Patents

Literature

58 results about "Urea formaldehyde foam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Urea-formaldehyde foam insulation (UFFI) dates to the 1930s and made a synthetic insulation with R-values near 5.0 per inch. It is a foam, like shaving cream, that is easily injected or pumped into walls.

Urea-formaldehyde foam plant cultivation substrate and method for preparing the same

ActiveCN101134803ANo residueReasonable content of ingredientsAgriculture gas emission reductionCultivating equipmentsPhosphoric acidUrea formaldehyde foam

The present invention discloses one kind of urea-formaldehyde foam as plant cultivating matrix and its preparation process. The urea-formaldehyde foam as plant cultivating matrix is prepared through the following steps: 1. mixing formaldehyde and urea to produce polycondensation reaction to obtain urea-formaldehyde resin solution; 2. mixing sodium butyl naphthalenesulfonate to obtain foaming liquid; 3. foaming the urea-formaldehyde resin solution with the foaming liquid in a foaming machine to obtain liquid foam; 4. solidifying the liquid foam and drying to operate foamed matrix; and 5. eliminating aldehyde group from the matrix to obtain urea-formaldehyde foam as plant cultivating matrix. The preparation process is simple and low in cost, and the prepared urea-formaldehyde foam as plant cultivating matrix has penetrating porous structure, high hydroscopicity and high soil-less culturing character.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

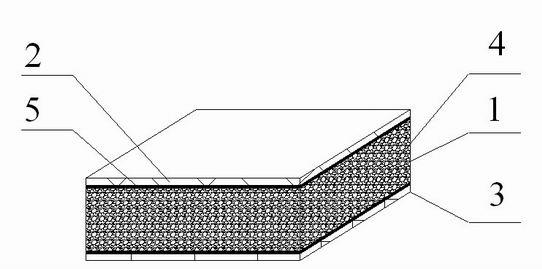

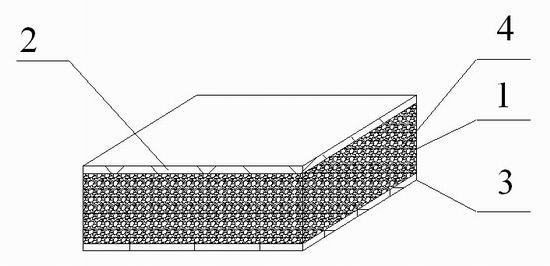

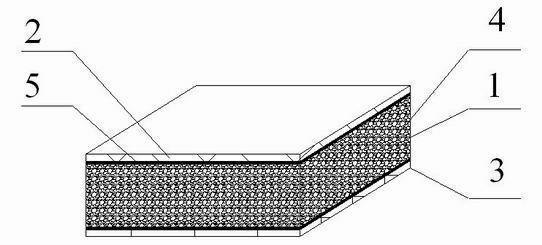

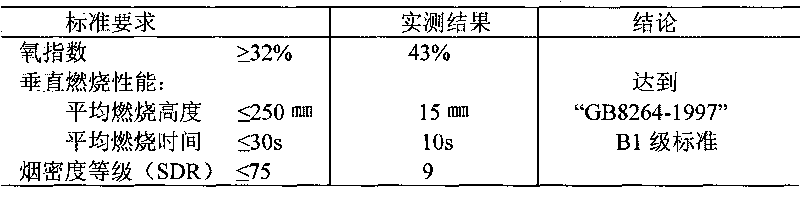

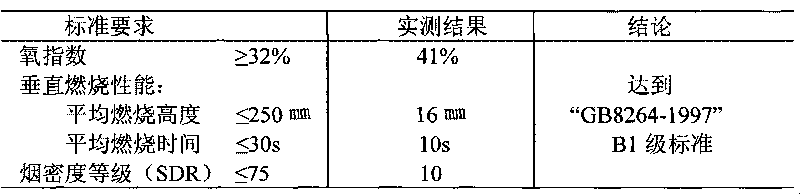

Wood fiber reinforced flame retardant foam composite plate and manufacturing method thereof

InactiveCN102114659AImprove use valueSolve the "Three Rural Issues"Wood working apparatusDomestic articlesAdhesive cementPhenolformaldehyde foam

The invention relates to a wood fiber reinforced flame retardant foam composite plate and a preparation method thereof. The external layer of the composite plate is a wood panel, and the foam core plate in the internal layer is a wood fiber reinforced phenol formaldehyde foam material or a melamine modified formaldehyde foam material. The wood fiber is treated by a coupling agent. The invention further relates to a manufacturing method of the plate. The wood panel is adhered to the external layer panel of the foam core plate. The plate can be manufactured by performing lamination thermal composition on the materials by using an adhesive, and also can be manufactured by directly foaming between fixed dual-layer panels. The foam core plate uses wood fiber reinforced phenol formaldehyde foam or melamine modified formaldehyde foam material. The flame retardant performance can accord with the specified standard. The foam core plate is flame retardant and small in smoke amount, generates no harmful gas, and meets requirement of environmental friendliness, so that the composite plate has excellent sound absorption and heat insulation properties. The fiber reinforced foam base material has an excellent mechanical property.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

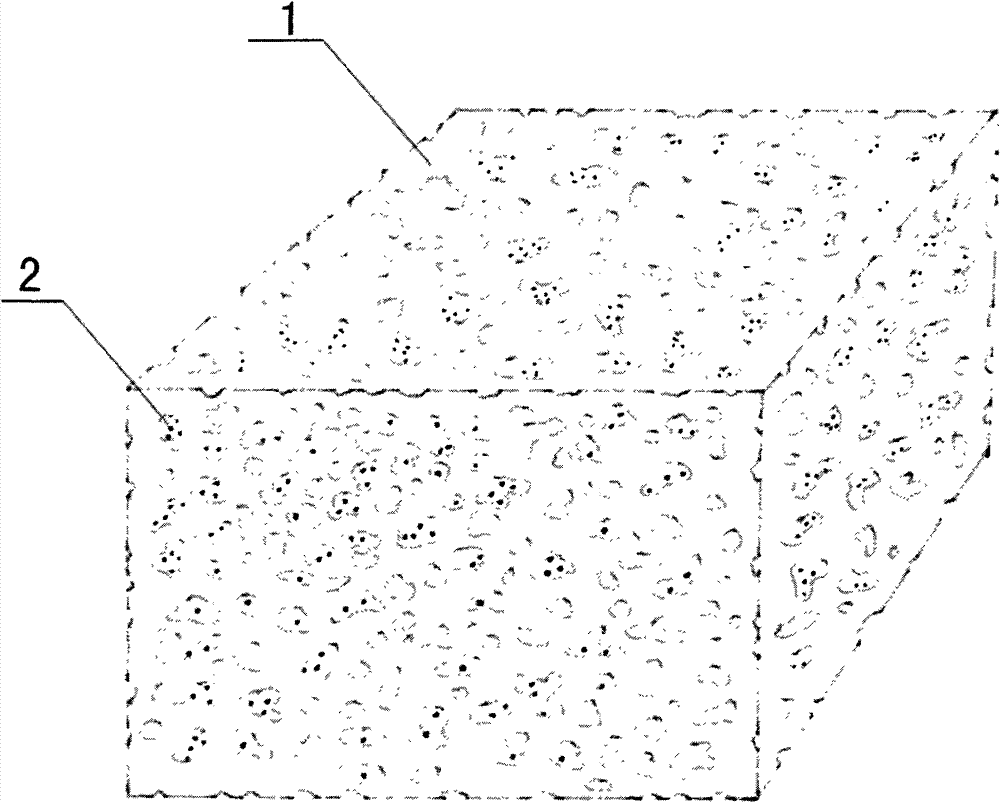

Urea-formaldehyde foam plastic cultivation substrate and preparation method thereof

InactiveCN102726276AModerate surface hardnessAvoid deformationCultivating equipmentsSoilless cultivationSuper absorbentProduct gas

The invention relates to a urea-formaldehyde foam plastic cultivation substrate. The urea-formaldehyde foam plastic cultivation substrate comprises water-absorbing particles and a solid substrate, wherein a large number of gas micropores are uniformly dispersed in and on the surface of the solid substrate, and the water-absorbing particles are fixed on hole walls of the gas micropores or dispersed in gaps of the gas micropores. A preparation method of the urea-formaldehyde foam plastic cultivation substrate comprises the following steps of: performing polycondensation on urea and formaldehydeto obtain a urea-formaldehyde resin solution; preparing a foaming solution; stirring the foaming solution to produce a large amount of foam, then adding the urea-formaldehyde resin solution, continuously stirring, spraying super absorbent resin particles during the volume expansion process of materials, and stirring and foaming continuously for forming a urea-formaldehyde resin foam matter; and curing the urea-formaldehyde resin foam matter in a plastic mold, simultaneously fixing the super absorbent resin particles on the walls of cured foam pores or dispersing in the gaps of the gas micropores, and forming the urea-formaldehyde foam plastic cultivation substrate. The urea-formaldehyde foam plastic cultivation substrate disclosed by the invention has the advantages of simplicity in production and processing, convenience in mounting, easiness in transportation and capability of cutting and forming the shape according to requirements.

