Patents

Literature

35results about How to "Guaranteed processing progress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

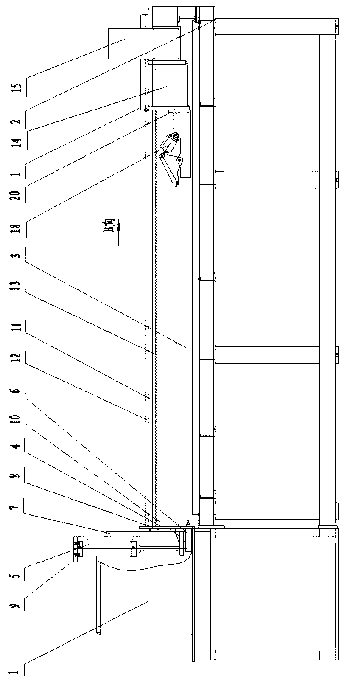

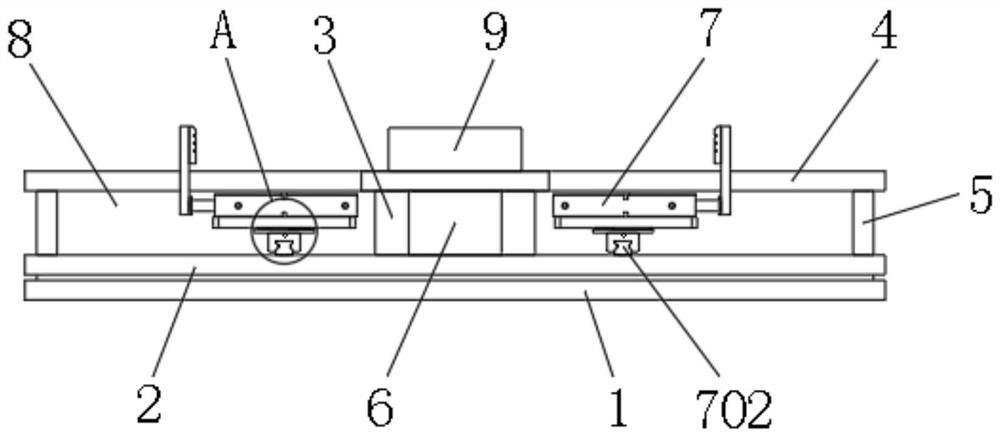

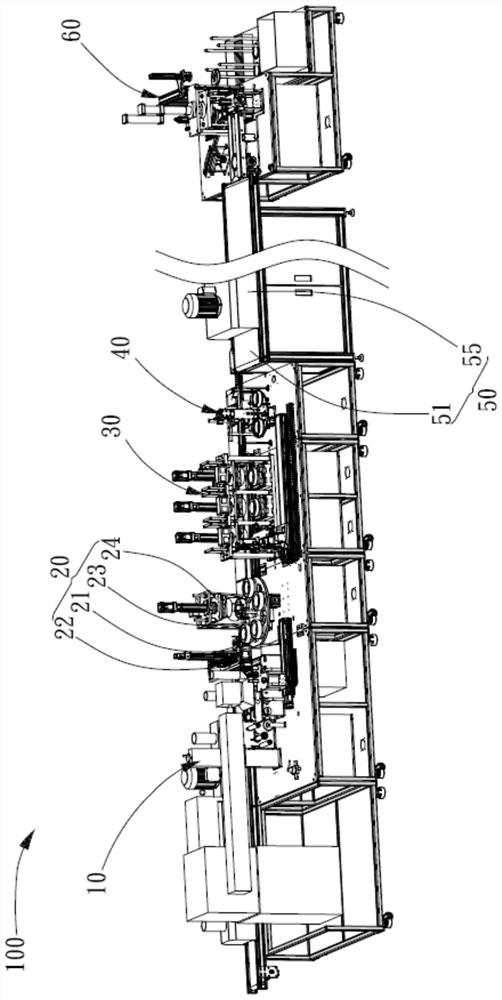

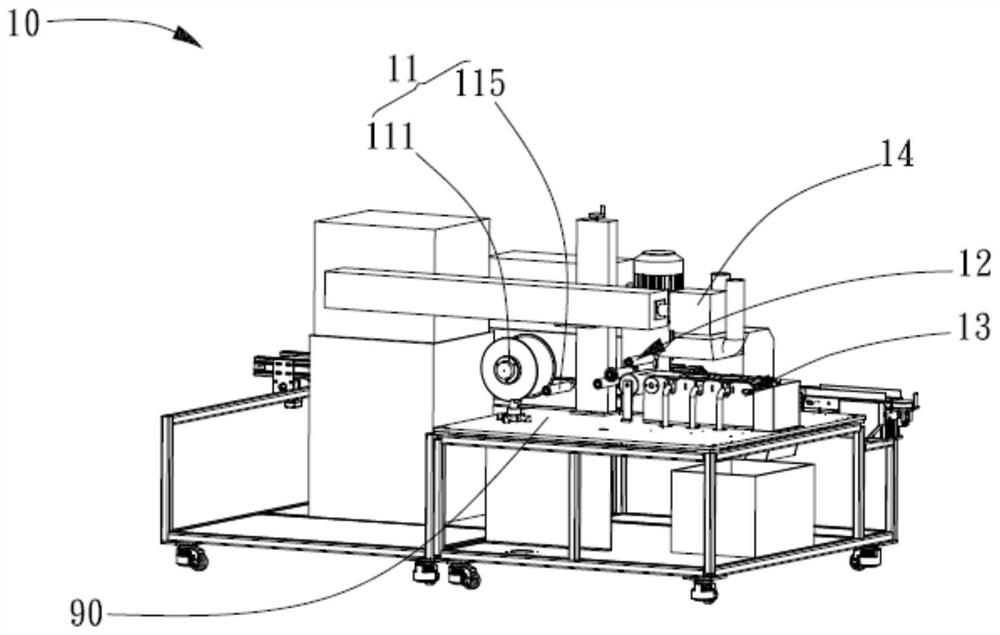

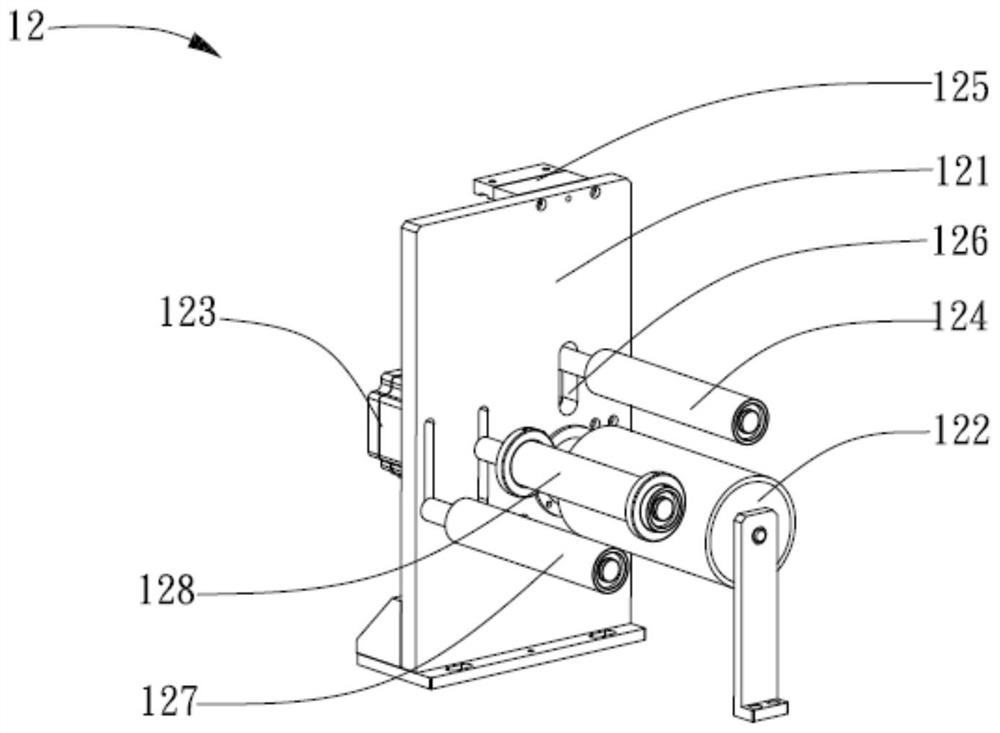

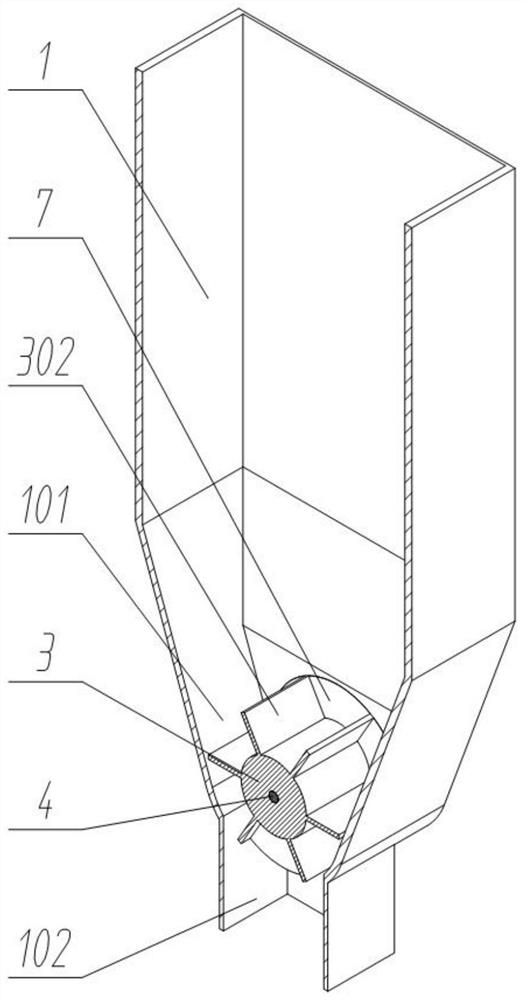

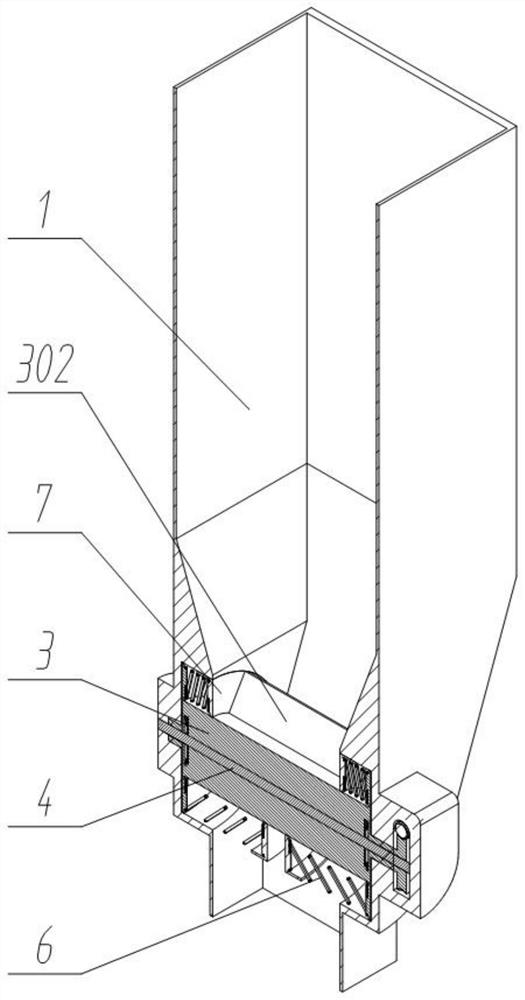

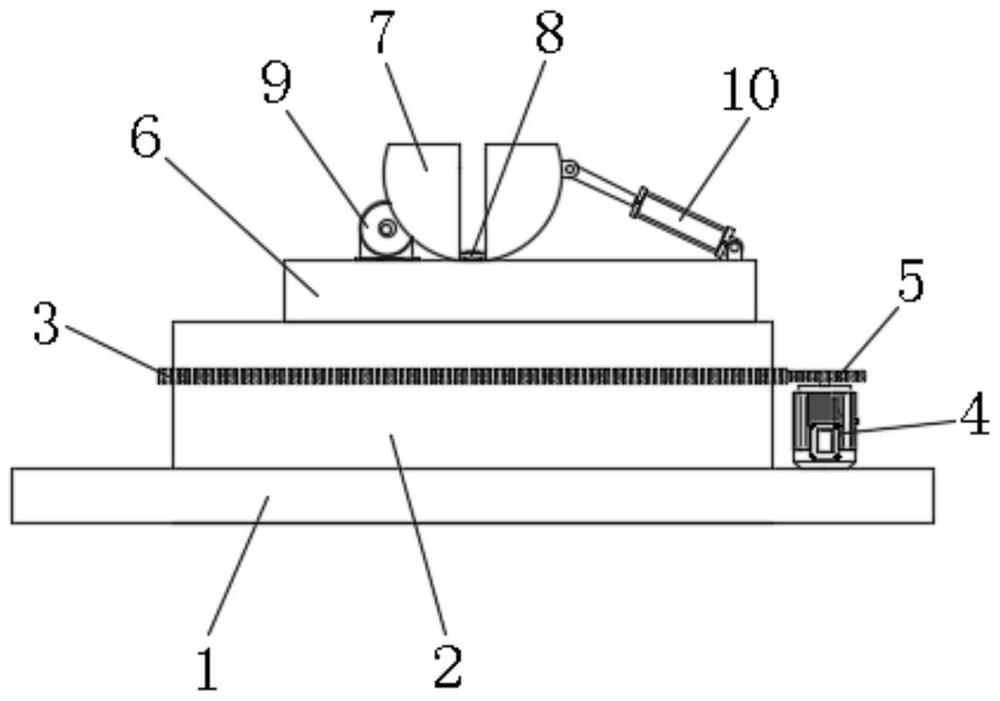

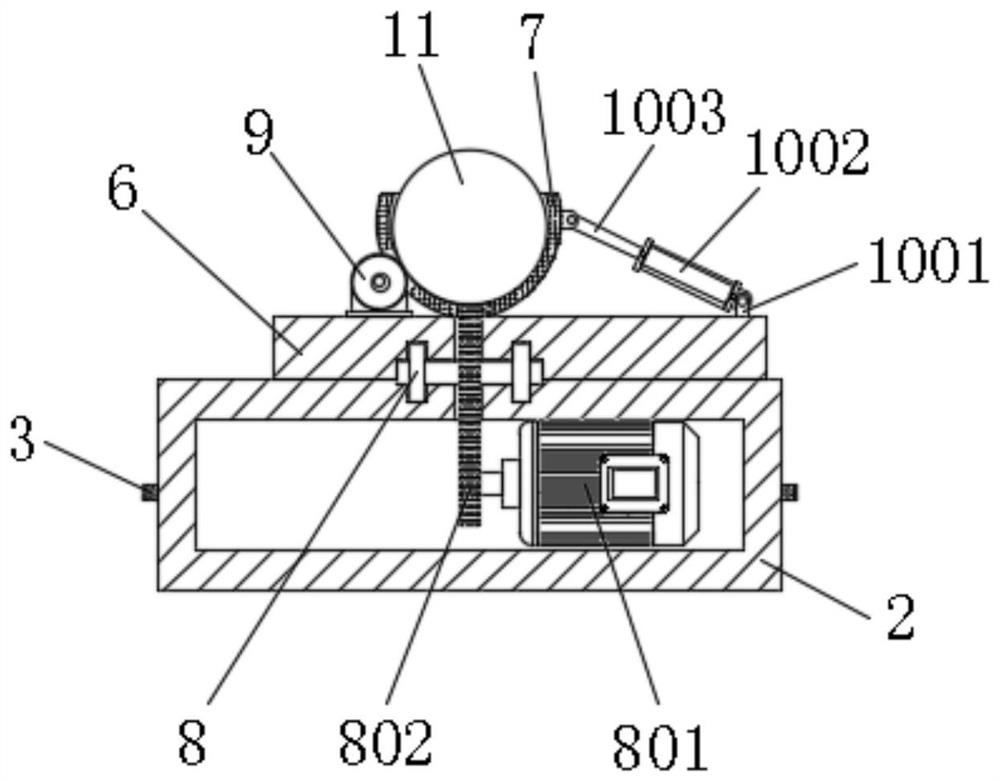

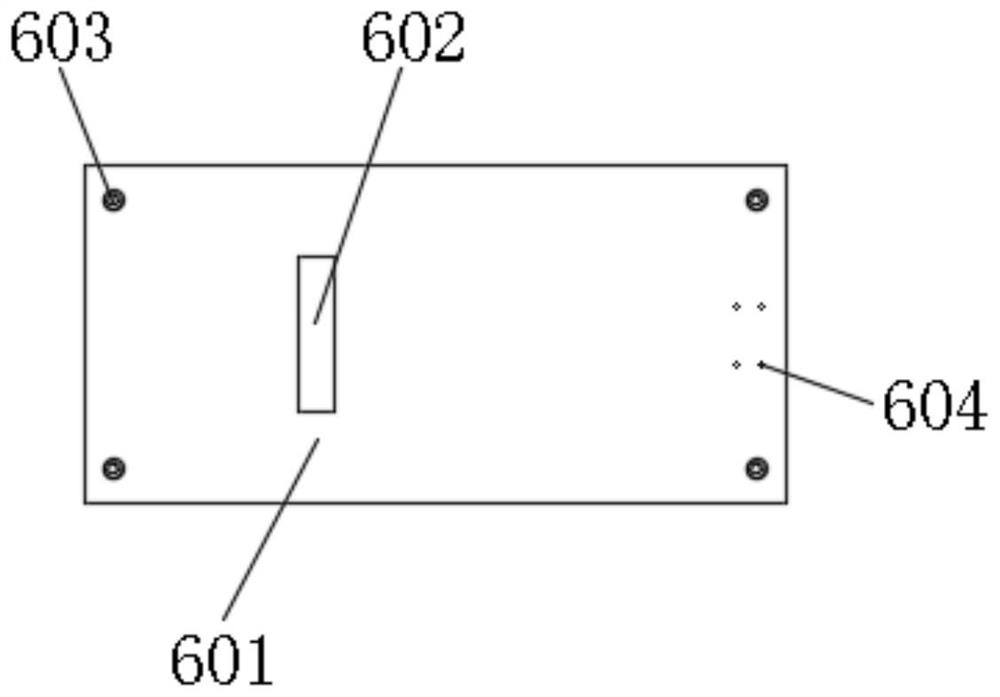

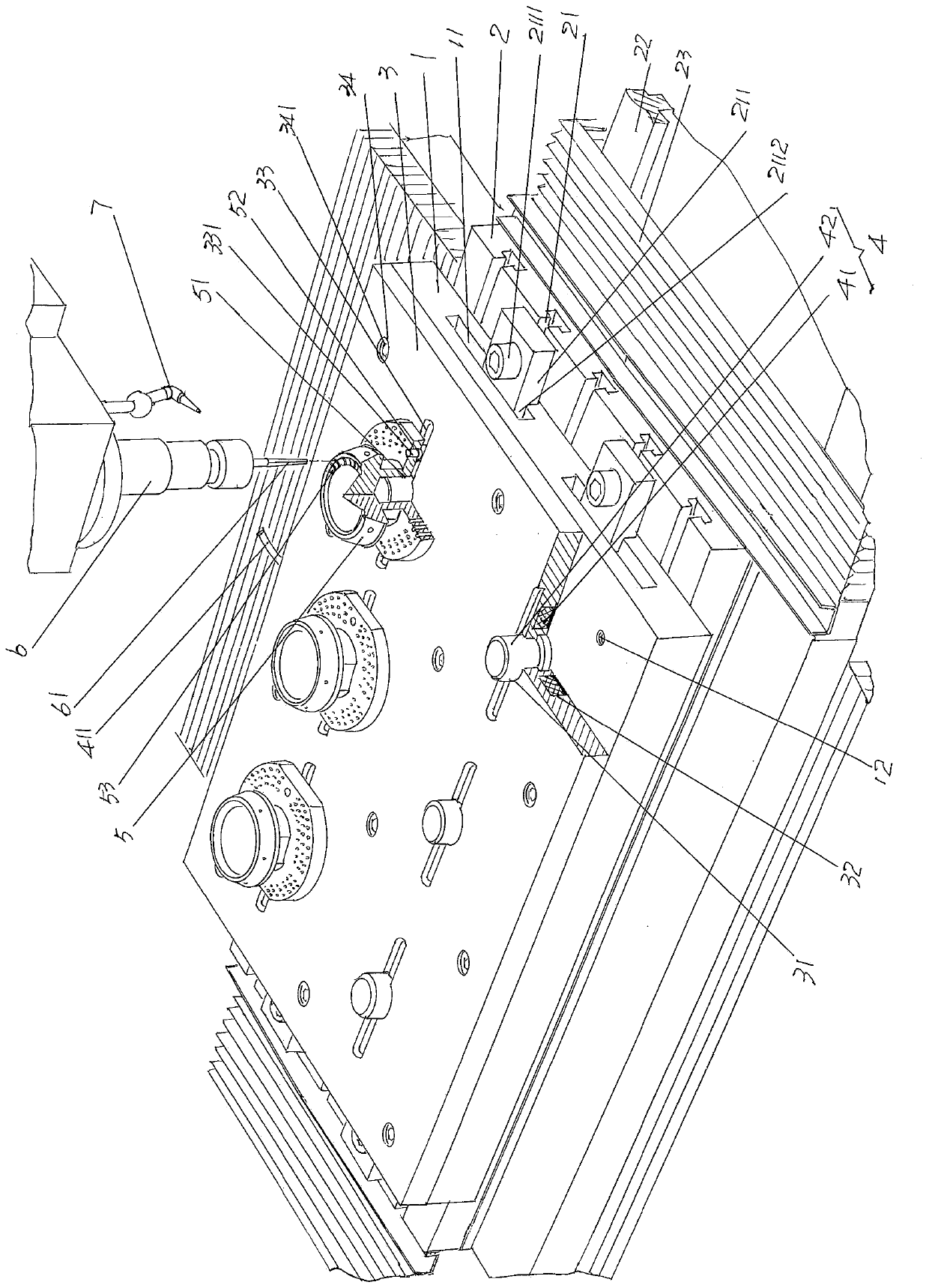

Material blocking and pushing device for electronic cut-to-size saw

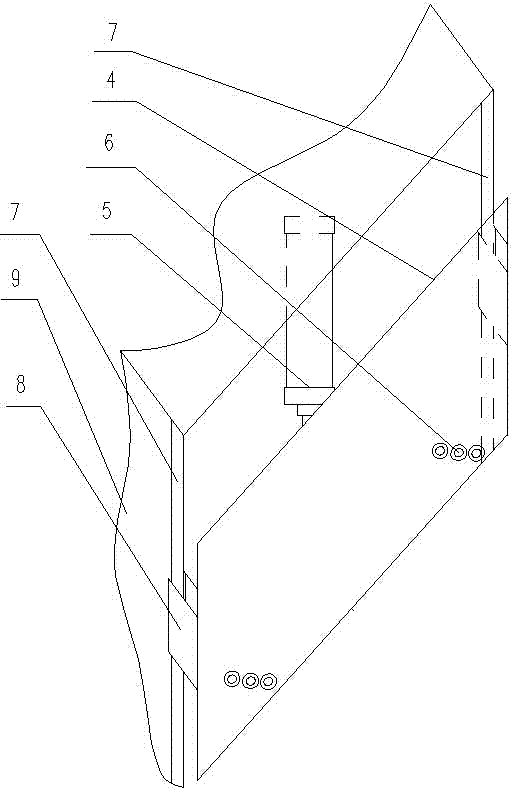

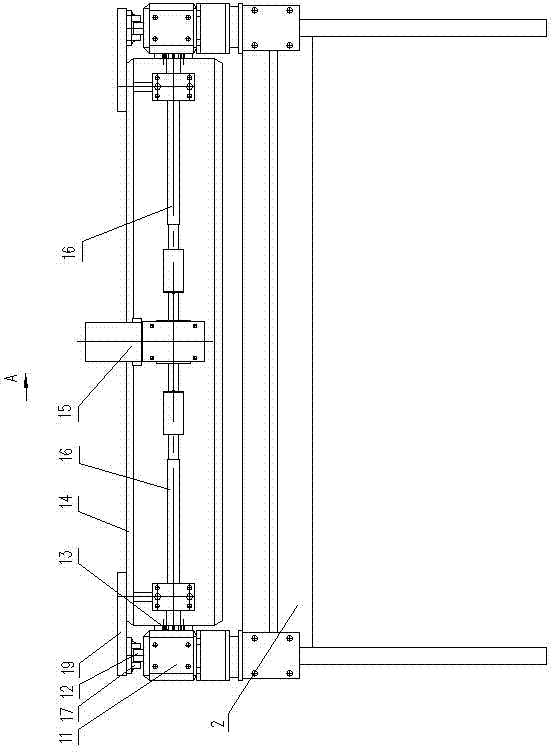

The invention discloses a material blocking and pushing device for an electronic cut-to-size saw. The material blocking and pushing device comprises a baffle assembly arranged on the right side of a box body provided with a cutting device and a material pressing device inside, a frame, a clamping feeding assembly and a feeding port, wherein the clamping feeding assembly and the feeding port are arranged at the right end of the frame. The material blocking and pushing device is arranged on the right side of the box body, and the feeding port is arranged between the baffle assembly and the clamping feeding assembly. The baffle assembly is composed of a baffle, a first air cylinder, a second air cylinder, a first linear guiding track and a first sliding block. The baffle moves back and forth along the first linear guiding track in the vertical direction through the first sliding block, and the clamping feeding assembly is fixed at the right end of the frame and composed of a frame traverse beam fixed at the upper end of the frame, a motor, a transmission shaft with a gear at the end, a second sliding block and a mechanical arm. By means of the technical scheme, the material blocking and pushing device is convenient to operate, safe and reliable and fast in machining, greatly improves efficiency, reduces labor intensity of workers and cost and improves machining precision of products.

