Impact piece exploder and manufacture method thereof

A shock plate and detonator technology, which is applied in the field of pyrotechnics, can solve the problems of low assembly accuracy and reliability, inconvenient automatic production, and low manufacturing efficiency, so as to facilitate automated mass production, high reliability, and manufacturing high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

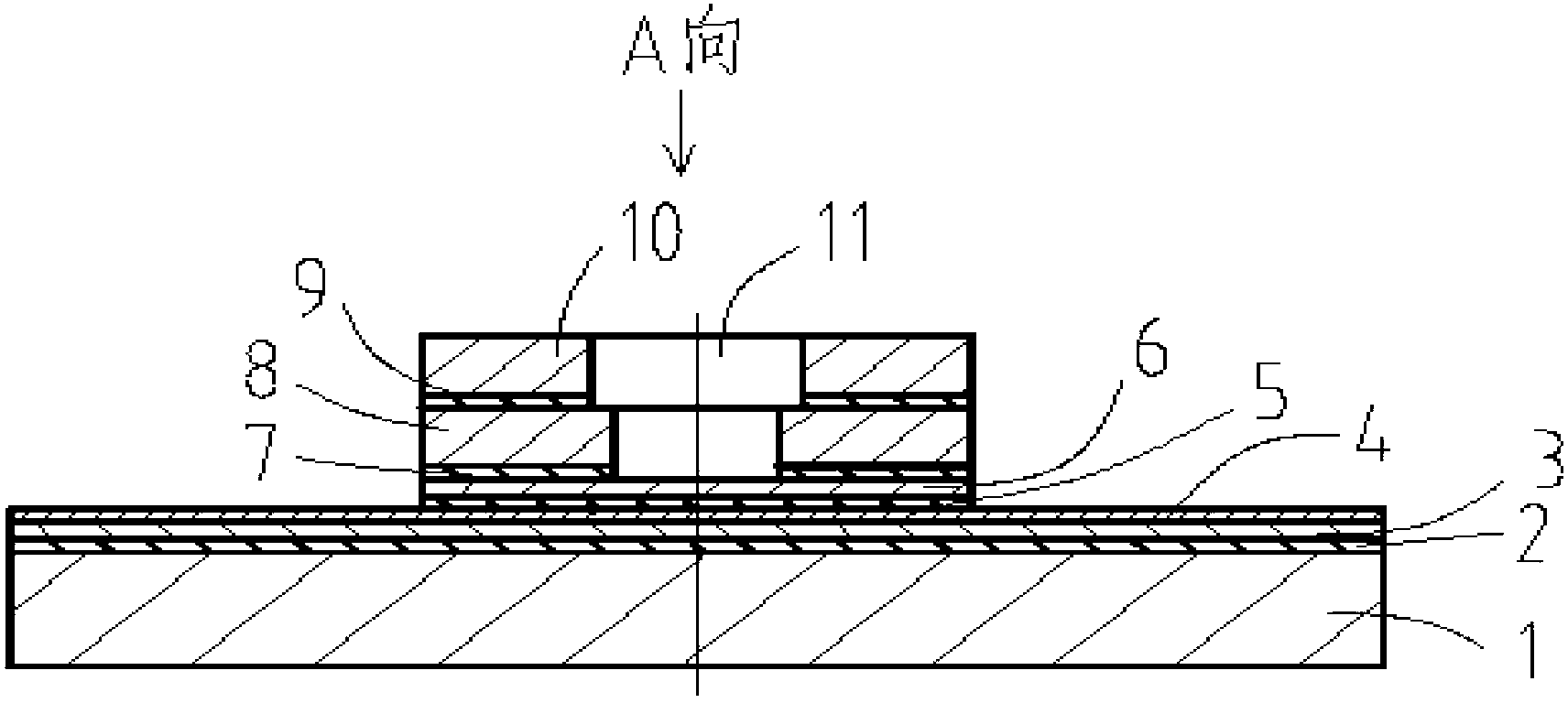

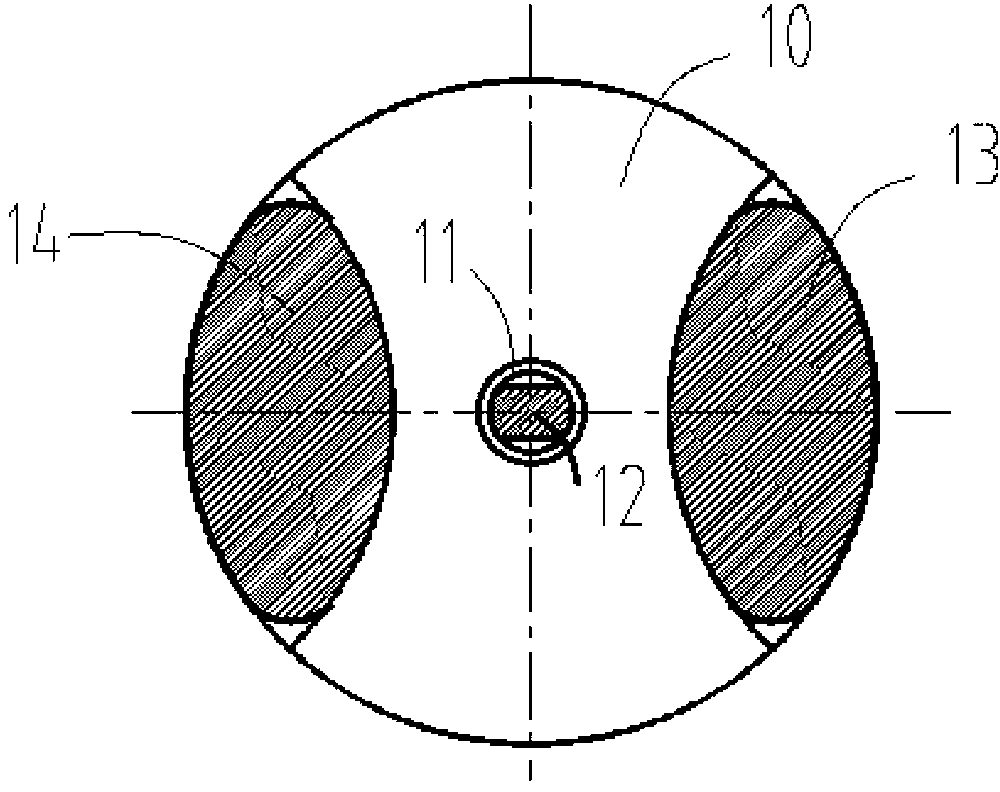

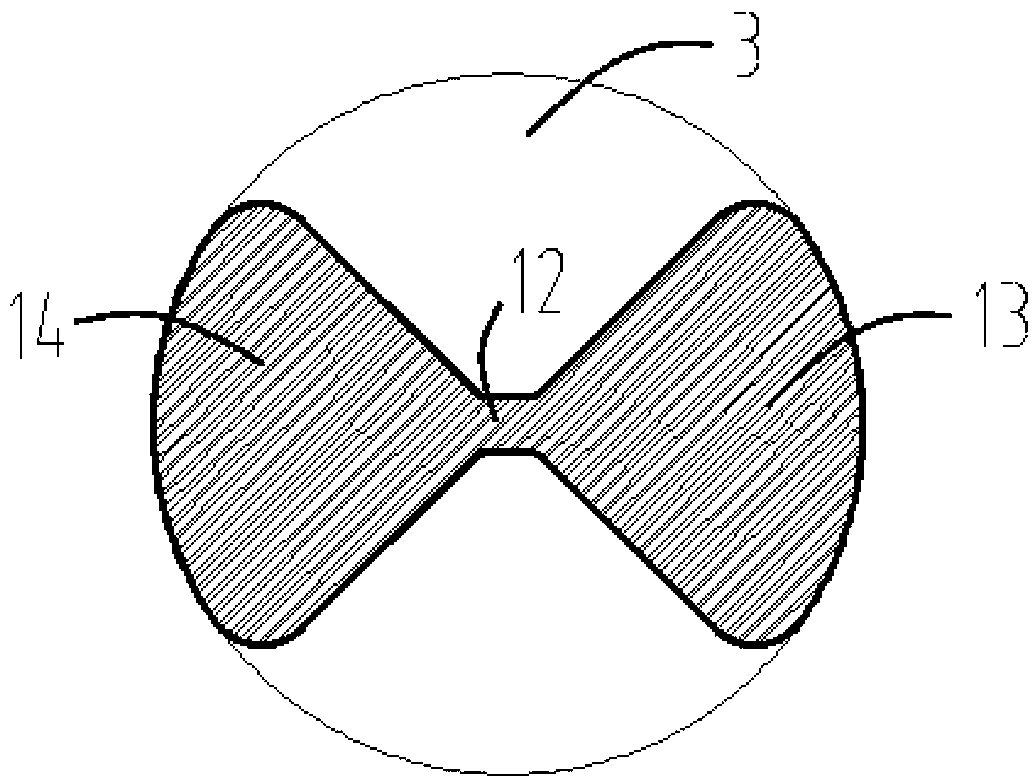

[0027] figure 1 It is a schematic diagram of the axial structure of the shock plate detonator of the present invention. From figure 1 It can be seen that the detonator includes a reflector 1 , a bridge foil 4 , a flyer 6 and an acceleration chamber 8 , 10 . Wherein, the reflector 1 is a relatively thick non-metallic plate, polyimide or other hard circuit boards can be selected; the material of the bridge foil 4 is copper, and the thickness can be selected according to needs, preferably 3 μm to 12 μm; 4 is covered with a layer of polyimide flying piece 6, preferably with a thickness of 10 to 90 microns; the accelerating bore is composed of two non-metallic plates 8 and 10 with the same thickness. In order to ensure the flying of the flying piece, the accelerating bore 11 consists of a The smaller hole on the non-metallic plate 8 and a slightly larger hole on the non-metallic plate 10 can avoid steps that prevent the fly from flying in the accelerating bore 11 during manufactu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com