Sorting and throwing method of particle and powder particle fertilizer, and seeds

A feeding method and fertilizer technology, applied in the field of powder fertilizer and seed sorting and feeding, can solve the problems of too dense or too thin, fast discharge speed of fertilizer, difficult to control the amount of discharge, etc., to improve the effect of fertilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

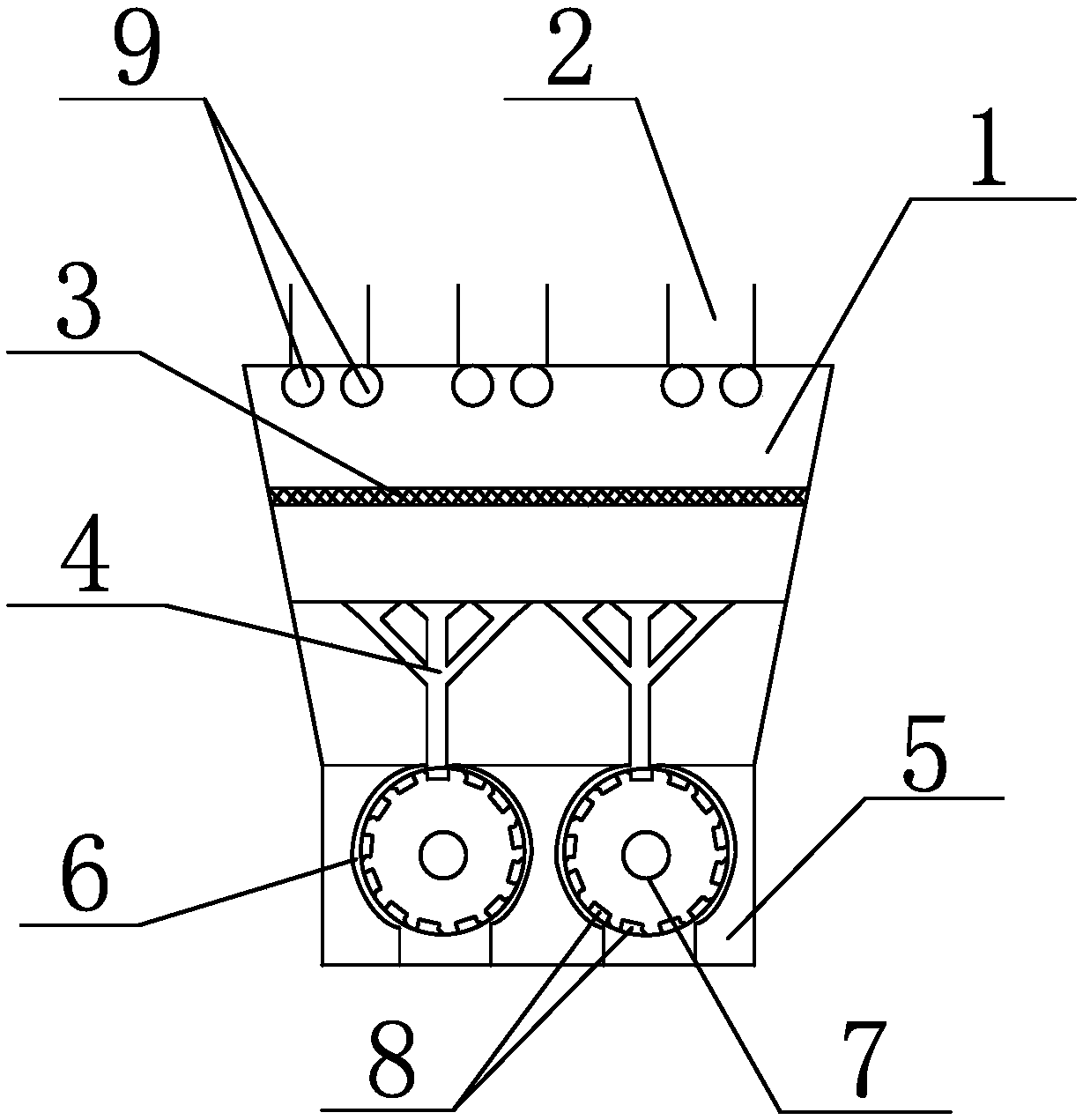

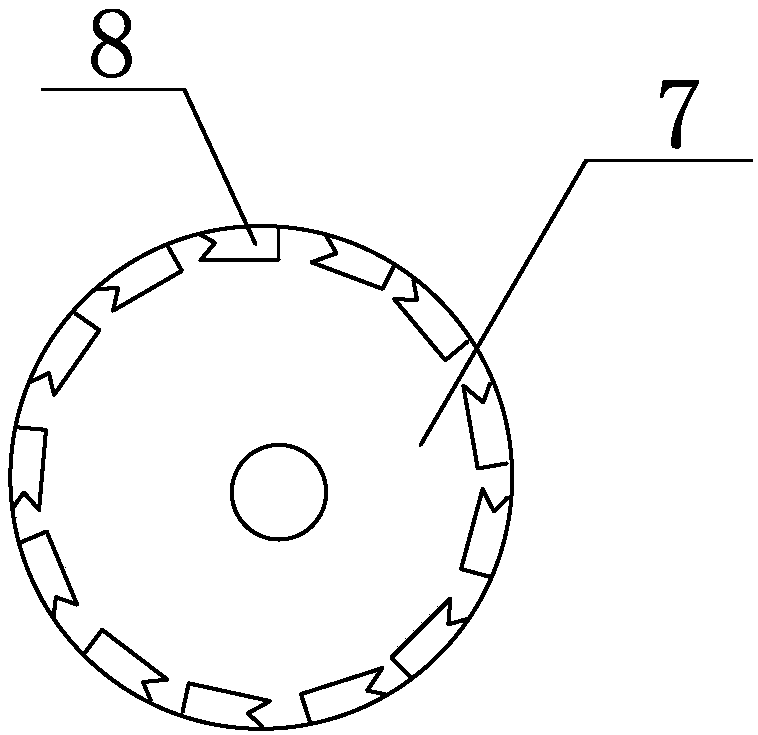

[0022] like figure 1 and 2 As shown, the method for sorting and putting in granules, granulated fertilizers and seeds of the present invention comprises the following steps: 1) dropping fertilizer or seeds into a sorting and putting device; wherein, the sorting and putting device includes a storage box 1, and The top of the material storage box 1 is provided with a plurality of material inlets 2, the bottom of the material inlet 2 is provided with a screen 3, the bottom of the material storage box 1 is connected with a plurality of discharge pipes 4, and the bottom of the discharge pipe 4 A material distribution box 5 is provided, and a plurality of cylindrical material distribution chambers 6 are arranged in the material distribution box 5, and a material distribution drum 7 is arranged in the material distribution chamber 6, and the material distribution drum 7 rotates around its own axis, The material distribution drum 7 is coaxial with the material distribution chamber 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com