Owner:重庆天开园林股份有限公司

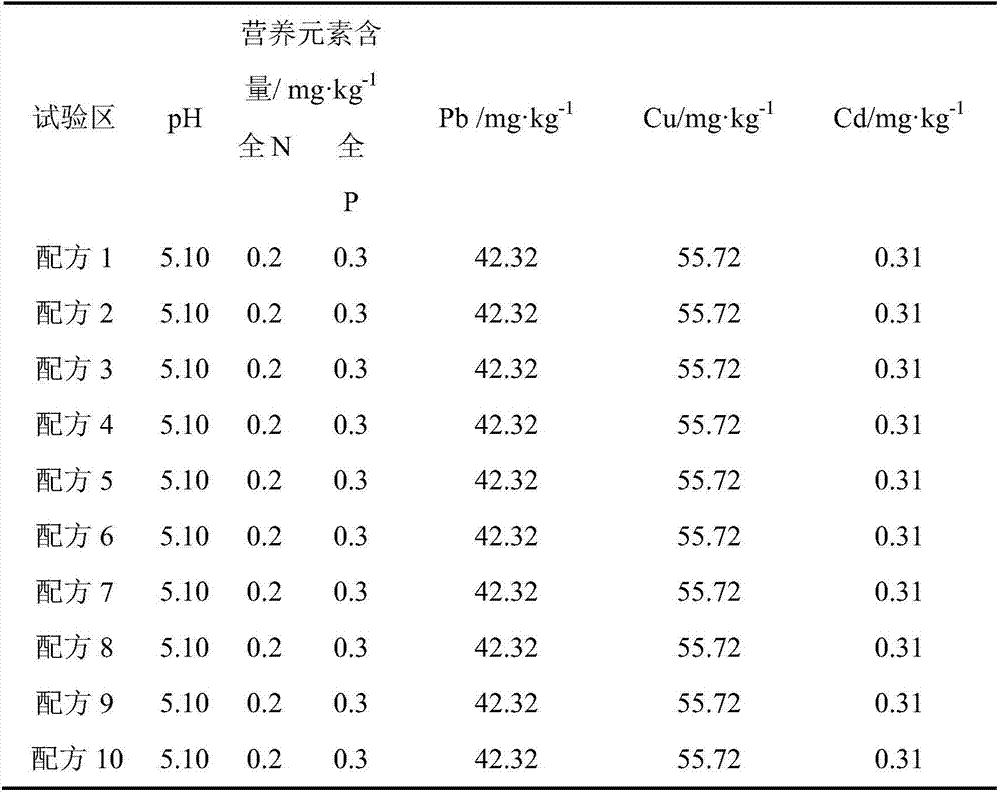

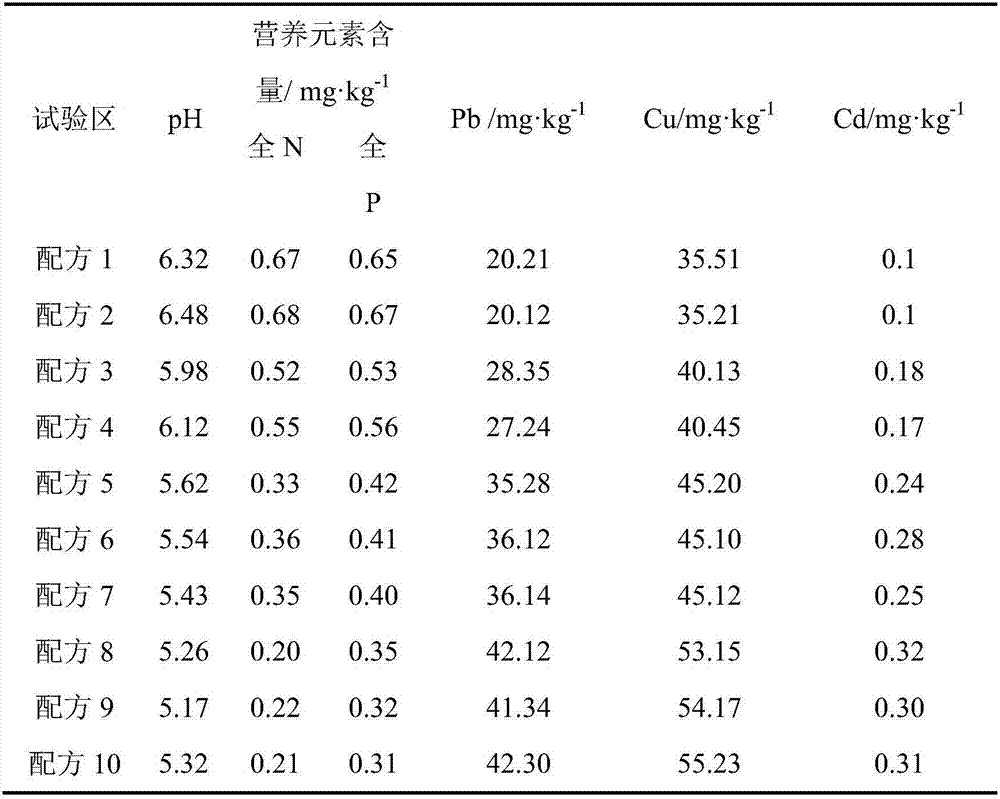

Growth and cultivation matrix used for ecological remediation and preparation method thereof

The invention relates to the field of water and soil conservation, in particular to a growth and cultivation matrix used for the ecological remediation and a preparation method thereof. Every 1500kg of matrix comprises 30-40kg of urea formaldehyde foam particle, 60-70kg of peat soil, 20kg of organic matter, 0.5-1kg of probiotics powder, 5-10g of water-retaining agent, 5-10g of adhesive, 0.5-1g of plant growth conditioning agent and 3.203kg of trace element. The growth and cultivation matrix disclosed by the invention is favorable for remediating, improving and stabilizing bare rock and ecological fragility areas as well as other environment bad for plants to grow, and especially has an obvious remediation action on slopes, elevations and bare rock surfaces bad for the plants to grow. Meanwhile, the growth and cultivation matrix is favorable for a remediated surface to quickly form a self-supply microecosystem, and the whole curing condition and cost can be lowered.

Owner:辽宁易发成林生态技术有限公司

Preparation method for degradable urea formaldehyde foam plant culture substrate

The invention relates to a preparation method of a degradable urea formaldehyde foam plant culture substrate. The preparation method comprises the following steps: mixing the components of the plant culture substrate according to a ratio and performing compression molding, wherein the components comprise urea formaldehyde resin, nekal, mixed liquid of phosphoric acid and oxalic acid, resorcinol, plant fibers, borax and glycerol; performing ammonium hydrogen carbonate and polyethylene glycol surface treatment respectively to obtain the degradable urea formaldehyde foam plant culture substrate. According to the preparation method of the degradable urea formaldehyde foam plant culture substrate, the sources of the raw materials are wide; the process is simple; the production is pollution-free; the use is pollution-free; the product is non-toxic and degradable; the product can provide abundant nitrogen sources in a using process and after being damaged; the culture substrate is abundant in the plant fibers, so that the water-absorbing performance and the water retention performance are greatly improved and the culture substrate is good for the growth of plants; the culture substrate is expected to be widely applied in the field of plant culture.

Owner:LINYI TAIER CHEMTECH

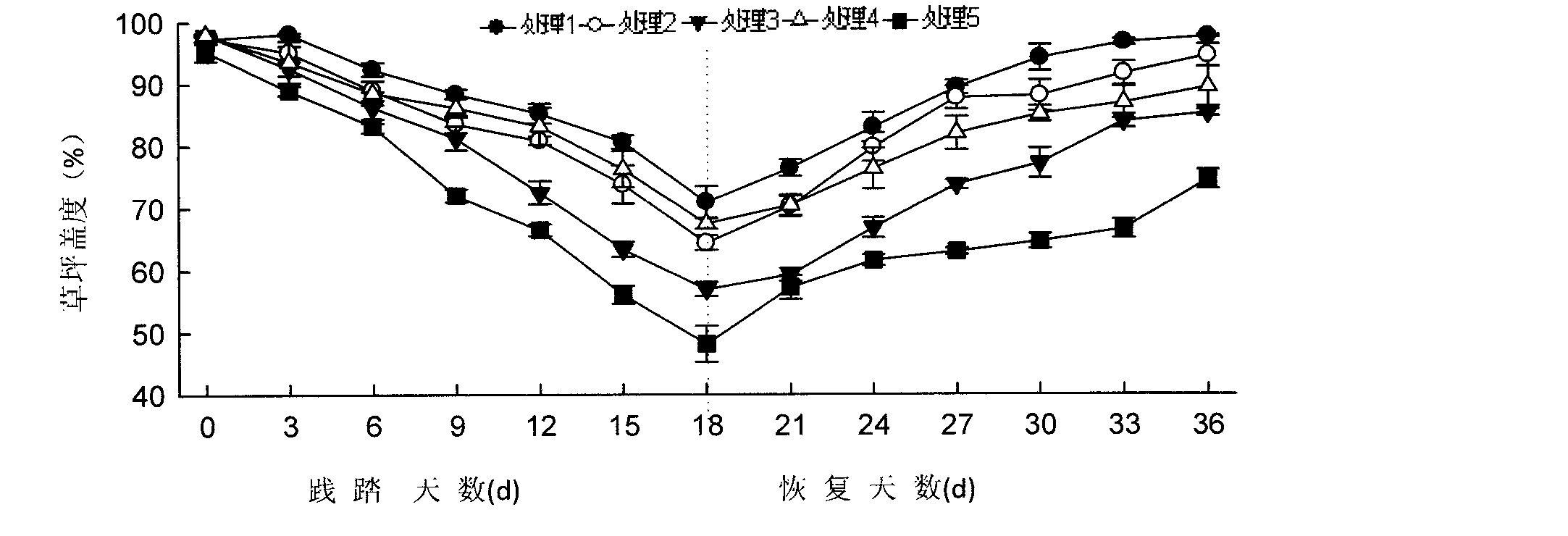

Production method for trampling-resistant soilless lawn matrix

ActiveCN102318483AWide variety of sourcesLow costAgriculture gas emission reductionCultivating equipmentsSludge compostSlag

