Quantitative discharging device for sodium silicate solution on intelligent production line

A sodium silicate solution, quantitative discharge technology, applied in the direction of liquid materials, packaging, transportation and packaging, etc., can solve the problems of uncontrollable discharge speed, production line that cannot meet quantitative filling, and quantitative control of discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

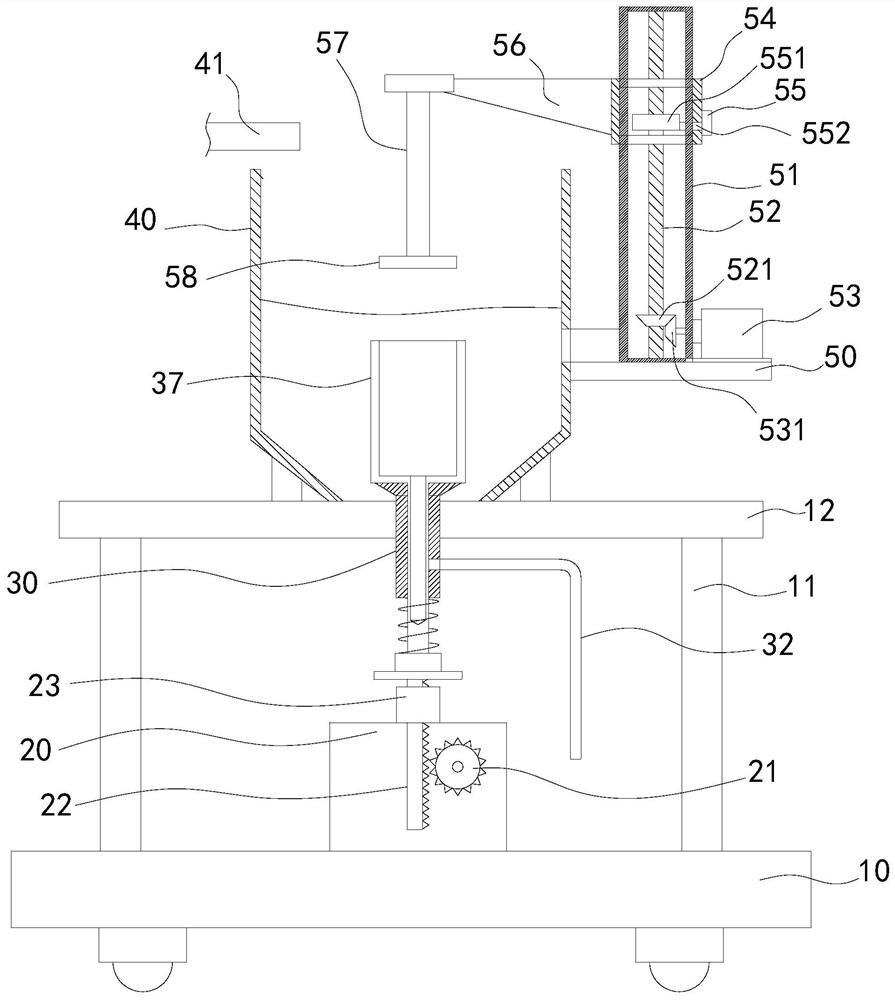

[0025] Such as Figure 1-Figure 6 As shown, the present invention provides the sodium silicate solution quantitative discharge device on the intelligent production line, comprising:

[0026] Movable base 10, movable base 10 is provided with support bar 11, and the top of support bar 11 is provided with workbench 12, and the middle position of workbench 12 is provided with liquid storage tank 40, in order to guarantee the stability of liquid storage tank 40, liquid storage tank The bottom of 40 can be provided with supporting parts, such as rods, etc., and the liquid inlet pipe 41 is arranged above the liquid storage tank 40. During specific implementation, the liquid storage tank 40 can be designed as an open type, and the liquid inlet pipe 41 is directly adjacent Located on the top side of the liquid storage tank 40, the liquid inlet pipe 41 is connected to the sodium silicate production device on the intelligent production line;

