An anti-loosening threaded connector and its components

A threaded connector and connector technology, which is applied to the parts of the connecting device, the device for connecting, connecting/disconnecting the connecting parts, etc., can solve the problems of displacement in the separation direction, and achieve the effect of preventing loosening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

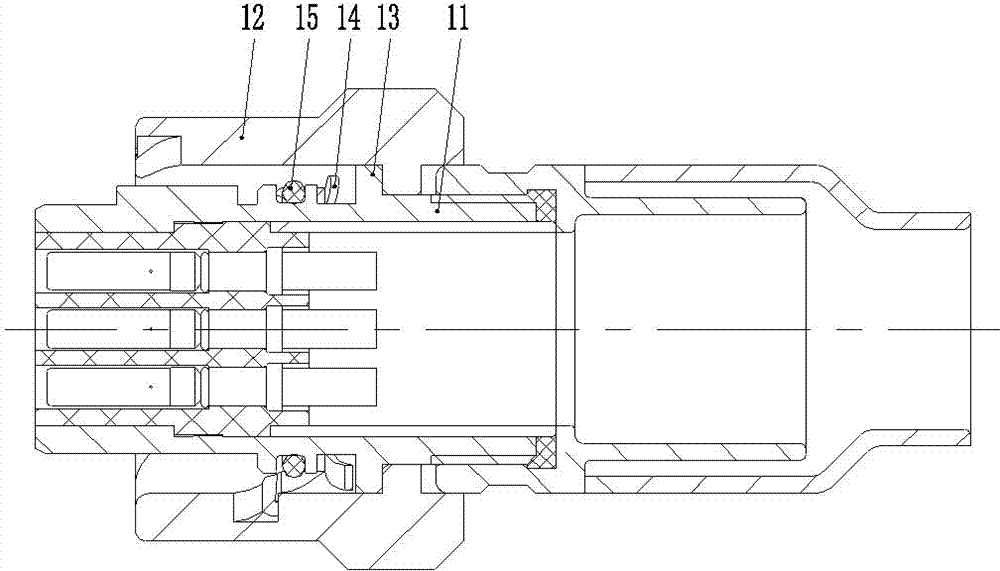

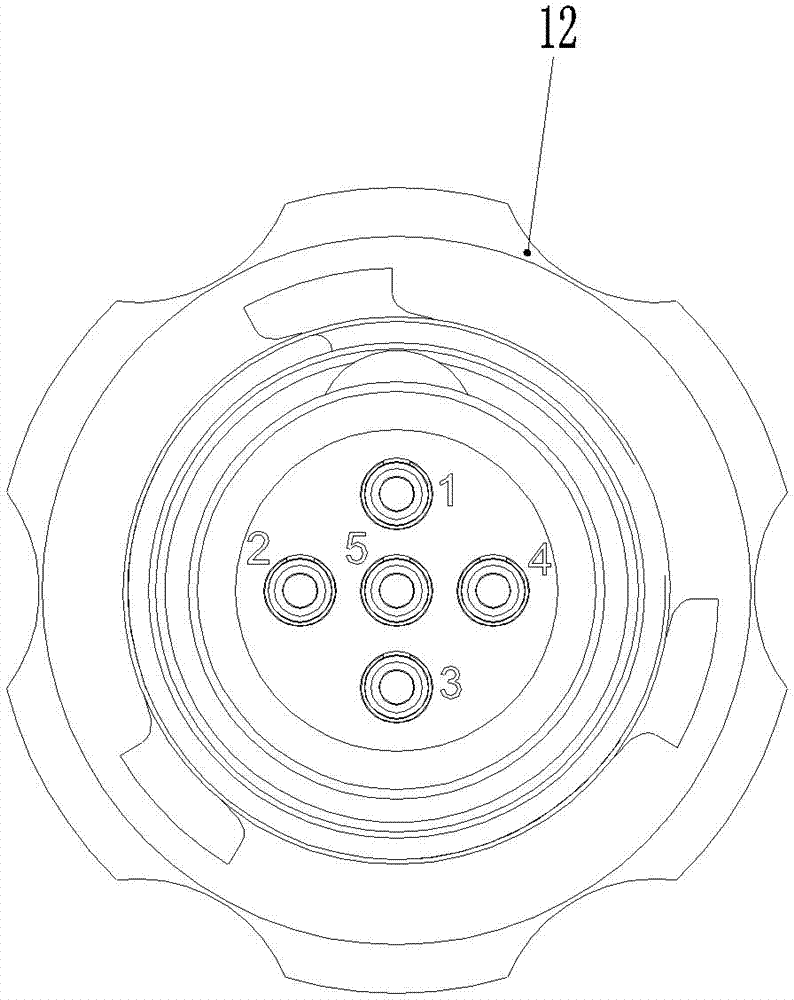

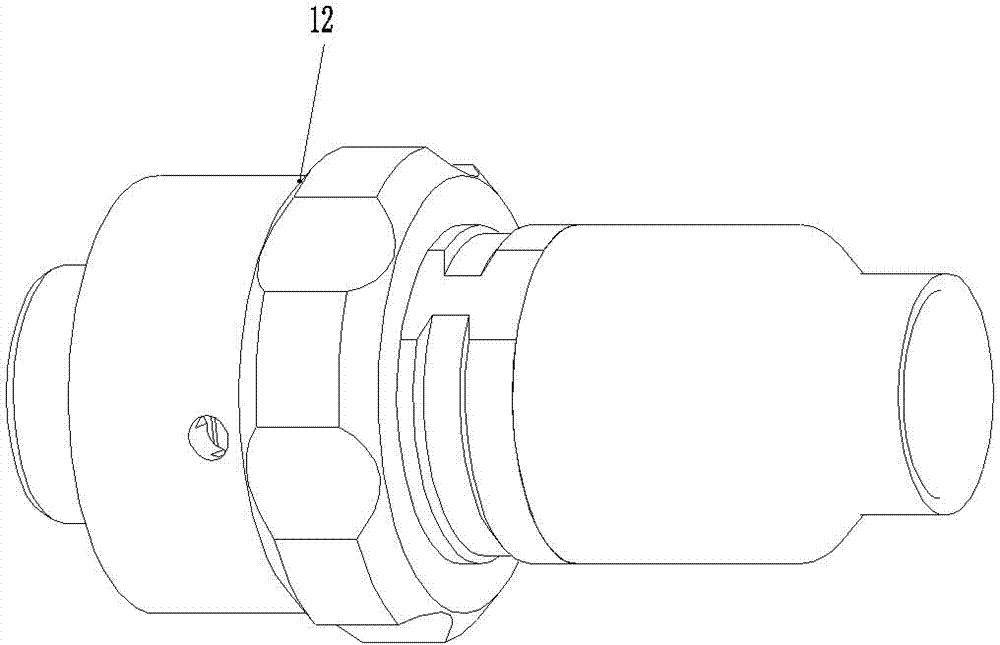

[0026] Embodiment 1 of the anti-loosening threaded connector of the present invention, such as Figure 1-3 As shown, it includes a housing 11, the housing 11 is cylindrical and is a metal housing, the front of the housing 11 has a plug-in portion, the plug-in portion can be inserted into the mating connector when the connector is working In the channel, the housing 11 is also rotatably equipped with a connecting nut 12, and the connecting nut 12 prevents it from coming off forward through the inversion edge of its rear part and the blocking cooperation of the rear side of the annular boss provided on the outer wall of the housing. Assembled on the housing, its structure and assembly relationship are all prior art, and will not be described here. It should be pointed out that there is a gap between the inner wall surface of the connecting nut and the outer peripheral surface of the housing for the adapter connector to pass through. The outer peripheral surface of the housing 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com