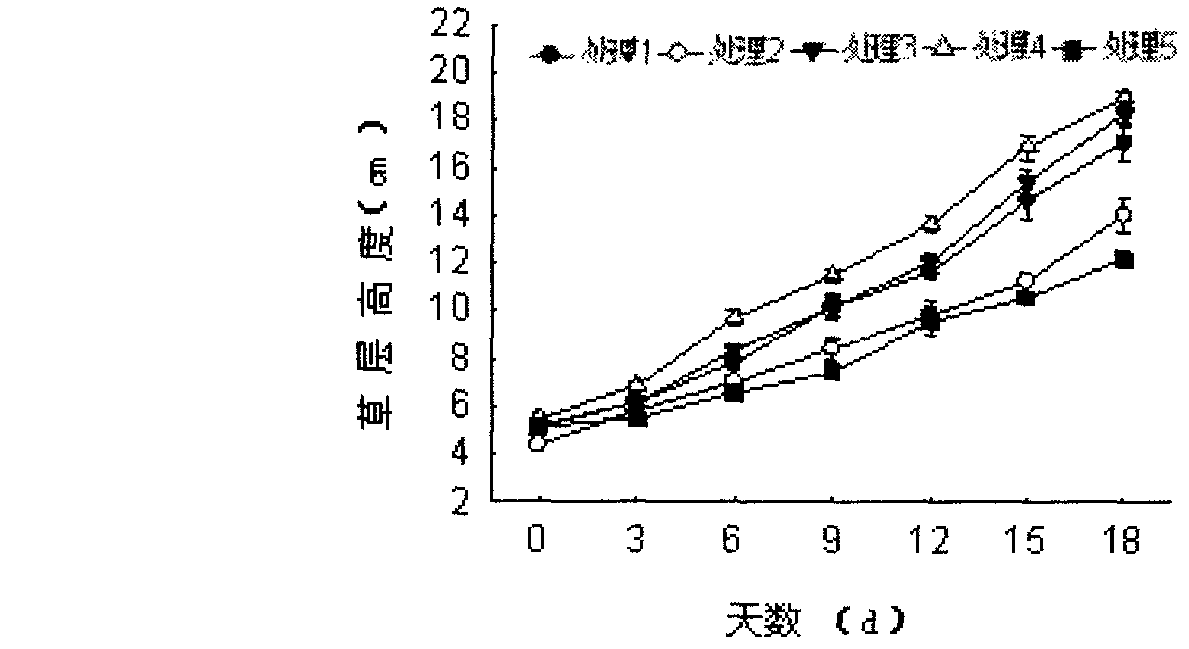

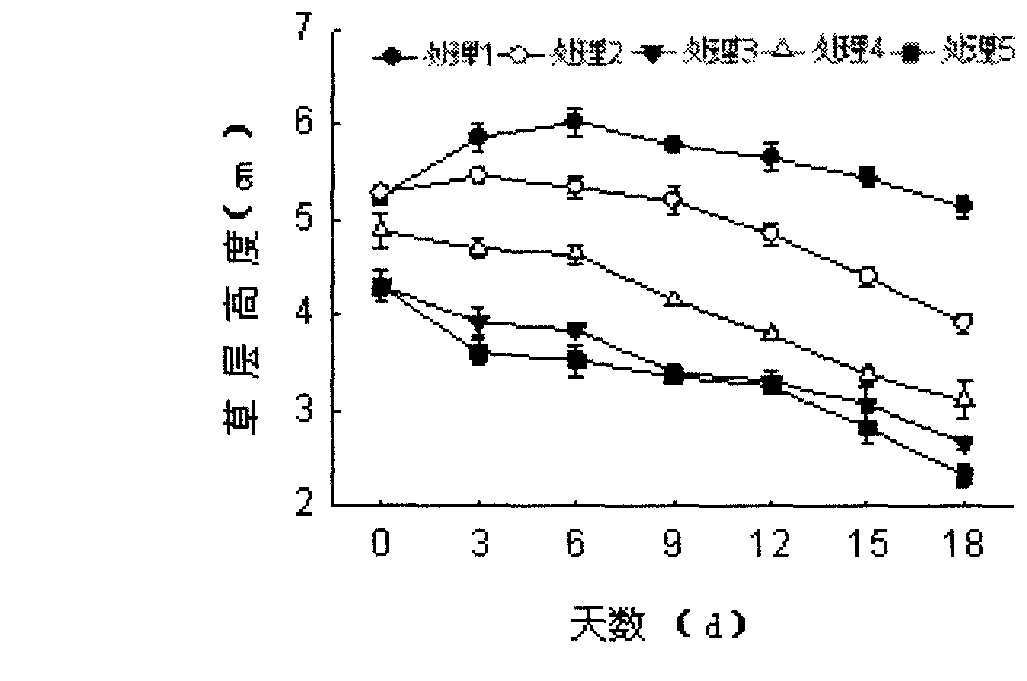

The invention relates to a production method for trampling-resistant soilless lawn matrix. The method comprises the following steps of: (1) selecting cool season lawn grass as seeds; (2) mixing slag and organic sludge compost in a ratio to form a matrix growth layer; (3) mixing mushroom production leftovers, saw dust, straw powder and industrial urea formaldehyde foam particles in a ratio to form an elastic material layer; (4) spreading a plastic mulching film serving as an isolation layer on the ground, and spreading a polypropylene fiber sunshade net serving as a turf bottom layer on the isolation layer; (5) sequentially spreading the matrix growth layer and the elastic material layer on the turf bottom layer; (6) sowing meadow grass and perennial ryegrass on the elastic material layer to form a seed layer, and covering and lightly pressing the seed layer by using a special non-woven fabric after sowing to form a bud protection layer so as to finish constructing a lawn bed; (7) controlling the growth environment of the lawn bed of the lawn; and (8) after the lawn is formed, performing trampling treatment by adopting an artificial trampling method. The trampling-resistant soilless lawn matrix has the characteristics of good recovery growth performance after the lawn is trampled, low cost and good water holding property.

Owner:LANZHOU UNIVERSITY

Urea-resin foaming thermal-insulating composite powder, the synthetic board therewith and method

A urea resin formaldehyde thermal-insulating composite powder and its production are disclosed. The composite powder consists of urea formaldehyde plastic 60-90 proportion, cellulosine or straw powder 5-20 proportion, fibrous glass 0.5-6 proportion, asbestos 1-8 proportion, gypsum 1-8 proportion, silicate 0.1-1.5 proportion and glycerin 0.5-3 proportion. It has excellent strength, fire-retardant and insulating performances. It can be used to substitute plastics, ceramics, cast iron and glass fiber reinforced plastics to produce pipes, flanged disk, valve and pump.

Owner:刘兴国

Urea formaldehyde foam matrix for cultivating cold-season turfgrass and preparation method thereof

InactiveCN101798437AThe method of establishment is simple and convenientImprove water absorption and retention capacityAgriculture gas emission reductionCultivating equipmentsCold seasonPhosphate

The invention discloses a urea formaldehyde foam matrix for cultivating cold-season turfgrass and a preparation method thereof. The method comprises the following steps that: (1) formaldehyde and urea are mixed to carry out polycondensation reaction, and urea-formaldehyde resin solution is prepared; (2) butyl naphthalene sulfonate, phosphate and water are mixed, and blister fluid is prepared; (3) the blister fluid and the urea-formaldehyde resin solution are foamed in a foaming machine, and liquid foam is prepared; (4) the liquid foam is cured and dried, and a foam matrix is prepared; and (5) aldehyde removal agent, hydrophilizing agent and potassium are dissolved into the water to prepare a mixture, the mixture is sprayed on the surface of the foam matrix and dried, and the urea formaldehyde foam matrix for cultivating cold-season turfgrass is prepared. The matrix is characterized in that water absorption and preservation properties are good, and releasing nitrogen nutrient and nutrition elements required by the growth of other turf are contained. When being used to turf establishment, the matrix not only can be used for turf production on a cultivated land and then paved on other lands, but also can be directly used for turf establishment, and has significant economic, social and ecological benefits.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

Heat insulation decoration integrated brick and method of manufacture

The invention relates to a building material and a method for manufacturing the same, in particular to a building material with the functions of heat insulation and decoration. The building material is divided into two parts of a heat-insulating layer and a protective decorative layer, wherein, the heat-insulating layer selects one type among heat-insulating materials such as polystyrene plastics, plastic extruding polystyrene, phenolic aldehyde foam, urea formaldehyde foam, grease recovery all-water-blown urethane foam, foam glass and so on, and the decorative layer is formed by mechanical mixing of one type or a plurality of types among fluoroacrylate emulsion, fluorosilicate emulsion, polyvinylidene chloride emulsion, silicone-acrylate emulsion, pure-acrylic emulsion, styrene-acrylic emulsion and unsaturated resin, one type or a plurality of types among materials such as natural colored stone dust, sandstone dust, light calcium carbonate, quartz sand and so on, and raw materials such as auxiliary agent and so on. The building material has simple manufacturing and construction techniques, short construction period, high efficiency, good heat insulation effect, beautiful appearance and durability.

