Patents

Literature

87results about How to "Small size shrinkage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ceramic material with multi-stage duct structure and manufacture method thereof

InactiveCN101885620ALow costMeet environmental protection requirementsSolid waste disposalFurniture waste recoveryMetallurgyDecomposition

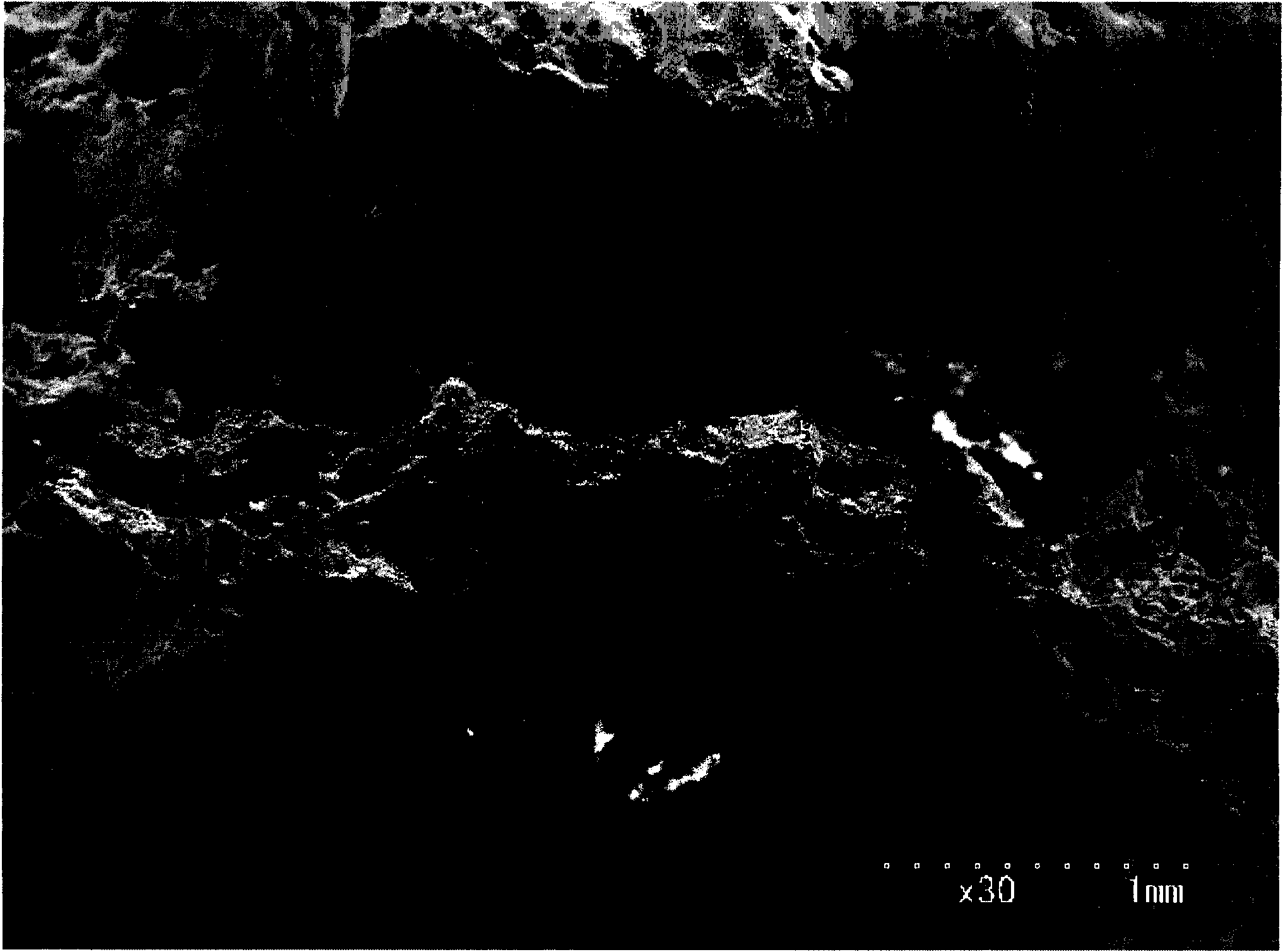

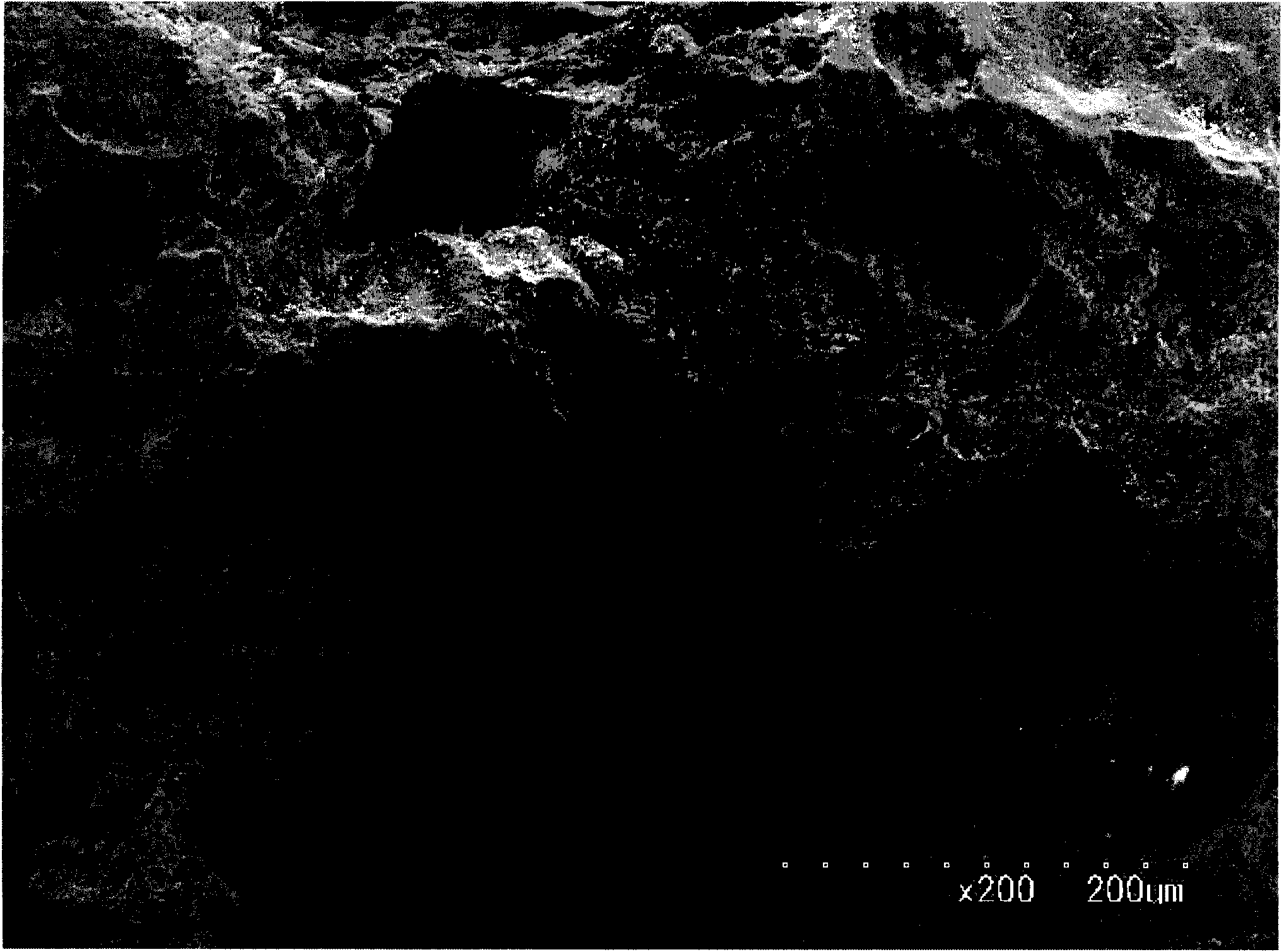

The invention provides a ceramic material with a multi-stage duct structure and a manufacture method thereof. The ceramic material is characterized by being provided with a plurality of macropores with millimeter grade, tens of middle pores with millimeter grade exist on the walls of the macropores, micropores with sizes less than microns exist on the walls of the middle pores. The ceramic material is manufactured by using 10-50 percent by mass of waste and 20-60 percent by mass of natural porous mineral and matching with 10-30 percent by mass of clay through the steps of adding water for mixing, forming, drying, preheating and sintering at a temperature of 1000-1200 DEG C, wherein the waste can be expanded at high temperature or has large ignition lost and easy decomposition and volatilization. The ceramic material has excellent water-absorbing and water-retaining properties, better water permeability, excellent absorption and filtration and light weight, and can be used as a water-absorbing material, a water-retaining material, a water permeating material, a sound insulating material, a heat insulating material, an indoor deodorizing material, an absorbing material, a filtering material and the like to be widely applied to various fields.

Owner:ZHE JIANG ECO ENVIRONMENTAL TECH CO LTD

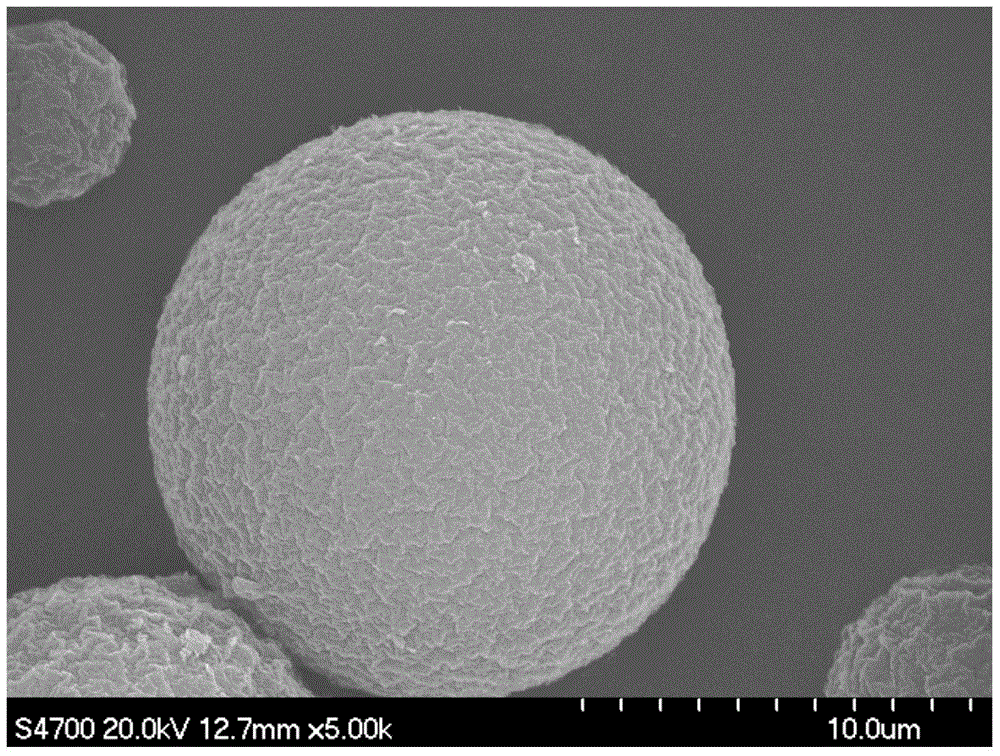

Method for preparing graphene microsphere through normal-pressure drying

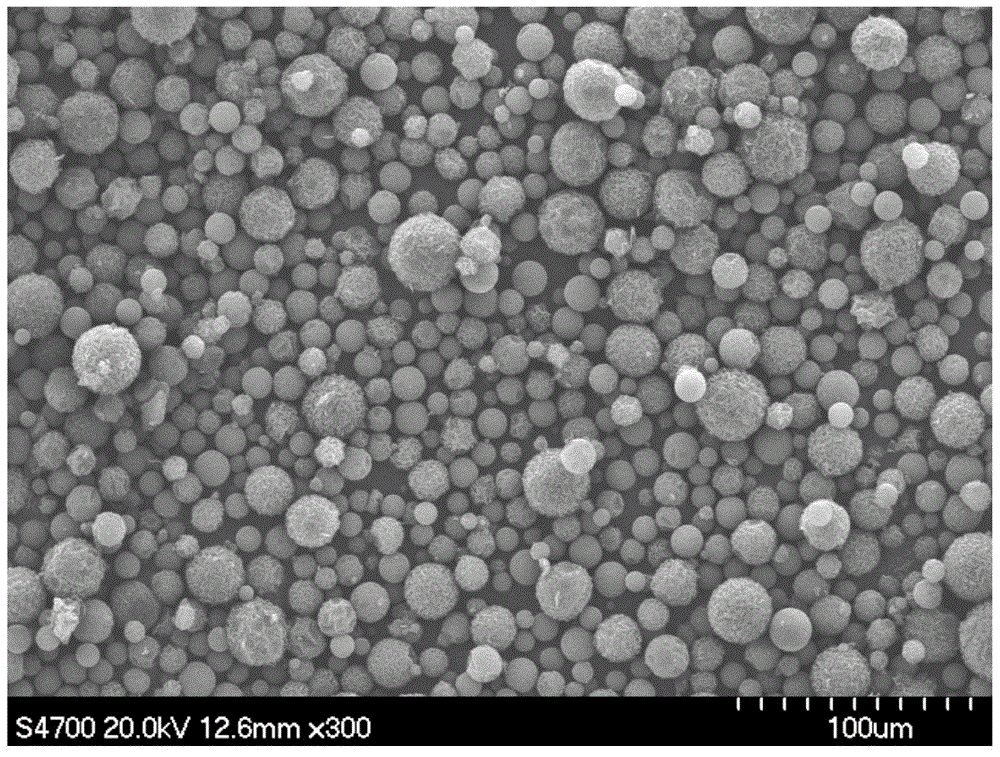

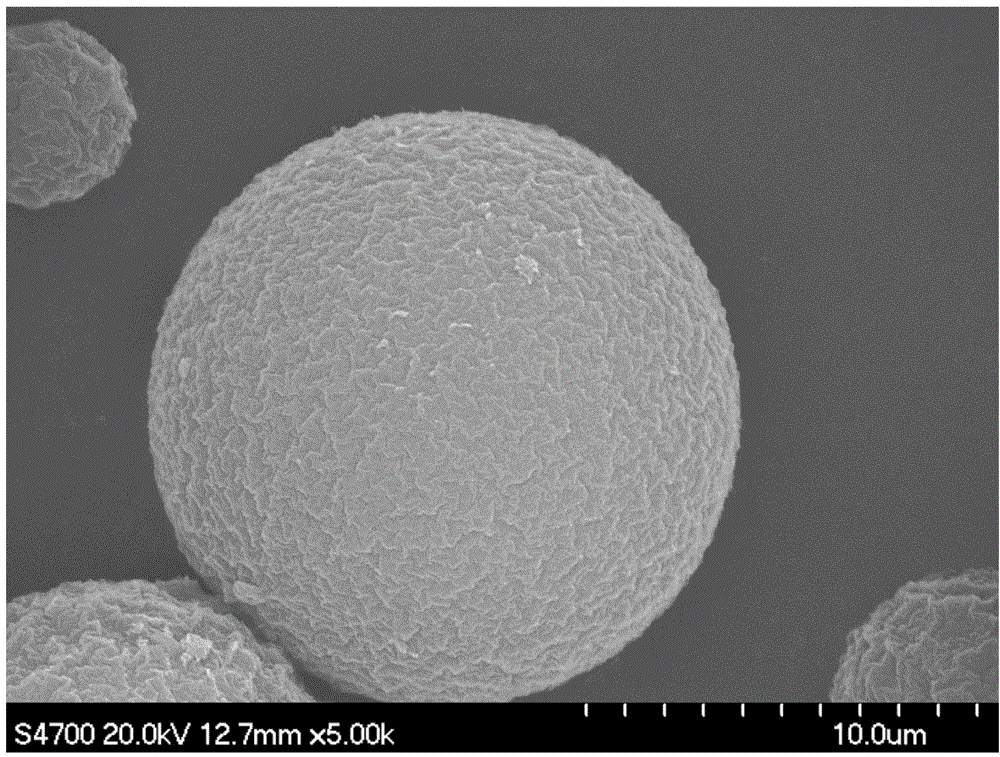

ActiveCN104401969ASpherical integrityUniform particle sizeMaterial nanotechnologyMicrosphereOil phase

The invention discloses a method for preparing a graphene microsphere through normal-pressure drying. A reaction system comprises graphenes, phenols, aldehydes, amines, a catalyst, a surfactant, an oil phase and water. A reaction is carried out in a reverse suspension polymerization manner. The graphene microsphere is prepared through the normal-pressure drying. In the method, the composite graphene microsphere is prepared through polymerization on a water / oil interface through a reaction solution. The employed oil phase can be used repeatedly during the preparation process. The method is simple and environmentally-protective. The graphene microsphere is low in preparation cost. In addition, an organic microsphere can be subjected to carbonization under an inert atmosphere to obtain the graphene microsphere. The graphene microsphere can be applied in the fields of micro-electronic, energy-storing materials, drug supporters, a lithium ion battery, a supercapacitor, an electro-adsorption electrode material and the like.

