Simple fertilizer-pesticide quantitative flushing applicator

A kind of flushing and simple technology, applied in the field of flushing and fertilizing tools, which can solve the problems of easy failure, limited use conditions, and large fluctuation of liquid level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

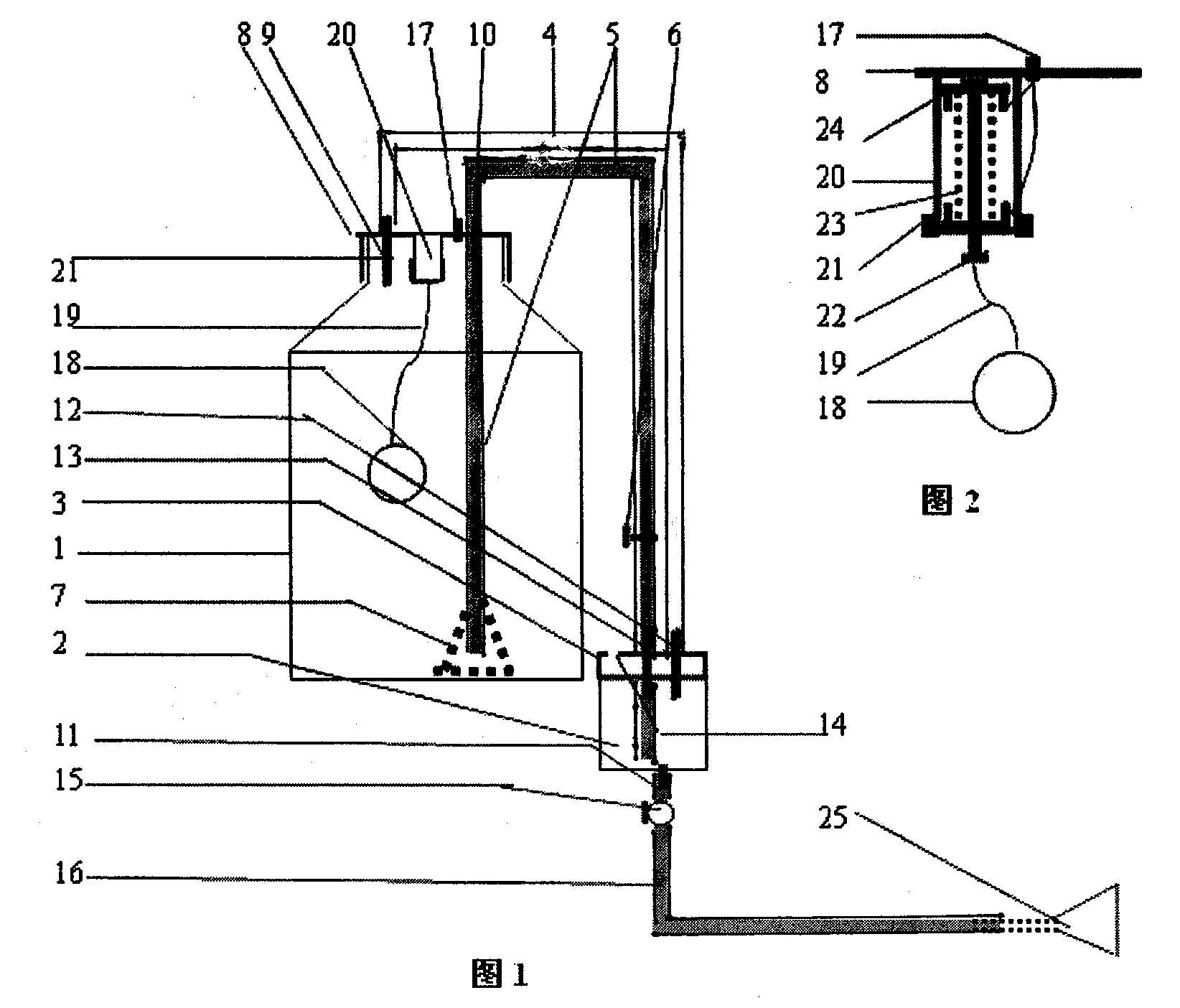

[0079] The characteristics of this embodiment flush applicator are as attached figure 1 , barrel bottle separation type, the air inlet nozzle (9) and the output liquid nozzle (10) and the caller switch are all located on the sealing cover (8) of the liquid storage barrel (1), and the liquid level stabilization bottle (2) is provided with a sealed Cover (3), a vent hole (14) is also established on its sealing cover, and the liquid level stabilization bottle (2) is hung below the liquid storage barrel (1), and the filter screen cover (7) is barrel bottle in the liquid storage barrel (1). On the water inlet of the pipe in the liquid communication pipe. The structure of the liquid level stabilizing bottle can generate negative pressure when the flushing applicator is started, and play the role of siphon suction.