Owner:王晓东

Multifunctional ecological soil conditioner

InactiveCN107129807AStrong ion exchange performanceFacilitated releaseAgriculture tools and machinesOther chemical processesEcological environmentMoisture

The invention discloses a multifunctional ecological soil conditioner. The soil conditioner comprises urea-formaldehyde foam containing organic matters, biochar, humic acid, wood vinegar, imidazole modified tapioca starch and azotobacter. The multifunctional ecological soil conditioner simultaneously has the multiple conditioning effects of stabilizing heavy metals, preserving moisture and fertility, realizing slow release and long-time action of nutrients, increasing the fertilizer utilization ratio, improving the soil structure and micro-ecological environment and the like, and can adapt to conditioning and restoration of various polluted soils.

Owner:HUNAN XISI ECOLOGY TECH

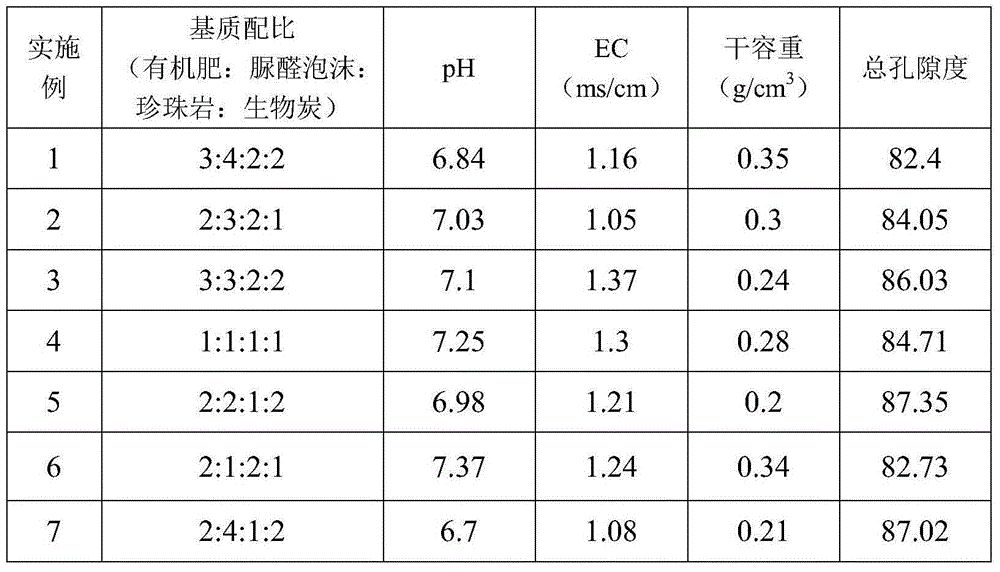

Wall body greening composite culture substrate and preparation method thereof

ActiveCN103098688AStrong water absorptionImprove water retentionCultivating equipmentsSoilless cultivationUrea formaldehyde foamEcology

The invention relates to plant culture substrates, and discloses a wall body greening composite culture substrate and a preparation method thereof. The culture substrate comprises moss, urea formaldehyde foam, vermiculite and perlite, wherein the volume ratio of the moss, the urea formaldehyde foam, the vermiculite and the perlite is 1-4:1-4:1-2:1-2. The preparation method comprises treating the perlite in an expansion mode to obtain granular perlite, cleaning and drying the moss and the granular perlit, and evenly mixing the moss, the granular perlit, the urea formaldehyde foam with the vermiculite to obtain the wall body greening composite culture substrate. According to the wall body greening composite culture substrate and the preparation method of the wall body greening composite culture substrate, the wall body greening composite culture substrate has the advantages of being simple in preparation, light in weight, strong in water retaining capacity, good in breathability and the like, and can reduce load of a wall body when being used for the wall body. Meanwhile, components are wide in sources and low in price, and cost of the prepared culture substrate can be reduced. The preparation of the wall body greening composite culture substrate is simple in process and convenient to operate.

Owner:SHENZHEN TECHAND ECOLOGY & ENVIRONMENT CO LTD

Continuous manufacturing method of steel mesh/phenol-urea-formaldehyde foam thermal insulating decoration board

InactiveCN101725229AImprove efficiencyShort curing cycleCovering/liningsFlat articlesSocial benefitsFoaming agent

The invention relates to a continuous manufacturing method of steel mesh / phenol-urea-formaldehyde foam thermal insulating decoration board. In the method, 7 raw materials: phenol-urea-formaldehyde resin, firming agent, surface active agent, foaming agent, stuffing, accessory ingredient and steel mesh are provided, a steel mesh flattening and positioning device is additionally provided.Through the optimization design of the steel mesh flattening and positioning device and phenol-urea-formaldehyde resin foaming and surface course compound technology, the continuously produced steel mesh / phenol-urea-formaldehyde foam thermal insulating decoration board is applied to outer wall for heat preservation and can meet national requirements on heat insulation and fire prevention, features high production efficiency, low construction and installation cost, short construction period, wide market and obvious economic and social benefits.

Owner:刘威

Plant cultivation substrate

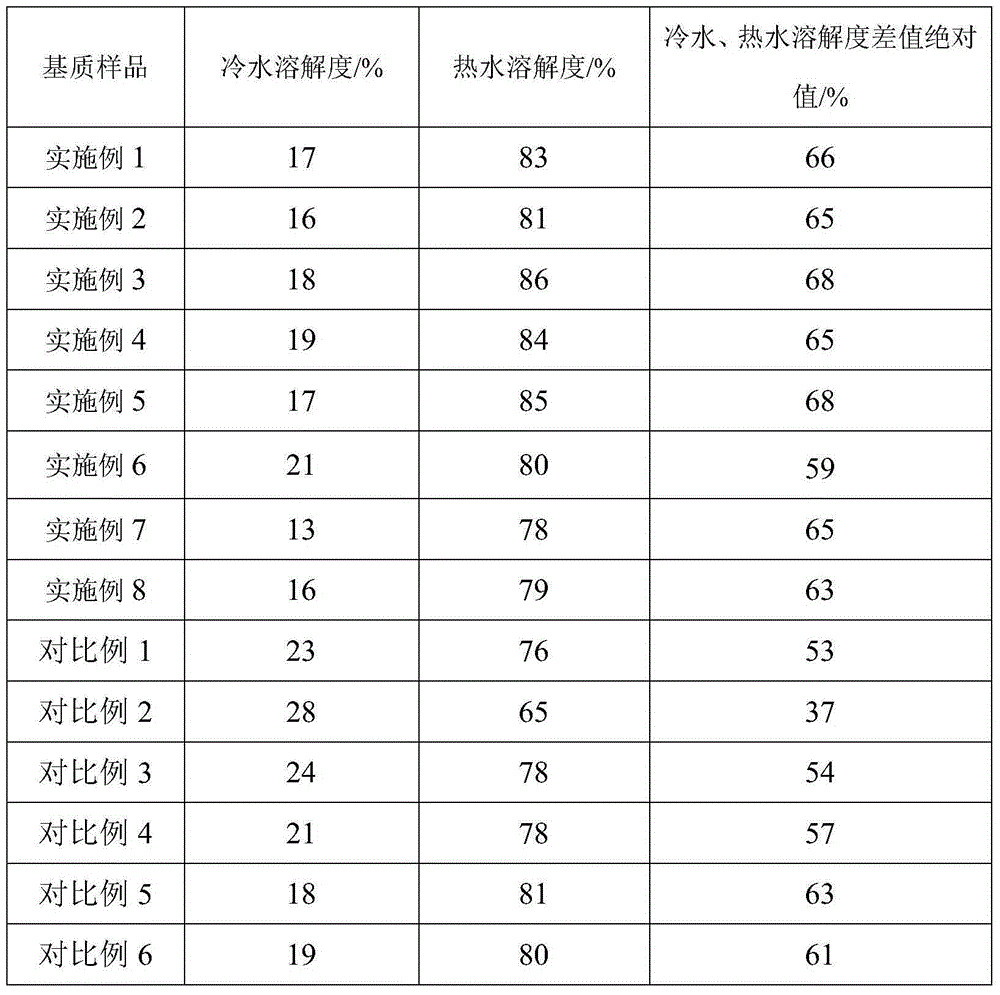

InactiveCN105036955ANutrient slow-release long-actingBio-organic fraction processingOrganic fertiliser preparationPotassiumOxygen

The invention discloses a plant cultivation substrate for the problem that a commonly-used cultivation substrate is insufficient in nutrient and needs to be additionally added with nutrients. The plant cultivation substrate comprises organic fertilizer, urea formaldehyde foam, biochar and perlite, and the organic fertilizer is prepared by performing aerobic fermentation on plant waste. The substrate is rich in slow-releasing and long-acting nutrients such as organic matter, humic acid, nitrogen, phosphorus, sulphur, potassium and zinc.

Owner:深圳风会云合生态环境有限公司

Light aggregate for composite thermal-insulation and fire-prevention wall material, and production method thereof

InactiveCN102807337ARealize comprehensive utilizationLight weightSolid waste managementBrickChipseal

The invention provides a light aggregate for a composite thermal-insulation and fire-prevention wall material, and a production method thereof, and relates to a light aggregate for preparing wall materials, and a production method thereof. A purpose of the present invention is to solve problems of large weight of the wall material prepared by adopting sand and broken stone as the aggregate, and the like in the prior art. The light aggregate comprises an aggregate core, wherein a middle layer is coated outside the aggregate core, and a shell layer is coated outside the middle layer. The production method comprise: adding cement and fly ash into a reel oscillating machine, adding water in a dropwise manner, and oscillating to form an aggregate core; spraying in the reel oscillating machine while adding a mixed material of cement and urea formaldehyde foam or polyphenyl foam powder to the reel oscillating machine to prepare a middle layer; spraying in the reel oscillating machine while adding a mixed material of cement and ash or carbon powder or polyphenyl foam powder to prepare a shell layer. The light aggregate of the present invention can be used for production of self-thermal insulation concrete, lightweight wall bricks, lightweight thermal insulation partition boards, and other interior wall and exterior wall materials.