Owner:JIANGSU MINGGE FORGING EQUIP CO LTD

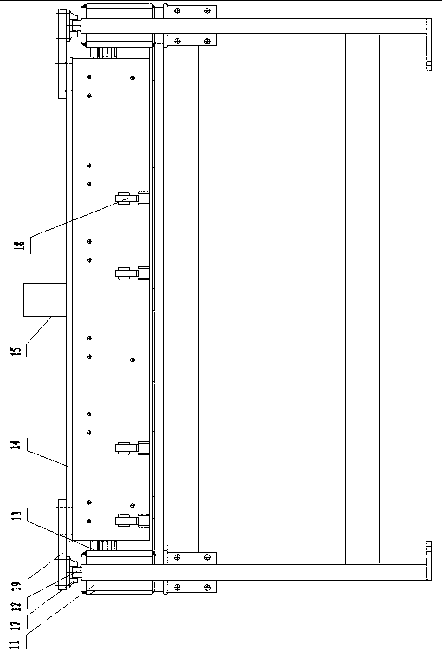

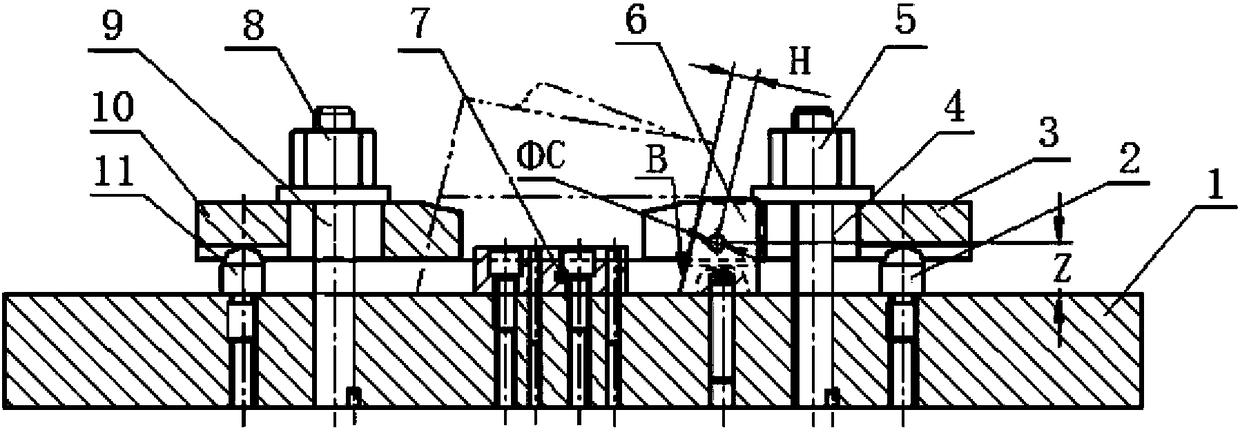

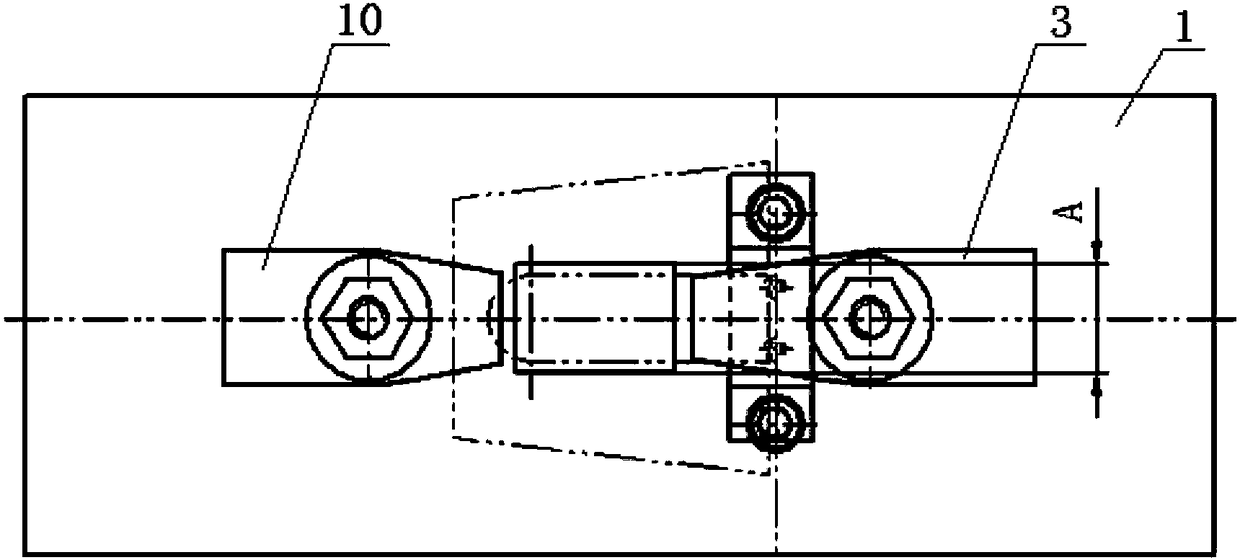

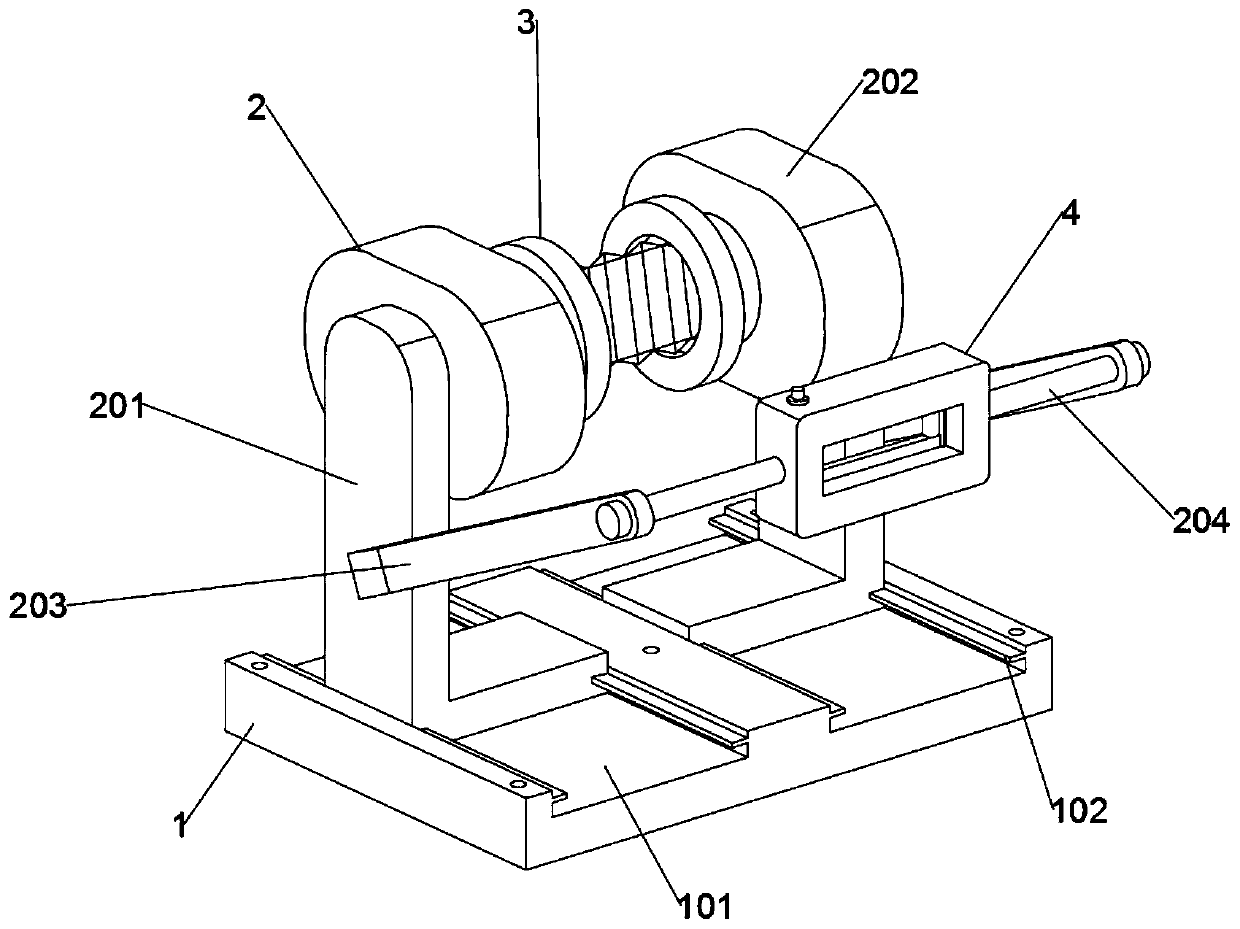

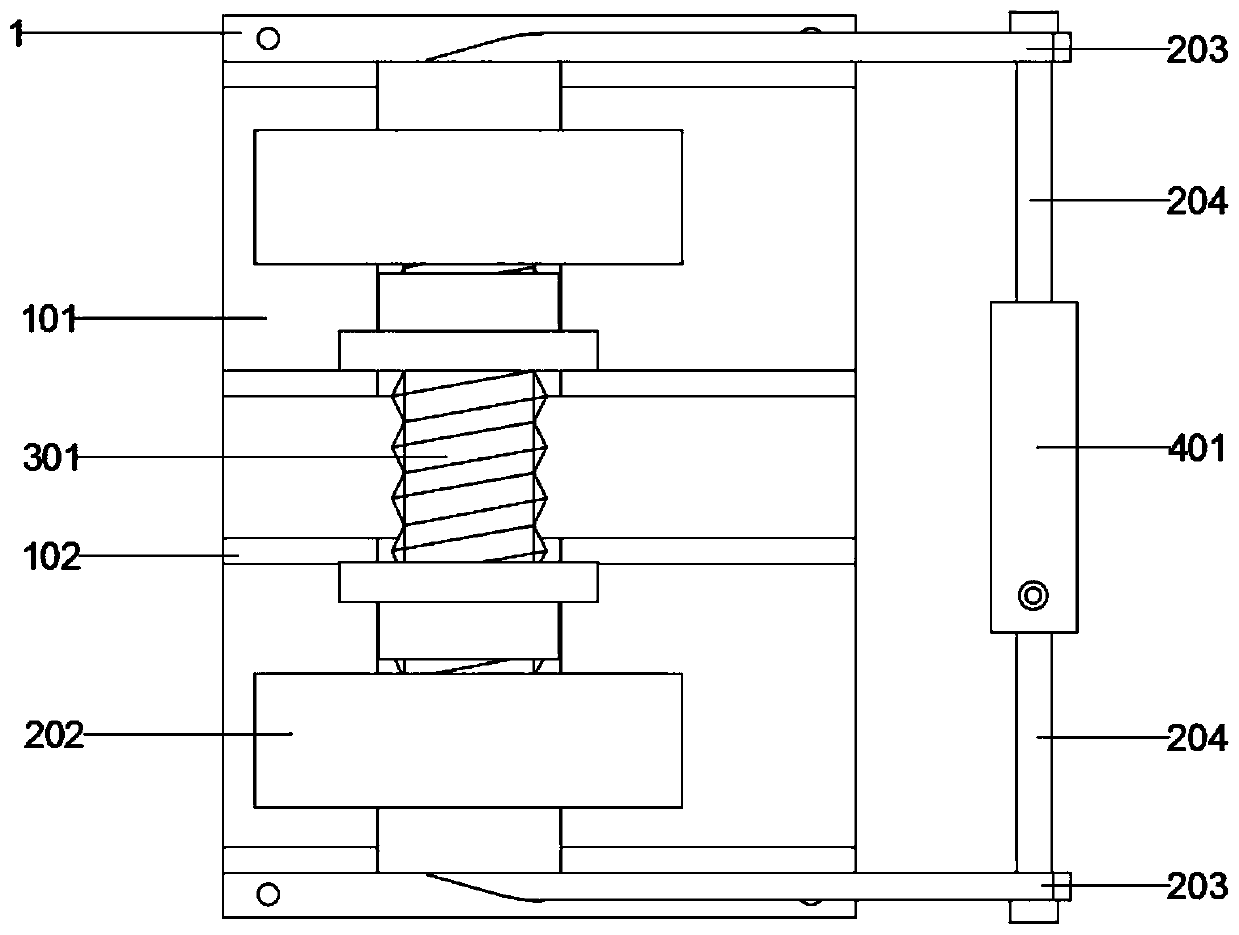

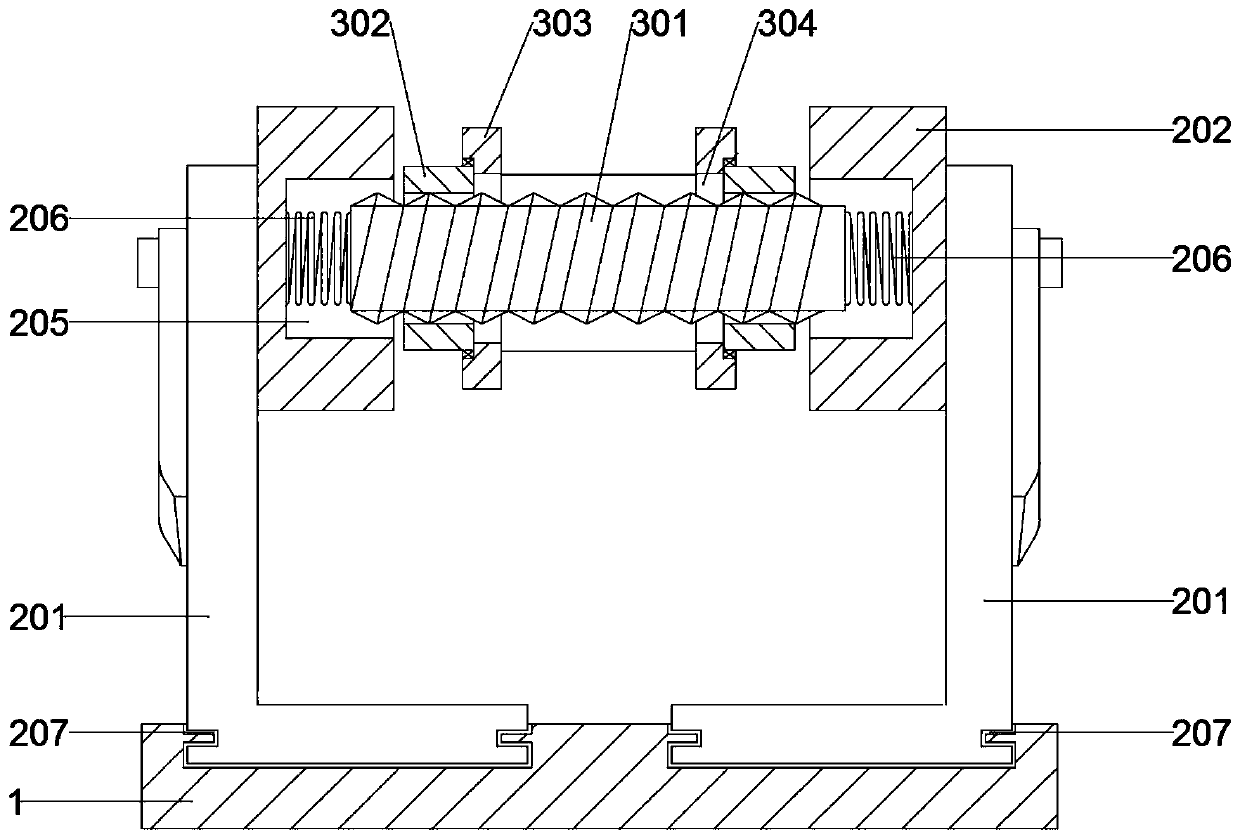

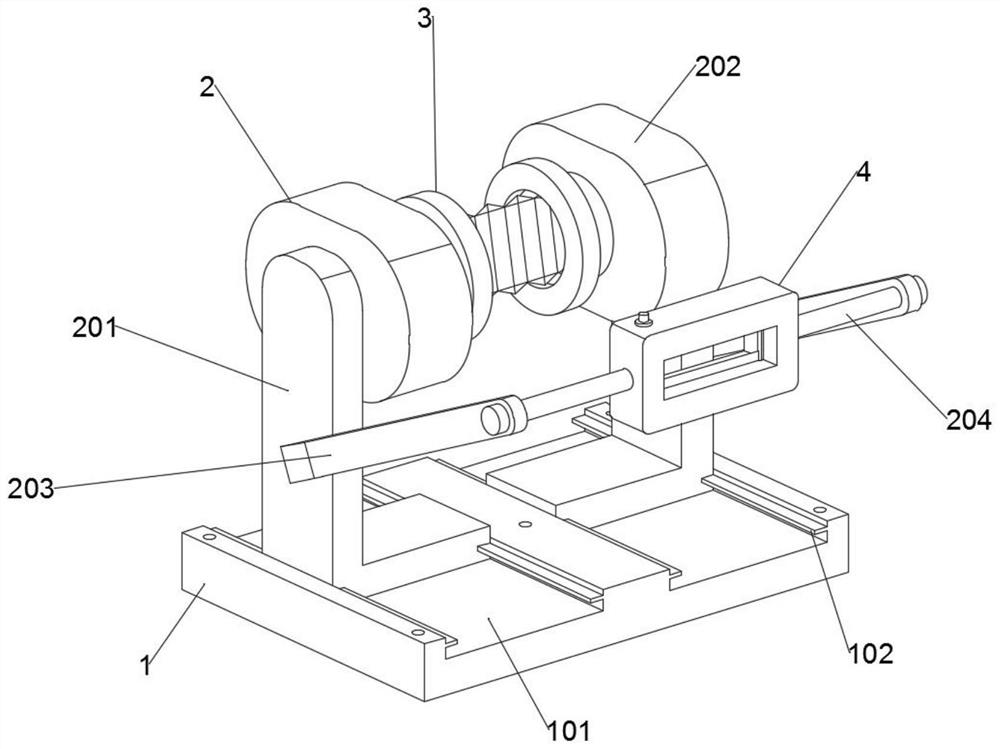

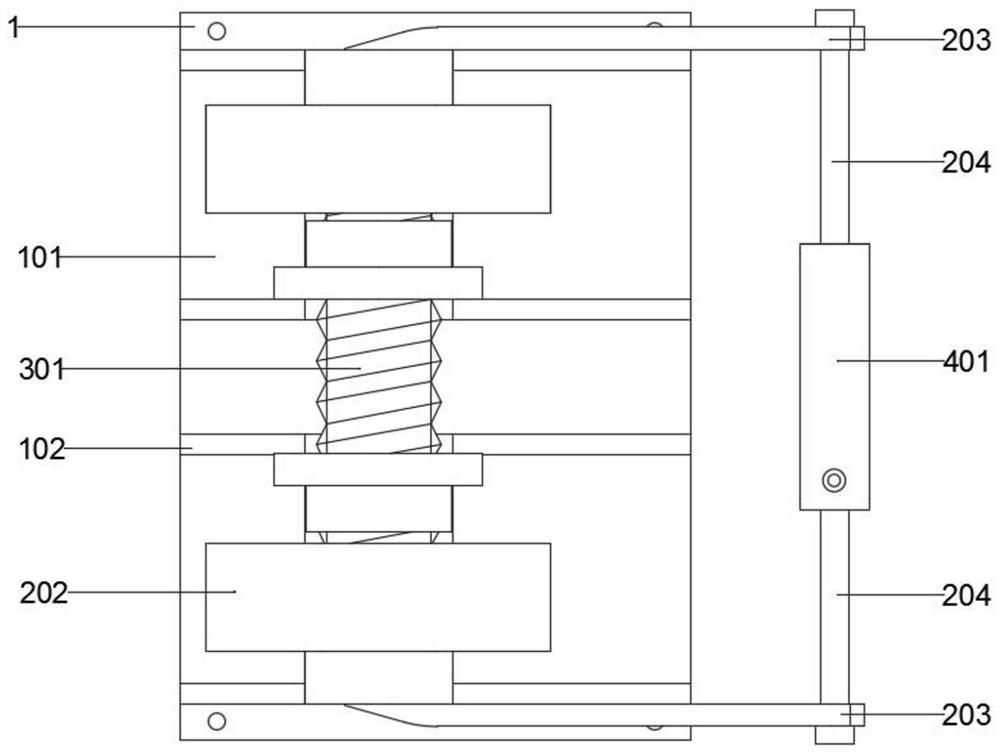

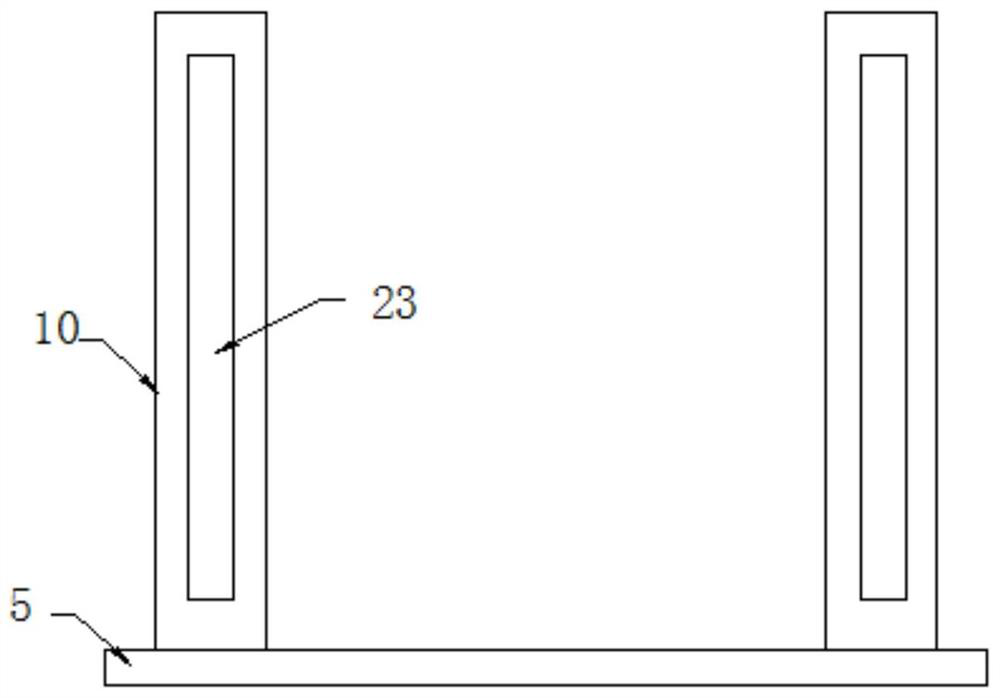

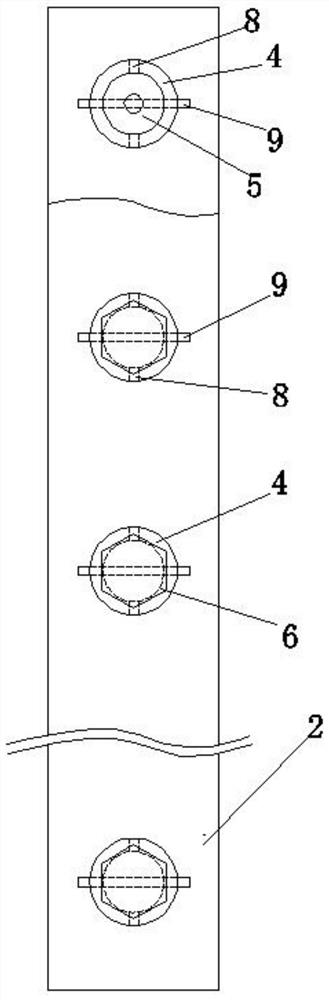

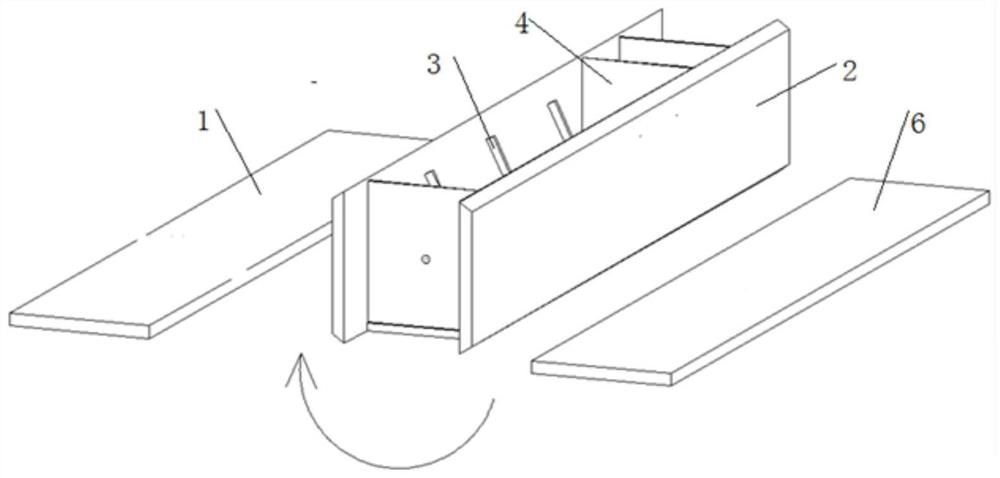

Special-shaped expansion block molded surface numerical control milling fixture and machining method

InactiveCN108098389ASimple structureReduce manufacturing difficultyMilling equipment detailsPositioning apparatusNumerical controlEngineering

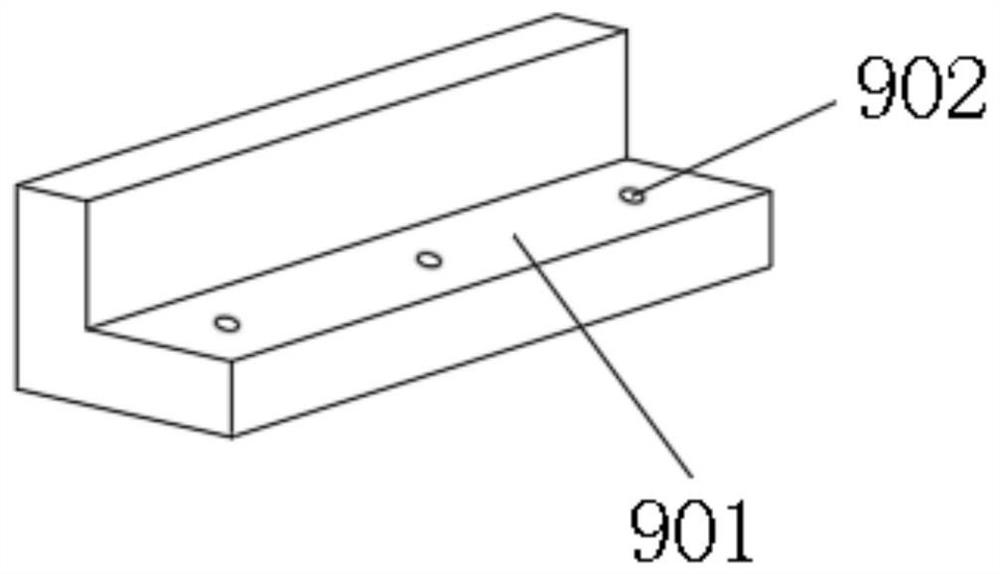

The invention discloses a special-shaped expansion block molded surface numerical control milling fixture and a machining method. The fixture comprises a bottom plate, a right support, a right pressing plate, a left pressing plate and a left support. The right pressing plate is mounted on the bottom plate through a right screw rod. The right support is mounted between the bottom plate and the right pressing plate and located on the right side of the right screw rod. The left pressing plate is mounted on the bottom plate through a left screw rod. The left support is mounted between the bottom plate and the left pressing plate and located on the left side of the left screw rod. A locating block is arranged on the inner side of the right pressing plate. The machining method comprises the steps of (1) design and manufacturing of the fixture; (2) alignment of the fixture; (3) clamping of an expansion block; (4) establishing of an expansion block digital model; and (5) machining of expansionblock molded surfaces. The special-shaped expansion block molded surface numerical control milling fixture is simple in structure and low in manufacturing difficulty. The fixture is used for conducting numerical control machining, parts are convenient to dismantle, the interchangeability is good; the machining consistency of the expansion block part molded surfaces can be effectively ensured, andmeanwhile, the labor intensity of workers is reduced.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

