Material mixing and plastering method for ceramic tiles

A ceramic tile and mixing technology, applied in chemical instruments and methods, mixing operation control, mixing operation control device, etc., to achieve the effect of reducing manual operation, high practicability and reliability, and strong versatility and practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

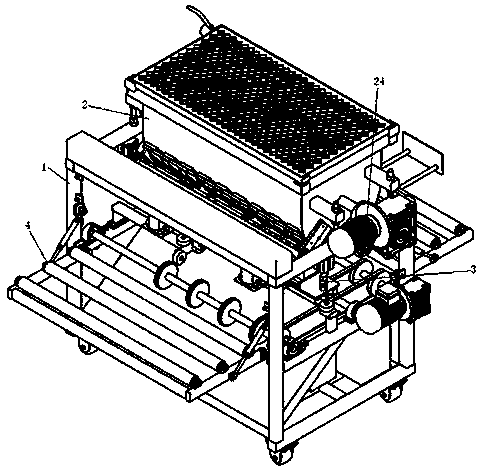

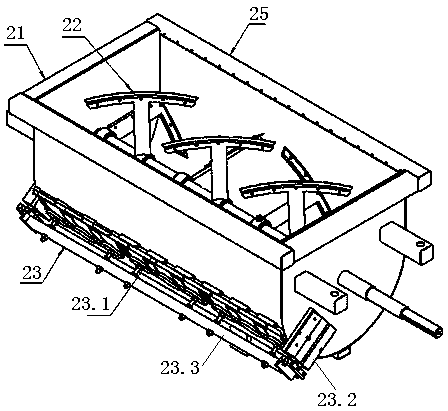

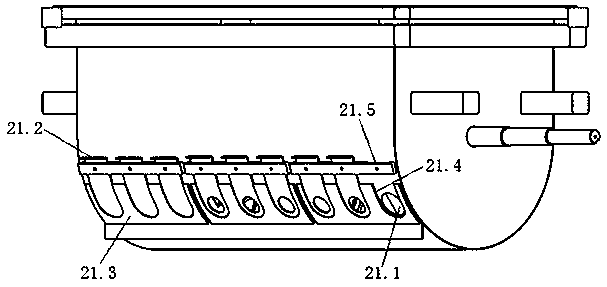

[0041] Combine below Figure 1 to Figure 8 Embodiments of the present invention are described in detail.

[0042] The method for ashing tiles, including a frame 1, on which a mixing device 2 for mixing materials, a distribution device 3 for distributing materials on the tiles, and a tile positioning transmission device 4 for positioning and transferring the tiles are installed from top to bottom on the frame 1, The material distributing device 3 is located directly below the outlet of the stirring device 2, and can be automatically lifted to contact or separate from the tiles on the tile positioning transmission device 4. It is characterized in that the method for mixing and dusting the tiles includes the following steps:

[0043] S1: Add the raw materials into the stirring device 2, and then start the stirring device 2 to stir the raw materials to form ash;

[0044] S2: Put the tiles to be dusted on the tile positioning transmission device 4 and position them during the raw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com