Patents

Literature

36results about How to "No thermal decomposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

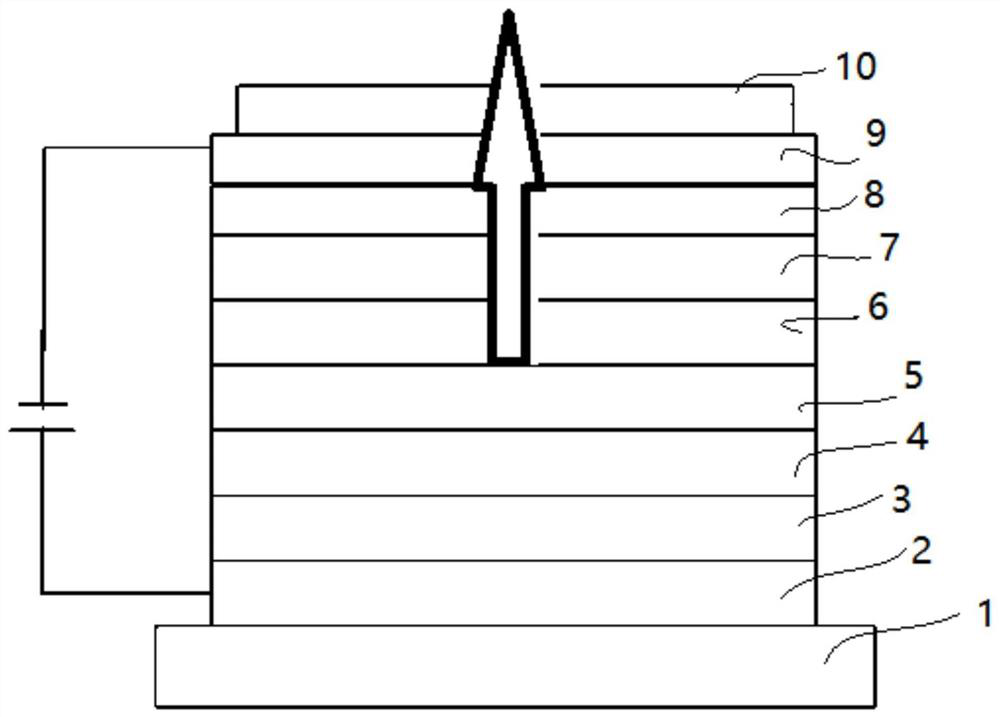

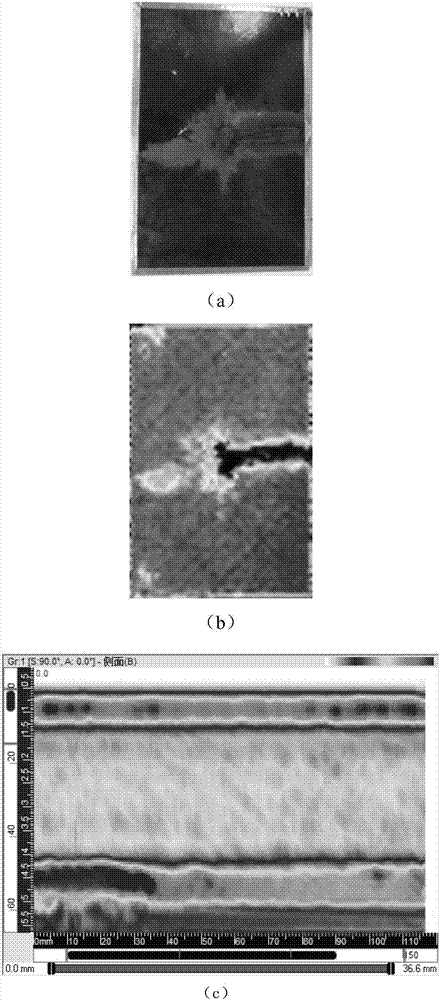

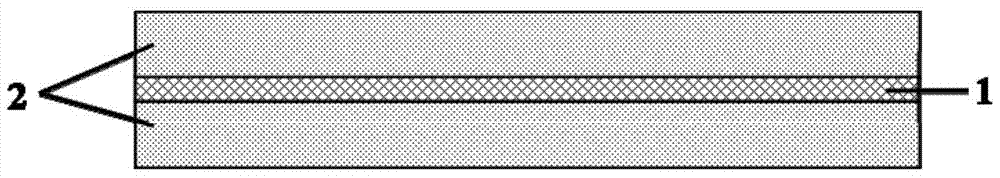

Insulating and thermal conductive ablation resistant adhesive and application thereof in lightning protection

ActiveCN104789175AAvoid failureImprove lightning protectionNon-macromolecular adhesive additivesSynthetic resin layered productsFiberCarbon fibers

Belonging to the technical field of lightning protection, the invention relates to an insulating and thermal conductive ablation resistant adhesive and application thereof in lightning protection. The adhesive is mainly prepared from the following raw materials: 20-100% and not up to 100% of a mixture of high temperature resistant resin and a curing agent, and 0-80% and greater than 0% of an insulating and thermal conductive ablation resistant inorganic filler. After curing, the electrical conductivity of the adhesive is in the range of 10<-8>-10<-20>S / m, the DC breakdown voltage in the air is in the range of 30-300kV / mm, the thermal conductivity is in the range of 0.2-3.0W / (m.K), and the ablation resistant temperature is up to 300DEG C. A certain thickness (30-250micrometer) of the insulating and thermal conductive ablation resistant adhesive is employed to stick a conductive film to the surface of a continuous carbon fiber laminated composite material part, thus preventing conduction of current to the continuous carbon fiber laminated composite material part and improving the lightning protection effect of the conductive film.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