Owner:BEIJING UNIV OF CHEM TECH

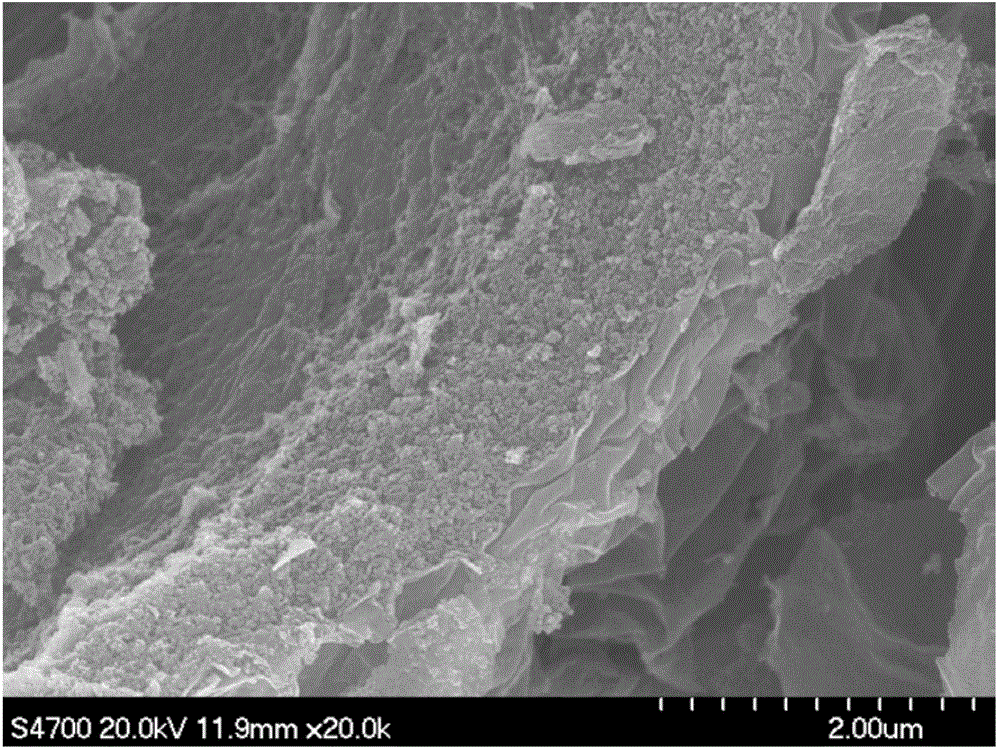

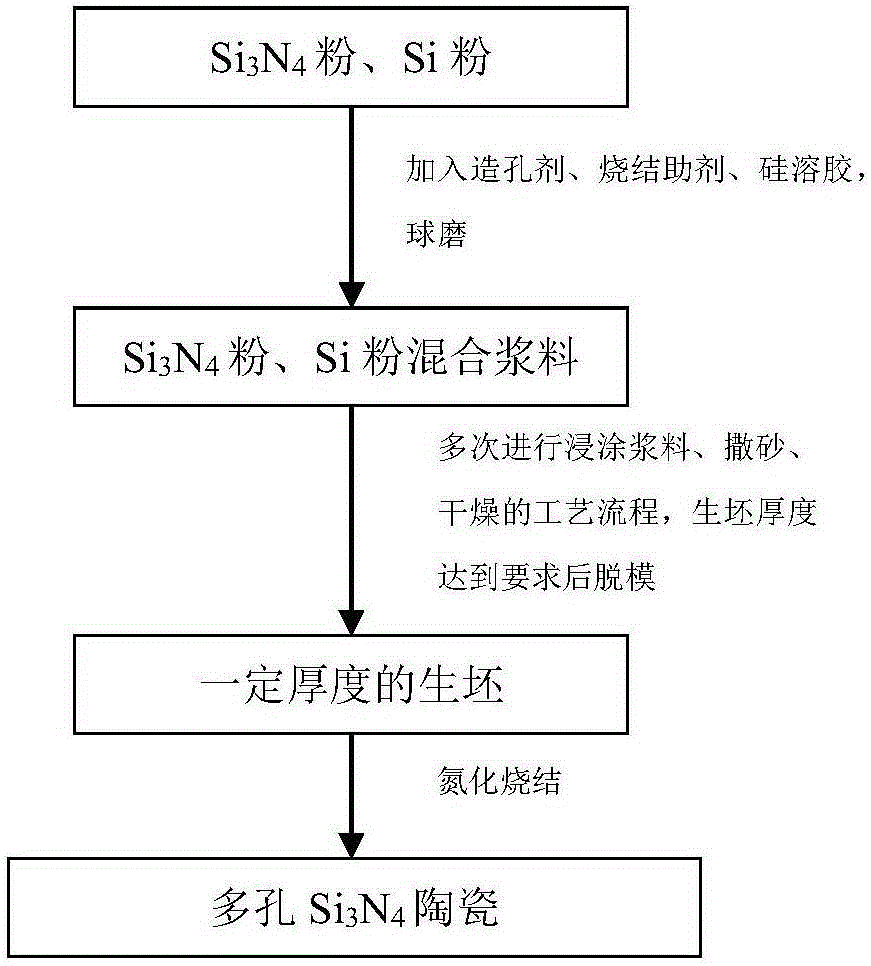

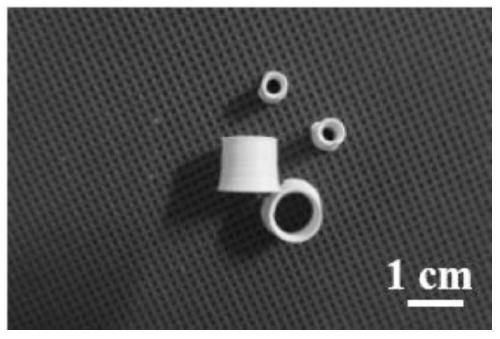

Method for producing complex-shaped porous silicon nitride ceramic product

InactiveCN105198475AImprove mechanical propertiesGood wave permeabilityCeramicwareParaffin oilsSlurry

The invention relates to a method for producing a complex-shaped porous silicon nitride ceramic product. The method includes: using Si3N4 powder, Si powder, sintering auxiliaries, pore forming agent and silica sol to prepare mixed slurry; producing a male die with an outer surface identical with the appearance and size of the inner cavity of the product, and coating paraffin on the surface of the die; soaking the die into the slurry to allow the slurry to be adhered to the surface of the die, and then spraying Si3N4 coarse powder to the surface of the die to allow a layer of Si3N4 coarse powder to be evenly adhered to the slurry adhered to the surface of the die; drying the die in a ventilated environment for 1-3 hours to consolidate and harden the slurry on the surface of the die; repeating the soaking, spraying and drying process for multiple times until the thickness of the outer powder layer of the die meets the requirement; placing the die into an oven to melt the paraffin so as to separate a ceramic green body from the die; performing nitridation sintering on the green body to obtain the porous silicon nitride ceramic product. The bending strength of the porous silicon nitride ceramic product produced by the method is not lower than 50MPa, and the porous silicon nitride ceramic product is good in wave transmission performance.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

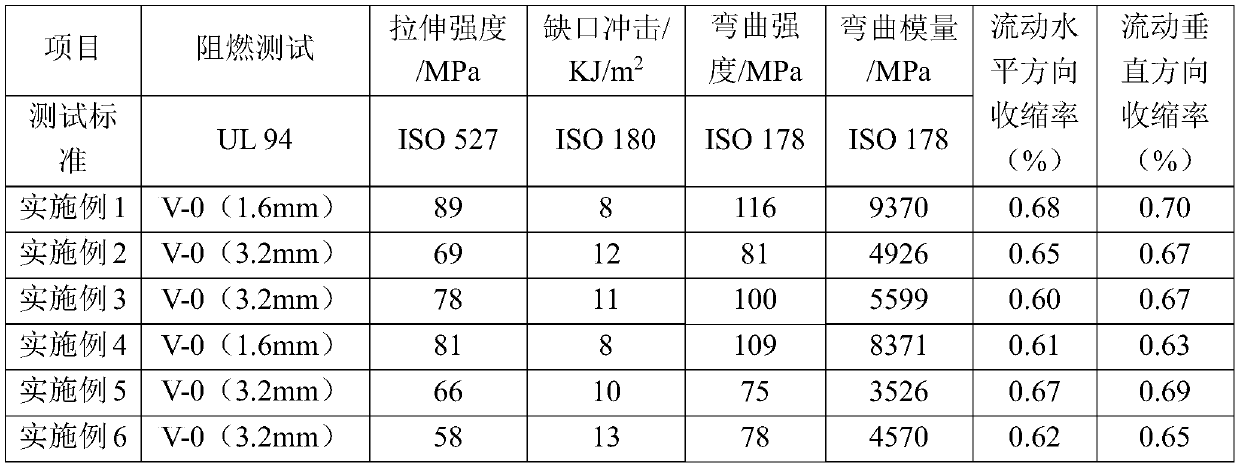

Efficient halogen-free intumescent flame-retardant glass fiber reinforced polypropylene material and preparation method thereof

InactiveCN110964256AReduce dosageSolve the shortcomings of long-term storage and precipitationGlass fiberFiber

The invention discloses an efficient halogen-free intumescent flame-retardant glass fiber reinforced polypropylene material. The raw materials comprise the following components in percentage by weight: 39-75 parts of polypropylene, 0-10 parts of coated ammonium polyphosphate, 1-15 parts of melamine and derivatives thereof, 1-15 parts of a halogen-free flame-retardant charring agent, 0-5 parts of aflame-retardant synergist, 5-30 parts of glass fibers subjected to surface treatment, 0.03-3 parts of a coupling agent, 0.5-8 parts of a compatilizer, 0-20 parts of a toughening agent, 0.1-1 part ofa lubricant and 0.01-4 parts of an antioxidant. The polypropylene material has the advantages of better flame retardancy, more outstanding water resistance and mechanical properties, the realization of the balance among processability, rigidity and toughness, lower dimensional shrinkage rate, the realization of very good rigidity and toughness balance and low shrinkage rate, no warping of a product, no floating fibers on a surface, and the enlargement of the application range of the polypropylene material.

Owner:重庆科聚孚新材料有限责任公司 +1

Foaming polyurethane rubber compound particles capable of being sulfurized and crossly linked as well as preparation method and molding technology of foaming polyurethane rubber compound particles

ActiveCN107828205AIncrease the degree of cross-linkingControl the degree of cross-linkingPore distributionPelletizing

The invention discloses foaming polyurethane rubber compound particles capable of being sulfurized and crossly linked as well as a preparation method and a molding technology of the foaming polyurethane rubber compound particles. The foaming polyurethane rubber compound particles capable of being sulfurized and crossly linked are prepared from an unsaturated polyurethane rubber compound, a foamingnucleating agent, a foam pore size stabilizer and a melt viscosity regulator; all the components are melted, blended and granulated to prepare blended particles; then supercritical fluid is used as afoaming agent to carry out foaming; finally, the foaming particles with stable quality, uniform foam pore distribution, high foaming rate, low size shrinkage rate and beautiful surface can be obtained; meanwhile, the obtained foaming particles also can be further sulfurized to form an interpenetrating or semi-interpenetrating network structure; the cross linking degree of the foaming particles isregulated and controlled; the obtained foaming polyurethane rubber compound particles can be widely applied to fields including vibration absorption materials, packaging materials, child toys, sportsgoods, model airplanes, heat-preservation and heat-insulation materials, automobile interior materials and the like.

Owner:福建安达福新材料科技有限公司

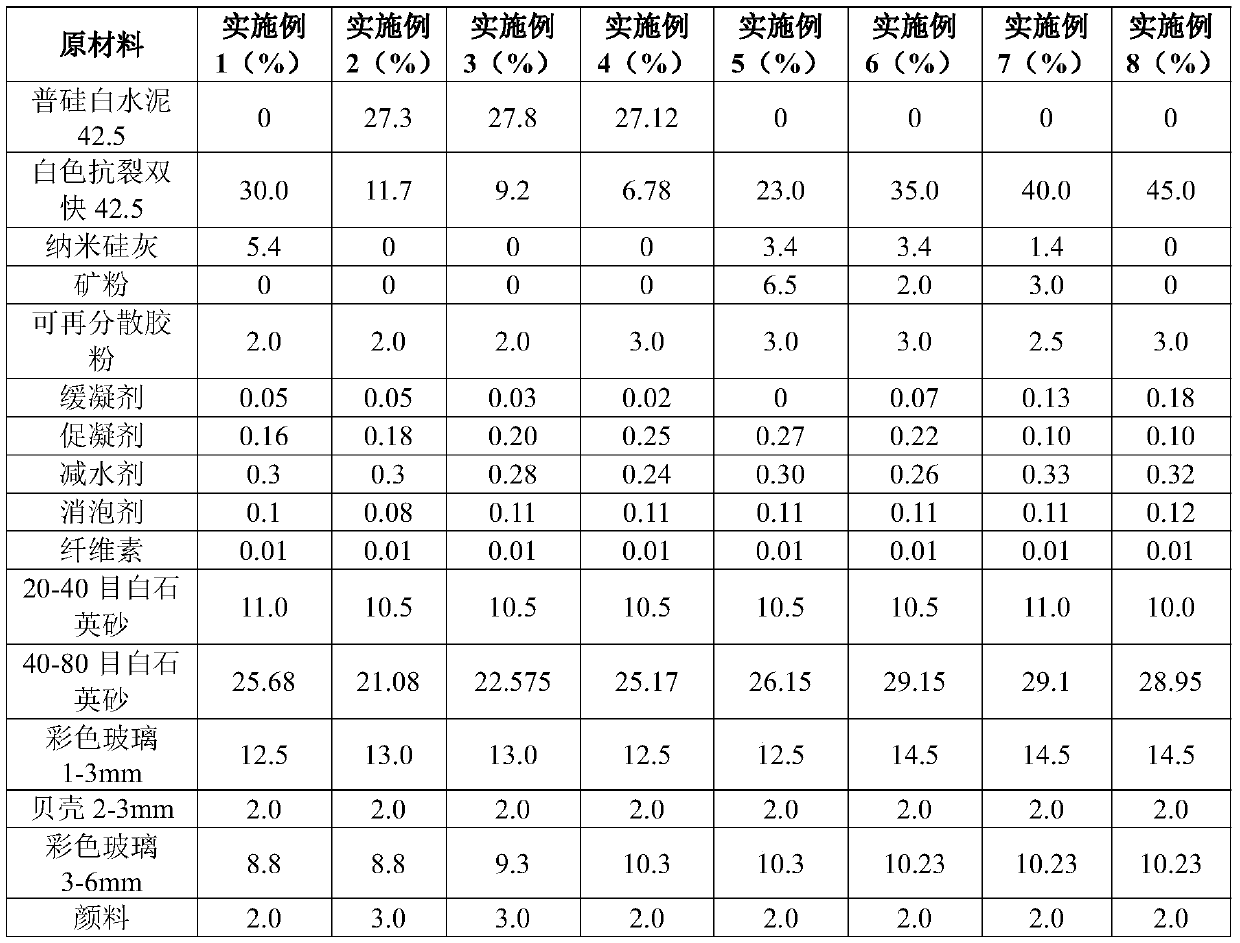

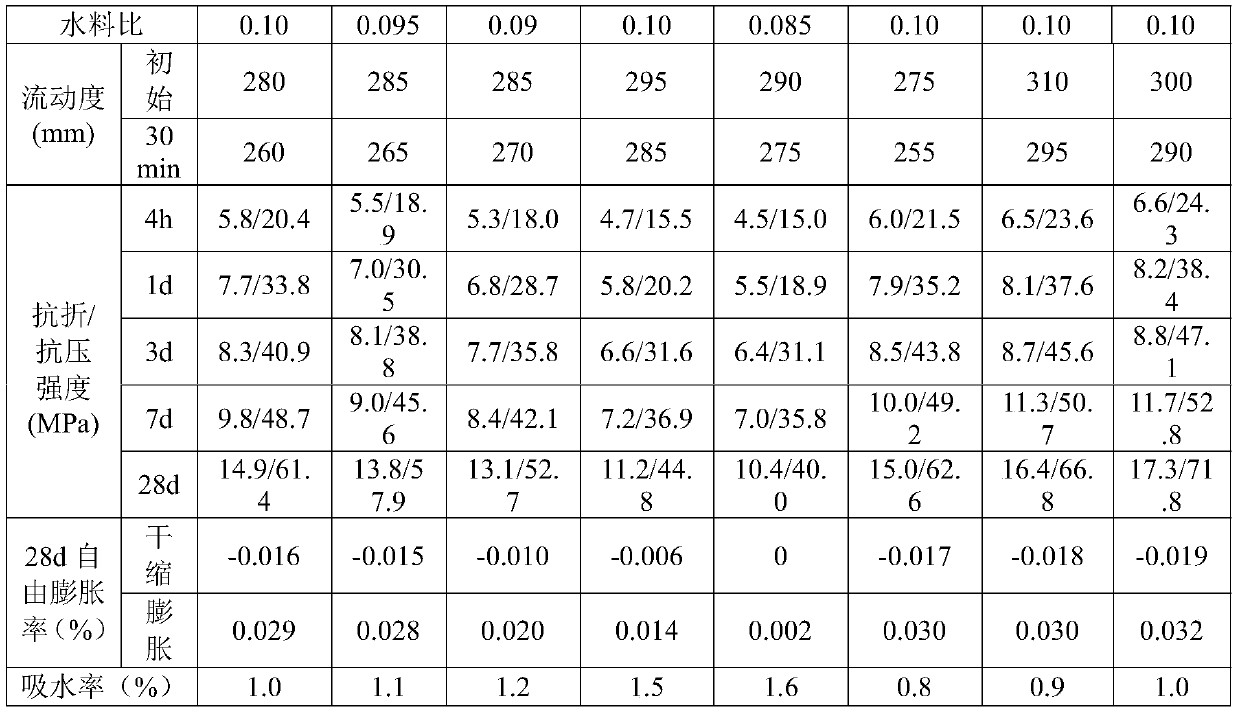

Surface layer mortar, grindstone, board and preparation method of grindstone and board

The invention discloses surface layer mortar, grindstone, a board and a preparation method of the grindstone and the board, and relates to the technical field of stone materials. The surface layer mortar is prepared from the following components in percent by mass: 20-45% of cement, 55-67% of aggregate, 0-5.4% of nanometer silica fume, 0-6.5% of mineral powder, 2-3% of dispersible rubber powder, 0-0.2% of a retarder, 0.1-0.3% of a coagulant, 0.1-0.3% of a water reducing agent, 0.05-0.3% of a defoaming agent, 0.01-0.02% of a thickening agent and 2-3% of pigment; the cement comprises high belitesulfoaluminate cement and optional ordinary cement, wherein the mass of the high belite sulfoaluminate cement accounts for 20-100% of the mass of the cement; and the water-material ratio of the surface layer mortar is 0.08-0.1. The fluidity, breaking and compressive strength and free expansion rate of the surface layer mortar meet related index requirements; and the grindstone or board prepared by adopting the surface layer mortar is small in size shrinkage, does not deform, does not crack, and has no alkali efflorescence.

