Mixing equipment special for test pieces of rock and soil tests

A technology for mixing equipment and testing, applied in the field of special mixing equipment for geotechnical test specimens, can solve the problems of slow mixing speed, low work efficiency, large labor and time consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

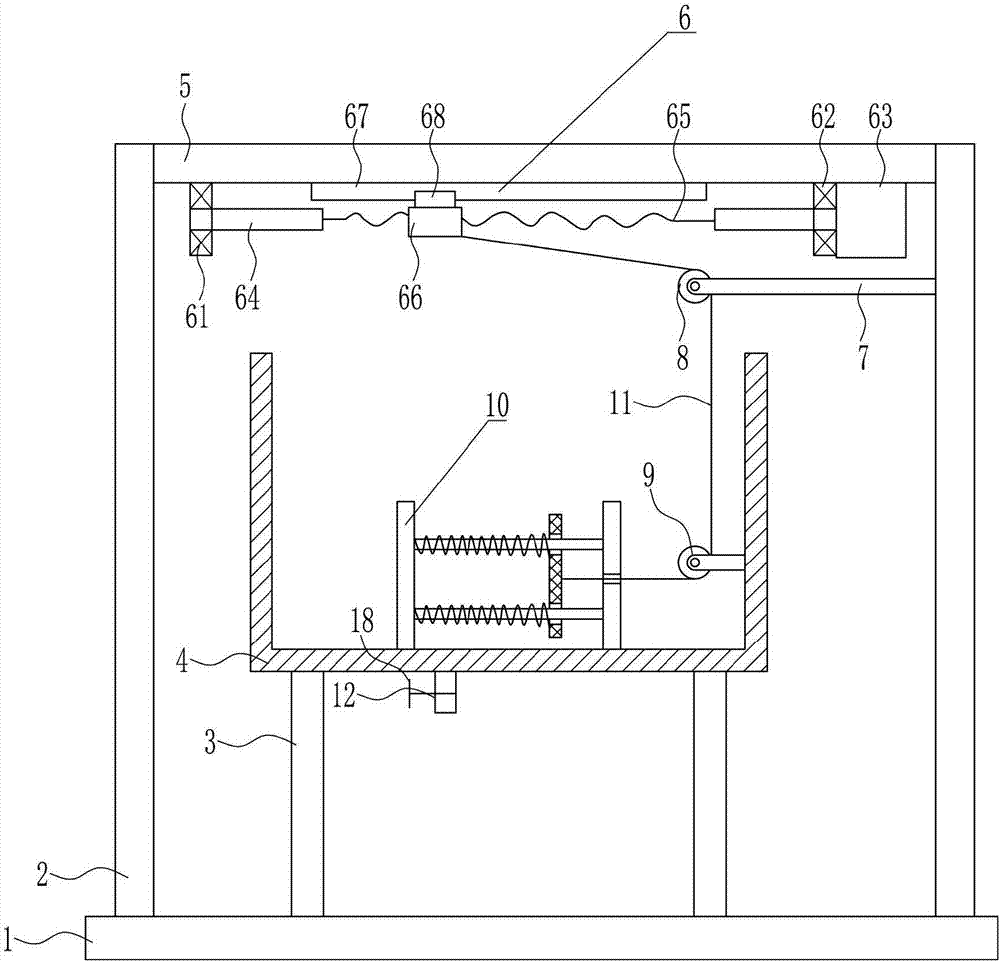

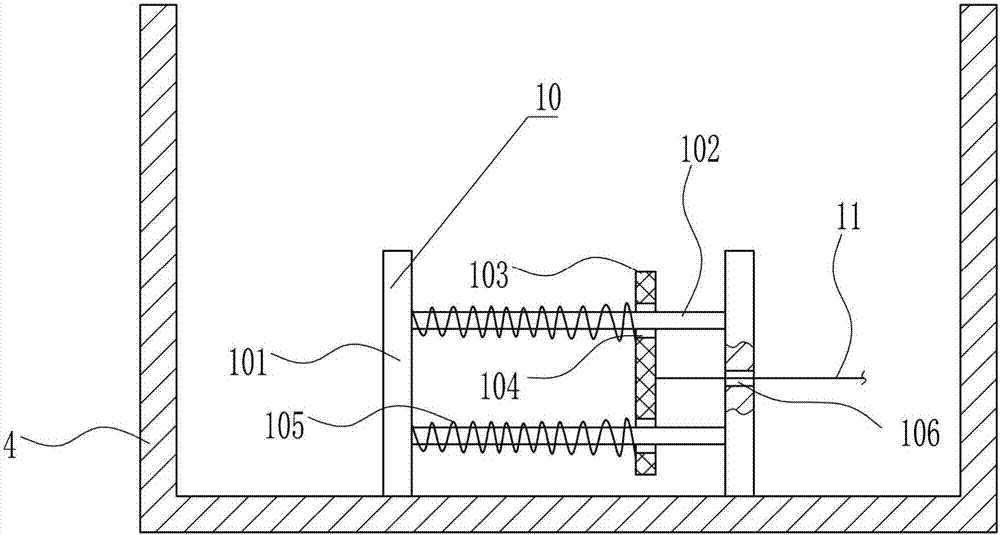

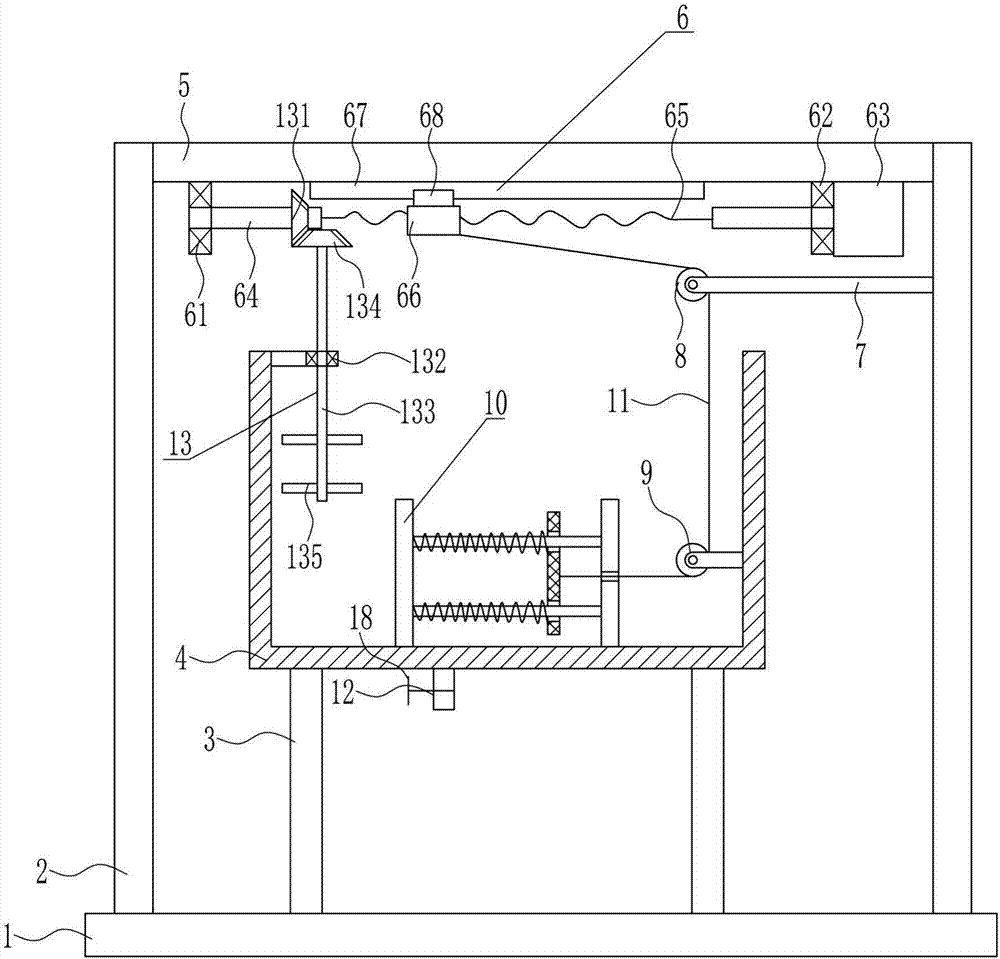

[0034] A special mixing equipment for rock and soil test specimens, such as Figure 1-6 As shown, it includes bottom plate 1, bracket 2, legs 3, mixing box 4, top plate 5, left and right moving device 6, cross bar 7, first pulley 8, second pulley 9, mixing device 10, pull wire 11, discharge The pipe 12 and the valve 18, the left and right sides of the bottom plate 1 are symmetrically connected by bolts to vertically install the bracket 2, the top of the bottom plate 1 between the two brackets 2 is installed with the outrigger 3, the top of the outrigger 3 is installed with the mixing box 4, the two brackets The top between the 2 is horizontally installed with a top plate 5 by means of bolt connection, the bottom of the top plate 5 is provided with a left and right moving device 6, the upper part of the left side of the right side bracket 2 is connected with a cross bar 7 by welding, and the left end of the cross bar 7 is installed with a second A pulley 8, a second pulley 9 is...

Embodiment 2

[0036] A special mixing equipment for rock and soil test specimens, such as Figure 1-6 As shown, it includes bottom plate 1, bracket 2, legs 3, mixing box 4, top plate 5, left and right moving device 6, cross bar 7, first pulley 8, second pulley 9, mixing device 10, pull wire 11, discharge