Tool platform for steel structure machining

A steel structure and platform technology, which is applied in the field of tooling platforms for steel structure processing, can solve the problems of troublesome adjustment operations, time-consuming and labor-intensive adjustments, and inflexible adjustment methods, and achieve the effects of reducing labor intensity, convenient use, and simple adjustment methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

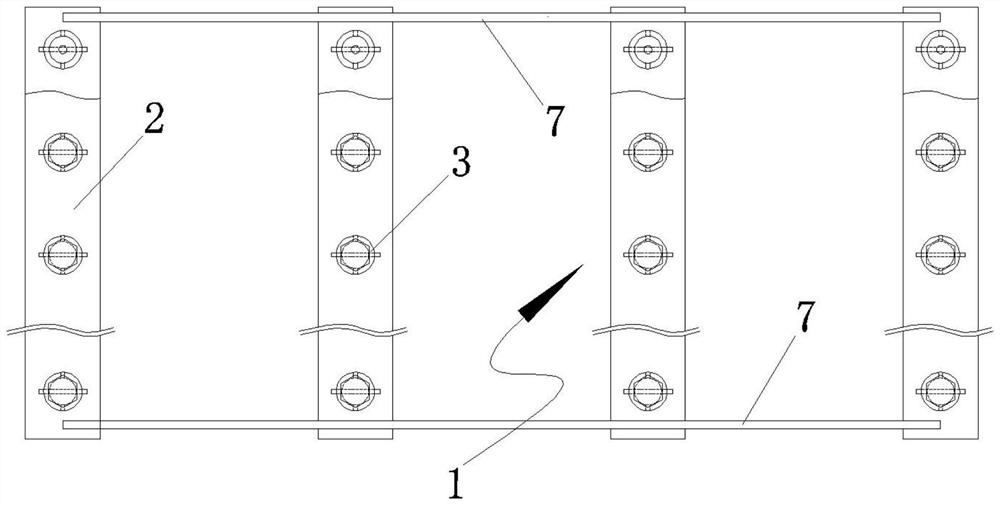

[0033] Example 1. This example 1 includes several tooling platform units 1 distributed side by side. The tooling platform unit 1 includes a base 2 and several adjustment mechanisms 3 arranged side by side and equidistant on the base 2 for adjusting the support height. The present invention is mainly composed of tooling platform units, several tooling platform units are distributed in parallel and equidistant, and the adjusting mechanism 3 is equidistantly distributed on the base 2 of the tooling platform unit 1, and the same tooling platform unit 1 can be adjusted through the adjusting mechanism 3 to adjust different The support height can meet the support requirements of special-shaped steel structure components. The adjustment method is simple and flexible.

example 2

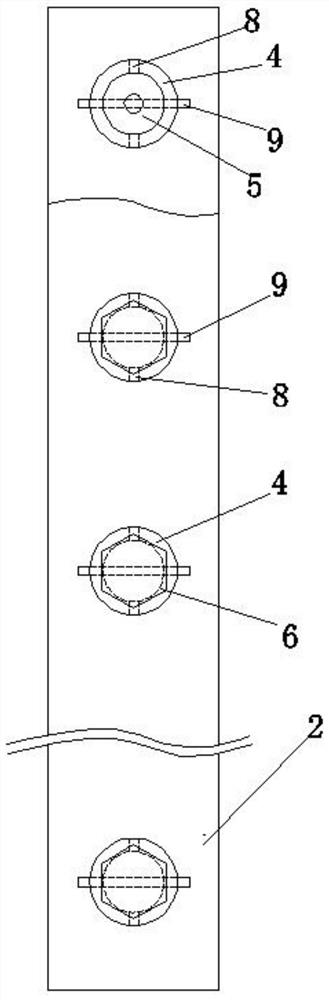

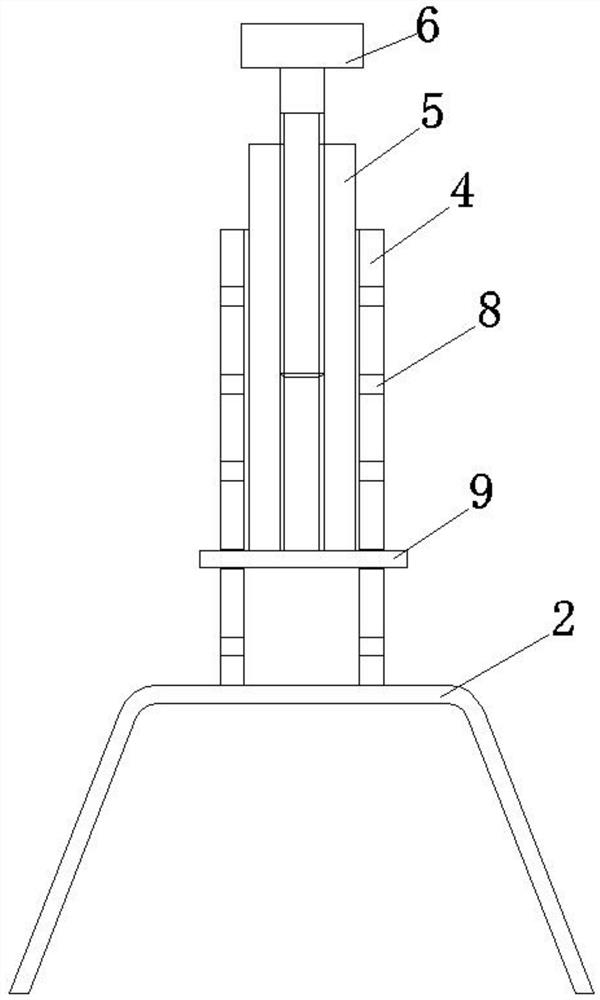

[0034] Example 2. This example 2 includes several tooling platform units 1 distributed side by side. The tooling platform unit 1 includes a base 2 and several adjustment mechanisms 3 arranged side by side and equidistant on the base 2 for adjusting the support height. The adjustment mechanism 3 includes a cylindrical outer seat 4 fixed on the base 2, an inner tube 5 sleeved in the outer seat 4 for adjusting the support height, and an adjusting bolt threaded in the inner tube 5 for fine-tuning the support height 6; The outer seat 4 is provided with a limit mechanism for adjusting the elevation of the inner tube 5 .

[0035] In Example 2, on the basis of Example 1, the structure of the adjustment mechanism 3 is optimally designed, and the adjustment is more convenient and flexible through the adjustment mechanism 3 composed of the outer seat 4, the inner tube 5, the adjustment bolt 6, and the limit mechanism. The structure is stable and the support performance is good.

example 3

[0036] Example 3. This example 3 includes several tooling platform units 1 distributed side by side. The tooling platform unit 1 includes a base 2 and several adjustment mechanisms 3 arranged side by side and equidistant on the base 2 for adjusting the support height. The adjustment mechanism 3 includes a cylindrical outer seat 4 fixed on the base 2, an inner tube 5 sleeved in the outer seat 4 for adjusting the support height, and an adjusting bolt threaded in the inner tube 5 for fine-tuning the support height 6; The outer seat 4 is provided with a limit mechanism for adjusting the elevation of the inner tube 5 . The limiting mechanism includes several pairs of pin through holes 8 equidistantly opened on the outer base 4 along the length direction of the outer base 4 , and adjusting pins 9 inserted into the through holes 8 to limit the adjustment of the inner tube 5 .

[0037] In Example 3, on the basis of Example 2, the structure of the limit mechanism is optimized. Through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com