[0080] The application process of this embodiment is as follows:

[0081] (1) Preparation of flushing device ① Calculate the concentration of fertilizer (drug), the p...

Embodiment 2

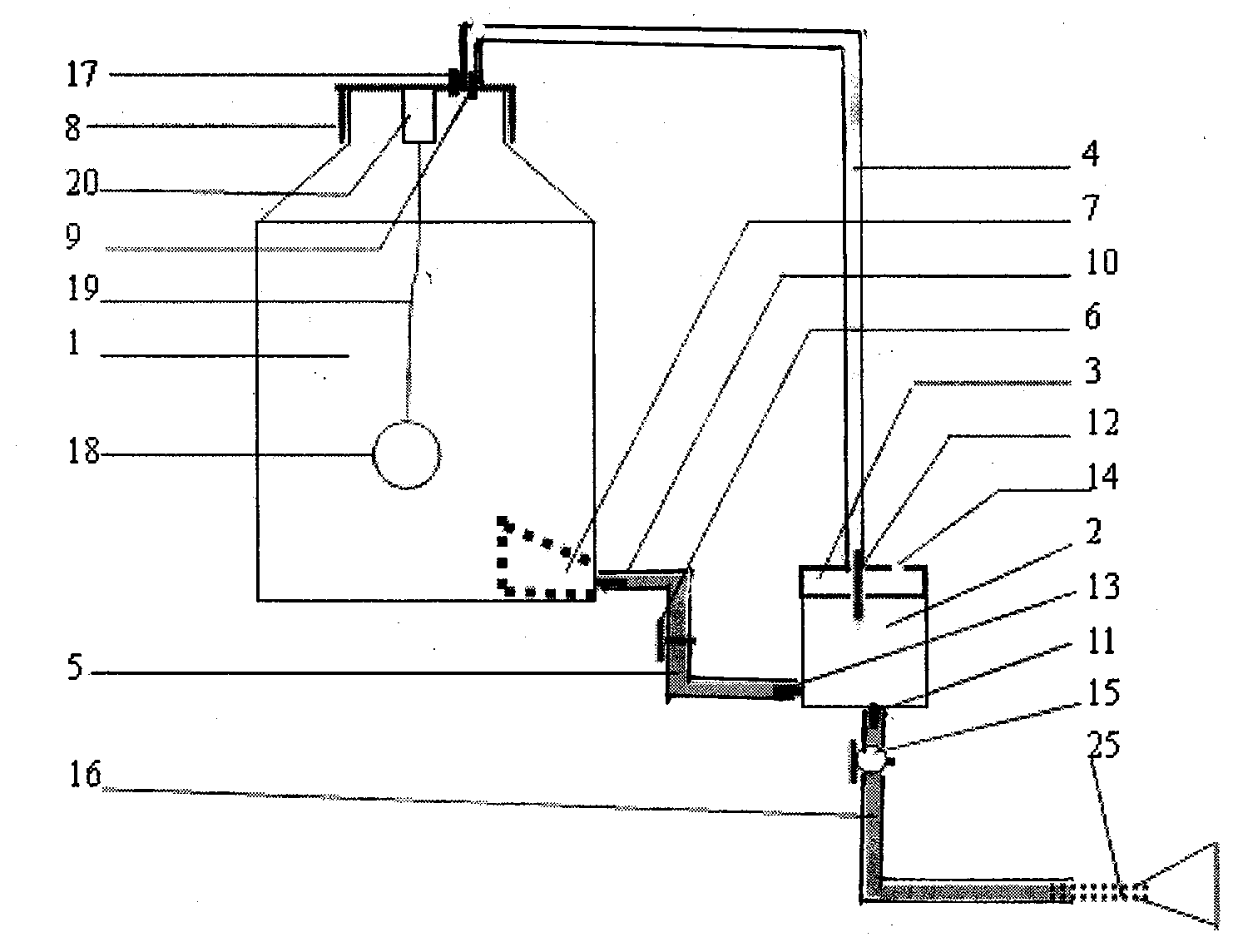

[0086] The characteristics of this embodiment flush applicator are as attached image 3 , barrel bottle separation type, the air inlet nozzle (9) is located on the sealing cover (8) of the liquid storage barrel (1), the output liquid nozzle (10) is located at the bottom of the barrel wall of the liquid storage barrel (1), and the liquid inlet pipe Mouth (13) is located at the bottom of liquid level stabilization bottle (2) bottle wall, and the lid of liquid level stabilization bottle (2) is dispensable.

[0087] The application process of this embodiment is as follows:

[0088] (1) Preparation of flushing device 1. repeating 1. of embodiment 1; 2. according to image 3 Assemble the applicator, close the liquid connection valve (6) of the barrel and bottle, and inject fertilizer liquid into the liquid storage barrel (1); ③Close the sealing cover (8) and straighten the float (18); ④Connect the caller Plug (17), adjust the output liquid switch (15) to the required flow.