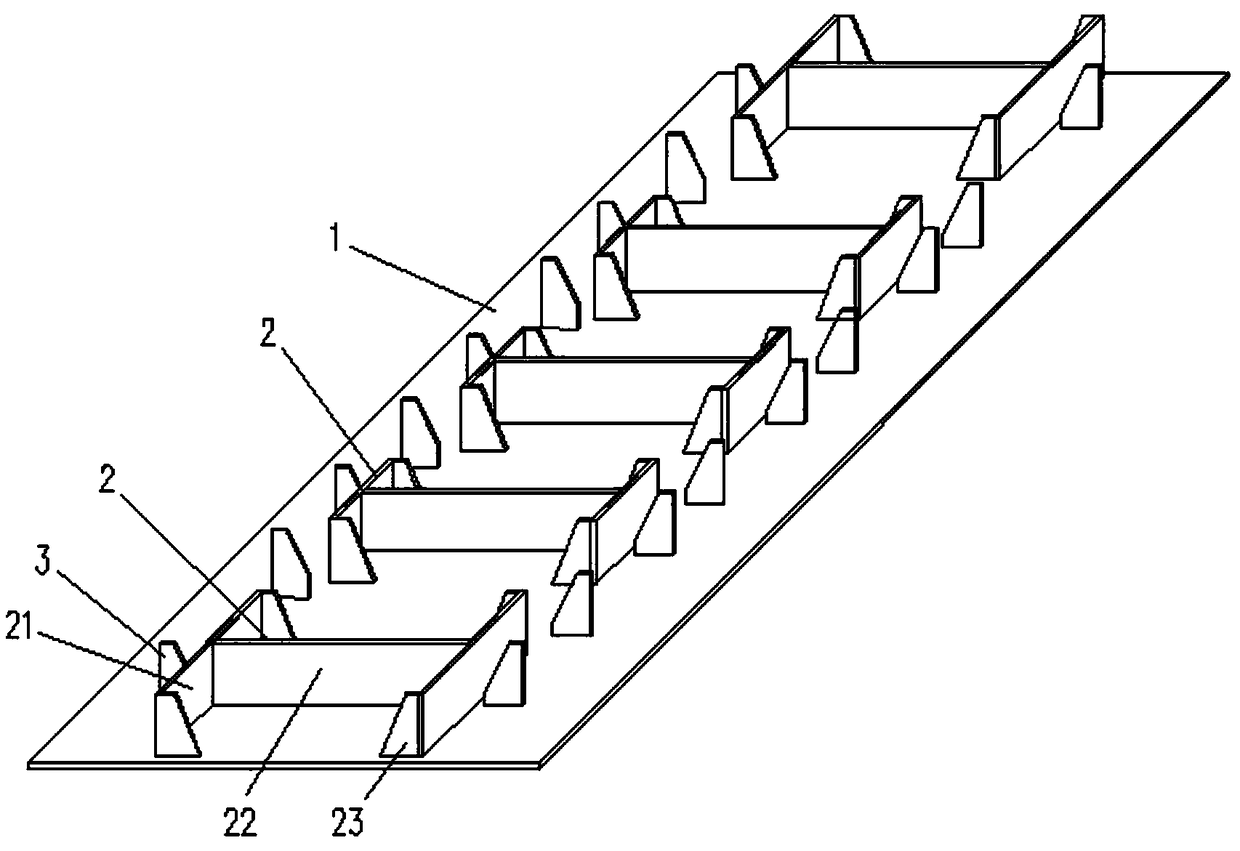

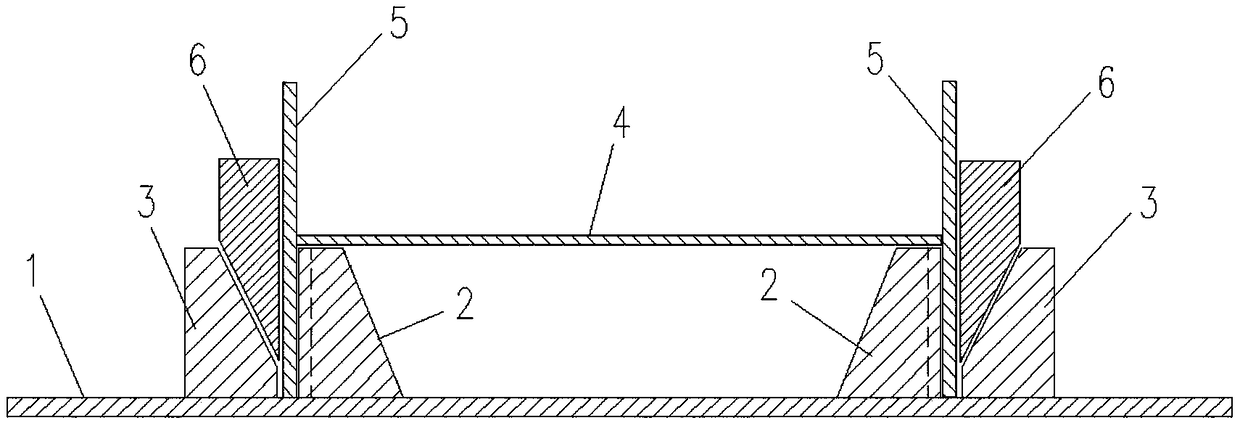

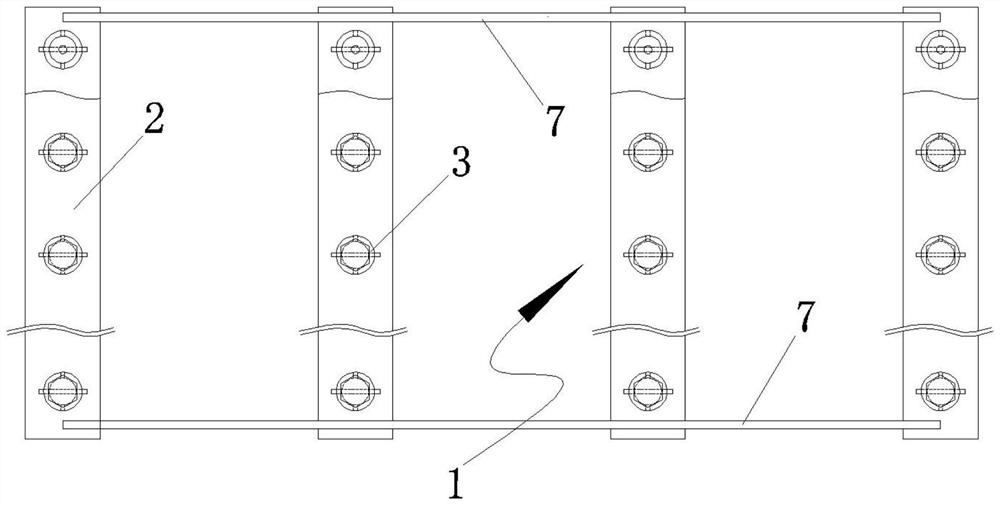

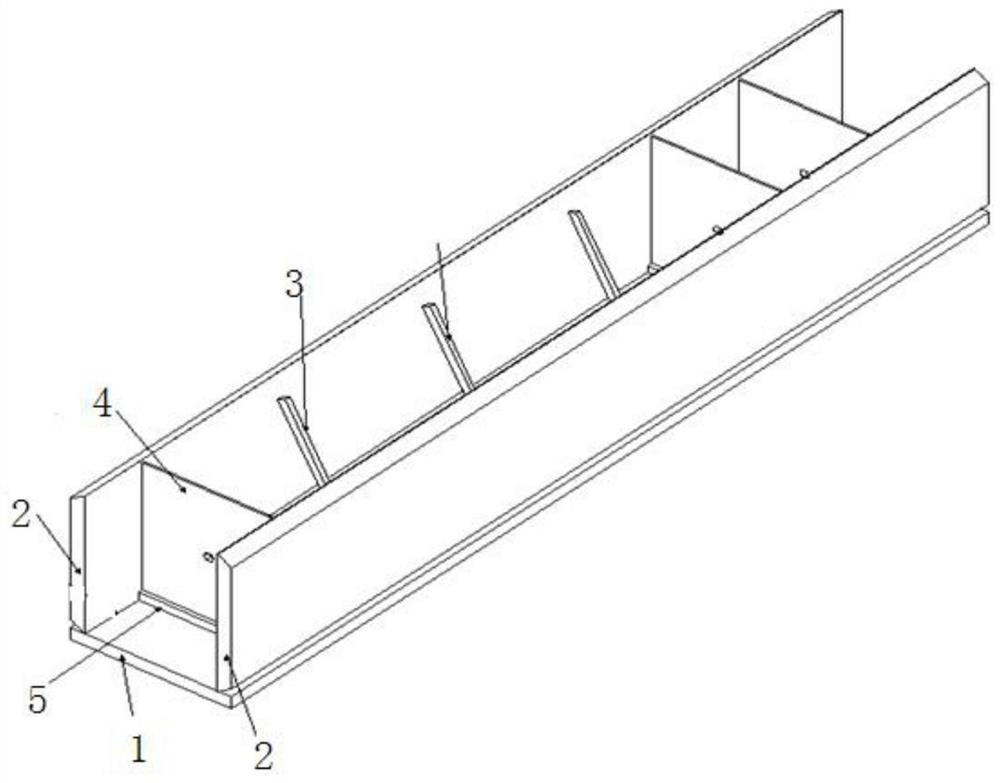

I-shaped steel welding platform and application method thereof

PendingCN108817788AEasy to manufactureSolve the problem of staggering 50cmWelding/cutting auxillary devicesAuxillary welding devicesSlurry wallArchitectural engineering

The invention provides an I-shaped steel welding platform and an application method thereof and belongs to the field of urban mass transit (interurban railway) open cut station foundation pit supportunderground continuous wall construction. The I-shaped steel welding platform comprises a platform body. Multiple web plate support brackets are arranged on the platform body in the length direction.The width of each web plate support bracket is the same as that of a middle web plate of corresponding I-shaped steel. The upper end faces of the multiple web plate support brackets are flush with oneanother. The two opposite sides of the multiple web plate support brackets are each of a plat plate structure perpendicular to the platform body and aligned with each other. Oblique plane limiting plates are fixed to the positions, at the two opposite sides of the web plate support brackets, of the platform body correspondingly. The inner sides of the oblique plane limiting plates are provided with oblique plane structures which are arranged toward the outer side from bottom to top in an inclined manner. The I-shaped steel welding platform and the application method thereof aim at improving machining efficiency and quality of underground continuous wall reinforcement cage I-shaped steel joints.