Owner:TANGSHAN POLAR BEAR BUILDING MATERIAL

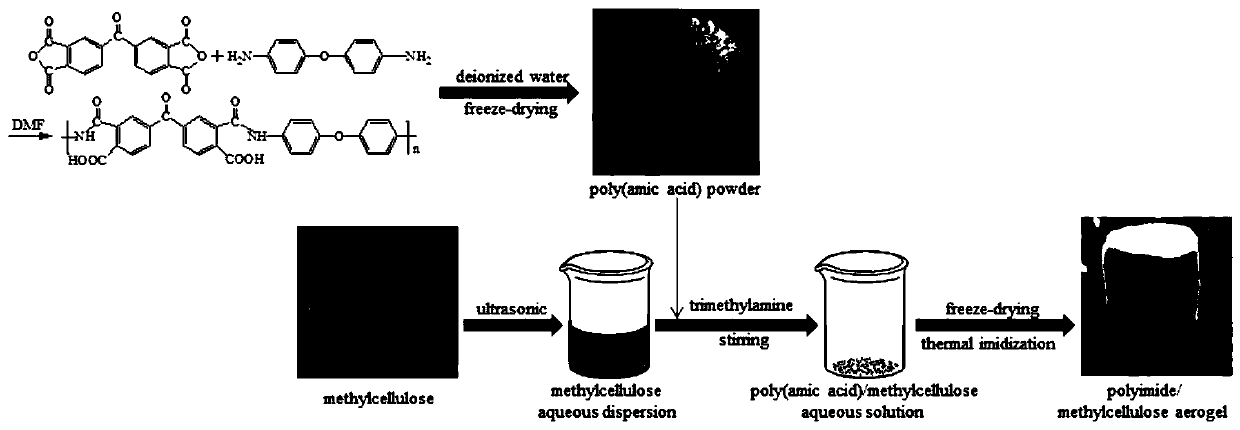

Method for preparing graphene/polyimide composite aerogel

The invention discloses a method for preparing graphene / polyimide composite aerogel and belongs to the technical field of materials. The method mainly comprises the steps of supplementarily preparinga polyamic acid aqueous solution through the assistance of a quaternary ammonium salt cationic surfactant and tertiary amine, then, uniformly dispersing graphene in the polyamic acid aqueous solutionso as to obtain a graphene / polyamic acid mixed solution, and carrying out aging, freeze drying and thermal imidization, thereby obtaining the graphene / polyimide composite aerogel. The method has the advantages of simplicity, high efficiency, low equipment requirements, wide applicable range, environment-friendliness and low cost, the problem that the traditional polyimide high-performance aerogelis difficult to prepare can be effectively avoided, and the obtained aerogel can be applied to gas adsorption, organic matter adsorption, heat-insulating materials and the like and has a very high potential application value in the fields of atmospheric pollution abatement, water pollution abatement, heat-insulating structural materials and the like.

Owner:SHAANXI UNIV OF SCI & TECH

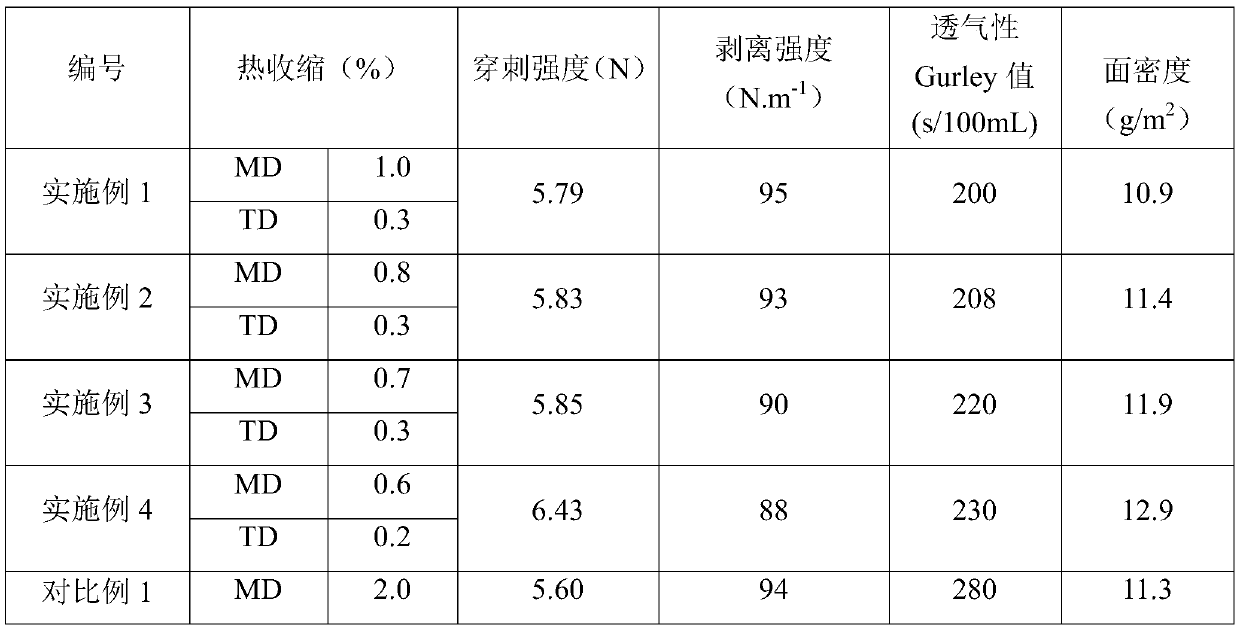

Polyimide microsphere slurry, composite separator and lithium ion battery

ActiveCN109817870AImprove mechanical propertiesEnsure safetyCell component detailsWater basedAdhesive

The invention relates to the technical field of lithium ion battery separator preparation, and discloses polyimide microsphere slurry, a composite separator and a lithium ion battery. The slurry comprises polyimide microspheres, a surfactant, a water-based adhesive, a wetting agent and deionized water. The composite separator prepared from the slurry is good in thermal stability, excellent in puncture resistance and good in air permeability, and compared with a ceramic coated separator, the surface density of a coating is lower, and relatively, the specific capacity of a lithium battery comprising the composite separator is higher.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

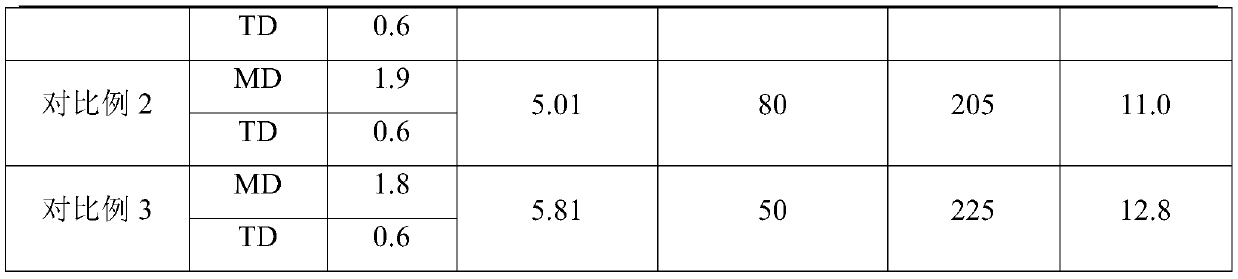

Halogen-free flame retardant high-temperature elastomer plug material and its preparation method

The invention provides a halogen-free flame retardant high-temperature elastomer plug material and its preparation method. The plug material is prepared by: taking 15-35% of polyphenyl ether, 20-40% of a hydrogenated styrene elastomer, and 5-15% polyolefin as the base materials, adding 10-20% of an intumescent flame retardant, 2-10% of a flame retardant synergistic agent, 5-15% of a softener, 0.2-1% of an antioxidizer and 0.5-2% of a processing modifier, then fully mixing the materials by a high mixing machine, and carrying out extrusion granulation through twin screws with a large length-diameter ratio. The product prepared by the method of the invention has a flame retardant grade up to UL94V0, can be used for injection molding of plugs with bright surfaces and good hand feel, moderate hardness and good toughness, excellent shock resistance, good electrical insulation performance, puncture resistance, and high temperature resistance. The plug material of the invention can be stably used for a long time under a temperature of 200DEG C, and can substitute silicon rubber to be widely used for plugs, sockets and connectors matching high temperature electric wires and lead wires in machinery, chemical and other industries.

Owner:中广核三角洲(江苏)塑化有限公司 +1

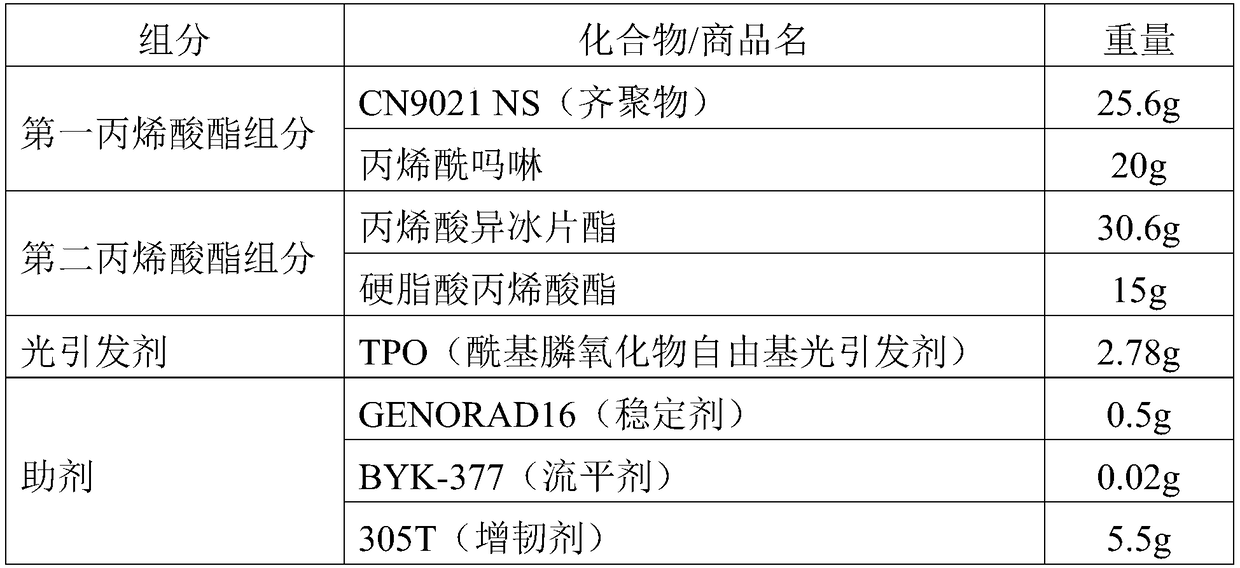

Photocurable non-transparent material for 3D printing, preparation method thereof, 3D printing product and 3D printer

ActiveCN109232791AImprove qualityAvoid easy cloggingManufacturing irradiation arrangements3D object support structuresDiacrylate esterEngineering

The invention provides a photocurable non-transparent material for 3D printing, a preparation method thereof, a 3D printing product and a 3D printer. The photocurable non-transparent material for 3D printing comprises the following components in parts by weight: 30-70 parts of a first acrylate component, 20-60 parts of a second acrylate component, 0.5-5 parts of a photoinitiator, 0.5-8 parts of anauxiliary agent and 0-4 parts of a colorant, wherein the first acrylate component is a polar acrylate component; and the second acrylate component is selected from at least one of weakly polar and non-polar acrylate components. According to the photocurable non-transparent material for 3D printing provided by the invention, a 3D printing product can be made non-transparent without adding white pigments such as titanium dioxide, so that the photocurable non-transparent material for 3D printing has the characteristics of high stability, the smoothness in a 3D printing process is ensured, the 3Dprinting product has good quality, and the 3D printer containing the photocurable non-transparent material for 3D printing has good performance.