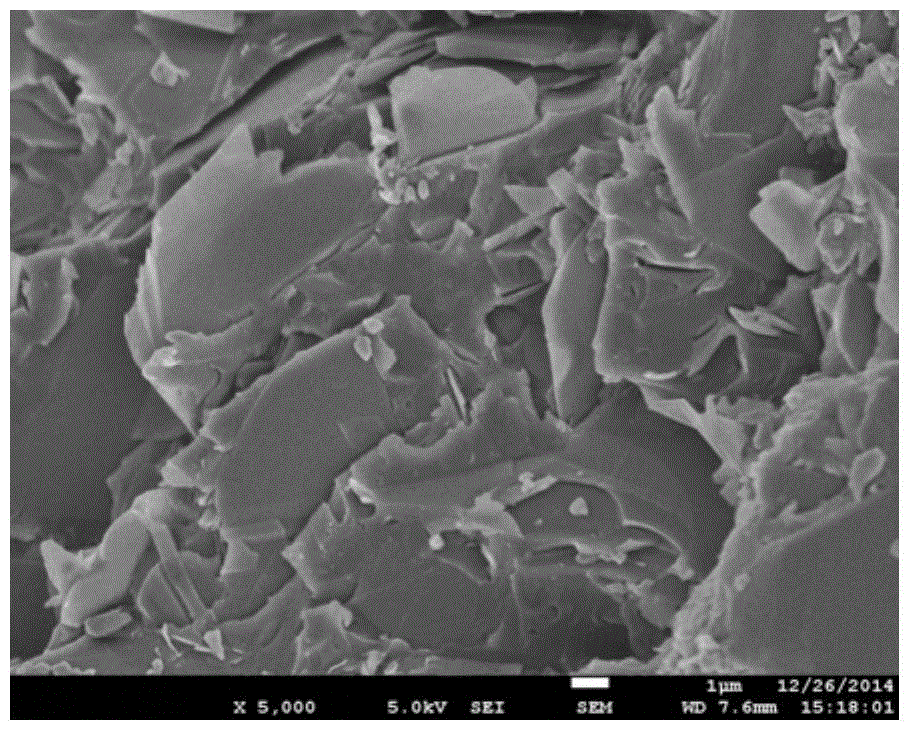

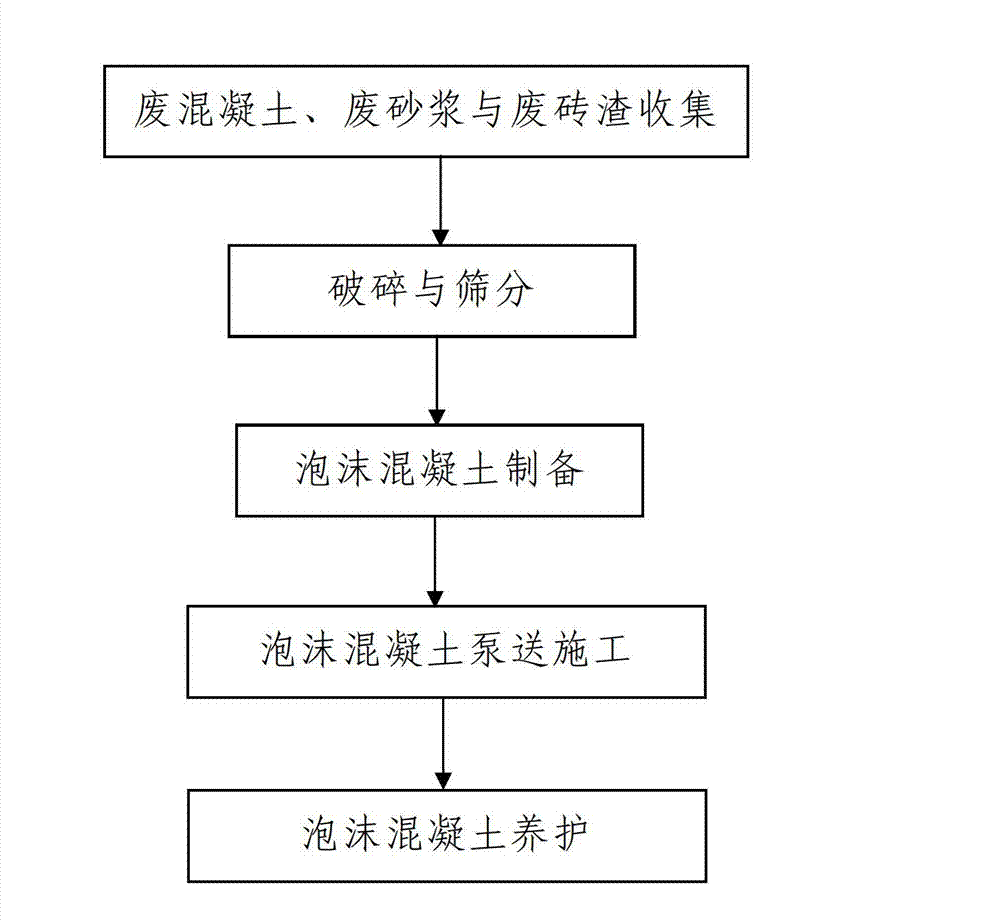

Construction waste recycling and reusing process

InactiveCN102815964AThe method steps are simpleReasonable designSolid waste managementBuilding material handlingFoam concreteBrick

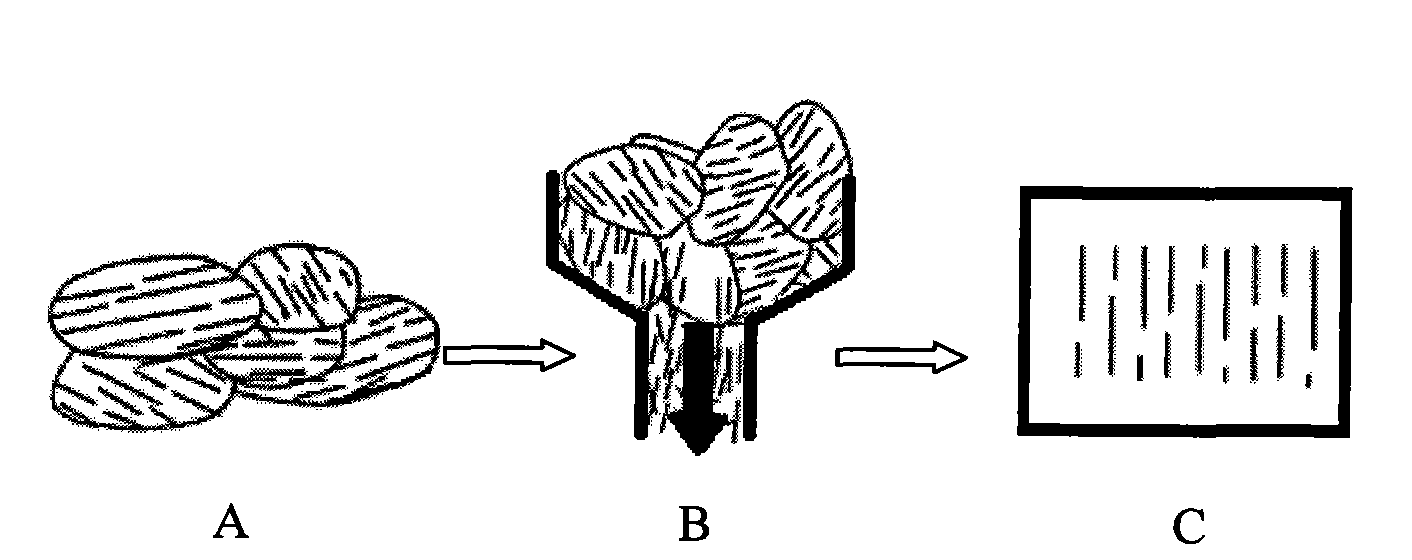

The invention discloses a construction waste recycling and reusing process, which comprises the following steps of: 1, collecting waste concrete, waste mortar and waste brick slag; 2, smashing and screening, namely smashing and screening the collected waste concrete, the collected waste mortar and the collected waste brick slag to obtain regenerative rough aggregates and regenerative fine aggregates; and 3, preparing foam concrete, namely firstly preparing cement slurry, namely uniformly stirring concrete, water, the regenerative rough aggregates and the regenerative fine aggregates to obtain the cement slurry, and secondly adding a foam dilution solution, namely adding the foam dilution solution formed by uniformly mixing a foaming agent and water into the cement slurry, and uniformly stirring to obtain the foam concrete. The steps of the process are simple; the investment cost is low; the process is simple, feasible and high in operability; the waste concrete, the waste mortar and the waste brick slag can be effectively reused; the economical benefit is outstanding; the produced foam concrete material is high in heat preservation performance; and the problems that the construction waste is abandoned and stacked randomly and occupies the land, the waste of resources is severe, and the environment pollution is severe are solved.