Owner:周大伟

Plate containing modified urea formaldehyde foam adhesive, as well as application and preparation method thereof

The invention relates to the field of plates, and specifically relates to a plate containing a modified urea formaldehyde foam adhesive, as well as application and a preparation method thereof. The plate containing the modified urea formaldehyde foam adhesive is prepared from the following raw materials: the modified urea formaldehyde foam adhesive and a powdery inorganic material carrier, wherein the inorganic material carrier comprises any one of perlite, vermiculite, gypsum, wollastonite, kieselguhr and cinerite; the modified urea formaldehyde foam adhesive is prepared from the following raw materials in parts by weight: 500-700 parts of formaldehyde, 200-350 parts of urea, 10-20 parts of melamine and 2-4.5 parts of hexamine. Compared with the prior art, the plate containing the modified urea formaldehyde foam adhesive has the advantages that the content of formaldehyde in the foam adhesive is reduced and carcinogenic harm and environmental pollution are avoided.

Owner:中建投(沈阳)易筑节能房屋科技有限公司

Method for preparing urea formaldehyde foam powder for plant culture medium through one-step method

InactiveCN104725647ANo pollution in the processEasy to joinCultivating equipmentsSoilless cultivationFORMALDEHYDE SOLUTIONPollution

The invention discloses a method for preparing urea formaldehyde foam powder for a plant culture medium through a one-step method and relates to a preparation method of plant cultivated culture medium. The urea formaldehyde foam powder for the plant culture medium is prepared by the following steps: preparing urea, a formaldehyde solution or paraformaldehyde solution into a mixed solution according to a proportion, adding a foaming agent and a curing agent, mixing uniformly, continuously stirring in the foaming process, and drying to obtain the urea formaldehyde foam powder after the urea formaldehyde resin forms a dispersed wet urea formaldehyde foam granule. The obtained powder is pollution-free, toxin-free and degradable, can be directly mixed with soil and can provide a rich nitrogen source for the plant; because the specific surface area of the foam is large and the water-absorption and water-retention properties are strong, the nutrient contents for each plant can be added so that the urea formaldehyde foam powder is very suitable for being used as a plant cultivated culture medium material in the agricultural field. The urea formaldehyde resin foam prepared by taking the urea-formaldehyde as the raw material through the one-step method can be widely used in the plant cultivation field.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Novel light, flame-proof, thermal insulation foam shuttering granular material and method for producing the same

InactiveCN101508822AStrong mixing affinityImprove flame retardant performanceCelluloseThermal insulation

The invention relates to a novel light flame-retardant insulating foam shuttering particle material and a preparation method thereof. The light flame-retardant insulating foam shuttering particle material comprises the components as follows: 70-85 weight portions of urea formaldehyde foam plastic, 10-20 weight portions of cellulose solution with the concentration of 15-25 percent and 5-10 weight portions of urea formaldehyde resin adhesive solution with the concentration of 30-50 percent. A layer of hard casing can be formed on the surface of foam, so that the light flame-retardant insulating foam shuttering particle material has the characteristics of light weight, high flame-retardant performance, high heat-resistance temperature of about 215 DEG C to 230 DEG C, good heat preservation and insulation performance, high compressive strength, environmental protection, good size stability, low heat conductivity coefficient, good water resistance and waterproofness and in particular the strong mixing affinity with cement. The light flame-retardant insulating foam shuttering particle material is the core master batch of heat insulation material in the building material field and various fields.

