Urea formaldehyde foam plant cultivation medium grinder

A technology for cultivation substrate and urea-formaldehyde foam, which is applied in the directions of grain processing, removal of smoke and dust, cleaning methods and utensils, etc., can solve the problems of low strength, low bulk density of urea-formaldehyde foam substrate, and difficulty in controlling the particle size of urea-formaldehyde foam cultivation substrate, and achieves safety. Good performance, improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the drawings and embodiments.

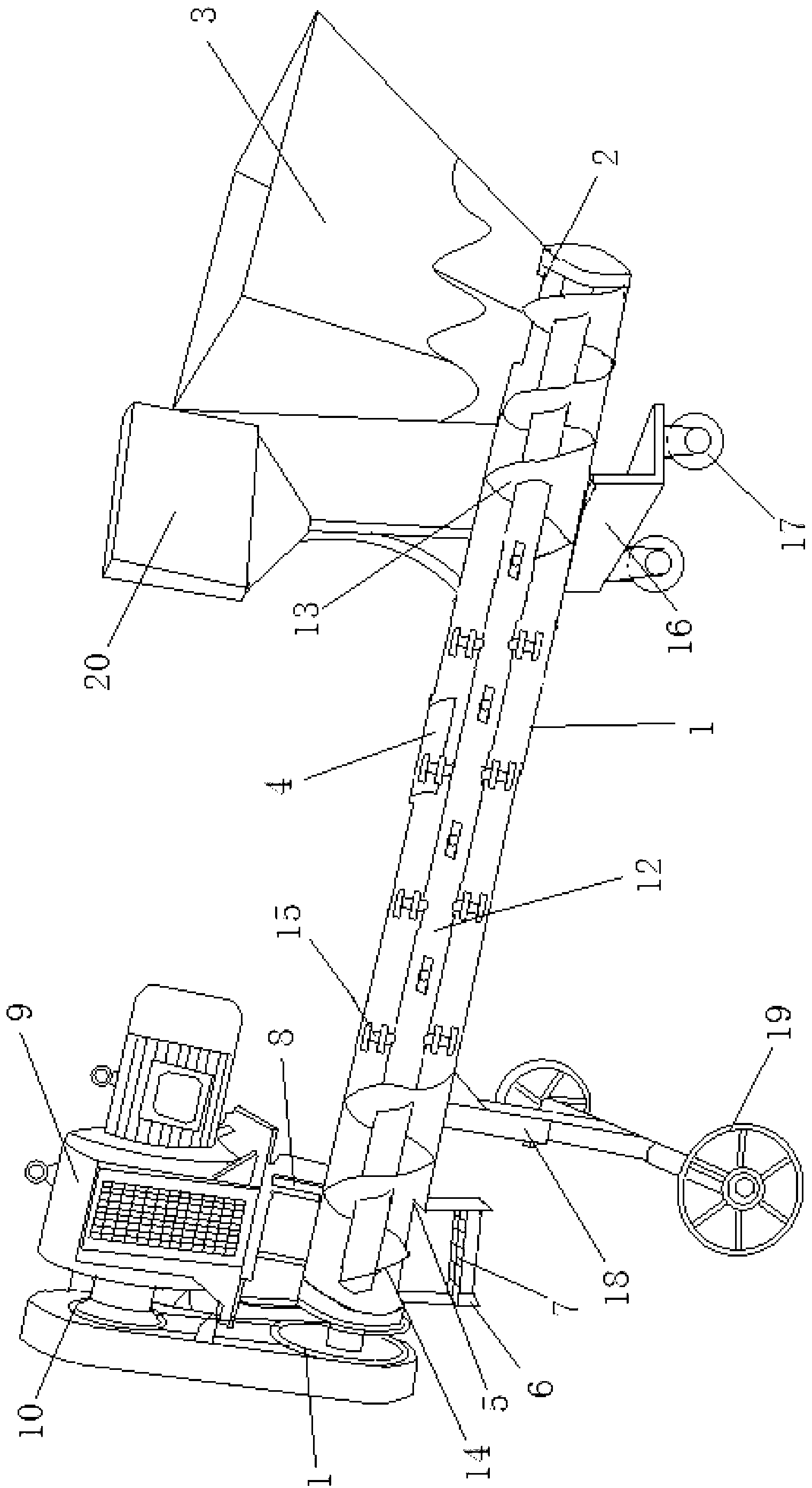

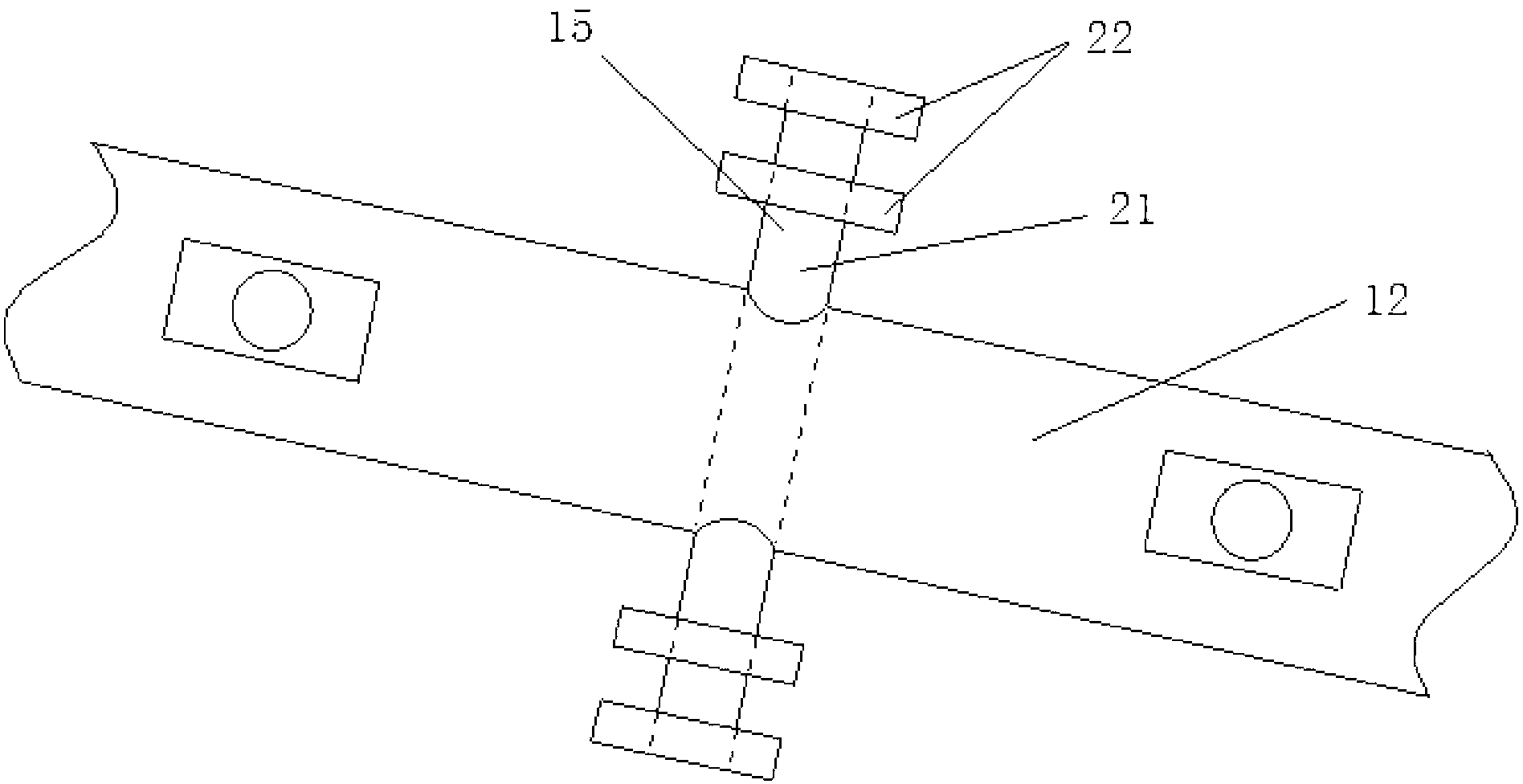

[0014] Such as figure 1 As shown, the present invention includes a crushing drum 1 arranged obliquely. The front end of the crushing drum 1 is short, and an upwardly opened feed port 2 is provided. The outer periphery of the feed port 2 is welded with a conical feed hopper 3, and the middle top of the crushing drum 1 A transparent observation window 4 is provided on the surface. The end of the crushing drum 1 is high, and the bottom is provided with a discharge port 5 that opens downwards. A rectangular discharge sleeve 6 is welded on the outer periphery of the discharge port 5, and a screen 7 that can be pulled and replaced is arranged in the discharge sleeve 6. A power fixed platform 8 is fixedly connected to the top of the end of the crushing drum 1, and a variable frequency motor speed controller 9 is fixedly connected to the top of the fixed platform 8 by bolts....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com