Owner:CHINA RAILWAY ERJU 1ST ENG

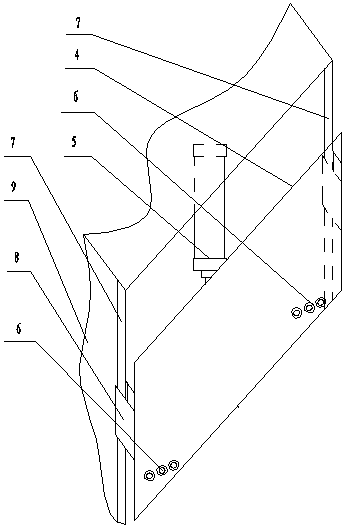

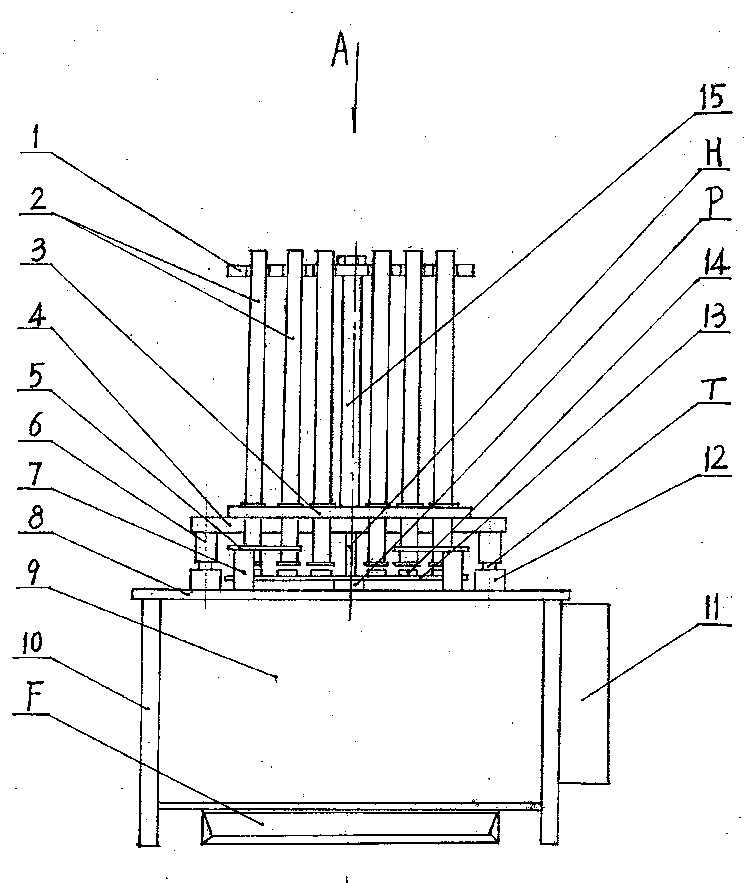

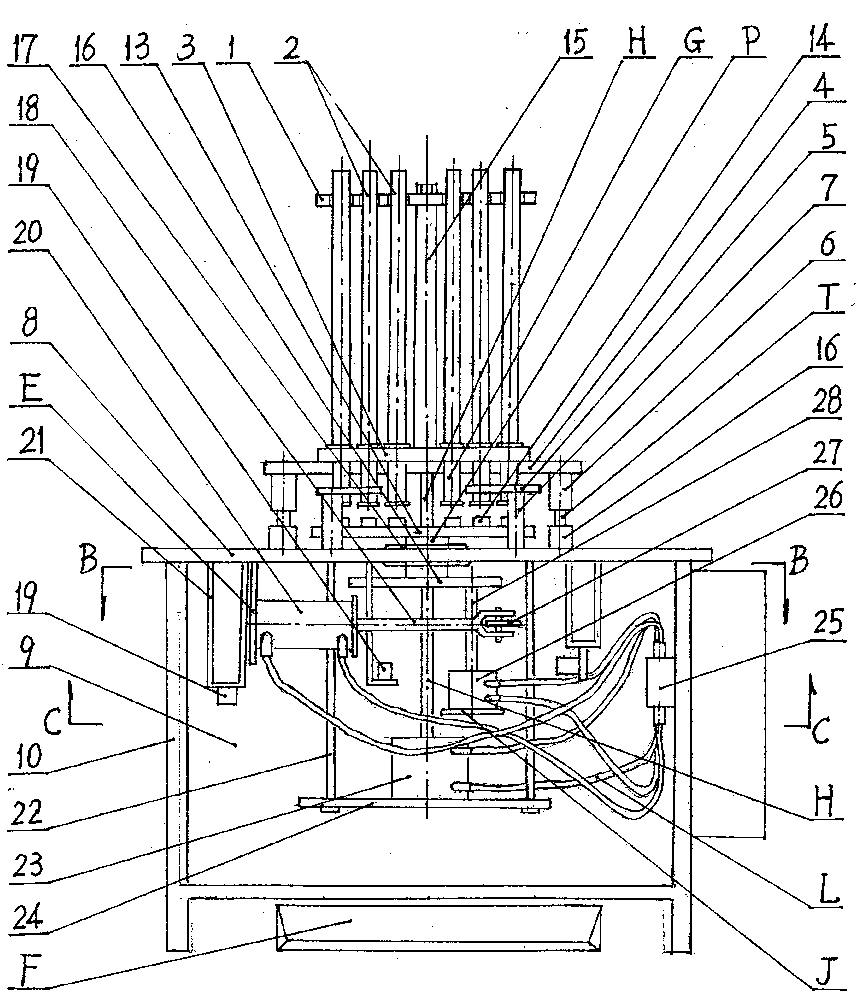

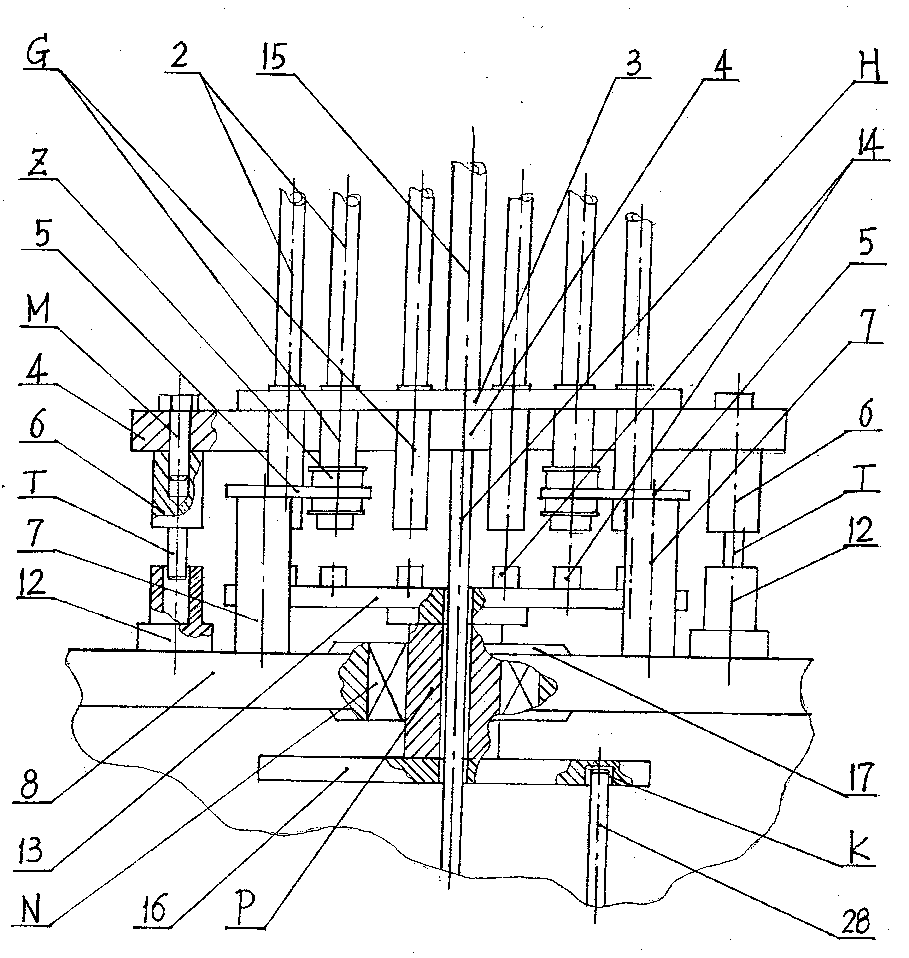

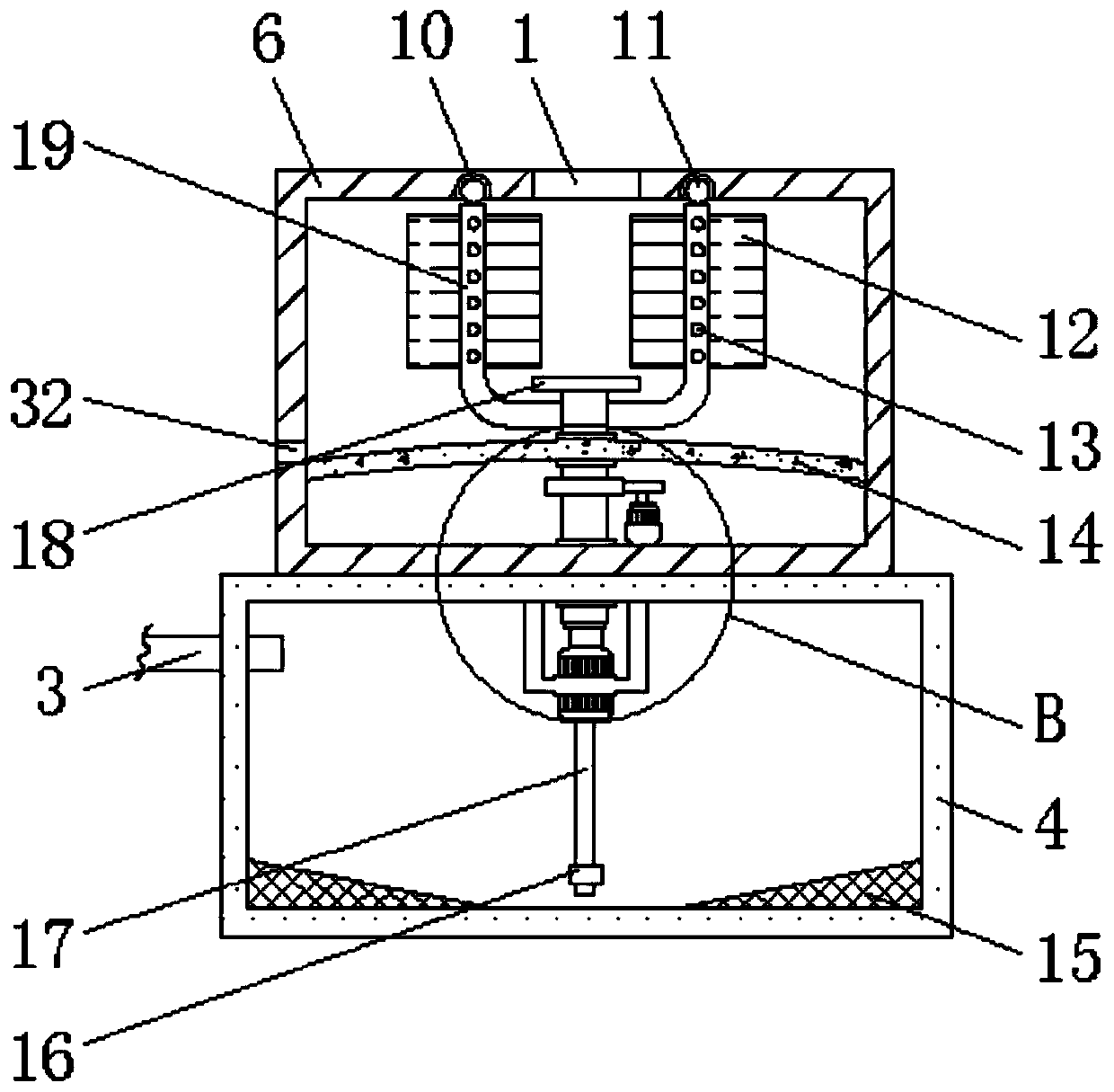

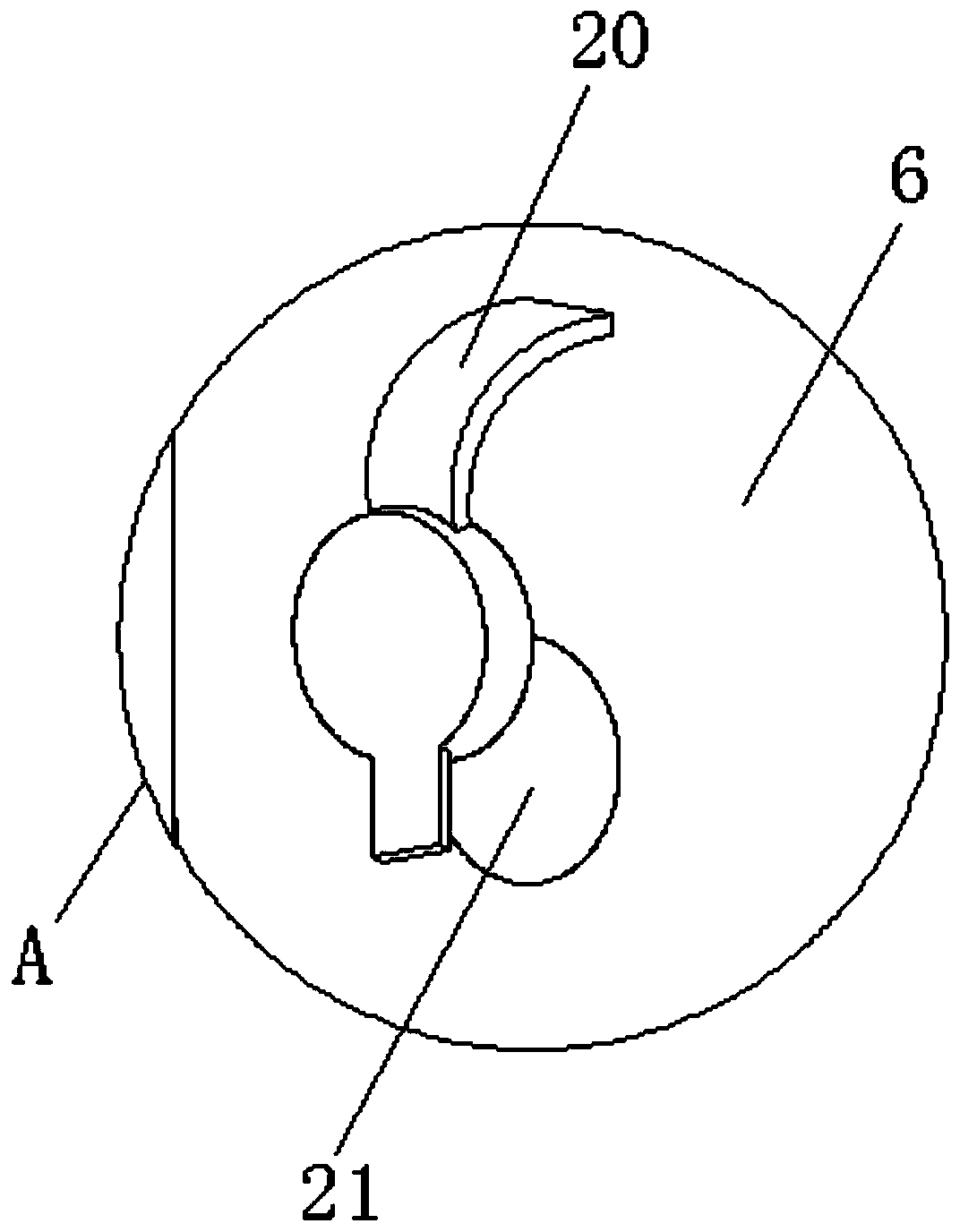

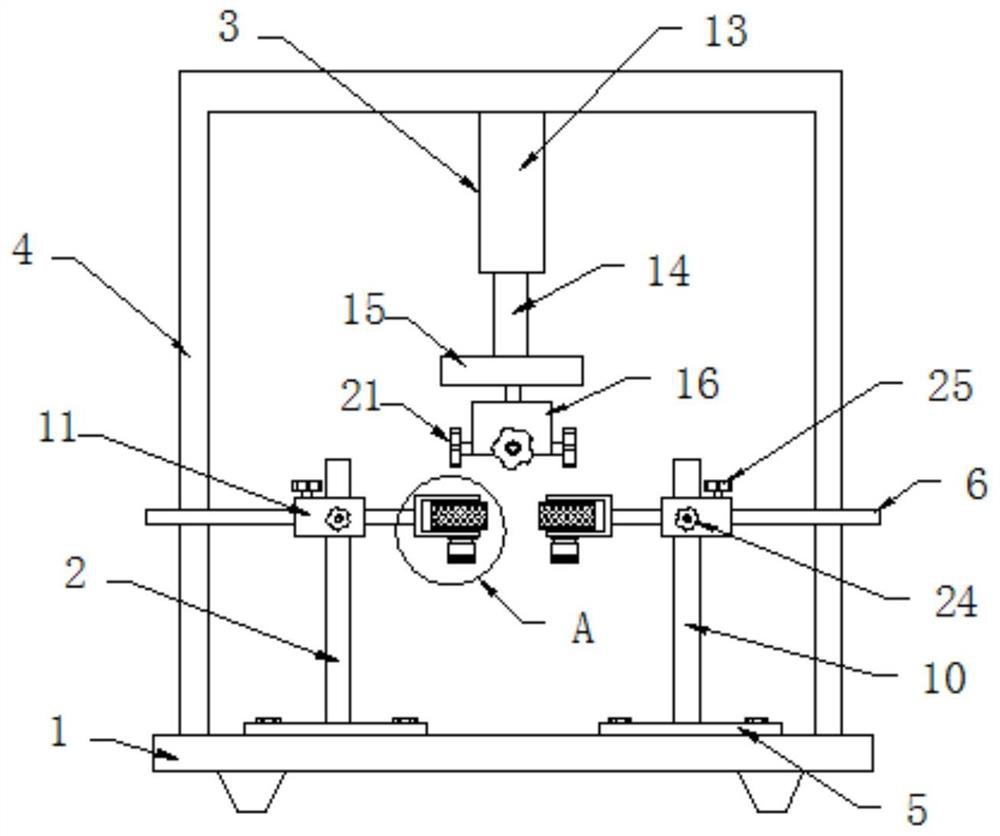

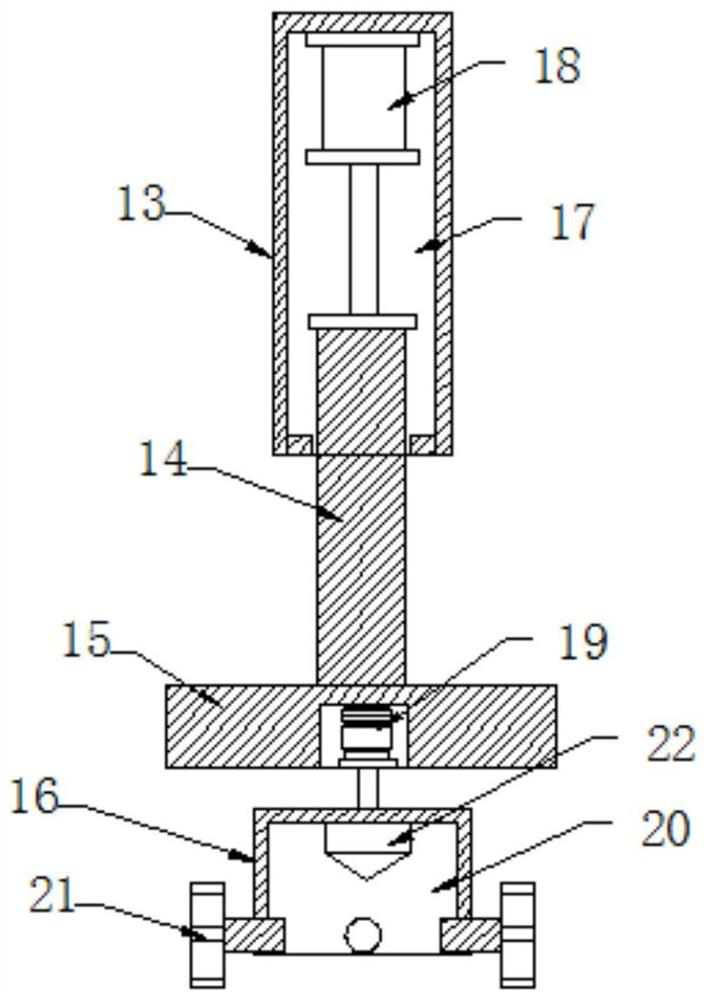

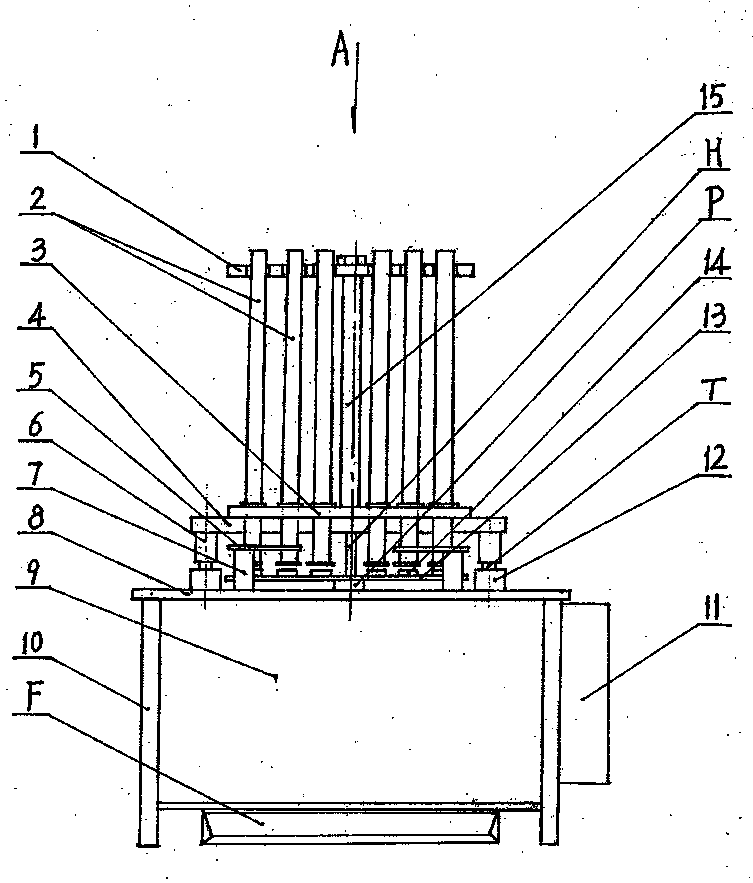

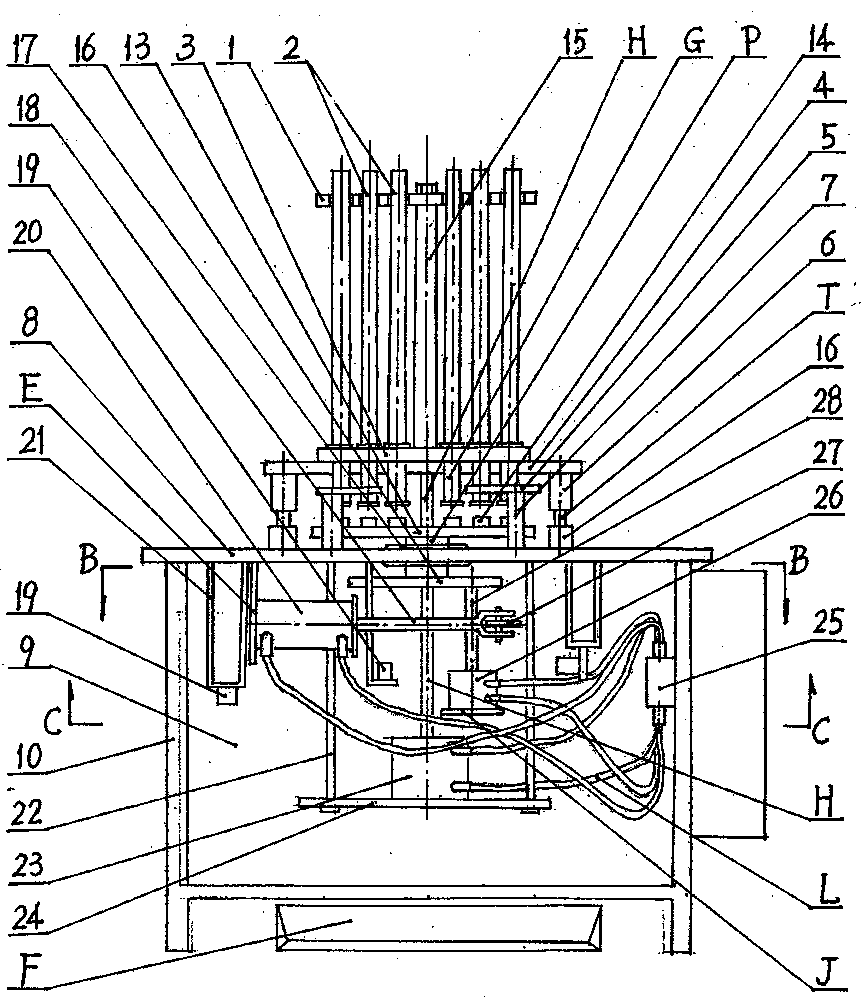

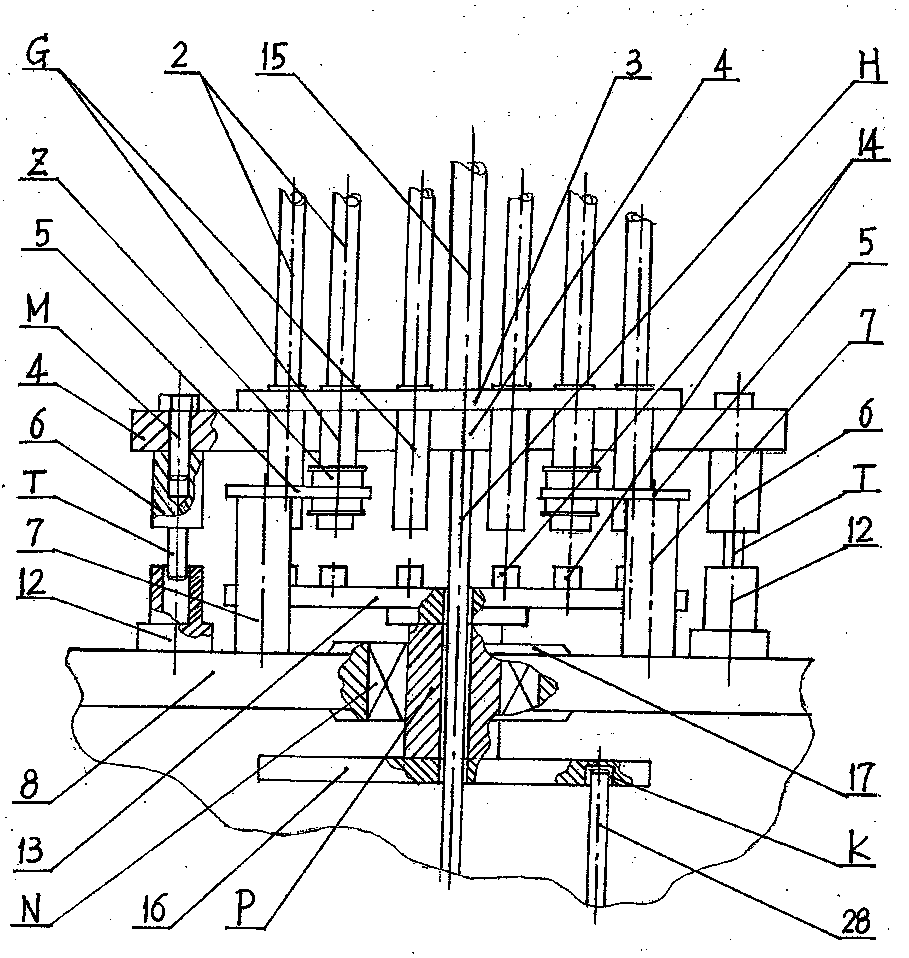

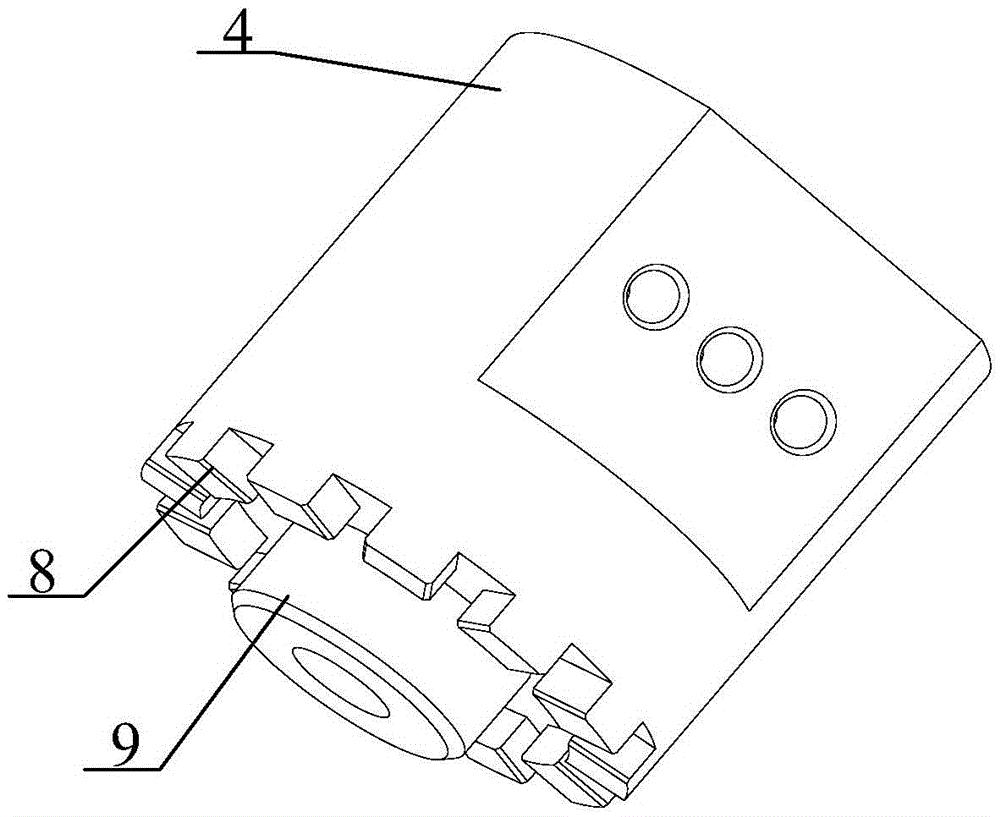

Automatic sorting machine for bearing retainer workpiece concave and convex surfaces

ActiveCN103212539AGuaranteed processing progressImprove performanceSortingProduction lineEngineering

The invention discloses an automatic sorting machine for bearing retainer workpiece concave and convex surfaces. A sorting turntable (13) on an engine base plate (8) is connected with a toggling disk (16) below the engine base plate (8), positioning sorting sleeves (G) are uniformly arranged on a positioning disk (3), sorting rods (2) can be inserted in the positioning sorting sleeves (G), and installed on the sorting turntable (13), a lifting cylinder (22) in an engine room (9) jacks up the positioning disk (3), a pushing and rotating cylinder (20) is connected with a pushing and rotating connecting rod (27) to drive a positioning cylinder (26) to rotate and push the toggling disk (16) to be connected with the sorting turntable (13) and rotate, when the lifting cylinder (22) descends, the positioning sorting sleeves (G) on the positioning disk (3) are matched with corresponding sorting bottom dies (14) on the sorting turntable (13) to enable irregular workpieces falling on the sorting bottom dies (14) to be sorted and classified and then sheathed on the sorting rods (2), and the pushing and rotating cylinder (20) is connected with the pushing and rotating connecting rod (27) to drive the positioning cylinder (26) to return to an original position and repeat the cyclic action. The automatic sorting machine is convenient to operate, reliable in performance, high in degree of automation and good in sorting effect, and can meet the machining needs of a matched production line.

Owner:聊城市义和轴承配件有限公司

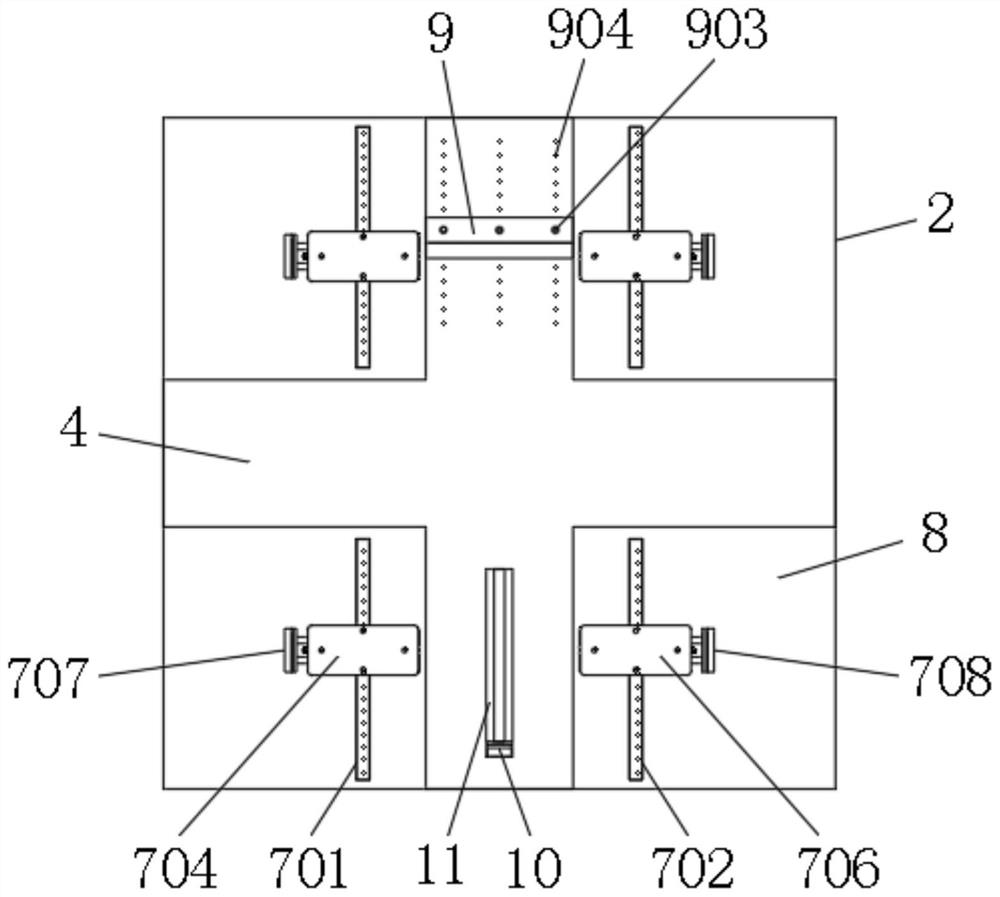

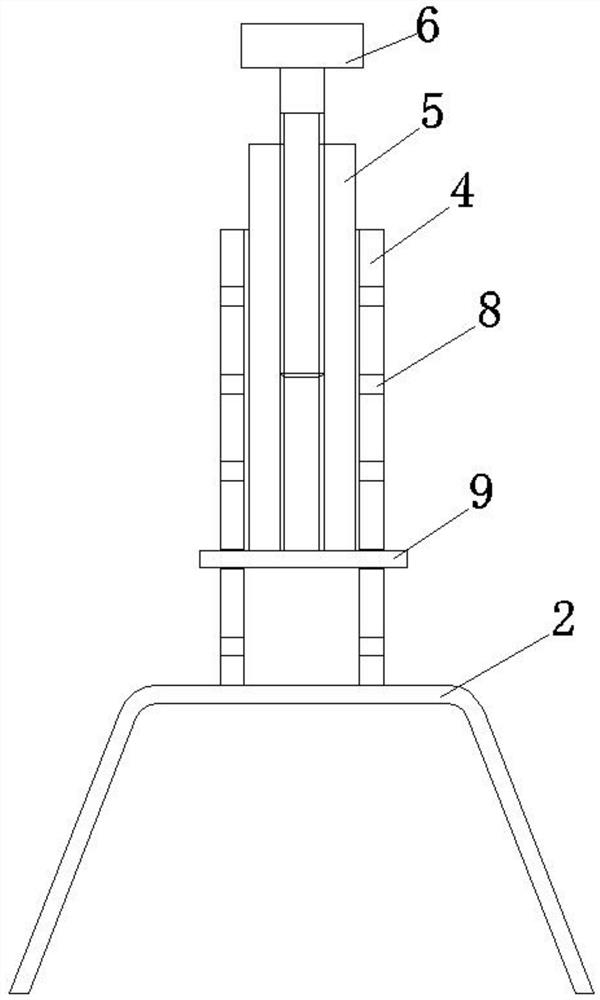

Air cylinder pressing clamp for numerical control machine tool

PendingCN112692617ARapid positioningQuick clampingPositioning apparatusMetal-working holdersNumerical controlEngineering

The invention provides an air cylinder pressing clamp for a numerical control machine tool, and relates to the technical field of numerical control machining. The air cylinder pressing clamp for the numerical control machine tool comprises a base, a rotating platform is rotationally connected to the top of the base, a center base is fixedly connected to the center of the top of the rotating platform, a supporting plate is fixedly connected to the top of the center base, and clamping mechanisms are fixedly installed at the front ends and the rear ends of the two sides of the top of the rotating platform; and openings corresponding to the clamping mechanisms are formed in the corners of the supporting plate, a limiting mechanism is installed at the rear end of the top of the supporting plate, and a pushing mechanism is installed between fixing blocks. By designing the clamping mechanisms, the limiting mechanism and the pushing mechanism, various to-be-machined workpieces of different shapes and sizes can be rapidly clamped and fixed, and after the workpieces are placed on the supporting plate, the pushing mechanism can automatically push the workpieces to move to the designated position, so that the overall working efficiency is greatly improved, and the clamp is worthy of vigorous popularization.

Owner:江苏艾克赛勒金属科技有限公司

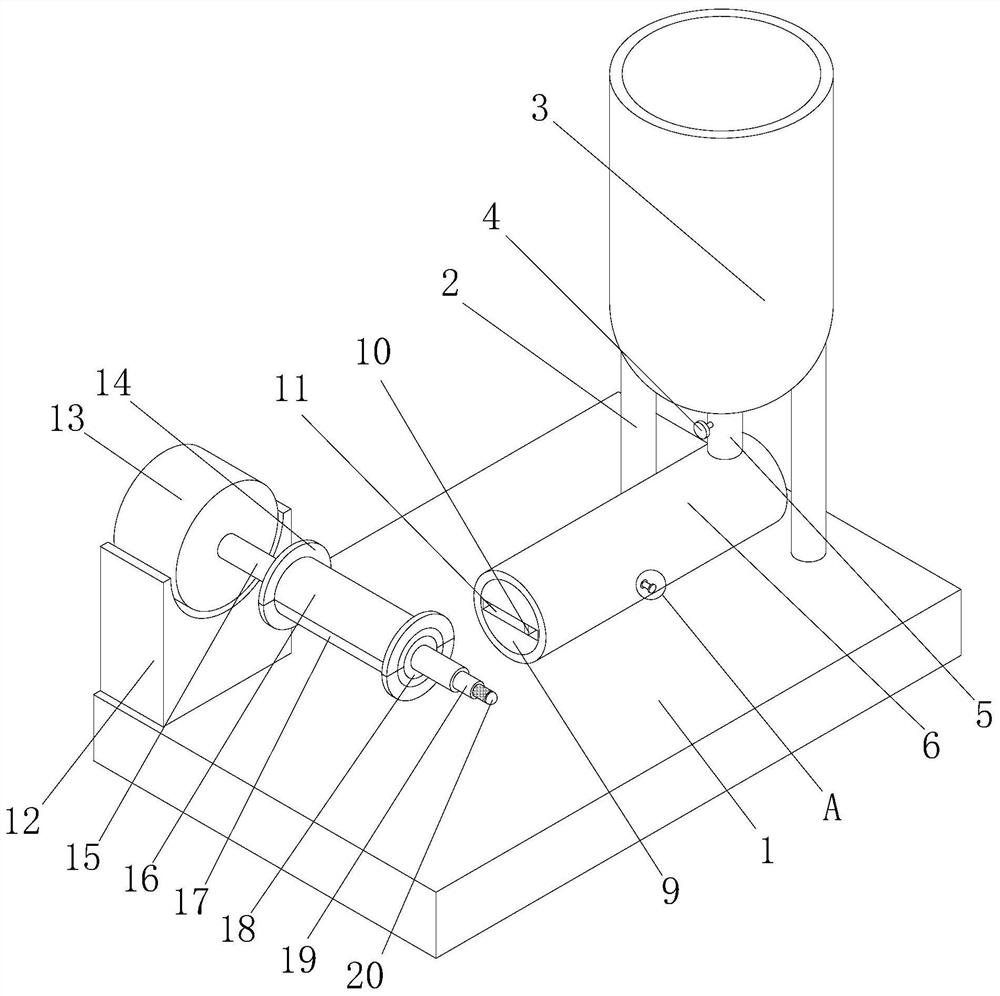

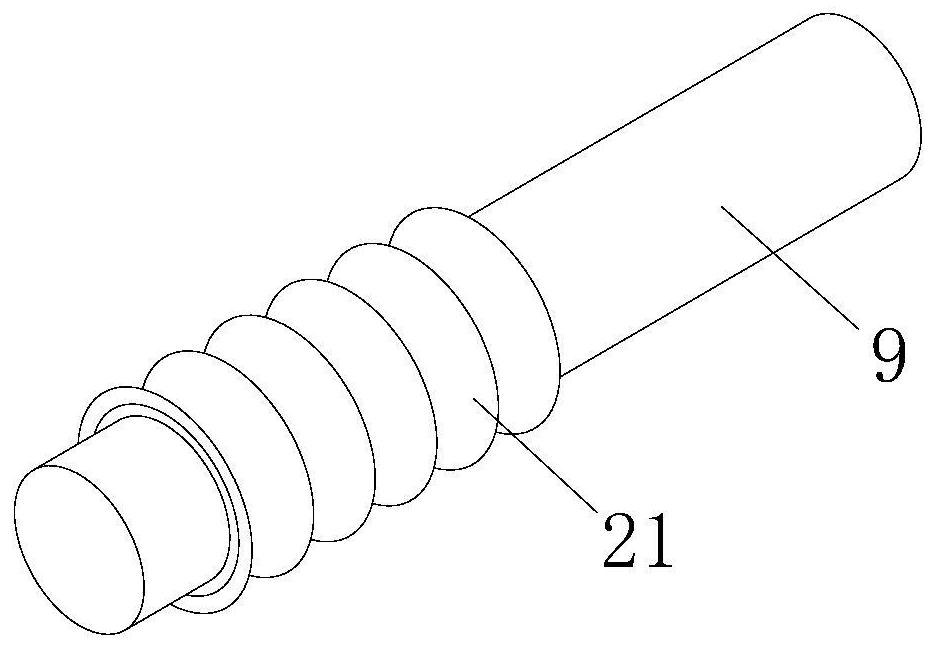

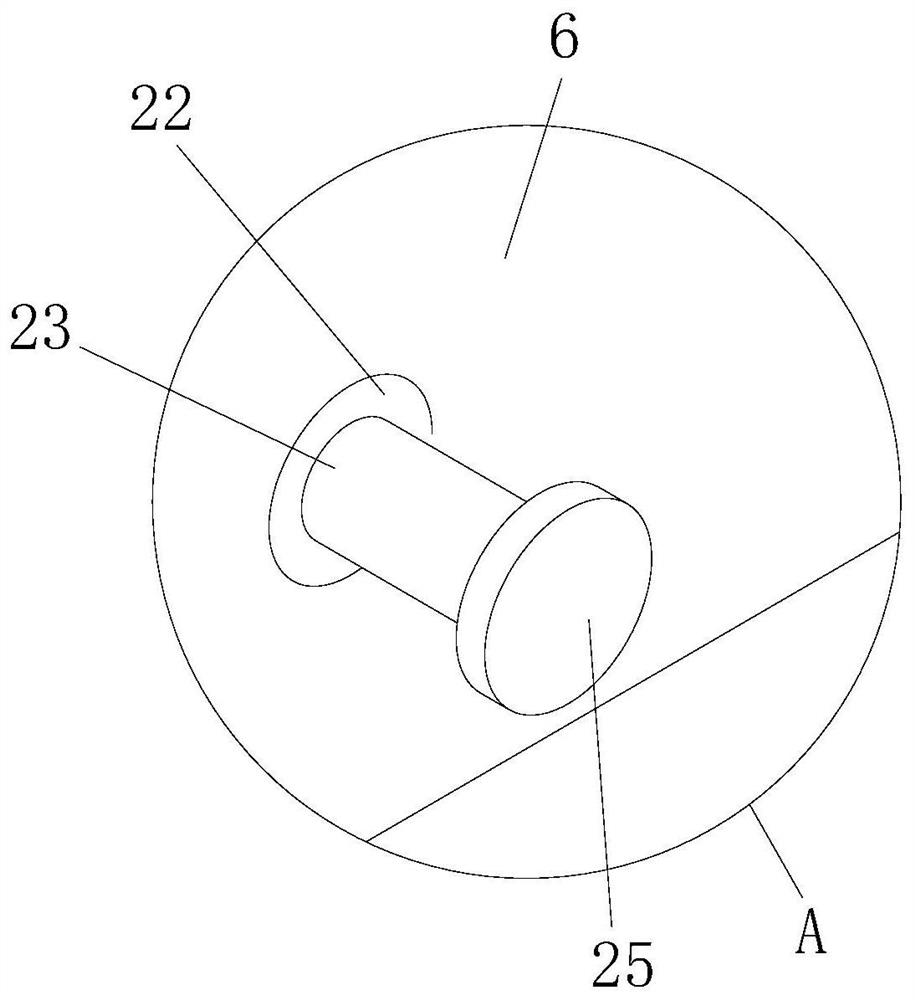

Rubber production pouring device and pouring method

PendingCN112810007AAvoid the phenomenon of replacing the support shaftShorten the timeBeltsMelting tankMechanical engineering

The invention relates to the technical field of production and processing of rubber, and discloses a rubber production pouring device. The rubber production pouring device comprises a base, wherein supporting legs are fixedly connected with the upper surface of the base, a melting tank is fixedly connected with the upper ends of the supporting legs, a discharging pipe is fixedly connected with the lower end of the melting tank, an electromagnetic valve is arranged on the discharging pipe, a sleeve is fixedly connected with the upper end of the base, the sleeve is of a hollow structure, and does not comprise a left side surface, a quick rubber belt forming device is arranged in the sleeve, a supporting board is fixedly connected with the upper end of the base, and an arc groove is formed in the upper end of the supporting board. According to the rubber production pouring device and a rubber production pouring method, by arranging a conical pushing rod, winding rollers of different diameters can be supported according to the requirements, thus the phenomenon that a supporting shaft needs to be replaced for the winding rollers of the different diameters is avoided, and then the time wasted in replacing the supporting shaft is shortened, so that the working efficiency is improved, and the labor intensity of an operator is reduced.