Owner:ZHUHAI SAILNER 3D TECH CO LTD

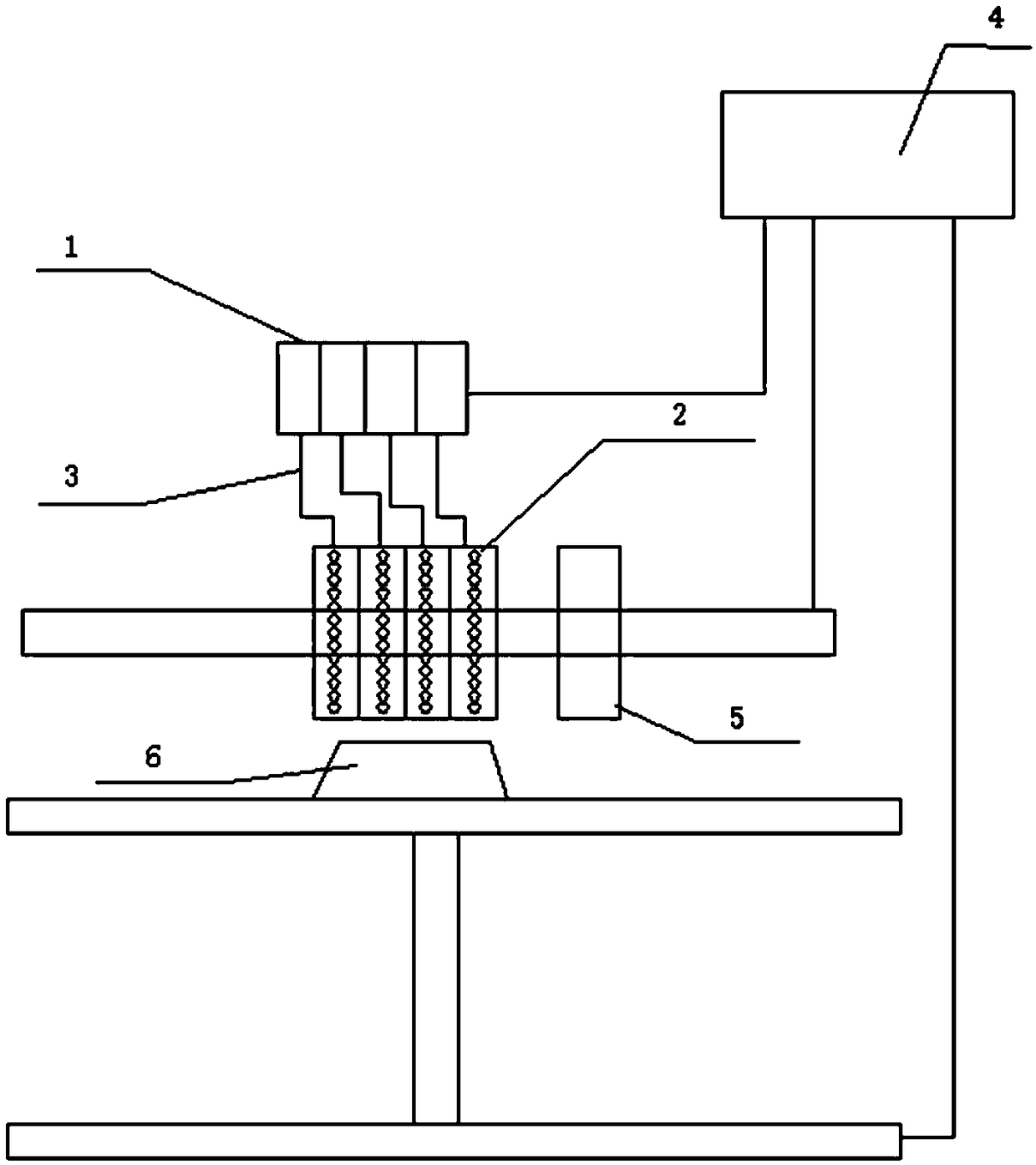

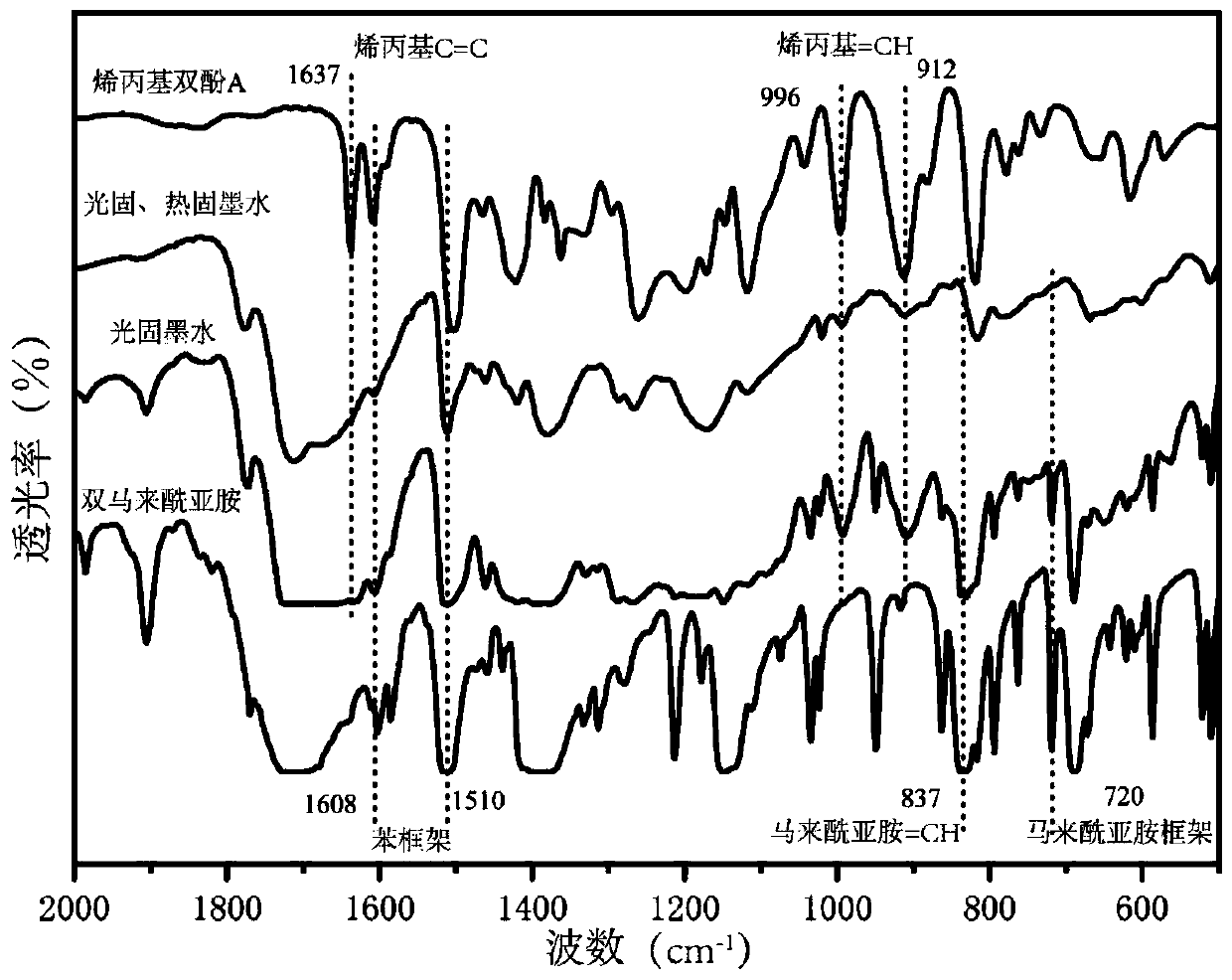

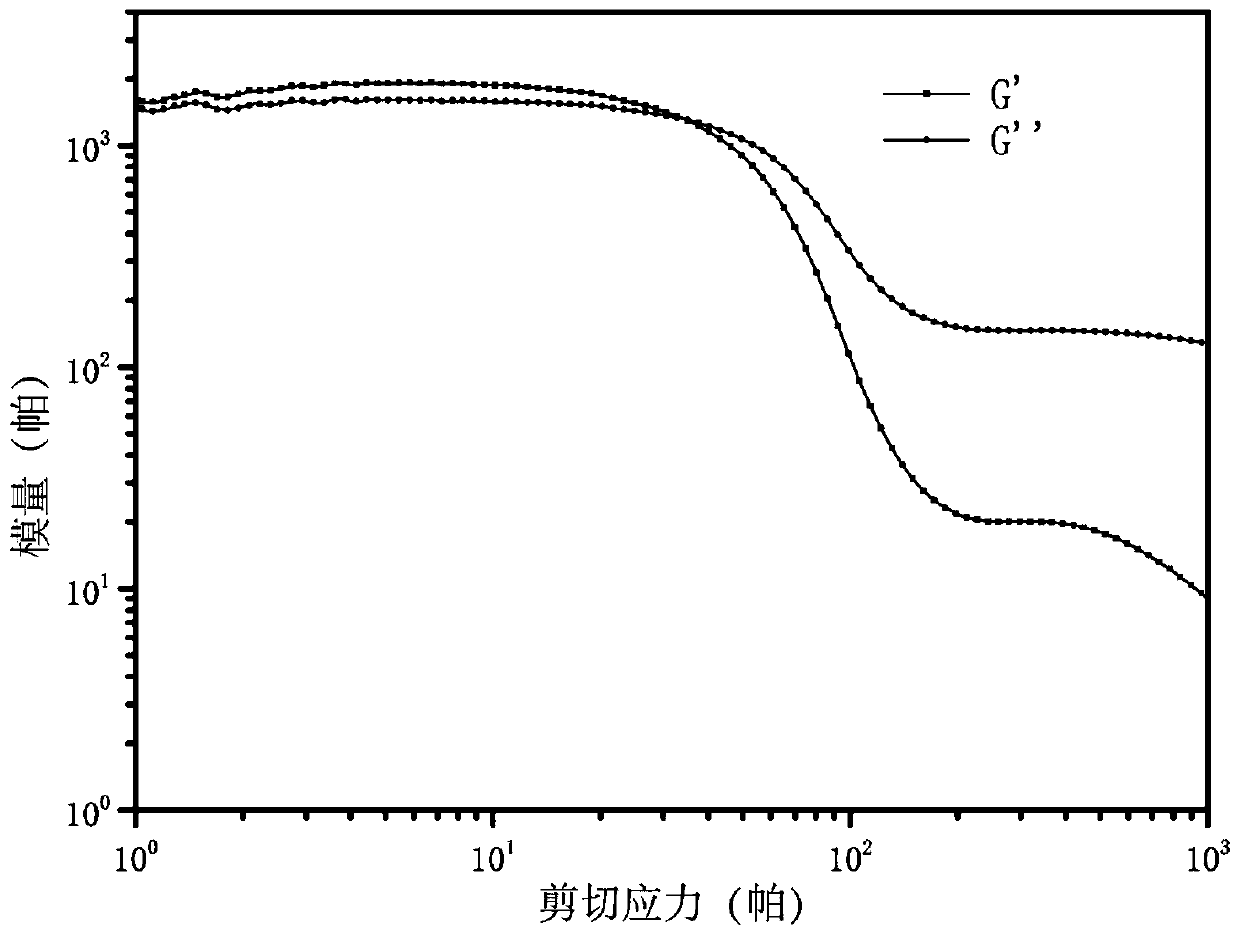

3D printed bismaleimide ink and preparation method and application thereof

ActiveCN109762111AImprove mechanical propertiesGood dimensional stabilityAdditive manufacturing apparatusEngineeringReactive diluent

The invention provides 3D printed bismaleimide ink and a preparation method and application thereof, and belongs to the field of 3D printed high-performance resin-based materials. Bismaleimide is prepolymerized with 2,2'-diallyl bisphenol A to obtain a prepolymer; and the prepolymer is mixed with a reactive diluent and a photoinitiator to obtain the 3D printed bismaleimide ink. The prepared 3D printed bismaleimide ink has the rheological property suitable for 3D printing, has good printability and high printing precision, has similar mechanical and heat resisting properties with traditional bismaleimide resin and has the ability to print complex structures, and printed molded parts have excellent mechanical properties and dimensional stability and can be widely used in aerospace and otherfields; and the 3D printing molding of the bismaleimide resin is realized for the first time.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

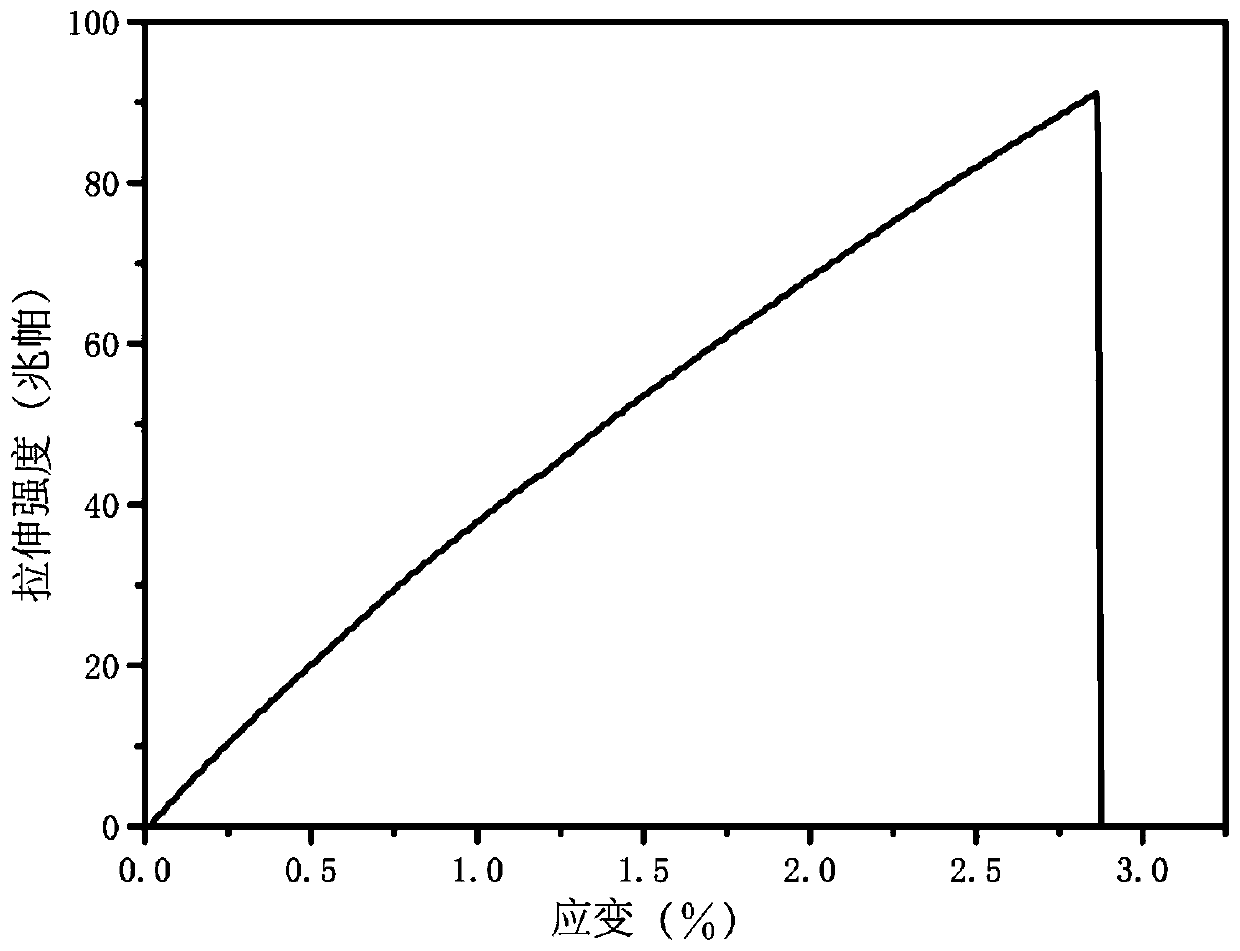

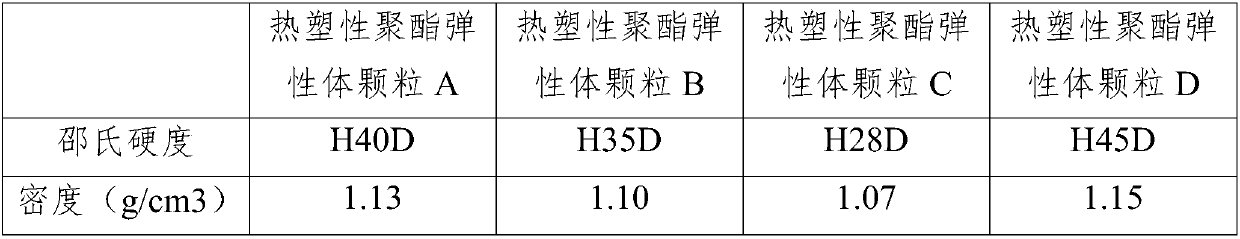

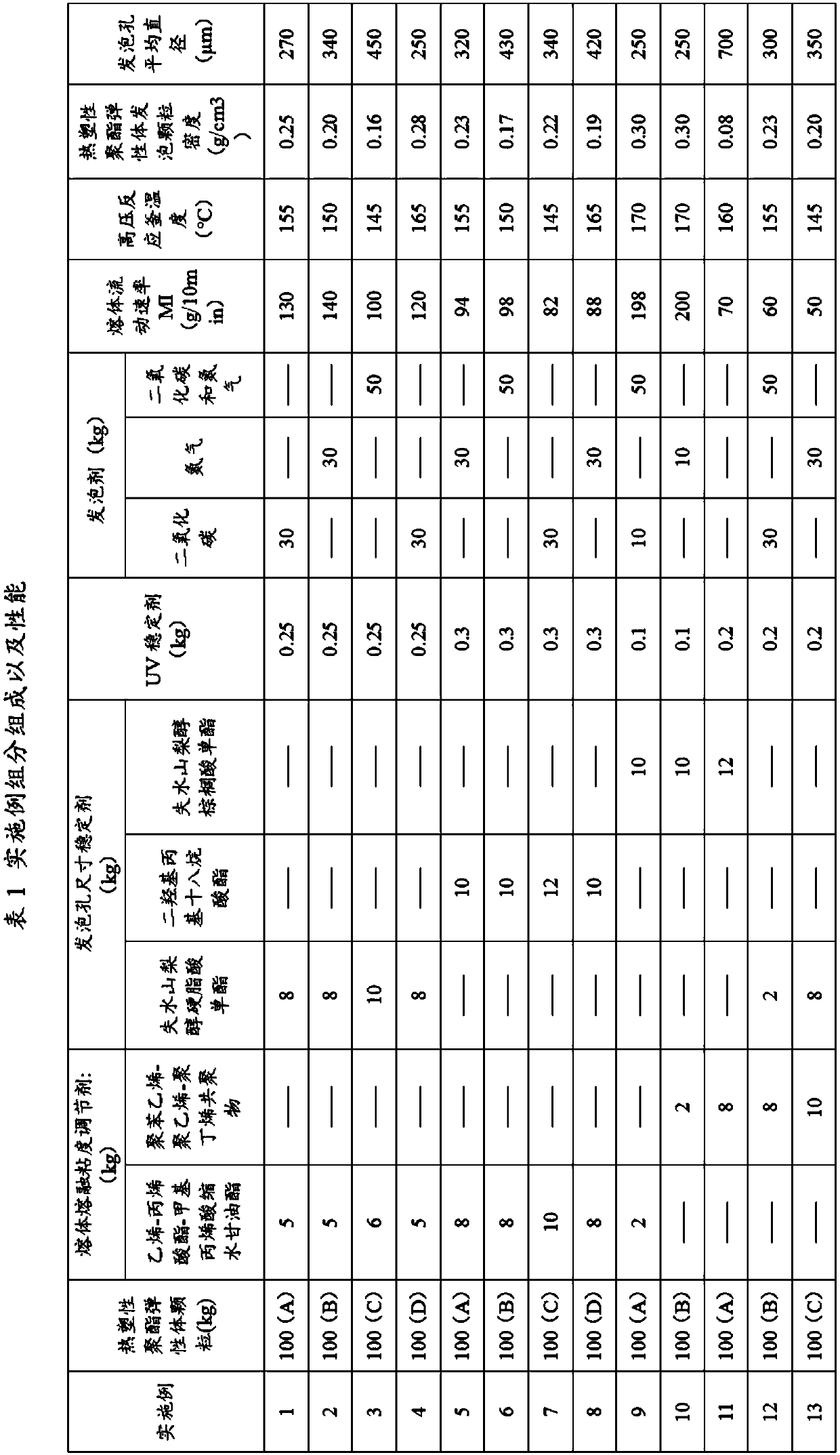

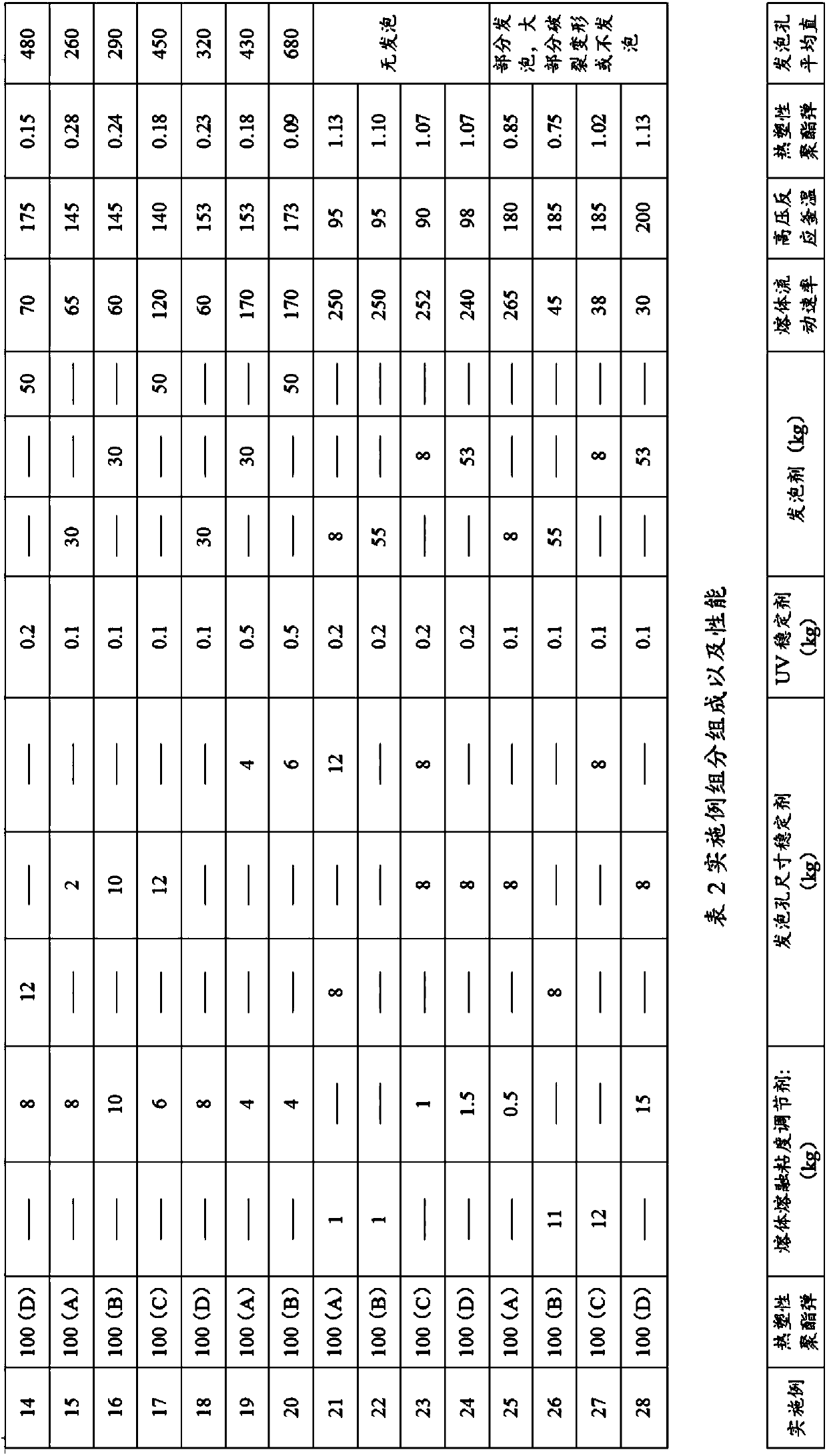

Precursor for foaming thermoplastic polyester elastomer, foaming body and its preparation method

Owner:唐靖

Wood plastic material and preparation method thereof

InactiveCN108250787AImprove flame retardant performanceImprove stabilityHazardous substancePlastic materials

The invention discloses a wood plastic material and a preparation method thereof, and relates to the technical field of wood plastic materials. The wood plastic material is prepared from the followingraw materials in parts by weight: 30 to 40 parts of wood powder, 20 to 45 parts of straw powder, 20 to 35 parts of polyvinyl chloride resin, 12 to 20 parts of polypropylene resin, 15 to 24 parts of nitrile butadiene rubber, 8 to 16 parts of polystyrene resin, 5 to 18 parts of glass fibres, 11 to 15 parts of boron carbide, 6 to 15 parts of nano-silicon carbide, 3 to 9 parts of expanded graphite, 3to 7 parts of aluminum oxide, 3 to 9 parts of a compatilizer, 2 to 6 parts of an antioxidant preservative, 1 to 3 parts of a lubricant, 2 to 8 parts of a flame retardant and 8 to 13 parts of a filling agent. The wood plastic material disclosed by the invention is good in flame retardance and stability, and high in mechanical strength, and does not fracture and deform easily; the preparation method is simple in process and high in operability, does not produce toxic or harmful substances, is environmentally friendly, and is suitable for industrial popularization.

