Patents

Literature

133results about How to "Control the output speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermoplastic composite solid propellant and preparation method thereof

ActiveCN109627133ALower melting temperatureImprove securityExplosive working-up apparatusPlasticizerSlurry

The invention relates to a thermoplastic composite solid propellant and a preparation method thereof, and belongs to the technical field of composite solid propellant preparation. The invention relates to the thermoplastic composite solid propellant and the preparation method thereof. The melting temperature of the thermoplastic composite solid propellant is lower than 95 DEG C on the premise thata solvent and a liquid plasticizer are not added, the viscosity of molten slurry is low, the safety performance is excellent, and additive manufacturing of the composite solid propellant can be achieved through a fused deposition technology; the energy level of the thermoplastic composite solid propellant is equivalent to that of a medium-energy thermosetting propellant, and the thermoplastic composite solid propellant can be used as a power source of a complex-drug-type solid engine and a layered variable-thrust solid engine in the future.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

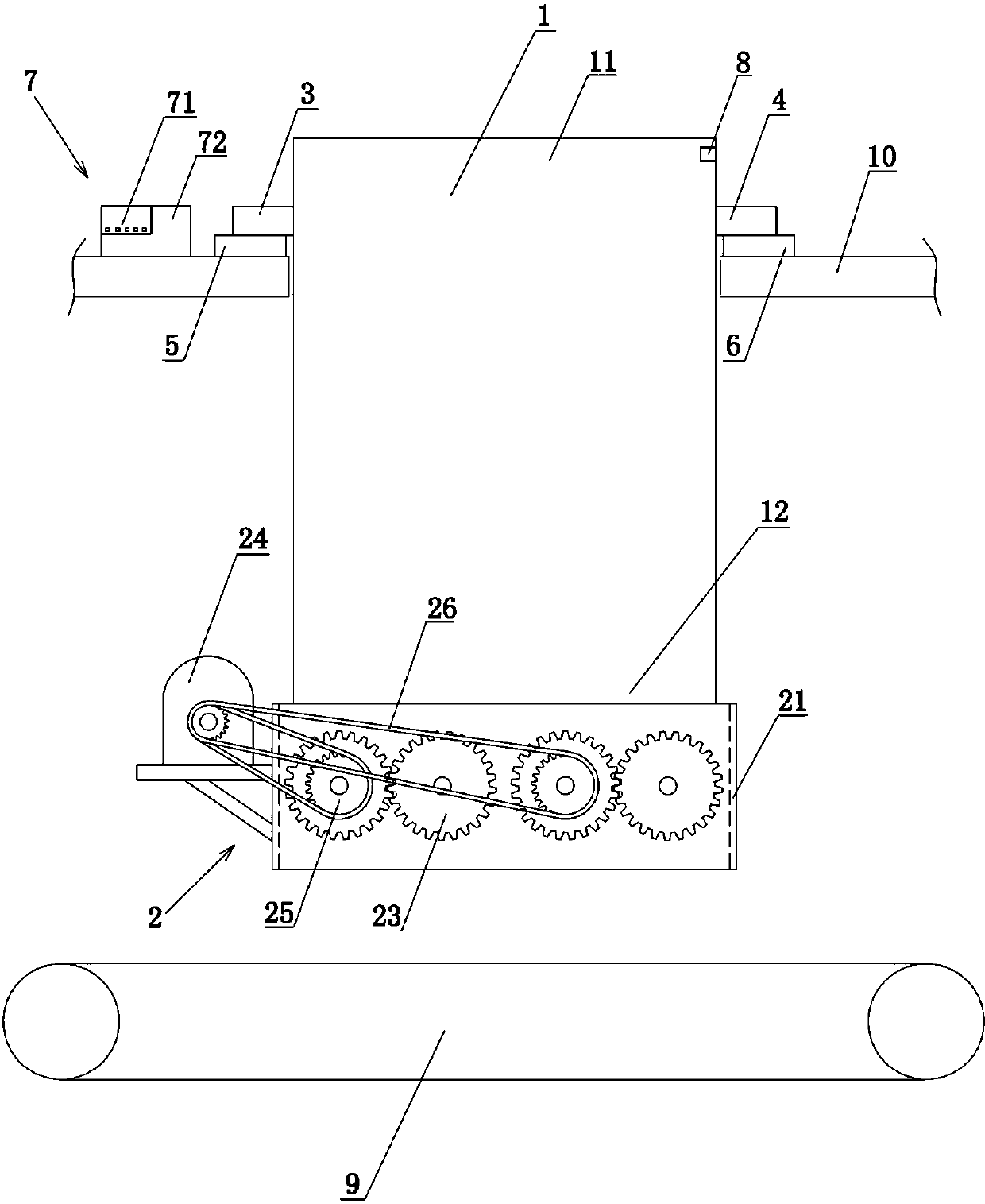

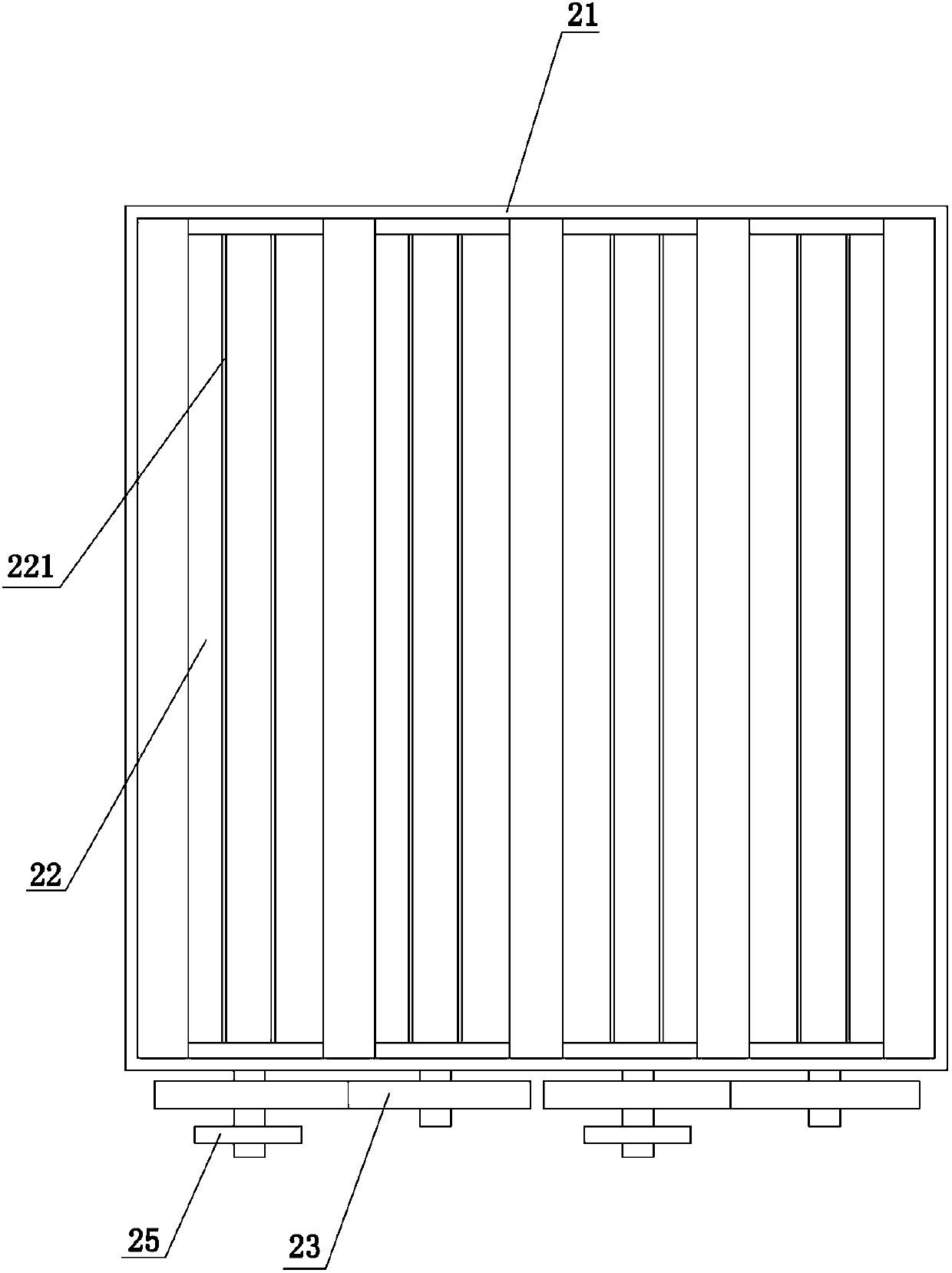

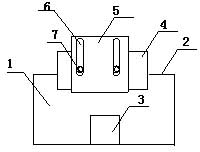

Rapid high-precision batching device

PendingCN108529177AControl precisionControl the output speedCleaningLarge containersEngineeringMixed materials

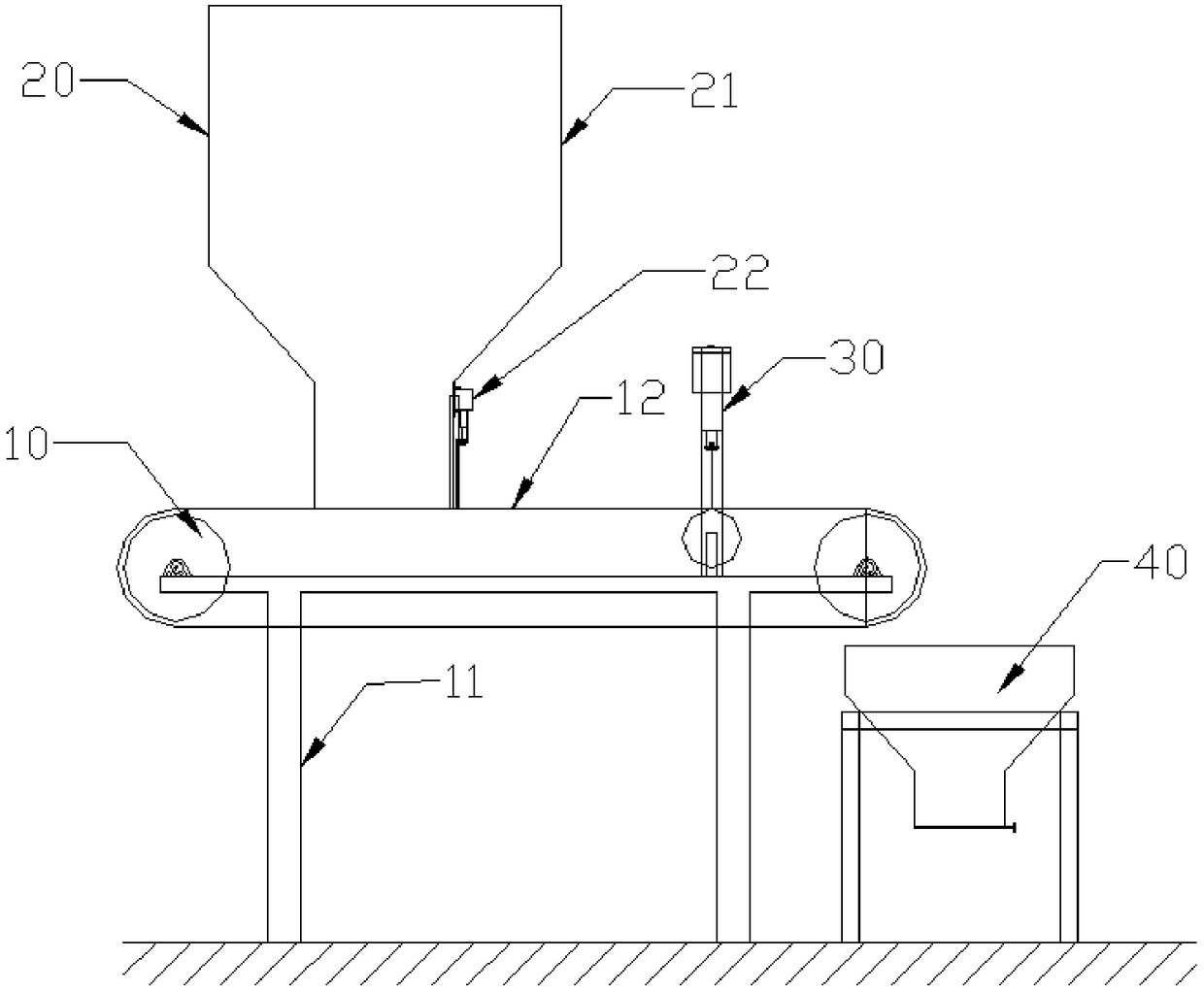

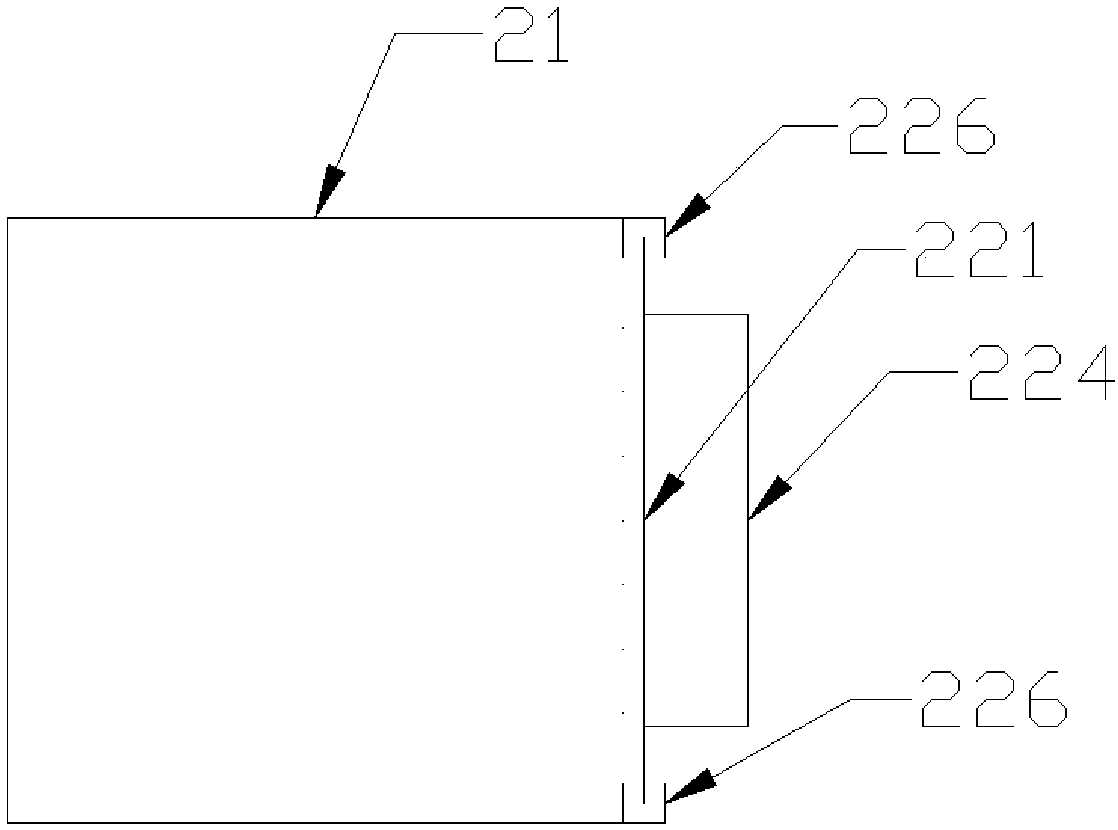

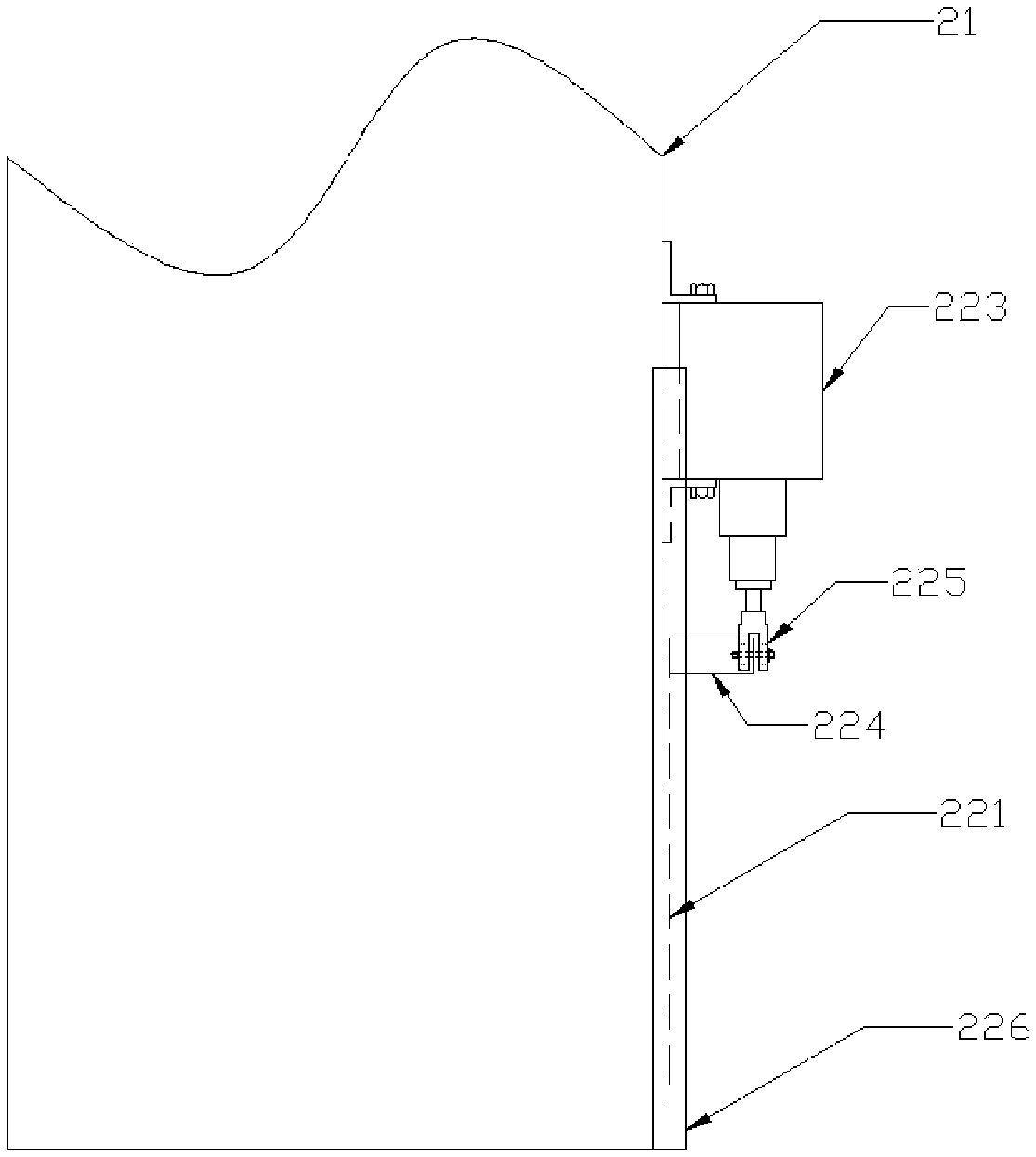

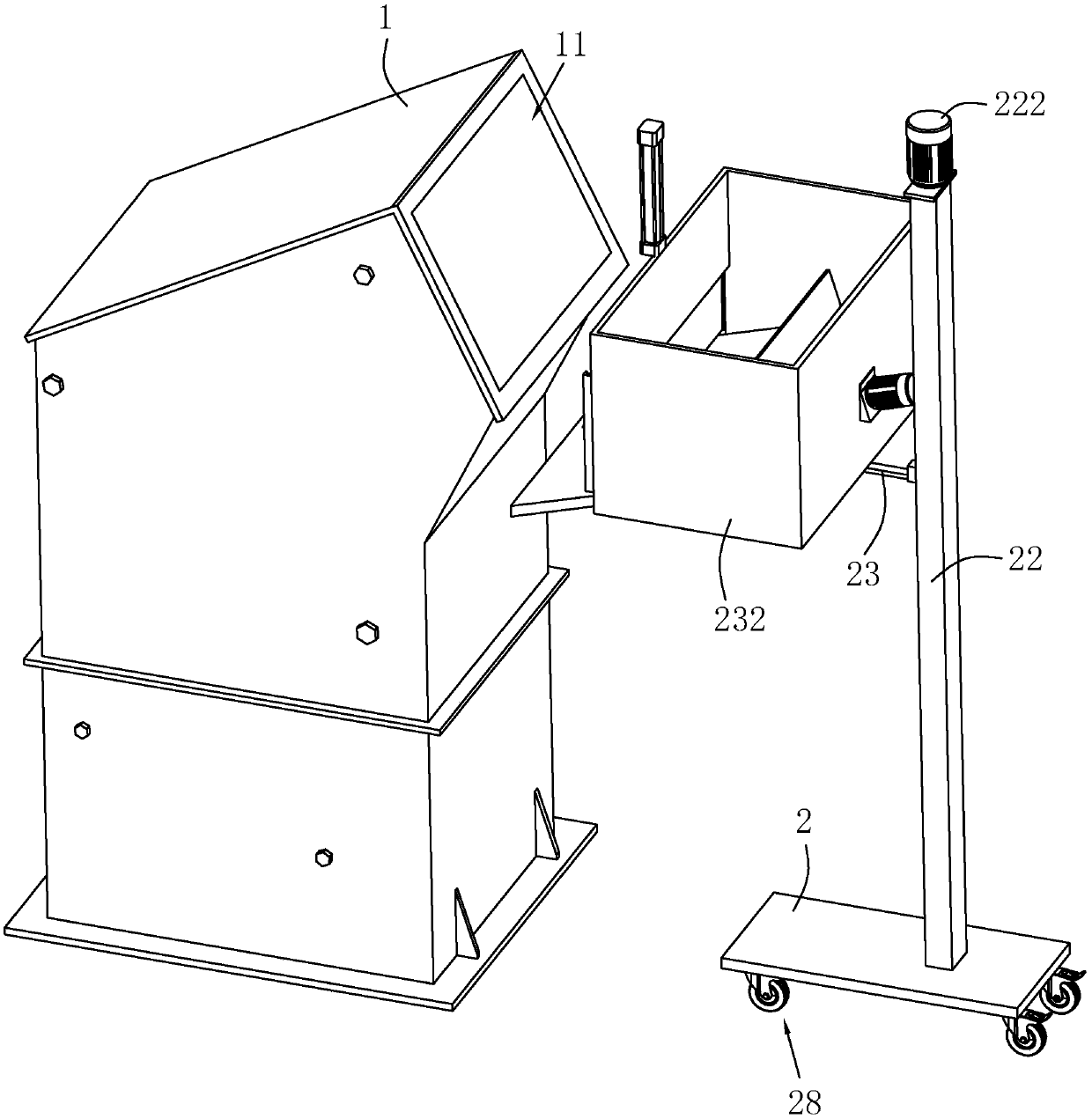

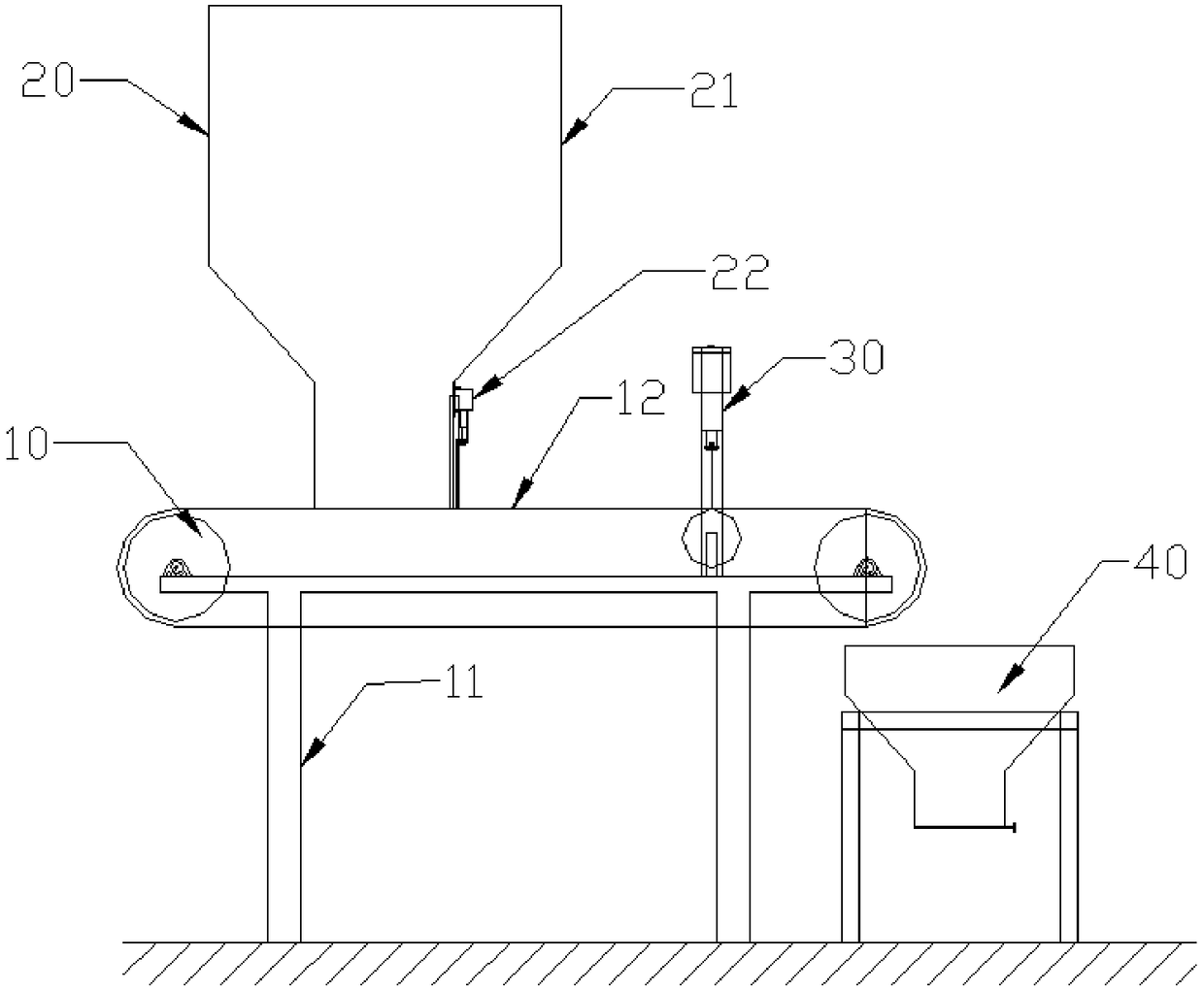

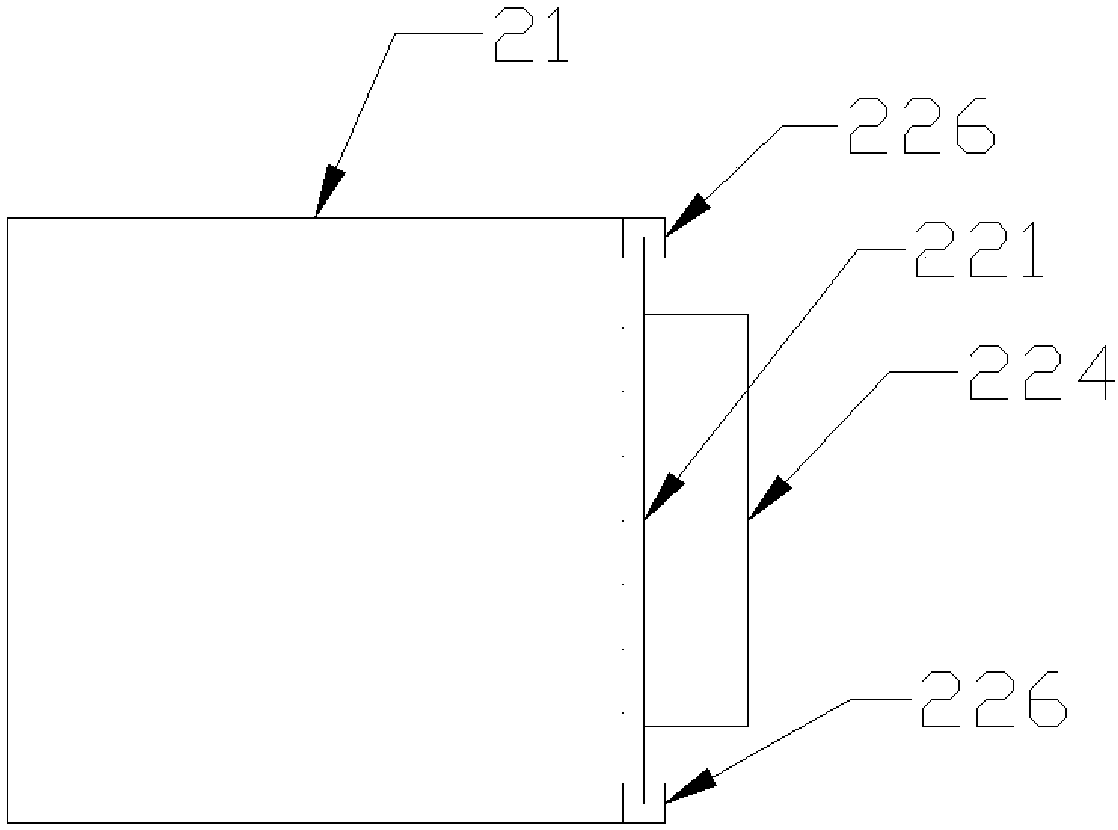

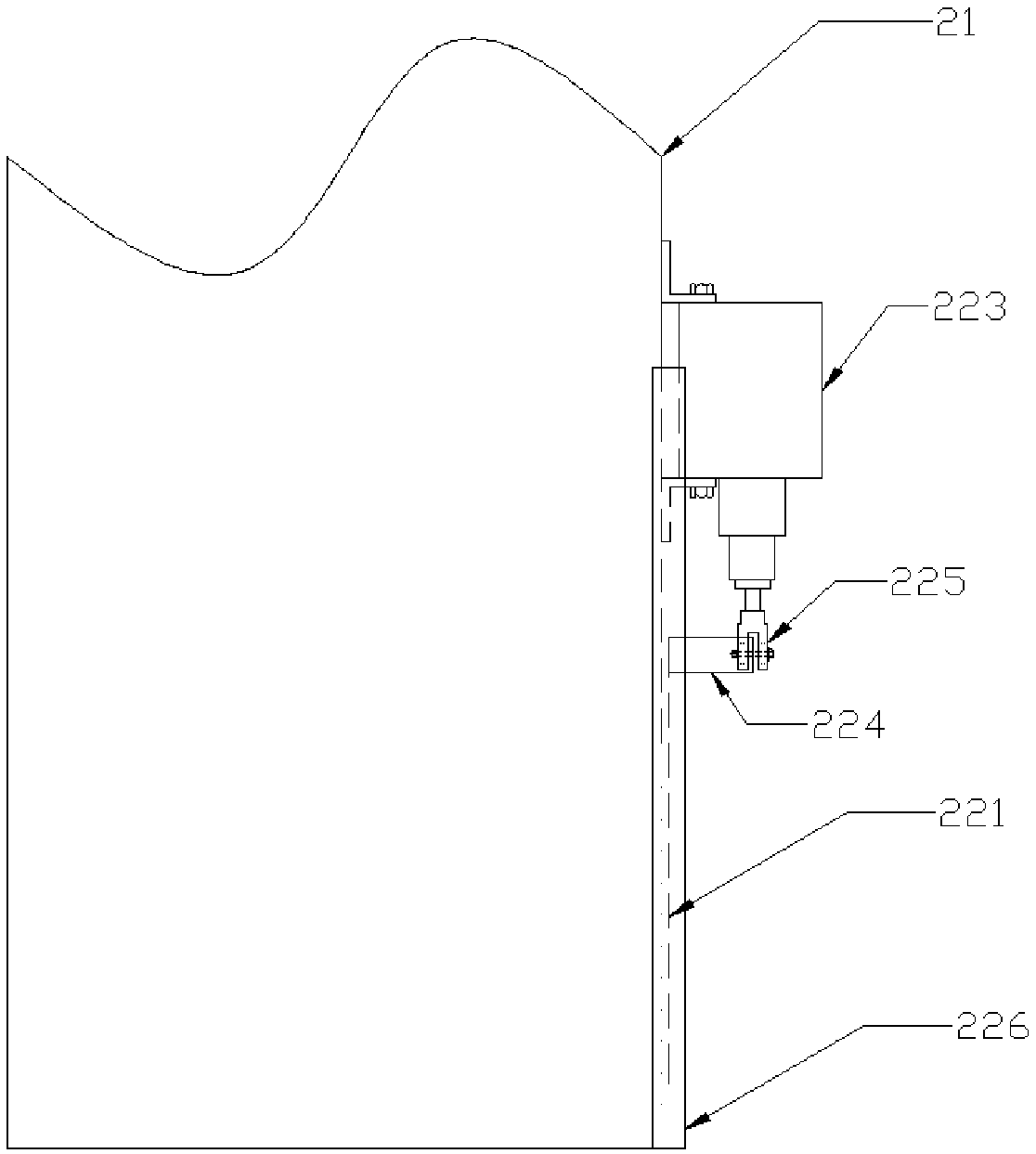

The invention discloses a rapid high-precision batching device. The device is characterized by comprising a belt type conveying device, a stock bin, a stop device, a weighing hopper and a control system. The stock bin is arranged above the conveying belt in a matched mode, the bottom of the stock bin is slightly higher than the conveying belt, the stock bin is used for storing materials and comprises a stock bin main body and a bin door, the stop device is fixed to the conveying belt in a matched mode, located above the conveying belt and perpendicular to the conveying belt, the stop device islocated behind the stock bin in the moving direction of the conveying belt, the weighing hopper is arranged below the tail end of the conveying belt in a matched mode, and the control system is usedfor receiving the data of the weighing hopper and calculating and controlling work of the belt type conveying device, the stock bin and the stop device. The device can achieve rapid feeding, medium-speed feeding, slow feeding and accurate feeding, is high in feeding precision, high in speed, suitable for solid granules, powder and adhesive mixed materials, small in repetition control precision deviation and free of caking.