Owner:陕西建工集团有限公司

Mother stock of polyvinyl carbon nanotube anti-static composite material and anti-static composite material based on mother stock

InactiveCN1670070AGood antistatic propertiesComprehensive mechanical propertiesAntistatic MaterialsMaleic anhydride

The invention relates to an anti-static modified material with carbon nanotubes (CNTs) predominantly and a process which is a thermal oxidation treatment with acid together with a ball grinding surface treatment to CNTs and comprises: adding maleic anhydride grafted polyethylene, coupling agents and EPT rubber to prepare the high concentration masterbatch of CNTs / PE anti-static composite material by solution blending and melt blending methods, mixturing the said masterbatch with common PE in a finite proportion to melt blend and prill, then getting the final CNTs / PE anti-static composite material. The electrical surface resistivity and volume resistivity can reach the operating requirements of the anti-static material when the content of CNTs is only 0.3 wt % in the CNTs / PE anti-static composite material in the invention.

Owner:EAST CHINA UNIV OF SCI & TECH

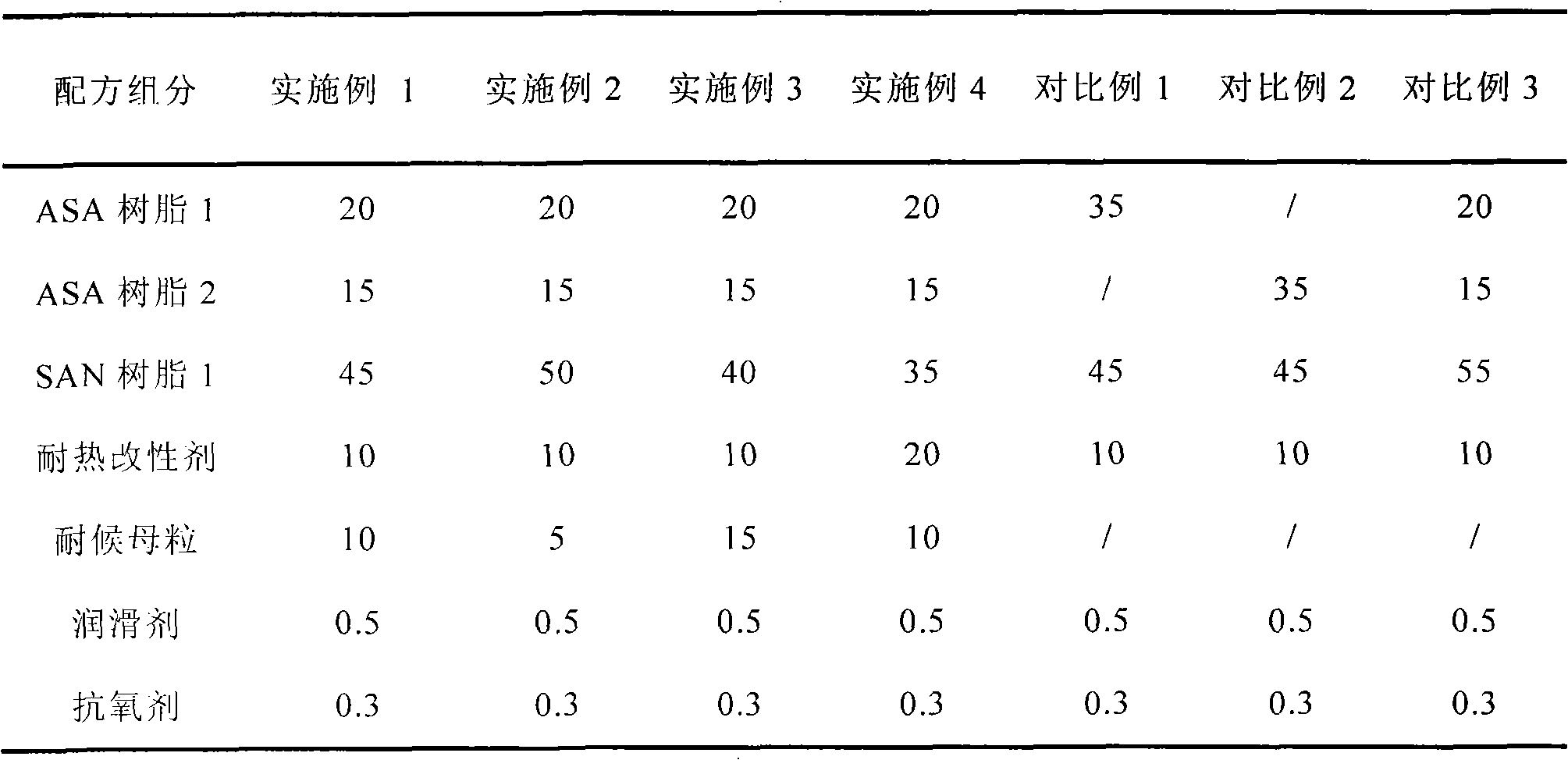

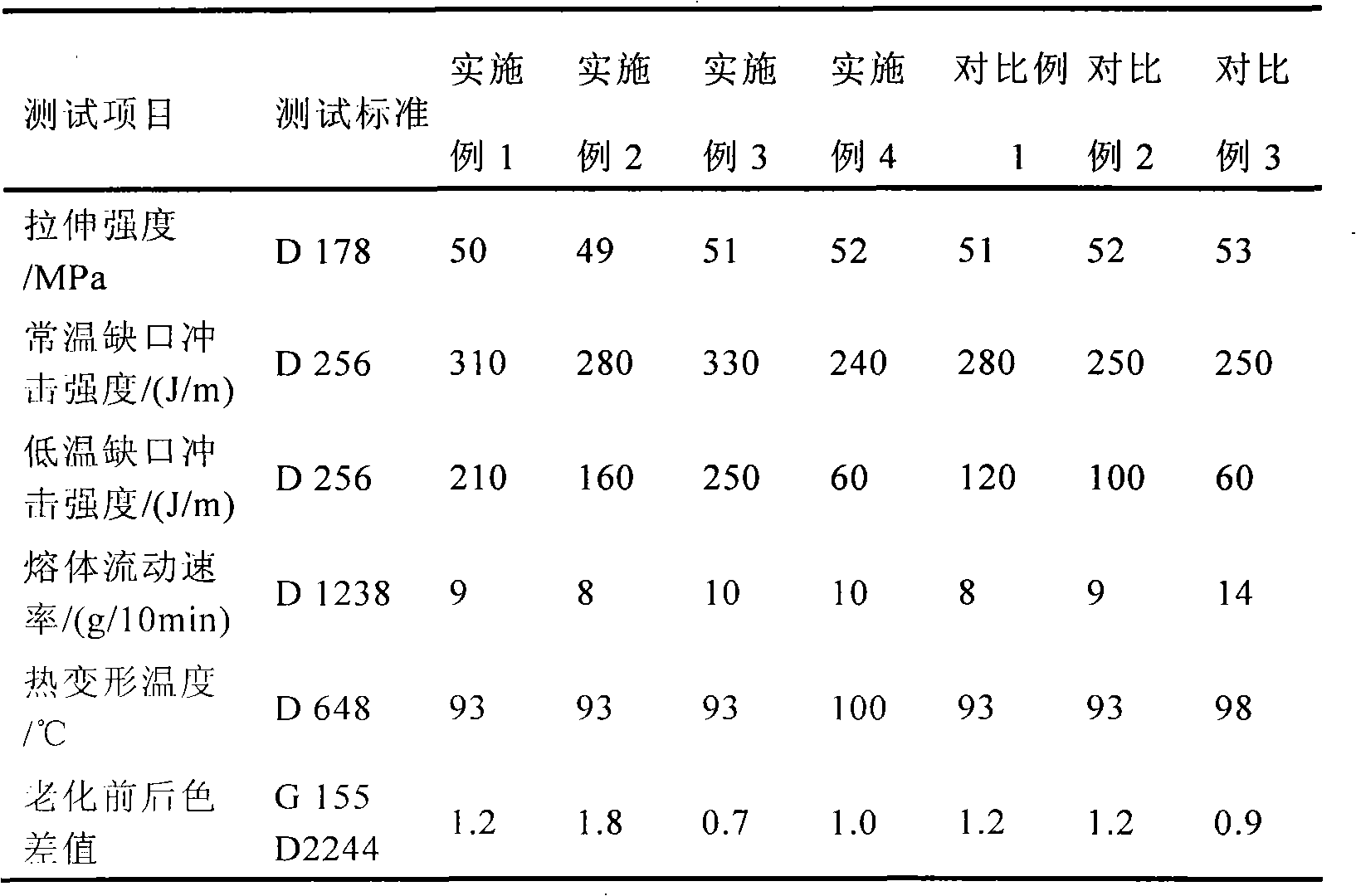

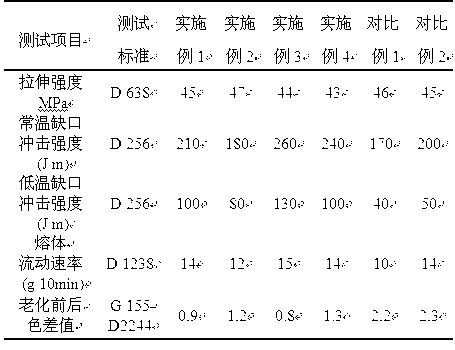

High-weather-resistance acrylate resin composition and preparation method thereof

The invention relates to a high-weather-resistance acrylate resin composition and a preparation method thereof. The raw materials of the high-weather-resistance acrylate resin composition comprise the following components in part by weight: 10 to 30 parts of acrylate rubber powder 1, 10 to 30 parts of acrylate rubber powder 2, 30 to 60 parts of SAN resin 1, 5 to 20 parts of heat-resistant modifier, 5 to 15 parts of weather-resistant master batch, 0.3 to 3 parts of lubricant and 0.05 to 0.5 part of antioxidant. The preparation method comprises the following steps of: stirring the raw materials except the weather-resistant master batch to obtain a mixture; adding the mixture from a main feed inlet of a double-screw extruder, and adding the weather-resistant master batch from a side feed inlet; and extruding and pelleting the raw