Owner:刘兴国

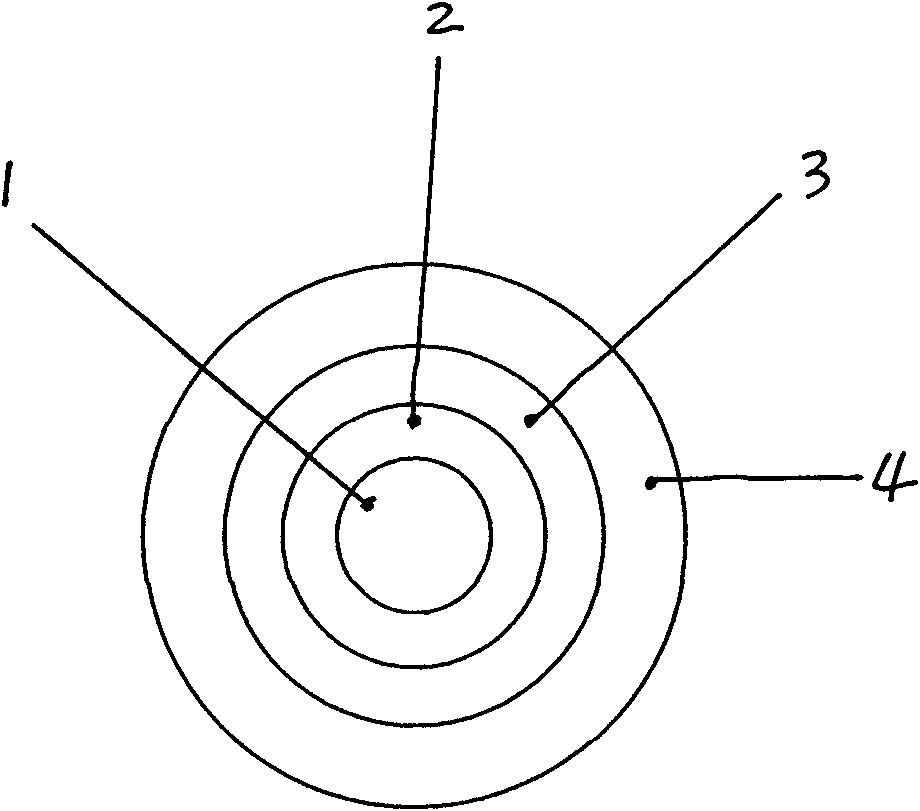

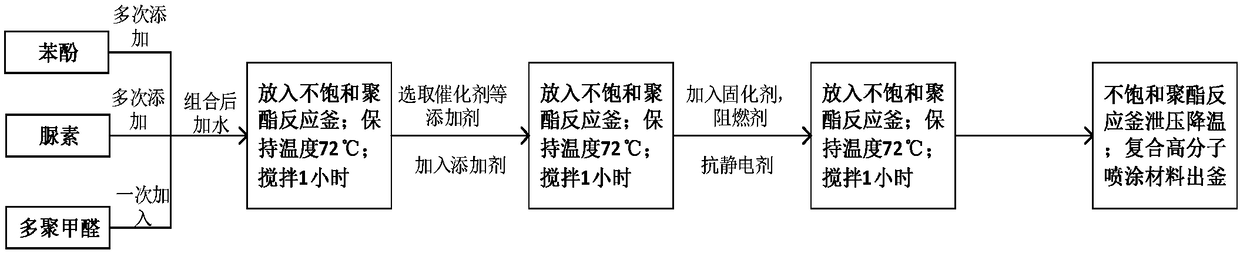

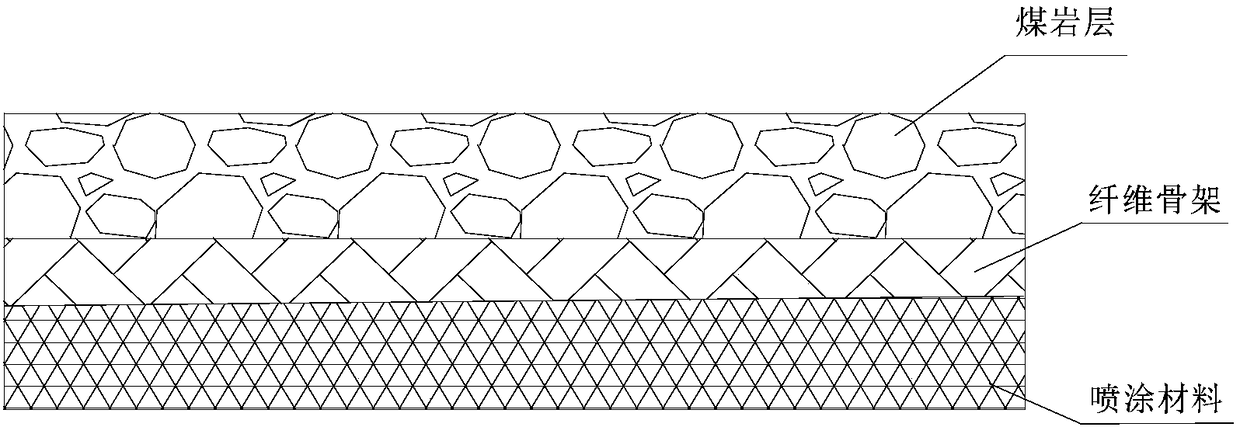

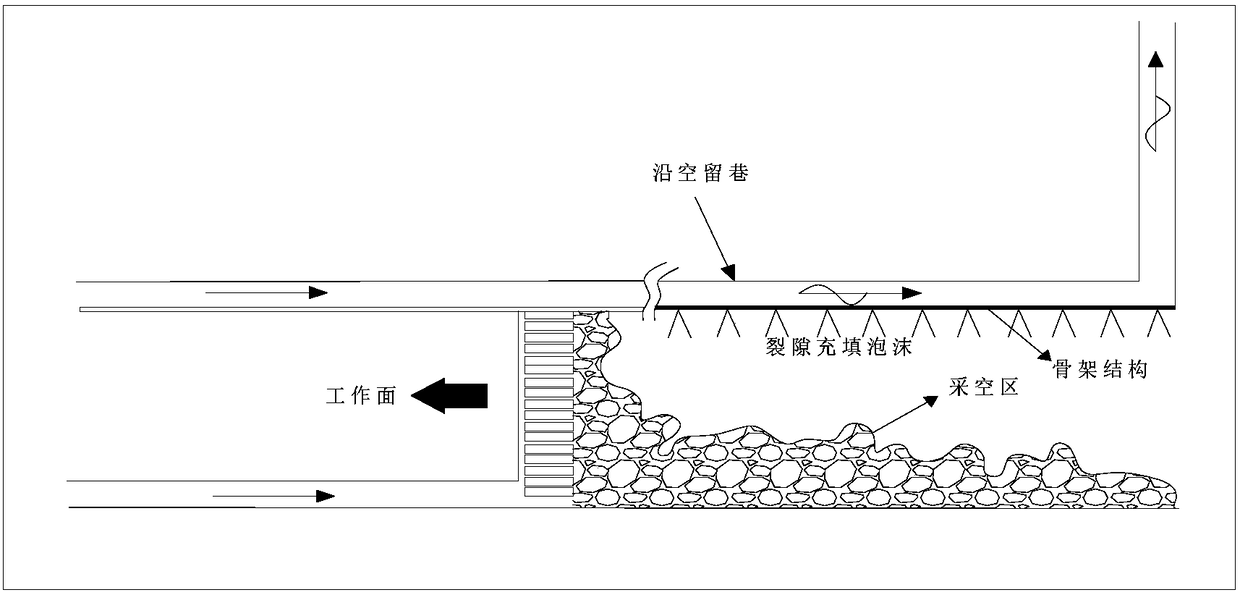

Composite spraying material and frame for downhole quick leaking stoppage and filling and implementing method thereof

InactiveCN108129943AImprove applicabilityImprove extraction efficiencyFireproof paintsProductsFoaming agentKevlar

The invention discloses a composite spraying material and frame for downhole quick leaking stoppage and filling and an implementing method thereof, and belongs to the composite spraying material and the sealing frame, and the implementing method thereof. A set reasonable proportion of phenolic foam, polyurethane foam and urea formaldehyde foam is selected, a base material of the spraying materialis synthesized, a proper flame retardant is added, and the properties of the base material are increased; an antistatic material, a catalyst, a curing agent, a surfactant, a foaming agent and other materials are added, and the flame-retardant and anti-static composite macromolecular spraying material is formed through specific technological process. Fiber-Kevlar is selected as a raw material to form the sealing frame and is used as a carrier of the spraying material, the structure deformation is flexible, and a whole for quick sealing and leaking stoppage is formed jointly. Through different embodiments, the composite spraying material is verified to have the characteristics of light mass, fast forming, strong sealing and good fire prevention and leaking stoppage effects, can effectively prevent downhole air leakage and harmful gas gushing and ensures the safety of workers.

Owner:CHINA UNIV OF MINING & TECH

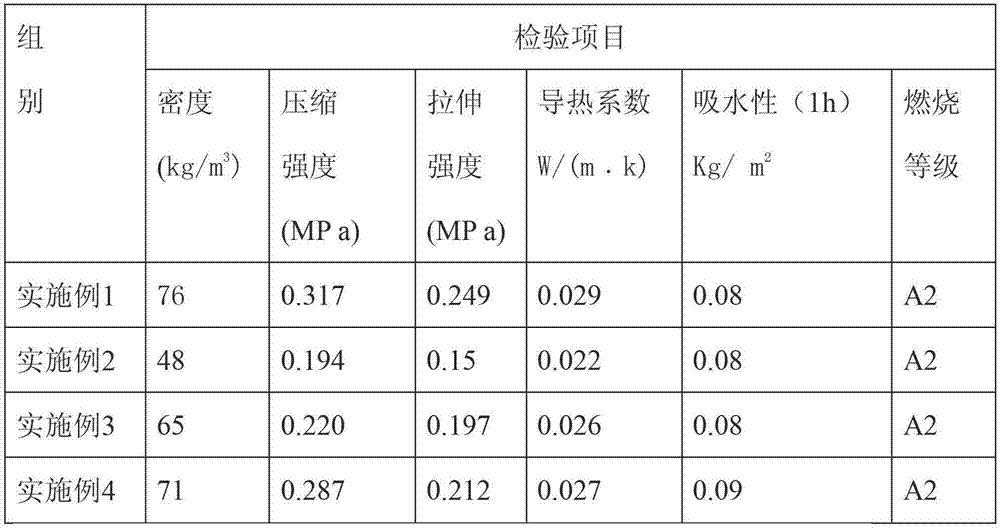

Urea-formaldehyde foam plastic insulation board and preparation method thereof

The invention relates to a urea-formaldehyde foam plastic insulation board, which is prepared from the following components in the ratio of parts by weight of urea resin to sodium dodecyl sulfate to phosphoric acid urea to mica powder to expanded perlite to water being (600-700) to (5-8) to (8-10) to (3-6) to (50-80) to (50-80) to (200-300). The solid substance in the product disclosed by the invention is even in distribution, and small in product density; light foam can be produced; the mica powder is mixed with the expanded perlite according to the graduation as a product aggregate, so as to form a stable volume structure; the shrinkage of the size of the product is reduced; meanwhile, the distribution of inner stress of the product is improved; chapping and bending are avoided; and the problems of bending, chapping and the like in the drying process are also solved. The insulation board disclosed by the invention has the characteristics of low heat-conducting coefficient, good insulating property, and good flame retardant property; and the burning grade is A2 level.

Owner:SHENYANG DEHUI NEW MATERIAL CO LTD

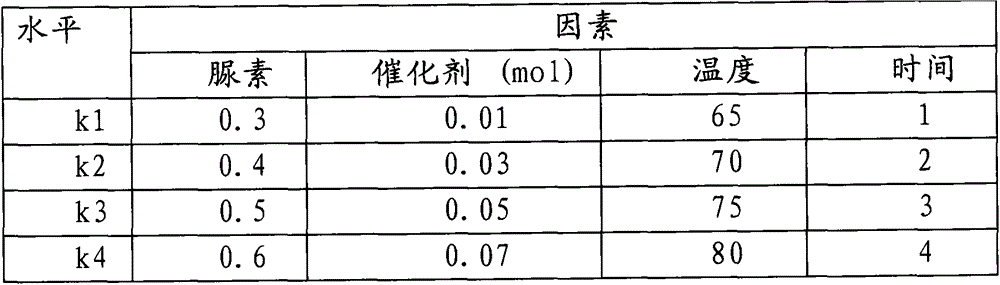

Inorganic composite phenol modified urea formaldehyde resin foam and preparation method thereof

The invention provides inorganic composite phenol modified urea formaldehyde resin foam and a preparation method thereof. The preparation method of the inorganic composite phenol modified urea formaldehyde resin foam comprises the following steps of: foaming and forming inorganic filler and phenol modified urea formaldehyde resin to obtain the inorganic composite phenol modified urea formaldehyde resin foam, wherein the weight-part ratio of the inorganic filler to the phenol modified urea formaldehyde resin is (0.1-0.5):1. According to the inorganic composite phenol modified urea formaldehyde resin foam material provided by the invention, the flame retardance is remarkably improved to the A2 level while guaranteeing the light weight and low heat conduction of the urea formaldehyde foam, and the material can be applied to external wall insulation and architectural decoration.