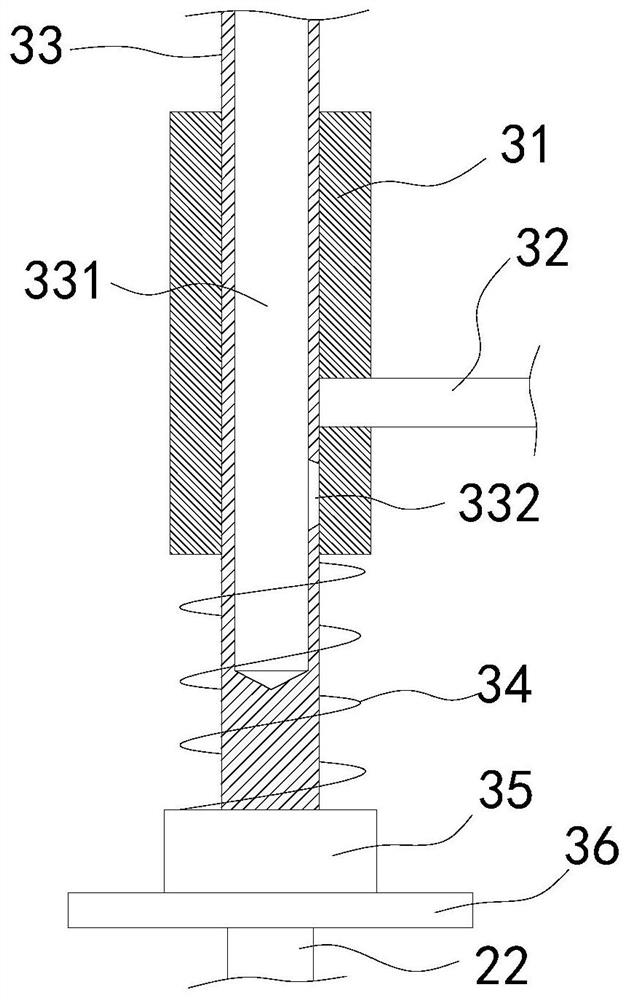

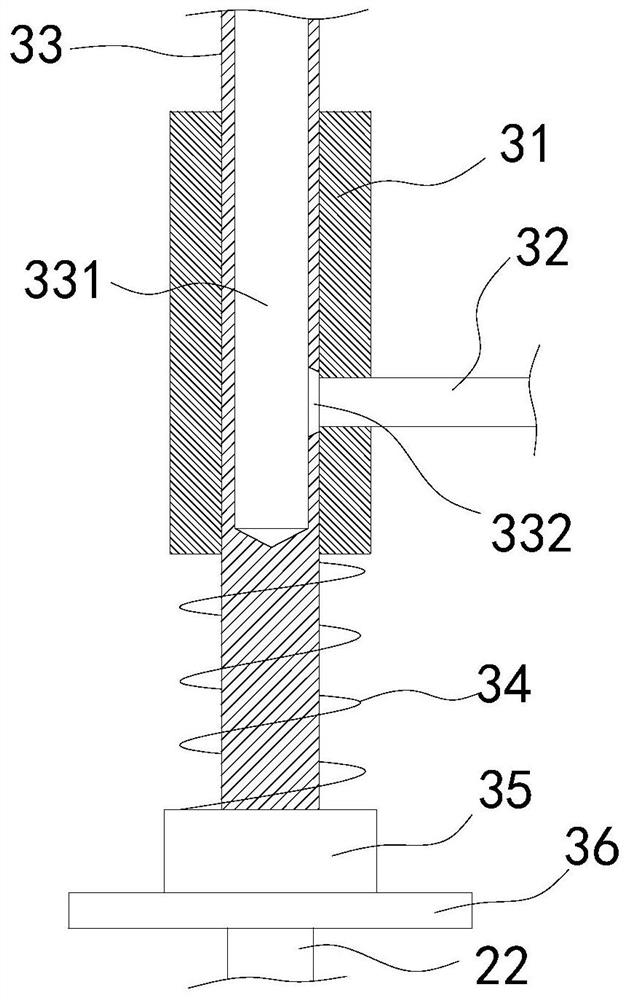

[0027] A discharge mechanism 30, the discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com