Owner:周俊玉

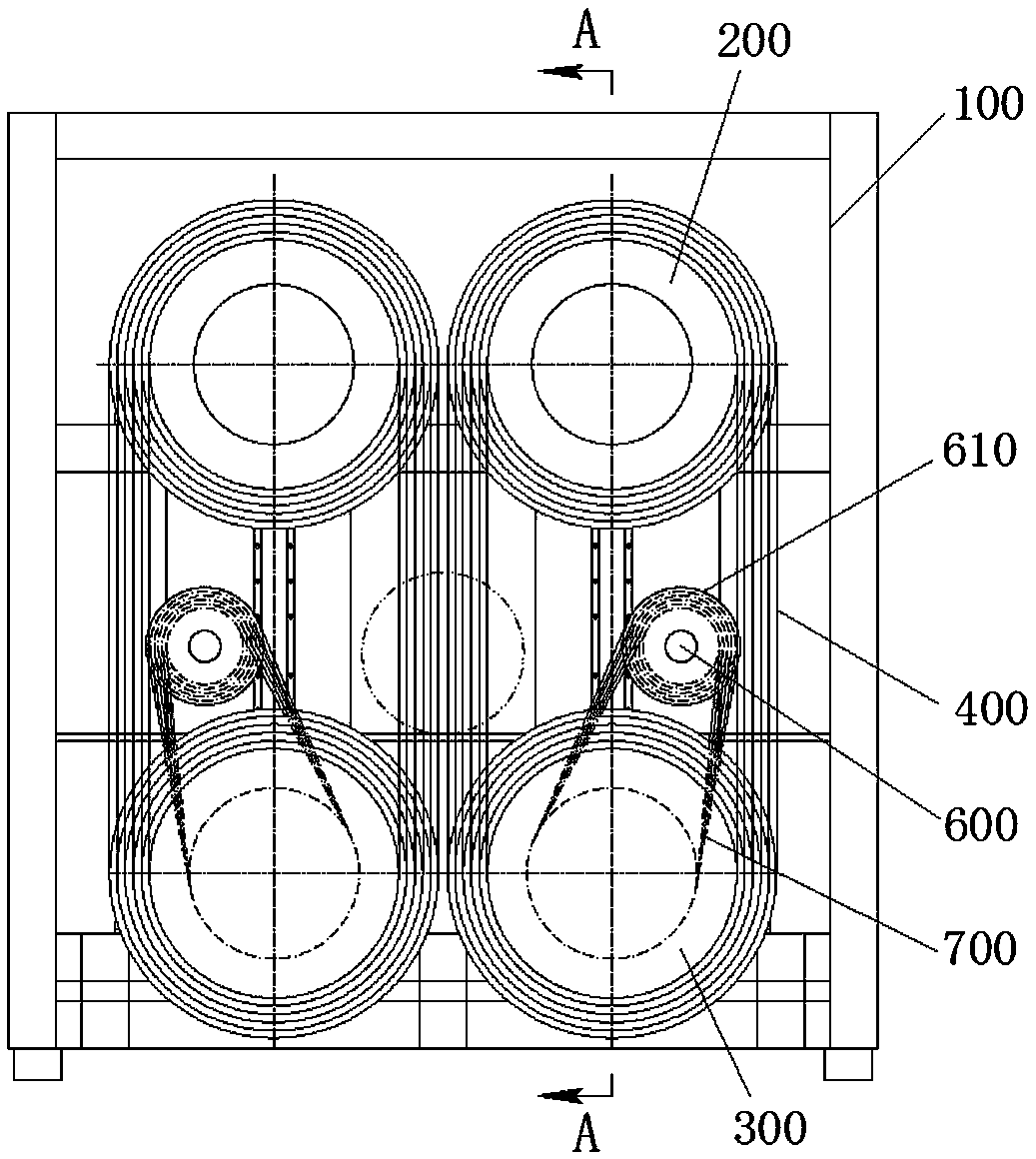

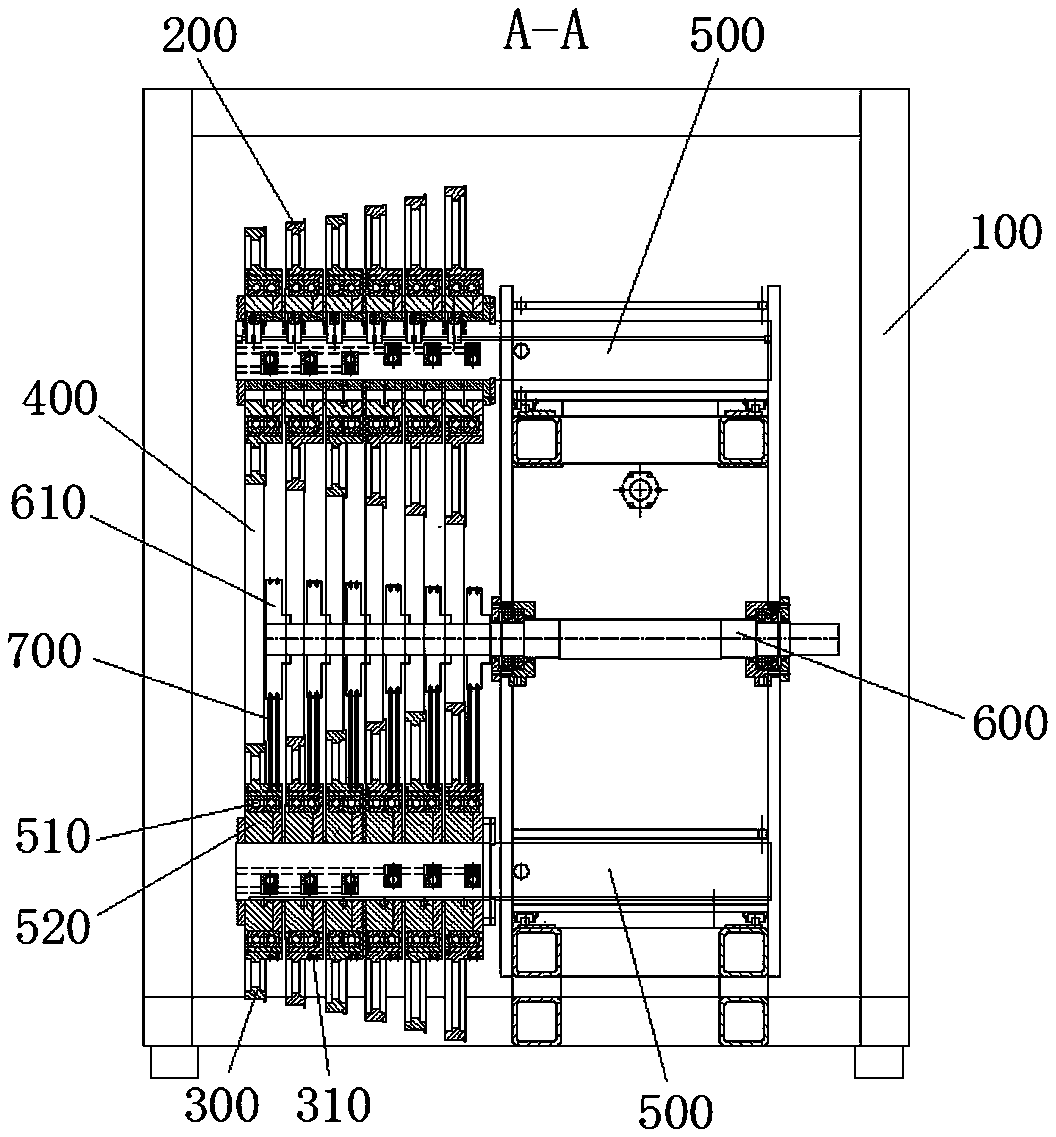

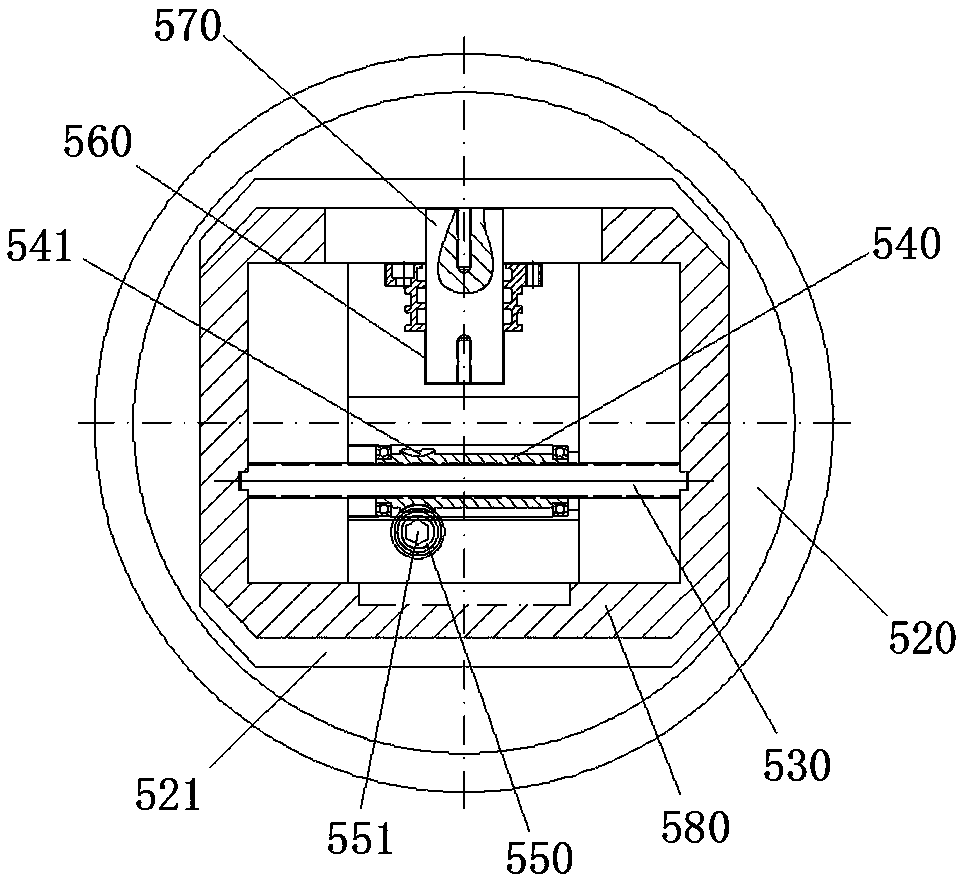

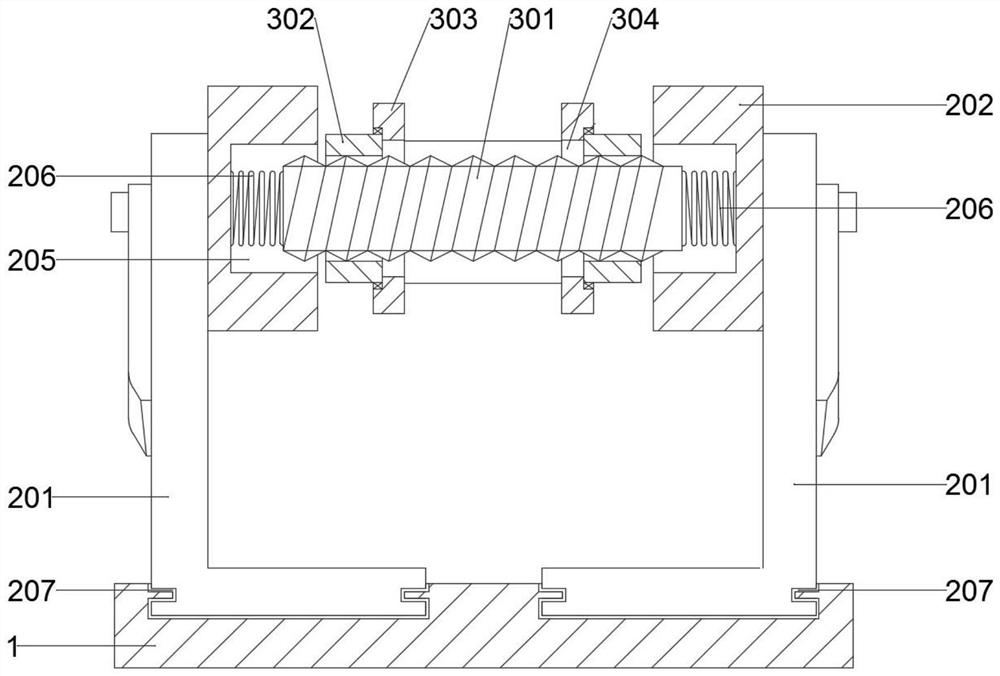

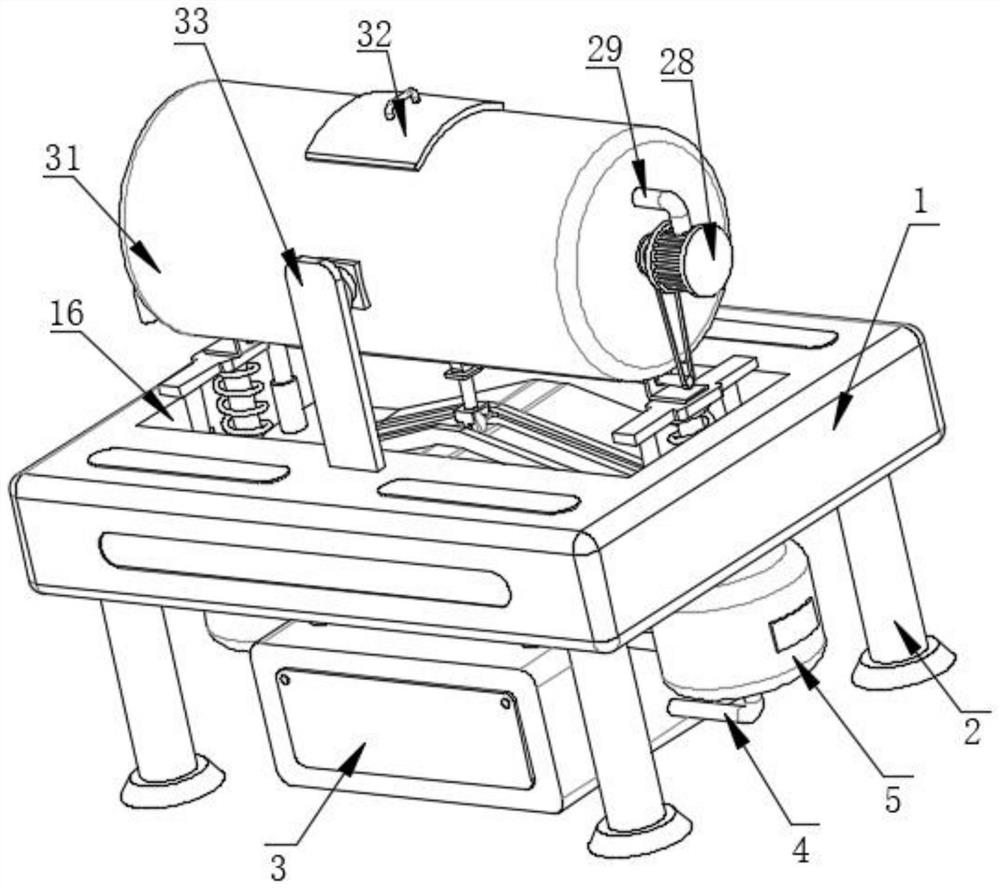

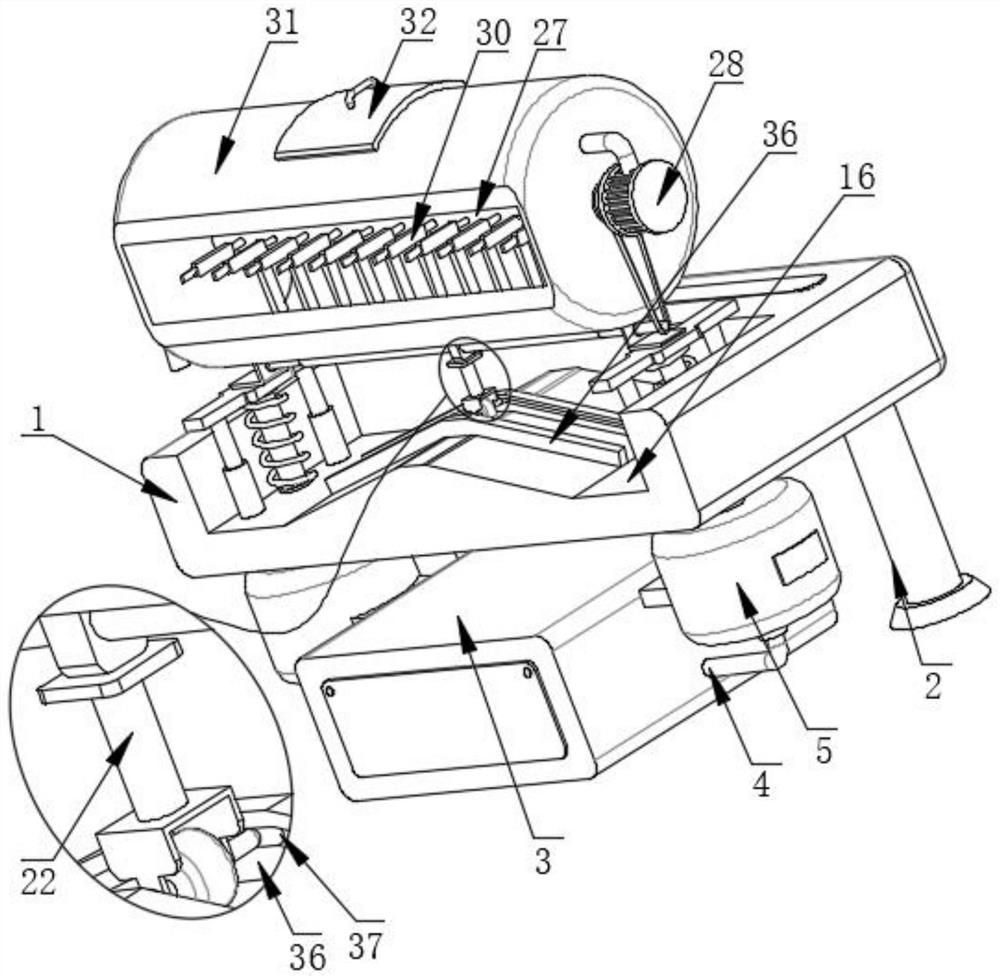

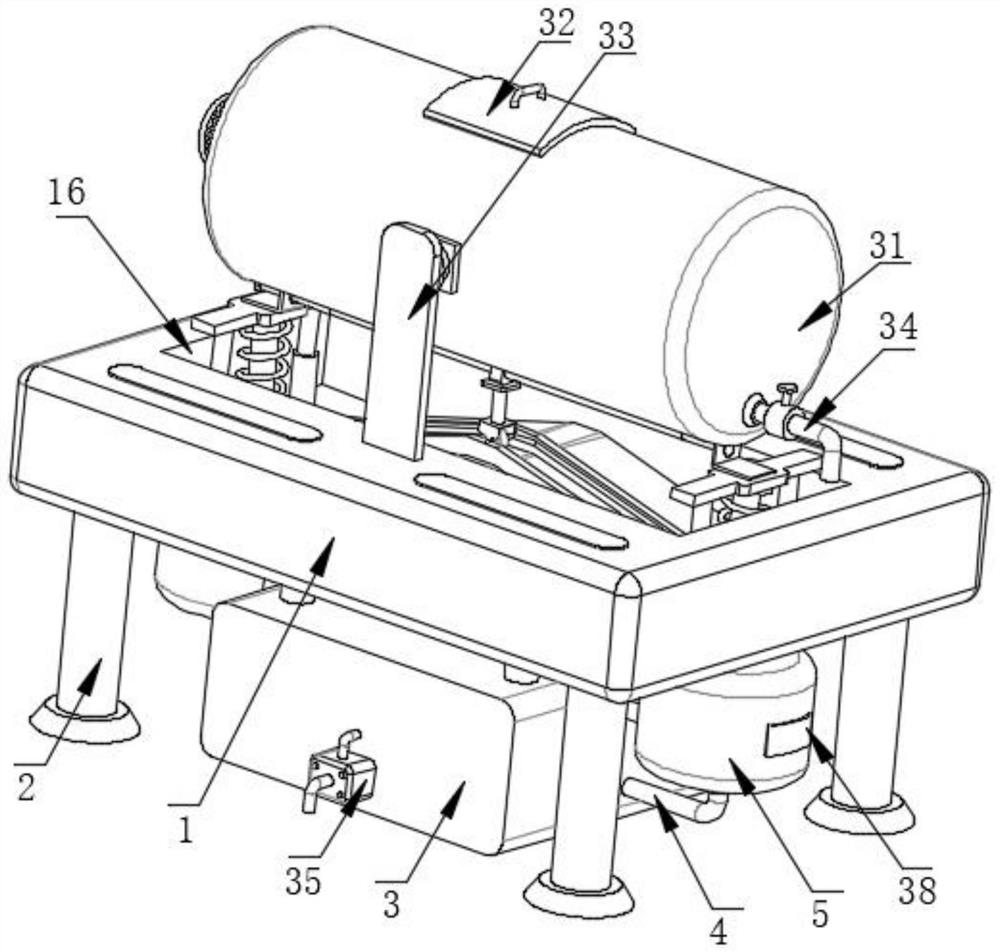

Multi-band saw with adjustable cutting thickness and working method thereof

The invention relates to a multi-band saw with the adjustable cutting thickness and a working method thereof. The multi-band saw comprises a machine frame, at least one set of band saws is arranged onthe machine frame, each set of band saws comprises a plurality of upper band wheels and lower band wheels arranged coaxially and with the gradual-increasing diameters and a plurality of band saw strips forming a multi-ring annular structure, square shafts used for mounting the upper band wheels and the lower band wheels are arranged at the upper and lower parts of the machine frame correspondingly, each upper band wheel and each lower band wheel are in rotatably matched with connecting discs through bearings respectively, each connecting disc is mounted on the corresponding square shaft in asleeving mode and can move left and right relative to the corresponding square shaft, and an adjusting mechanism used for adjusting the left and right positions of each connecting disc is arranged onthe corresponding square shaft. The multi-band saw with the adjustable cutting thickness achieves the rapid adjustment of thickness cutting, and does not need to replace the upper and lower band wheels of different diameters to adjust, the adjustment is simple, the operation is simple, the time and labor are saved, the processing progress is ensured, meanwhile, all the band saw strips can maintainthe consistent linear speed for working, and the fact that the service life of all the band saw strips is tend to be consistent is ensured.

Owner:MINHOU MINTAI MACHINERY CO LTD

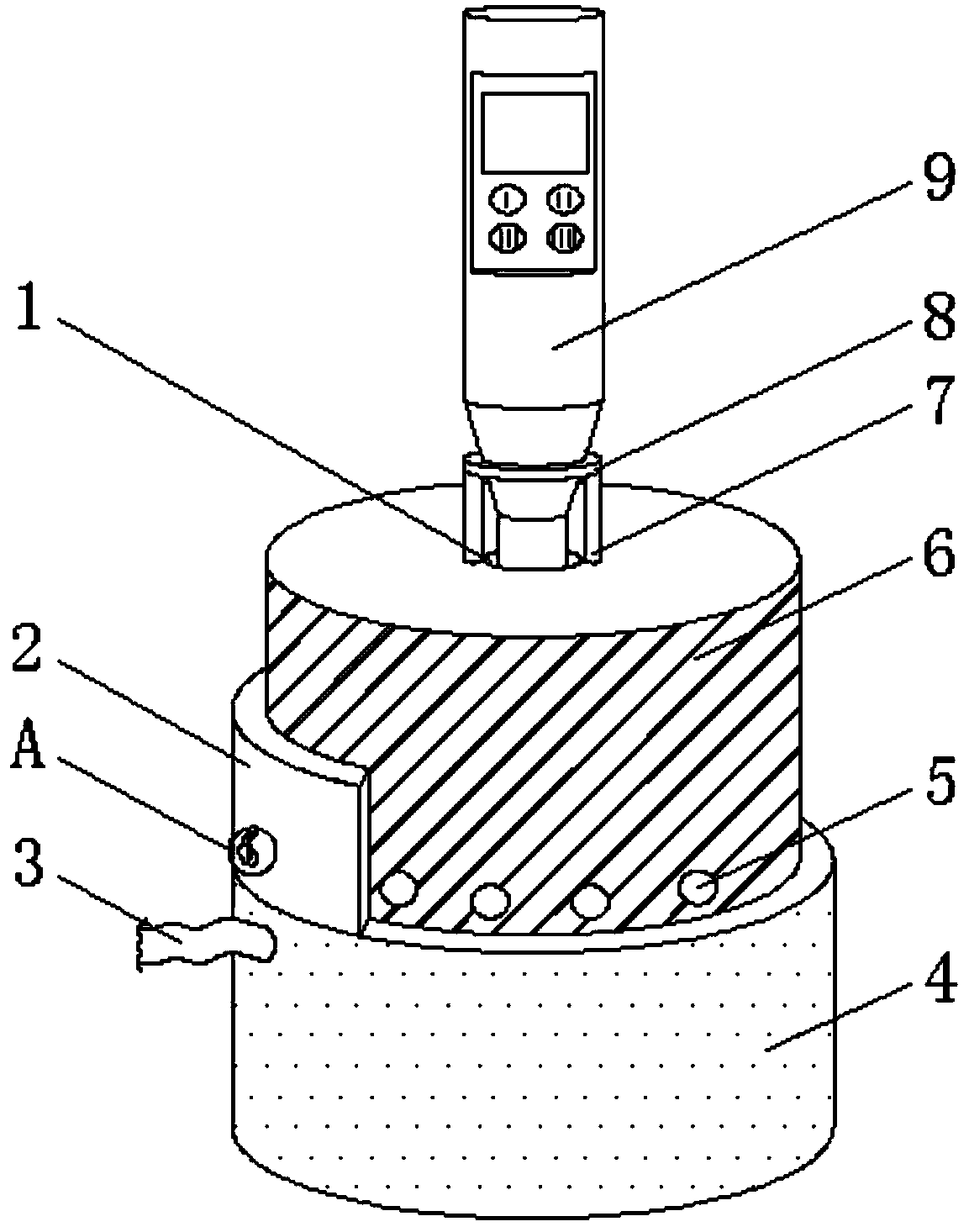

Food detection device for food processing factory

InactiveCN110927350AFast cleaningGuaranteed processing progressTesting foodMaterial electrochemical variablesCleansing AgentsIndustrial engineering

The invention discloses a food detection device for a food processing factory, and relates to the technical field of food processing. The food detection device comprises a water tank, the upper surface of the water tank is fixedly connected with a cleaning tank, the outer surface of the water tank is fixedly communicated with a water delivery pipe, a first sealing bearing is fixedly embedded in the bottom surface of the cleaning tank, a second sealing bearing is fixedly embedded in the upper surface of the water tank, and the first sealing bearing is located right above the second sealing bearing. The design structure is reasonable, a sugar solution cleaning agent can be guided into a water tank through a water inlet pipe; a worker inserts the detection end of the PH meter into the cleaning tank from the insertion groove; a micro pump is started to enable a sugar solution cleaning agent to enter the conveying pipe through a water inlet pipe and a rotating pipe and to be sprayed out from a water spraying opening to make contact with the PH meter; the micro motor is started to drive the rotating pipe, the brush and the conveying pipe to wash the PH meter, the situation that manual wiping is needed when PH timing is frequently used is avoided, the cleaning speed is increased, and the overall measuring speed and the machining progress are guaranteed.

Owner:合肥民祯健康科技有限公司

Tympanic membrane production device

PendingCN114257947AImprove machining accuracyGuaranteed machining accuracyDiaphragm materialsDiaphragm constructionTympanic MembranesSurgery

The invention relates to a tympanic membrane production device which comprises a vibrating ring cutting mechanism, a laminating mechanism, a hot pressing mechanism and a material arranging mechanism, the laminating mechanism comprises a vibrating ring feeding manipulator, a carcass feeding manipulator, a material placing assembly and a pressing assembly; the material arranging mechanism comprises a punching feeding mechanical arm, a punching assembly, a punching taking mechanical arm and a stacking assembly. And the punching and feeding manipulator is used for conveying the heated and dried semi-finished tympanic membrane to the punching assembly for punching so as to obtain a finished tympanic membrane product. According to the tympanic membrane production device, the vibrating ring is firstly subjected to hot-press fitting and hot-press forming, and finally the tympanic membrane with the unified size specification is obtained through punching, so that the influence of high temperature on the size change of the vibrating ring is eliminated, and the machining precision of the tympanic membrane is improved; and the carcass is made of a hard material, and the carcass is firstly attached to the vibrating ring, so that the moving of the vibrating ring can be realized by grabbing the carcass, the deformation of the soft vibrating ring is further prevented, and the processing precision of the tympanic membrane is further ensured.