Owner:郑州鼎源自动化科技有限公司

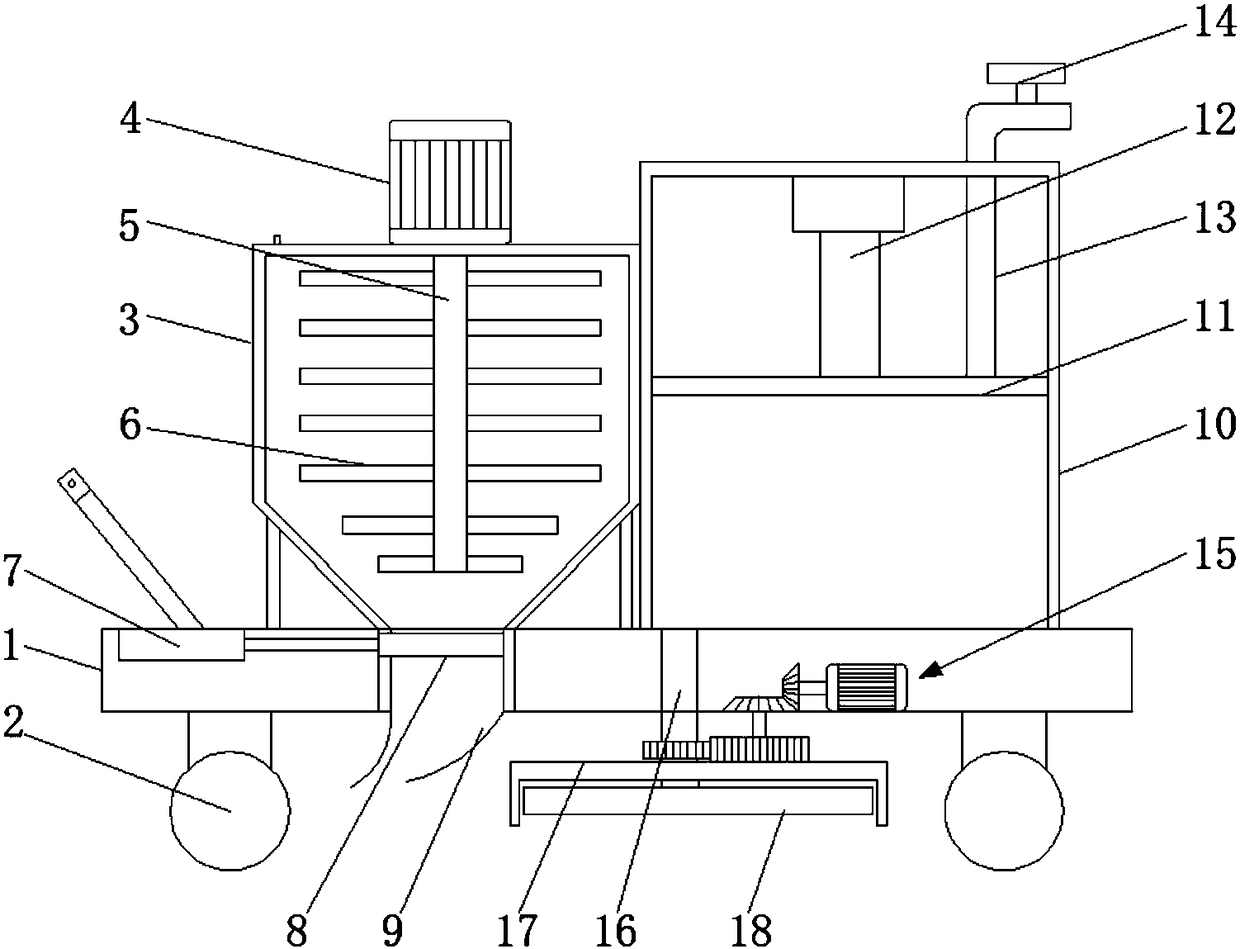

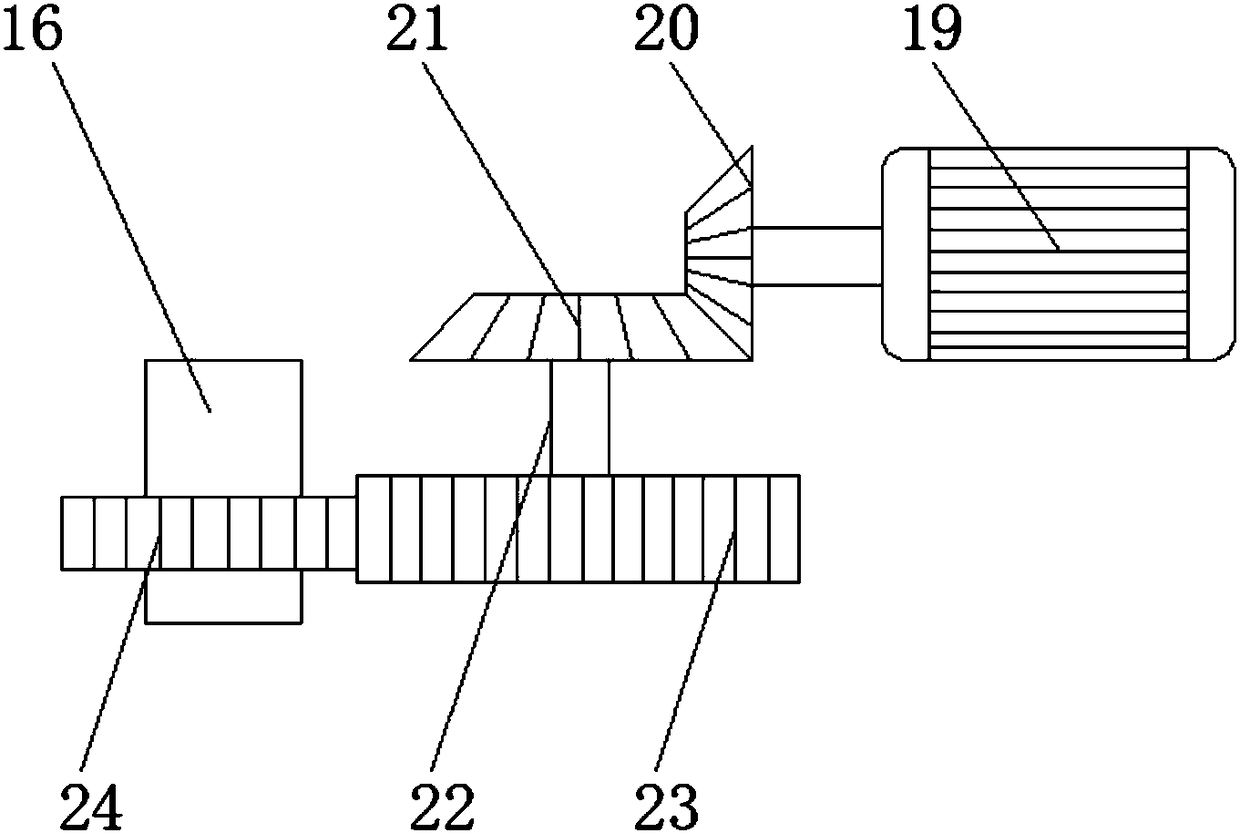

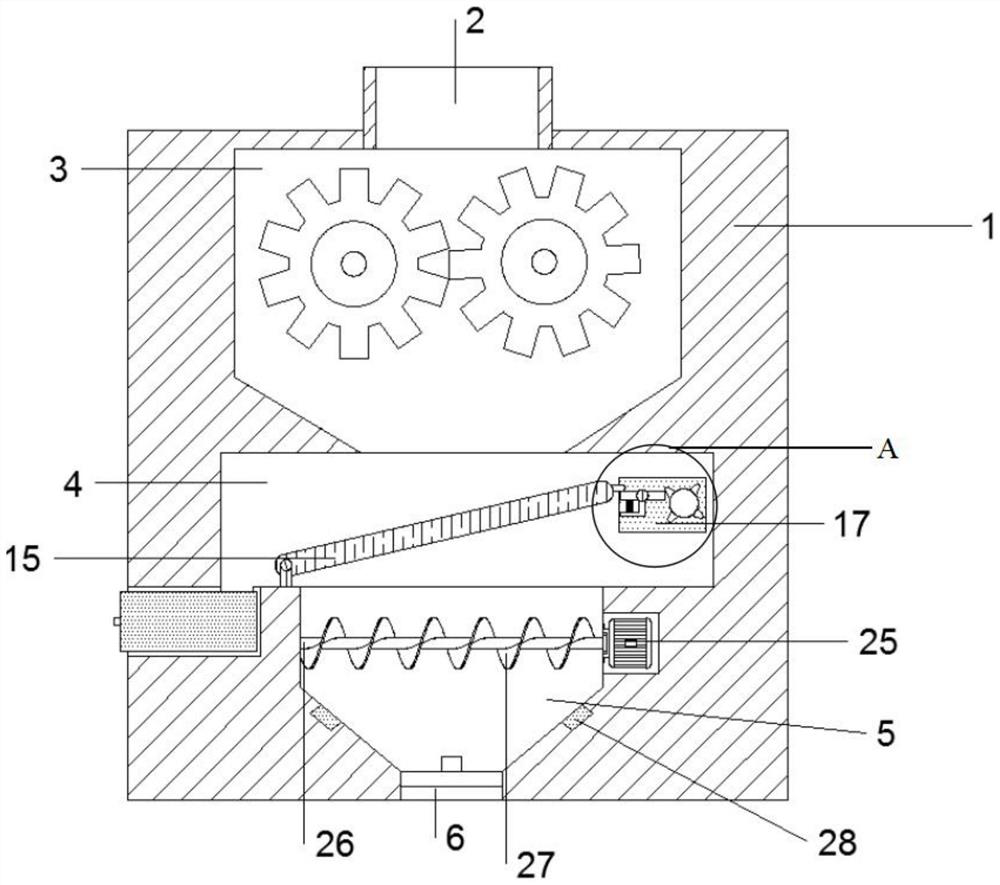

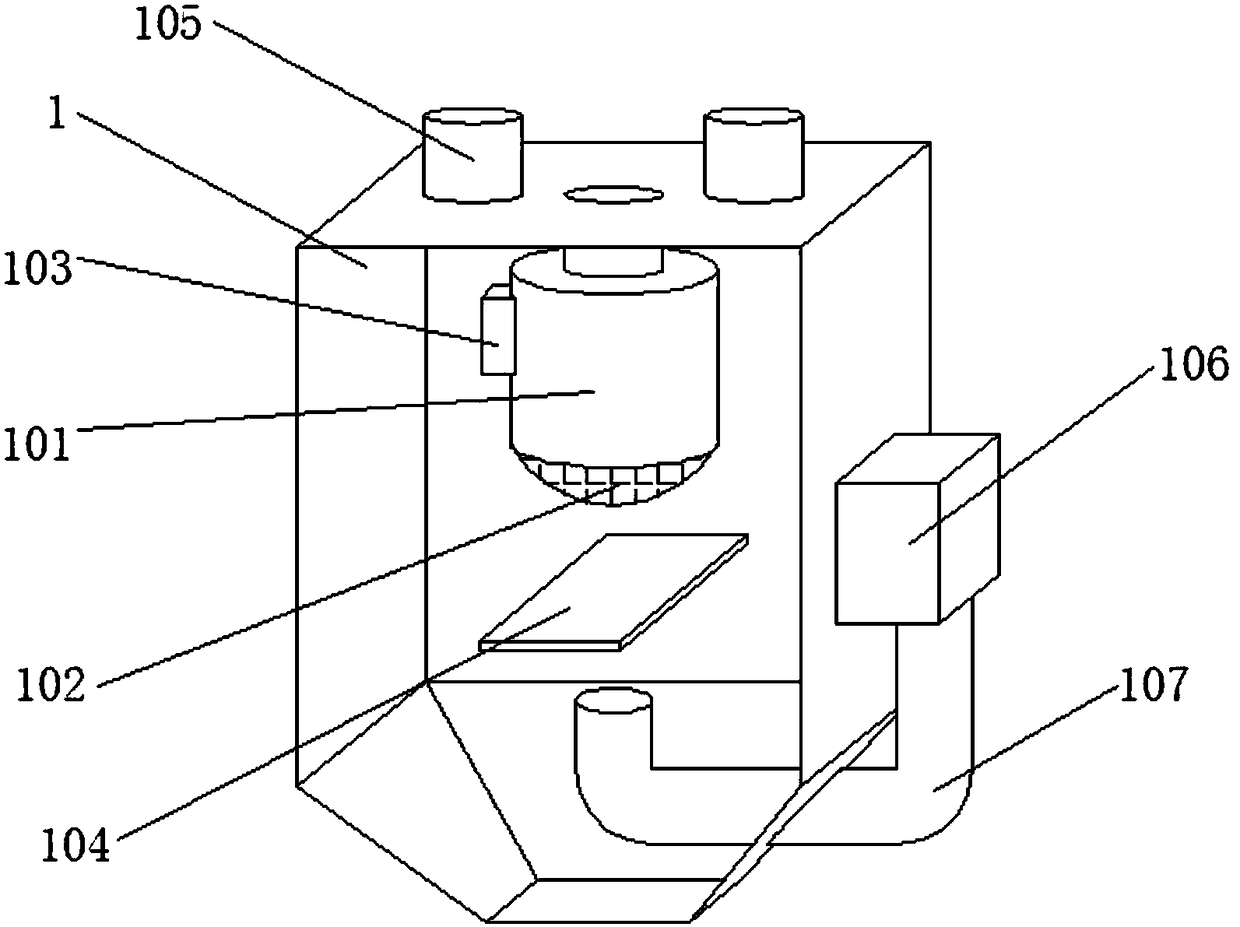

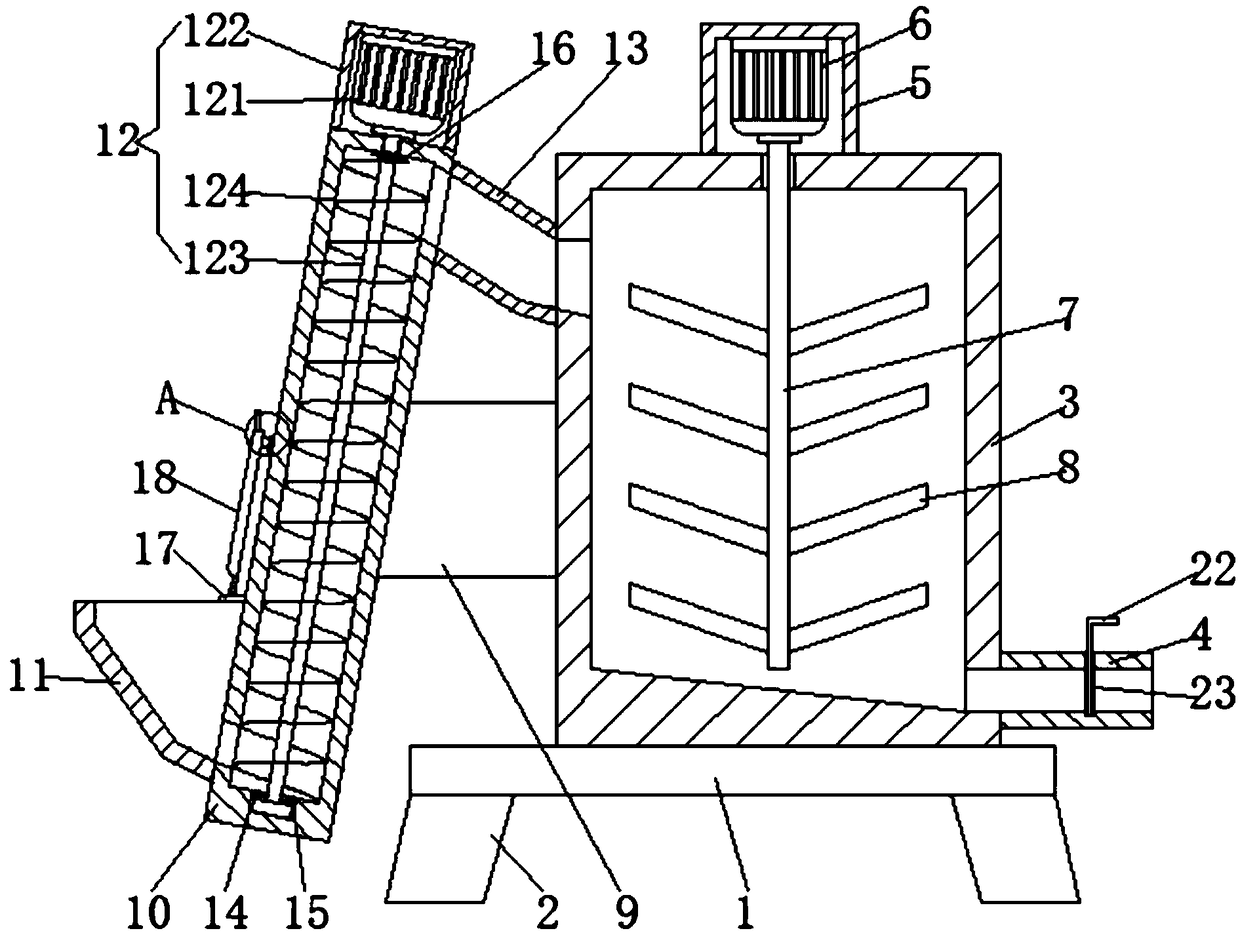

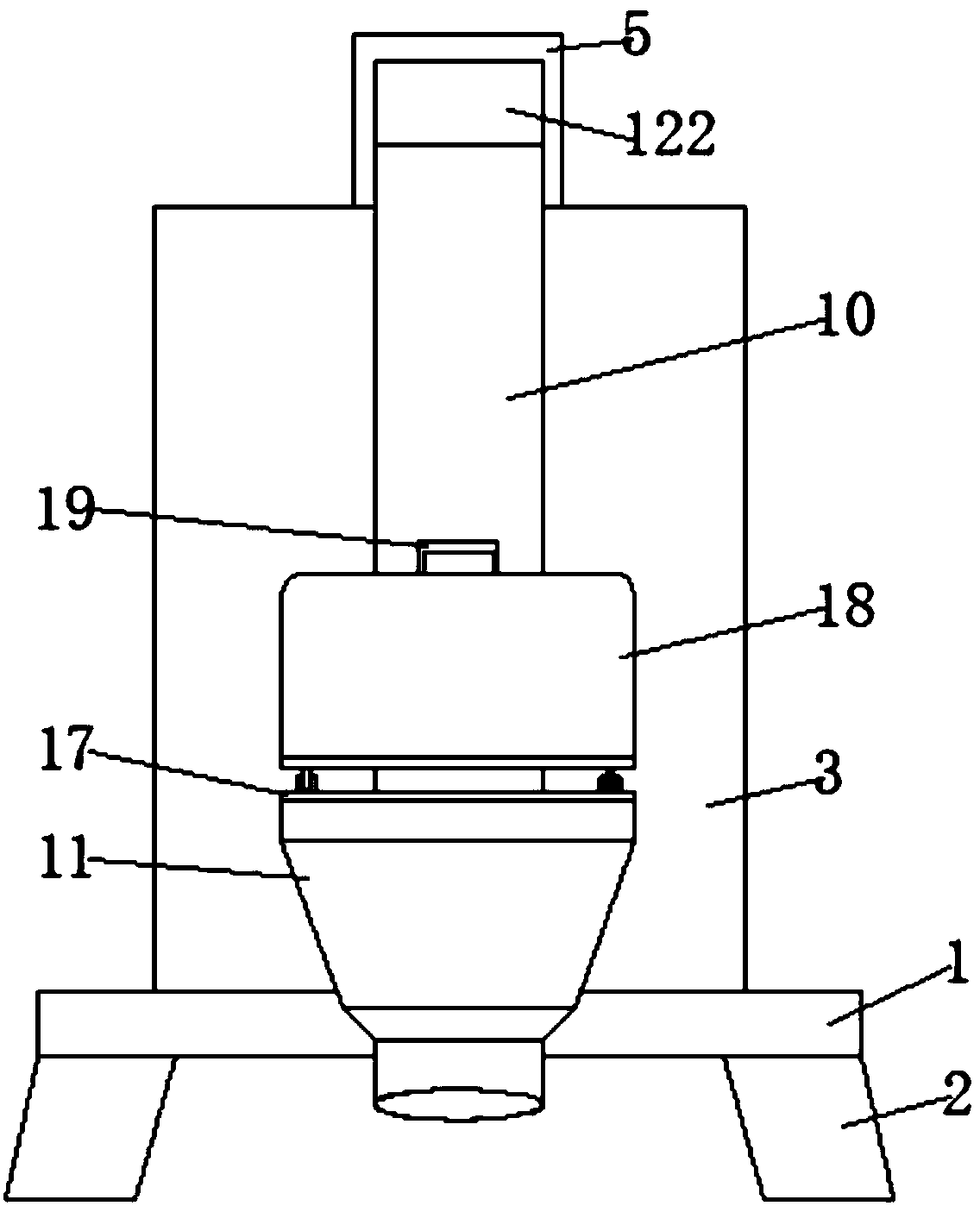

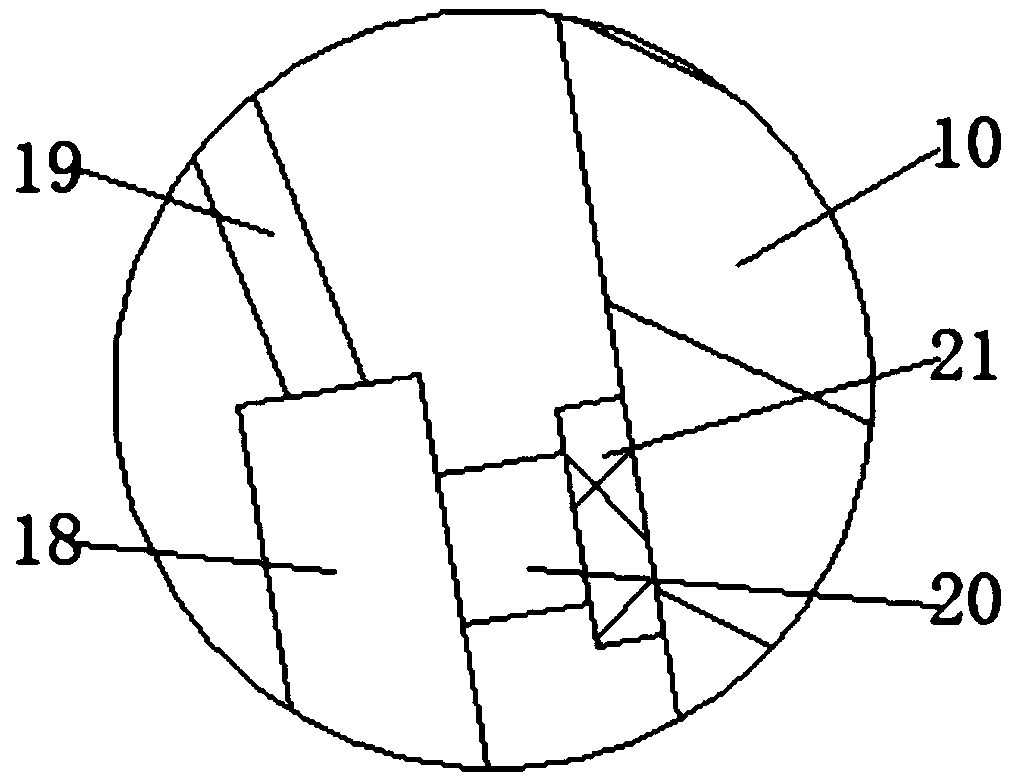

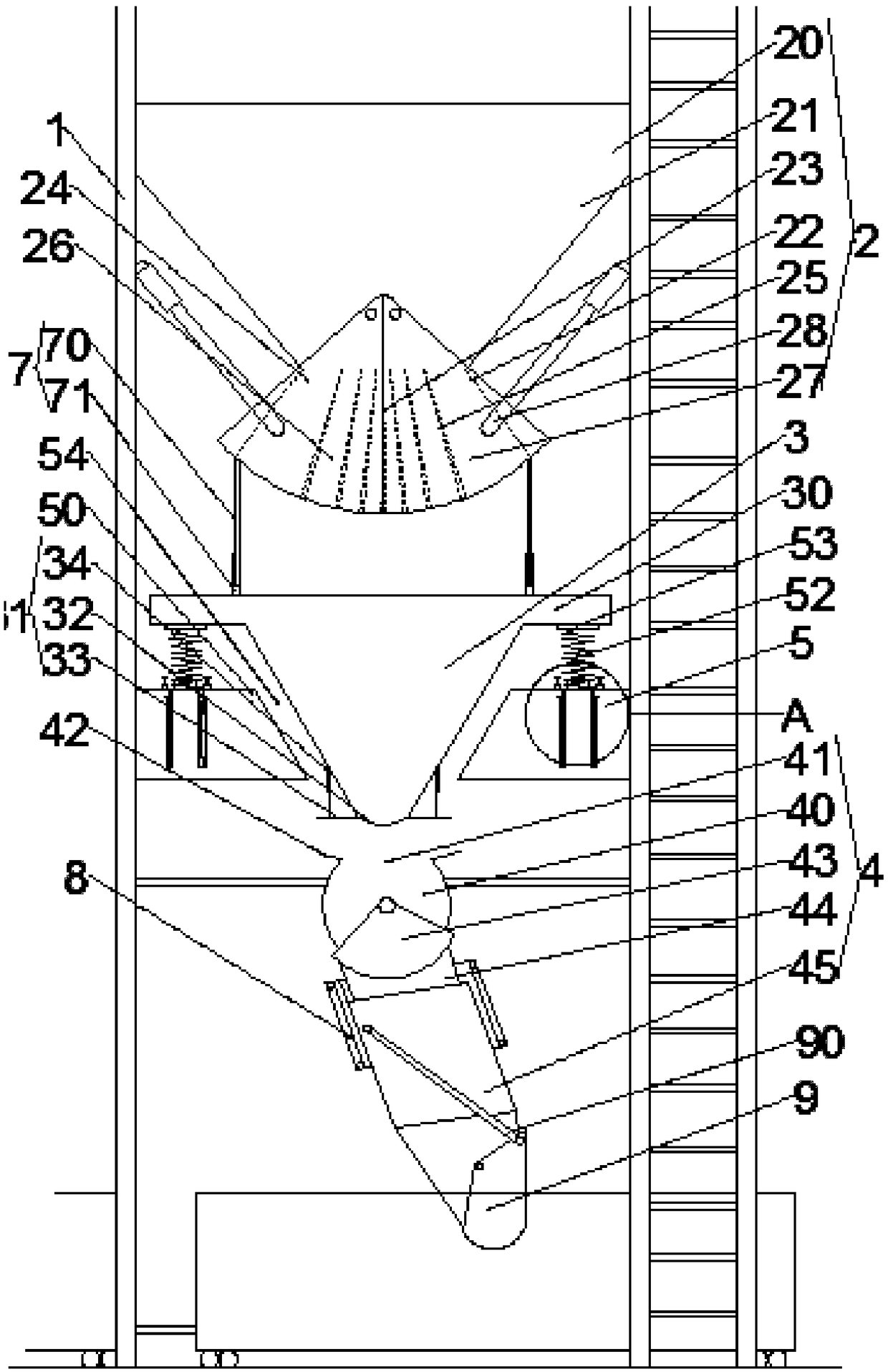

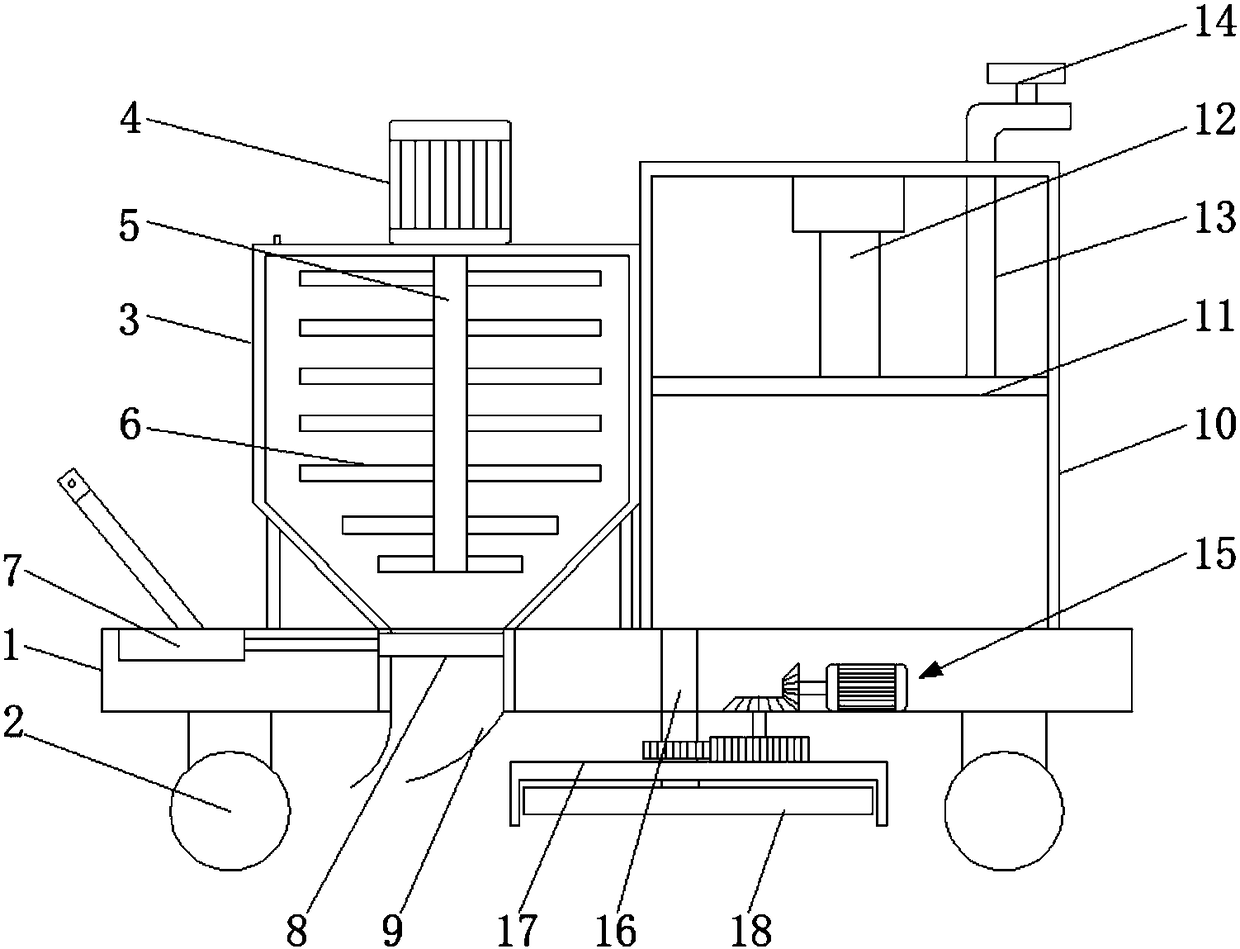

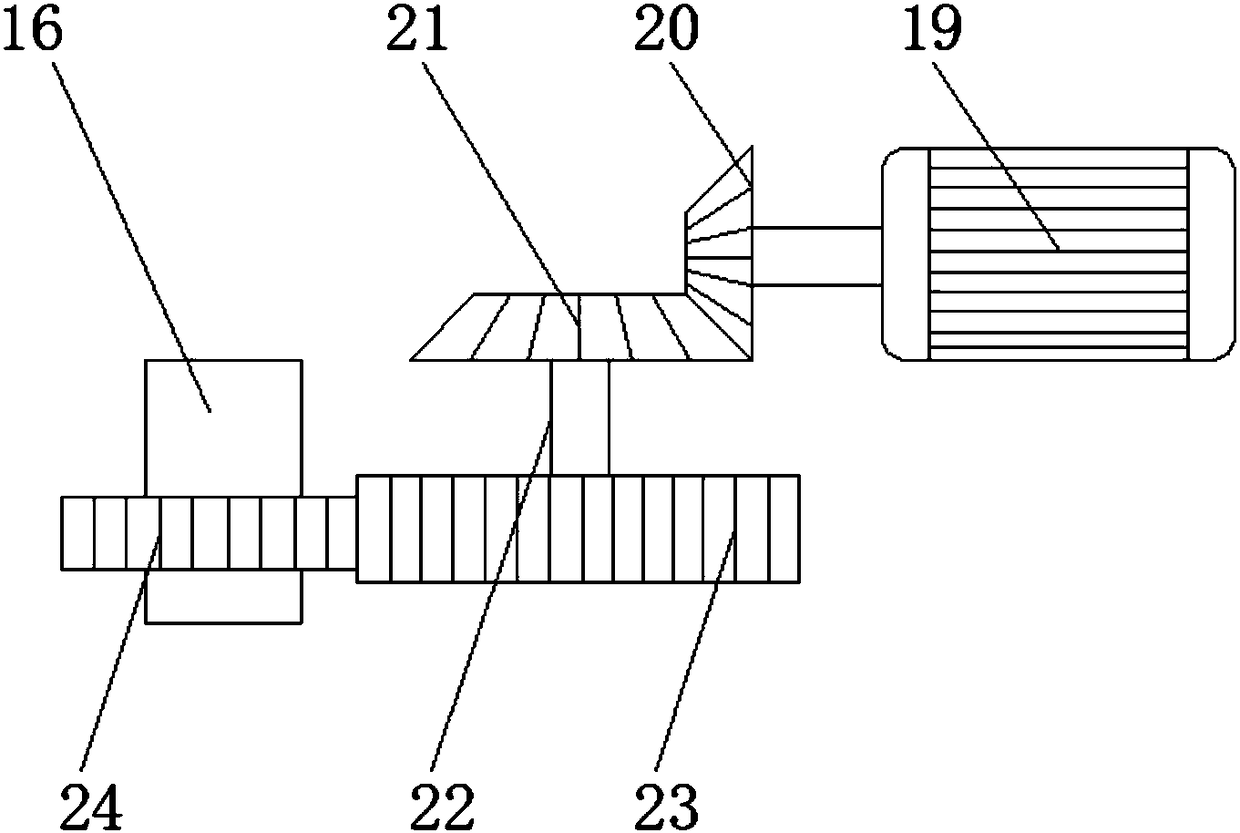

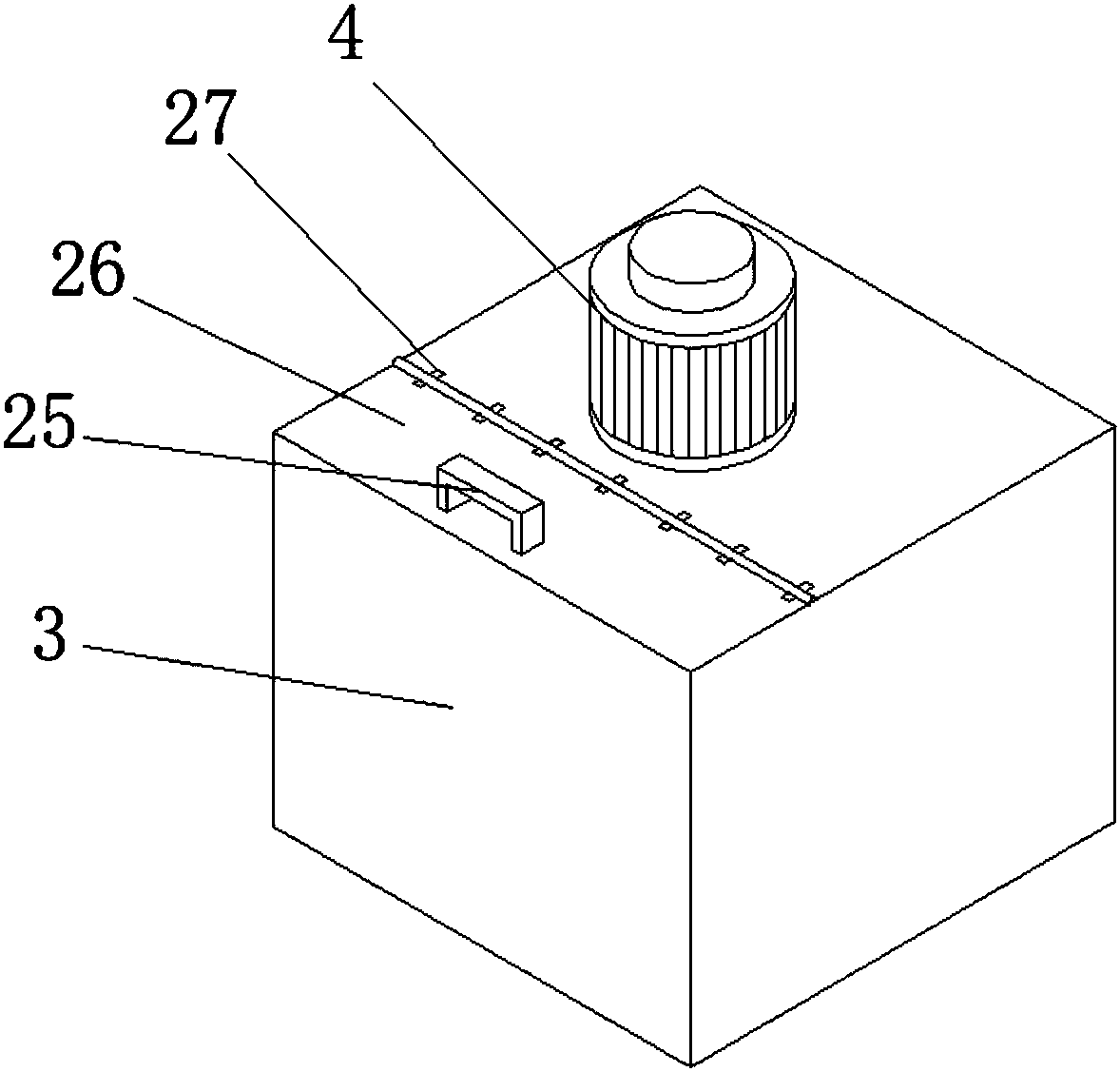

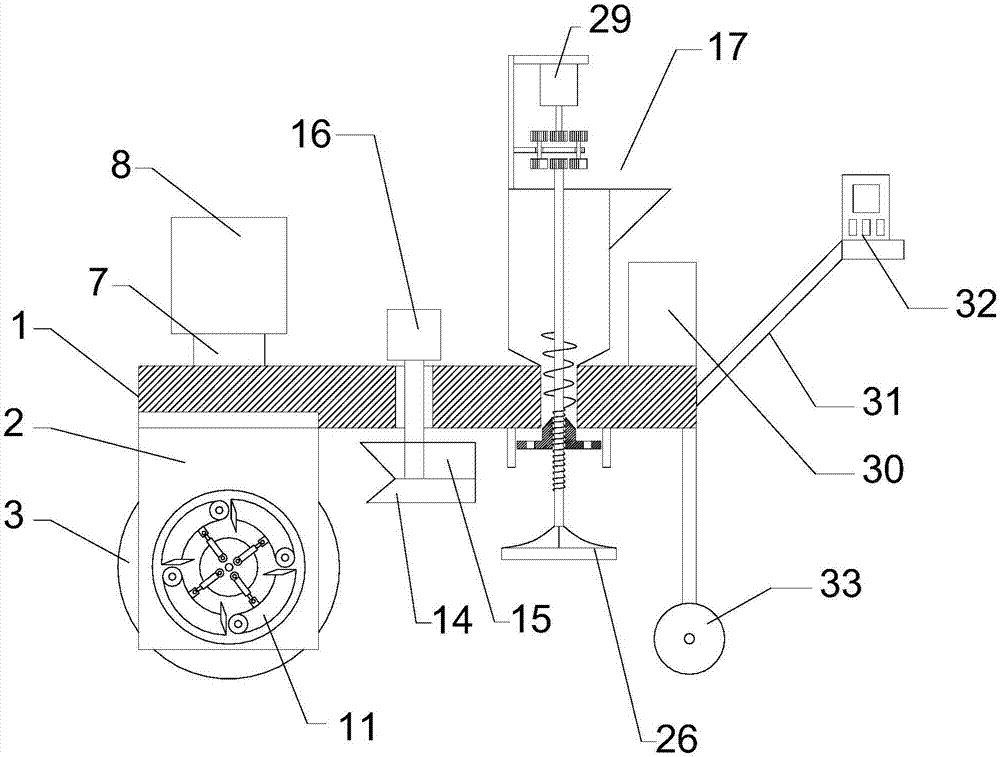

Automatic feeding device of construction waste crusher

The invention relates to an automatic feeding device of a construction waste crusher, and relates to the technical field of construction waste treating equipment. The automatic feeding device comprises a machine body, wherein a charging opening is formed in the machine body; a feeding device for delivering materials to the charging opening is arranged at a position, on one side of the machine body, of the charging opening, and comprises a bottom plate; a tank body which is perpendicular to the bottom plate is arranged on the bottom plate; the end, far away from the bottom plate, of the tank body extends to a position higher than that of the charging opening; the feeding device further comprises a moving rod which is arranged between the tank body and the charging opening in the horizontaldirection; a sliding block which is connected to the inner part of the tank body in a sliding manner is arranged at one end of the moving rod, and a feeding box is arranged at the other end of the moving rod; the upper part of the feeding box is opened; a lifting driving mechanism for driving the sliding block to drive the feeding box to move to a position higher than that of the charging openingis arranged in the tank body; a material delivering device for delivering construction waste into the charging opening when the feeding box moves to the position higher than that of the charging opening is arranged on the feeding box, so that the construction waste is convenient to deliver into the machine body.

Owner:四川志德公路工程有限责任公司

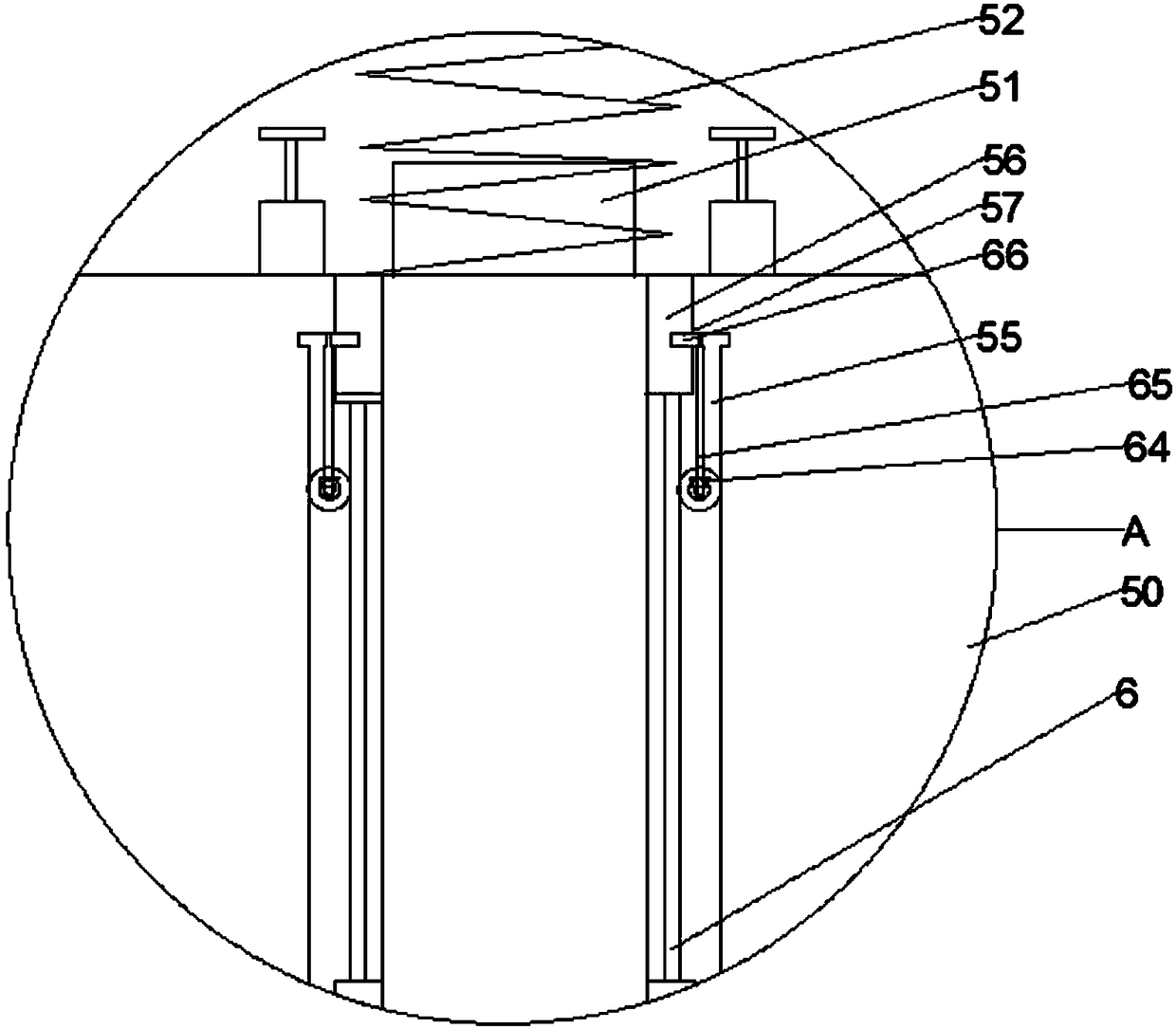

Storage device

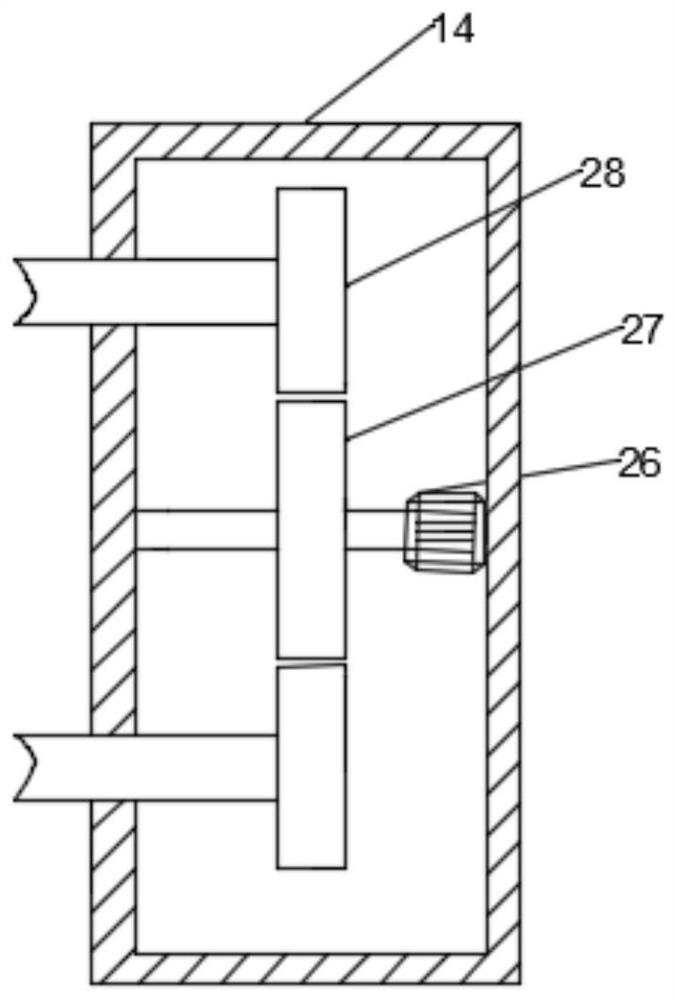

InactiveCN108455050ARealize automatic reclaimingControl the output speedDischarging meansDe-stacking articlesHydraulic cylinderOn board

The invention relates to a storage device. The storage device comprises a base plate. A conveying belt is mounted on the base plate. A storage box is arranged above the middle of the conveying belt. Both the upper portion and the lower portion of the conveying belt are open. An opening is formed in the lower portion of the front side of the storage box. The right end of the storage box abuts against a long frame. A discharging groove which is matched with an opening is formed in the bottom of the long frame in the front-back direction. A hydraulic cylinder is connected to the rear end of the long frame. The storage device is convenient to use; and on the basis that wooden boards are stored in a stacked mode, the wooden boards are conveyed through the belt, and cooperation between the discharging groove and the opening is controlled so that the wooden boards can be automatically fetched, and the discharging speed of the wooden board can be controlled.

Owner:ANHUI GUANGMING GRAIN & OIL IND

Fertilizing device for agricultural use

InactiveCN108551825AAvoid conversionIncrease profitFertiliser distributersPressurised distribution of liquid fertiliserAgricultural engineeringFunnel shape