materials by the double-screw extruder to obtain a sample. The high-weather-resistance acrylate resin composition prepared by the method has higher heat resistance, low-temperature impact resistance, weather resistance, excellent size stability and processing property, and is particularly suitable for automobile exterior trim parts, such as radiator grilles, rear-view mirrors, license plates, central pillar plates, outdoor triangular blocks and the like, with high requirements on weather resistance, heat resistance and low-temperature impact resistance.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

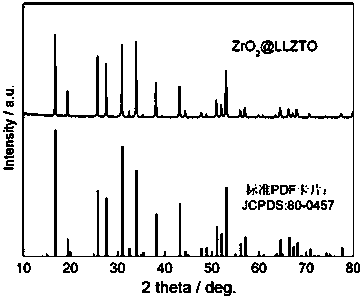

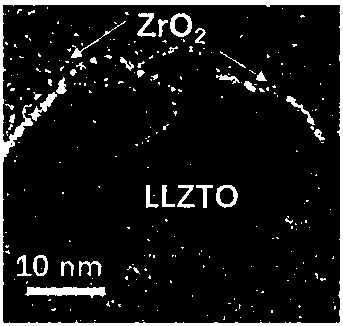

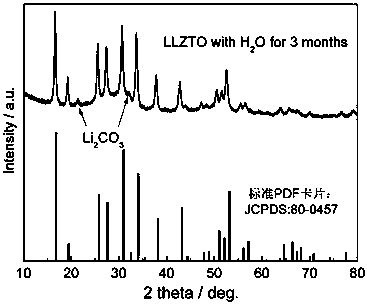

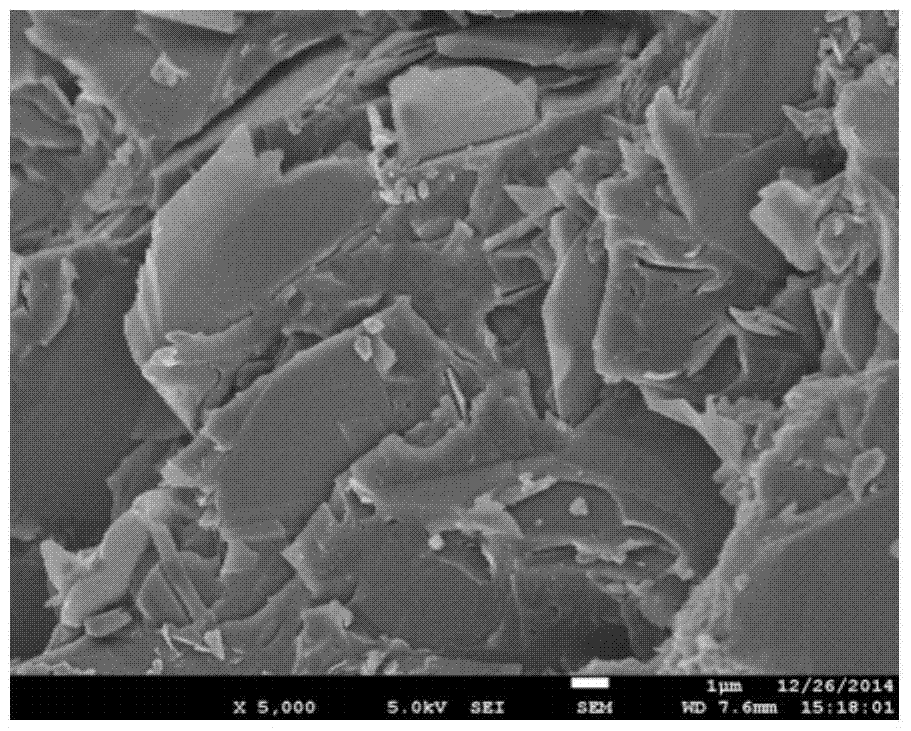

Lithium-lanthanum-zirconium oxide-based solid electrolyte material with stable surface, and preparation method and application thereof

ActiveCN110176628AGood chemical stabilityStop erosionFinal product manufactureElectrolytesZirconium hydrideLanthanum

The invention discloses a lithium-lanthanum-zirconium oxide-based solid electrolyte material with stable surface, and a preparation method and an application thereof. The solid electrolyte material comprises an inner core and a coating layer which coats the surface of the inner core; the inner core is a lithium-lanthanum-zirconium oxide-based solid electrolyte (LLZO); and a material of the coatinglayer is an oxide. The inner core part, namely, the LLZO is coated with the oxide coating layer; and the LLZO can maintain a stable three-dimensional phase structure with high ionic conductivity, sothat phase change or thermal decomposition does not occur. The material of the oxide coating layer can change the chemical composition and surface acid-base property of the surface of the LLZO, and can block the erosion of air and water to the LLZO, so that the chemical stability of the LLZO in the air and the water is greatly improved, the application range, the processing environment and the using condition of the LLZO are expanded, and the energy density and the cycling stability of a lithium-lanthanum-zirconium oxide-based battery are improved.

