially encircled by a plurality of die plates, wherein the die plates are the same in length, a rotatable transmission rod is arranged in the frame body in a length direction, and the transmission rod is provided with a plurality of middle die assemblies at intervals in the axial direction; each middle die assembly comprises a middle moving block, a guide rod stretching out towards the corresponding die plate from the middle moving block, and a slide block fixed to one end of the guide rod andaway from the middle moving block; each die plate is provided with a slide way allowing the corresponding slide block to carry out reciprocating slide and inclined relative to the central axis of thetransmission rod; and the transmission rod is capable of driving the die plates to stretch towards a direction away from the transmission rod simultaneously or retreat towards the direction of the transmission rod simultaneously while driving the middle die assemblies to carry out reciprocating movement in the axial direction. The telescopic inner die has the advantages of being reasonable in structure, variable in size, and convenient to draw out.

Owner:周兆弟

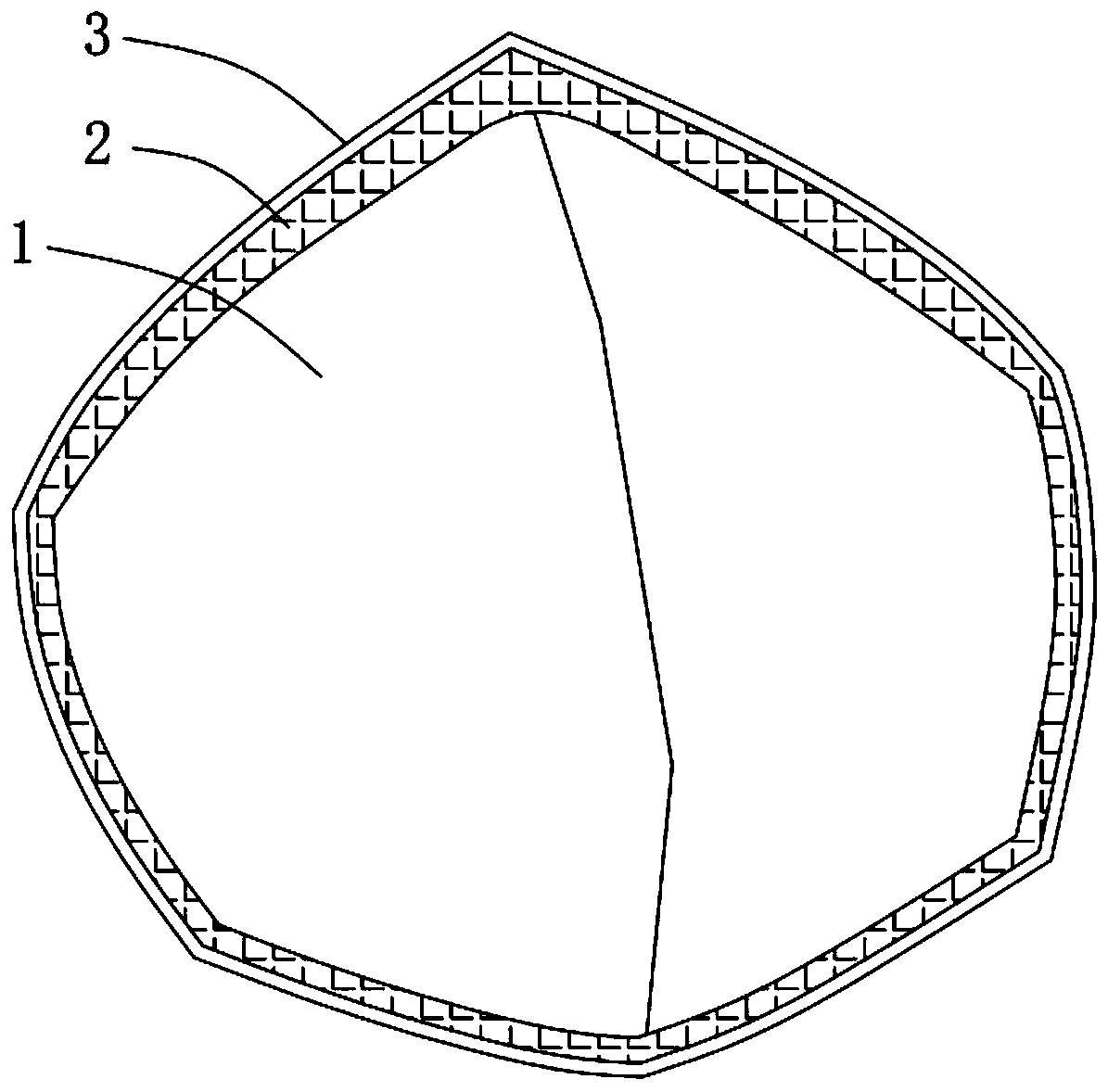

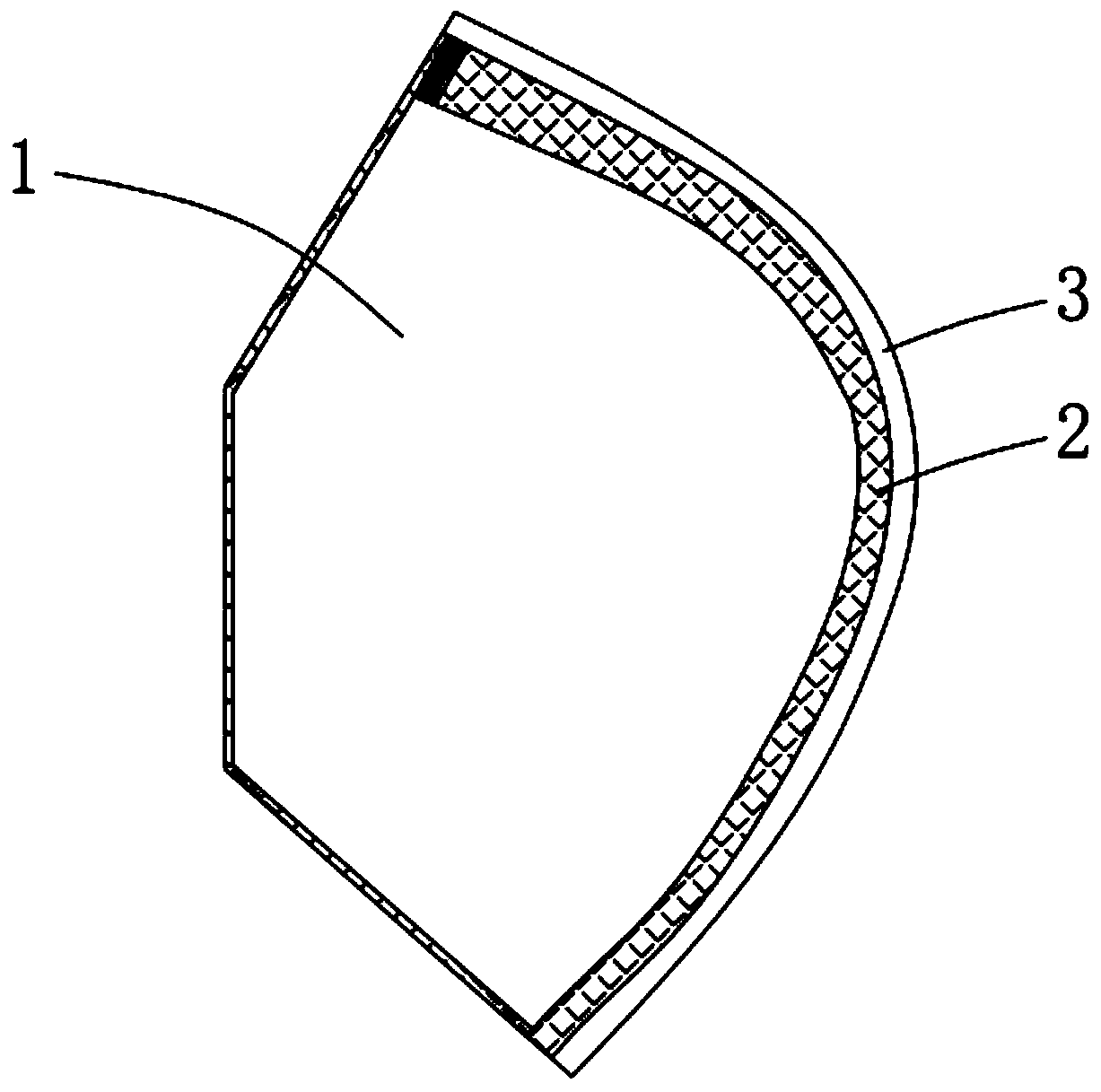

Adhesive mask

The invention relates to the technical field of medical equipment, in particular to an adhesive mask. The mask comprises a mask body, wherein a fitting part is arranged on the mask body; the fitting part is used for being attached to a local area of the face of a user. The fitting part has stickiness, so that the fitting part can be attached to the face of the user, the fitting part is annular. After the user wears the mask, the fitting part surrounds the mouth and the nose of the user, and the inner side of the fitting part is further