The invention discloses a fertilizing device for agricultural use. The fertilizing device for agricultural use comprises a pedestal, a solid material box and a liquid material box; universal wheels are fixedly arranged at the four corners of the bottom end of the pedestal through supporting legs; the solid material box and the liquid material box are fixed on the pedestal; the solid material box is arranged on the left side of the liquid material box; a stirring device is arranged in the solid material box; the stirring device comprises a stirring motor, a stirring rod and a stirring paddle; the upper end of the solid material box adopts a cuboid structure and the lower end of the solid material box adopts a funnel-shaped structure; the bottom end of the solid material box is provided witha discharging port in the pedestal; and a first electric telescopic rod is fixedly arranged at the top end of the internal part of the pedestal on the left side of the discharging port. The fertilizing device for agricultural planting is provided with the solid material box and the liquid material box so as to perform fertilizing utilization on different types of fertilizer and save the use costof various fertilizing device, and performs rotary spraying in a retaining disk so as to prevent a discharging spray head from being blocked and realize uniform spraying.

Owner:NANAN WENFA ELECTRONICS TECH CO LTD

Material mixing and plastering method for ceramic tiles

InactiveCN109760210AImprove mechanical propertiesImprove efficiencyMixing operation control apparatusMetallurgyMaterial distribution

The invention provides a material mixing and plastering method for ceramic tiles. A machine frame, a stirring device, a material distribution device and a ceramic tile positioning and conveying deviceare included. The material mixing and plastering method for the ceramic tiles includes the following steps that raw materials are added in the stirring device, and then the stirring device is startedto stir the raw materials to form an ash material; in the raw material stirring process, the ceramic tiles to be subjected to plastering are placed on the ceramic tile positioning and conveying device and are positioned, and the material distribution device is lowered to the upper surfaces of the end portions of the ceramic tiles; a discharge port of a stirring hopper device is opened after stirring is completed and the stirring device is stopped, the ash material subjected to stirring forming is fed into the material distribution device, and the discharge port of the stirring hopper device is closed after the material distribution device is full filled with the ash material; the material distribution device is lifted, the ceramic tile positioning and conveying device is started at the same time so that the ceramic tiles can move on the ceramic tile positioning and conveying device, the ash material falls onto the ceramic tiles along with movement of the ceramic tiles, and the ash material is smoothed through the bottom of the material distribution device; and the multiple ceramic tiles sequentially move on the ceramic tile positioning and conveying device to be subjected to plastering till the ash material in the material distribution device is used up.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

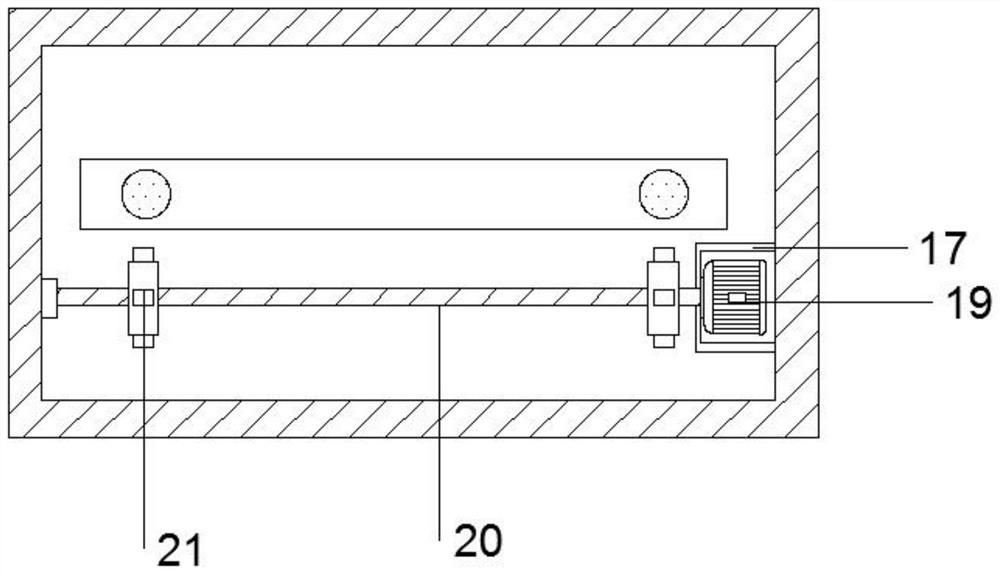

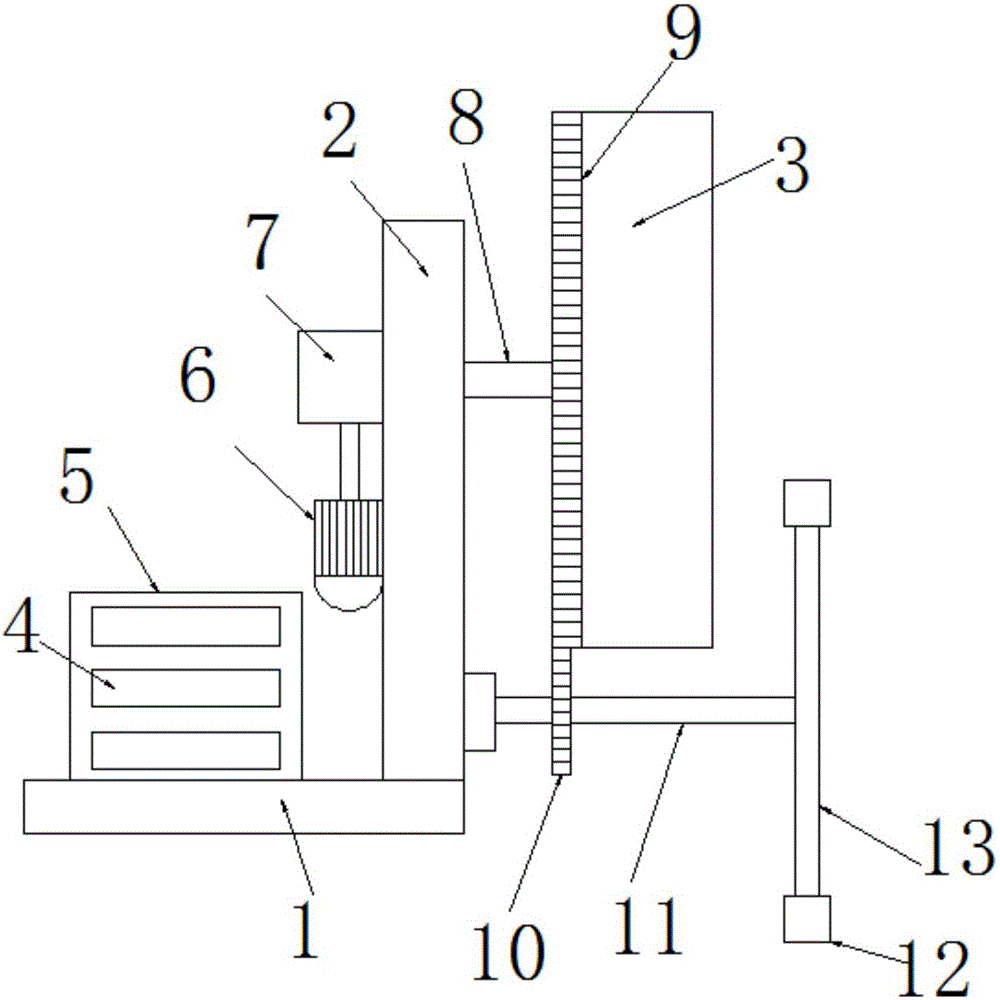

Method and device for automatically controlling discharging amount of waste plastics

InactiveCN103342224AControl the output speedAccurate output speedConveyor partsAutomatic controlEngineering