Owner:ANHUI YINUO WOOD PLASTIC SHEET TECH CO LTD

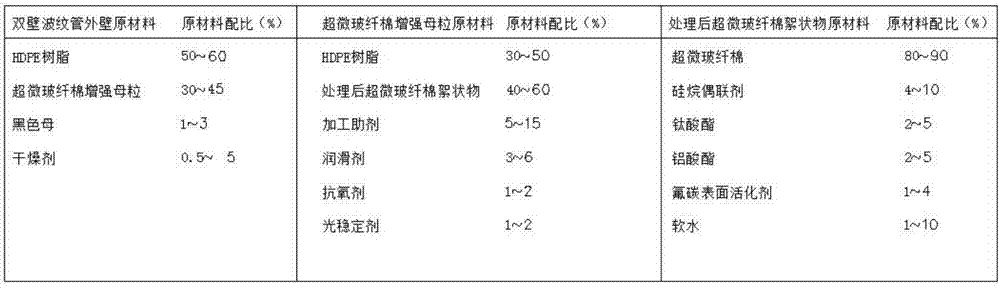

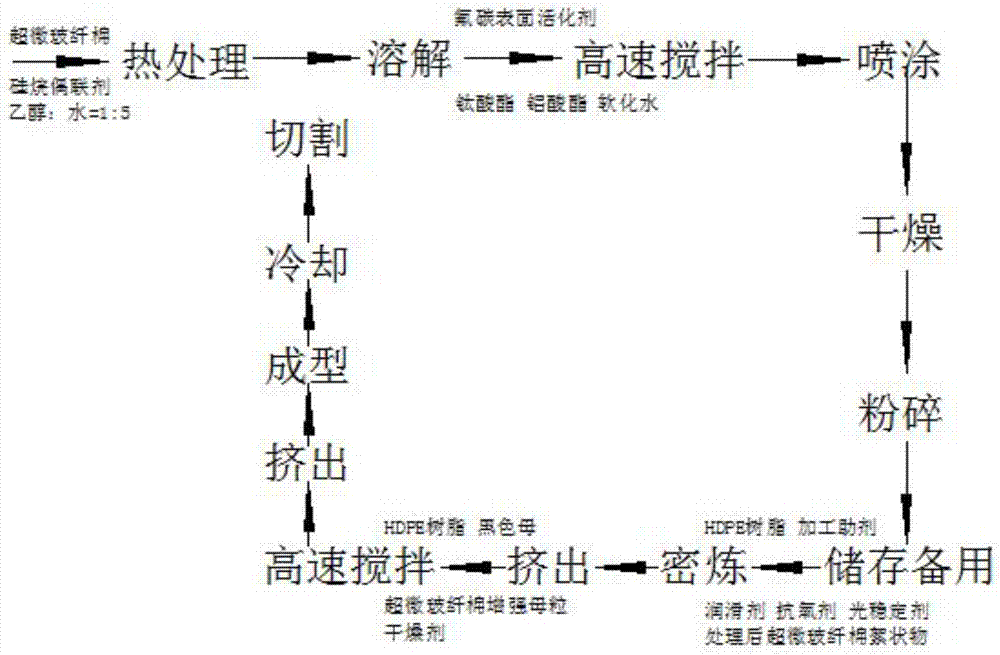

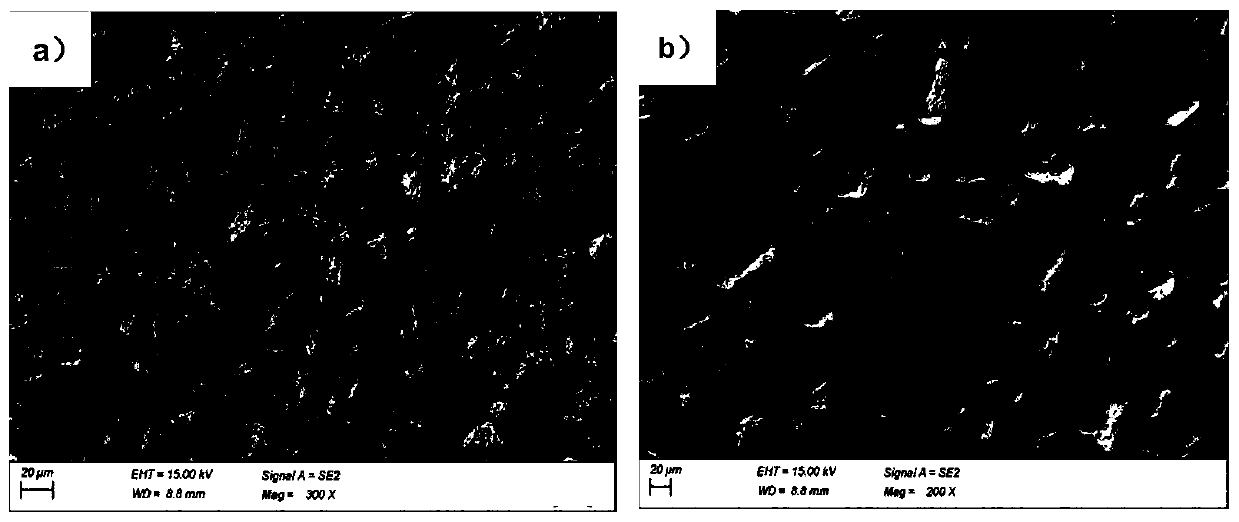

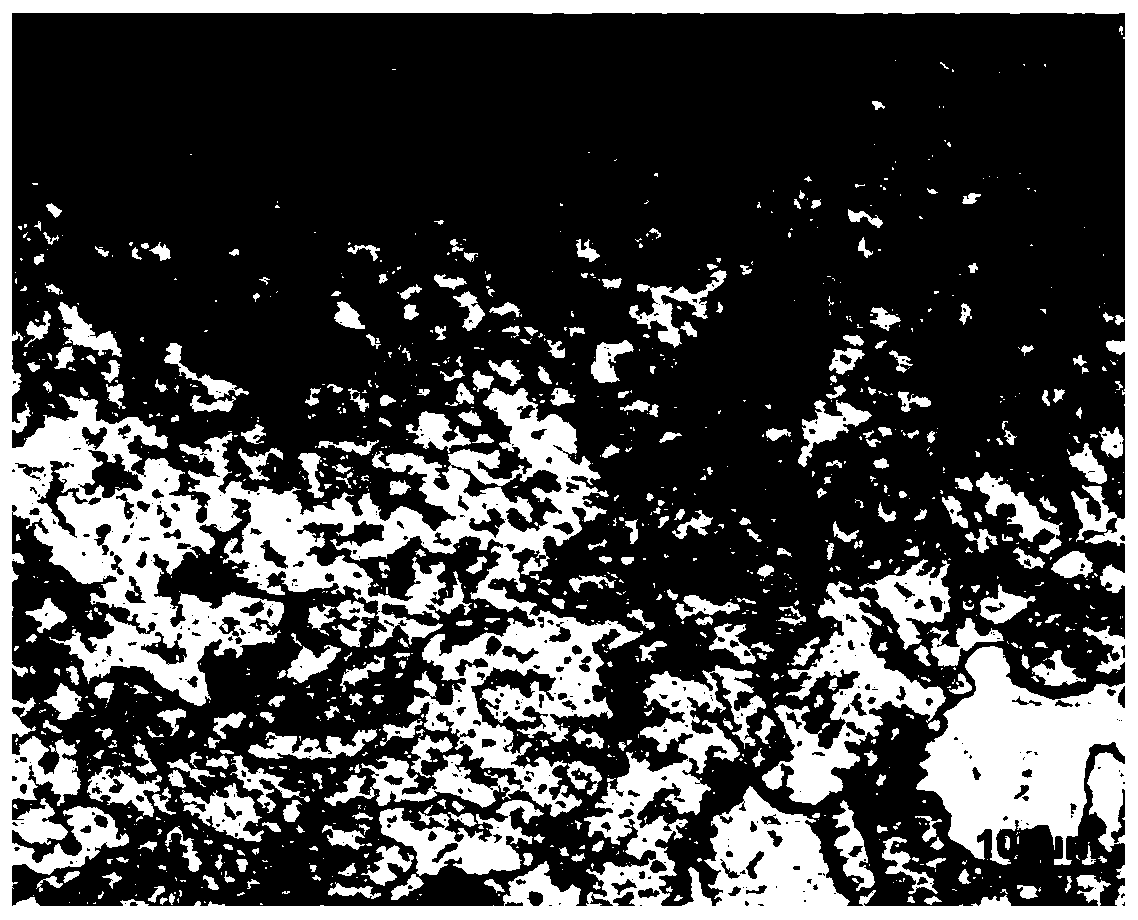

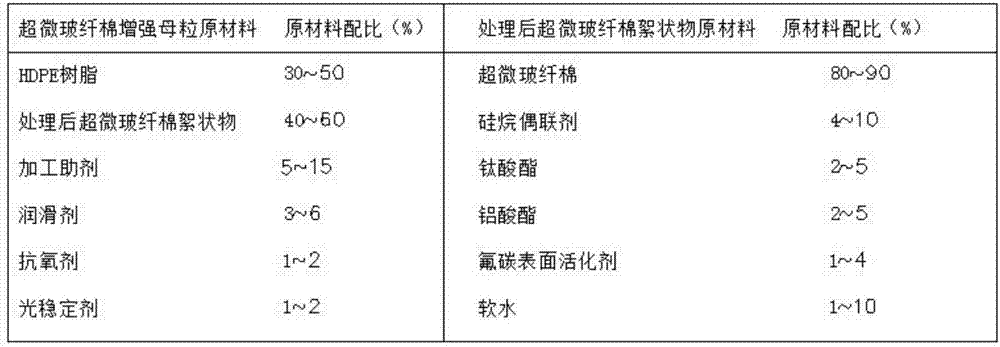

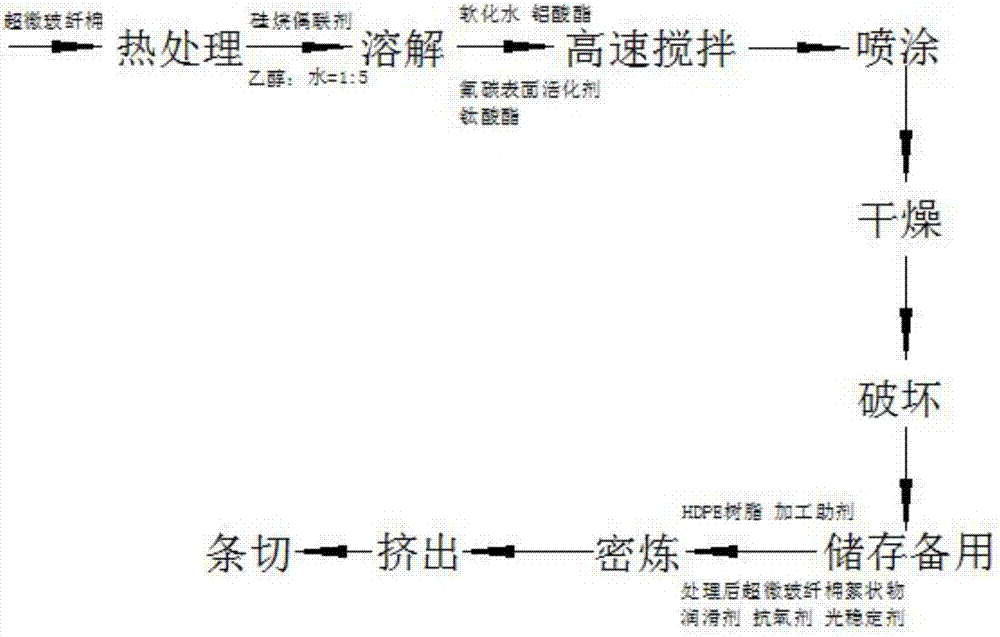

Ultrafine glass fiber reinforced HDPE double-wall corrugated pipe

The invention discloses an ultrafine glass fiber reinforced HDPE double-wall corrugated pipe. The ultrafine glass fiber reinforced HDPE double-wall corrugated pipe is prepared through the following four steps: surface activation of glass fibers; preparation of ultrafine glass fiber reinforced master batch; extrusion molding of the HDPE double-wall corrugated pipe; and performance testing of the pipe. The HDPE double-wall corrugated pipe prepared from the ultrafine glass fiber reinforced master batch has the advantages of small dimensional shrinkage, high elastic modulus and high ring stiffness.

Owner:ANHUI JIELANTE NEW MATERIAL CO LTD

Method of using steel slag as filler for plastic product

The present invention is method of using steel slag as filler for plastic product. Steel slag is first iron eliminated and ground into powder, the steel slag powder is then mixed with plastic, including regenerated plastic, and the mixture is finally extruded in a screw extruder to form. The present invention has waste utilized to lower material cost, raise the heat resistance, mechanical strength and rigidity of material, reduce shrinkage of product and raise the size stability of product.

Owner:陈涛

Activated sintering preparation method for high-density titanium product

ActiveCN110280760AReduce oxygen contentHigh densityTransportation and packagingMetal-working apparatusVolumetric Mass DensityHigh activity

The invention provides an activated sintering preparation method for a high-density titanium product and belongs to the technical field of powder metallurgy. The activated sintering preparation method comprises the following steps: firstly, carrying out modifying treatment on titanium powder by adopting a fluidized bed jet mill; secondly, adjusting the frequency of a sorting wheel by a fluidizing process to obtain high-activity titanium powder with different particle size ranges; carrying out die forming on the obtained titanium powder with different particle sizes; carrying out high vacuum sintering by adopting a vacuum tungsten coil furnace or high vacuum molybdenum wire furnace to obtain a high-density titanium sintered product. The high-density titanium powder with narrow particle size distribution, adjustable powder particle size, large specific area and low oxygen content can be obtained by a fluidization-airflow classification technique; compared with a titanium part which is not subjected to powder modifying treatment and is obtained by molded sintering, a titanium powder sintered part subjected to activating treatment has the characteristics of small dimensional shrinkage, high density, high tensile strength, better plasticity, well-closed formation, fine grains and the like; the titanium powder subjected to activating treatment can reach higher density in the sintering process at higher sintering rate within short soaking time.

Owner:UNIV OF SCI & TECH BEIJING

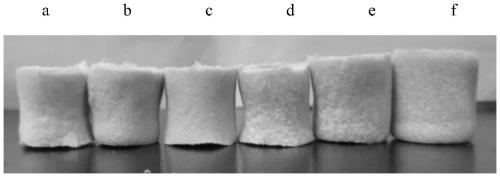

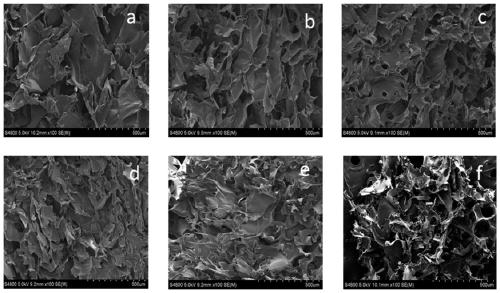

Preparation method cellulose / polyimide composite aerogels

The invention discloses a preparation method cellulose / polyimide composite aerogels, and belongs to the technical field of materials. The preparation method includes the following steps: polyamic acid is dissolved in a cellulose aqueous dispersion through a solubilizer; through freezing, drying, and thermal imidization, the cellulose / polyimide composite aerogels are obtained. The preparation method has the advantages of simpleness, high efficiency, low requirements for equipment, an extensive application scope and friendly environment. The problem that traditional polyimide type high-performance composite aerogels are difficult to prepare is effectively avoided. The obtained composite aerogels can be applied to air adsoprtion, organic substance adsorption, heat insulation materials andthe like and have great potential application value in the field of air pollution treatment, water pollution treatment, heat insulation structured materials and the like.

Owner:SHAANXI UNIV OF SCI & TECH

Gel injection molding material composition for aluminium silicon carbide integrated circuit pipe shell and method for preparing products

InactiveCN101117558ALow costLarge batchOther chemical processesSemiconductor/solid-state device detailsEthylenediamineGel casting

The invention discloses a gel-casting material composition of aluminum silicon carbide integrate circuit tube casing and preparation method thereof. The composition comprises silicon carbide micro powder, deionized water, acrylamide, methylene-bis-acrylamide, ammonium persulfate, tetramethyl ethylenediamine and dispersant. The preparation method includes the following steps: weighing substances in the formulation proportionally and pouring into a ball mill; ball milling and filtering; stirring in a regulating tank for 2 hours; adjusting the pH value of the slurry to about 10 with ammonia and vacuum pumping for 2 hours above the vacuum degree of -700mmHg; adding ammonium persulfate and tetramethyl ethylenediamine solutions dropwise in stirring, and then continuing to stir for 1 minute and turning off the stirrer; injecting the slurry into a mould to fill the mould sufficiently; demoulding, drying and polishing to get a tube casing preform with complete shape. The invention has the advantages of low cost, large batch, complete shape, small dimension shrinkage rate, thus the invention is a near net shape molding method for preparation of deformed parts with complicated shapes.

Owner:西安明科微电子材料有限公司

Ultra-micro glass fiber enhanced master batch applied to HDPE (High-density Polyethylene) double-wall corrugated tubular product

The invention discloses an ultra-micro glass fiber enhanced master batch applied to an HDPE (High-density Polyethylene) double-wall corrugated tubular product. The ultra-micro glass fiber enhanced master batch is prepared by internally mixing by utilizing an internal mixer to obtain a uniform melt and extruding and granulating the molded uniform melt through a single-screw extruder. Nano carbon black in the ultra-micro glass fiber enhanced master batch prepared by the invention has the advantages of great strength and light weight; the HDPE double-wall corrugated tubular product prepared from the ultra-micro glass fiber enhanced master batch has the advantages of small dimension shrinkage rate, smooth and clean surface, high elastic modulus and high ring stiffness.