separably covered with a film coating layer., The mask body is attached to the face of the user through the fitting part in an attaching mode. By means of the mode, the risk that the face is pressed and injured due to the fact that binding belts or ear beltsare too tight is directly avoided, medical staff can use the mask conveniently, the problems of wound infection and the like caused by pressing and injury are solved, and in the embodiment, the fitting part is made of medical adhesive materials such as medical application which are not prone to allergy.

Owner:成都市第三人民医院

Yarn collar mold

InactiveCN104499197ASolve the cumbersome processing methodAvoid uneven tracesWork-feeding meansYarnEngineering

A yarn collar mold comprises a base plate, a cushioning plate and a cover plate. One side of the base plate, the cushioning plate and the cover plate share a shaft and are hinged. A base plate sewing through groove, a cushioning plate sewing through groove and a cover plate sewing through groove which are capable of overlapping mutually and matched with the shape of the yarn collar are formed in the base plate, the cushioning plate and the cover plate. An upper cushioning block and a lower cushioning block are arranged at bent positions of the upper and lower ends of the base plate sewing through groove along the inside bent angles. By means of the yarn collar mold, the technical problems of tedious processing modes, inconvenient positioning and high requirements for worker operation levels during yarn collar making are solved, integral forming is achieved through a base plate, cushioning plate and cover plate matched mode, and the technical problems of tedious processing modes and high requirements for worker operation levels during yarn collar making are solved fundamentally.