Owner:福建三宏再生资源科技有限公司

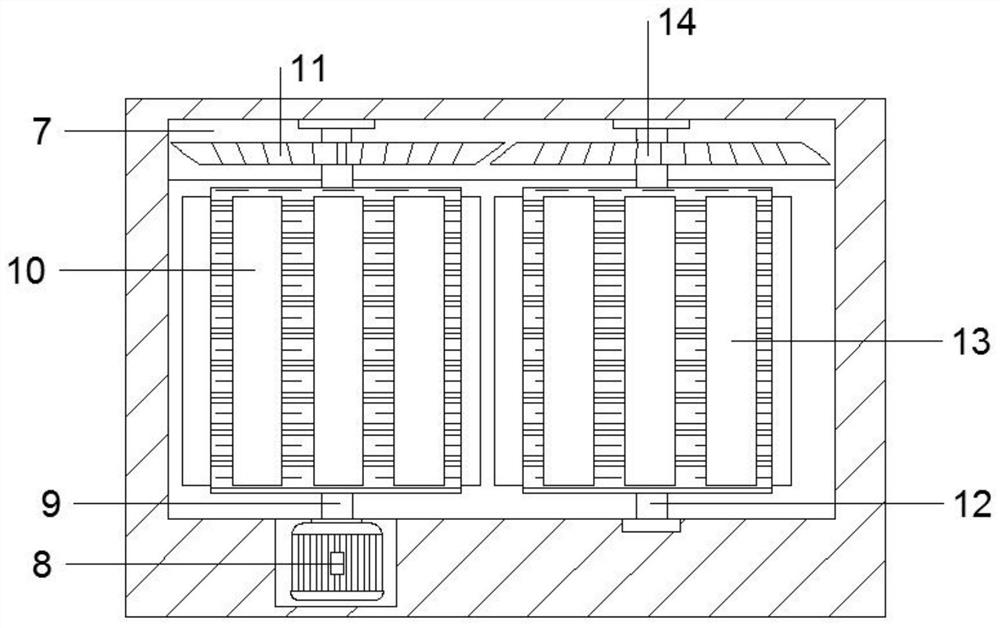

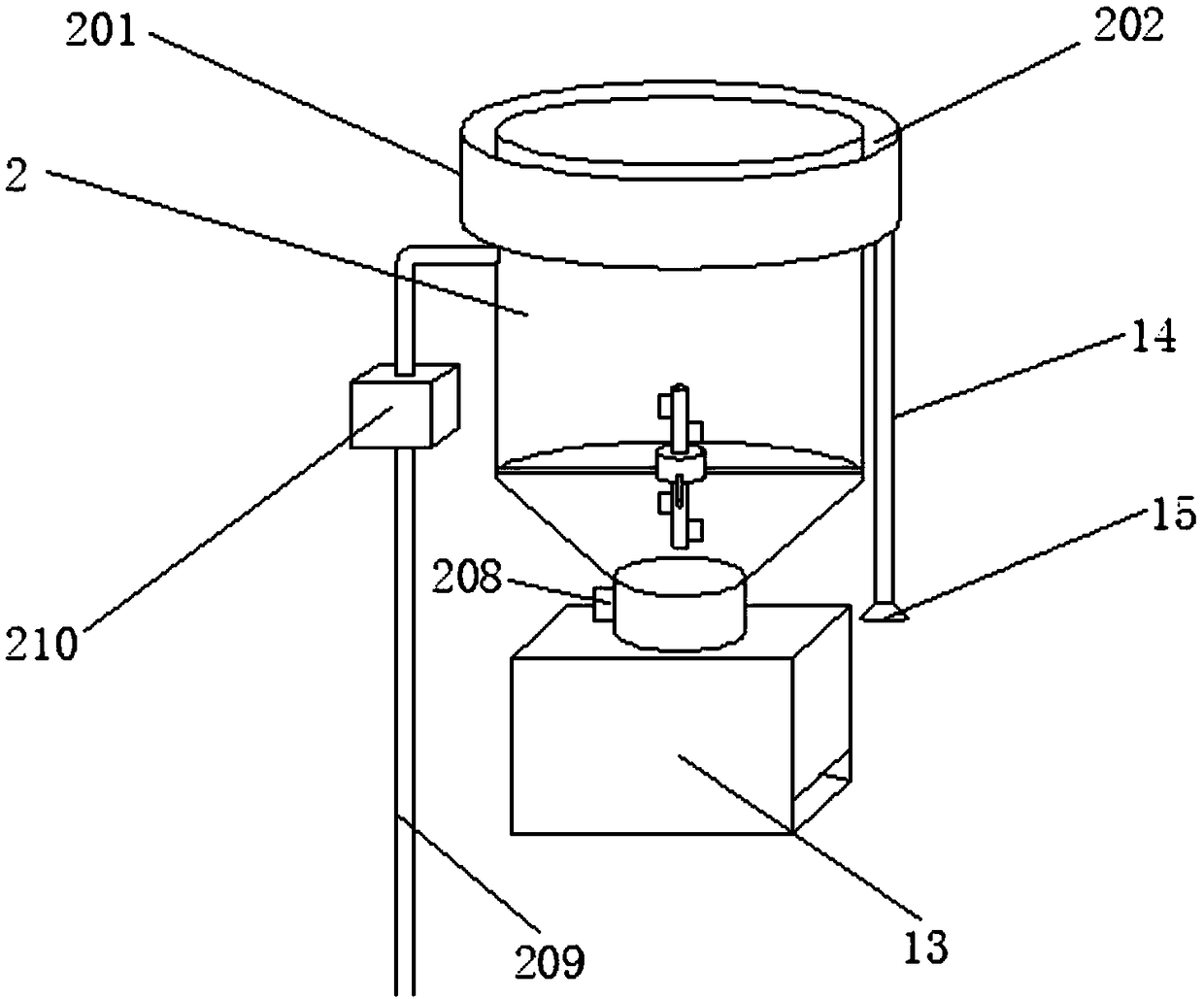

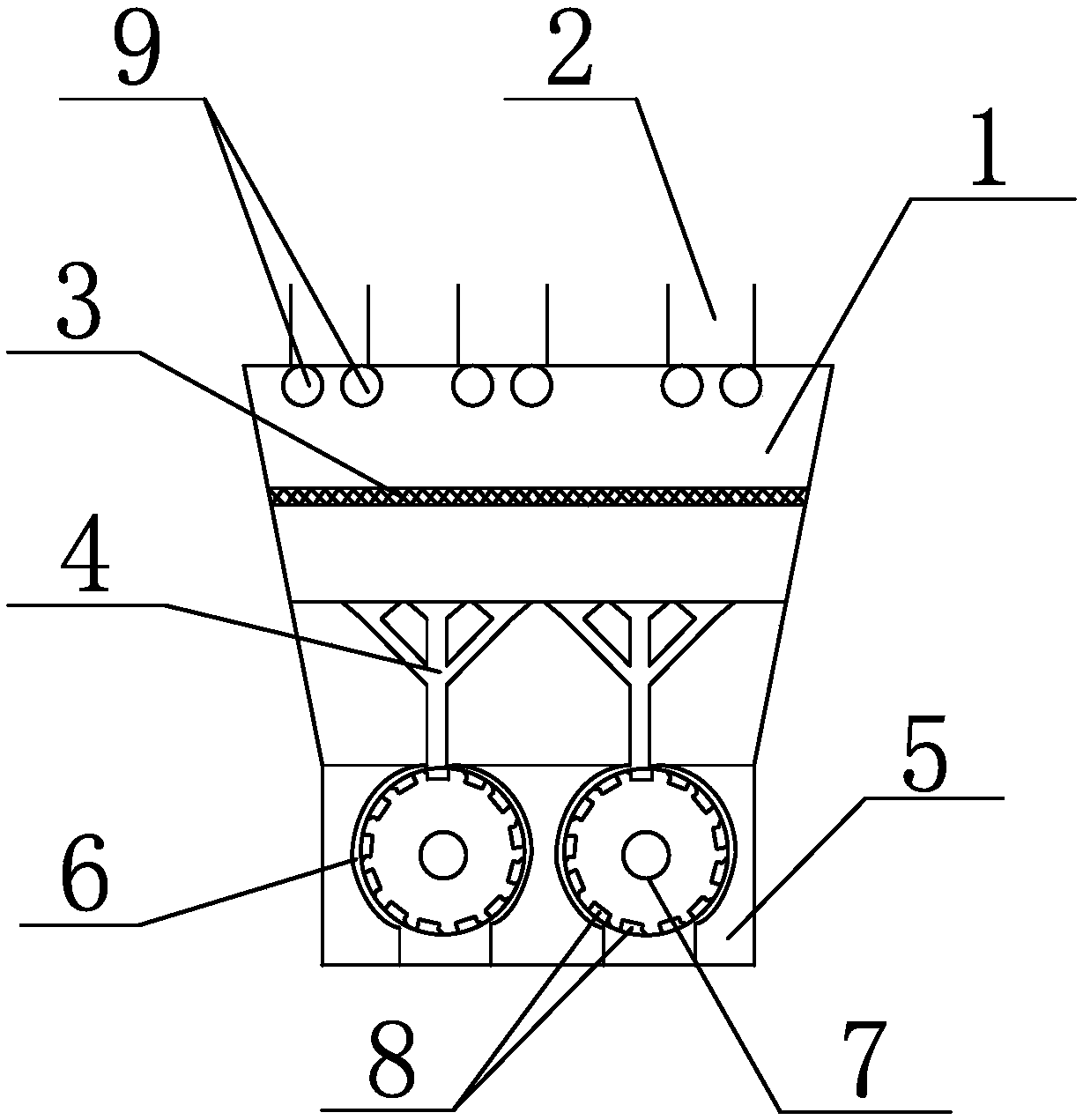

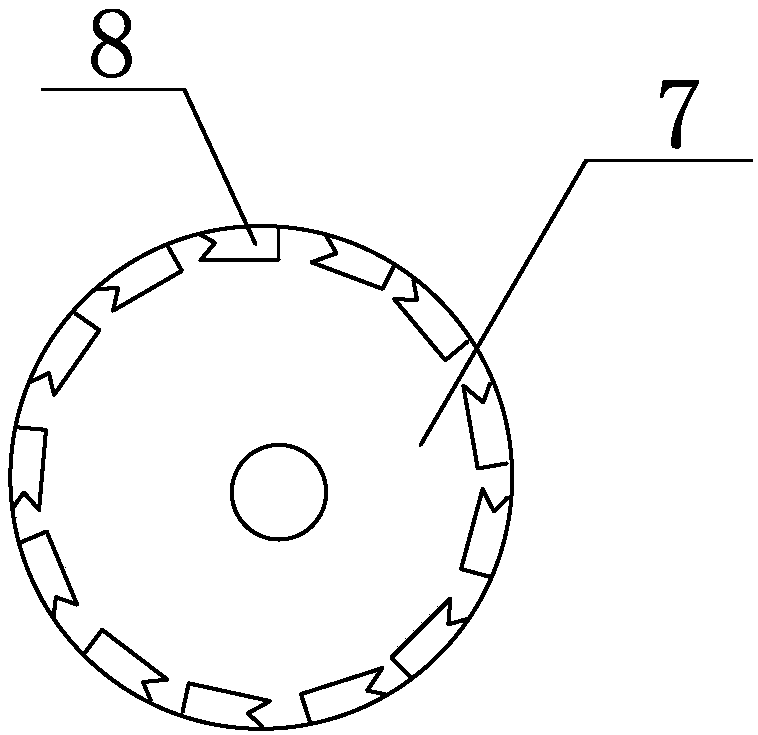

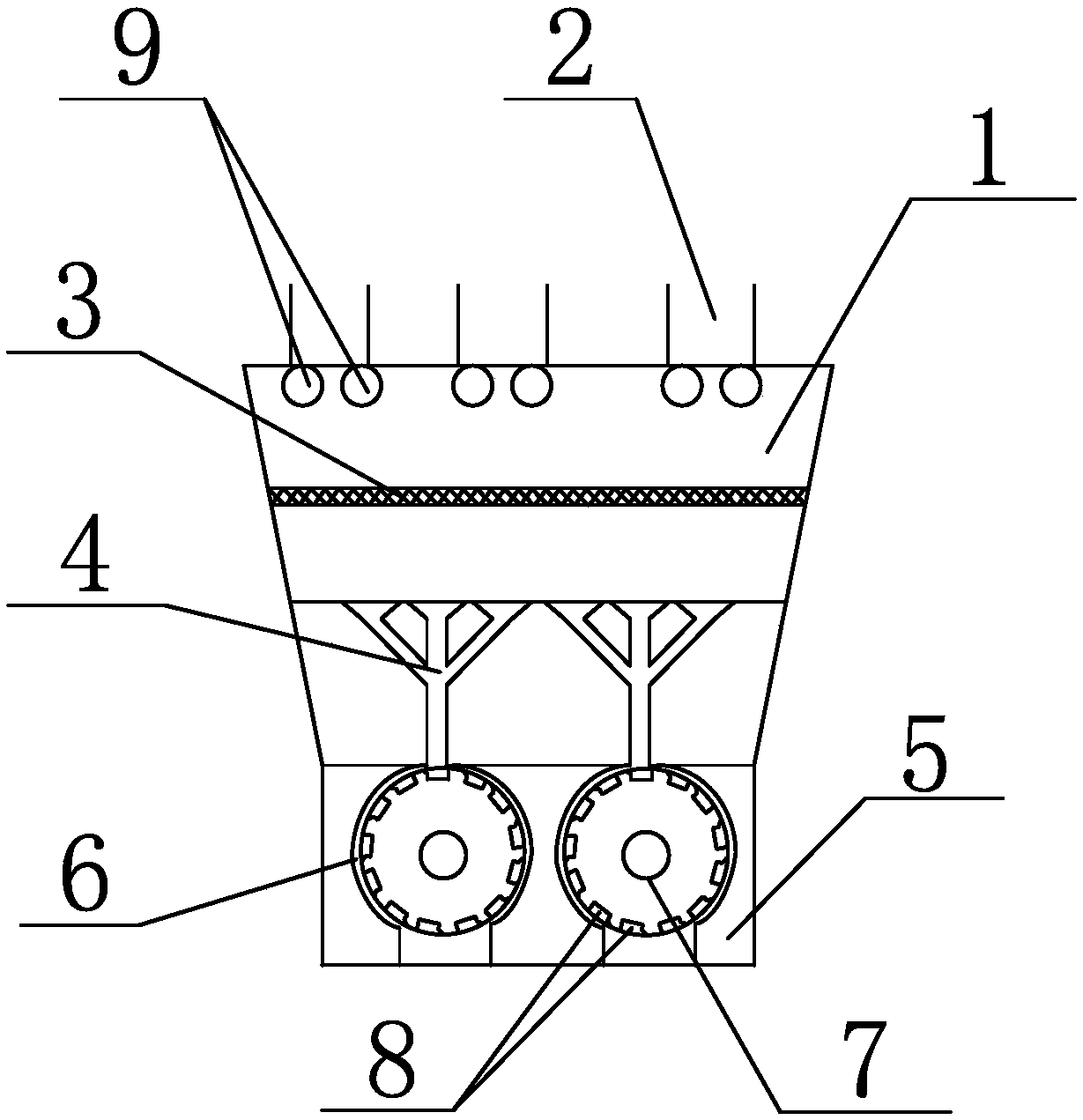

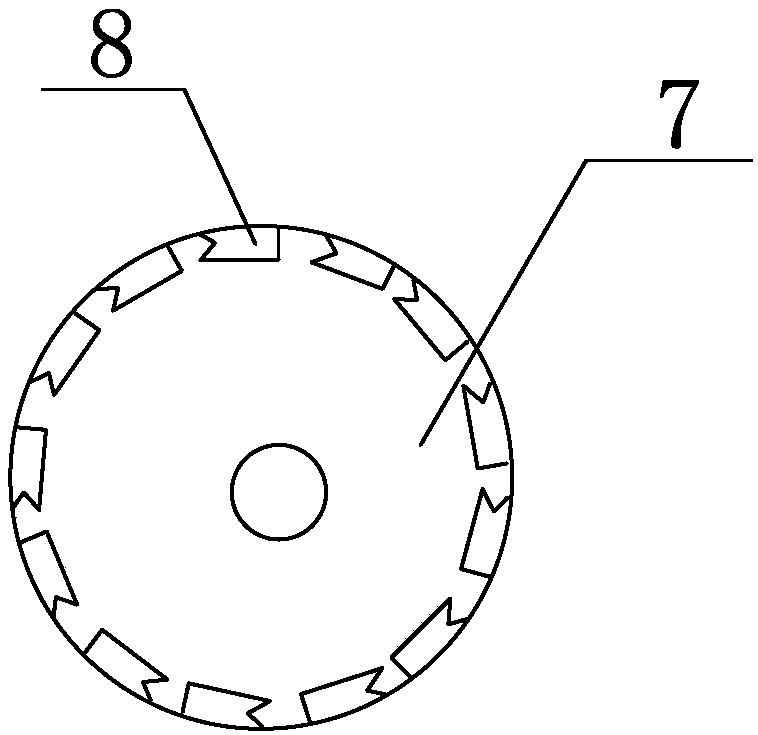

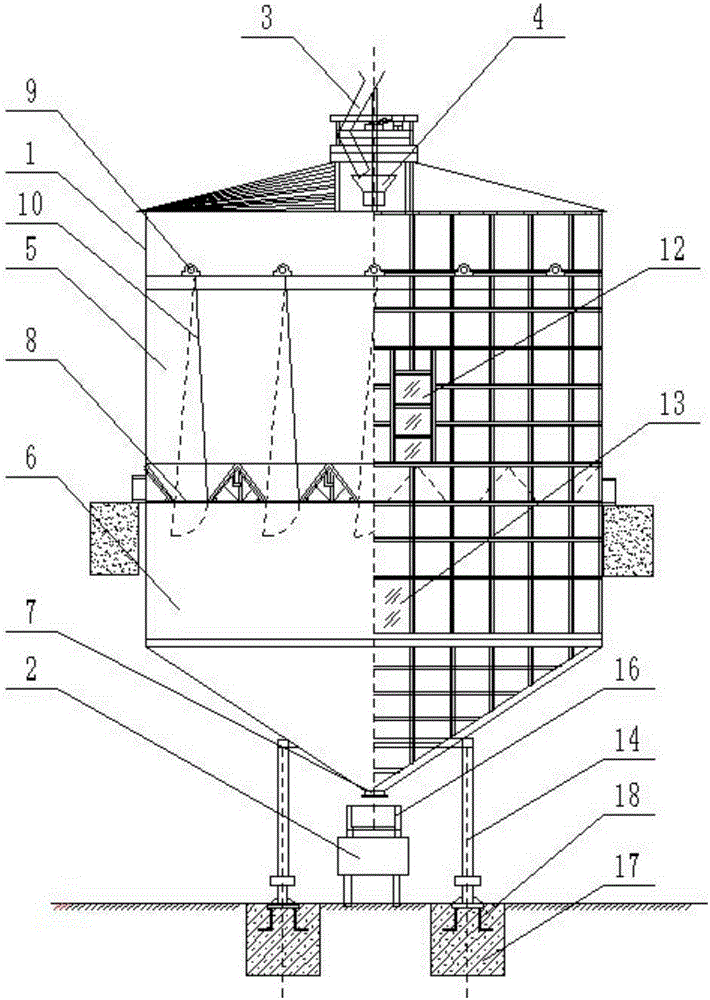

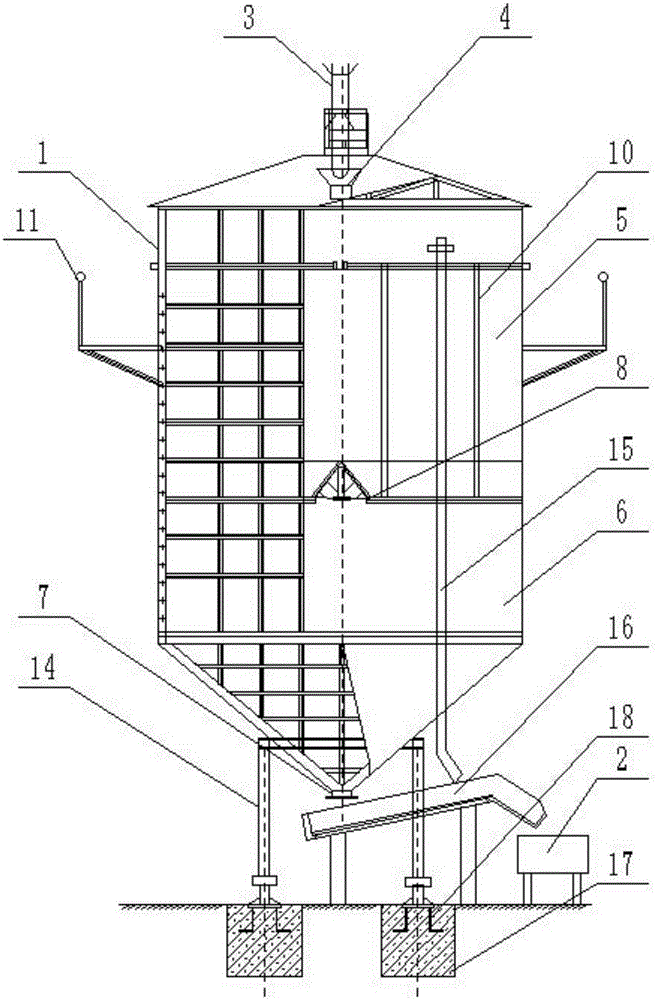

Rare earth waste roasting uniform feeding device

InactiveCN112414147AAvoid uneven heatingReduce manufacturing costSievingScreeningElectric machineProcess engineering

The invention provides a rare earth waste roasting uniform feeding device. The device comprises a feeding box, a feeding port is formed in the top of the feeding box, a smashing cavity is formed in the bottom of the feeding port, a filtering cavity is formed in the bottom of the smashing cavity, a stirring cavity is formed in the bottom of the filtering cavity, a discharging port is formed in thebottom of the stirring cavity, an adjusting table is clamped in the discharging port, a motor groove is formed in one side of the smashing cavity, and a mounting groove is formed in the other side ofthe smashing cavity. Rare earth waste can be smashed through the smashing cavity, when the smashed rare earth waste enters the filtering cavity, a screening net can be driven by a rotating motor to vibrate, accordingly, the rare earth waste is screened, and the screened rare earth waste enters the stirring cavity to be stirred and heated, so that the rare earth waste can be preheated, the workingefficiency of waste roasting is improved, when the rare earth waste passes through the discharging port, the adjusting table can adjust the discharging speed of the rare earth waste, and therefore thesituation that the rare earth waste is accumulated is prevented.

Owner:萍乡鑫森新材料有限责任公司

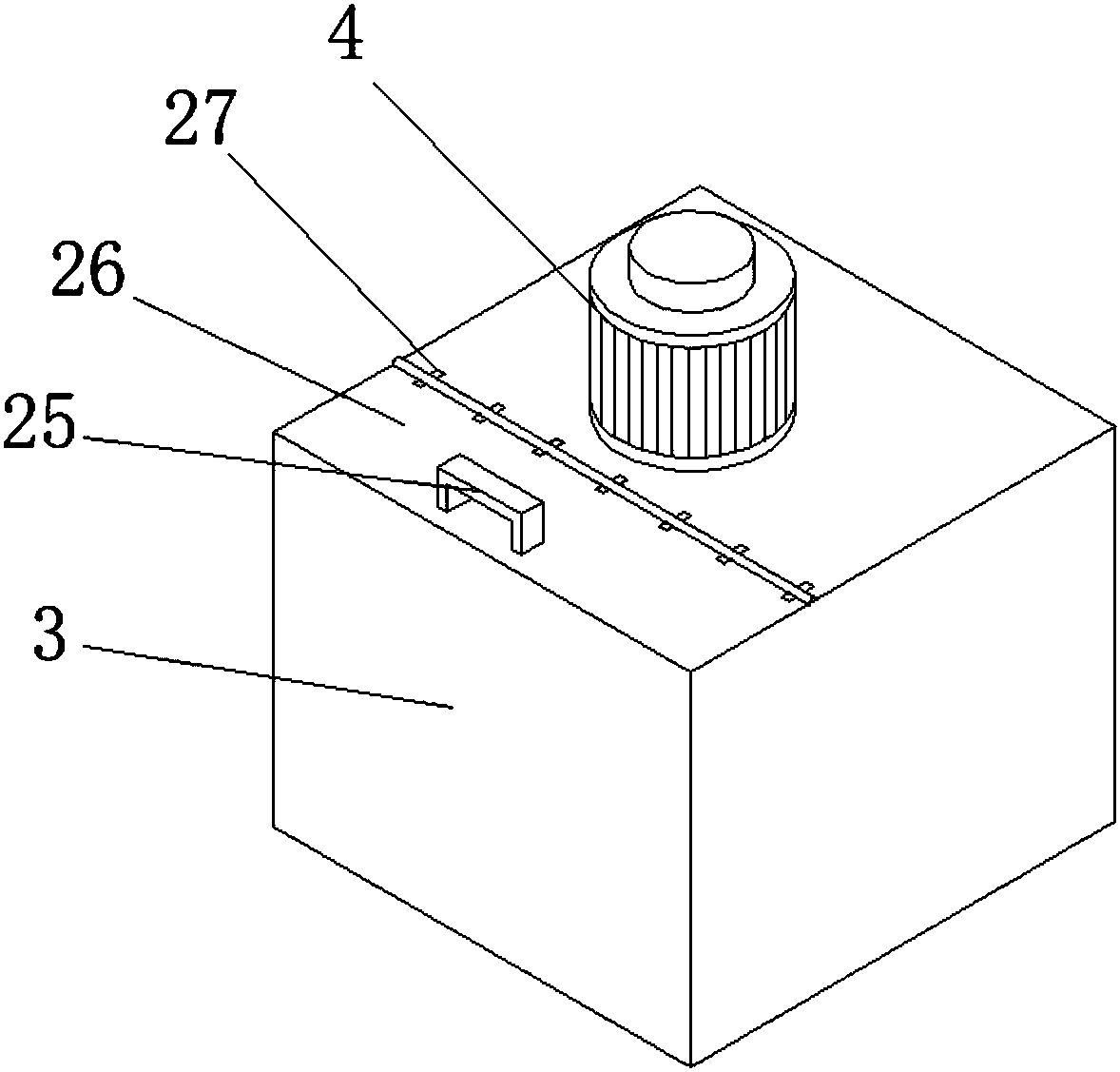

Seed cleaning device

InactiveCN108580026APrevent fallingControl the output speedSievingGas current separationEngineeringAir blower

The invention provides a seed cleaning device comprising a hopper, a screening box, a liquid separating cylinder and a control cabinet. The bottom of the feeding hopper is connected with a screening cylinder through a connection pipe. A baffle is arranged in the screening box. The side wall of the screening box is provided with an air blower. An output opening of the air blower is connected with an air intake pipe. The liquid separating cylinder is arranged under the screening box. A wizened seed filtering cavity is arranged on the outer side of the top of the liquid separating cylinder. A discharging box is fixedly connected with a bottom discharging opening of the liquid separating cylinder. A conveyer belt is arranged below the discharging box. A water trough is arranged below the conveyer belt, and multiple water holes are formed in the surface of the conveyer belt. A water tank is arranged on one side of the liquid separating cylinder. One side of the liquid separating cylinder and one side of the water tank both extend into the water trough through water pipes and water pumps. A drying box is arranged below the tail end of the conveyer belt. The seed cleaning device achievesautomatic machining of seeds, reasonably utilizes resources, reduces cost and improves the seed quality.

Owner:HUZHOU GUOXIN MATERIALS

Building stirring device with efficient stirring function

InactiveCN108748684AEfficient mixingStir wellDischarging apparatusMixing operation control apparatusEngineeringRaw material

The invention discloses a building stirring device with an efficient stirring function. The stirring device comprises a shell body, a bottom plate is fixedly connected to the bottom of the shell body,a transmission box is fixedly connected to the top of the shell body, the bottom of the right side of the shell body communicates with a discharging pipe, the top of the right side of the shell bodycommunicates with a guide funnel, and the left side of the shell body is fixedly connected with a supporting plate. According to the building stirring device with the efficient stirring function, thequality of raw materials is improved by synchronously adding water in the raw material adding process, moreover, a transmission motor, a transmission rod, a stirring rod, blades, a supporting rod anda stirring rod are arranged and used for stirring the raw materials inside the shell body one by one, and therefore, the mixing quality is improved, and the problems that an existing stirring device cannot be used for quickly and uniformly mixing raw materials in the bottom of a shell body and raw materials in the top of the shell body together, so that stirring is not uniform, and the stirring efficiency is low are solved; and the building stirring device with the efficient stirring function has the advantages of being high in stirring efficiency and uniform in stirring.

Owner:吴子翻

Feed hopper with screening function

ActiveCN108706234AAvoid clearingSave manpower and material resourcesSievingScreeningMotor driveMaterial resources

The invention discloses a feed hopper with a screening function, and relates to the technical field of material feeding. The feed hopper with the screening function comprises a shell, wherein a clamping plate is fixed to the inner surface of the shell and is in snap fit to a screening barrel; a cavity is arranged on one end surface of the screening barrel; a penetrating hole is formed in one end surface of the screening barrel; through holes are uniformly formed in the inner surface of the cavity in an array way; a first limiting ring is fixed to the peripheral side surface of the screening barrel; four rectangular grooves are formed in one end surface of the screening barrel; four rectangular blocks are fixed to the peripheral side surface of the clamping plate and are in snap fit to thefour rectangular grooves; a first connecting rod is fixed to one surface of the clamping plate; stirring blades are fixed to the peripheral side surface of the first connecting rod; an air cylinder isfixed to one end surface of the first connecting rod; and a servo motor is fixed to one end surface of the air cylinder. According to the feed hopper with the screening function provided by the invention, the servo motor drives the clamping plate to rotate, the clamping plate is in snap fit to the screening barrel so as to drive the screening barrel to rotate, and under the actions of the stirring blades and the centrifugal force, impurities of materials are separated into the cavity, so that an extra impurity removal process is avoided, and manpower and material resources are saved.

Owner:合肥通快钣金科技有限公司

Sorting and throwing method of particle and powder particle fertilizer, and seeds

InactiveCN107710988AFertilize evenlyControl the amount of fertilizerFertiliser distributersSingle grain seedersAgricultural sciencePrimary screening

The invention discloses a sorting and throwing method of particle and powder particle fertilizer, and seeds. The sorting and throwing method comprises following steps: 1, fertilizer or seeds are thrown into a sorting and throwing device; 2, primary screening is carried out; 3, seeds or fertilizer is introduced into discharging pipes; 4, material distributing rotating cylinders are driven to rotate, wherein material distributing grooves are designed to shape like a seed or be capable of accommodating a plurality of fertilizer parts; 5, only one seed or fertilizer of a same amount is dischargedwhen each material distributing groove is driven to pass through and move back from a corresponding inlet. The sorting and throwing method is capable of realized uniform and quantified discharing of seeds or fertilizer, ensuring excellent control on sowing amount and fertilizing amount of soil in a certain distance in moving forward process of a working vehicle, controlling discharging speed and quality, improving sowing and fertilizing uniformity, realizing one by one throwing of seeds and throwing of one seed in a unit time period, and realizing throwing of fertilizer of the same volume in aunit time period.