The pipe 12 and the valve 18, the left and right sides of the bottom plate 1 are symmetrically connected by bolts to vertically install the bracket 2, the top of the bottom plate 1 between the two brackets 2 is installed with the outrigger 3, the top of the outrigger 3 is installed with the mixing box 4, the two brackets The top between the 2 is horizontally installed with a top plate 5 by means of bolt connection, the bottom of the top plate 5 is provided with a left and right moving device 6, the upper part of the left side of the right side bracket 2 is connected with a cross bar 7 by welding, and the left end of the cross bar 7 is installed with a second A pulley 8, a second pulley 9 is...

Embodiment 3

[0039] A special mixing equipment for rock and soil test specimens, such as Figure 1-6 As shown, it includes bottom plate 1, bracket 2, legs 3, mixing box 4, top plate 5, left and right moving device 6, cross bar 7, first pulley 8, second pulley 9, mixing device 10, pull wire 11, discharge The pipe 12 and the valve 18, the left and right sides of the bottom plate 1 are symmetrically connected by bolts to vertically install the bracket 2, the top of the bottom plate 1 between the two brackets 2 is installed with the outrigger 3, the top of the outrigger 3 is installed with the mixing box 4, the two brackets The top between the 2 is horizontally installed with a top plate 5 by means of bolt connection, the bottom of the top plate 5 is provided with a left and right moving device 6, the upper part of the left side of the right side bracket 2 is connected with a cross bar 7 by welding, and the left end of the cross bar 7 is installed with a second A pulley 8, a second pulley 9 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com