Owner:天津东方三达服装科技有限公司

Check valve and central fume purification equipment

PendingCN108194671AImprove sealingGuaranteed tight fitDomestic stoves or rangesLighting and heating apparatusEngineeringAngular rotation

The invention provides a check valve and central fume purification equipment, and relates to the technical field of purification equipment. The check valve comprises a valve body and a valve sheet; the valve body is provided with a drive device and a connecting arm which are fixedly connected, the valve sheet is hinged to the free end of the connecting arm, the drive device drives the connecting arm and the valve sheet to move in the axial direction of the valve body, a drive part is arranged in the valve body, the drive part moves in the axial direction of the valve body along with the valvebody to drive the valve sheet to achieve angular rotation, the blockage state of the valve sheet to the valve body is changed, and the central fume purification equipment comprises a kitchen ventilator and the check valve; the check valve communicates between an exhaust opening of the kitchen ventilator and an air outlet of a public flue. The valve sheet achieves the angular rotation under drive of the connecting arm and drive of the drive part, the blockage control over the valve body is achieved, the valve sheet is good in blockage seal on the valve body, and fume reinjection and squealing of fume can be reduced.

Owner:HANGZHOU ROBAM APPLIANCES CO LTD

Tubular shaft hinge

PendingCN108118990AGuaranteed tight fitOptimize the connection methodPin hingesPlate heat exchangerEngineering

The invention discloses a tubular shaft hinge which comprises a pivot, a first hinge plate, a second hinge plate, a first branch tube and a second branch tube. The first hinge plate and the second hinge plate are rotatably connected with the pivot, the first branch tube is connected with the first hinge plate, the second branch tube is connected with the second hinge plate and comprises an extension section and a vertical section which are connected with each other, the vertical section of the second branch tube is inserted into the first branch tube and hermetically matched with the first branch tube, and the vertical section of the second branch tube, the first branch tube and the pivot of the hinge are coaxially arranged. The tubular shaft hinge thoroughly solves the technical problem that a flexible tube has to be used for connecting a back plate heat exchanger with a circulating tube in the prior art.

Owner:GUANGDONG SHENLING ENVIRONMENT SYST CO LTD

High-pressure slurry-casting ram pump piston system with split rear cover

InactiveCN101634296AImprove sealingImprove work efficiencyPositive displacement pump componentsLiquid fuel engine componentsWear resistantSlurry

The invention provides a high-pressure slurry-casting ram pump piston system with a split rear cover. The piston rear cover of the system is provided with an inner clamping sleeve and an outer clamping sleeve which are split, and a free space is remained between the inner clamping sleeve and the outer clamping sleeve. The invention solves the problem that a seal washer of the prior high-pressure slurry-casting ram pump piston is often scratched by slurry hardening objects, thereby reducing the replacement time of the seal washer, leading the high-pressure slurry-casting ram pump piston to be in a good work state in a long period, and improving the medium pouring quality and the machine work efficiency. The high-pressure slurry-casting ram pump piston system with a split rear cover has simple structure, greatly improves the processing difficulty of the original rear cover, not only can ensure the tight fit with a piston rod, but also can allow larger operating errors, and can be directly replaced without changing the specifications of the piston system and other subassemblies; and otherwise, the inner clamping sleeve with smaller volume can be made of high wear-resistant materials is tightly fit with the piston rod so as to resist wear and can prolong the service life of the piston system.

Owner:鲍春

High-pressure slurry-casting ram pump piston system with split rear cover

InactiveCN101634296BImprove sealingImprove work efficiencyPositive displacement pump componentsLiquid fuel engine componentsWear resistantEngineering

The invention provides a high-pressure slurry-casting ram pump piston system with a split rear cover. The piston rear cover of the system is provided with an inner clamping sleeve and an outer clamping sleeve which are split, and a free space is remained between the inner clamping sleeve and the outer clamping sleeve. The invention solves the problem that a seal washer of the prior high-pressure slurry-casting ram pump piston is often scratched by slurry hardening objects, thereby reducing the replacement time of the seal washer, leading the high-pressure slurry-casting ram pump piston to be in a good work state in a long period, and improving the medium pouring quality and the machine work efficiency. The high-pressure slurry-casting ram pump piston system with a split rear cover has simple structure, greatly improves the processing difficulty of the original rear cover, not only can ensure the tight fit with a piston rod, but also can allow larger operating errors, and can be directly replaced without changing the specifications of the piston system and other subassemblies; and otherwise, the inner clamping sleeve with smaller volume can be made of high wear-resistant materials is tightly fit with the piston rod so as to resist wear and can prolong the service life of the piston system.

Owner:鲍春

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com