Owner:JIANGSU FENGDI TECH CO LTD

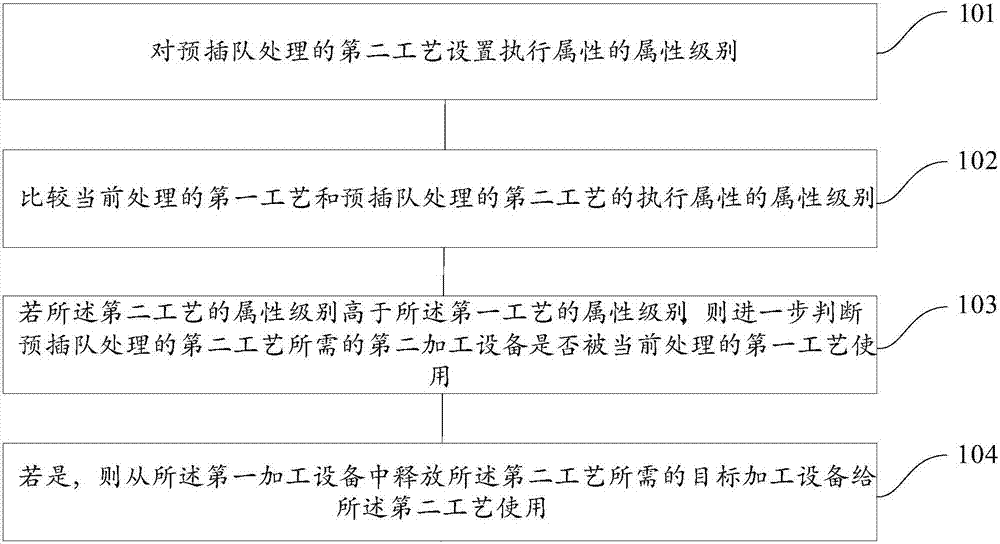

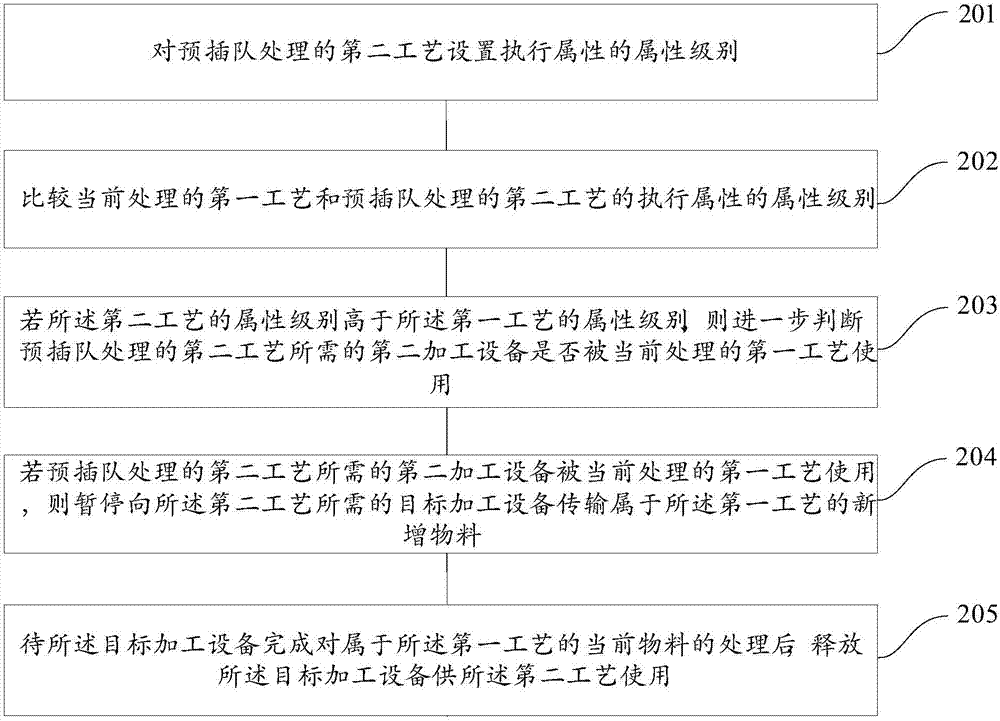

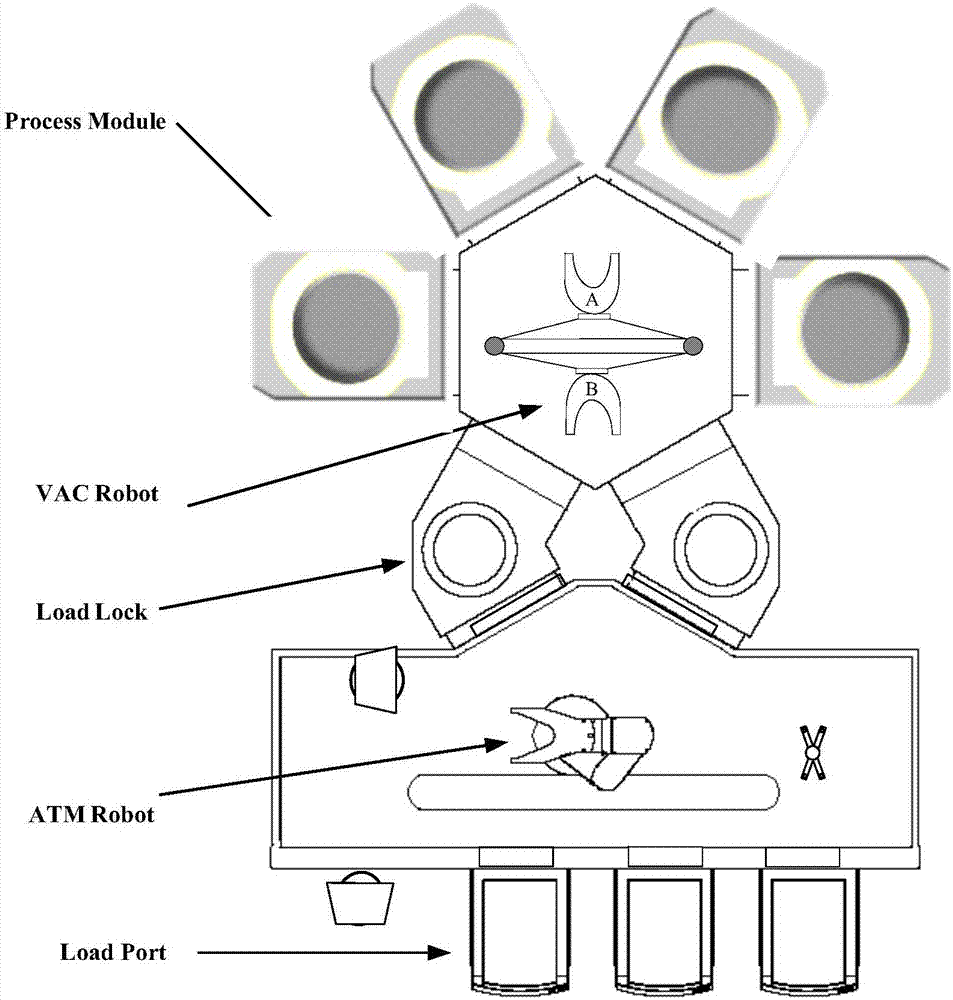

Procedure sequence control method and apparatus

ActiveCN107367976AOvercoming Handling DeficienciesReduce waiting timeProgramme controlComputer controlParallel computingProcedure sequence

The invention discloses a procedure sequence control method and apparatus. The method includes the steps of setting an attribute level of an execution attribute for a second procedure to be subjected to queue jumping processing; comparing an attribute level of an execution attribute of a currently processed first procedure with the attribute level of the execution attribute of the second procedure to be subjected to the queue jumping processing; if the attribute level of the second procedure is higher than the attribute level of the first procedure, further determining whether a second processing device required by the second procedure to be subjected to queue jumping processing is used by the currently processed first procedure; and if so, releasing a target processing device required for the second procedure from a first processing device for the use in the second procedure. The invention realizes the queue jumping processing for the second procedure which is urgently needed to be processed, overcomes the defect of a conventional method that the first processing device currently used for the first procedure cannot be used for processing the second procedure which is urgently needed to be processed until the currently processed first procedure is finished, and ensures processing progress of the second procedure which is urgently needed to be processed.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Double-sided adhesive tape convenient for automatic cut-off and processing process thereof

ActiveCN111268490AEasy to useEasy to installArticle deliveryWebs handlingStructural engineeringMicro motor

The invention relates to the technical field of double-sided adhesive tapes, in particular to a double-sided adhesive tape convenient for automatic cut-off and a processing process thereof. The double-sided adhesive tape is clamped by a threaded sleeve block and clamping blocks, and a distance between the left and right side clamping blocks can be adjusted to clamp double-sided adhesive tapes of different widths, so that the production and use of the double-sided adhesive tapes of different widths are convenient; a compression spring is arranged in a mounting slot hole, so that mounting and dismounting of a threaded rod are convenient, and therefore, mounting efficiency in a processing process is improved, and processing progress is guaranteed; a micro motor drives a two-way threaded rod to rotate, so that an upper cutting blade and a lower cutting blade generate relative movement under limitation of a guide rod to quickly cut off the double-sided adhesive tape, and therefore, cut-offquality of the double-sided adhesive tape is guaranteed, adhesion at the cut-off hole is avoided, next-time use is not affected, and working efficiency of a user is effectively improved; the double-sided adhesive tape is fixed onto an operation desktop of a user through a mounting plate, so that use of the user is convenient; and the double-sided adhesive tape does not move in use through a fixingsupporting mechanism.

Owner:NINGGUO QIANHONG ELECTRONIC CO LTD

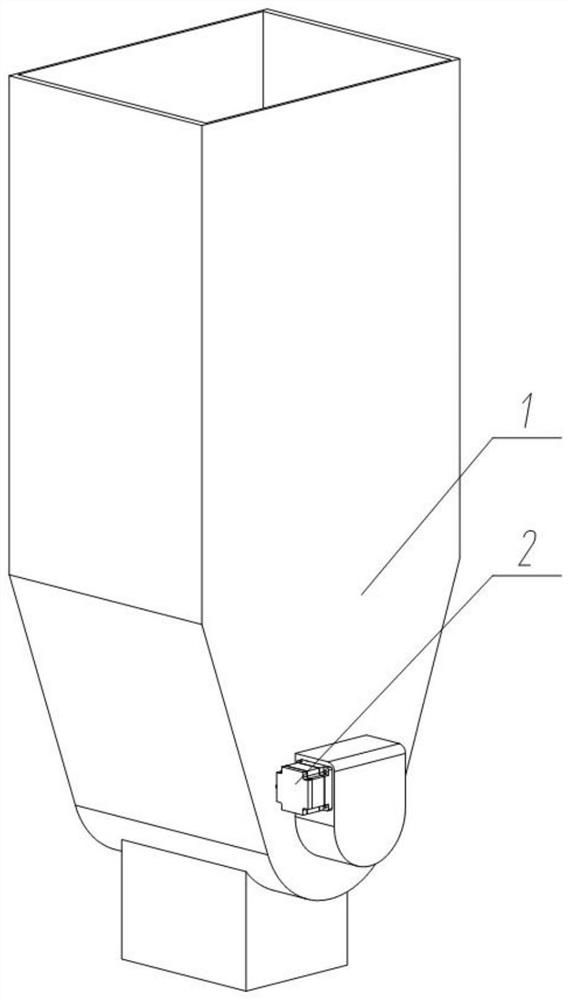

Clinker discharging device for cement production and processing

ActiveCN114684631AAvoid cloggingControl the output speedLarge containersLoading/unloadingProcess engineeringMechanical engineering

The invention provides a clinker discharging device for cement production and processing, and relates to the technical field of cement production. The discharging speed control part is rotationally connected to the lower part of the interior of the clinker discharging hopper; the discharging transmission mechanism is arranged in the right side of the clinker discharging hopper; the cleaning push plates are arranged in pairs, the six pairs of cleaning push plates are arranged, and the six pairs of cleaning push plates are distributed in a circumferential array mode and are slidably connected to the left side and the right side of the clinker discharging hopper; and the cleaning driving mechanism is arranged in the discharging speed control piece, and the discharging speed control piece drives the cleaning push plate to slide left and right through the cleaning driving mechanism. The discharging speed is effectively controlled, materials are effectively prevented from being hardened and blocking the discharging port, smooth discharging is guaranteed, the discharging speed is increased, the follow-up machining quality is guaranteed, and the problems that the discharging speed of an existing clinker bin is difficult to control, and the materials are prone to being hardened and blocking the discharging port to affect the discharging effect are solved.

Owner:GUANGYUAN GUANGWANG LUJIABA CEMENT

A kind of double-sided adhesive tape which is convenient for automatic cutting and its processing technology

The invention relates to the technical field of double-sided adhesive tape, in particular to a device for automatically cutting double-sided adhesive tape and its processing technology. The distance between them can clamp double-sided tapes of different widths, which is convenient for the production and use of double-sided tapes of different widths; there is a compression spring in the installation notch, which is convenient for the installation and removal of the threaded rod, and improves the installation efficiency during processing. Guarantee the processing progress; the micro-motor drives the two-way threaded rod to rotate, so that the upper cutting blade and the lower cutting blade move towards each other under the restriction of the guide rod, and quickly cut off the double-sided adhesive tape, ensuring the cutting quality of the double-sided adhesive tape, so that the cutting edge does not Adhesion does not affect the next use, and effectively improves the user's work efficiency; the installation plate fixes the double-sided adhesive on the user's operating table, which is convenient for the user to use, and fixes the support mechanism so that the double-sided adhesive can be used when it is in use. , no movement occurs.

Owner:NINGGUO QIANHONG ELECTRONIC CO LTD

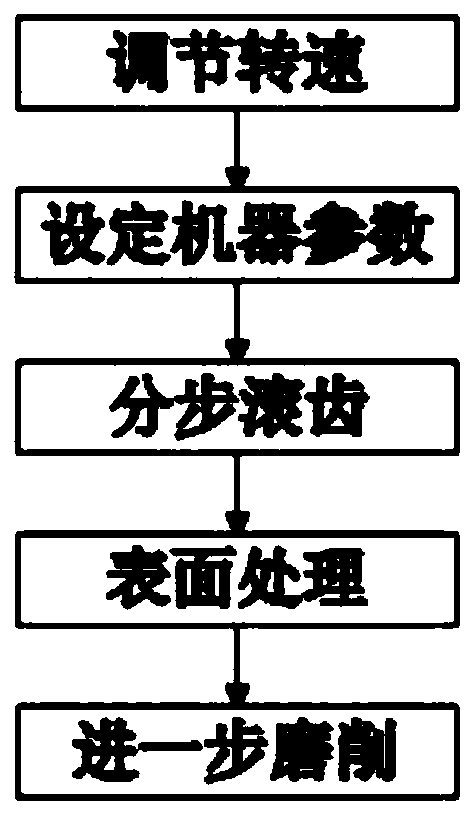

A rough machining method for tooth arc

Owner:JIANGYIN YONGXING MACHINERY MFG

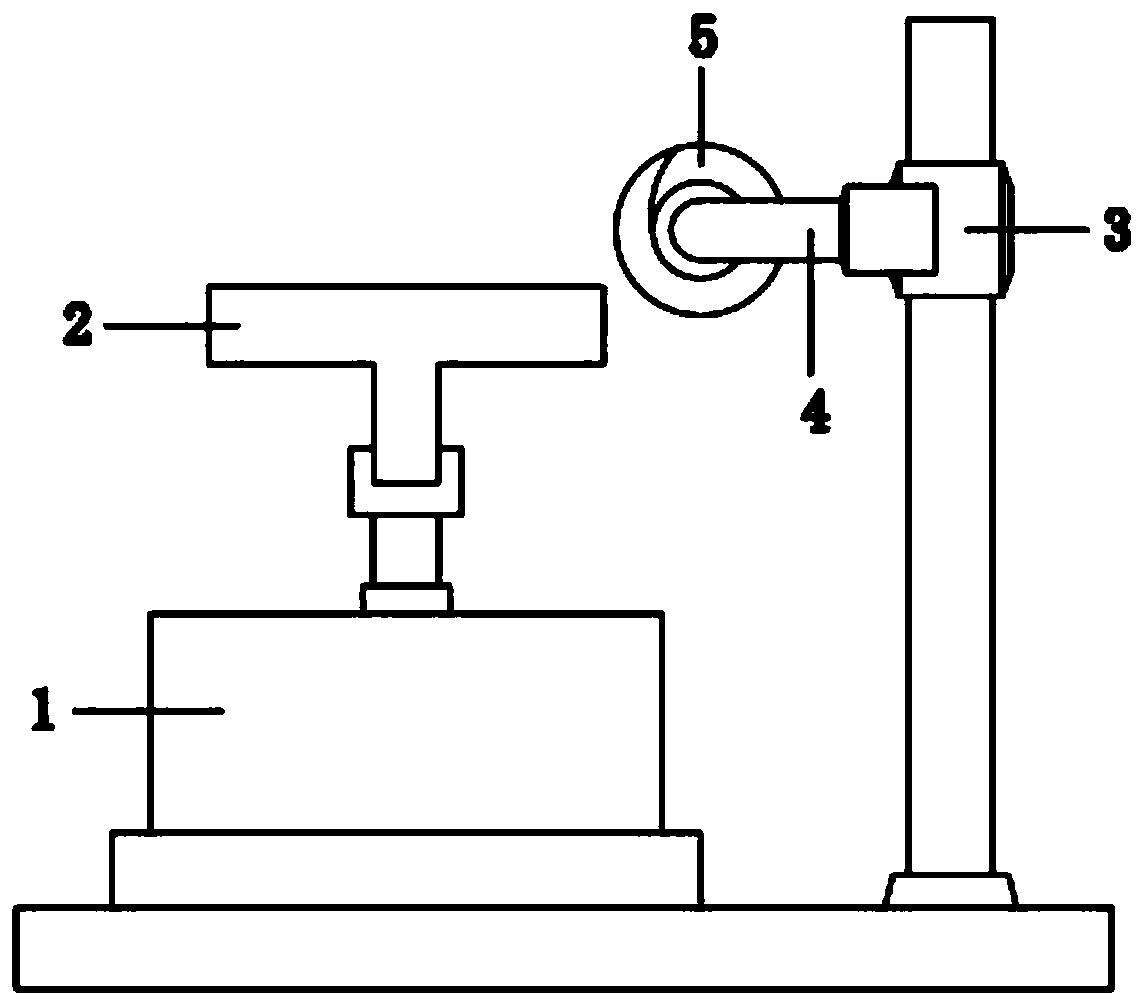

A metal pipe grinding device

ActiveCN108381345BReasonable structural designIncrease sanding speedGrinding drivesBelt grinding machinesPipe fittingElectric machinery

Owner:湖南冶盈金属材料有限公司

Tool platform for steel structure machining

PendingCN112959281AImprove processing efficiencyReduce labor intensityWork benchesMachiningIndustrial engineering

The invention discloses a tool platform for steel structure machining, and solves the technical problems that in the prior art, a universal tool platform is not flexible in adjustment, and time and labor are wasted during adjustment. The tool platform comprises a plurality of tool platform units which are distributed side by side, wherein each tool platform unit comprises a base and a plurality of adjusting mechanisms which are arranged on the base side by side at equal intervals and used for adjusting the supporting height. The tool platform is simple in structure, scientific and reasonable in design and convenient to use. The supporting height can be adjusted according to the structure and appearance of a steel structural component, and the adjusting mode is simple, convenient and flexible. Meanwhile, the labor intensity of manual adjusting operation can be effectively reduced, the tool adjusting time is saved, the machining efficiency of the steel structural component is improved, and the machining progress of the steel structural component is guaranteed.

Owner:CHINA MCC5 GROUP CORP

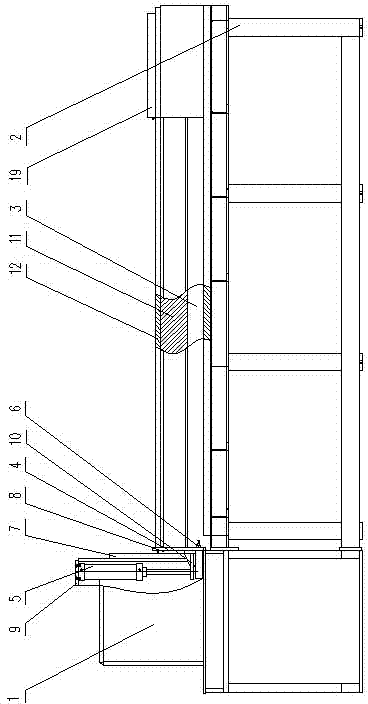

An electroslag welding anti-spill box structure and its processing method

ActiveCN109202334BReduce processing difficultyReduce processing costsWelding/cutting auxillary devicesAuxillary welding devicesSlag (welding)Electroslag welding

The invention discloses a casing structure preventing electric welding slag from overflow. The structure comprises upper and lower cover plates arranged in parallel, two web plates are arranged in parallel between the upper and lower cover plates, support rods and internal separator plates are arranged between the two web plates, an included angle is formed between each support rod and each web plate, positions where each web plate makes contact with the upper and lower cover plates are provided with electric welding slag liner plates respectively, and each electric welding slag liner plate clings the inner side surfaces of the upper and lower covers plates and the corresponding web plate. The invention also discloses a processing method of the casing structure. Via the processing method,the size precision of the casing type separator plates and web plates is improved, the processing difficulty is reduced, the electric welding slag liner plates need no machining, the processing cost is reduced, the clinging degree between the electric welding slag liner plates and the upper and lower cover plates is detected in a visualized way, and the electric welding slag is prevented from overflow.

Owner:SHAANXI WEIHONG STEEL STRUCTURE CO LTD

Material blocking and pushing device for electronic cut-to-size saw

Owner:JIANGSU MINGGE FORGING EQUIP CO LTD

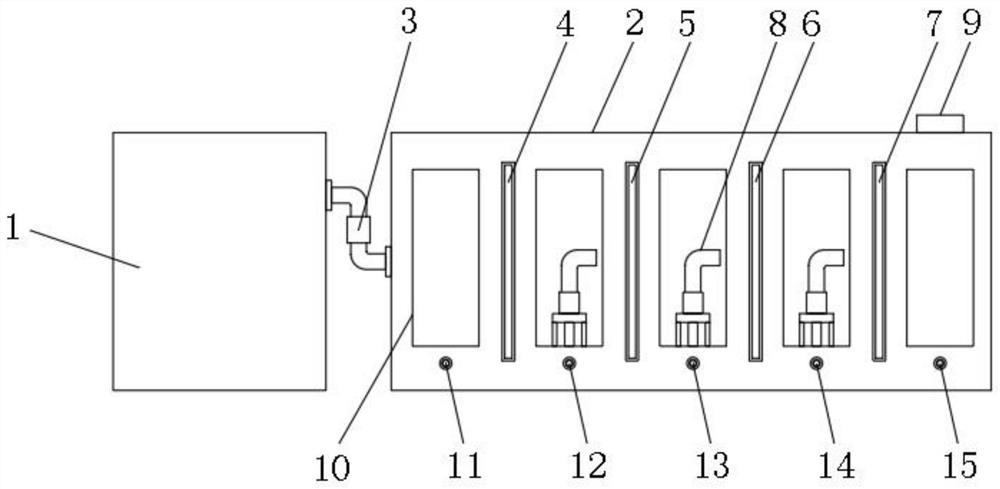

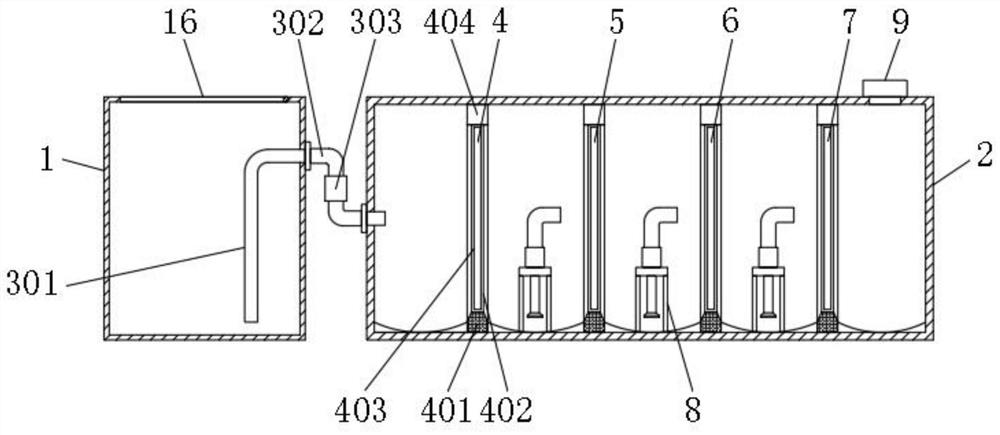

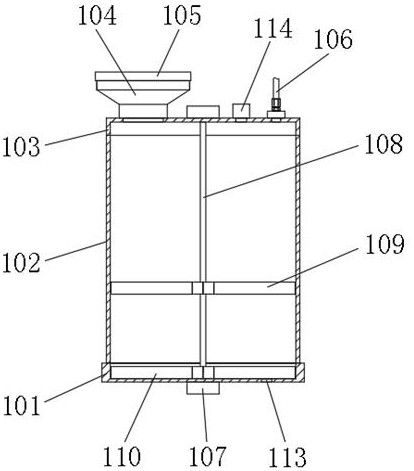

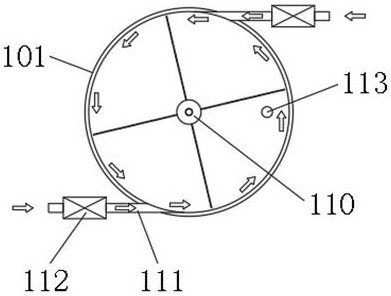

Powder storage and supply system

InactiveCN112693043AEvenly graded filtrationMeet supply demandProcess engineeringMechanical engineering

The invention provides a powder storage and supply system, and relates to the technical field of powder supply. The powder storage and supply system comprises a storage bin and a screening bin; a suction mechanism is arranged between the storage bin and the screening bin; a first screening mechanism, a second screening mechanism, a third screening mechanism and a fourth screening mechanism are arranged in the center of the screening bin; a plurality of blowing mechanisms corresponding to the second screening mechanism, the third screening mechanism and the fourth screening mechanism are arranged at the bottom of the center of the screening bin; an exhaust mechanism is fixedly connected to one side of the top of the screening bin; and a plurality of observation windows are installed on the outer surface of the front end of the screening bin. By designing the storage bin and the classified screening bin, the powder can be well stored, and meanwhile, the stored powder can be quickly classified, screened and supplied, so that the overall working efficiency is greatly improved, and the system is worthy of vigorous popularization.