Owner:CHENGDU HONGDE YONGXING BREEDING CO LTD

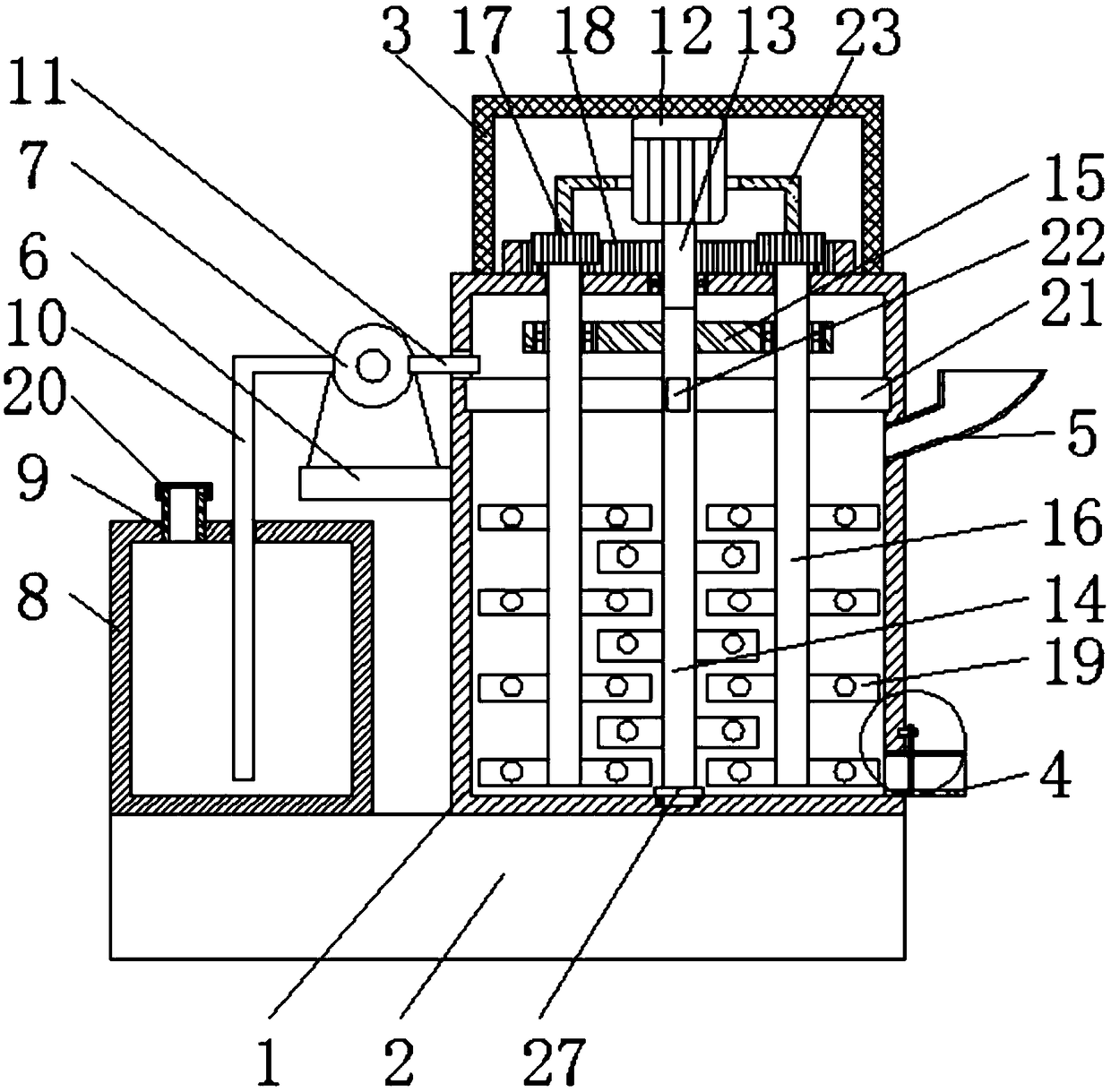

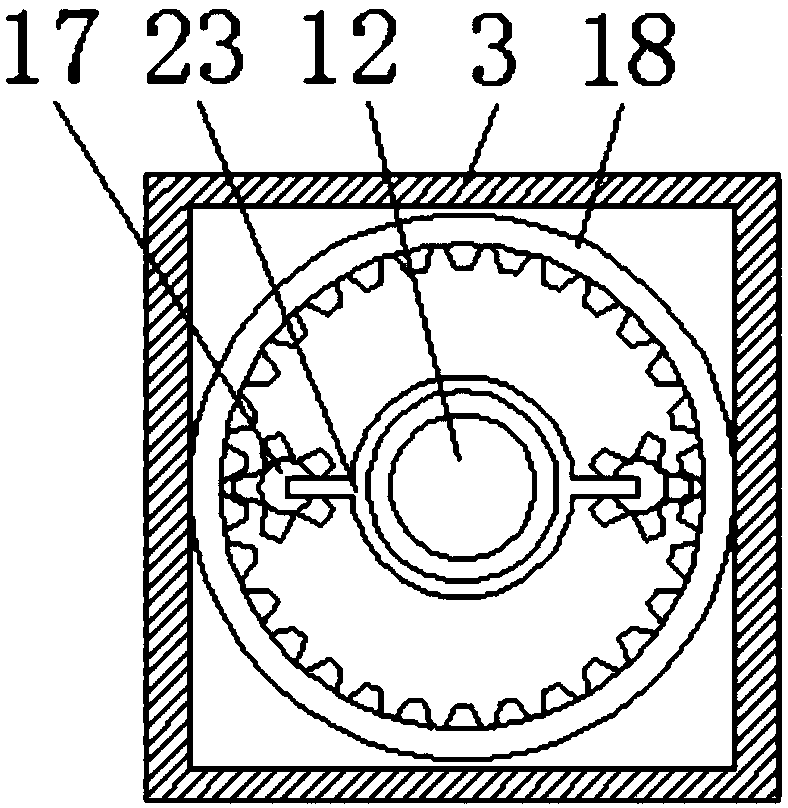

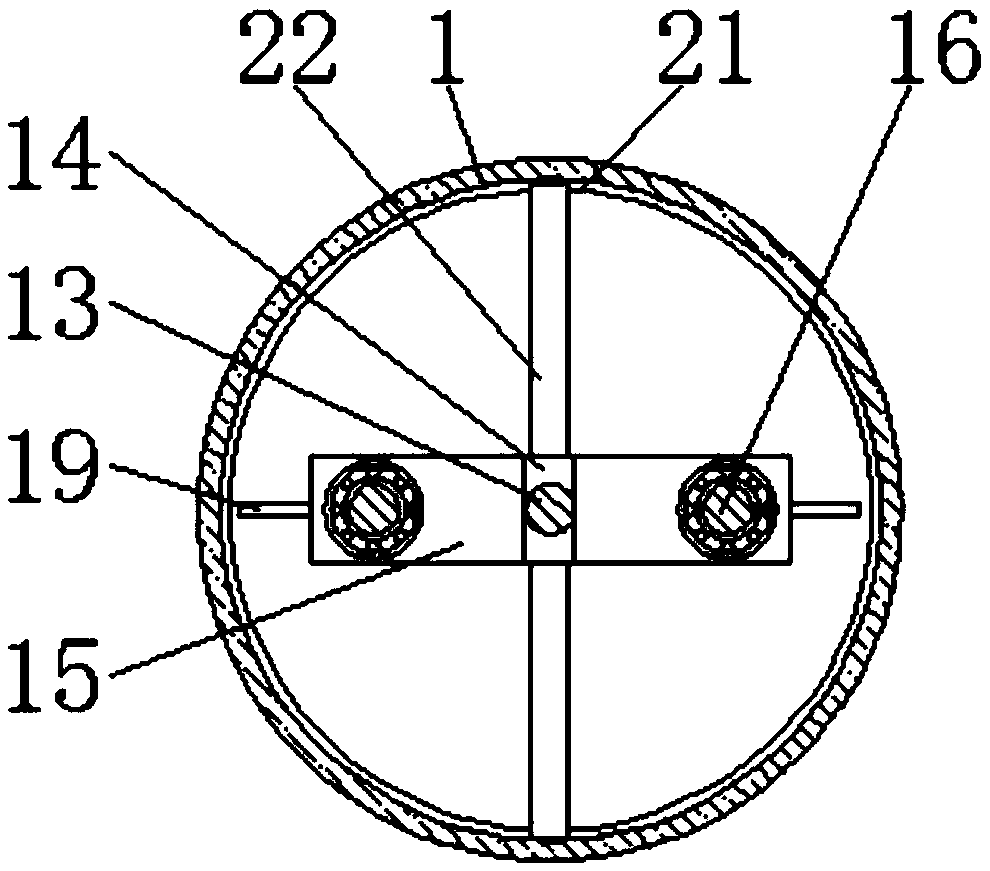

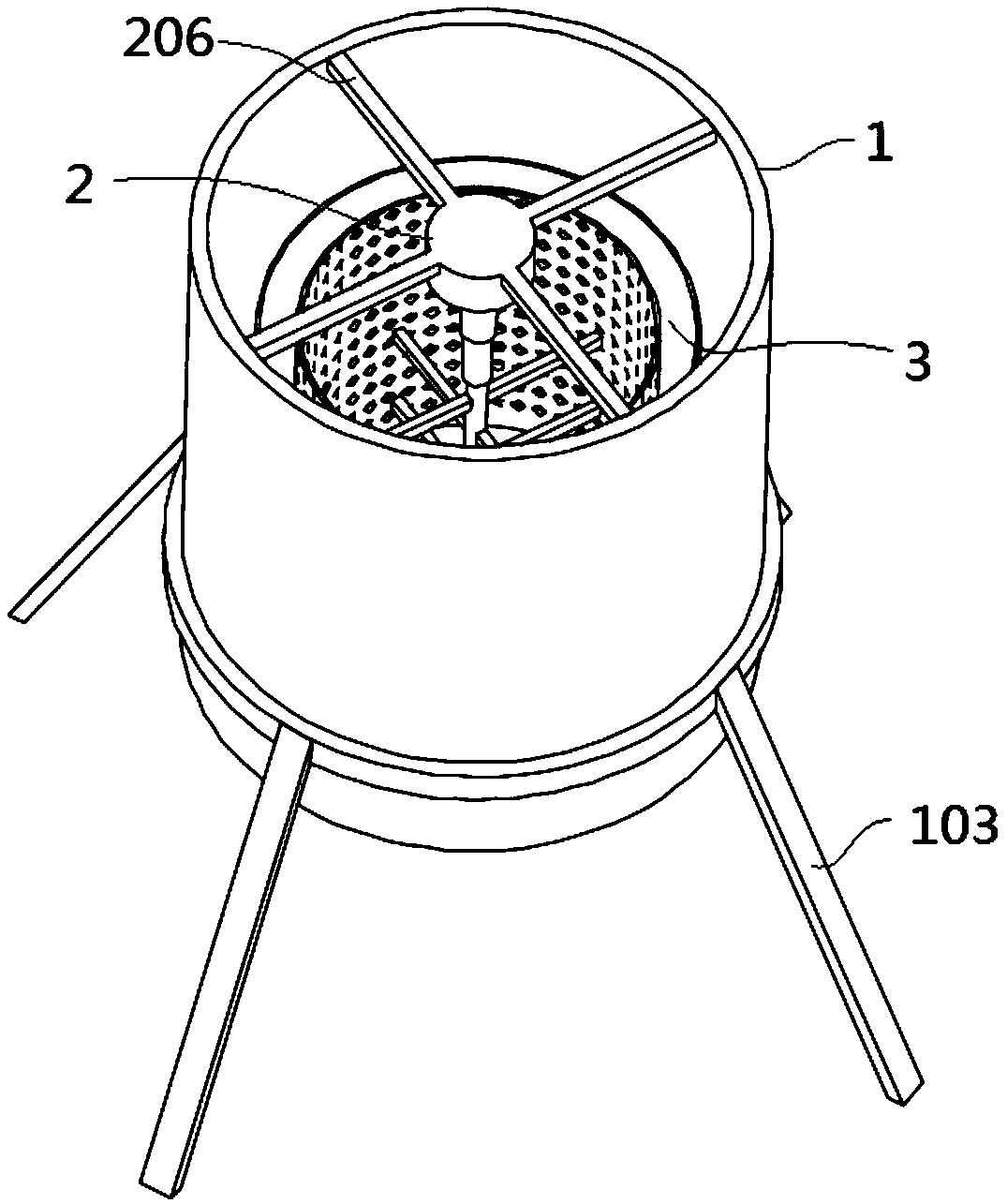

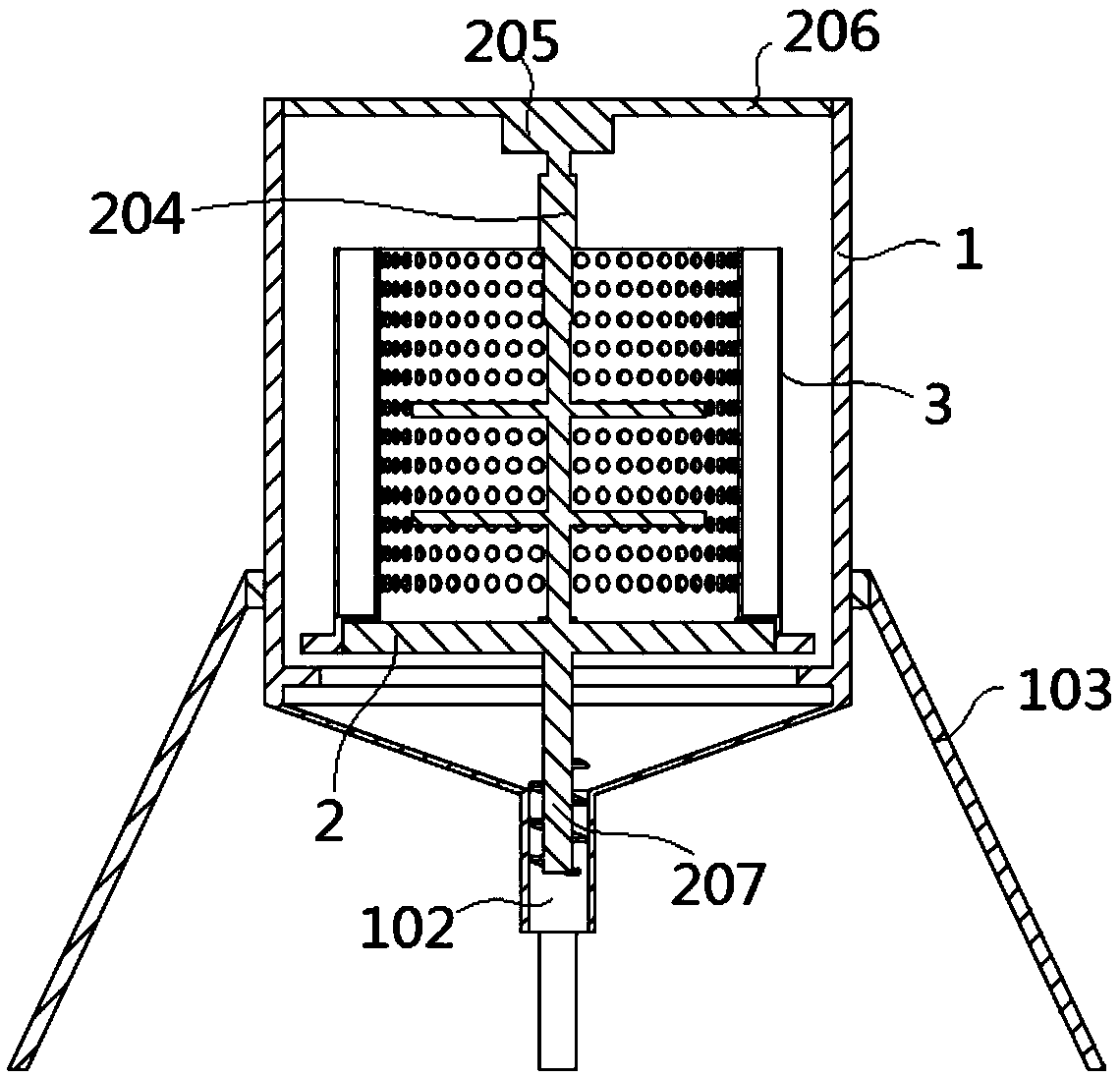

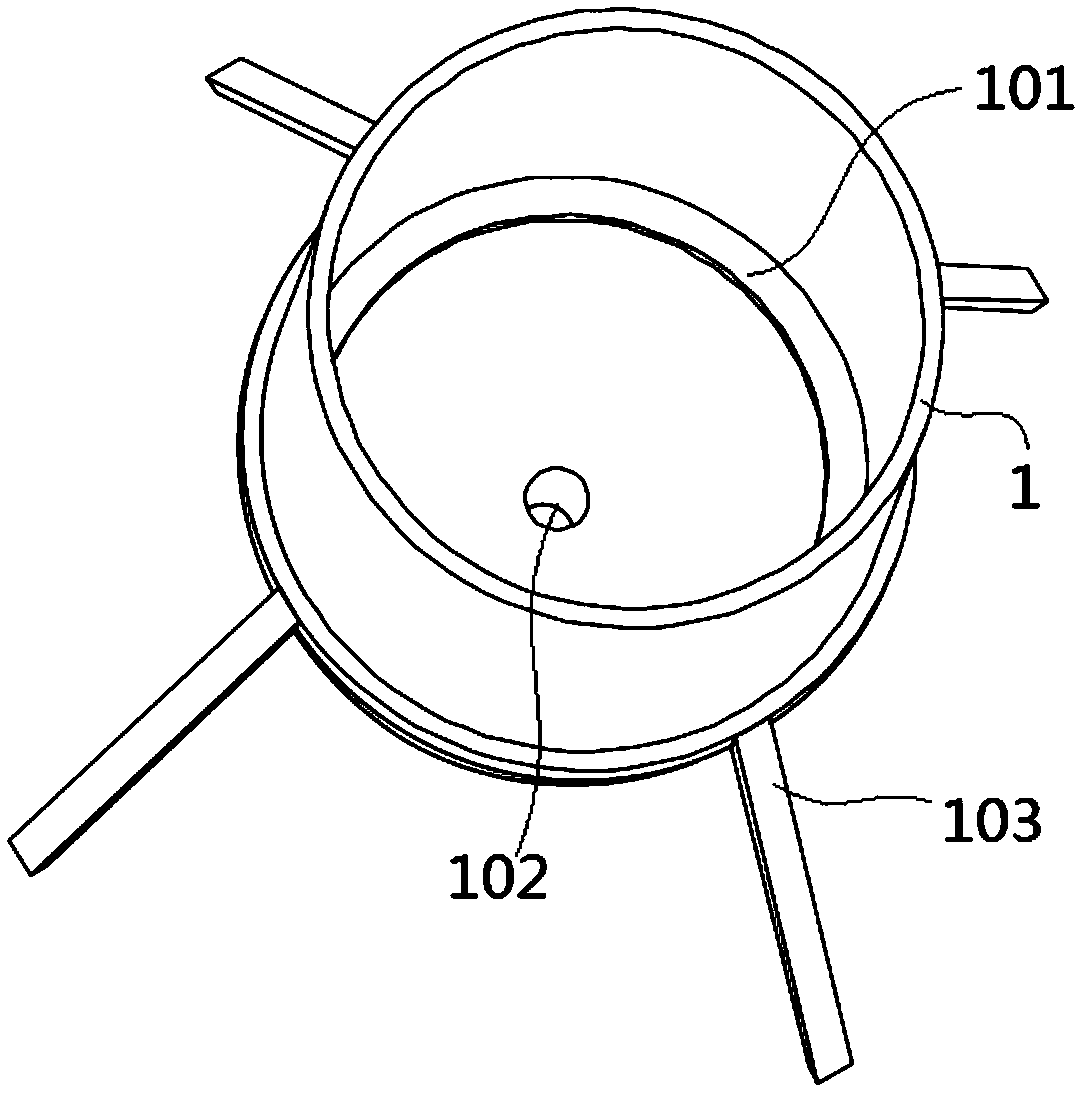

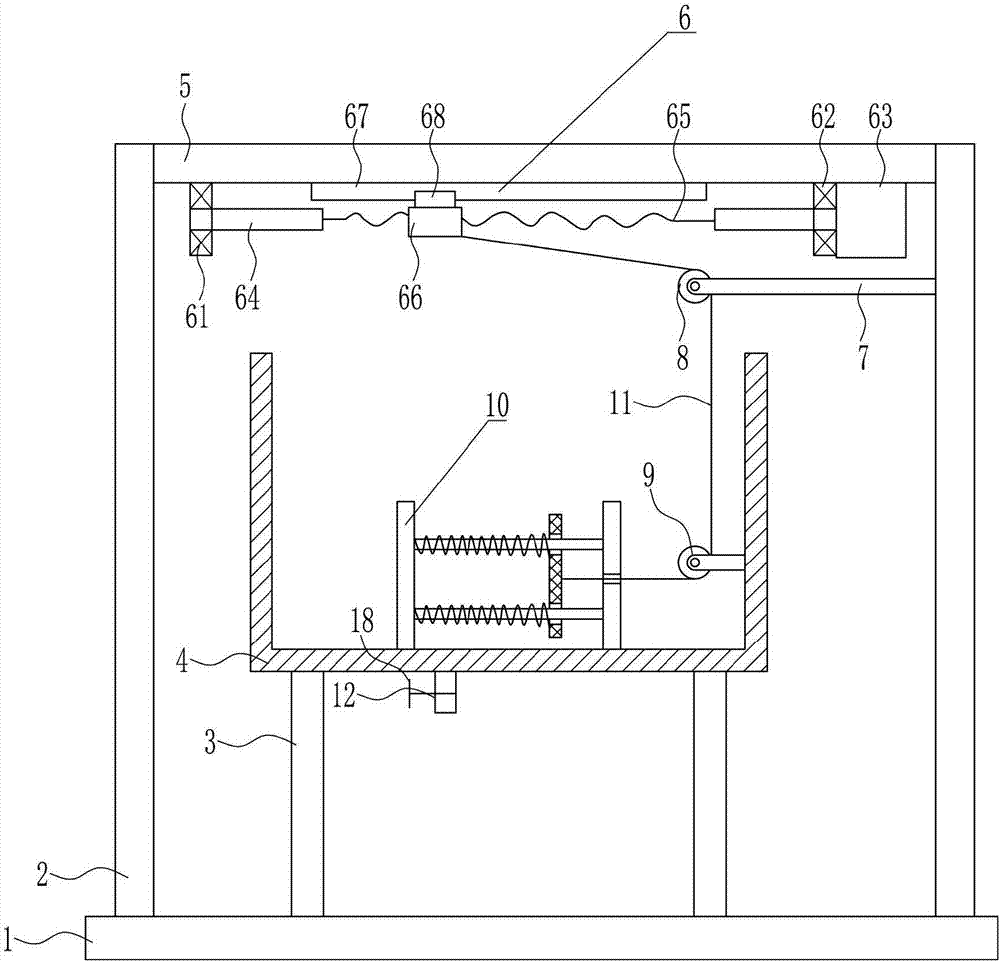

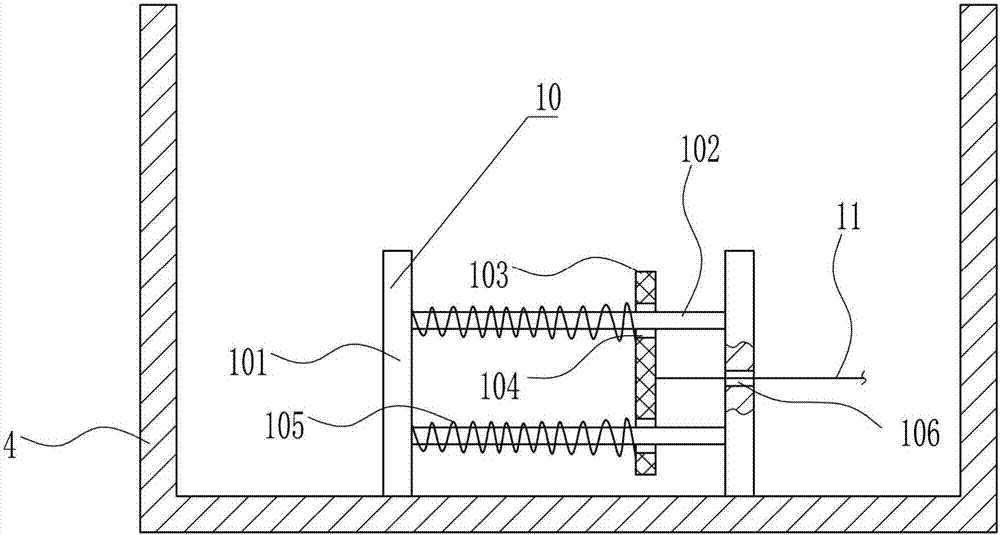

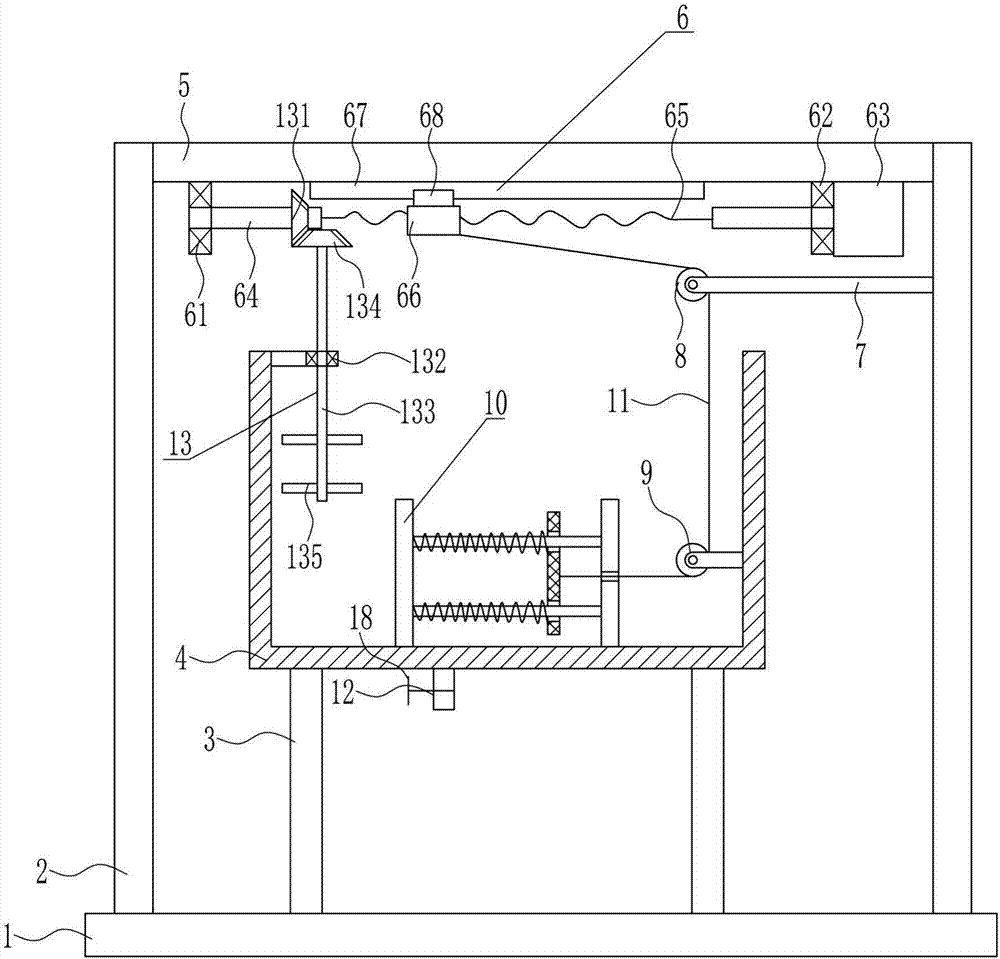

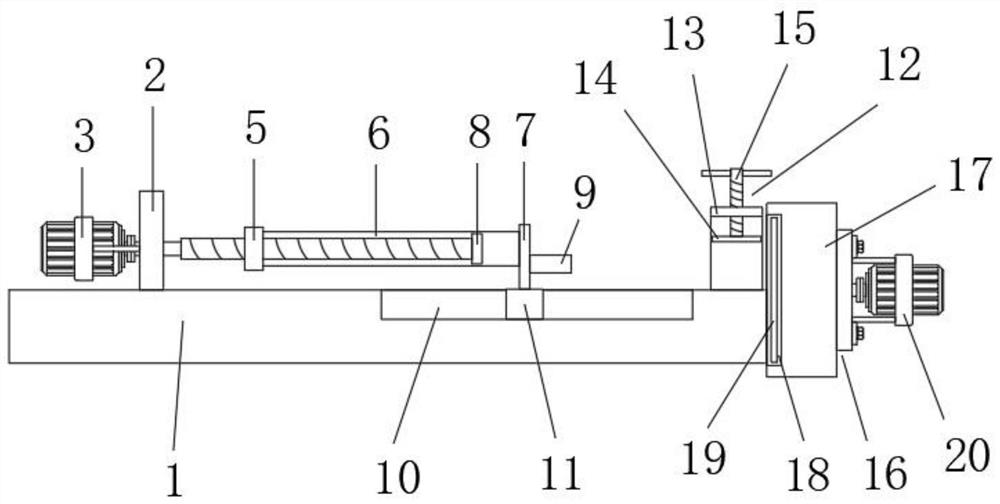

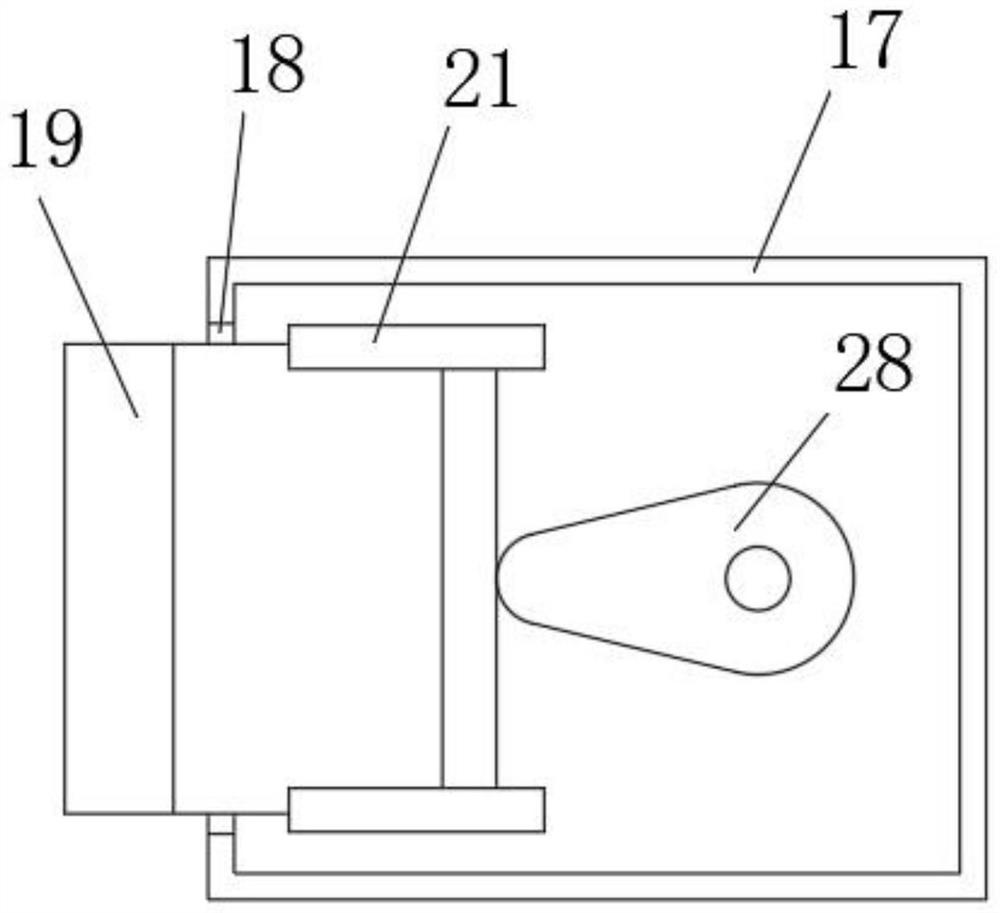

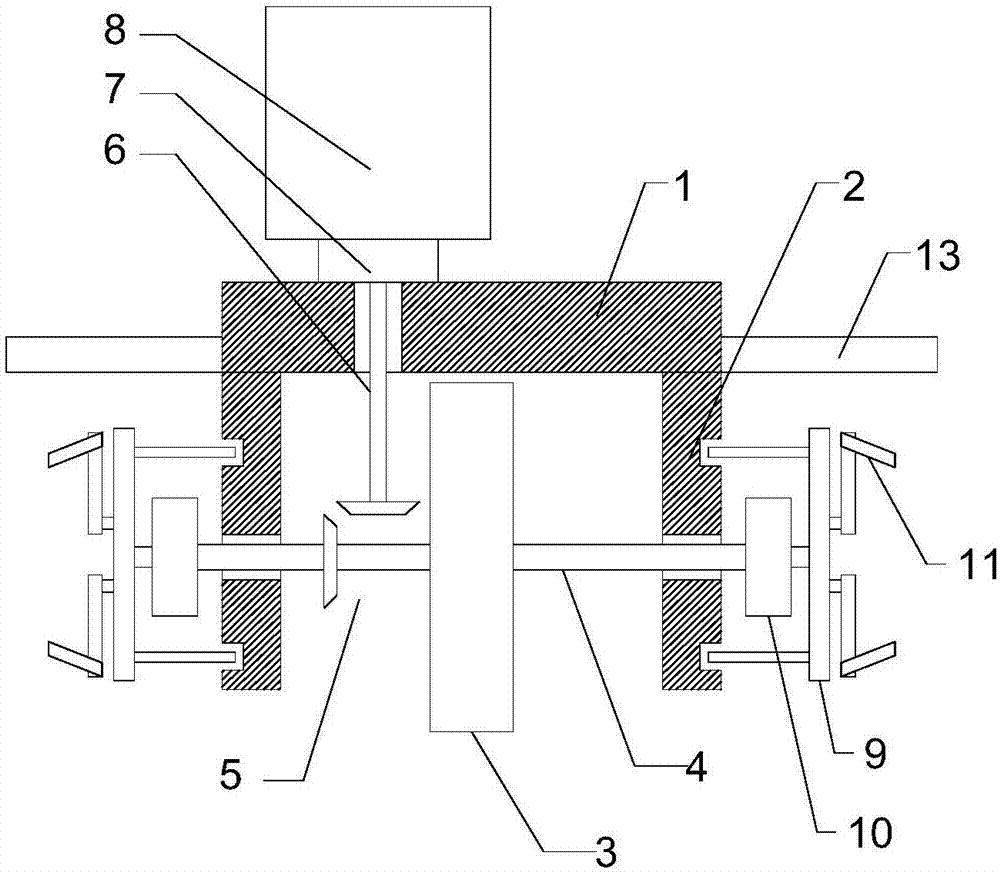

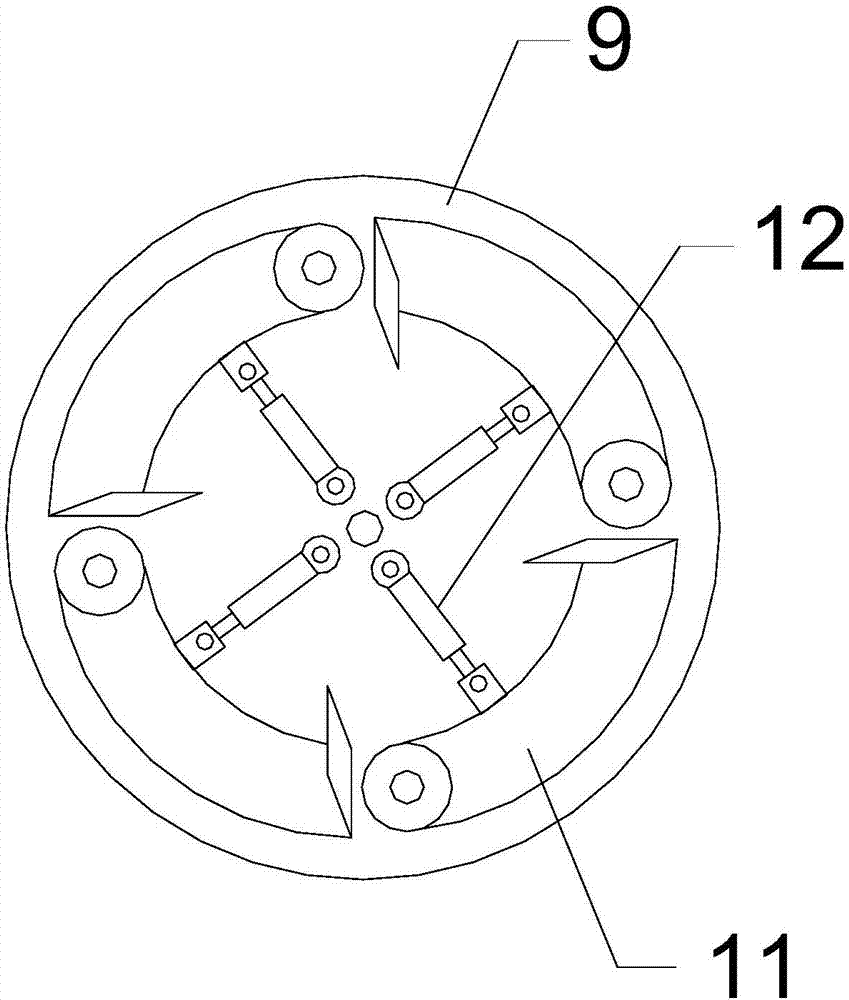

Mixing equipment special for test pieces of rock and soil tests

InactiveCN107351243AImprove the mixing effectControl the output speedDischarging apparatusCement mixing apparatusMixing effectBolt connection

The invention belongs to the technical field of rock and soil tests, and in particular relates to a special mixing equipment for rock and soil tests. The technical problem to be solved by the present invention is to provide a special mixing equipment for rock and soil test specimens with good mixing effect, saving manpower and time, fast mixing speed and high working efficiency. In order to solve the above-mentioned technical problems, the present invention provides such a special mixing equipment for rock and soil test specimens, including a bottom plate, a bracket, legs, a mixing box, a top plate, a left and right moving device, a cross bar, a first pulley, a second Pulleys, mixing devices, pull wires, etc.; the top of the bottom plate is vertically installed with brackets by means of bolt connection, outriggers are installed on the top of the bottom plate between the two brackets, a mixing box is installed on the top of the legs, and the top between the two brackets is passed The way of bolting is installed horizontally with a top plate. The invention achieves the effects of good mixing effect, saving manpower and time, fast mixing speed and high working efficiency.

Owner:向远虎

Fertilizer storage box capable of improving fertilization quality and efficiency

InactiveCN107694679AFertilize evenlyAvoid fertilization effectsFertiliser distributersGrain treatmentsEngineeringGood control

The invention discloses a fertilizer storage box capable of improving fertilization quality and efficiency. The fertilizer storage box capable of improving fertilization quality and efficiency comprises a materiel storage box body. A plurality of materiel feeding ports are arranged at the top of the materiel storage box body. A screen cloth is arranged below the materiel feeding ports. A pluralityof material discharging pipes are connected with the bottom of the materiel storage box body. A material dividing box is arranged under the material discharging pipes. A plurality of cylinder-shapedmaterial dividing cavities are arranged in the material dividing box. Material dividing rotary drums are arranged in the material dividing cavities and a plurality of material dividing grooves are arranged on the side walls of the material dividing rotary drums. Inlets are arranged on the walls of the tops of the material dividing cavities and the bottoms of the material discharging pipes communicate with the inlets. Outlets are arranged on the walls of the bottoms of the material dividing cavities. According to the fertilizer storage box, particle fertilizer can be contained and reserved during the course of fertilization and the discharging of the fertilizer can be uniform and quantitative when the fertilizer needs to be applied, so that good control of the fertilization capacity of soilat a distance can be guaranteed during the advance of a tumbril, at the same time the soil at the distance can be fertilized uniformly, the material discharging speed and quality can be controlled and the fertilization effect can be improved.