Owner:ANHUI JIELANTE NEW MATERIAL CO LTD

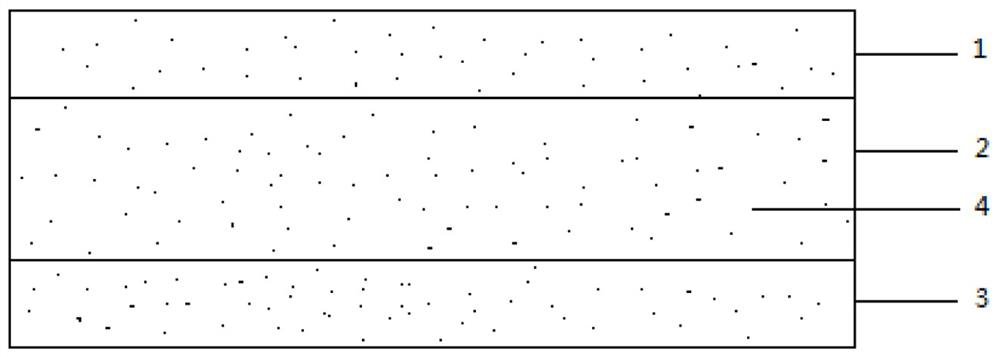

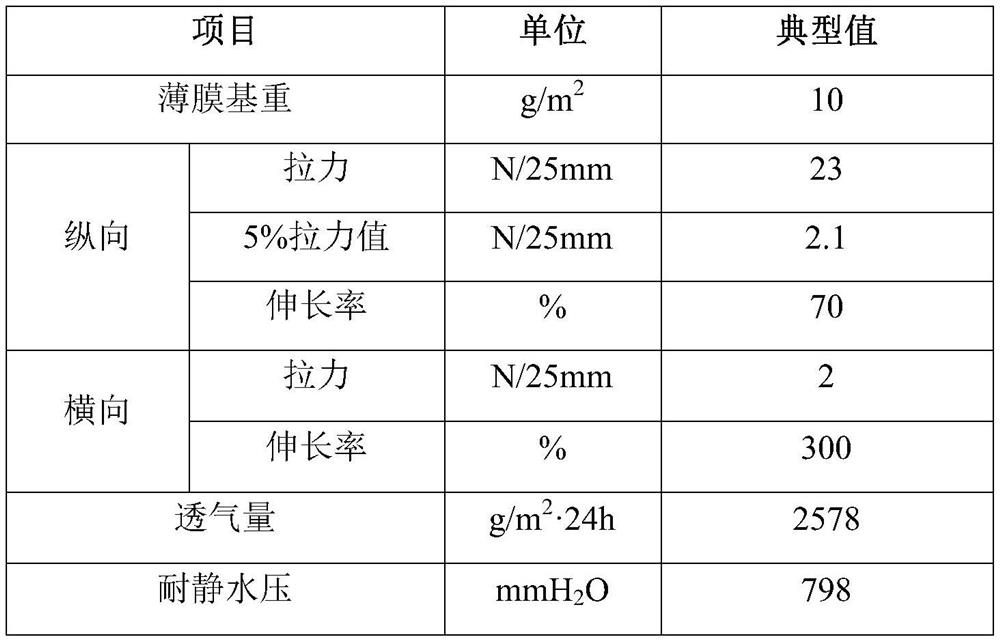

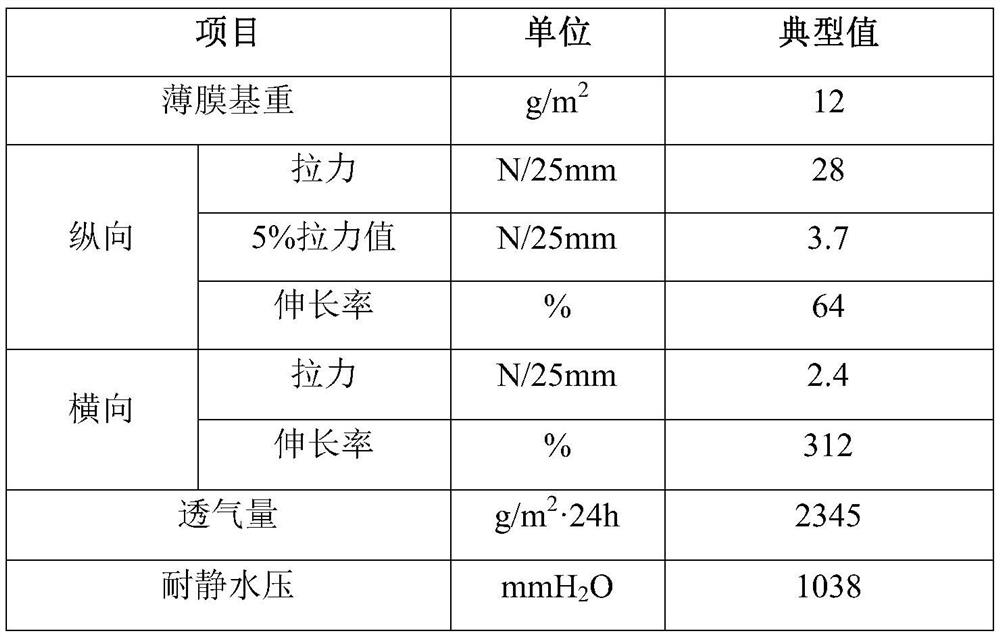

Ultrathin polyethylene microporous breathable film and preparation method thereof

InactiveCN111890767AExcellent physical and chemical propertiesSmall size shrinkagePersonal careSynthetic resin layered productsMasterbatchPolymer science

The invention provides an ultrathin polyethylene microporous breathable film. The breathable film is characterized by comprising an outer layer, a middle layer and an inner layer which are subjected to co-extrusion forming through a film blowing machine, and the inner layer is formed by blending, by weight, 45-60 kg of calcium carbonate master batch, 25-30 kg of polyethylene, 18-25 kg of ethyleneand octene copolymerized polyethylene and 1-3 kg of lubricant; the middle layer is formed by blending the following materials in parts by weight: 60-70kg of calcium carbonate master batch, 25-30kg ofpolyethylene and 1-3kg of lubricant; the outer layer is formed by blending, by weight, 45-60 kg of calcium carbonate master batch, 25-30 kg of polyethylene, 18-25 kg of ethylene and octene copolymerized polyethylene and 1-3 kg of lubricant. The breathable film product produced through the film blowing process is excellent in physical and chemical properties of materials, meets the requirements that the gram weight is 10-14 gsm, the moisture permeability is 1800-3200 g / 24 h / m < 2 > and the hydrostatic pressure resistance is larger than or equal to 50 mmH2O, the breathable film product is an upgraded and updated product of a traditional curtain coating breathable film, and has the advantages of being low in gram weight, high in breathability, resistant to permeation and the like. The film produced by the patent technology is small in size shrinkage rate so that colorful patterns can be formed after flexible surface printing, and the film is applied to infant diapers.

Owner:湖北宏裕新型包材股份有限公司

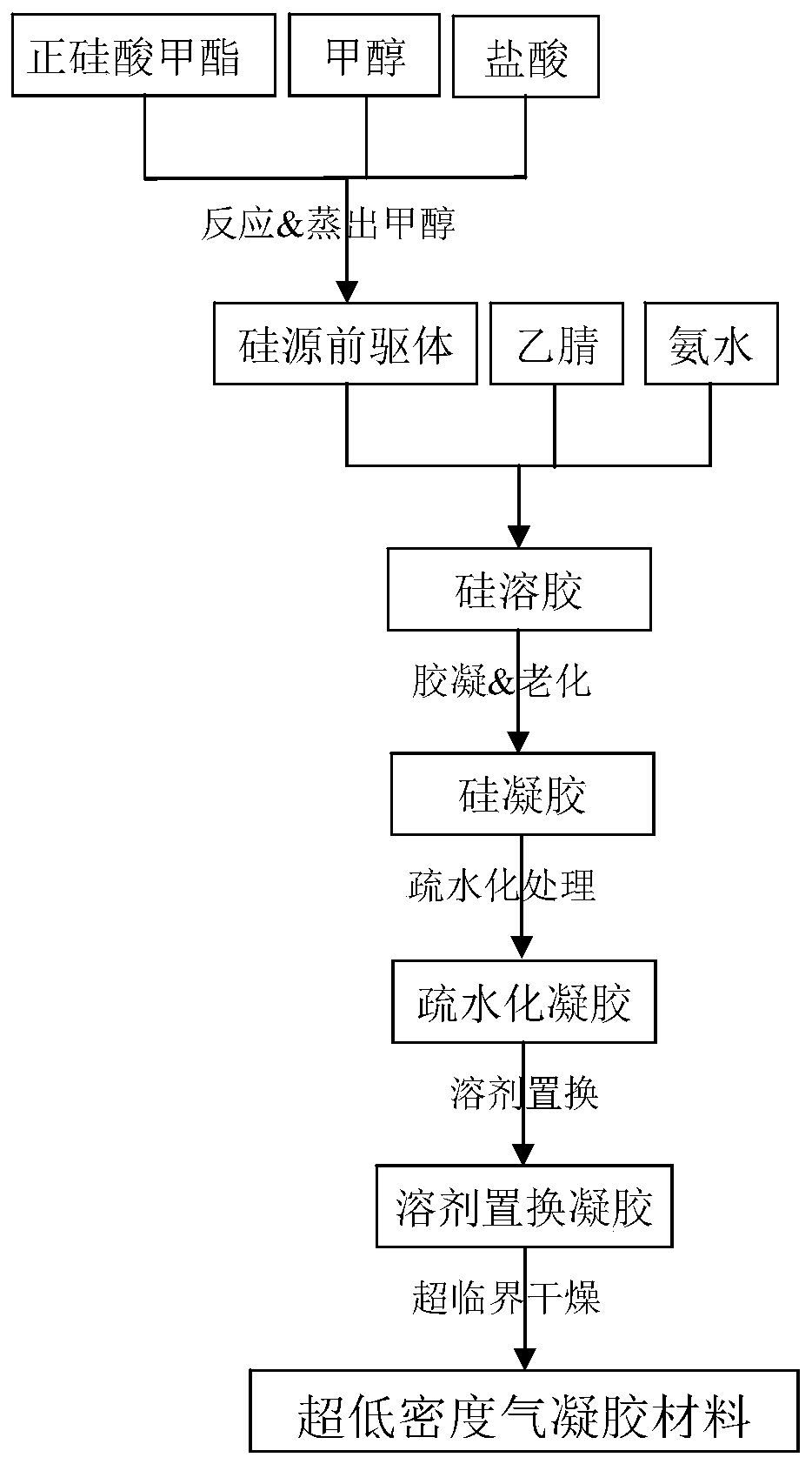

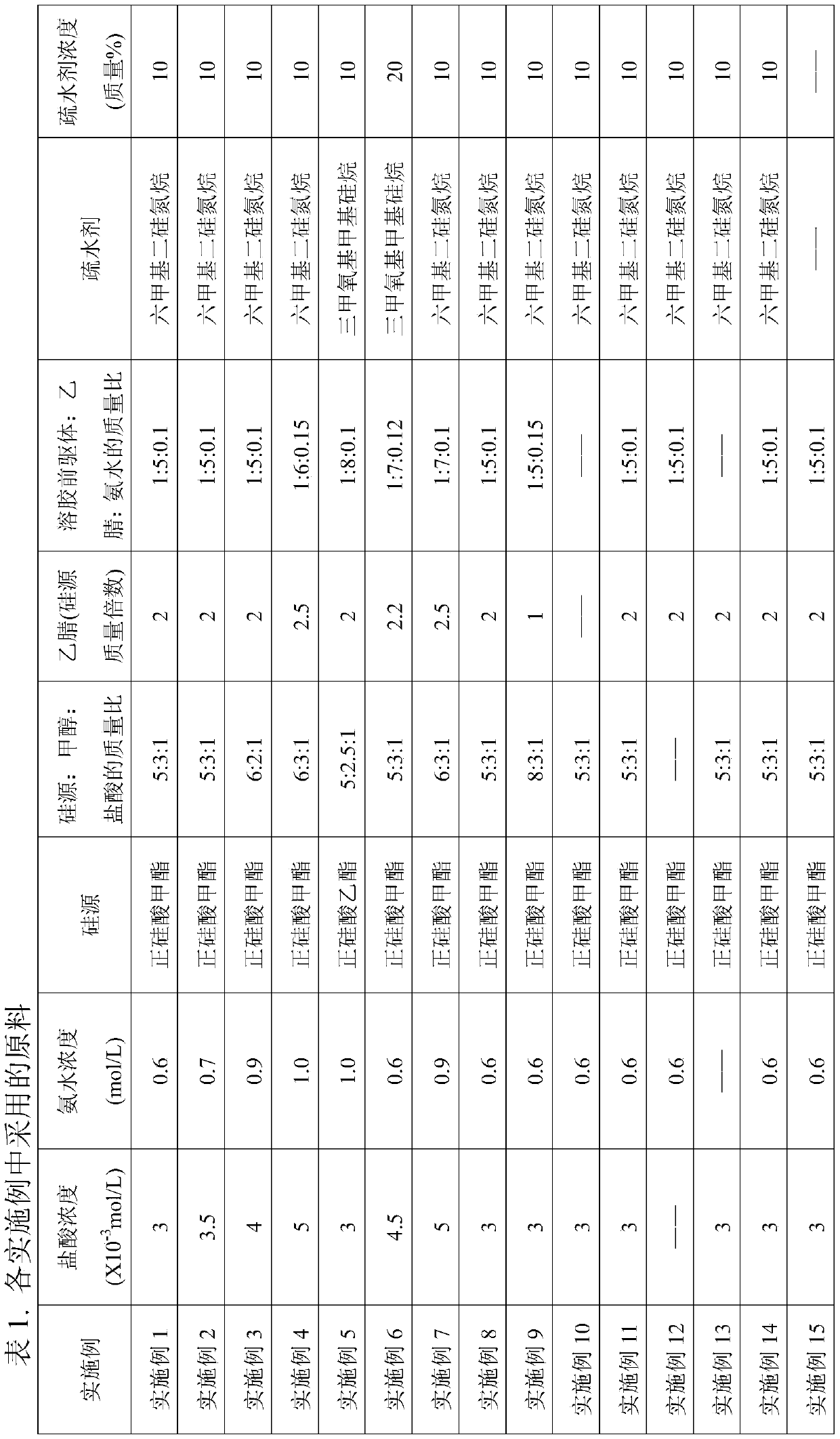

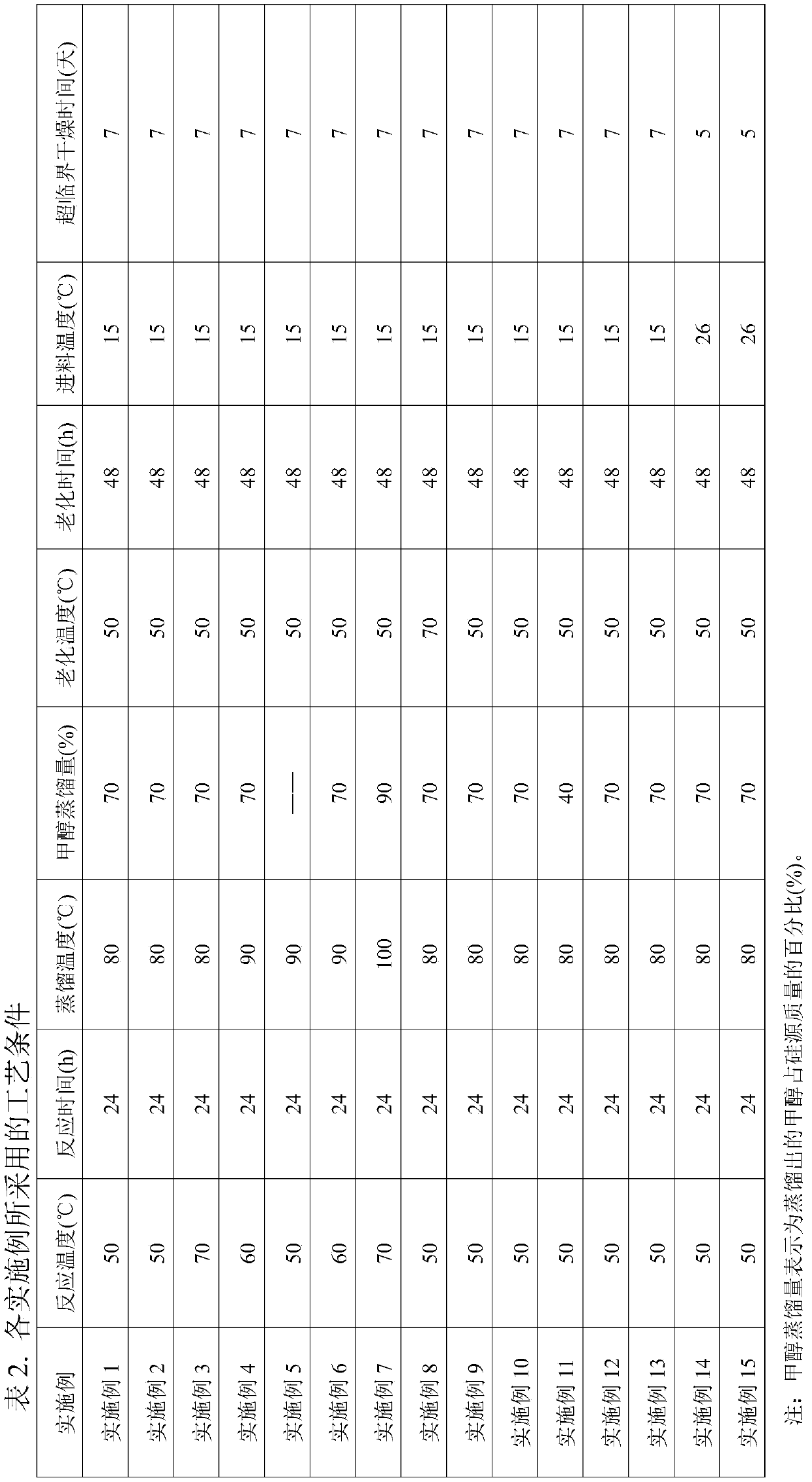

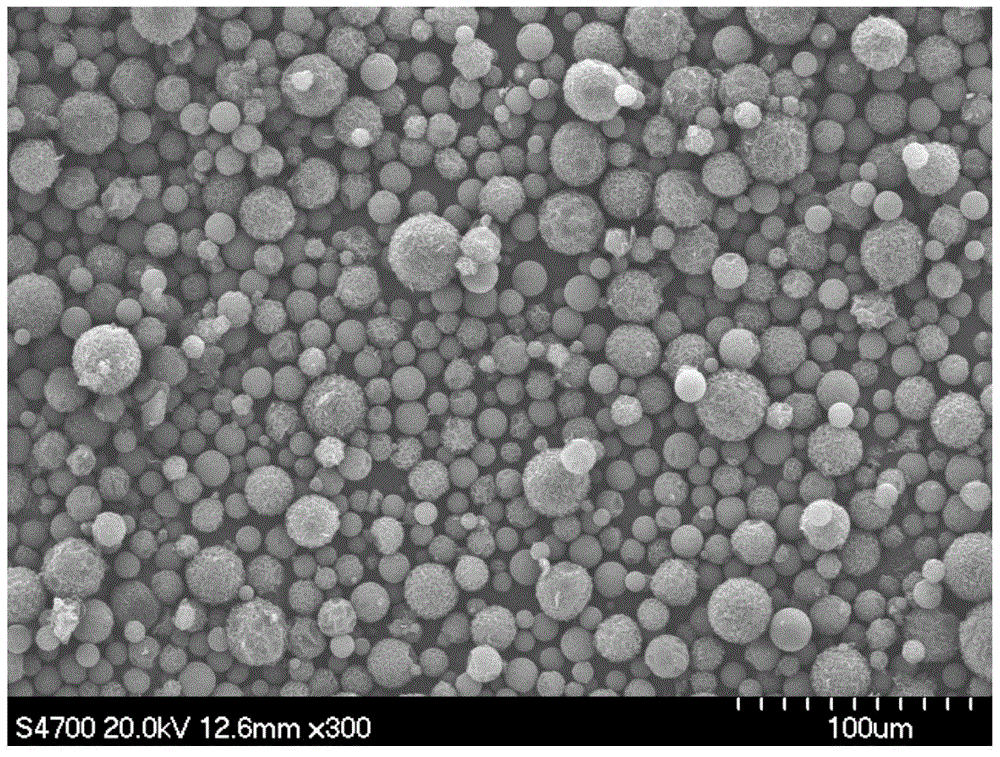

Ultra low density aerogel material, and preparation method and applications thereof

The invention provides a preparation method of an ultra low density aerogel material. The preparation method comprises following steps: a silicon source, methanol, and hydrochloric acid are added formixed reaction, distillation is carried out to remove methanol, and acetonitrile is added so as to obtain a sol precursor; the sol precursor is mixed with ammoniacal liquor, and acetonitrile is addedto prepare silica sol; the silica sol is subjected to gelling and aging successively so as to obtain a wet gel material; a hydrophobic agent is adopted for hydrophobization treatment of the wet gel material so as to obtain a hydrophobized gel material; the hydrophobized gel material is subjected to solvent displacement so as to obtain a solvent displaced gel; the solvent displaced gel is introduced into a drying kettle for supercritical drying so as to obtain the ultra low density aerogel material. The largest complete size of the ultra low density aerogel material is 300mm*300mm, the thickness ranges from 10 to 30mm; the density is lower than 20kg / m3, the size shrinkage rate is lower than 1%, the agglutinable volatile matter content is 0.06% or lower. The invention also provides applications of the ultra low density aerogel material in the field of deep space detection.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

A method for preparing graphene microspheres by atmospheric pressure drying

ActiveCN104401969BSpherical integrityUniform particle sizeMaterial nanotechnologyPtru catalystActive agent

The invention discloses a method for preparing a graphene microsphere through normal-pressure drying. A reaction system comprises graphenes, phenols, aldehydes, amines, a catalyst, a surfactant, an oil phase and water. A reaction is carried out in a reverse suspension polymerization manner. The graphene microsphere is prepared through the normal-pressure drying. In the method, the composite graphene microsphere is prepared through polymerization on a water / oil interface through a reaction solution. The employed oil phase can be used repeatedly during the preparation process. The method is simple and environmentally-protective. The graphene microsphere is low in preparation cost. In addition, an organic microsphere can be subjected to carbonization under an inert atmosphere to obtain the graphene microsphere. The graphene microsphere can be applied in the fields of micro-electronic, energy-storing materials, drug supporters, a lithium ion battery, a supercapacitor, an electro-adsorption electrode material and the like.