Owner:石柱土家族自治县茶园建筑材料有限公司

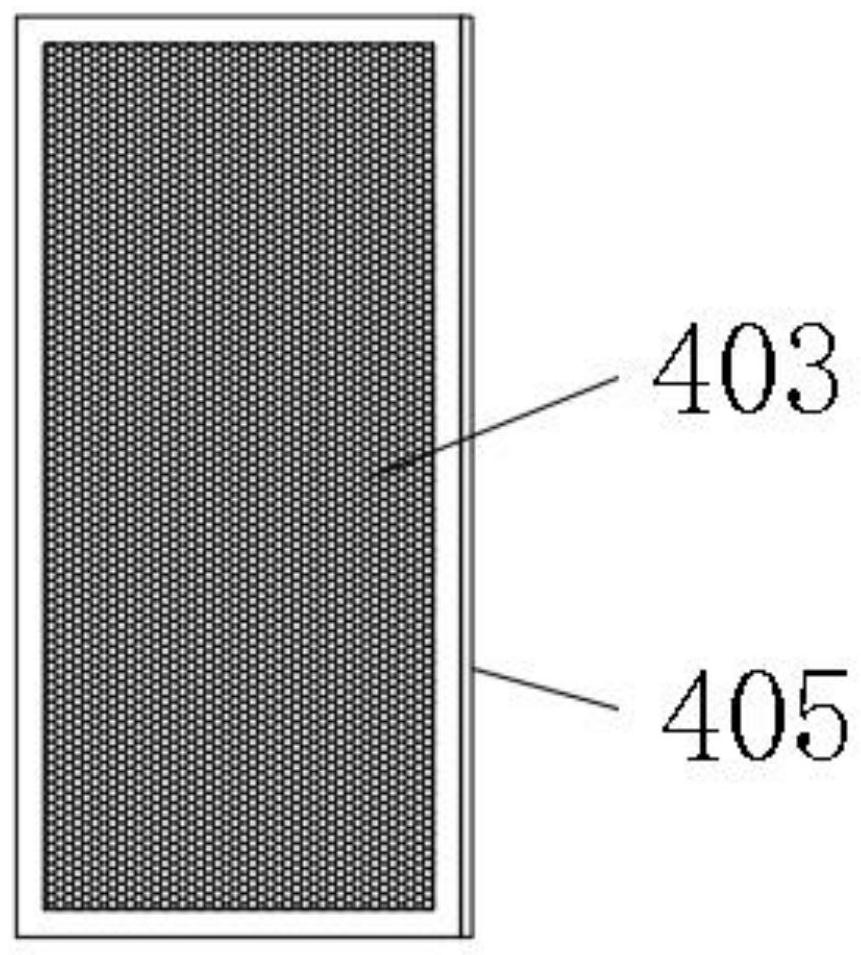

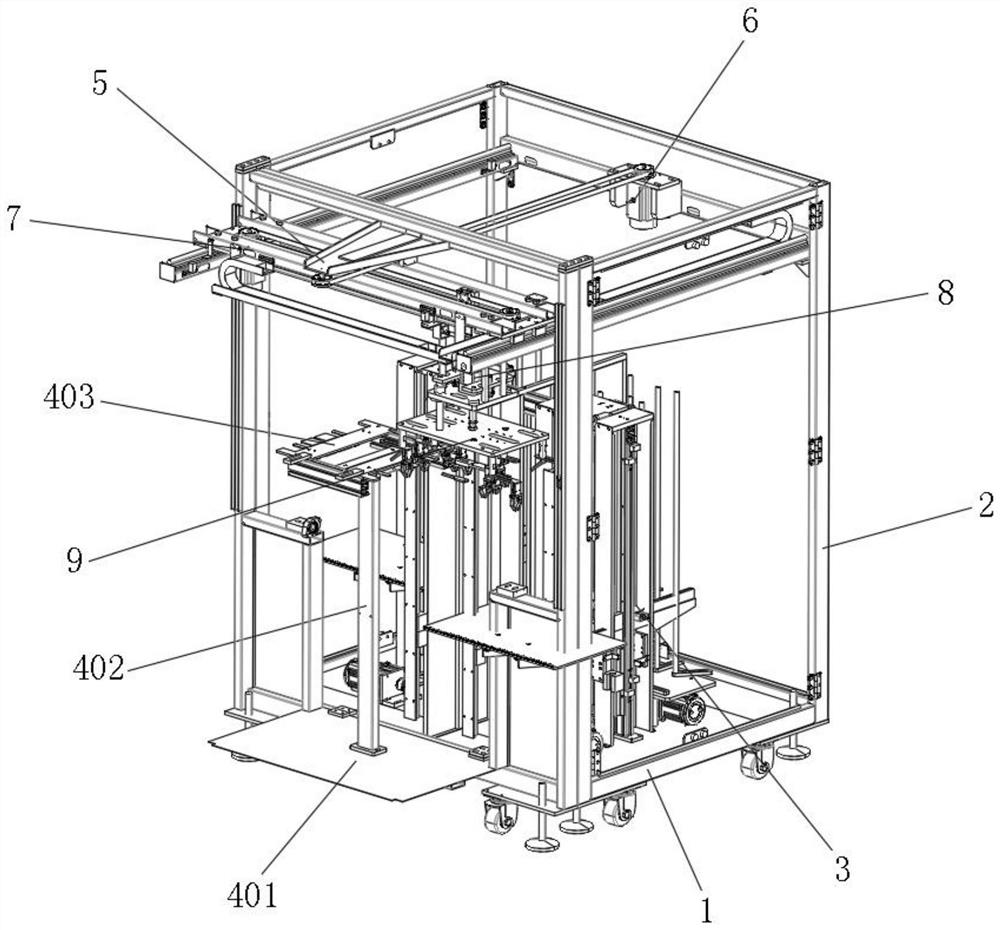

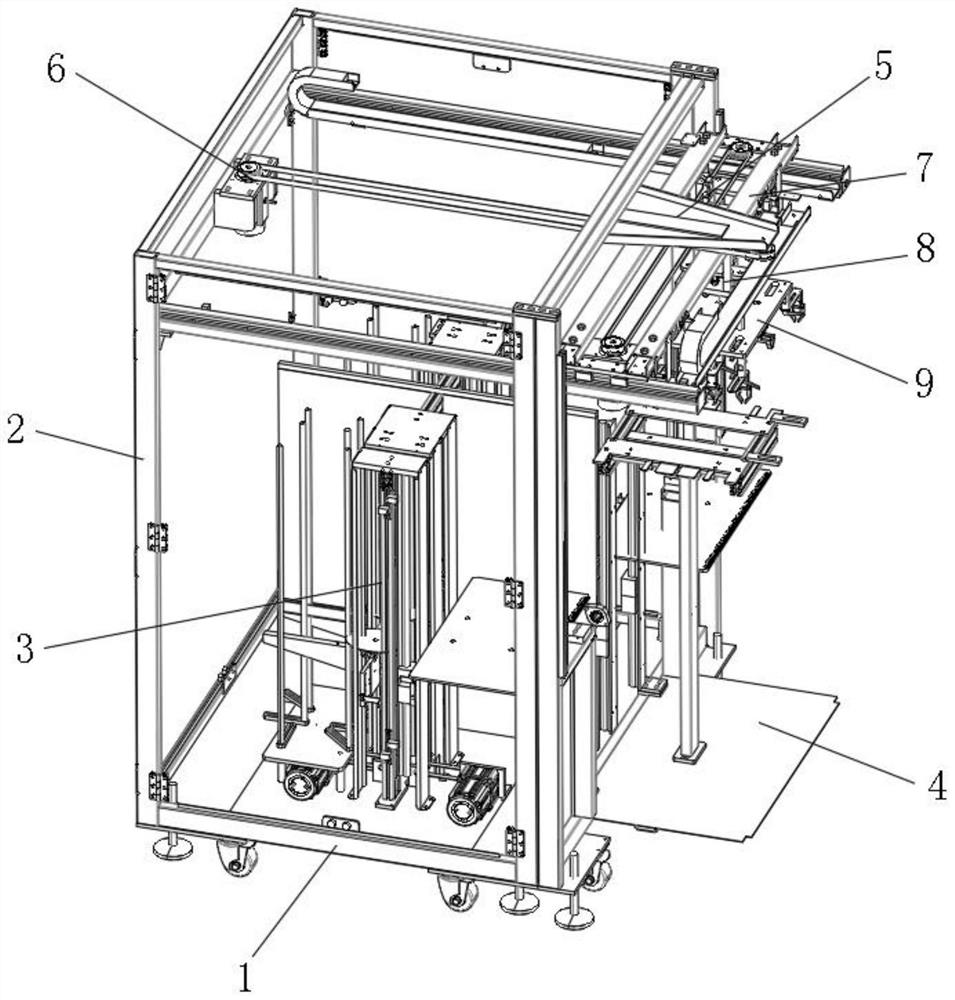

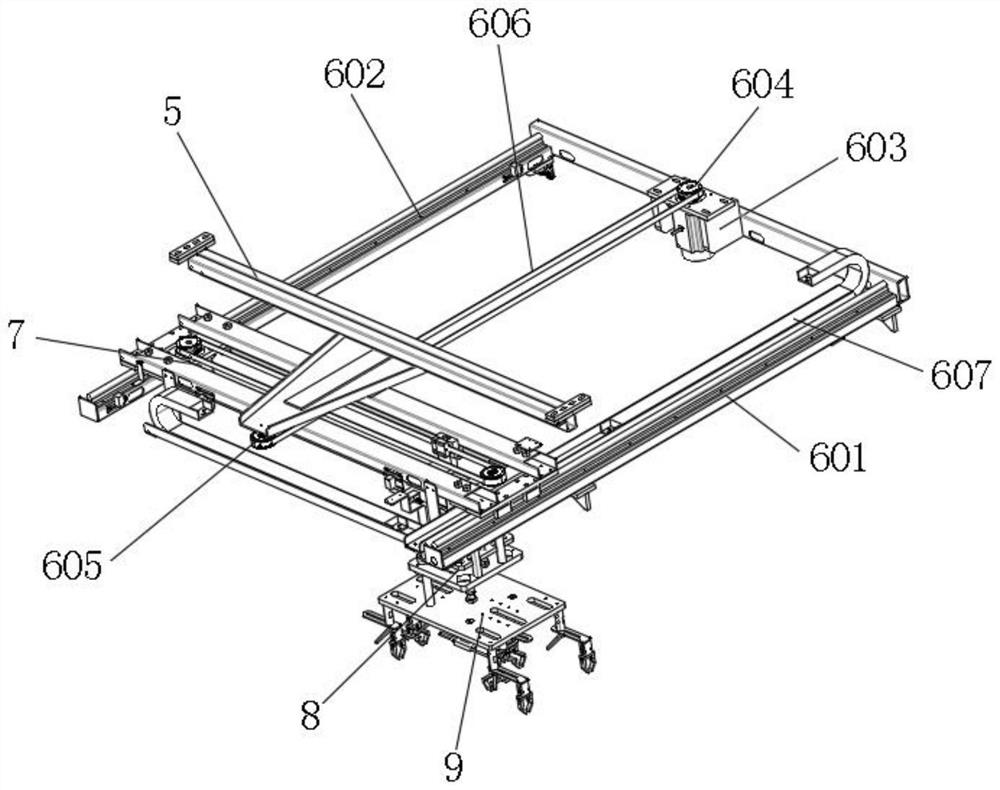

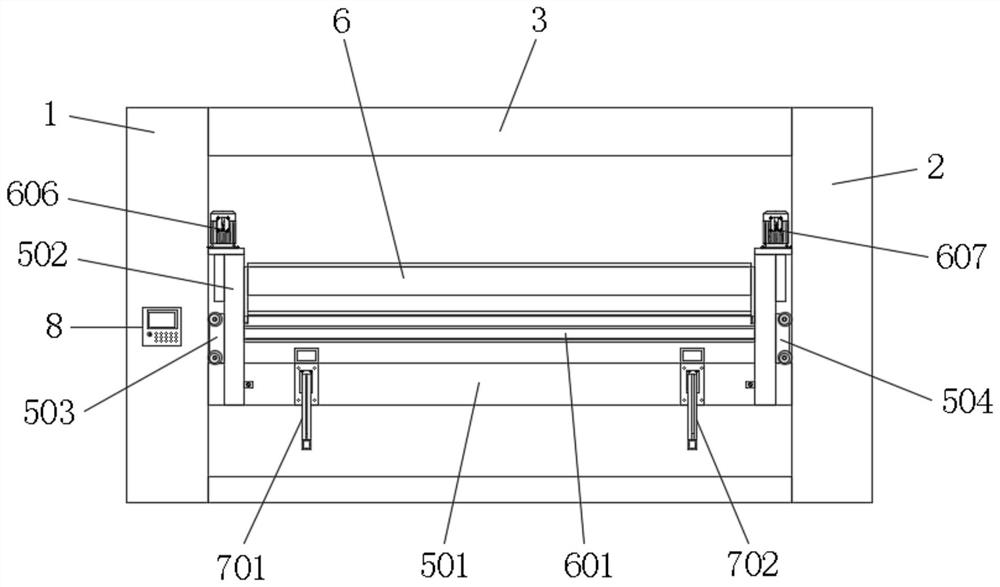

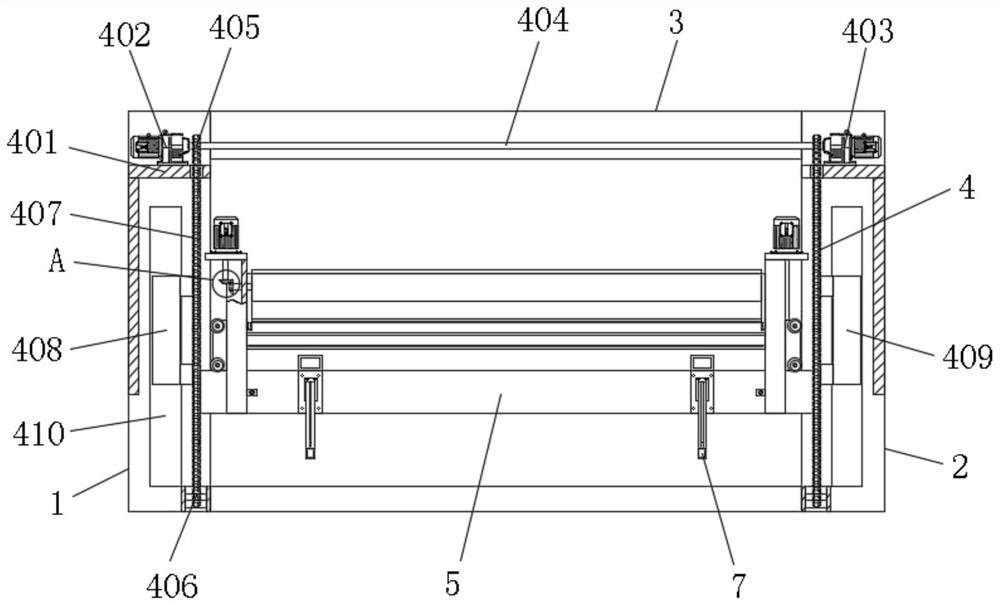

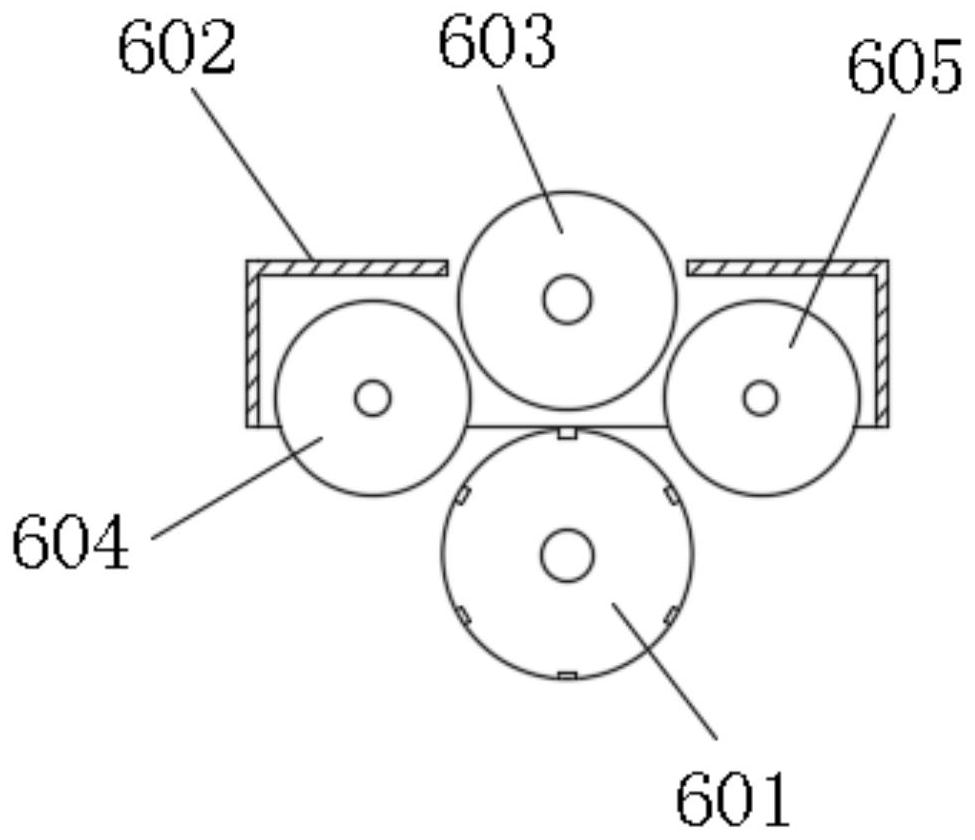

Multifunctional feeding equipment for intelligent hot press

PendingCN114044350AImprove work efficiencyGuaranteed processing progressBrassieresCorsetsManipulatorServo

The invention provides multifunctional feeding equipment for an intelligent hot press, which relates to the technical field of female underwear production and processing equipment. The multifunctional feeding equipment for the intelligent hot press comprises a fixed bottom, the top of the fixed bottom is fixedly connected with an outer frame, and a multi-station servo feeding mechanism is arranged in the center of the top of the fixed bottom; a fixed frame is fixedly connected to the center of the side, close to the material placing platform, of the top of the outer frame, and a transverse driving mechanism is arranged between the outer frame and the fixed frame; a longitudinal driving mechanism is arranged on one side of the bottom of the transverse driving mechanism, and a pneumatic lifting mechanism is installed at the bottom of the longitudinal driving mechanism; and the bottom end of the pneumatic lifting mechanism is fixedly connected with a grabbing manipulator. By designing the transverse driving mechanism, the longitudinal driving mechanism and the pneumatic lifting mechanism, the material grabbing mechanical arm can be driven to complete high-precision material grabbing and conveying work in the space, manual material stacking can be replaced, and the working efficiency is greatly improved.

Owner:东莞市群欣智能科技有限公司

Arc-shaped mesh bending machine for reinforcing mesh machining

PendingCN112775236AGuarantee processing qualityGuaranteed processing progressMetal-working feeding devicesPositioning devicesMesh reinforcementMachine

The invention provides an arc-shaped mesh bending machine for reinforcing mesh machining, and relates to the technical field of mesh bending machines. The conical and arc-shaped mesh bending machine comprises a first fixing frame and a second fixing frame, wherein a connecting frame is fixedly connected to the top between the first fixing frame and the second fixing frame, and a lifting mechanism is arranged between the first fixing frame and the second fixing frame; a supporting mechanism corresponding to the lifting mechanism is arranged between the first fixing frame and the second fixing frame, and a mesh bending mechanism is arranged at the top of the supporting mechanism; and the front end of the supporting mechanism is fixedly connected with a material guiding mechanism, and a master control box is installed in the center of the front end of the first fixing frame. By designing the lifting mechanism, the supporting mechanism, the mesh bending mechanism and the material guiding mechanism, automatic mesh bending machining of a reinforcing mesh can be rapidly completed, and the reinforcing mesh is machined to be in a certain radian, so that the overall working efficiency is greatly improved, and the arc-shaped mesh bending machine is worthy of being vigorously popularized.

Owner:上海电气研砼(木垒)建筑科技有限公司

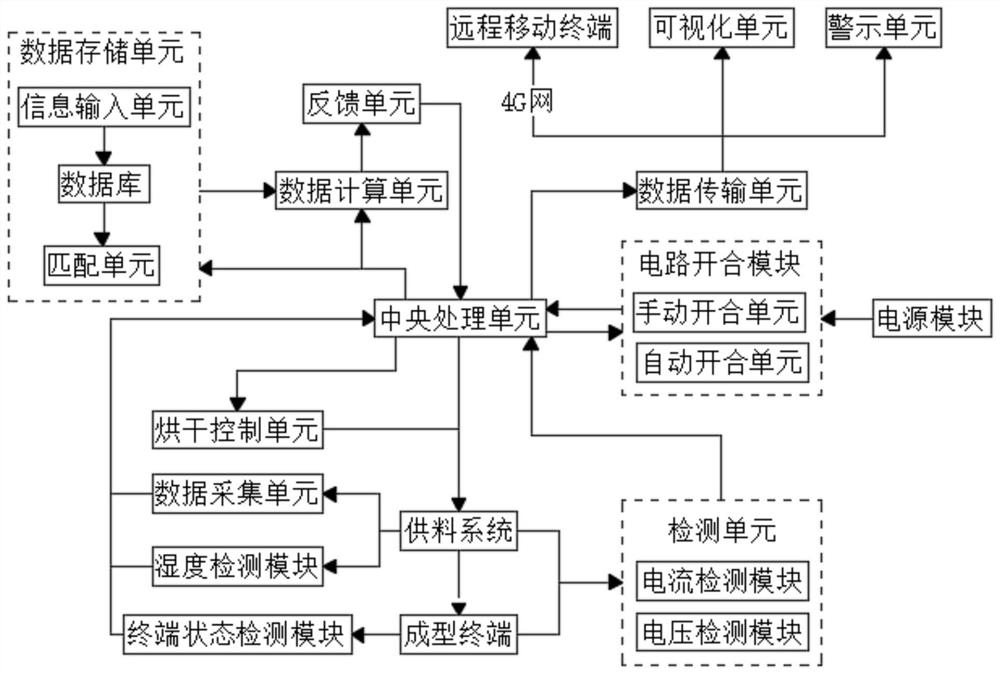

Automatic material conveying control system capable of reducing electric energy consumption

PendingCN113848833AGuaranteed processing progressThe calculation result is accurateProgramme total factory controlData acquisition unitControl system

The invention discloses a material conveying automation control system capable of reducing electric energy consumption, and particularly relates to the technical field of material supply. The material conveying automation control system comprises a feeding system, a humidity detection module, a data calculation unit, a central processing unit, a visualization unit, a drying control unit and a data acquisition unit; the humidity detection module detects the humidity of raw materials in the feeding system, the data calculation unit calculates the working parameters of the drying machine required by the normal drying time under the humidity condition of the raw materials through a neural network calculation model, and the drying control unit adjusts working parameters of a drying machine. Meanwhile, the time point of material shortage of the forming operation is calculated by combining the batch and the number of the to-be-processed products and the forming time of the forming terminal, a worker is reminded of the time of material supplementing operation in advance, it can be guaranteed that the drying time of raw materials with different humidity is the same to a certain extent, and timely material supplementing is guaranteed; and continuity between the feeding step and the forming step is achieved, and the overall machining progress is guaranteed.

Owner:武汉市志和达机械有限公司

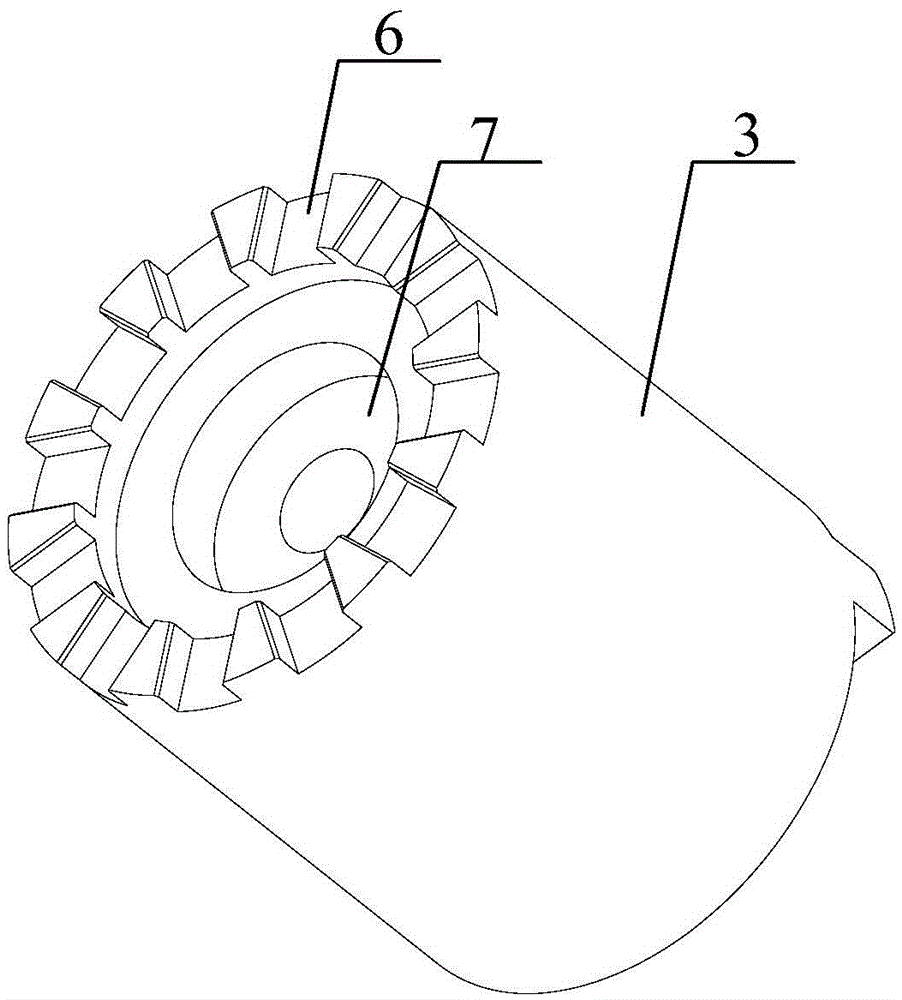

Positioning device for ball rotating in forged ball production

ActiveCN113084069AQuick job locationSave manpower and material resourcesForging/hammering/pressing machinesGear wheelMachining process

The invention provides a positioning device for ball rotating in forged ball production and relates to the technical field of forged ball production. The positioning device for ball rotating in forged ball production comprises a rotating base, wherein a rotary body is rotationally connected to the center of the top of the rotating base, an outer gear ring is fixedly connected to the outer wall of the rotating body, a first servo motor is installed at one side of the top of the rotating base, and a first transmission gear is fixedly connected to the top end of an output shaft of the first servo motor; a fixing mechanism is fixedly connected to the top of the rotary body, a positioning mechanism is installed at the top of the fixing mechanism, and a forged ball body is arranged in the center of the positioning mechanism; and a first turnover mechanism corresponding to the forged ball body is installed in the center of the rotary body. Through the rotating mechanism, the fixing mechanism, the positioning mechanism, the first turnover mechanism, a second turnover mechanism and a clamping mechanism which are simple in design, the forged ball can be quickly positioned and fixed, and meanwhile, the forged ball can be conveniently driven to rotate at multiple angles in the machining process.

Owner:山东中天重工有限公司

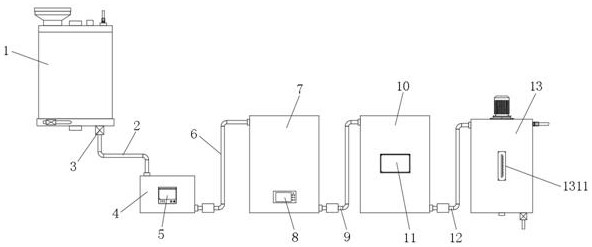

Continuous amylase conversion device

PendingCN114032170AAchieve recyclingEasy maintenanceBioreactor/fermenter combinationsBiological substance pretreatmentsAmylasePapermaking

The invention provides a continuous amylase conversion device, and relates to the technical field of papermaking. The continuous amylase conversion device comprises a pre-mixing mechanism, a low-temperature heater, a heat preservation cabinet, a high-temperature cooking cabinet and a concentration adjusting mechanism, wherein the bottom end of the pre-mixing mechanism is fixedly connected with a discharging pipe, a discharging electromagnetic valve is installed at the end, close to the pre-mixing mechanism, of the discharging pipe, the end, away from the pre-mixing mechanism, of the discharging pipe is fixedly connected with the low-temperature heater, a first control panel is arranged in the center of the outer surface of the front end of the low-temperature heater, and the pre-mixing mechanism comprises a fixed base. According to the invention, by designing the split type premixing mechanism, the low-temperature heater, the heat preservation cabinet, the high-temperature cooking cabinet and the concentration adjusting mechanism, amylase conversion processing can be carried out in batches according to needs, all the mechanisms only need to complete respective work in a short time, and continuous work is not needed in other time, so that the working efficiency is greatly improved while the energy consumption is also reduced.