Owner:CHENGDU HONGDE YONGXING BREEDING CO LTD

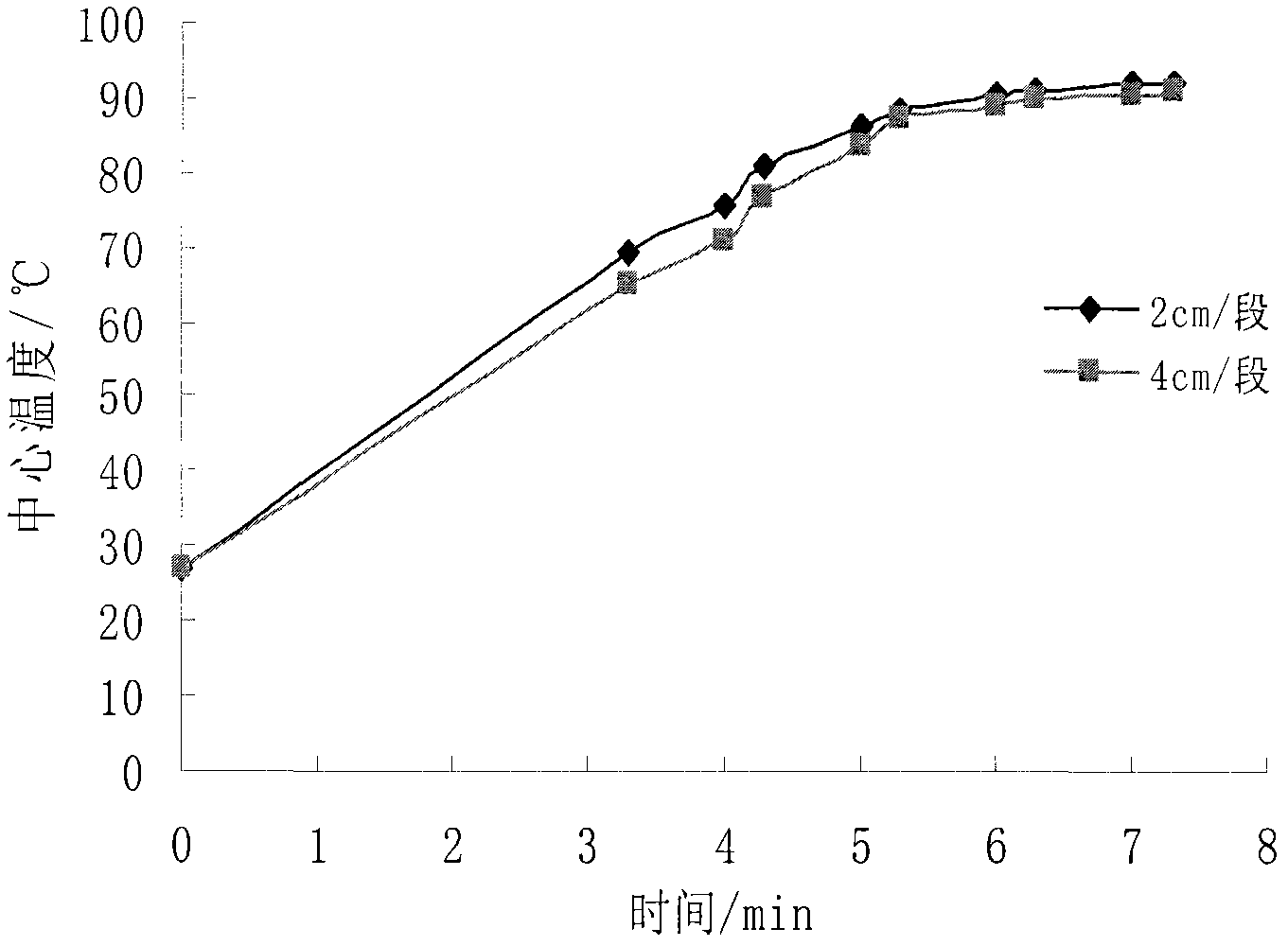

Method for processing fruit and vegetable beverage by efficiently carrying out enzyme-killing color protection

InactiveCN102578651AImprove crushing effectReasonable designFood scienceProcess equipmentCrop protection

The invention discloses a method for processing a fruit and vegetable beverage by efficiently carrying out enzyme-killing color protection. The method is characterized in that in the process of processing the fruit and vegetable beverage, when the pressure of steam in a steam tube of a fruit-vegetable enzyme killing and crushing plant reaches 0.15 to 0.18 MPa and the temperature of the steam reaches over 110 DEG C by regulation, cleaned fruit and vegetable raw materials are directly put into the inner cavity of the plant through a material feeding opening and a crushing tool is simultaneouslystarted; when the material temperature at a discharge port reaches over 85 DEG C, the discharge port is opened; and the materials discharged from the discharge port are blended, clarified, sterilizedand aseptically filled to obtain the fruit and vegetable beverage finished product. The method disclosed by the invention has a reasonable process equipment design; process parameters are properly selected; the method is very suitable for crushing and enzyme killing of fruits easy to brown and has excellent enzyme-killing color protection and fruit and vegetable crushing effects; the problem of great loss of the content of soluble solids in fruits, which is caused by blanching enzyme killing is solved; and the method has the advantages of short heat treatment time and low equipment investment. The method disclosed by the invention is very suitable to popularize and apply in the actual production.

Owner:JIANNING FUXIN LIANYE FOOD CO LTD

Tea uniform blending machine

PendingCN105166098ACompact structureReduce manufacturing costPre-extraction tea treatmentAutomatic controlEngineering

The invention discloses a tea uniform blending machine. The tea uniform blending machine comprises a uniform blending opening, a coveyer belt, a control box and a uniform blending box. A tea speader assembly, an upper end control cabin, a lower end control cabin and a discharging pipe are arranged in the control box from top to bottom in order. A separation plate is arranged between the upper end control cabin and the lower end control cabin. A plurality of shutter doors are distributed on the separation plate in order. Tea is subjected to secondary uniform blending in the control box, then goes into the uniform blending box and is subjected to third uniform blending. The structure is simple and compact, and the production cost is low. Uniform blending for three times are carried out by utilization of the uniform blending opening, the control box and the uniform blending box, and tea is mixed uniformly. Automatic control of all the parts is carried out through a controller, labor is saved greatly, the production efficiency is raised, the health degree is raised, and stability of product quality is ensured. There are two control cabins, when the second control cabin at the bottom is full of materials, the shutters are closed, then the first control cabin is used for material storage, production continuity is ensured, reasonable distribution of work personnel is achieved and labor cost is lowered.

Owner:YUNNAN DIANHONG GRP

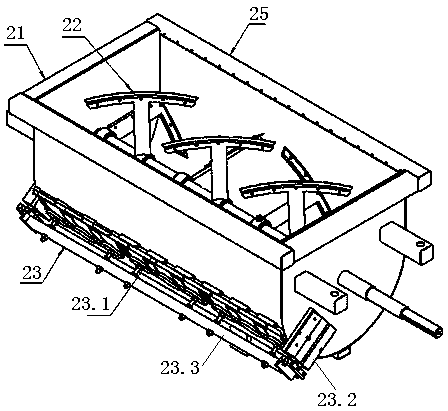

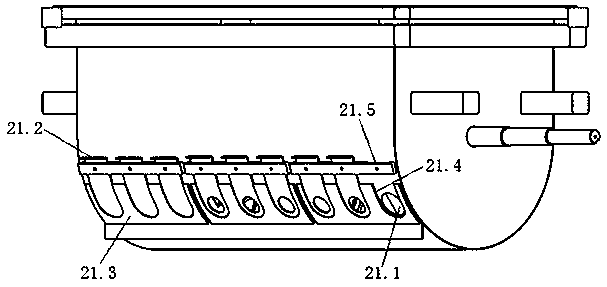

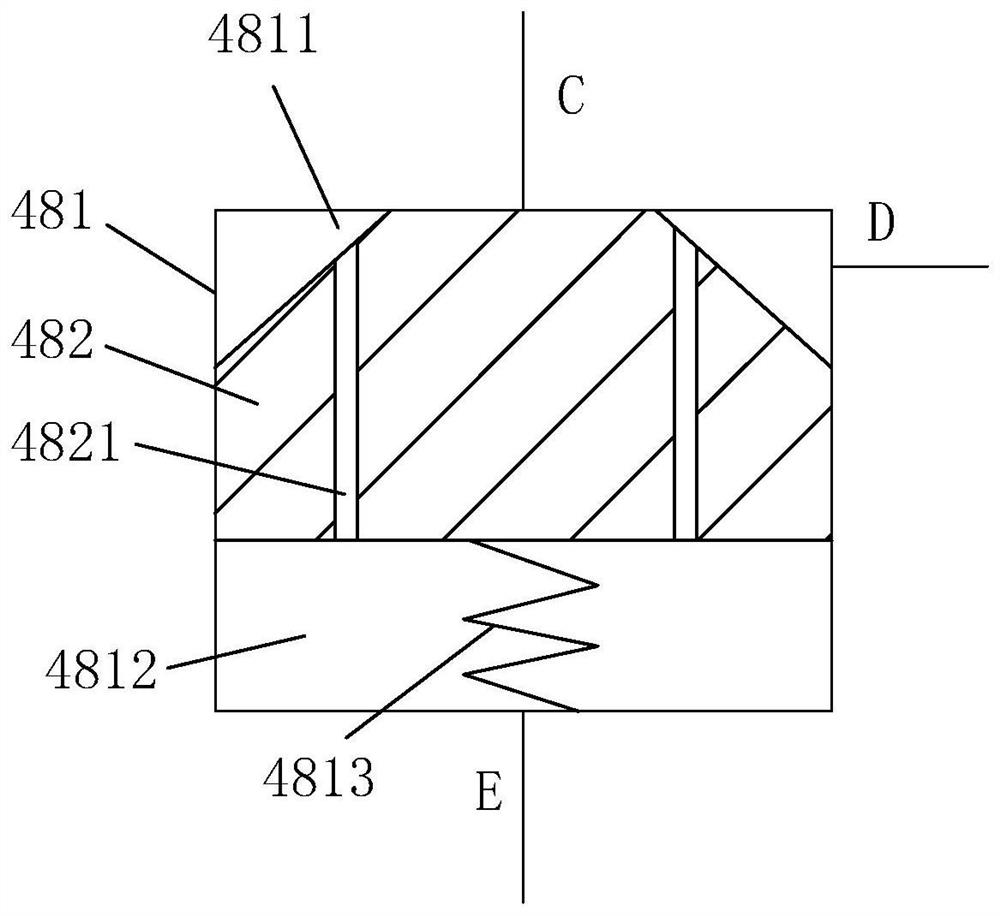

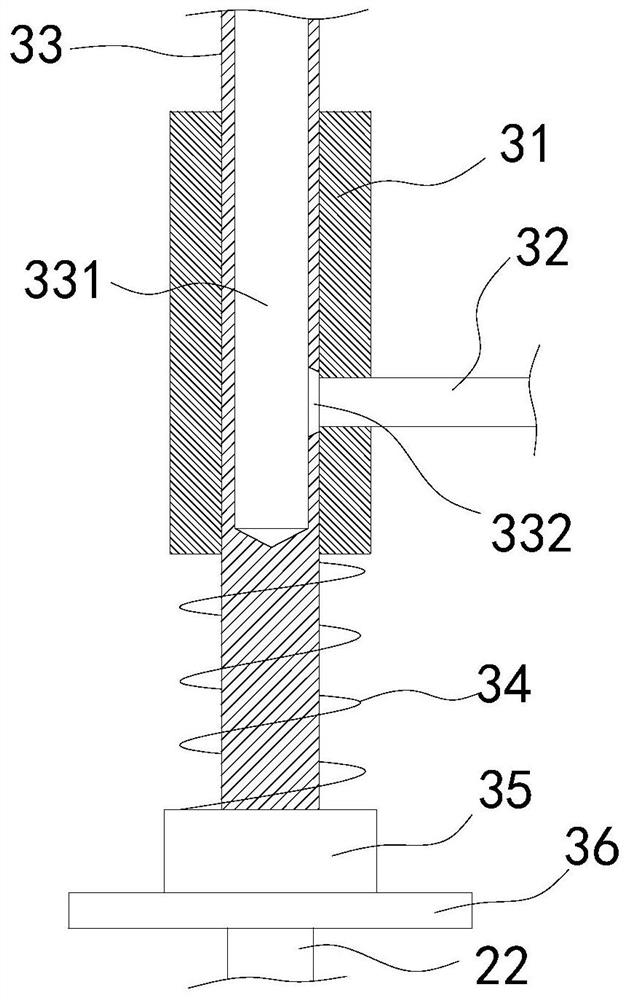

Rapid high-precision distribution device with breaking device

PendingCN108557289AControl precisionControl the output speedLarge containersConveyor partsSolid particleEngineering

The invention discloses a rapid high-precision distribution device. The rapid high-precision distribution device comprises a belt-type conveying device, a material cabin, a material blocking device, aweighing hopper, and a control system. The material cabin is cooperatively installed above a conveying belt, and the bottom thereof is slightly higher than the conveying belt. The material cabin is used for storing a material, and comprises a material cabin body and a cabin door. The material blocking device is cooperatively and fixedly installed with the conveying belt, positioned above the conveying belt, and perpendicular to the conveying belt. The material cabin is positioned behind a moving direction of the conveying belt. The weighing hopper is cooperatively installed below the tail endof the conveying belt. The control system is used for receiving data of the weighing hopper, calculating, and controlling the work of the belt-type conveying device, the cabin door and the material blocking device. The device is capable of realizing rapid-speed feeding, intermediate-speed feeding, slow-speed feeding, and accurate feeding; high in feeding precision, rapid in speed, and suitable for solid particles, powder, and an adhesion mixture; and small in repetitive control precision deviation without a loose material.

Owner:郑州鼎源自动化科技有限公司

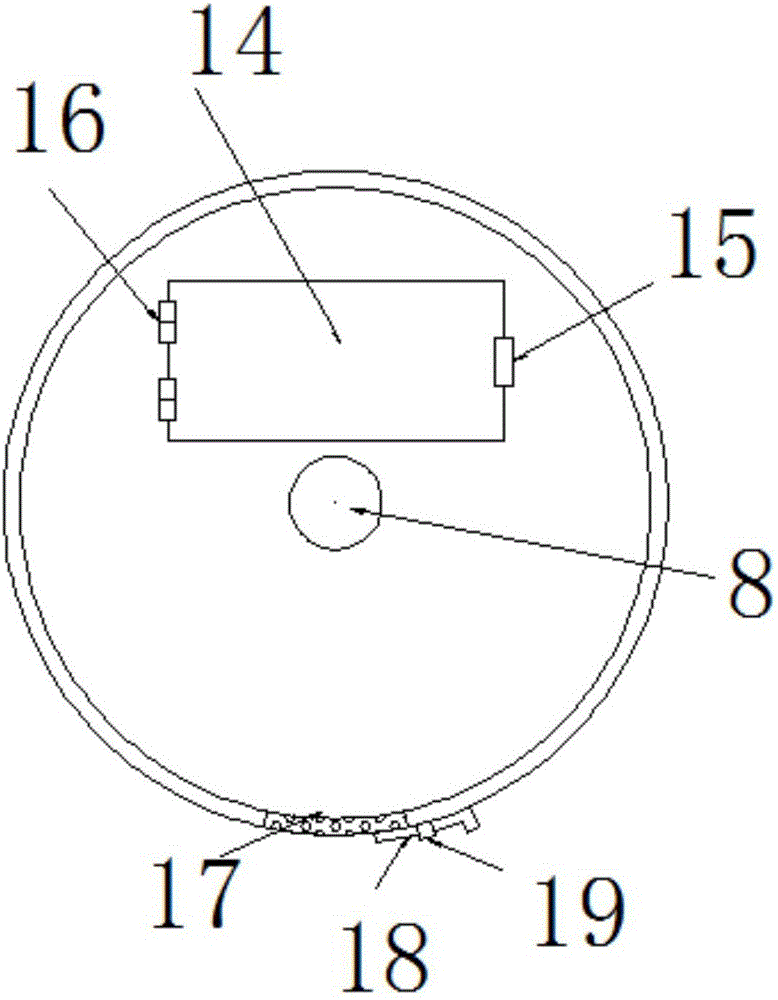

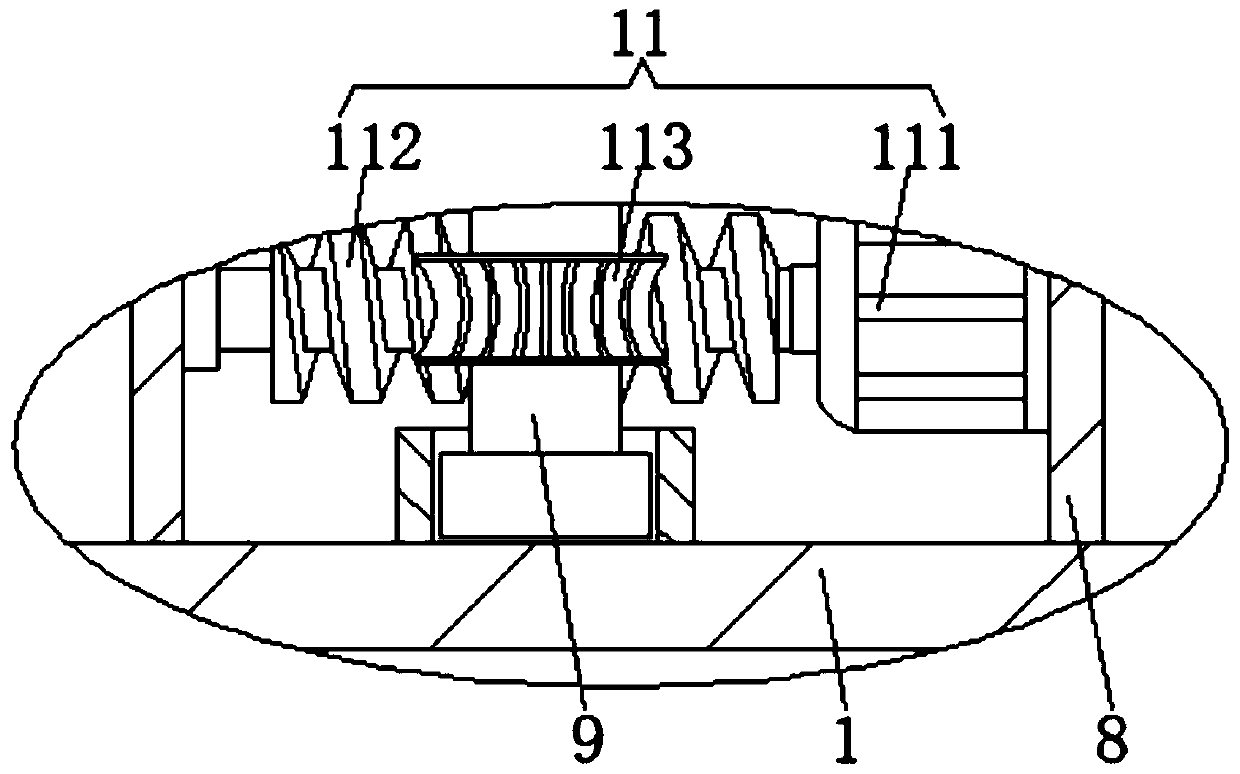

Oxygen-supplying and feeding device for fish tank

InactiveCN106376508AEasy to eatSimple structureClimate change adaptationPisciculture and aquariaReduction driveDrive shaft

The invention discloses an oxygen-supplying and feeding device for a fish tank. The oxygen-supplying and feeding device comprises a counterweight base, a support plate and a storage tray, wherein a box body is arranged on the upper-left side of the counterweight base; a plurality of accommodation drawers are arranged on the box body; the support plate is vertically arranged on the upper-right end of the counterweight base; a driving shaft is arranged on the support plate in an insertion way; the left end of the driving shaft passes through the support plate, and is connected with a speed reducer on the left side of the support plate; the input end of the speed reducer is connected with a servo motor; the storage tray is arranged at the right end of the driving shaft; the storage tray is a cylindrical tray body which is hollow inside; the storage tray is made of a transparent material; a charging door is fixed to the front side of the storage tray through hinges; a lock catch is arranged at a movable end of the charging door; an arc-shaped surface of the storage tray is provided with a plurality of discharging holes; a discharging tray on the right side of the discharging holes is provided with a sliding fixing block; an adjustment baffle plate is arranged on the sliding fixing block in a sliding way; a driven shaft is rotationally arranged on the support plate below the storage tray. The oxygen-supplying and feeding device has a simple and reasonable structure, automatic feeding of the device is realized, and convenience is brought to feeding of fishes.

Owner:ZHENGZHOU TIANSHUN ELECTRONICS TECH CO LTD

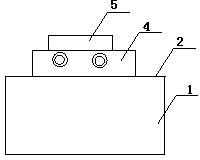

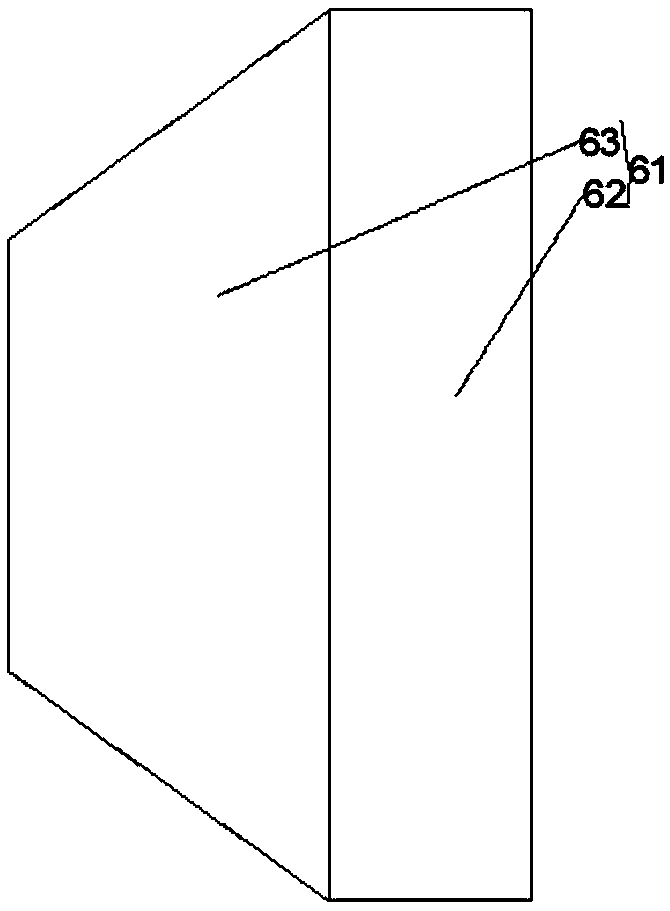

A feed bin for an x-ray machine

InactiveCN102284342AAvoid the speed of output is too fastEnsure hygiene and safetyGrain treatmentsAgricultural engineeringFood hygiene

The invention discloses a feeding bin for an X-ray machine. The feeding bin has a feeding port and a feeding port. The outside of the feeding bin is a square, and a fixed block is arranged on the On the top of the outer surface where the outlet is located, a baffle is fixed directly above the discharge port, and two waist-shaped holes are opened on the left and right sides of the baffle, and each waist-shaped hole passes through each of the bolts Fix the baffle on the fixing block. Beneficial effects of the present invention: the discharge speed can be better controlled to avoid excessive discharge speed, and the X-ray machine can be better sensed, so that the dehydrated vegetables can be screened better, ensuring the hygiene of food Safety.

Owner:XINGHUA DINGNENG FOODS

Portable stirring device for food production and processing

InactiveCN109012469AFast feeding speedReduce labor intensityRotary stirring mixersTransportation and packagingRaw materialBiochemical engineering

The invention discloses a portable stirring device for food production and processing. The portable stirring device comprises a bottom plate, four corners of the bottom of the bottom plate are fixedlyconnected to support columns, the top of the bottom plate is fixedly connected to a stirring box, the bottom in the right side of the stirring box is communicated with a discharge pipe, the top of the stirring box is fixedly connected to a storage box 1, the top of the inner wall of the storage box 1 is fixedly connected to a motor 1 and an output end of the motor 1 is fixedly connected to a rotation rod. Food raw materials are poured into a feeding hopper, a motor 2 drives a transmission rod to rotate, and the transmission rod drives the food raw materials to move upward through a spiral piece so that the raw materials slide down into the stirring box. The portable stirring device is convenient in feeding into the stirring device, solves the problem that the height of a feeding inlet ofthe stirring device is high and the feeding difficulty of the stirring device is high, has strong practicability and is easy to use.

Owner:湖州吾爱食品有限公司

Slicing device for traditional Chinese medicine processing

InactiveCN111890430AControl thicknessAvoid cutting efficiency reductionMetal working apparatusMedicinal herbsReciprocating motion

The invention discloses a slicing device for traditional Chinese medicine processing. The slicing device comprises a processing table, two first sliding grooves are oppositely formed in the two sidesof one end of the top of the processing table, sliding blocks are slidably connected into the first sliding grooves, a second push plate is fixedly connected to the tops of the two sliding blocks, a limiting mechanism is arranged on the side, close to the first sliding grooves, of the top of the processing table, a cutting mechanism is arranged on the side wall of the end, close to the limiting mechanism, of the processing table, the cutting mechanism comprises a protective cover, a cutter outlet is formed in the side, opposite to the limiting mechanism, of the protective cover, a cutting blade is slidably connected into the cutter outlet, in the interior of the cutting mechanism, a cam is driven to rotate by means of a second motor, and the cutting blade reciprocates towards the cutter outlet side by means of a protrusion of the cam. According to the slicing device, the cutter outlet speed of the cutting blade can be adjusted by adjusting the rotating speed of the cam, manual work isreplaced by a mechanical transmission mode, the situation that the cutting efficiency is reduced due to fatigue in the later period of cutting is avoided, and the thickness of medicinal material slices can be controlled by controlling the rotating speeds of the two motors.