Owner:BEIJING UNIV OF CHEM TECH

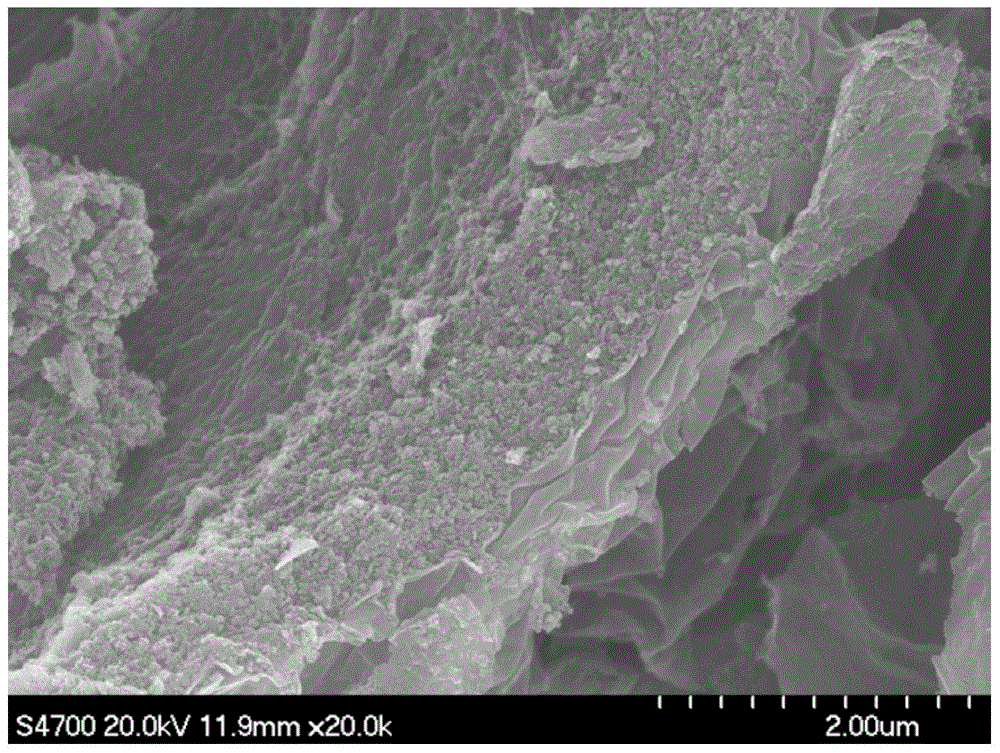

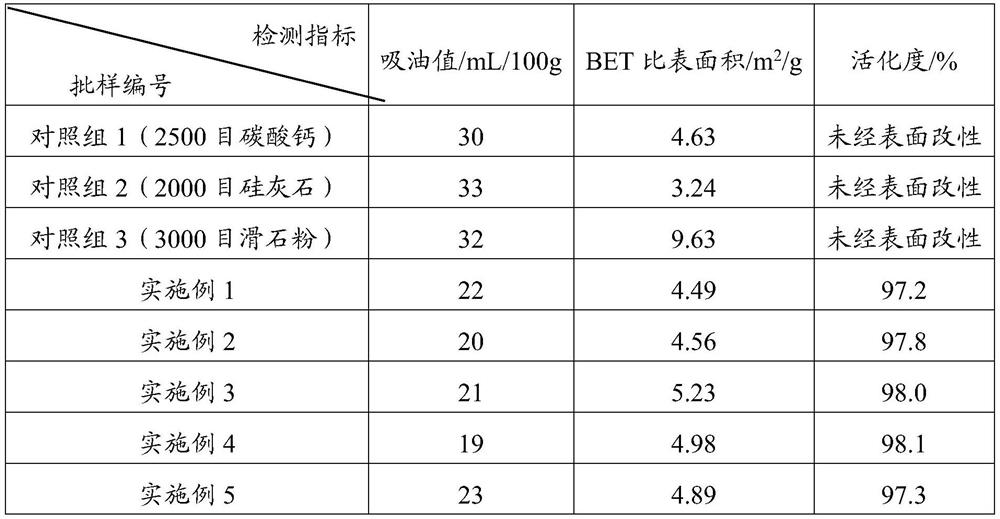

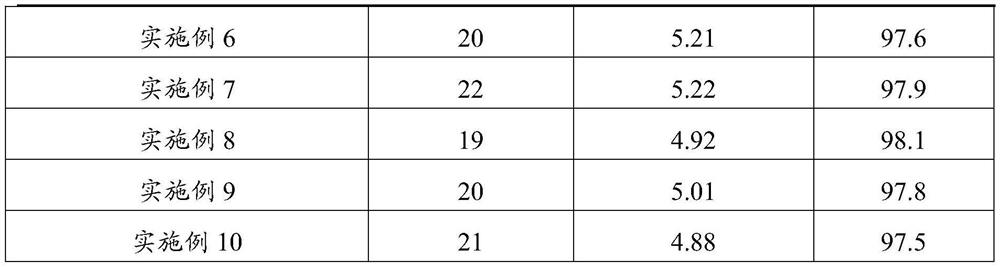

Composite mineral powder capable of reducing size shrinkage rate of plastic as well as preparation method and application of composite mineral powder

ActiveCN111892748ASmall size shrinkageImprove performancePigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsComposite materialSurface modification

The invention provides composite mineral powder capable of reducing the size shrinkage rate of plastic as well as a preparation method and application of the composite mineral powder, and belongs to the technical field of fine chemical engineering. According to the composite mineral powder capable of reducing the size shrinkage rate of the plastic as well as the preparation method and applicationof the composite mineral powder of the invention, three inorganic minerals, namely the silica powder, the talcum powder and the wollastonite powder, are compounded, so that the composite mineral powder can remarkably reduce the size shrinkage rate of a plastic product compared with a single mineral; with a composite dispersing agent adopted, the dispersity of the mineral powder can be improved; with a pH regulator and an antistatic agent added, agglomeration of the mineral powder can be reduced, and then full play of the effect of the mineral powder is facilitated; a composite surface modifieris adopted to perform surface modification treatment on the mineral powder, and therefore, the binding force between the composite mineral powder and the plastic matrix resin can be enhanced; the components cooperate with each other, so that the obtained composite mineral powder can significantly improve the comprehensive performance of the plastic product while the size shrinkage rate of the plastic product is reduced.

Owner:JIANGXI GUANGYUAN CHEM

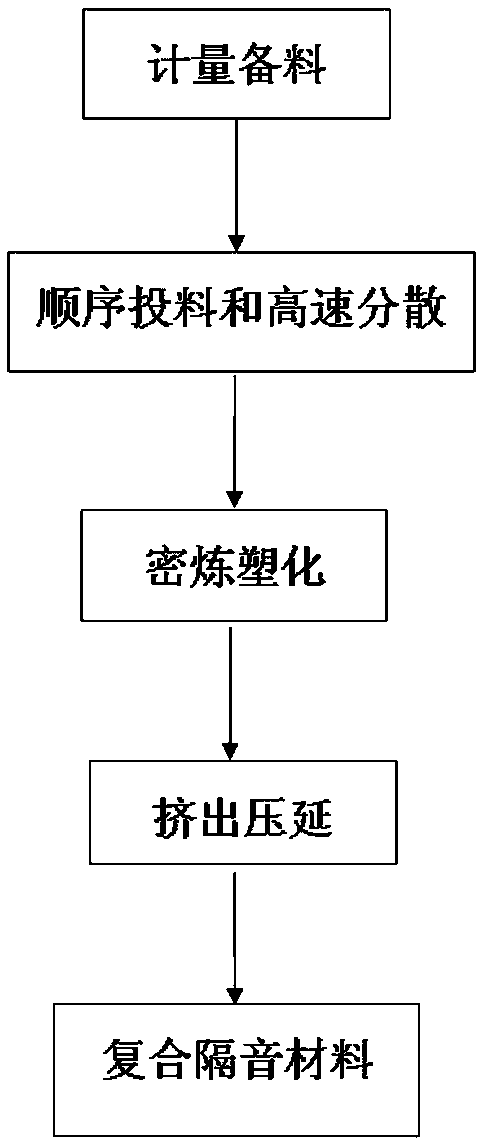

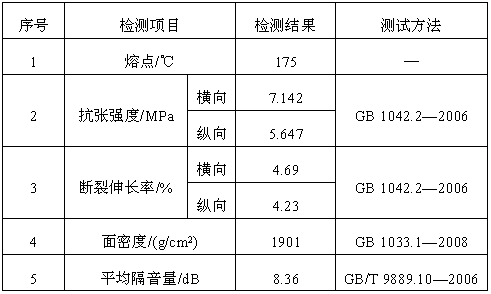

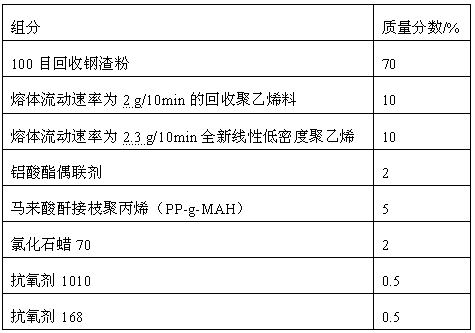

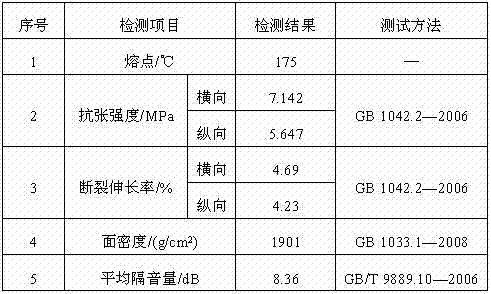

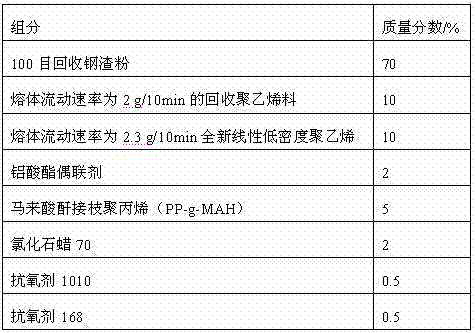

A kind of composite sound insulation material and preparation method thereof

Owner:KUNMING IRON & STEEL HLDG CO LTD

Dental ceramic material and preparation method and application thereof

InactiveCN110041066AGood biocompatibilityHigh solid contentAdditive manufacturing apparatusTissue regenerationBiocompatibility TestingSlurry

The invention provides a dental ceramic material and a preparation method and an application thereof, and belongs to the field of dental ceramic materials. The preparation method includes the following steps: mixing zirconia ceramic powder and an inorganic phosphate solution to obtain ceramic slurry; carrying out 3D printing or injection molding on the ceramic slurry to obtain ceramic body; and dehydrating and sintering the ceramic body in order to obtain the dental ceramic material. The dental ceramic material of the invention adopts the inorganic phosphate as a binder, does not undergo thermal decomposition under the condition of ensuring good bonding performance, changes from an amorphous phase to a crystalline phase when reaching phase transition temperature, which means the inorganicphosphate is converted into a corresponding crystalline phase during the sintering process, so as to further increase the solid content and compactness of bioceramic. In addition, in the invention, the zirconia ceramic powder has good biocompatibility and has lower size shrinkage compared with ceramic prepared by conventional organic binder ceramic slurry.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

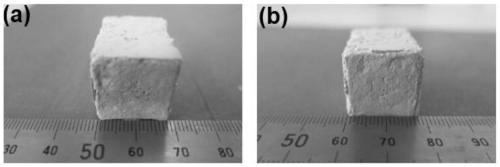

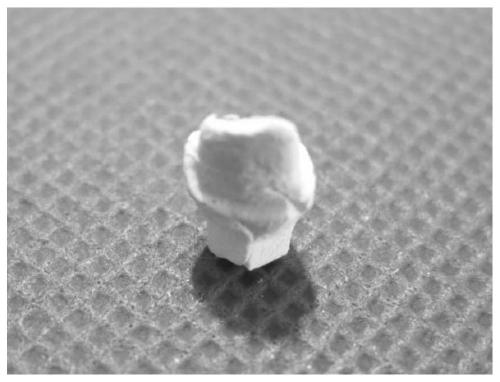

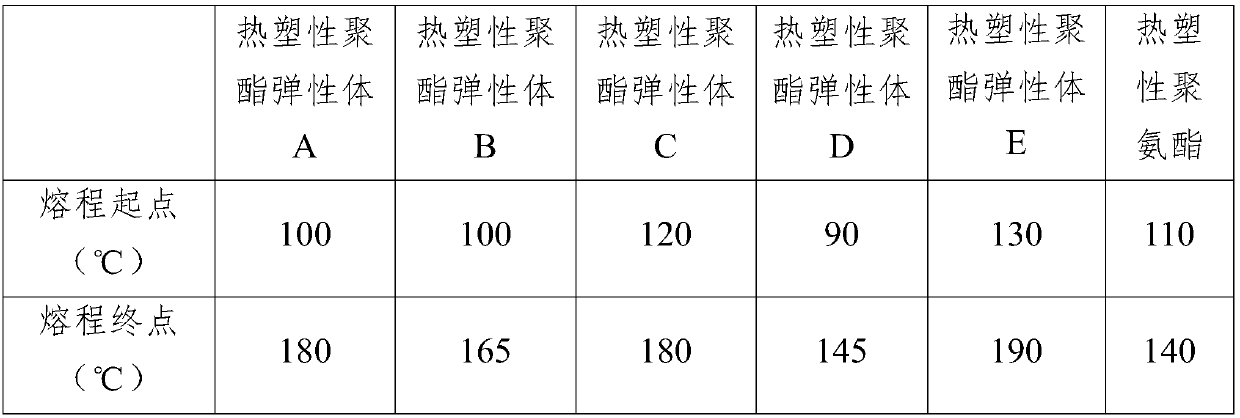

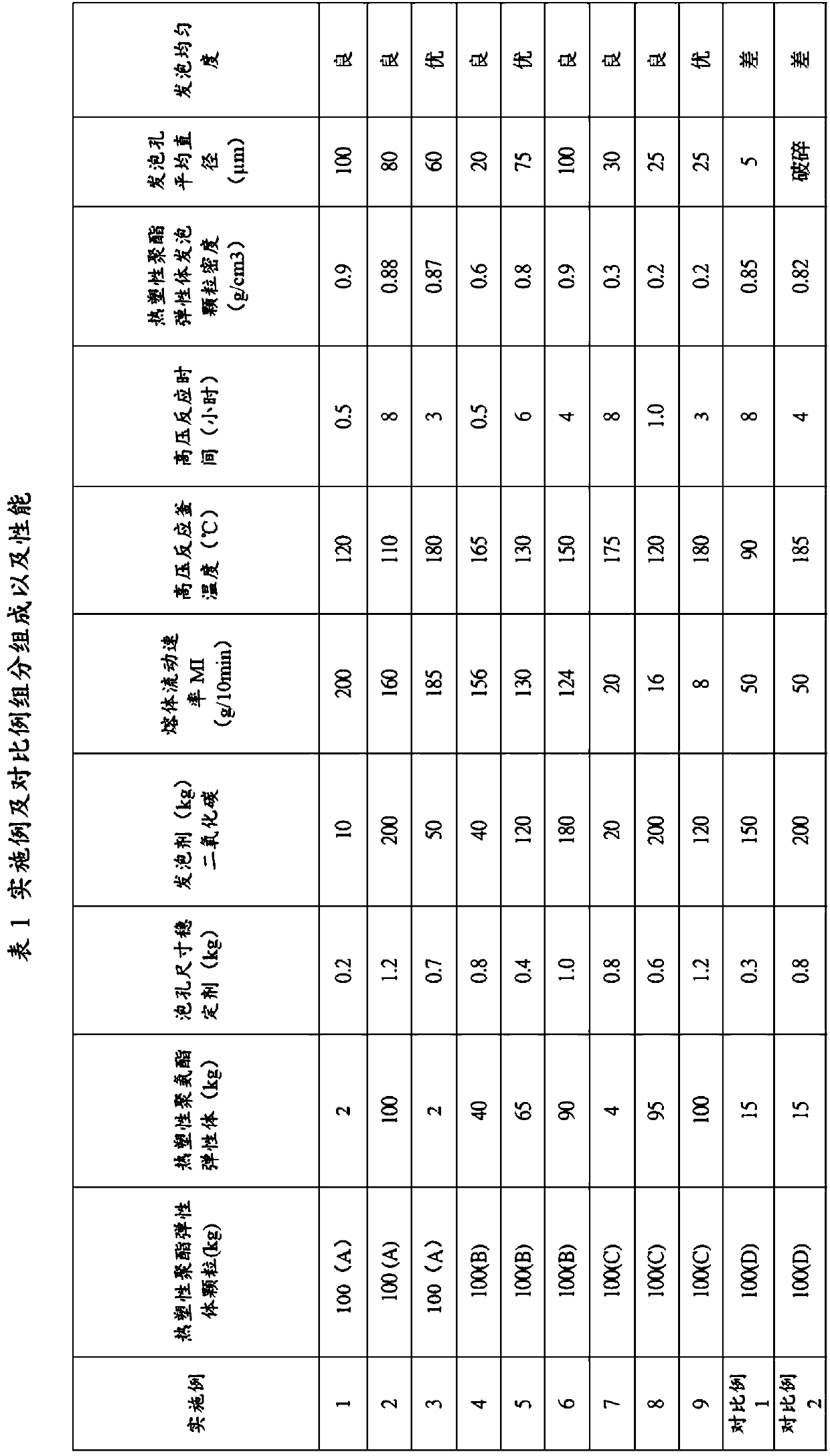

Precursor for thermoplastic polyeher ester elastomer foaming, foaming body and preparation method thereof

In order to overcome the problem that the existing thermoplastic polyeher ester elastomer is difficult to foam, the invention provides a precursor for thermoplastic polyeher ester elastomer foaming. The precursor comprises the following components: a thermoplastic polyeher ester elastomer and a melt melting viscosity regulator, wherein the melting range starting point of the thermoplastic polyeherester elastomer is not smaller than 100 DEG C, and the melting range terminal point is not greater than 180 DEG C. Meanwhile, the invention further discloses thermoplastic polyeher ester foam and a preparation method thereof. The thermoplastic polyeher ester foam has the advantages of low weight, excellent appearance, excellent elasticity and stable optothermal characteristic.

