Compound tool for processing guide pipe hole of cylinder cover and conical surface of valve seat

A composite tool and conduit hole technology, which is used in manufacturing tools, metal processing equipment, reamers, etc., can solve the problems of inability to process products and the difficulty of straightness of conduit holes, saving raw materials, saving adjustment time, The effect of improving the processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

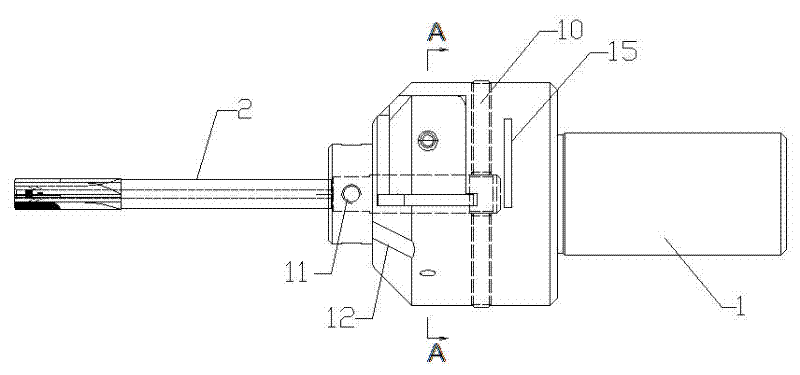

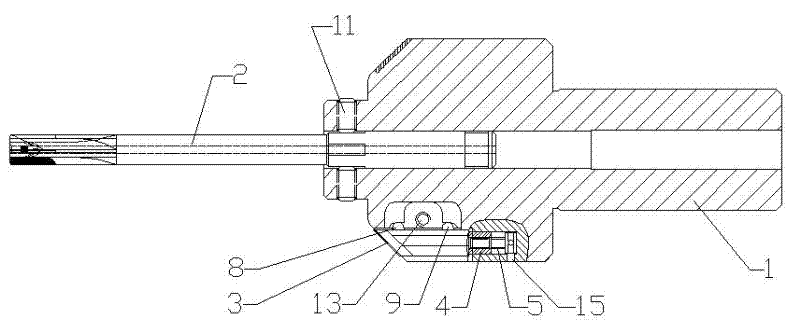

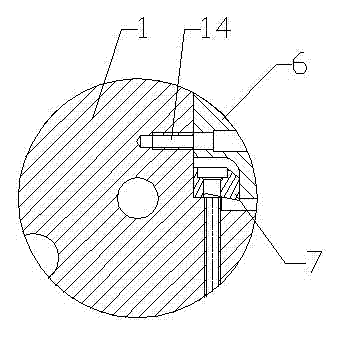

[0023] Such as figure 1 , figure 2 , image 3 with Figure 4 The compound tool shown for processing the valve seat cone surface and the cylinder head conduit hole includes a tool handle 1, a reamer 2 and a blade 3, and the reamer 2 passes through two symmetrically arranged locking jackscrews 10 on the tool handle 1 Locked in the handle 1, four symmetrically arranged adjusting jackscrews 11 at the front end of the handle 1 are in contact with the reamer 2 to adjust the beating degree of the reamer 2 by means of a knife adjuster. The blade 3 is movable and pressed on the conical surface of the knife handle 1 through the pressure plate 7 and the pressure plate screw 13 on the cone surface of the knife handle 1. The head and tail of the blade 3 are respectively provided with a limit pin 8 and an adjustment pin 9. The limit pin 8 The blade 3 head is positioned, and the adjustment pin 9 is used to adjust and change the inclination angle of the blade 3 cutter head, and the cutter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com