Owner:WUHAN YIWEIDENG TECH DEV

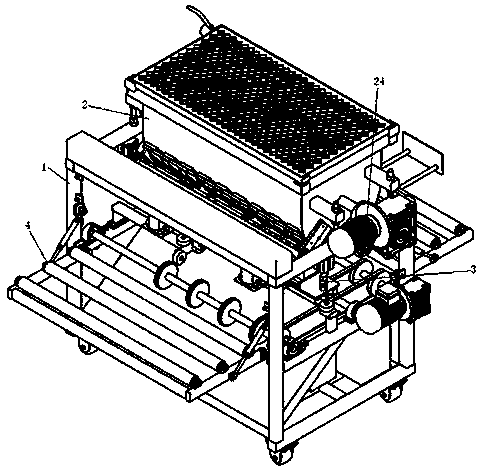

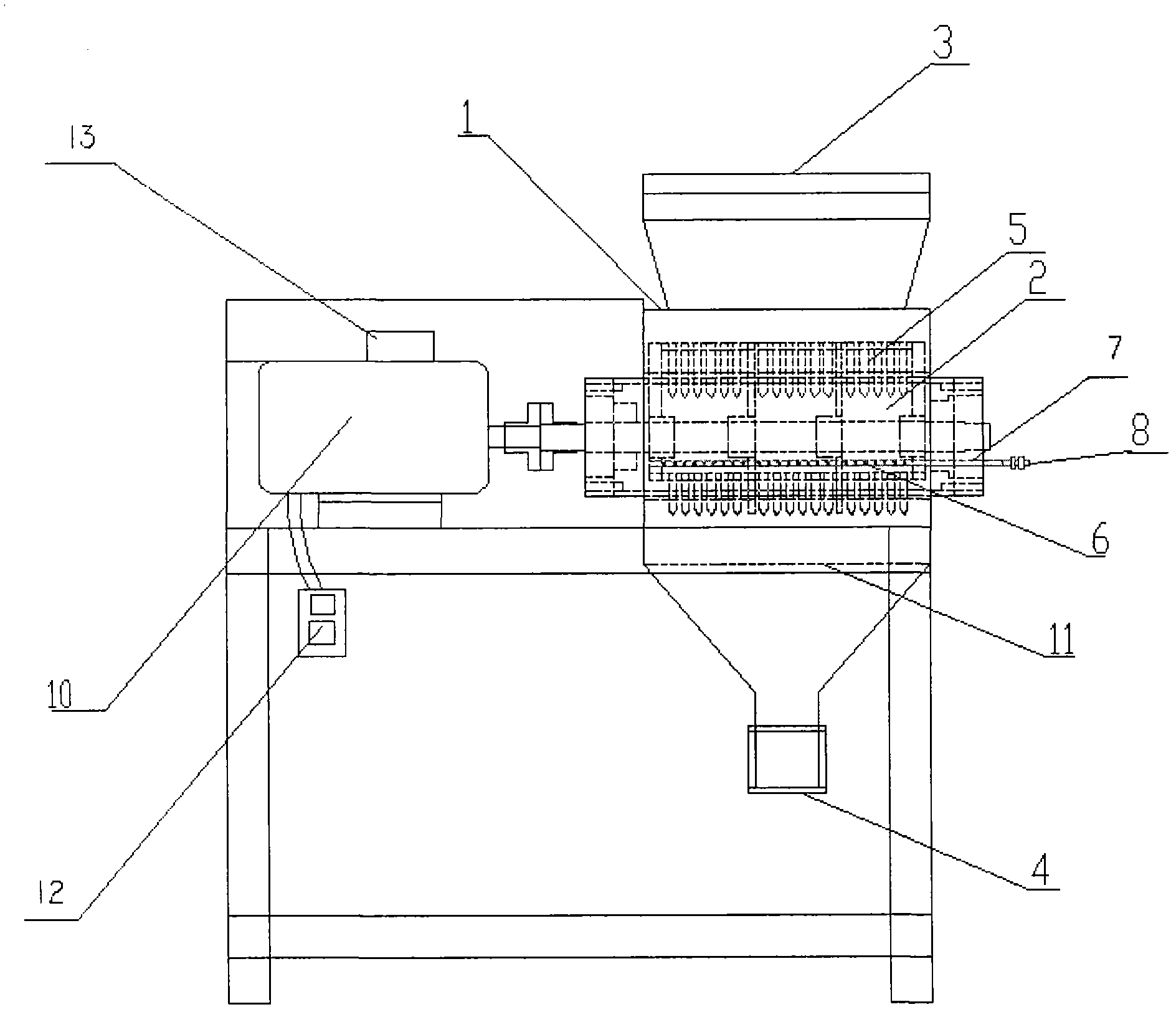

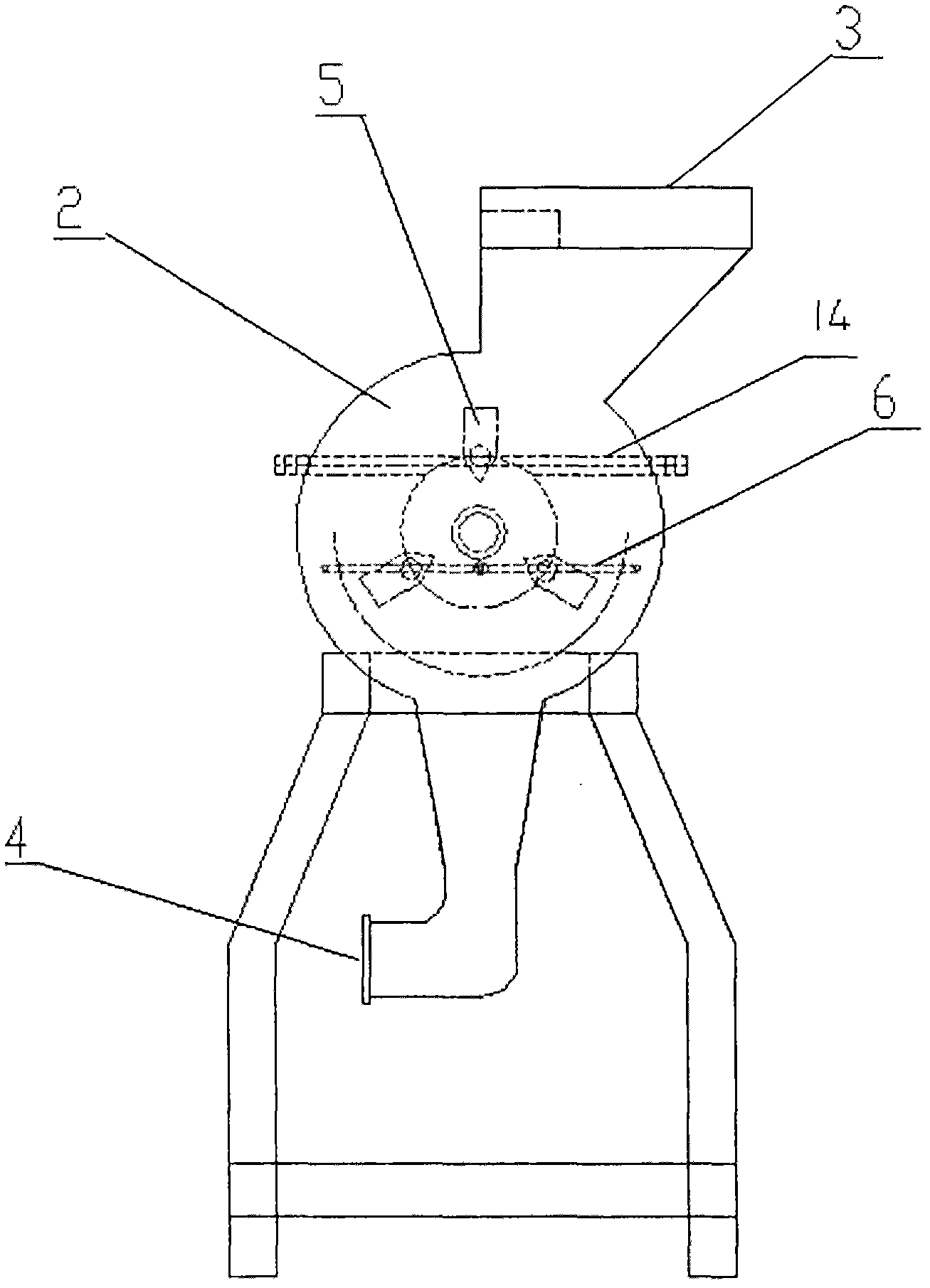

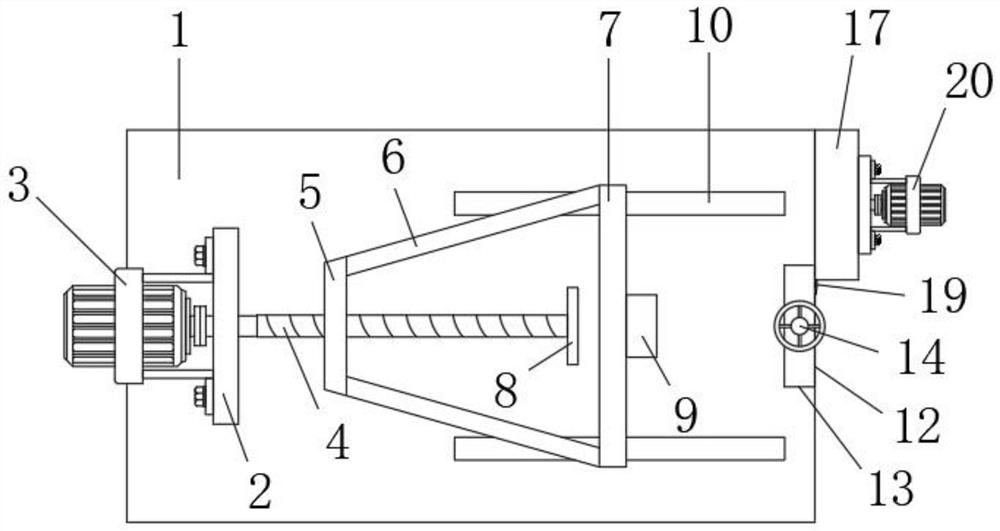

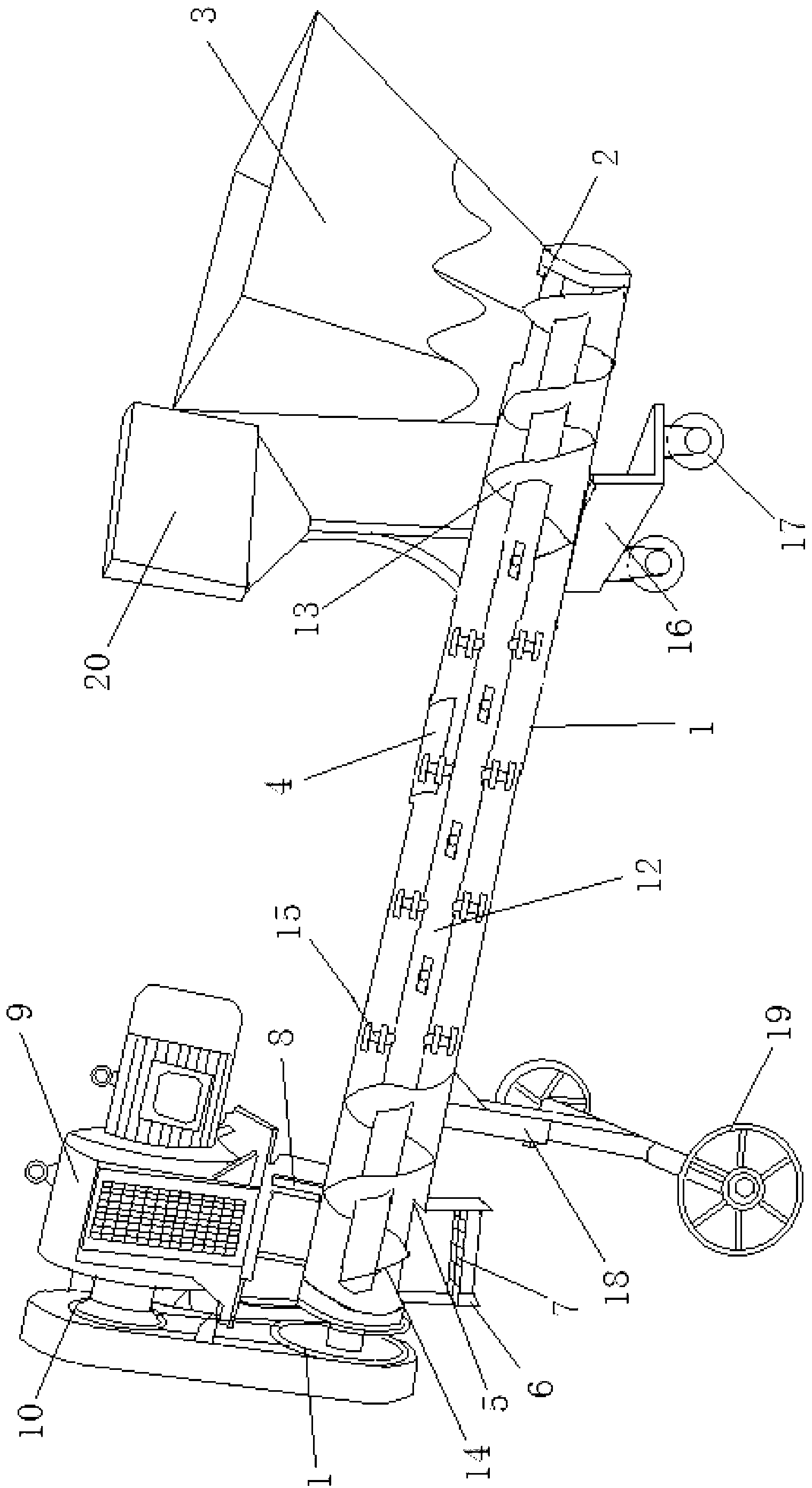

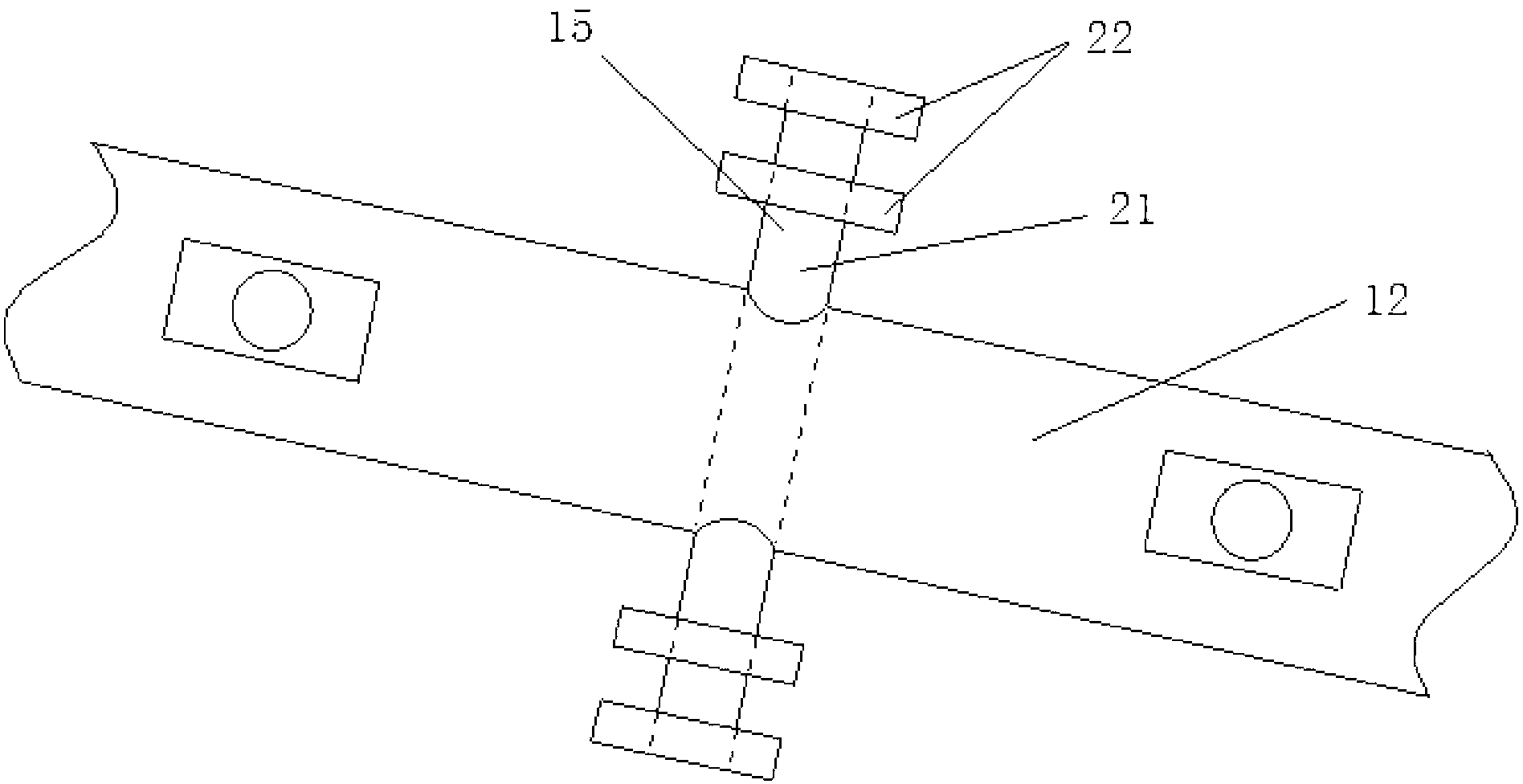

Urea formaldehyde foam plant cultivation medium grinder

ActiveCN103240145AGood securityIncrease productivityDirt cleaningGrain treatmentsPulverizerFrequency conversion

The invention relates to a urea formaldehyde foam plant cultivation medium grinder which is characterized by comprising an oblique grinding cylinder, wherein the front end of the oblique grinding cylinder is low, and is provided with a material inlet which is open upward; a material charge hopper is welded at the material inlet; the middle part of the grinding cylinder is provided with a transparent observation window; the tail end of the grinding cylinder is high, and is provided with a material outlet which is open downward; a material discharge sleeve is welded at the material outlet; the material discharge sleeve is internally provided with a drawable screen; a frequency conversion motor speed regulator is connected above the tail end of the grinding cylinder through a platform, and the output end of the frequency conversion motor speed regulator is connected with a small belt wheel; the small belt wheel is connected with a large belt wheel through a belt; the large belt wheel is connected with a main shaft which penetrates through the grinding cylinder and is rotatably connected with the grinding cylinder; packing augers are respectively welded at two ends of the main shaft; a plurality of pairs of stirring teeth are arranged between the two packing augers at intervals; each pair of stirring teeth are radially and symmetrically arranged, and are crossed with adjacent stirring teeth by 90 degrees; the front end of the bottom of the grinding cylinder is provided with a fixing support connected with a pair of front vehicle wheels, and the rear end of the bottom of the grinding cylinder is provided with a height adjusting support connected with a pair of rear vehicle wheels; and the grinding cylinder is provided with a control panel. The urea formaldehyde foam plant cultivation medium grinder provided by the invention can be widely used for grinding urea formaldehyde foam media with different grain diameters.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

Rapid quantitative loading system for common use of ordinary train and container train

ActiveCN108946215APrevent splashControl the output speedControl devices for conveyorsLoading/unloadingAutomotive engineeringVehicle identification

The invention discloses a rapid quantitative loading system for a common use an ordinary train and a container train. The rapid quantitative loading system for the common use of the ordinary train andthe container train comprises a PLC centralized control center, a vehicle identification module and an accident carriage processing module, wherein the vehicle identification module is connected withthe PLC centralized control center; the vehicle identification module is used for reading a loading wagon number and a carriage serial number, the loading wagon number and the carriage serial numberreceived and read by the PLC centralized control center are compared with preset to-be-loaded wagon number and carriage serial number, if consistent, the PLC centralized control center controls the carriage corresponding to the carriage serial number to be loaded; the accident carriage processing module is used for reading an accident wagon number and an accident carriage serial number, and the PLC centralized control center receives and skips the accident carriage serial number. The rapid quantitative loading system for the common use of the ordinary train and the container train has the beneficial effects that the rapid quantitative loading of the ordinary train and the container train is realized in a combined mode, the loading efficiency is improved, a stockpiling area is polluted by asecondary transportation and loading of a loading machine or a simple belt conveyor is reduced, and the labor intensity of workers is reduced synchronously.

Owner:CCCC MECHANICAL & ELECTRICAL ENG

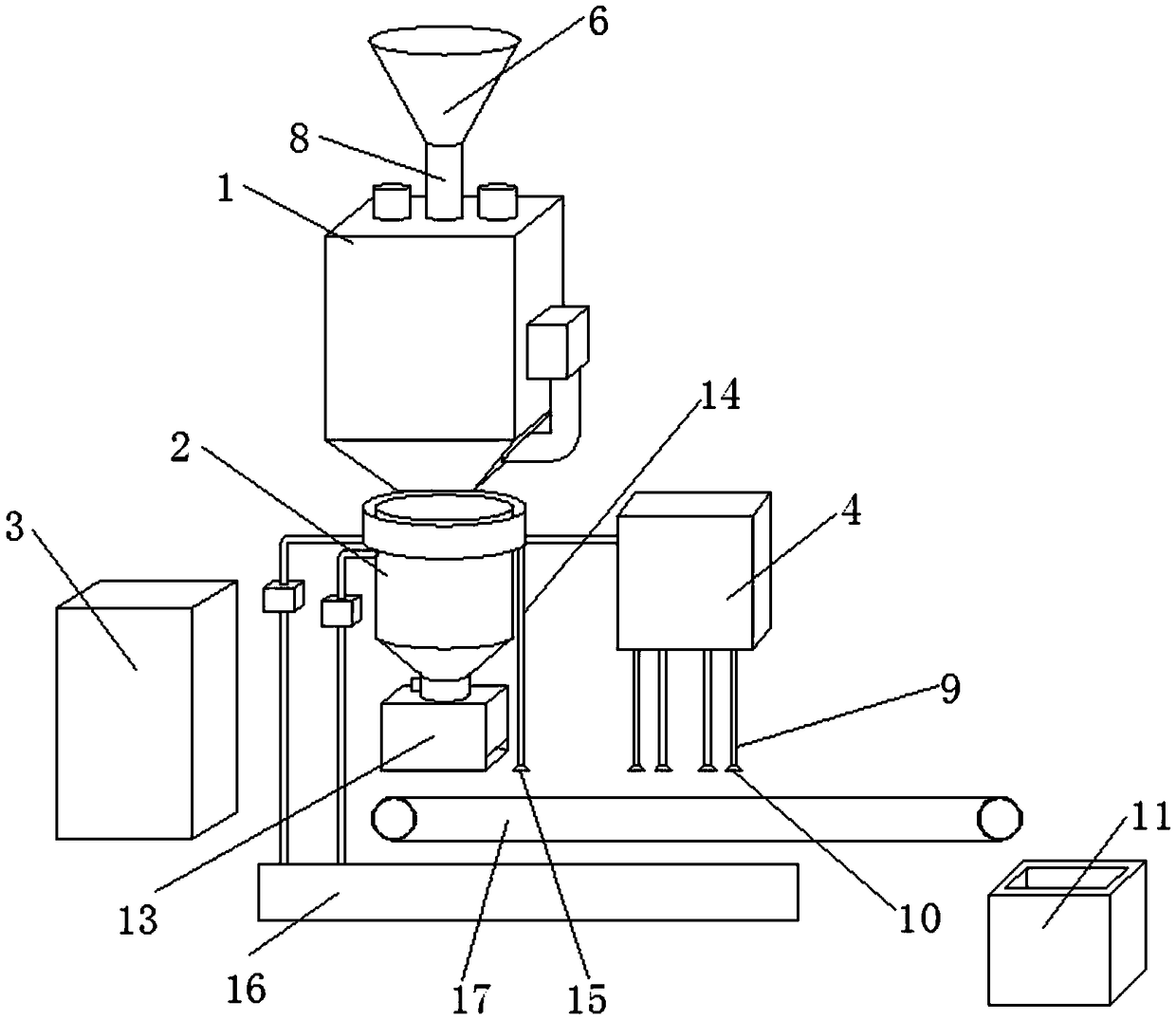

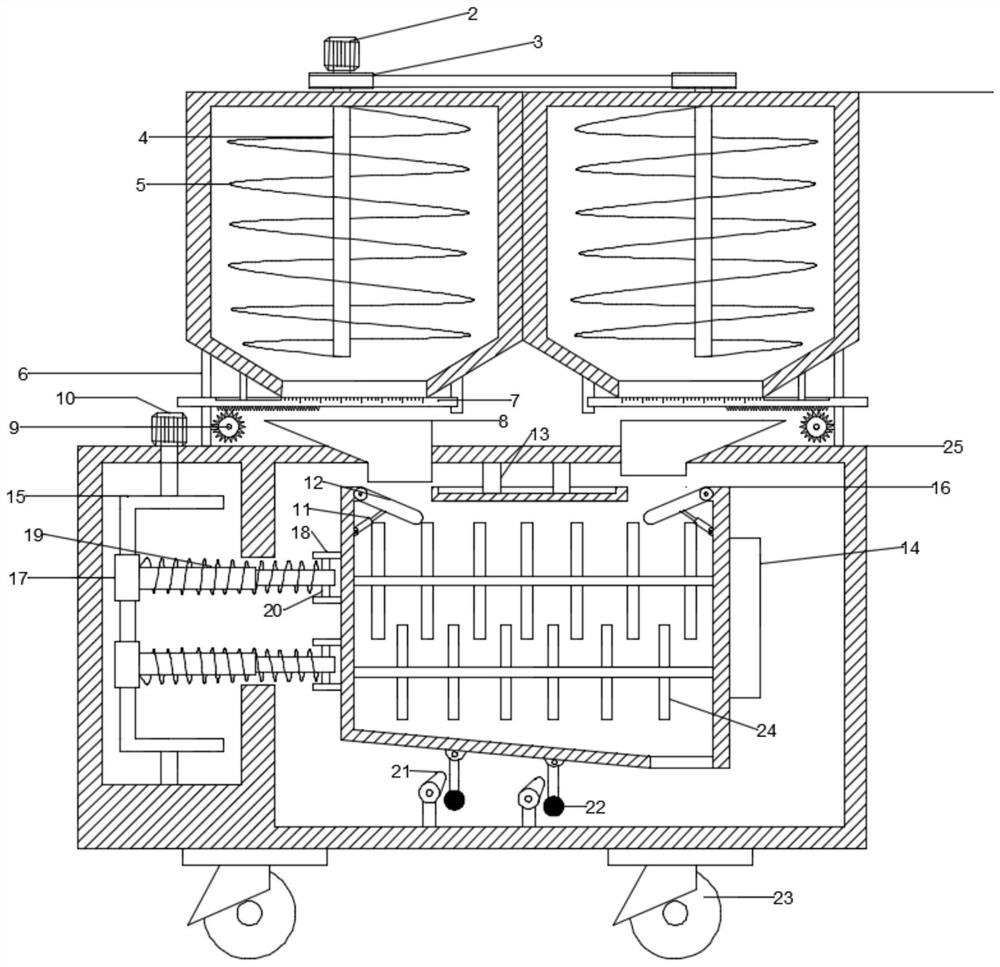

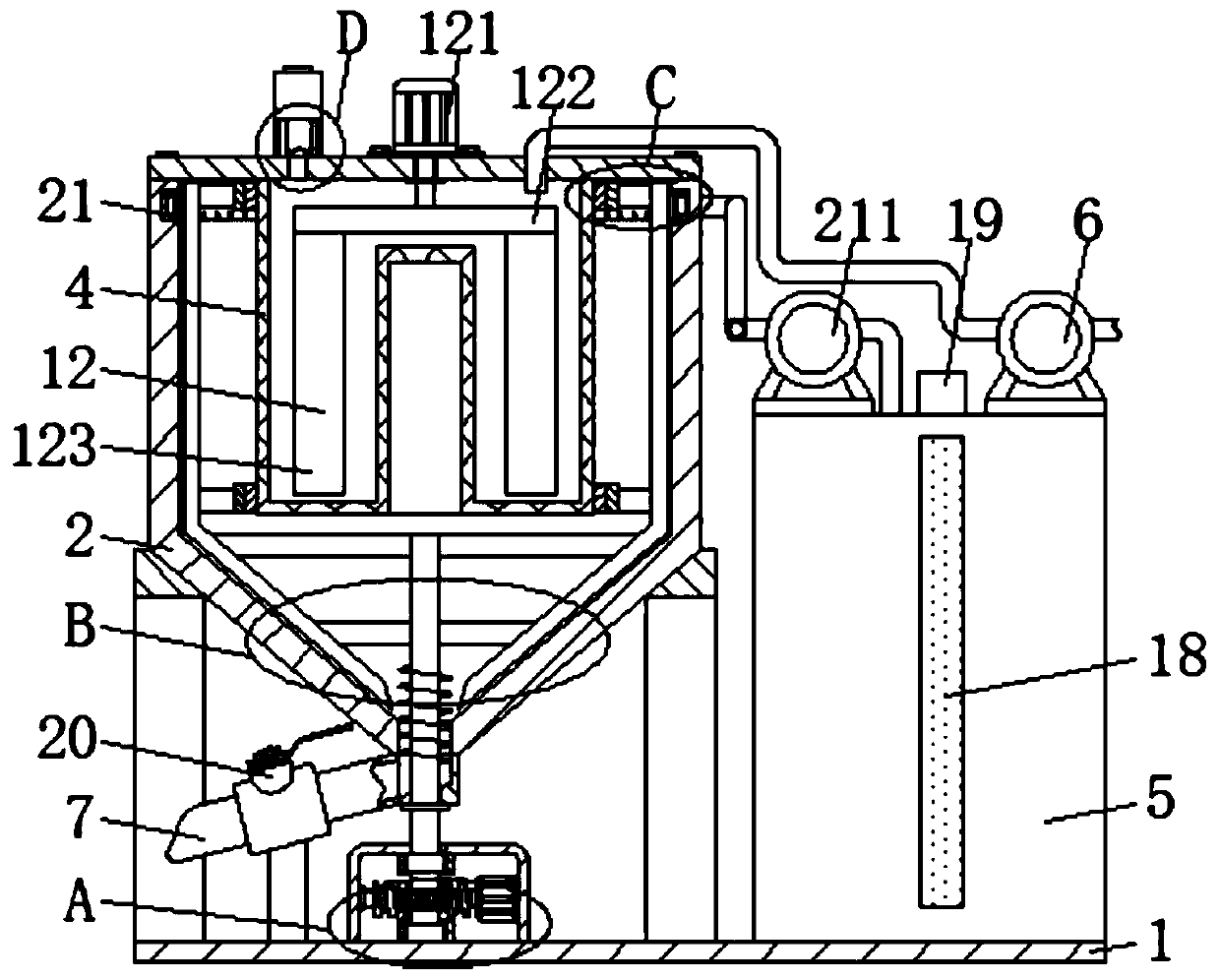

Efficient metal powder raw material mixing device of 3D printer

PendingCN113181822AWell mixedControl the output speedAdditive manufacturing apparatusTransportation and packagingElectric machineryEngineering

The invention discloses an efficient metal powder raw material mixing device of a 3D printer. The device comprises a first raw material box and a second raw material box, a first motor is installed at the top of the first raw material box, the output end of the first motor is fixedly connected with a first rotating shaft, a first belt pulley is installed on the first rotating shaft, the first belt pulley is connected with a second belt pulley through a belt, the second belt pulley is installed on a second rotating shaft, the first rotating shaft and the second rotating shaft extend into the first raw material box and the second raw material box respectively, and stirring blades are installed on the first rotating shaft and the second rotating shaft. The first rotating shaft is driven by the first motor to rotate, the first belt pulley drives the second rotating shaft to rotate through a belt, raw materials needing to be mixed are stirred in advance through the stirring blades on the first rotating shaft and the second rotating shaft, and some caked large-particle powder can be stirred and crushed, so that the subsequent mixing effect is better.

Owner:JIANGSU VILORY ADVANCED MATERIALS TECH CO LTD

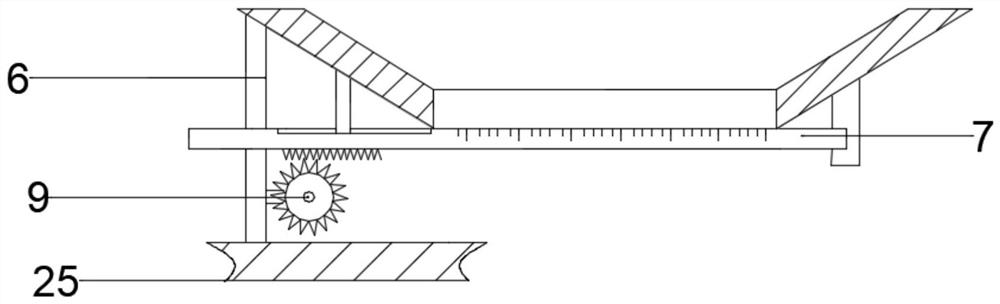

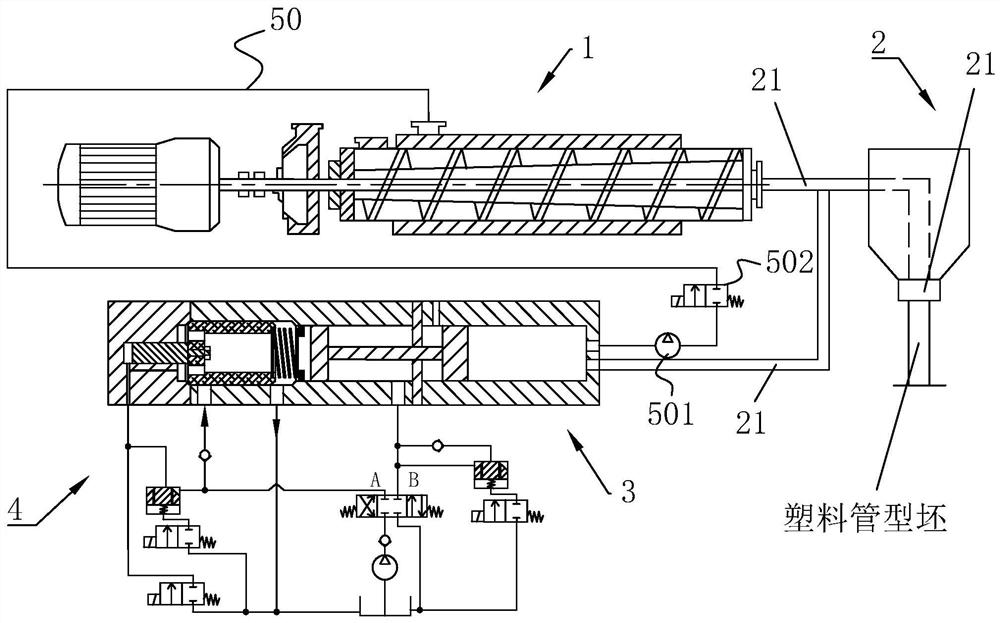

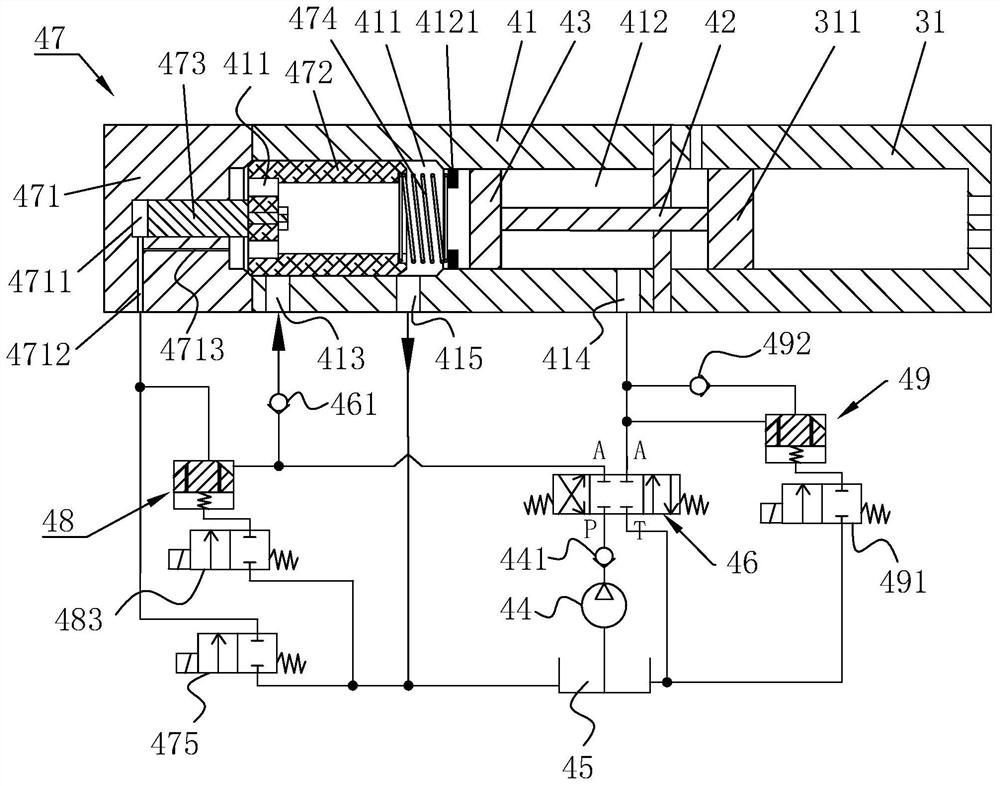

Plastic pipe extrusion molding equipment and control method thereof

ActiveCN111688145ASlow down the feed rateIncrease feed rateProcess engineeringMechanical engineering

The invention discloses plastic pipe extrusion molding equipment and a control method thereof. The plastic pipe extrusion molding equipment comprises an extrusion device and a forming die, and furthercomprises a speed detection device and a flow speed control device, wherein the extrusion device melts and extrudes plastic particles; the forming die is connected with a discharge port of the extrusion device through a first conveying pipe so as to extrude an inflowing molten material through a die head in the forming die and form plastic pipe parisons, and the plastic pipe parisons are segmented by an automatic cutting device in unit time; the speed detection device is used for detecting the discharging speed of the die head of the forming die in real time; and the flow speed control deviceis connected with a branch port of the first conveying pipe so as to divide or converge the molten materials flowing out of the discharge port of the extrusion device and further adjust the dischargespeed of the forming die head. According to the extrusion molding equipment, the output speed of the extruded plastic pipe parisons can be correspondingly adjusted and controlled, so that the lengthof the plastic pipe parison extruded in each period is uniform, the meter weight is similar, the material waste is reduced, and the defective rate of finished products is reduced.

Owner:TAIZHOU AOBO PIPE

Stirring tank device for processing new resin textile material

InactiveCN110141988AEasy to useAvoid shakingRotary stirring mixersTransportation and packagingMotor driveHeat conducting

The invention discloses a stirring tank device for processing a new resin textile material. The device comprises a shell, four corners of the bottom of the shell are fixedly connected with supportingpillars, a stirring cylinder is arranged in the shell, water outlet tubes are arranged at the bottoms of both sides of the shell, one ends, close to the stirring cylinder, of the water outlet tubes are communicated with the shell, and four corners of the bottom of the stirring cylinder are fixedly connected with first fixing blocks. Hot water is injected into the shell from a water inlet tube, anda motor drives a square plate and a sieve plate through a rotating rod and a first connecting plate to stir the material in order to make the material fully contact with the inner wall of the stirring cylinder and the surface of a heat conducting sleeve, so the stirring tank device for processing the new resin textile material has the advantages of convenience in resin heating, and solving of theproblems of failed resin heating of existing stirring tank devices and high thickness of the resin at a low temperature, avoiding of the difficult stirring and low stirring efficiency phenomena caused by the high thickness of the resin, and convenience for people to use.