Owner:济宁克莱泰格新能源科技有限公司

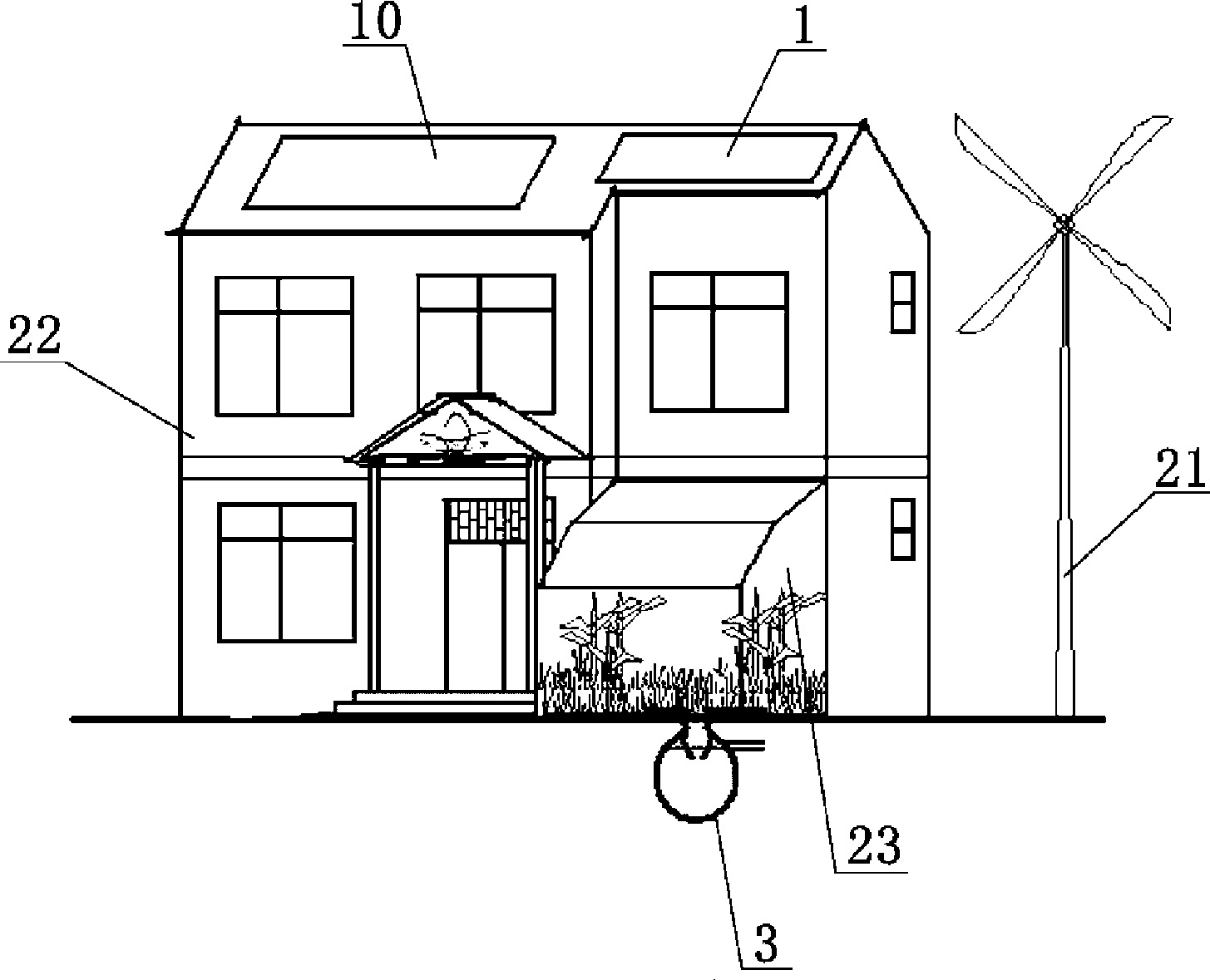

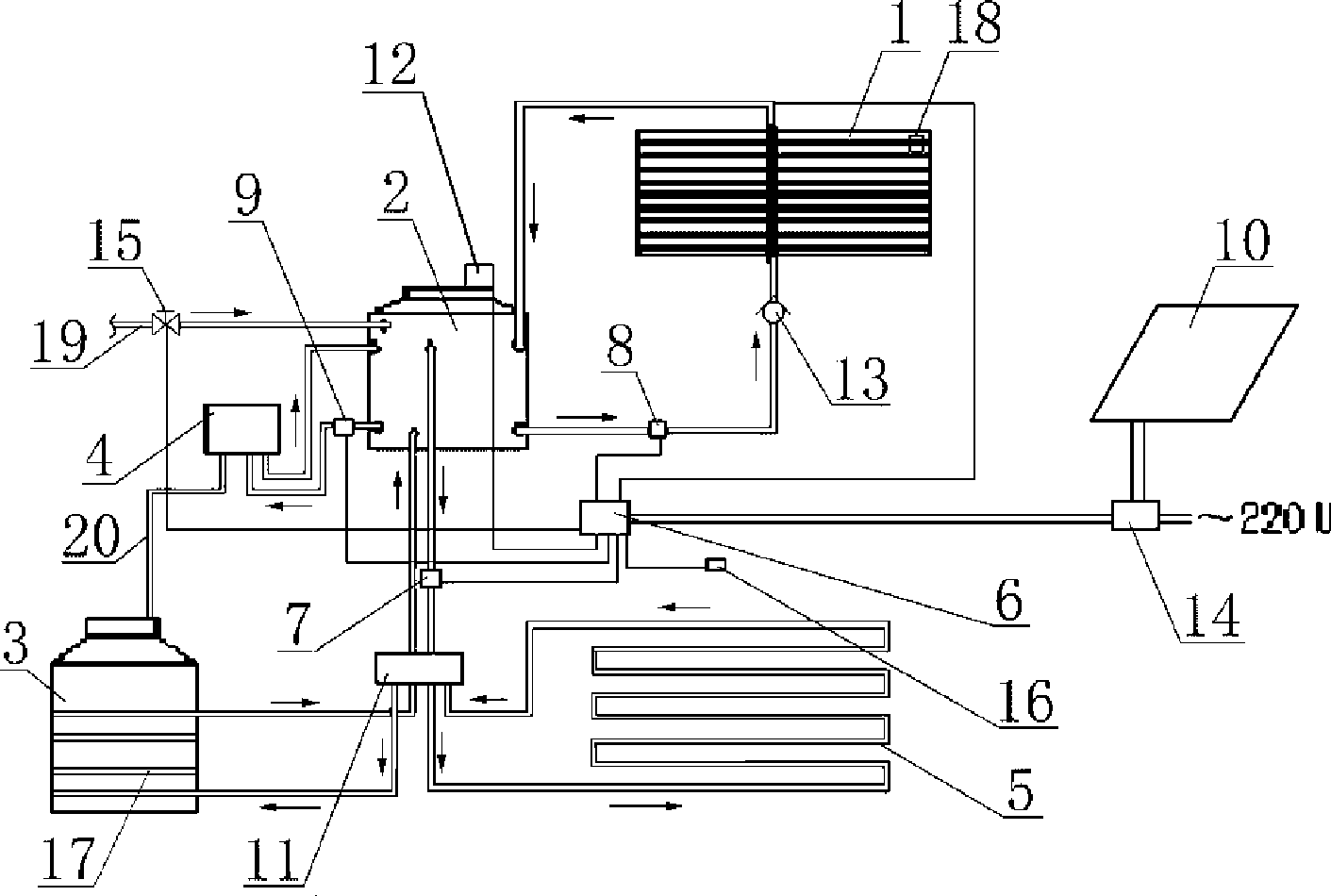

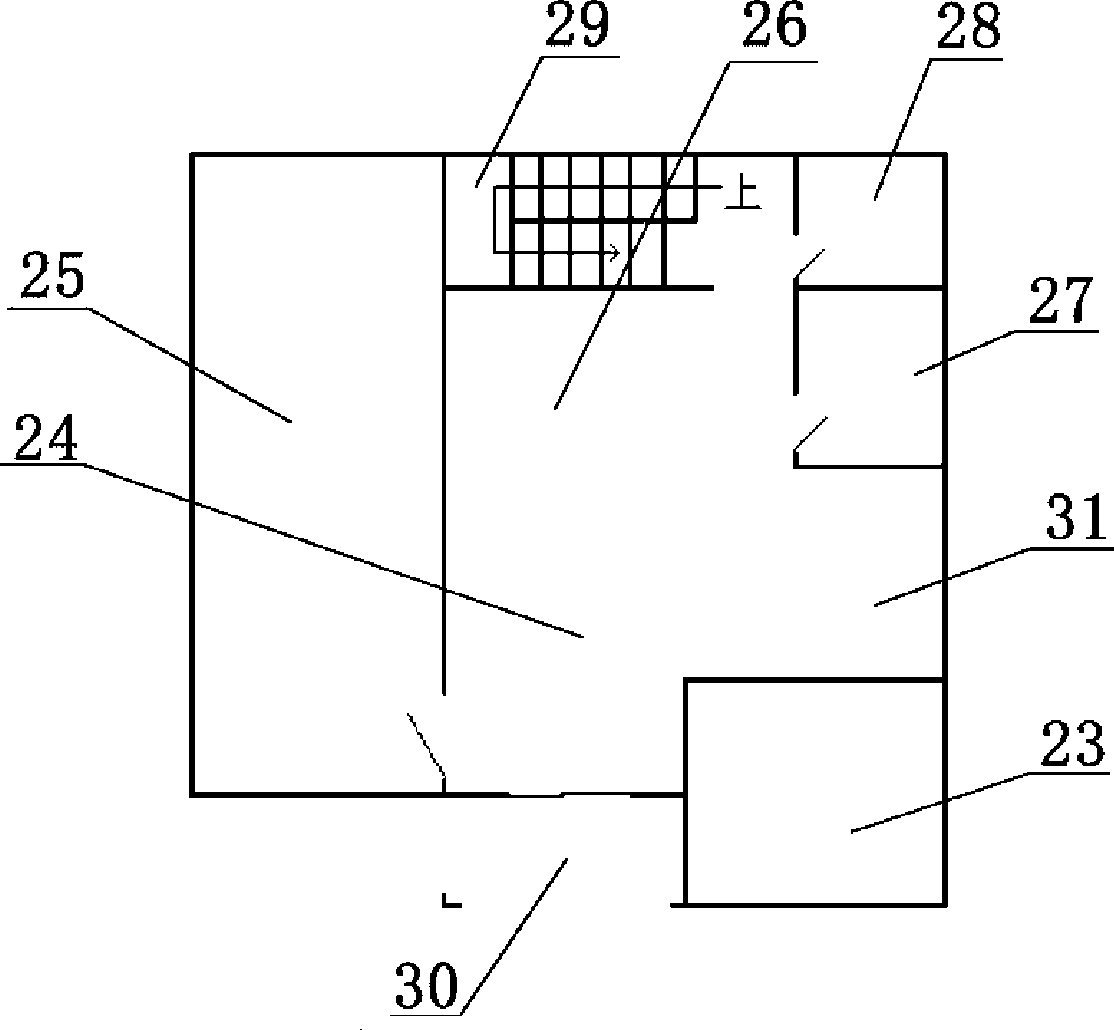

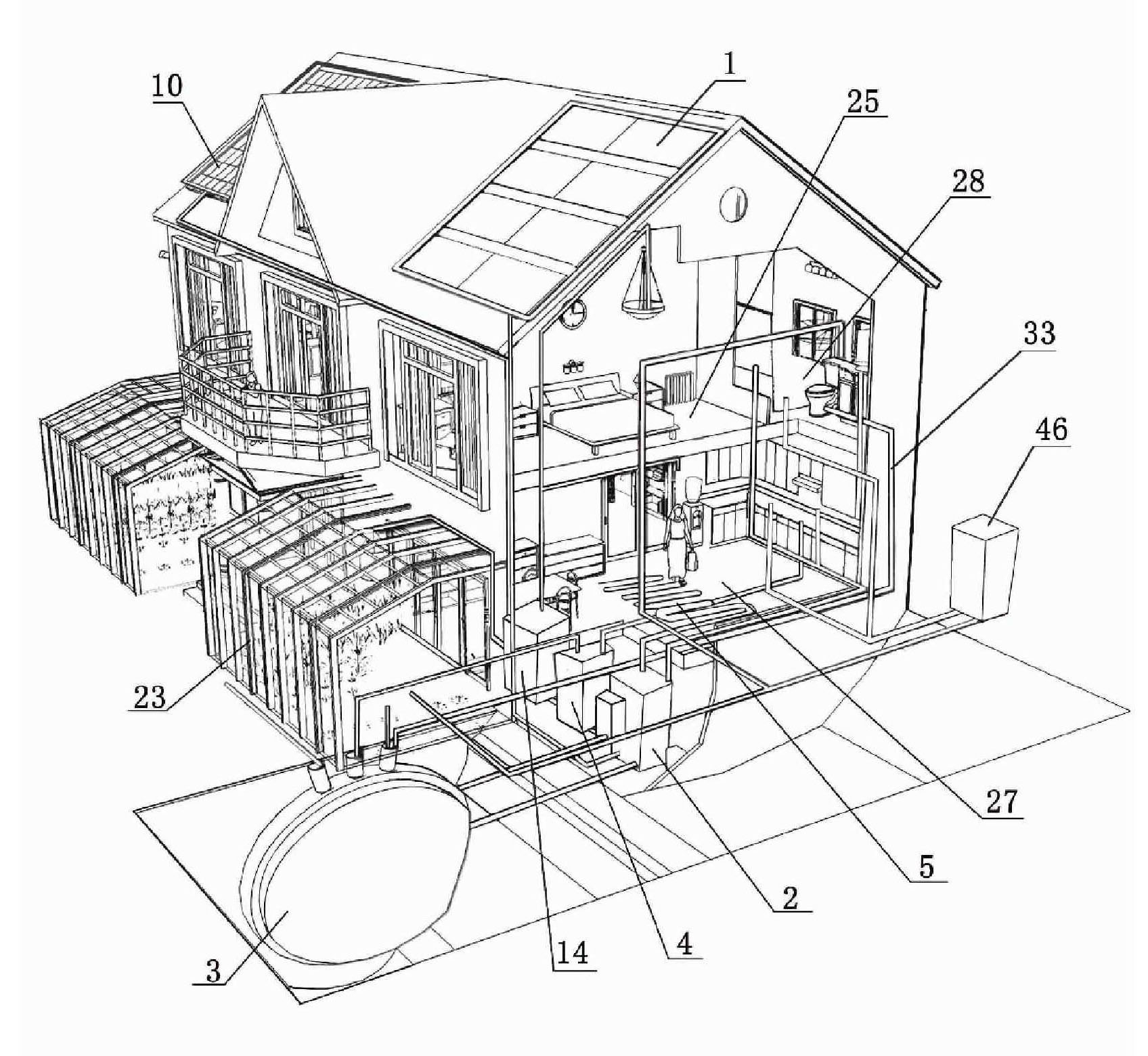

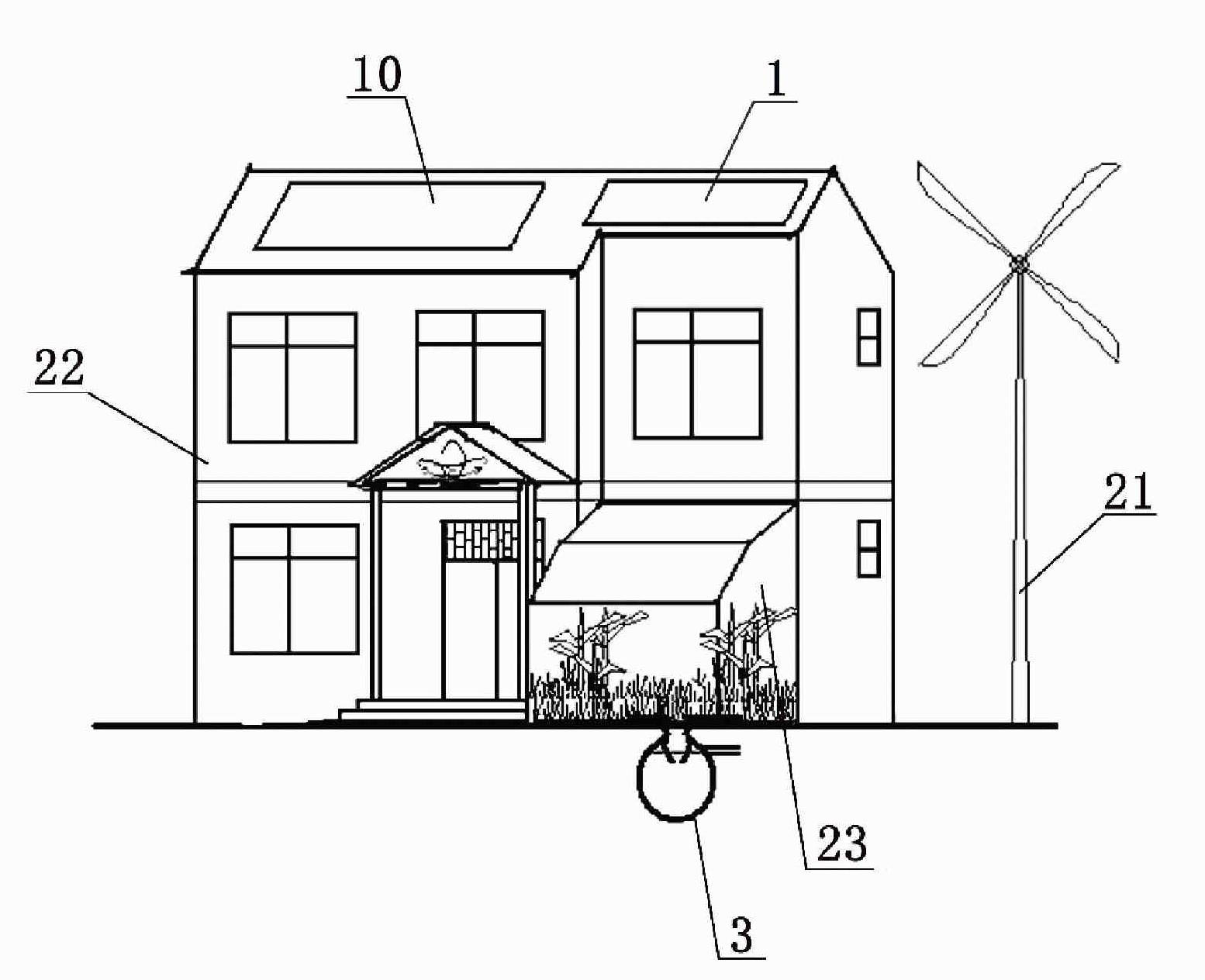

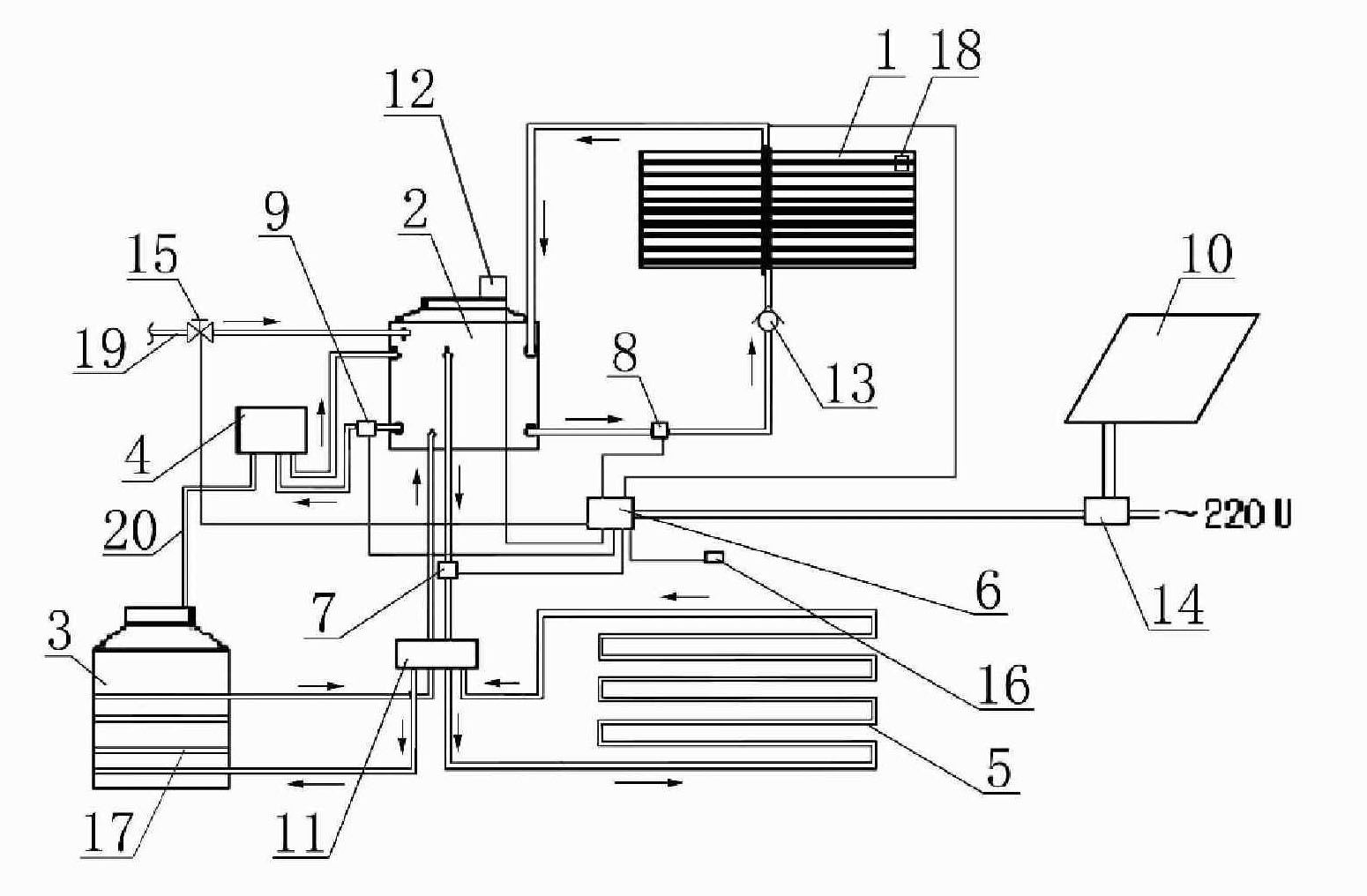

Green ecological zero energy consumption integration house

InactiveCN101457594AIncrease heatIncrease gas productionWallsSolar heat devicesLiving roomCollector device

The invention relates to a green ecological zero energy integrated building, a first floor of the building is provided with a living room, a bedroom, a dinning room, a kitchen, a toilet; a second floor of the building is provided with a bedroom and a toilet; a heat supply system is arranged inside the room, the building is connected with a heliogreenhouse on the ground and is connected with a methane tank under the ground. A solar thermal collector arranged at the top of the building is communicated with a temperature-holder box arranged inside the rooms of the building by a circulating pipe of the first line, the temperature-holder box is communicated with a water heating pipe of a gas-fuel heater by the circulating pipe, a gas line of the gas-fuel heater