I-shaped steel welding platform and application method thereof

A technology for welding platforms and I-beams, applied in welding equipment, welding accessories, auxiliary welding equipment, etc., can solve problems such as poor processing quality, poor flatness, and potential safety hazards, and achieve guaranteed processing progress, simple production, and guaranteed processing quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

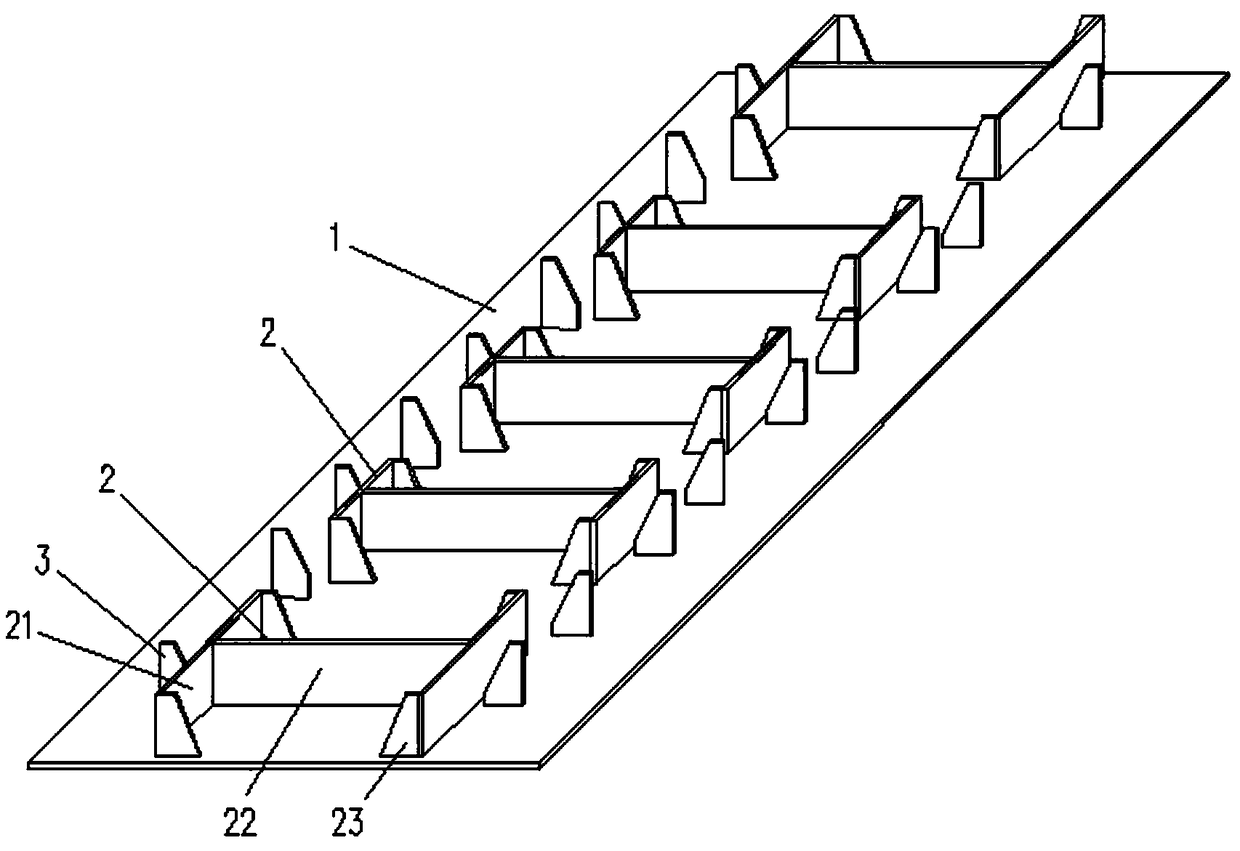

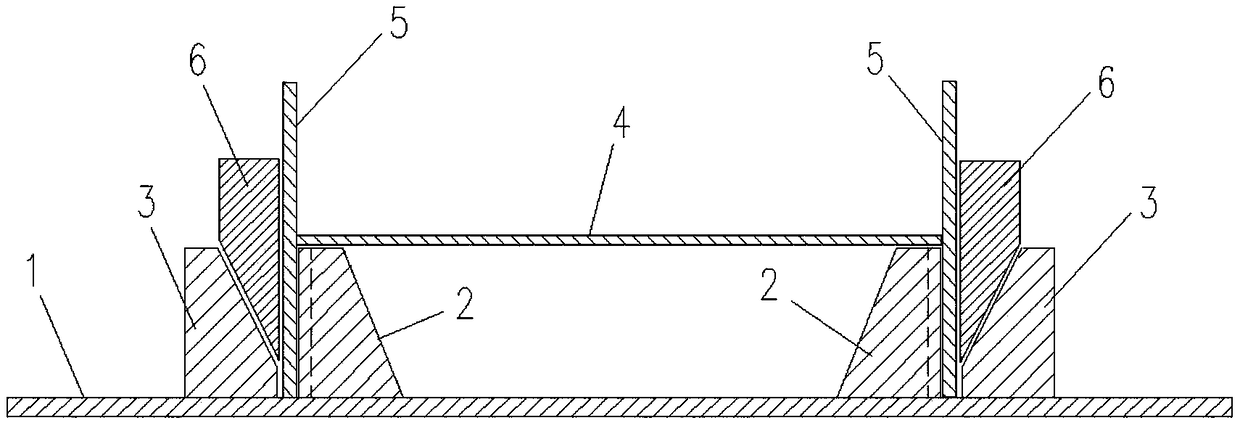

[0023] refer to figure 1 and figure 2 , the present embodiment provides a kind of I-steel welding platform, comprises platform 1, the rectangular steel plate of platform 1, and platform 1 is provided with a plurality of web supporting frames 2 along the length direction of platform 1, and each web supporting frame 2 The structures and specifications are the same, the width of the web support frame 2 is the same as the width of the middle web of the I-beam, the opposite sides of the web support frame 2 are flat plate structures perpendicular to the platform 1, and the multiple The opposite sides of the web support frame 2 are arranged in alignment, and the platforms 1 on the opposite sides of the web support frame 2 are respectively fixed with inclined-plane limiting plates 3, and the inner side of the inclined-plane limiting plate 3 has an inclination from bottom to top toward the outside. Set of bevel structures.

[0024] Each web support frame 2 comprises two supporting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com