Owner:JIANGSU MEILONG AVIATION COMPONENTS

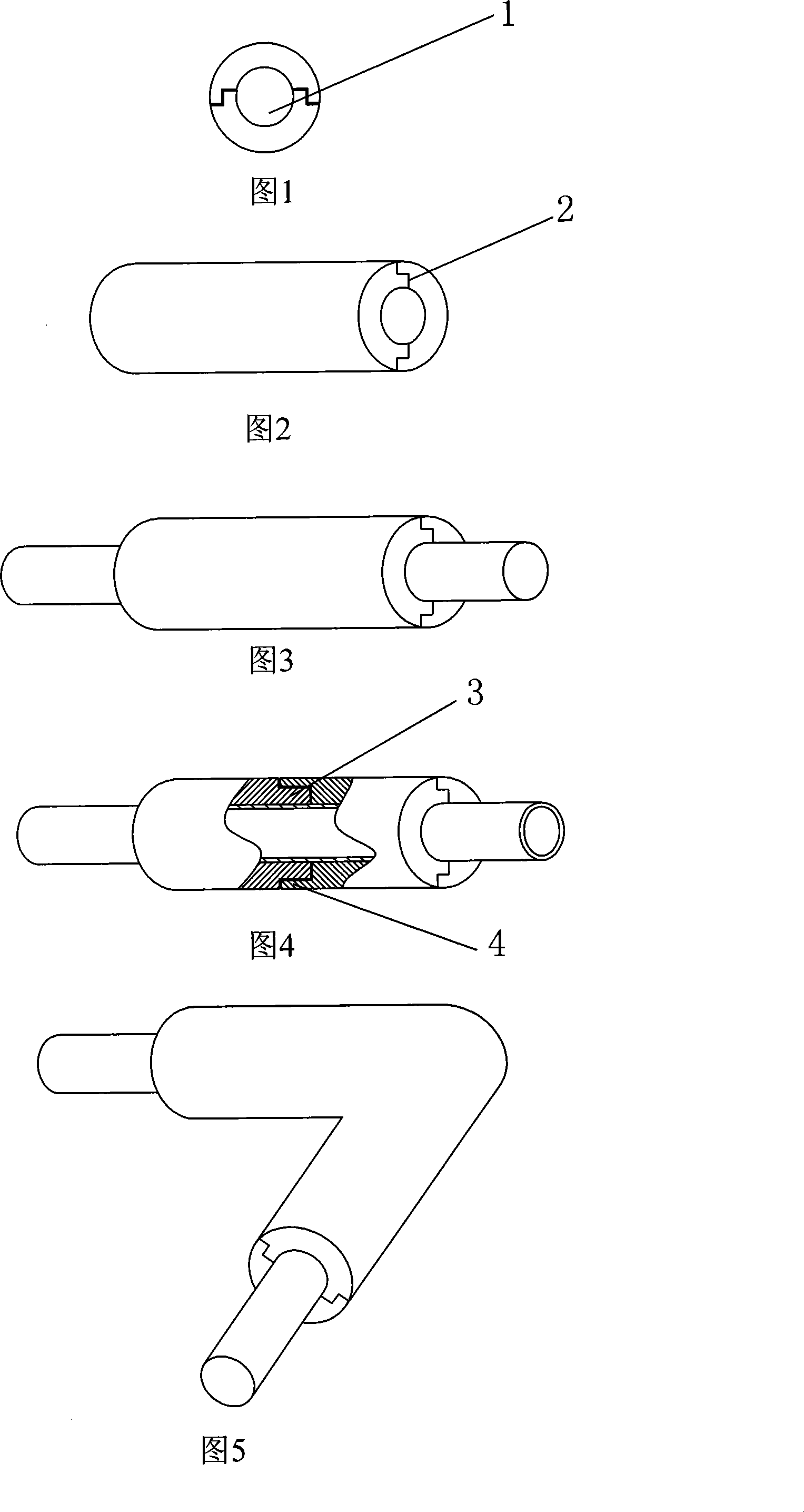

Pipeline thermal insulation tile and preparation method thereof

InactiveCN101235185APrevent or reduce incomingReduce incomingThermal insulationPipe protection by thermal insulationCellulosePolyvinyl alcohol

The invention relates to a pipe insulation tile which is produced by urea-formaldehyde foam powder and a preparation process. The pipe insulation tile is formed by the following components according to the ratio of parts by weight, urea-formaldehyde foam powder: polyvinyl alcohol gelatin powder: cellulose ether: waterproofing agent: water =80-120:0.5-2:0.1-0.3:0.2-0.8:5-15. The invention has small thermal conductivity factor, can effectively prevent or reduce heat in the surrounding environment from transmitting into devices, pipes and accessories under constant temperature, reduces cold loss, saves energy, prevents or reduces the temperature of cold dialectic in the devices and pipes under the constant temperature from increasing, and prevents the temperature of outer walls from lowering the temperature of the surrounding environment, and prevents the outer surface condensation of the pipe to damage a cold insulation structure, thereby prolonging the service life of cold insulation devices, and being beneficial for improving working environments. The pipe insulation tile has the advantages of corrosion resistance, anti-aging, excellent heat insulation and sound insulation value, light weight, convenient installation, durable service, long service life, environmental protection and beauty appearance.

Owner:刘兴国

A kind of urea-formaldehyde foam composition and preparation method thereof

InactiveCN102277175APrevent compaction effectAddresses weaknesses that are prone to compactionOrganic fertilisersSoil conditioning compositionsParticulatesUrea formaldehyde foam

The invention discloses a urea-formaldehyde foam composition and a preparation method thereof. The urea-formaldehyde foam composition is mainly formed by mixing urea-formaldehyde foam, peat soil and a wetting agent; the urea-formaldehyde foam is urea-formaldehyde foam particles with a diameter of 0.1 to 1.0 cm. Among them, the mixing volume ratio of peat soil and urea-formaldehyde foam particles is peat soil: urea-formaldehyde foam = 1:0.2~250. In the present invention, when the peat soil is pulverized and ground, the liquid wetting agent is sprayed on the peat soil in the form of a mist, stirred and mixed evenly, and then the peat soil or peat-like humus soil is ground into fine powder and then pulverized into granular urea-formaldehyde The materials of the foam are mixed evenly. When peat soil powder infiltrated with wetting agent and granular foam material are evenly mixed, the synthetic raw material not only has strong water retention, but also eliminates the weakness of the original foam material that is easy to be compacted.

Owner:赵艳丽

Micron hydrogel micro-nano dual channel regulation concentrated fertilizer for fig and preparation method thereof

InactiveCN105294297ARich pore sizeImprove dynamic sustained release performanceFertilizer mixturesMicro nanoPhosphate

The invention belongs to the field of slow release fertilizer, and specifically discloses a micron hydrogel micro-nano dual channel regulation fertilizer for fig. The fertilizer is characterized by comprising the following components by weight: nano chitosan modified attapulgite, fish skin peptone, a thickfruit millettia seed or fruit extract, a the root of Chinese pulsatilla extract, a micron silica active powder, a silica powder, black alum, urea formaldehyde foam, molasses powder, fulvic acid, seaweed powder, sweet potato powder, phosphate citric acid residue and sodium peroxide. The invention employs nano chitosan modified attapulgite and urea formaldehyde foam as the basic coating material; the basic coating material is supplemented with substances in different dimensions, such as micrometer composite hydrogel made from fish skin peptone, and silica powder and black alum, so as to enrich the pore size of the coating material, improve the dynamic release properties and nutrient use efficiency of fertilizer, ensure the regulation of fertilizer efficiency, promote absorption and usage of different nutrition by the fig, enrich the nutrition of fig, and promote efficient cultivation.

Owner:HEFEI YONGSHENG CULTIVATION CO LTD

Mining wind-leaking-stoppage phenol-urea-formaldehyde foam resin, composite foam and preparation method of composite foam

ActiveCN104017150AReduce manufacturing costHigh foaming ratioMaterial fill-upPolyethylene glycolPhenol

The invention provides a mining wind-leaking-stoppage phenol-urea-formaldehyde foam resin, wherein the raw materials of the mining wind-leaking-stoppage phenol-urea-formaldehyde foam resin include phenol, urea and paraformaldehyde, the molar ratio of phenol to urea to paraformaldehyde is 1:0.5:3. The invention further provides a method for preparing the mine wind-leaking-stoppage composite foam by utilizing the phenol-urea-formaldehyde foam resin. Low-cost foam resin is synthesized, a suitable catalytic system is screened, and the foam resin is modified by utilizing polyethylene glycol, glass fiber and nanometer clay, so that the foam material has high foaming times, and the production cost is low; the foam material has good anti-static electricity performance, fire resistance and thermal stability, is adjustable in the foaming speed in a mining filling process and is suitable for long-distance conveyance; in addition, the foam material has relatively high elasticity and compression strength and strong binding power; foam holes are of closed-hole structures which ensures a good wind-leaking stoppage effect; and the composite foam is very suitable for stopping wind leaking underground a coal mine; the problems of self-combustion of coal, methane accumulation and the like can be effectively prevented.

Owner:胡相明

Foam powder insulation wall hollow brick and preparation method thereof

InactiveCN101255036ASimple preparation processNo pollutionSolid waste managementCeramicwareBrickPolyvinyl alcohol

The invention relates to a foam powder insulation wall hollow brick and method for the production thereof. The hollow brick comprises the following components by a weight ratio of cement: urea-formaldehyde foam powder: aggregate: PVA powder: water is 8-25:35-55:40-70:1- 8:0.1-2. The foam powder insulation wall hollow brick has advantages of simple preparation, low production cost, environmental friendliness, non-environment pollution, good compressive strength and good seismic performance. The inventive hollow brick requires no external wall heat insulating engineering in the south owing to the low thermal conductivity and saved energy. The hollow brick is easy-to-get in raw material and suitable for large production.

Owner:刘兴国

Special pipeline heat insulation material for heating system and preparation method thereof

InactiveCN108276676AInsulation material has good flame retardant performanceImprove flame retardant performanceCelluloseAntioxidant

The invention discloses a special pipeline heat insulation material for a heating system. The special pipeline heat insulation material is prepared from the following raw materials in parts by weight:13 to 19 parts of urea-formaldehyde foam plastic powder, 30 to 45 parts of polypropylene resin, 10 to 20 parts of silane grafted polyethylene, 16 to 23 parts of polyether glycol, 7 to 14 parts of modified diatomite, 12 to 18 parts of expanded vitrified microspheres, 3 to 6 parts of cellulose ether, 2 to 4 parts of foaming agent, 1 to 3 parts of ultraviolet absorbent and 1 to 2 parts of antioxidant. The special pipeline heat insulation material for the heating system, disclosed by the invention, has the advantages of good flame-retarding performance, low thermal conductivity coefficient, goodheat insulation performance, high safety performance and low production cost.