[008...

Embodiment 3

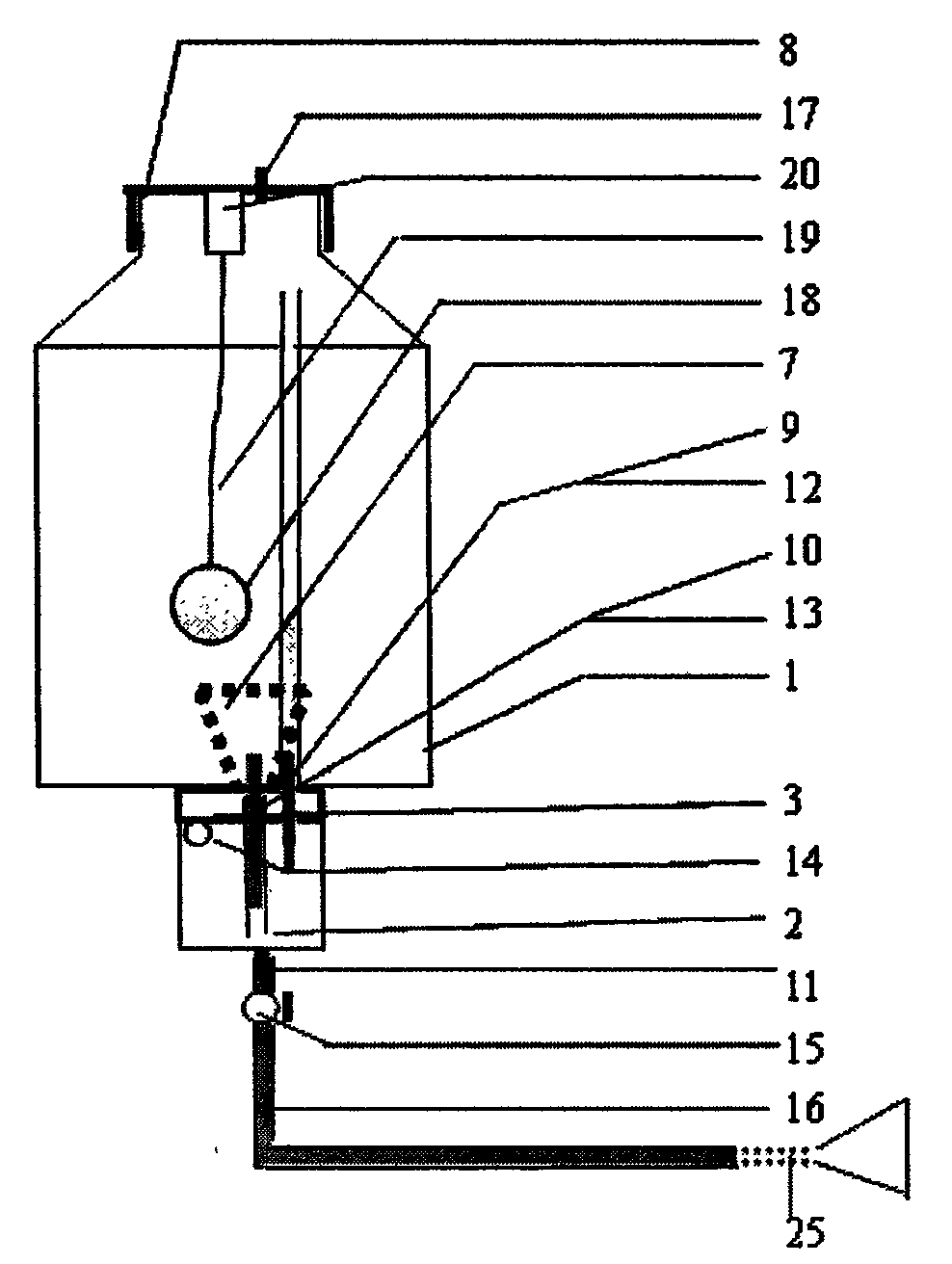

[0093] The characteristics of this embodiment flush applicator are as attached Figure 4 , the end of the barrel bottle is butt-connected, the air inlet nozzle (9) and the output liquid nozzle (10) are all located on a back cover at the bottom of the liquid storage barrel (1), and the back cover of the liquid storage barrel is stable with the liquid level The sealing cap (3) of bottle is combined into one, and the gas delivery pipe nozzle (12) of air inlet nozzle (9) and liquid level stabilization bottle is combined into one, saves the outer pipe of barrel bottle gas connecting pipe (4); The liquid nozzle (10) and the liquid inlet nozzle (13) of the liquid level stabilization bottle are combined into one, saving the outer pipe of the barrel bottle liquid communication pipe (5); ).

[0094] The application process of this embodiment is as follows:

[0095] (1) preparation of flushing applicator 1. repeating 1. of embodiment 1; 2. according to attached Figure 4 Assemble the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com