Pipeline thermal insulation tile and preparation method thereof

A technology of pipeline insulation and waterproofing agent, which is applied in the direction of pipeline protection, heat preservation, and pipeline protection through heat insulation. It can solve the problems of mucous membrane hazards in the respiratory system, poor fire resistance of polyurethane, and hazards to the human body, and achieve light weight and heat insulation. Good, good airtight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

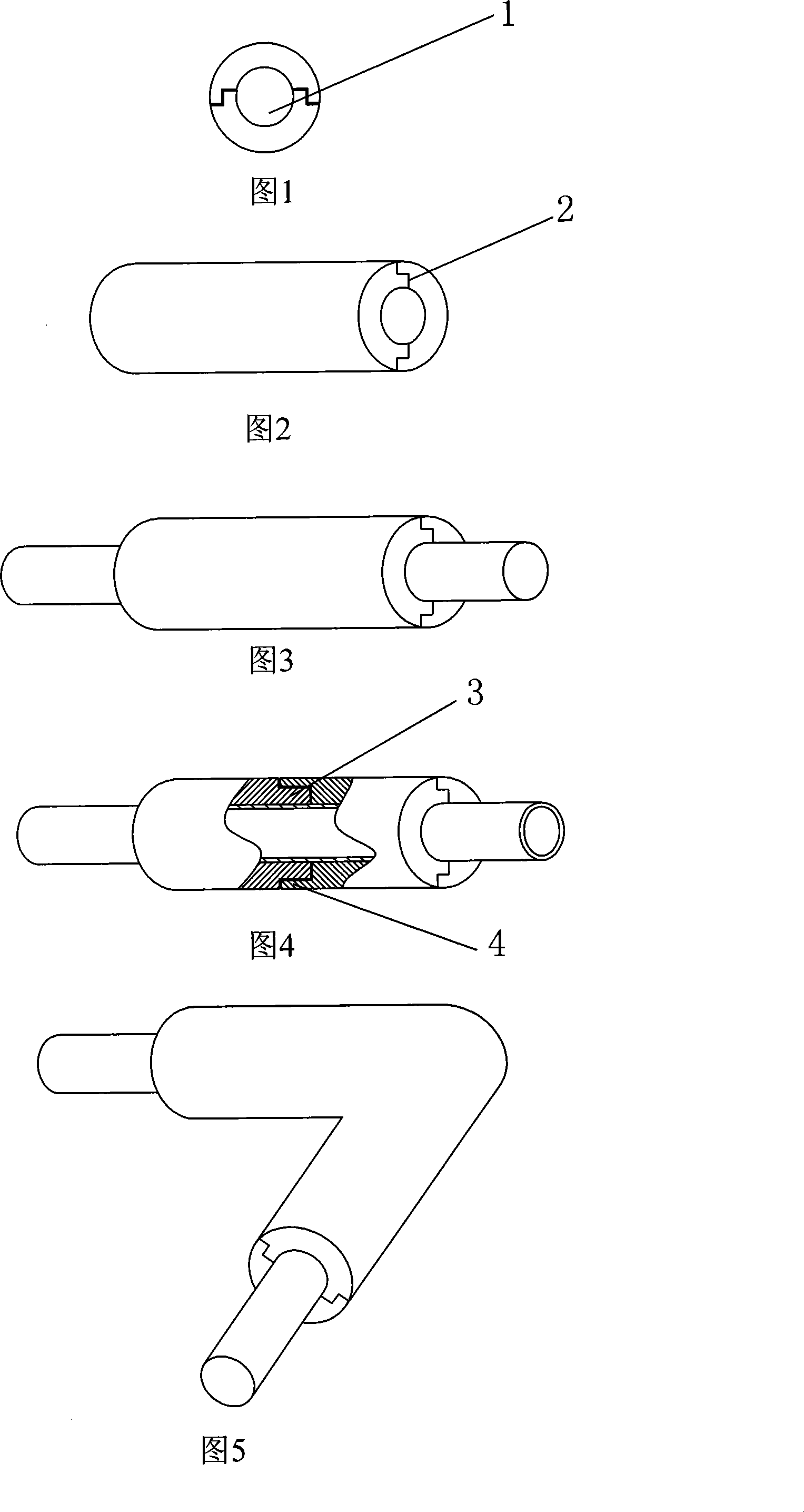

Image

Examples

Embodiment 1

[0030] Pipe insulation tiles are composed of the following components in the following parts by weight:

[0031] 80 parts of urea-formaldehyde foam plastic powder; 2 parts of polyvinyl alcohol rubber powder; 0.3 part of cellulose ether; 0.8 part of waterproofing agent; 15 parts of water.

[0032] The urea-formaldehyde foamed plastic powder is made by crushing a urea-formaldehyde foamed plastic insulation board into 20-100 mesh powder. The preparation method of urea-formaldehyde foam plastic insulation board has been disclosed in the Chinese invention patent whose patent number is 200510046937.3 and publication number is CN1736936. Let's explain in detail:

[0033] The urea-formaldehyde foam insulation board is composed of the following components in the following parts by weight:

[0034] The urea-formaldehyde resin of 50 parts by weight, the sodium lauryl sulfate of 1.5 parts by weight, the phosphoric acid of 0.5 parts by weight, the oxalic acid of 0.5 parts by weight, the ...

Embodiment 2

[0043] Pipe insulation tiles are composed of the following components in the following parts by weight:

[0044] 120 parts of urea-formaldehyde foam plastic powder; 0.5 part of polyvinyl alcohol rubber powder; 0.1 part of cellulose ether; 0.2 part of waterproofing agent;

Embodiment 3

[0046] Pipe insulation tiles are composed of the following components in the following parts by weight:

[0047] 110 parts of urea-formaldehyde foam plastic powder; 1 part of polyvinyl alcohol rubber powder; 0.15 part of cellulose ether; 0.4 part of waterproofing agent; 8 parts of water, and the rest are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com