is communicated with the methane tank by a methane pipe. A hot water outlet of the temperature-holder box is respectively communicated with a PE-RT pipe and a heating pipe of the methane tank which is buried near the methane tank. A water tank temperature sensor, a room temperature sensor and a collector temperature sensor are connected with an intelligent controller. With the solar energy, bioenergy and wind energy complementing each other, the building has the characteristics of comfort, environmental protection, energy saving and zero-pollution.

Owner:赵民忠

Crude polypropylene fiber for concrete and preparation method thereof

InactiveCN101629332AHigh breaking strengthIncrease elasticityFilament manufactureArtificial filament heat treatmentWater bathsPolymer science

The invention relates to a crude polypropylene fiber for concrete and a preparation method thereof. The crude polypropylene fiber comprises polypropylene, a thermotropic liquid crystal polymer being 0.1-25 percent by weight of the polypropylene, a compatilizer being 0.1-5.0 percent by weight of the polypropylene, an antioxidant being 0.1-0.5 percent by weight of the polypropylene and an ultraviolet absorption agent being 0.1-0.3 percent by weight of the polypropylene. The preparation method comprises the following steps: drying the polypropylene, the thermotropic liquid crystal polymer and other components to constant weight and then uniformly mixing the components; extruding the dried components by a spinneret plate of a double-screw extruder and then cooling an obtained extruded material in a water bath; stretching the cooled material in different stages for multiple times at a temperature being higher than the vitrification temperature of the polypropylene; spraying a conventional oil agent used for polypropylene spinning on an obtained fiber bundle and carrying out thermal shaping; and then carrying out indentation processing on the surface of the fiber. The thermotropic liquid crystal polymer strengthens the crude polypropylene fiber in the form of a microfiber so as to greatly improve the mechanical property of the crude polypropylene fiber, thereby enhancing or improving the crude polypropylene fiber to enhance the performances of anti-cracking, permeability resistance, breaking resistance, toughness, impact resistance, freezing and thawing resistance, fire resistance, bursting resistance, and the like of the concrete.

