Dental ceramic material and preparation method and application thereof

A technology for dental ceramics and ceramic slurry, which is used in medical science, additive processing, prosthesis, etc., and can solve problems such as poor compactness and dimensional shrinkage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a kind of preparation method of dental ceramic material, comprises the following steps:

[0026] mixing zirconia ceramic powder with inorganic phosphate solution to obtain ceramic slurry;

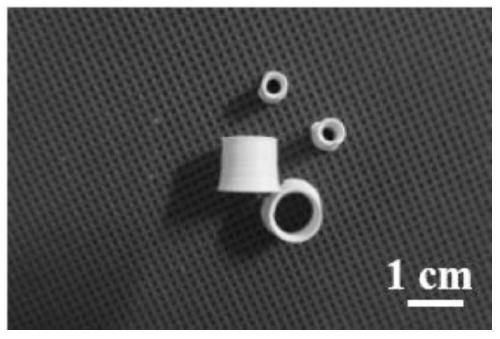

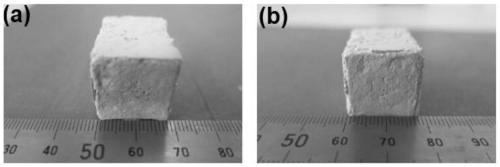

[0027] 3D printing or injection molding the ceramic slurry to obtain a ceramic green body;

[0028] The ceramic body is sequentially dehydrated and sintered to obtain a dental ceramic material.

[0029] The invention mixes zirconia ceramic powder with inorganic phosphate solution to obtain ceramic slurry. In the present invention, the inorganic phosphate solution preferably includes aluminum dihydrogen phosphate, aluminum hydrogen phosphate and aluminum phosphate normal salt. In the present invention, the inorganic phosphate solution is preferably prepared through the following steps: after mixing aluminum hydroxide and phosphoric acid in a molar ratio of 1:3 to 3.5, liquid phase synthesis is carried out, and the temperature of the liquid phase synthesis is 9...

Embodiment 1

[0046] Feed phosphoric acid and aluminum hydroxide at a molar ratio of 3:1, stir at 95°C for 2.5 hours to obtain a transparent and uniform phosphorus-containing binder, and continue mechanical stirring during the reaction to finally obtain an aluminum phosphate inorganic binder sol. After the aluminum phosphate sol is cooled to room temperature, the yttria-stabilized zirconia nano-powder is added into the phosphorus-containing binder in five batches, wherein the average grain size of the yttrium-stabilized zirconia nano-powder is 50nm, and the yttrium-stabilized zirconia nano-powder The mass ratio of the zirconium nanopowder to the phosphorus-containing binder is 1:1, and the ceramic slurry is prepared by ball milling. The rotational speed of the ball mill is 2500rmp, the time is 5min, and the number of repetitions is 3 times.

[0047] The ceramic slurry is injected into the barrel of the 3D printer, the printing parameters are adjusted, and the designed ceramic body is printed...

Embodiment 2

[0051] Feed phosphoric acid and aluminum hydroxide at a molar ratio of 3.5:1, stir at 90°C for 2 hours to obtain a transparent and uniform phosphorus-containing binder, and continue mechanical stirring during the reaction to finally obtain an aluminum phosphate inorganic binder sol. After the aluminum phosphate sol is cooled to room temperature, the yttria-stabilized zirconia nano-powder is added into the phosphorus-containing binder in six batches, wherein the average grain size of the yttrium-stabilized zirconia nano-powder is 80nm, and the yttrium-stabilized zirconia nano-powder The mass ratio of the zirconium nanopowder to the phosphorus-containing binder is 1:2, and the ceramic slurry is prepared by ball milling. The rotational speed of the ball mill is 2000rmp, the time is 2min, and the number of repetitions is 5 times.

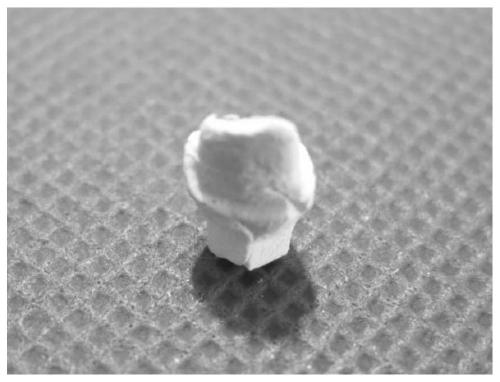

[0052] A mold of human teeth is prepared by photo-curing printing, and then ceramic slurry is injected into the mold by injection molding to prepare cor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

| Storage modulus | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com