Owner:唐靖

Polyvinyl acetal foam material, preparation method thereof and cervical dilatation device

PendingCN110835448ADifficult to dissolveLow densityObstetrical instrumentsCompression moldingPolymer science

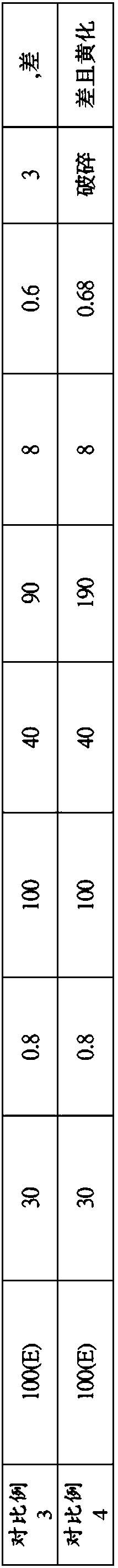

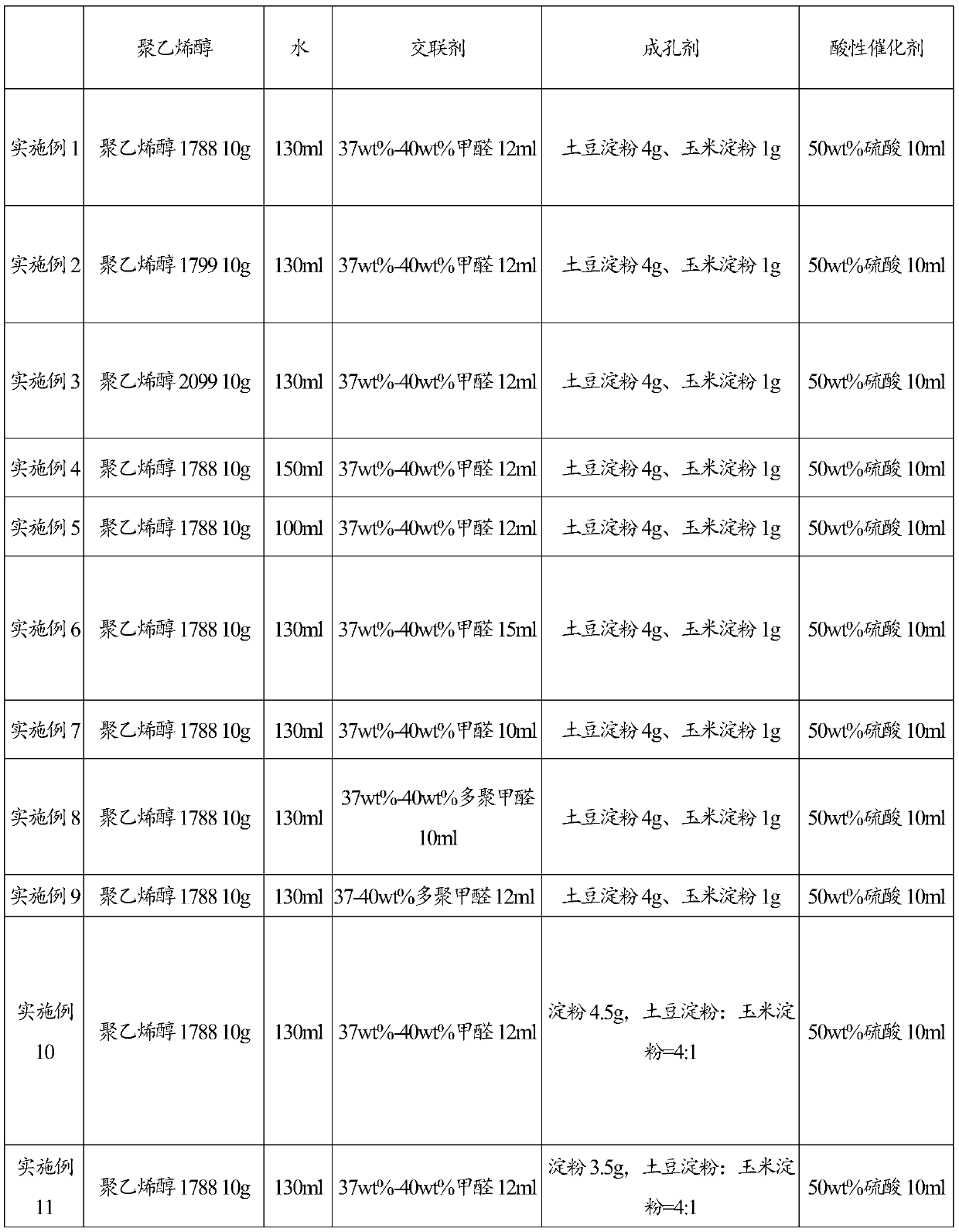

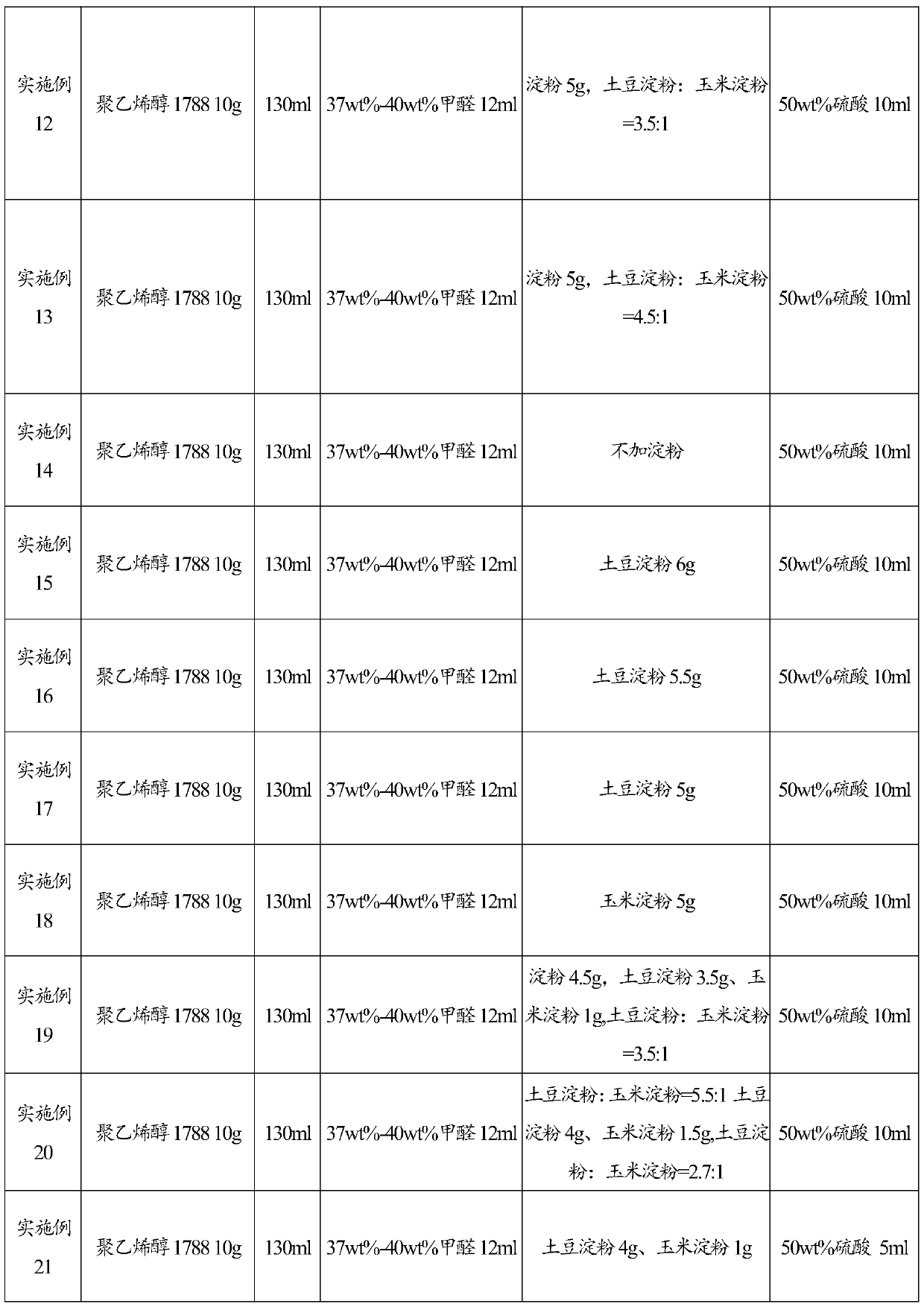

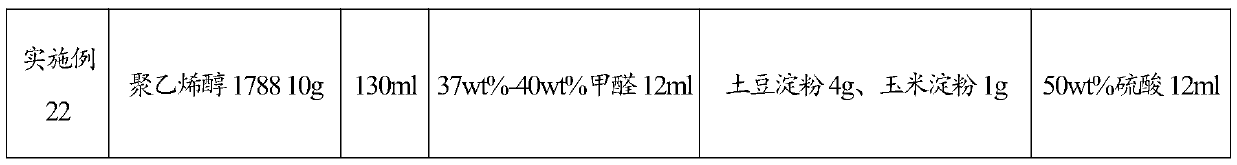

The invention discloses a polyvinyl acetal foam material, a preparation method thereof and a cervical dilatation device. The preparation method comprises the following steps: (1) preparing polyvinyl acetal porous foam: mixing raw materials, and reacting the obtained mixture to obtain the polyvinyl acetal porous foam, wherein the raw materials consist of polyvinyl alcohol, water, a cross-linking agent, a pore-forming agent and an acidic catalyst; (2) cutting the foam; (3) drying the foam; and (4) carrying out compression molding. The polyvinyl acetal foam material has the advantages of smooth and defect-free macroscopic surface, high surface layer toughness, safety to use, good water absorption, high tensile strength and good resilience, and can be used as a cervix uteri expansion rod bodyfor the cervical dilatation device.

Owner:成都博创必成生物技术有限公司

Three-dimensional pattern layer manufacturing method for vamp

ActiveCN109203743AHigh tensile strengthImprove crispnessShoemaking devicesOther printing apparatusWater basedMixing ratio

The invention relates to a three-dimensional pattern layer manufacturing method for a vamp. The method is characterized in that a three-dimensional pattern layer is lightweight and subjected to buffering protection while high three-dimensional vision effect is realized. The method comprises the following steps: manufacturing at least one silk-screen board based on a designed pattern; performing silk-screening on the vamp through one of the silk-screen boards, and drying to obtain a water-based resin combining layer; performing silk-screening before an outer layer of the water-based resin combining layer is completely dried, and drying to form a water-based foamed ink layer, wherein the water-based foamed ink layer contains an ultraviolet attenuator; irradiating the surface of the water-based foamed ink layer for 15-20s through UV to obtain a modified foamed ink layer of which the melt strength is gradually reduced from outside to inside; physically processing the surface of the modified foamed ink layer to form a plurality of pre-mixing concave areas, drying; performing silk-screening on the outer surface of the modified foamed ink layer through any one of the silk-screen boards, and drying to obtain a foamed color paste layer, wherein the foamed color paste layer is divided from inside to outside through three layers which are formed by coating with different mixing ratio; andthen pressing through a die, and foaming.

Owner:FUJIAN MEIMINGDA SHOES DEVING

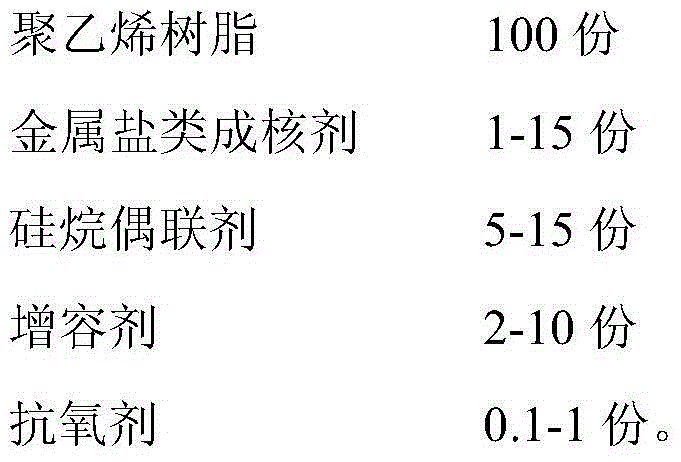

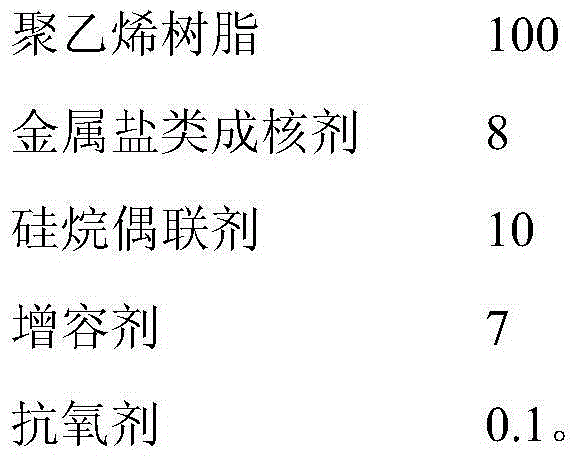

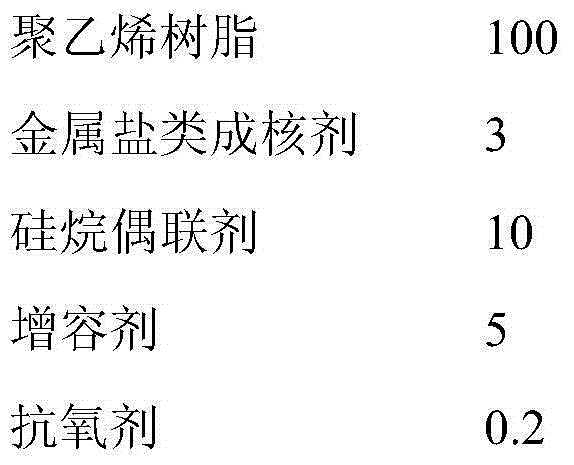

Composition for enhancing dimensional stability of HDPE water supply pipe

The invention discloses a composition for enhancing dimensional stability of an HDPE water supply pipe, wherein the composition comprises the following raw material components in parts by weight: 100 parts of polyethylene resin, 1-15 parts of a metal salt nucleating agent, 5-15 parts of a silane coupling agent, 2-10 parts of a compatibilizer, and 0.1-1 part of an antioxidant. In the technical scheme of the invention, through mutual cooperation and combined action of the various components, the obtained composition has an obvious effect on enhancing the dimensional stability of the HDPE water supply pipe, the processing technology is simple and easy to control, and other properties of the water supply pipe keep similarly excellent.

Owner:SHANGHAI BANGZHONG NEW MATERIAL

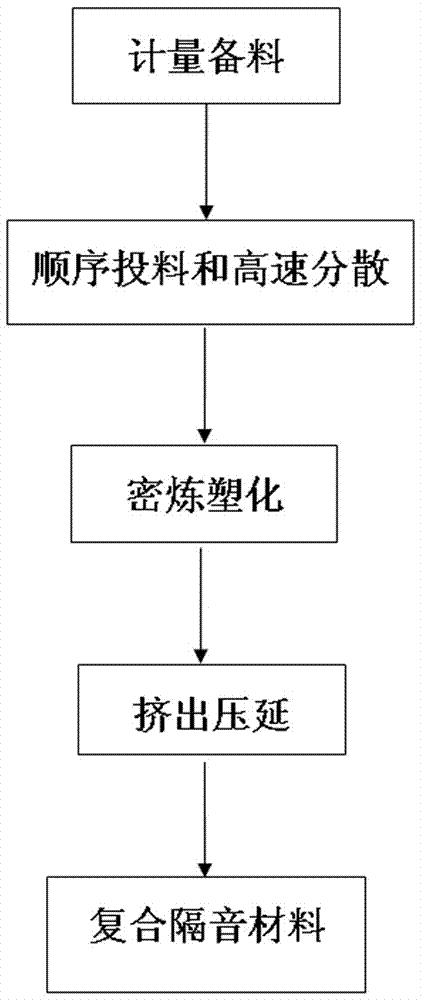

Composite sound-insulation material and preparation method thereof

The invention discloses a composite sound-insulation material and a preparation method thereof. The composite sound-insulation material is composed of the following components in percentage by mass: 65-75% of reclaimed steel slag powder, 10-20% of reclaimed polyethylene, 5-10% of linear low-density polyethylene, 2.5-5% of high-polymer compatilizer, 1-2% of diluter, 1-2% of coupling agent and 0.5-1% of antioxidant. The preparation method comprises the following steps: metering and preparing materials, sequentially adding the materials, dispersing at high speed, banburying, plastifying, extruding, calendering and the like. The steel scrap slag and waste plastic are recycled, thereby implementing reutilization of the waste resources. The composite sound-insulation material has the advantages of low cost, high constructability and the like, is easy for secondary processing and applicable to sound insulation treatment of irregular objects.

Owner:KUNMING IRON & STEEL HLDG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com