Owner:枣庄全鼎生物科技股份有限公司

Automatic sorting machine for bearing retainer workpiece concave and convex surfaces

ActiveCN103212539BGuaranteed processing progressImprove performanceSortingProduction lineEngineering

The invention discloses an automatic sorting machine for bearing retainer workpiece concave and convex surfaces. A sorting turntable (13) on an engine base plate (8) is connected with a toggling disk (16) below the engine base plate (8), positioning sorting sleeves (G) are uniformly arranged on a positioning disk (3), sorting rods (2) can be inserted in the positioning sorting sleeves (G), and installed on the sorting turntable (13), a lifting cylinder (22) in an engine room (9) jacks up the positioning disk (3), a pushing and rotating cylinder (20) is connected with a pushing and rotating connecting rod (27) to drive a positioning cylinder (26) to rotate and push the toggling disk (16) to be connected with the sorting turntable (13) and rotate, when the lifting cylinder (22) descends, the positioning sorting sleeves (G) on the positioning disk (3) are matched with corresponding sorting bottom dies (14) on the sorting turntable (13) to enable irregular workpieces falling on the sorting bottom dies (14) to be sorted and classified and then sheathed on the sorting rods (2), and the pushing and rotating cylinder (20) is connected with the pushing and rotating connecting rod (27) to drive the positioning cylinder (26) to return to an original position and repeat the cyclic action. The automatic sorting machine is convenient to operate, reliable in performance, high in degree of automation and good in sorting effect, and can meet the machining needs of a matched production line.

Owner:聊城市义和轴承配件有限公司

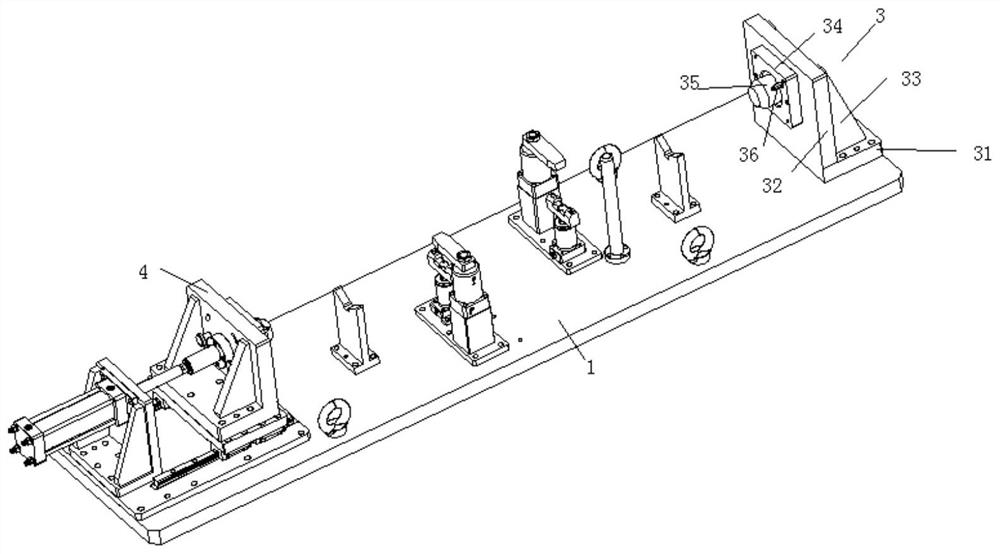

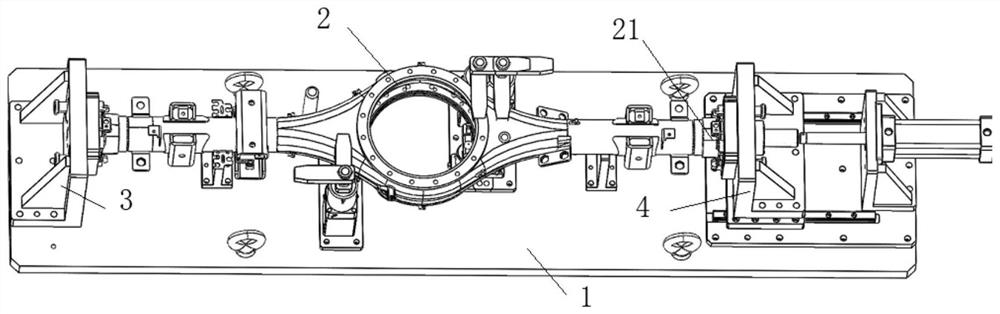

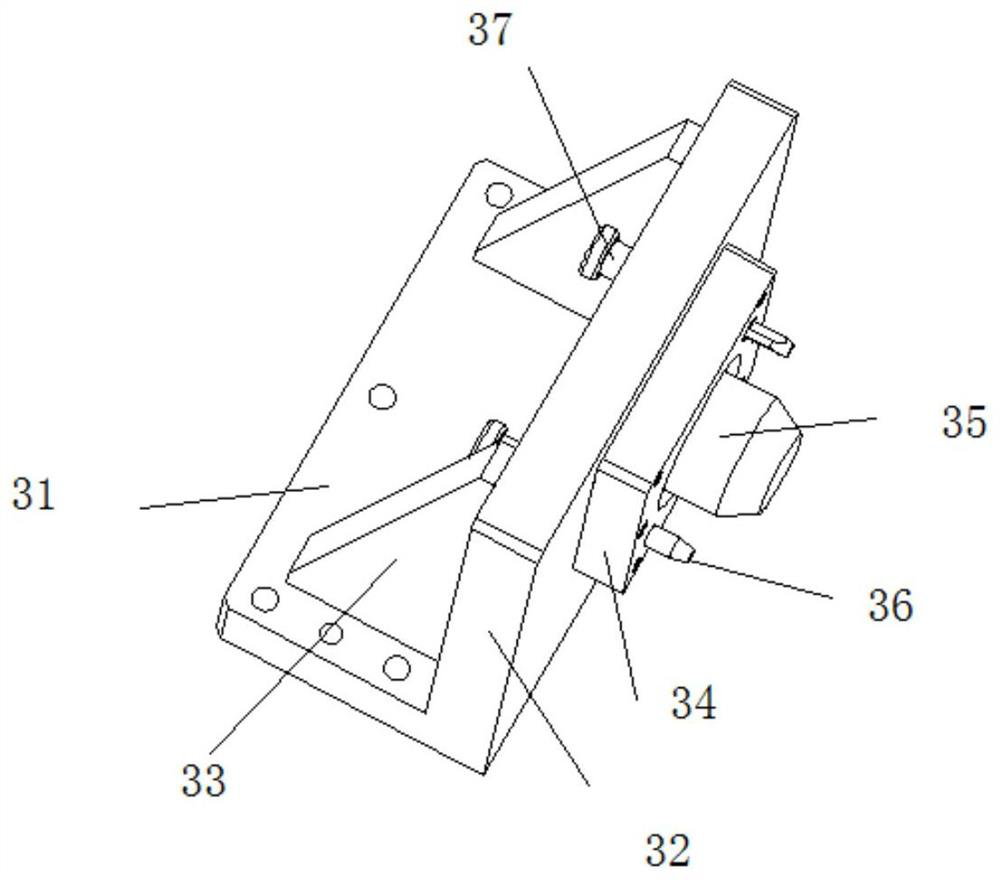

Angle-adjustable locating tool for automobile axle housing machining and locating process

InactiveCN112621289AEasy to disassembleGuaranteed concentricity requirementsLarge fixed membersPositioning apparatusRotational axisMachining

The invention discloses an angle-adjustable locating tool for automobile axle housing machining and an locating process. The locating tool comprises a fixing tool body used for fixing an axle housing body, wherein the two ends of the axle housing body are each connected with a transition connecting disc, a first locating mechanism is fixed to one end of the fixing tool body, a second locating mechanism capable of moving transversely is mounted at the other end of the fixing tool body, the first locating mechanism and the second locating mechanism are the same in structure, the first locating mechanism comprises a bottom plate fixed to the fixing tool body, a vertical plate in the vertical direction is integrally arranged at the top of each bottom plate, an angle plate is fixed between one side of each vertical plate and the corresponding transition connecting disc, a locating pin is arranged at the side, away from the corresponding angle plate, of each vertical plate, a locating pin rotating shaft is arranged on each locating pin, and a locating plate is rotationally mounted on each locating pin rotating shaft. According to the scheme, machining of multiple vertical milling faces can be completed under the condition that a workpiece is clamped at a time, so that the machining progress of a product is guaranteed, the production takt is shortened, and the production efficiency is improved.

Owner:ANHUI ZHONGGONG TECH

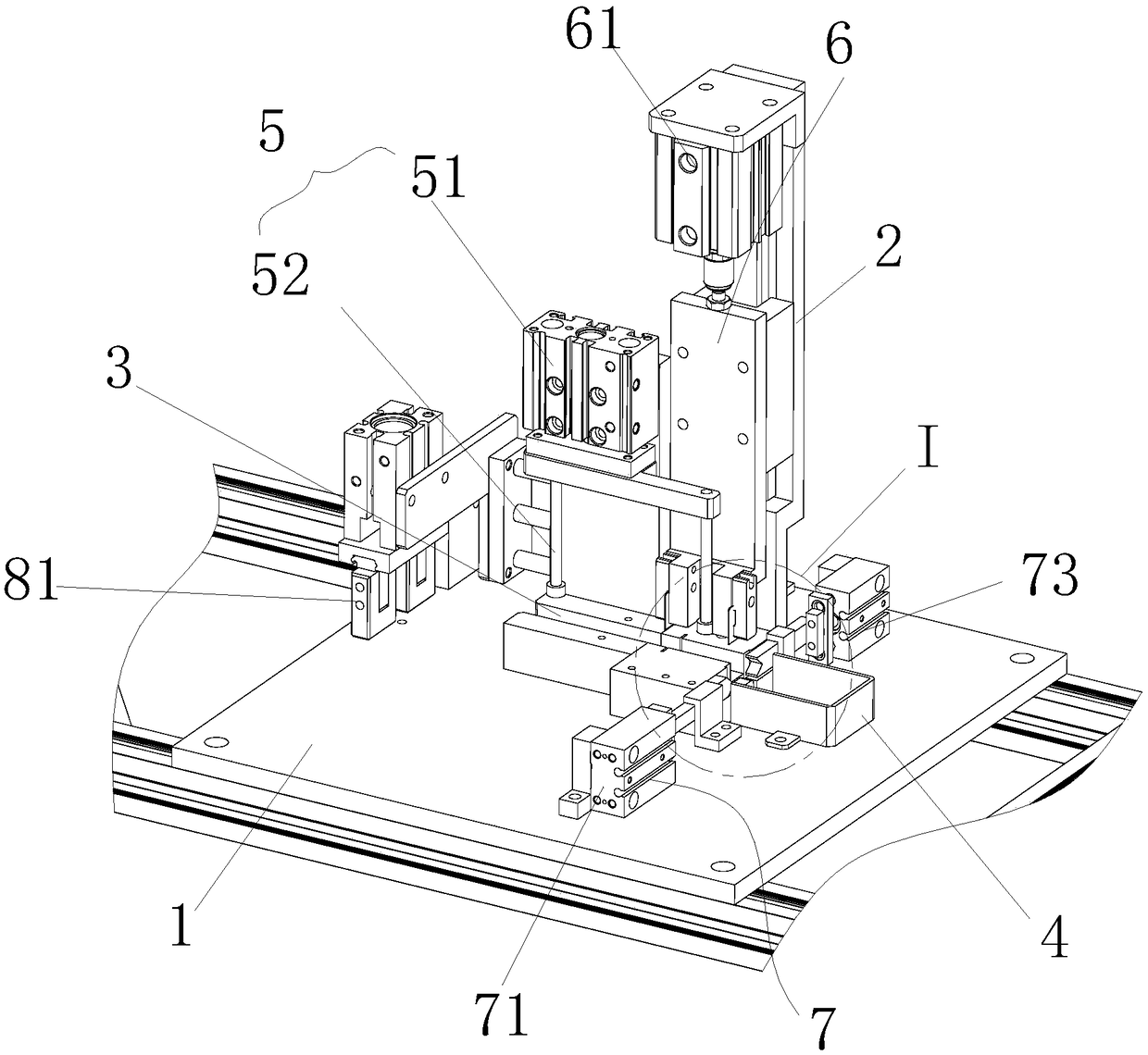

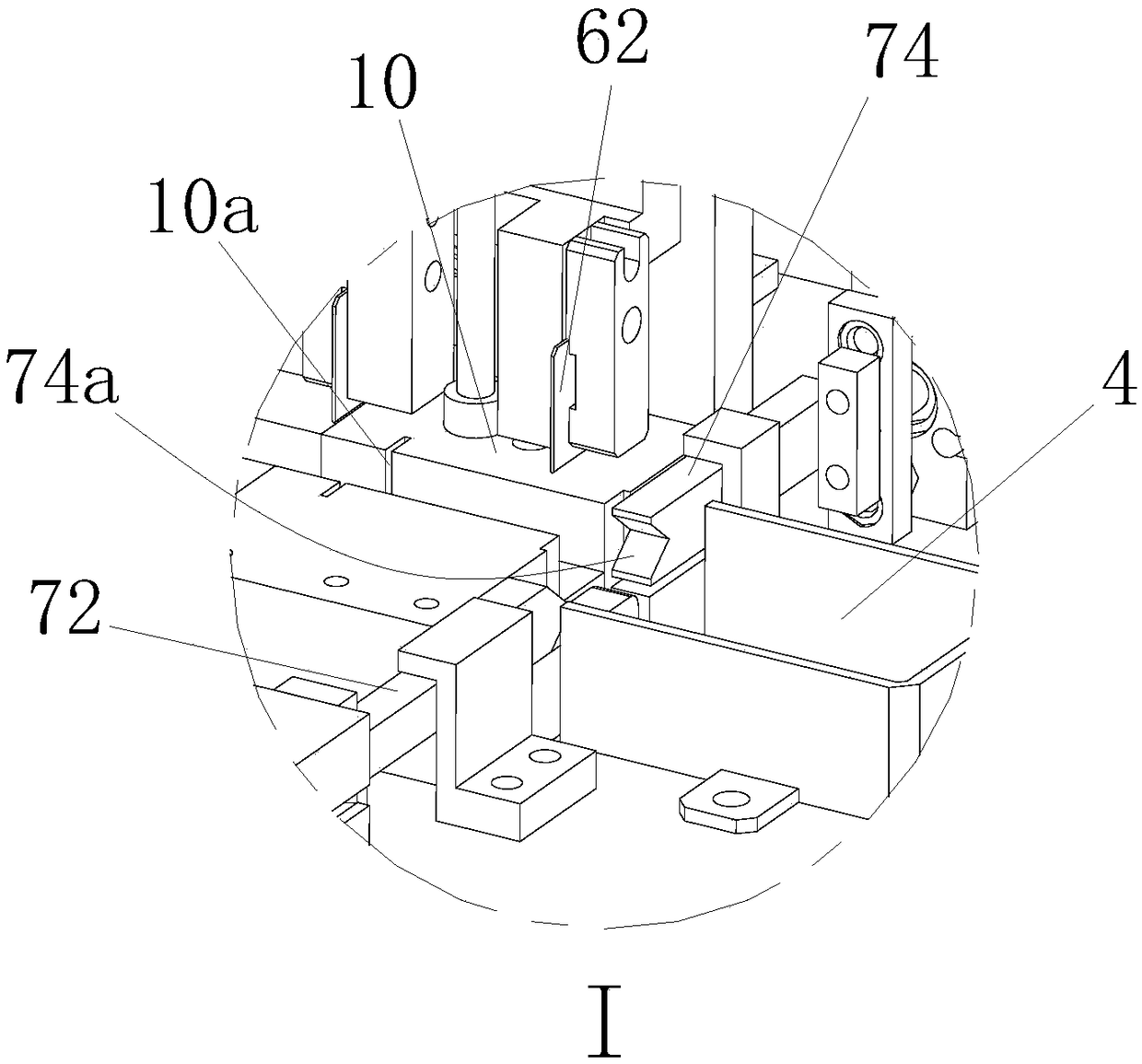

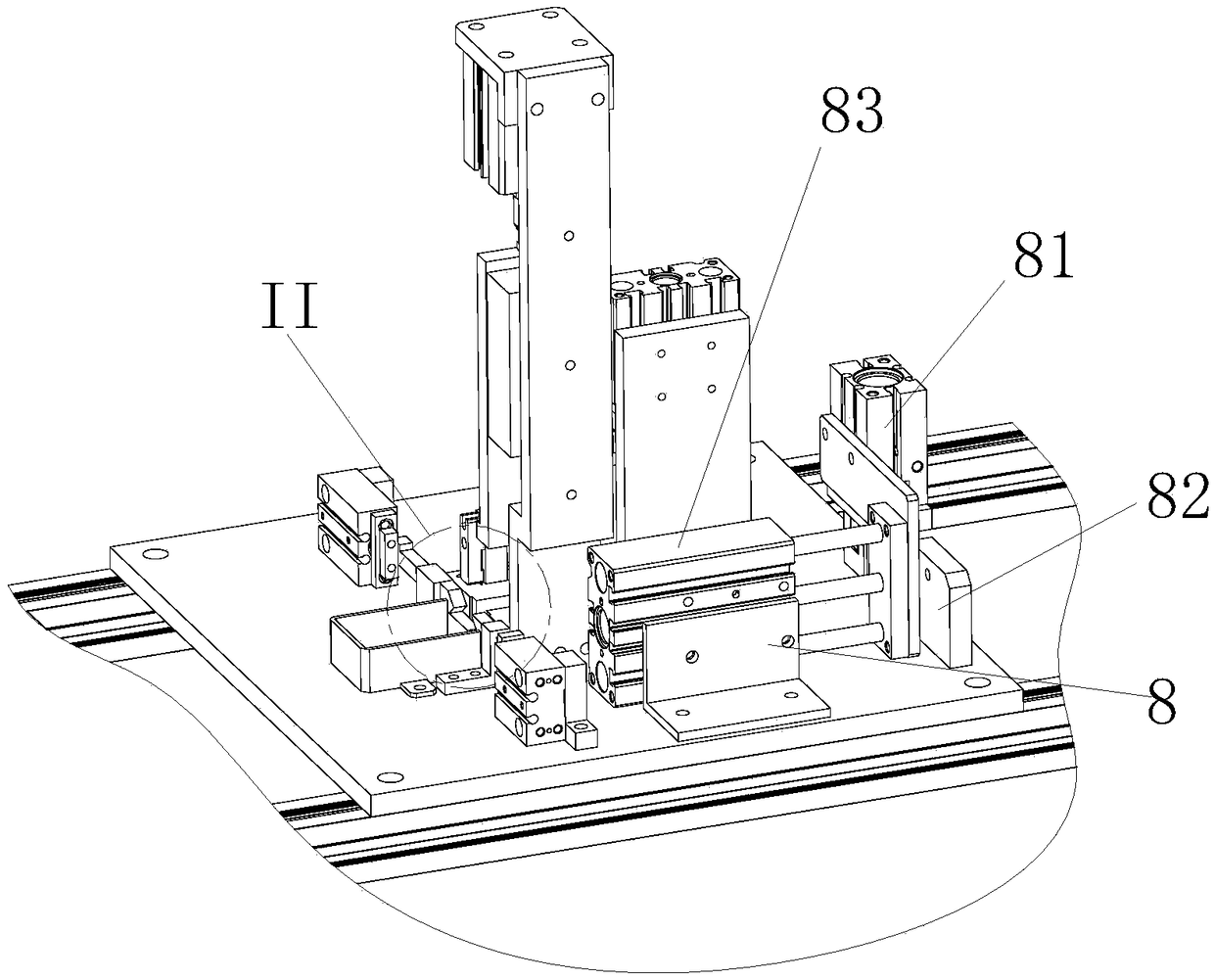

Clamp for machining of glass mold bottle bottom mold

PendingCN110561151AReduce occupancyIncrease the number ofPositioning apparatusMetal-working holdersManufacturing cost reductionBiochemical engineering

The invention belongs to the technical field of work fixtures and provides a clamp for machining of a glass mold bottle bottom mold. The clamp comprises a mold holding platform base plate fixed to a machine tool moving workbench, a mold holding platform fixed to the surface of the upward side of the mold holding platform base plate and a group of bottle bottom mold locating mechanisms arranged onthe mold holding platform. The clamp for machining of the glass mold bottle bottom mold is characterized in that each bottle bottom mold locating mechanism comprises an electromagnet and a mold holding locating column, wherein the electromagnet is arranged on the side, facing the mold holding platform base plate, of the mold holding platform and is electrically connected with an external electrical controller through a wire, the mold holding locating column is arranged on the mold holding platform and corresponds to the center position of the electromagnet, the bottom of the mold holding locating column is supported by the mold holding platform base plate, and the upper portion of the mold holding locating column extends out of the upper surface of the mold holding platform. The clamp formachining of the glass mold bottle bottom mold lowers manufacturing cost, lowers fault probability, guarantees machining progress, reduces the area of the occupied part of the mold holding platform, can increase the number of arranged bottle bottom molds at the same area, improves mold holding efficiency and guarantees the mold holding accuracy.

Owner:CHANGSHU JIANHUA MOLD TECH

Sleeve pipe section cutting and denting device

PendingCN108857436AAccurate clamping and positioningImprove processing efficiencyOther manufacturing equipments/toolsMetal working apparatusEngineeringMachining process

The invention relates to a sleeve pipe section cutting and denting device. The sleeve pipe section cutting and denting device comprises a bottom plate; a supporting base, a guiding grooved block, a U-shaped baffle plate, a compressing mechanism, a cutting mechanism, two extrusion moulding mechanisms and a conveying mechanism are arranged on the bottom plate; the guiding grooved block is used for asleeve pipe to penetrate through; the U-shaped baffle plate is located at the free end part of the sleeve pipe; the compressing mechanism is fixed on the supporting base and moves downwards to abut against the sleeve pipe; the cutting mechanism is used for cutting off the sleeve pipe; the two extrusion moulding mechanisms are located on two sides of the axis of the sleeve pipe; and the conveyingmechanism is close to the material inlet end of the guiding grooved block. By adopting the sleeve pipe section cutting and denting device, manpower can be replaced for achieving stable conveying for the sleeve pipe; labor intensity is alleviated; manual error is avoided; the machining process is ensured; further, the sleeve pipe can be accurately positioned and clamped; cutting stability is higher; product quality is better; the whole device is simple to operate and convenient to use; automatic operation is favorably realized; and machining efficiency of sleeve pipes is improved.

Owner:ANHUI PALLET INTELLIGENT EQUIP CO LTD

Preparation process and preparation device of high-concentration health-care wine

PendingCN114733428AMix thoroughlyWell mixedTransportation and packagingMixersRotational axisReciprocating motion

The invention discloses a high-concentration health-care wine preparation process and a preparation device thereof, and particularly relates to the technical field of wine processing.The preparation device comprises a middle plate, the lower surface of the middle plate is fixedly connected with the upper surface of a collecting frame, and the left side face and the right side face of the collecting frame are fixedly connected with the opposite faces of two crushing frames respectively; a filter plate is arranged on the inner wall of the crushing frame, and an extrusion crushing plate is slidably connected to the inner wall of the crushing frame. By arranging the driving assembly, the supporting seat, the mixing frame, the reciprocating screw rod, the thread cap, the rotating shaft, the extension groove, the moving wheel and the extension rod, the reciprocating screw rod controls the thread cap and the moving wheel to realize reciprocating motion in the left-right direction while rotating, and the rotating shaft is limited by the extension groove, so that the mixing frame swings left and right around the supporting shaft; the raw materials in the mixing frame slide in the left-right direction, meanwhile, the extending rods stir the raw materials sliding in the left-right direction, more sufficient and thorough mixing is achieved, and the overall using and mixing effect is better.

Owner:湖北汉哥生物科技有限公司

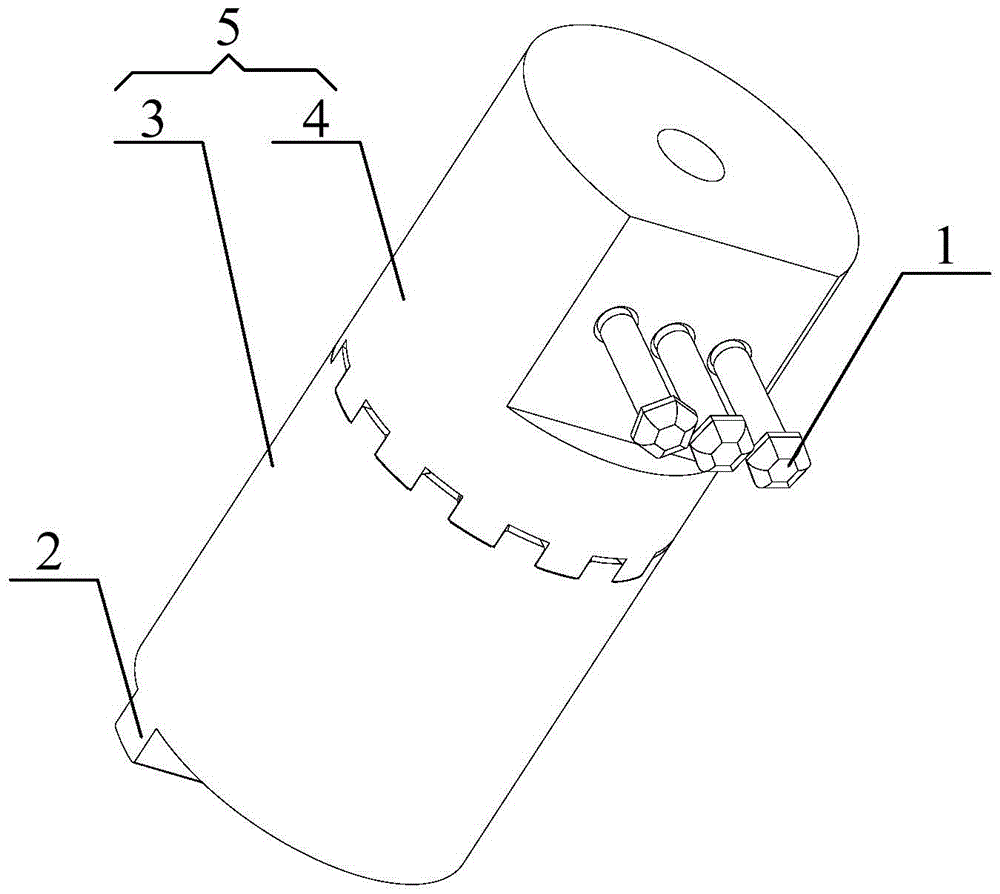

A tool used to limit the degree of freedom of workpiece rotation

InactiveCN103495896BEasy to fixTurn to blockPositioning apparatusMetal-working holdersRotational degrees of freedomMachining process

The invention relates to a tool for limiting the rotating freedom degree of a workpiece. The tool for limiting the rotating freedom degree of the workpiece comprises a supporting pillar body and cap pillars, wherein a mounting part capable of being reliably fixed on a machining platform is arranged at one end of the supporting pillar body, and the cap pillars are arranged at the other end of the supporting pillar body and are used for abutting against the surface of the workpiece to be machined. When the workpiece in tight contact with the cap pillars has rotating tendency, the cap pillars supply acting force which is parallel to the machining platform and opposite to the rotating tendency of the workpiece to prevent the workpiece from rotating, and the cap pillars can be reliably supported by the supporting pillar body. Compared with the mode that the workpiece is prevented from rotating through friction force in the prior art, the supporting capability of the cap pillars in the tool to the workpiece is much larger that the friction force between the workpiece and a press block and the friction force between the workpiece and the machining platform, therefore, the workpiece pressed on the machining platform tightly can be effectively prevented from rotating in the machining process, and the machining progress and the machining precision of the workpiece are ensured.

Owner:浙江嵘翔机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com