Owner:都吉宽

Fertilizing device for agricultural planting

InactiveCN108353601AAvoid conversionIncrease profitLiquid fertiliser distributionFertiliser distributersAgricultural engineeringSpray nozzle

The invention discloses a fertilizing device for agricultural planting. The fertilizing device comprises a base, a solid material tank and a fluid material tank, wherein universal wheels are fixedly arranged at four corners of the bottom end of the base through supporting legs; the solid material tank and the fluid material tank are both fixedly arranged on the base; the solid material tank is arranged at the left side of the fluid material tank; a stirring device is arranged in the solid material tank; the stirring device comprises a stirring motor, a stirring rod and stirring paddles; the upper end of the solid material tank is of a cuboid structure, and the lower end is of a funnel-shaped structure; a material outlet is formed in the bottom end of the solid material tank and located inthe base; a first electric telescopic rod is fixedly arranged on the top end of the inner part of the base at the left side of the material outlet. According to the fertilizing device for the agricultural planting, disclosed by the invention, through the arrangement of the solid material tank and the fluid material tank, different types of fertilizer can be fertilized and utilized, and the using cost of various fertilizing devices can be saved; meanwhile, rotary spraying is carried out in a baffle disc, so that not only a material discharging spray nozzle can be prevented from being blocked, but also the spraying is uniform.

Owner:NANAN WENFA ELECTRONICS TECH CO LTD

Micro tillage machine with fertiliziation function

InactiveCN107535105AAddressing Size and MobilityEasy to move and transportSpadesPloughsFertilizerAgricultural engineering

The invention discloses a micro tillage machine with fertilization function, which comprises a vehicle plate; a symmetrical side plate is fixedly connected to the bottom of the left side of the vehicle plate, and driving wheels are arranged between the side plates; a symmetrical The runner is connected to the horizontal shaft through a magnetic coupling; the outer surface of the runner is distributed with rotary tillage blades; the right side of the car plate is equipped with a fertilizer uniform spreading device. The present invention effectively solves the contradiction between the volume and the mobility of the tiller by providing the rotary tiller blade and the magnetic coupler which can be rotated and contracted, and is convenient for transportation and movement; Compact the opened ditch to ensure the effect of ditching; the invention is equipped with a fertilizer uniform spreading device, which prevents the discharge pipe from being blocked by providing a spiral blade, and controls the discharge speed by providing a moving plug that moves up and down. There is a sprinkler plate to spread the fertilizer evenly, improve the uniformity of fertilization and save fertilizer.

Owner:临泉县生产力促进中心

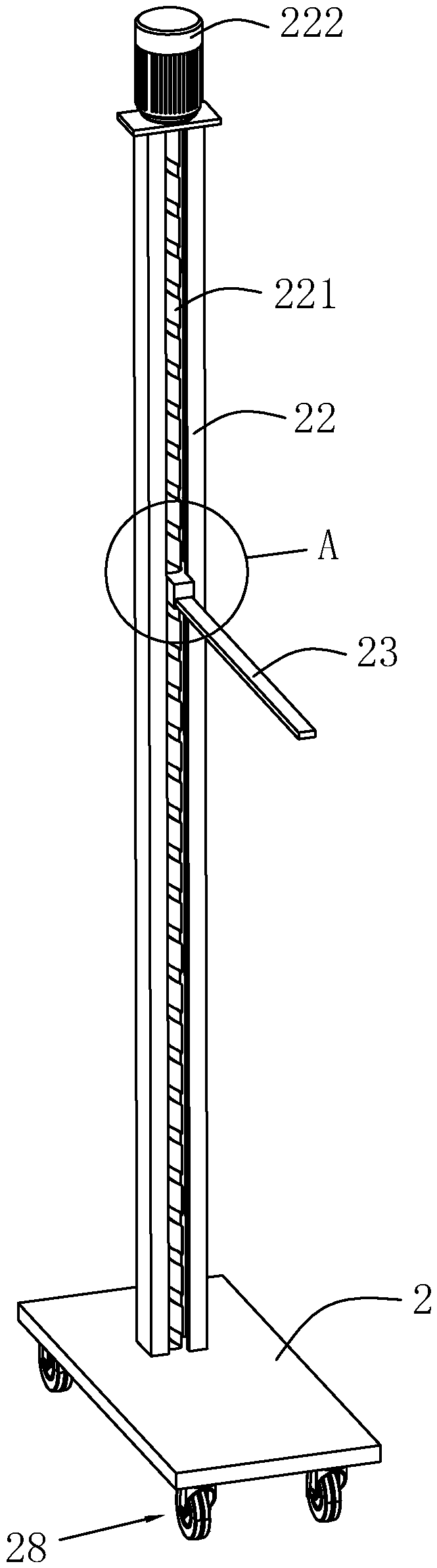

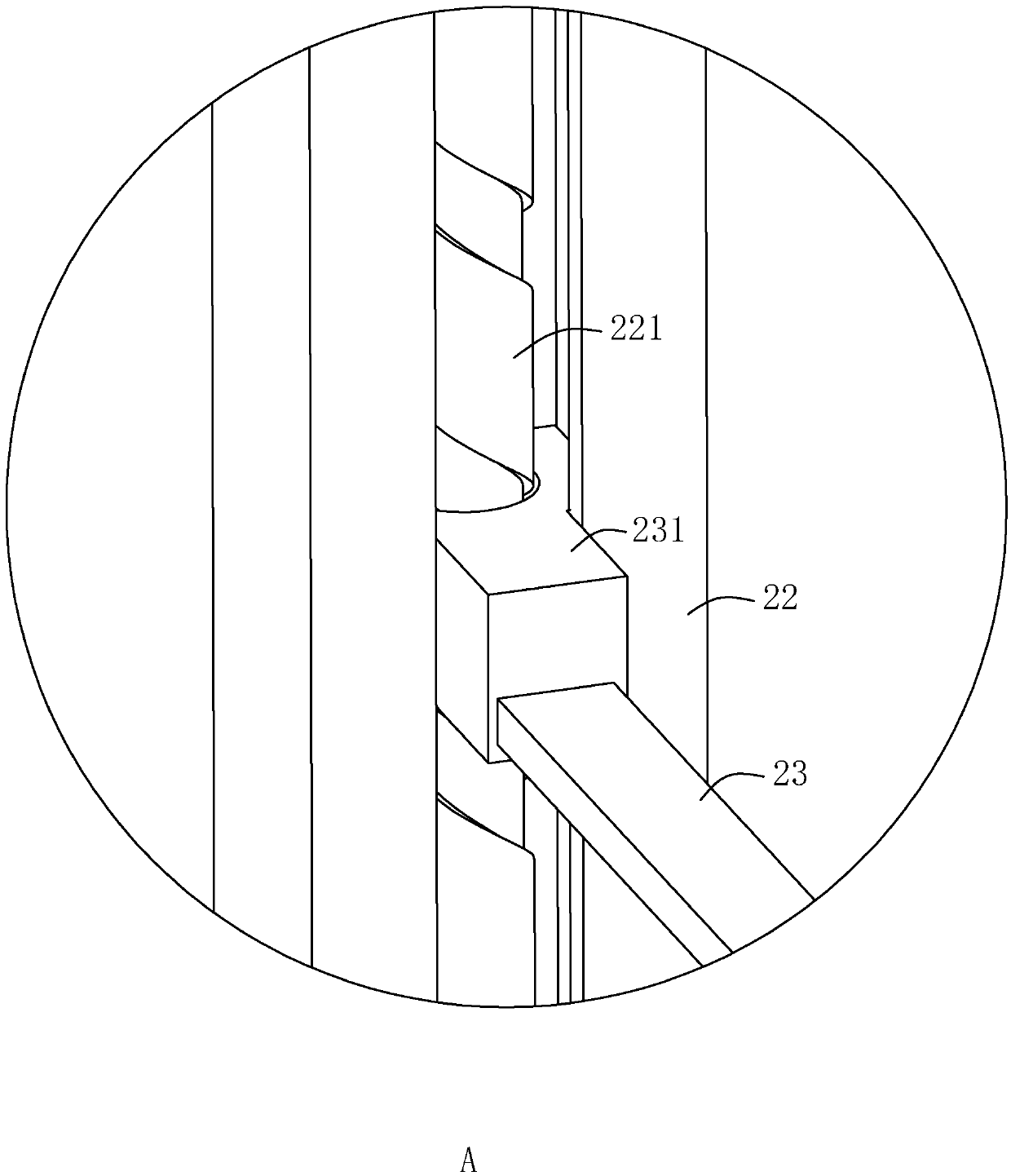

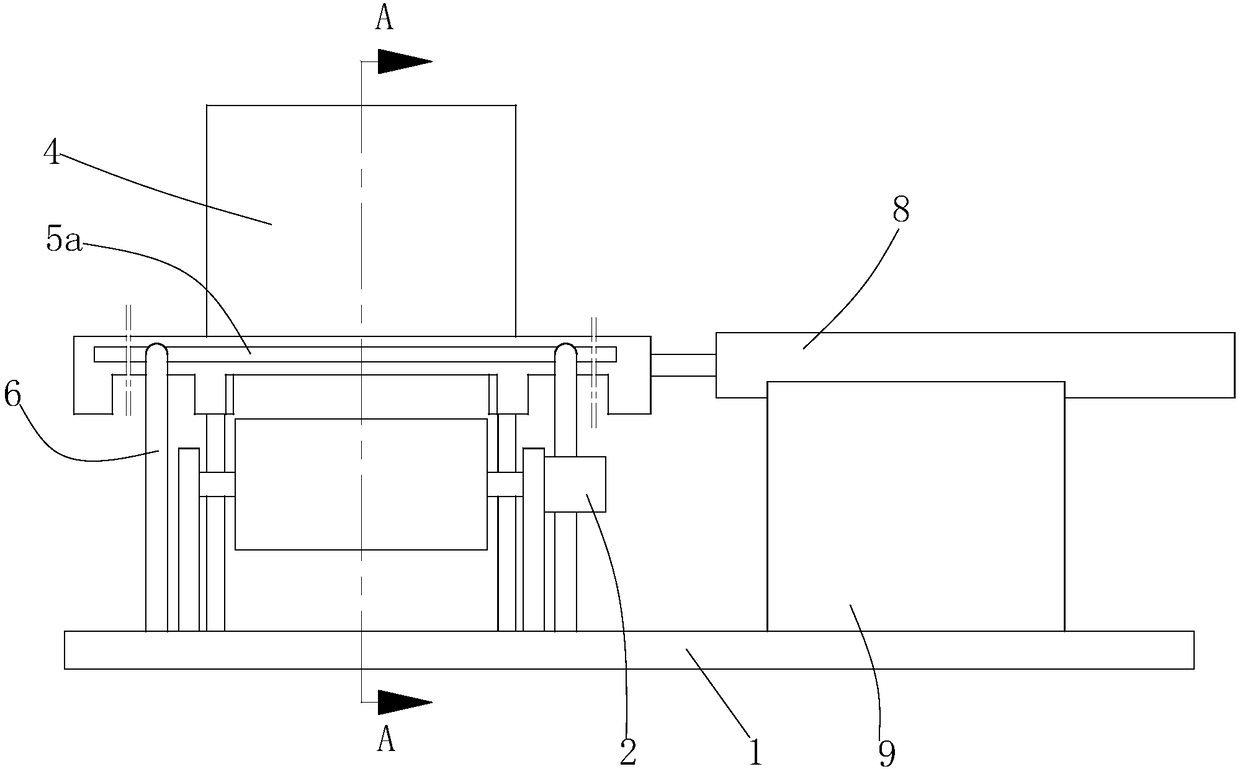

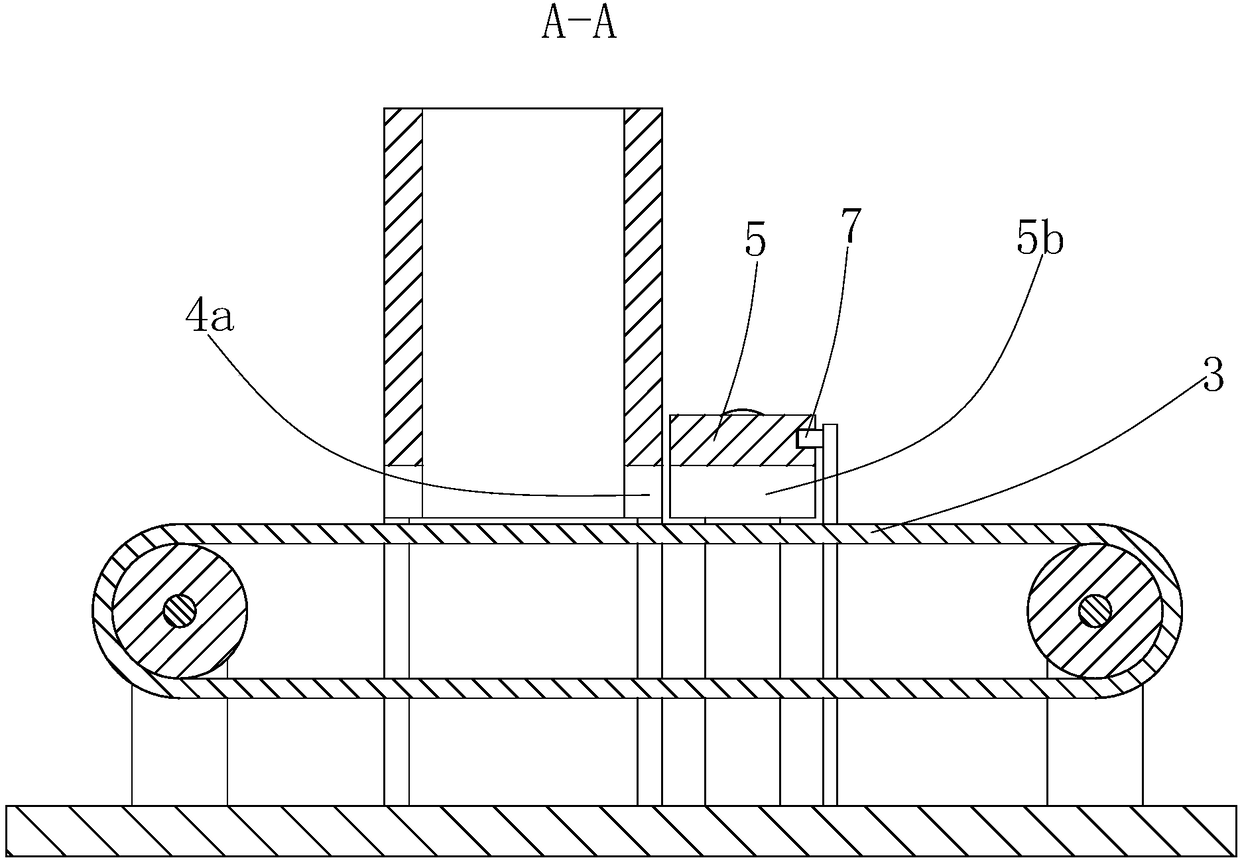

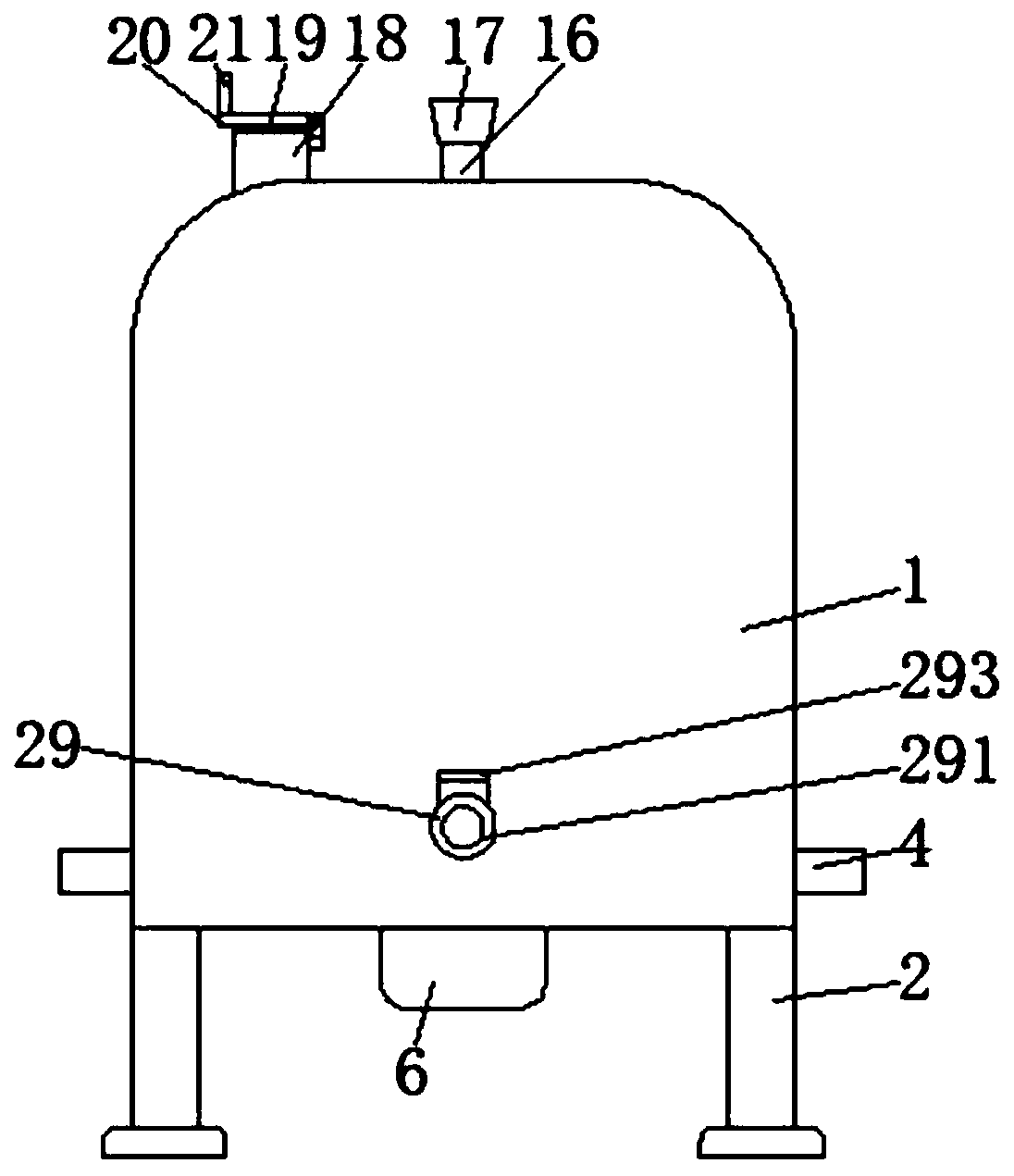

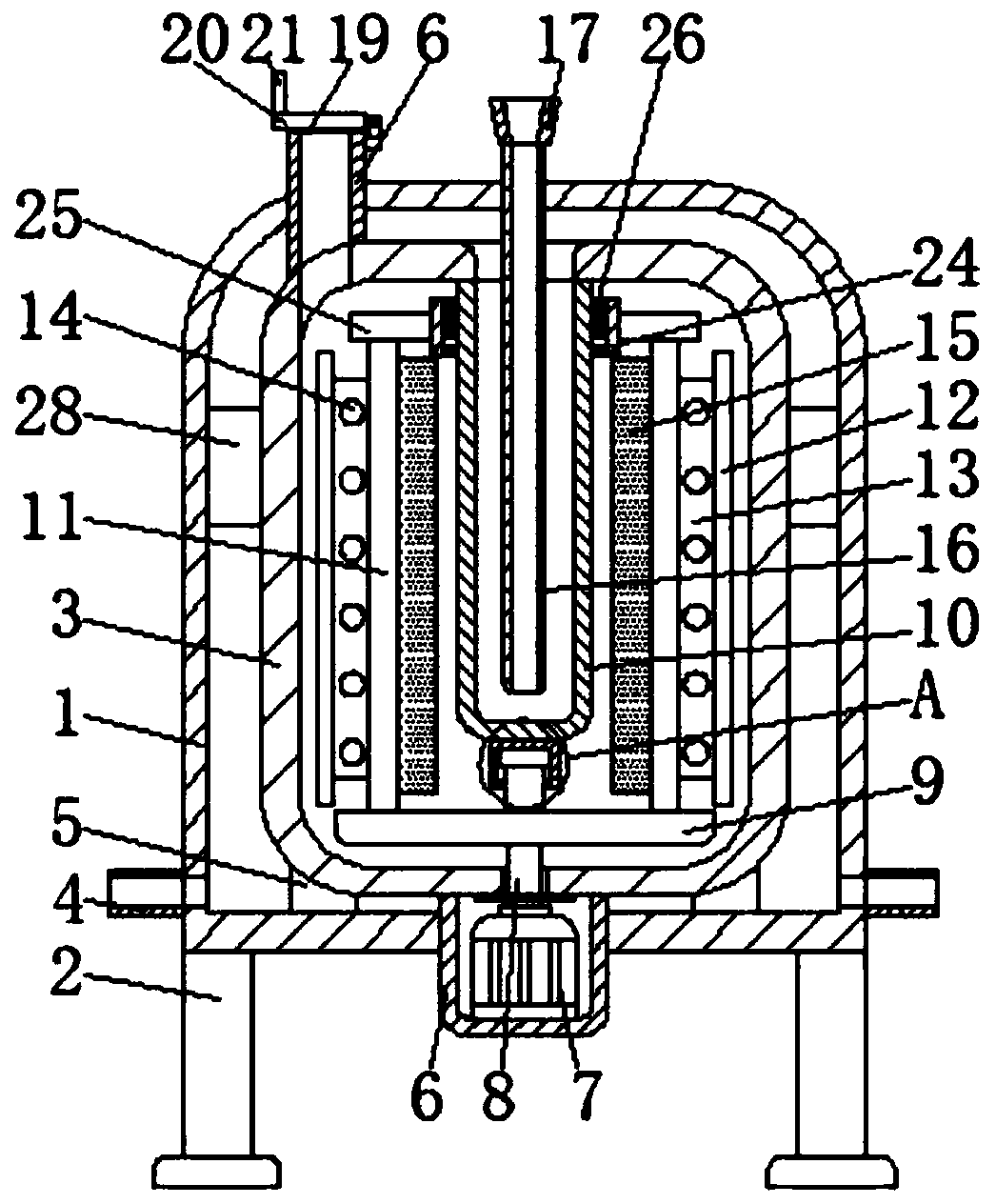

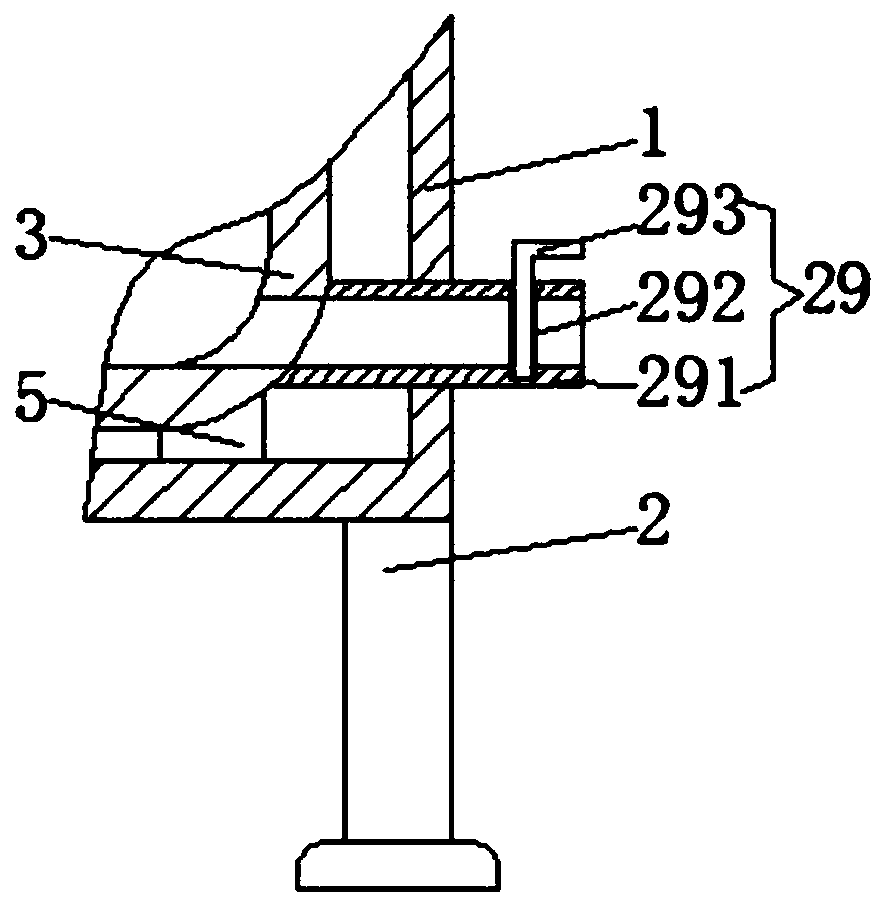

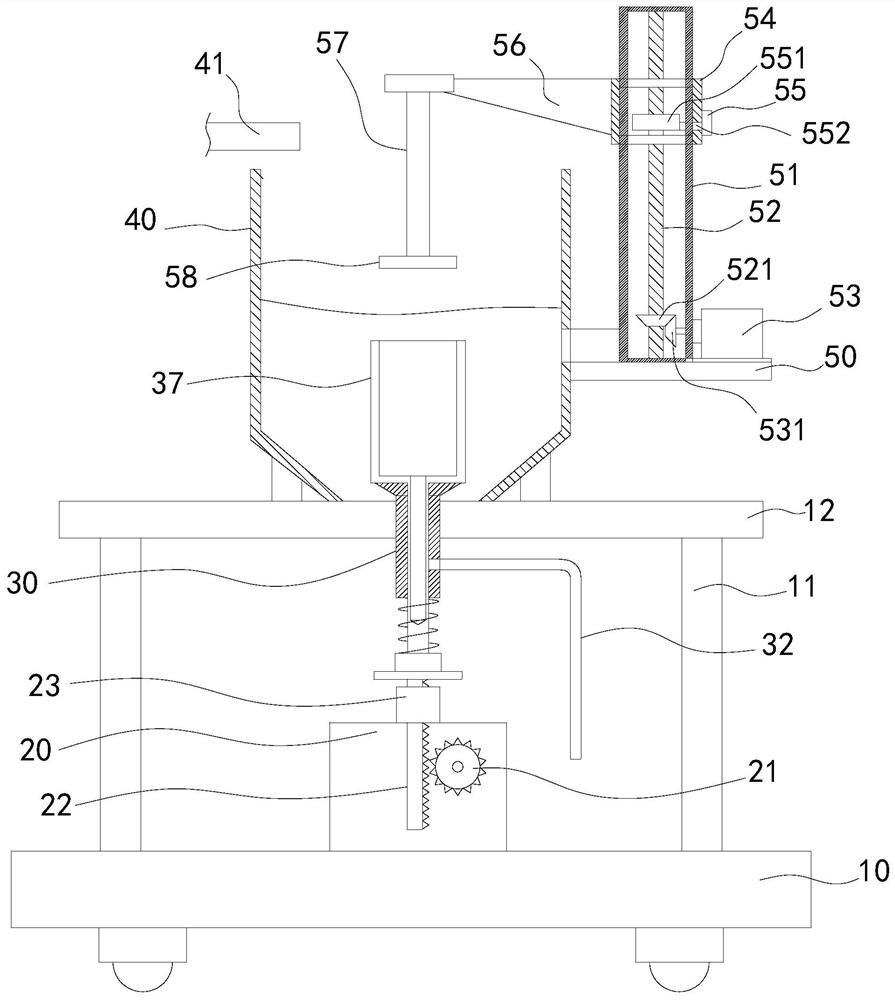

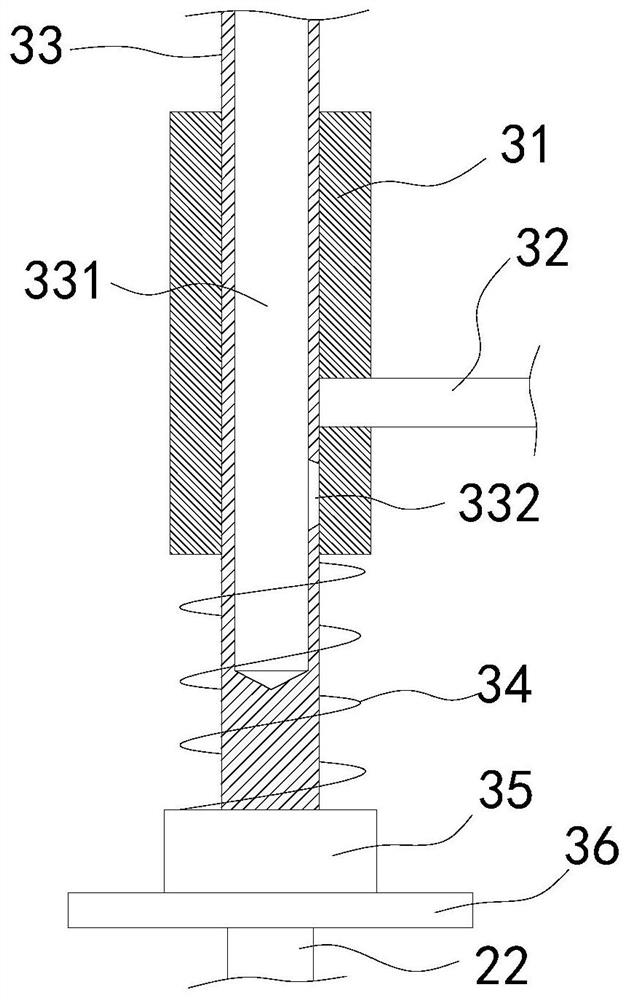

Quantitative discharging device for sodium silicate solution on intelligent production line

ActiveCN111731535ARealize quantitative outputControl the output speedLiquid materialThermodynamicsLiquid state

The invention discloses a quantitative discharging device for a sodium silicate solution on an intelligent production line. The device comprises a movable base, a discharging mechanism and a driving mechanism. Supporting rods are arranged on the movable base, the top ends of the supporting rods are provided with a workbench, the middle of the workbench is provided with a liquid storage tank, and aliquid inlet pipe is arranged above the liquid storage tank. The discharging mechanism is arranged in the middle of the liquid storage tank and comprises a fixing pipe arranged in the center of the bottom of the liquid storage tank, the fixing pipe is arranged on the workbench in an embedded manner, a liquid outlet pipe communicates with the outer wall of the fixing pipe, a movable rod verticallypenetrates through the interior of the fixing pipe, and the top end of the movable rod is provided with a liquid inlet cylinder. The driving mechanism is arranged below a connection plate. Compared with the prior art, the quantitative discharging device can achieve quantitative discharging of liquid sodium silicate by arranging the discharging mechanism and can also control the discharging speed.

Owner:桐乡市恒立化工股份有限公司

Electroplating solution filtering device

InactiveCN110372047AEasy to cleanEasy to useSpecific water treatment objectivesTreatment involving filtrationEngineeringElectroplating

The invention discloses an electroplating solution filtering device. The electroplating solution filtering device comprises a bottom plate, a barrel body is arranged at the top of the left side of thebottom plate, the surface of the barrel body is fixedly connected to the top of the bottom plate through a connecting frame, a sealing cover is fixedly mounted at the top of the barrel body through abolt, and a concave-shaped filtering barrel located in the barrel body is fixedly mounted at the bottom of the sealing cover through a bolt. According to the electroplating solution filtering device,a scraping mechanism is driven by a transmission mechanism through a rotary rod to scrap the inner wall of the barrel body to a certain degree, then water in a water tank is injected into the barrelbody through a cleaning mechanism to clean, thus crud is discharged through a discharging pipe, the advantage that the inner wall of a fixing barrel is conveniently cleaned is achieved, and the problem that a fixing barrel of an existing filtering device is not provided with a certain cleaning mechanism, consequently the inner wall of the fixing barrel is prone to being tainted with much impurities after a long time using, cleaning is conducted by a user with a hand tool after a cover is opened, and the cleaning efficiency is lowered is solved.

Owner:ANHUI QIMING SURFACE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com