Owner:HEBEI JIASHICHENG ENERGY TECH CO LTD

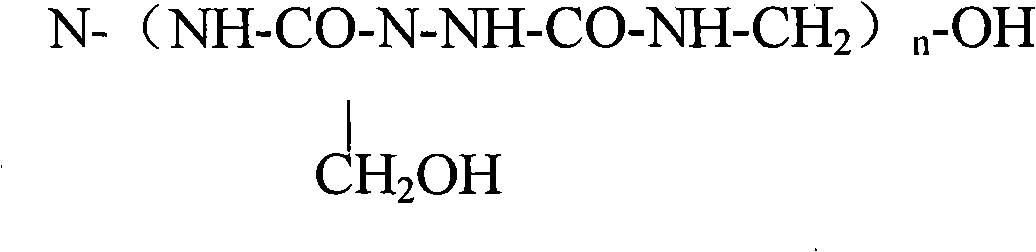

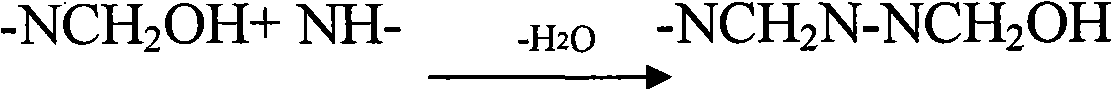

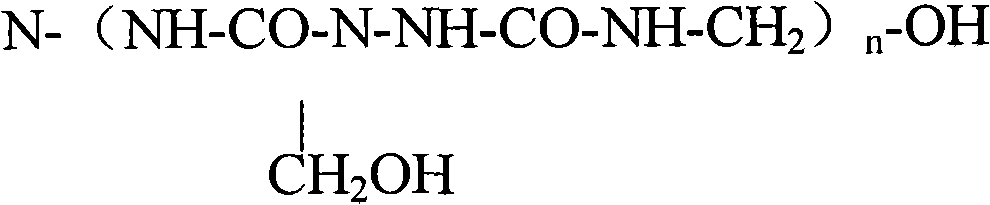

Manufacturing method of urban energy-saving and environmental-friendly cultivation medium

InactiveCN102101933AAvoid burning seedlingsIncrease matrix nutrientsCultivating equipmentsSoilless cultivationElastomerMethyl group

The invention relates to a manufacturing method of an urban energy-saving and environmental-friendly cultivation medium, which comprises the following implementation steps: in the first phase of an addition reaction, urea and formaldehyde are allowed to perform a hydroxymethylation reaction in a medium with a neutral or slightly alkaline pH of 7-8 to obtain monomethylol urea and dimethylol urea; further reaction is performed to obtain trimethylol urea and tetramethylol urea when the molar ratio of formaldehyde and urea (F / U) is higher; in the second phase of a polycondensation reaction, various methylol ureas are allowed to perform condensation in a weak acid condition with a pH of 4-6 to obtain a hydrophilic resin, wherein in the molecular structure, the hydroxymethyl group and the hydrogen connected to the nitrogen have a polycondensation capability; with the progress of the above reaction, the molecular weight increases gradually, and the molecular state becomes more complex, and even a network structure is formed, so the resin becomes an elastomer with a stereo configuration. The invention uses urea formaldehyde foam plastics as a novel plant cultivation medium to substitute soil, is environmental-friendly and can effectively save resources.

Owner:天津市津鸥化肥有限责任公司

Flexible urea-formaldehyde foam and preparation method thereof

The invention relates to a flexible urea-formaldehyde foam and a preparation method thereof, particularly relates to a degradable raw material for seedling culture and cultivation of crops and a preparation method of the degradable raw material. The degradable raw material in the formula comprises the following components: urea-formaldehyde resin, a strongly acid ion exchange resin curing agent, a papermaking black liquid foaming agent and flexibilizer; the preparation method can be realized by adopting the following steps: firstly weighing metered urea-formaldehyde resin solution, adding metered papermaking black liquid to the urea-formaldehyde resin, stirring at a high speed, foaming, adding metered strongly acid ion exchange resin to the mixed liquor, continuously stirring, finally pouring the liquid foam, curing, and then drying to obtain the matrix of the flexible urea-formaldehyde foam. The flexible urea-formaldehyde foam and the preparation method thereof have the advantages as follows: the formula is simple, the obtained urea-formaldehyde foam is high in flexibility and bendable, powdering is avoided, the water-absorbing capacity is great, and high easiness in degradation is achieved, therefore, the flexible urea-formaldehyde foam is very suitable for being used as trays for agricultural seedling culture.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Wall body greening composite culture substrate and preparation method thereof

ActiveCN103098688BStrong water absorptionImprove water retentionCultivating equipmentsSoilless cultivationUrea formaldehyde foamMoss

The invention relates to plant culture substrates, and discloses a wall body greening composite culture substrate and a preparation method thereof. The culture substrate comprises moss, urea formaldehyde foam, vermiculite and perlite, wherein the volume ratio of the moss, the urea formaldehyde foam, the vermiculite and the perlite is 1-4:1-4:1-2:1-2. The preparation method comprises treating the perlite in an expansion mode to obtain granular perlite, cleaning and drying the moss and the granular perlit, and evenly mixing the moss, the granular perlit, the urea formaldehyde foam with the vermiculite to obtain the wall body greening composite culture substrate. According to the wall body greening composite culture substrate and the preparation method of the wall body greening composite culture substrate, the wall body greening composite culture substrate has the advantages of being simple in preparation, light in weight, strong in water retaining capacity, good in breathability and the like, and can reduce load of a wall body when being used for the wall body. Meanwhile, components are wide in sources and low in price, and cost of the prepared culture substrate can be reduced. The preparation of the wall body greening composite culture substrate is simple in process and convenient to operate.

Owner:SHENZHEN TECHAND ECOLOGY & ENVIRONMENT CO LTD

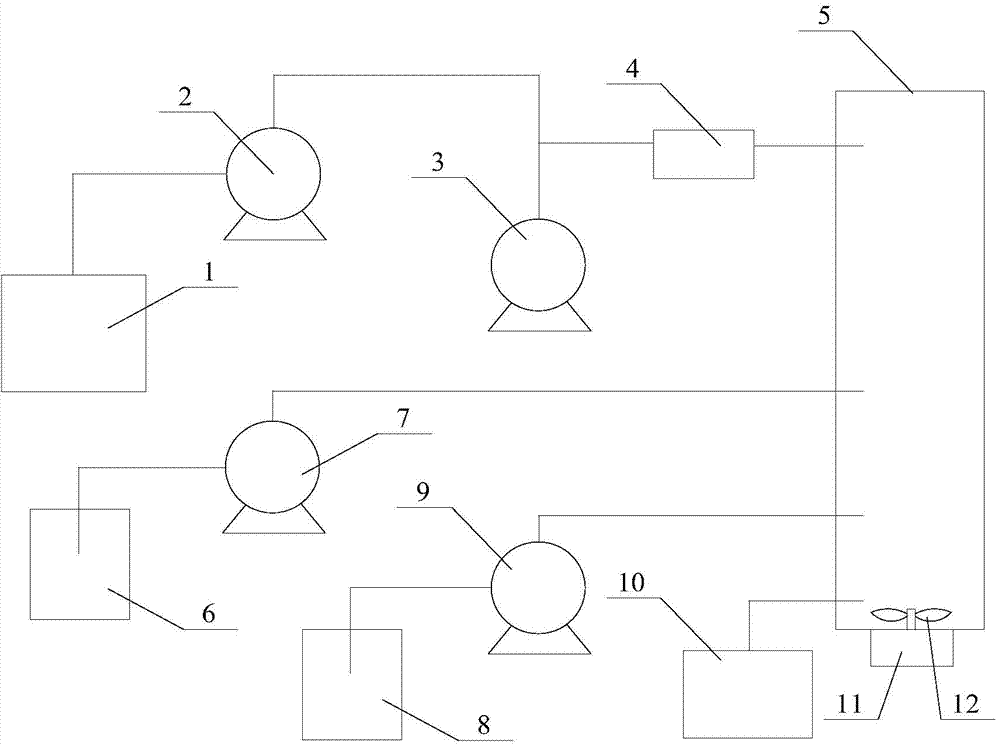

Urea-formaldehyde foamed plastic for heat preservation and insulation and preparation method and apparatus thereof

InactiveCN104725772AGood value for moneyMeet environmental protection requirementsSlurryUrea formaldehyde foam

The invention provides urea-formaldehyde foamed plastic for heat preservation and insulation and a preparation method and a preparation apparatus thereof. The urea-formaldehyde foamed plastic for heat preservation and insulation is composed of the following raw materials in percentage by mass: 40-45% of urea-formaldehyde resin, 46-50% of water, 0.4-0.5% of a surfactant, 2-3% of a curing agent, and the balance of inorganic filler. The preparation method comprises the following steps: diluting urea-formaldehyde resin, and stirring for completely dissolving the urea-formaldehyde resin so as to obtain raw material slurry, wherein the density of the raw material slurry can be arbitrarily adjusted as required; adding the surfactant into the raw material slurry; injecting the raw material slurry in which the surfactant is added into a foaming machine, and injecting the curing agent and inorganic filler into the foaming machine; and uniformly stirring the raw materials injected into the foaming machine so as to obtain a foaming body, and conveying the foaming body to a finished product box to cure and mold. The preparation apparatus comprises a raw material solution pool, a raw material delivery pump, an air pump, the foaming machine, a curing agent solution pool, a curing agent delivery pump, a filler pool, a filler pump, a finished product container, a motor and a stirring head.

Owner:朱琦云

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com