Owner:JIANGSU SUBOTE MATERIAL +1

Post-curing 3D printing method

InactiveCN106493943AImprove uniformityImprove reliabilityAdditive manufacturing apparatus3D object support structuresEngineeringUltimate tensile strength

The invention discloses a post-curing 3D printing method. The post-curing 3D printing method includes treating the original sand with anhydrous ethanol and phenolic resin to form coated sand, and then spraying the dissolving agent at the time of printing, dissolving the phenolic resin on the coated sand and sticking, molding the coated sand, heating the molded workpiece and curing the molded workpiece for the second time. The post-curing 3D printing method of the present invention can enhance printing stability and workpiece strength, and can reduce the workpiece processing cost and store the printing material for a long time.

Owner:GUANGZHOU OGGI3D ELECTROMECHANICAL

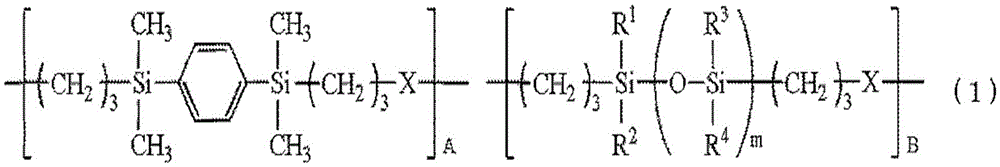

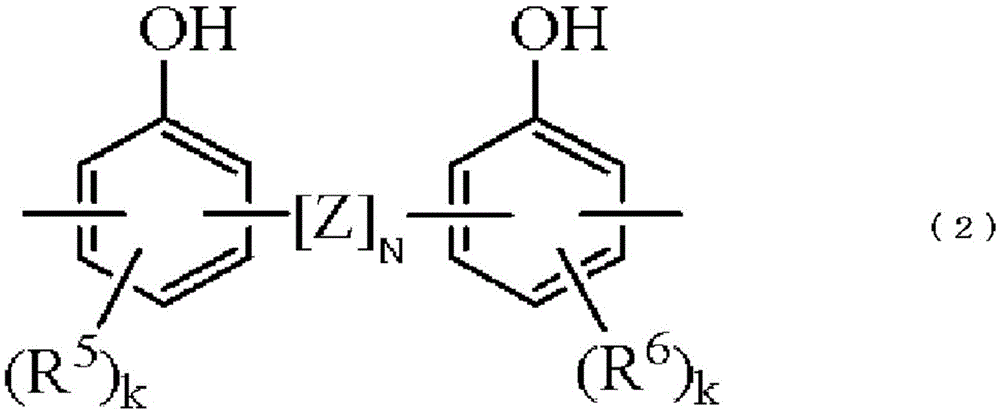

Liquid crystal aligning agent and method for forming liquid crystal alignment films

ActiveCN101990650AGood liquid crystal alignment abilityImprove heat resistanceNon-linear opticsHydrogen atomHydrogen

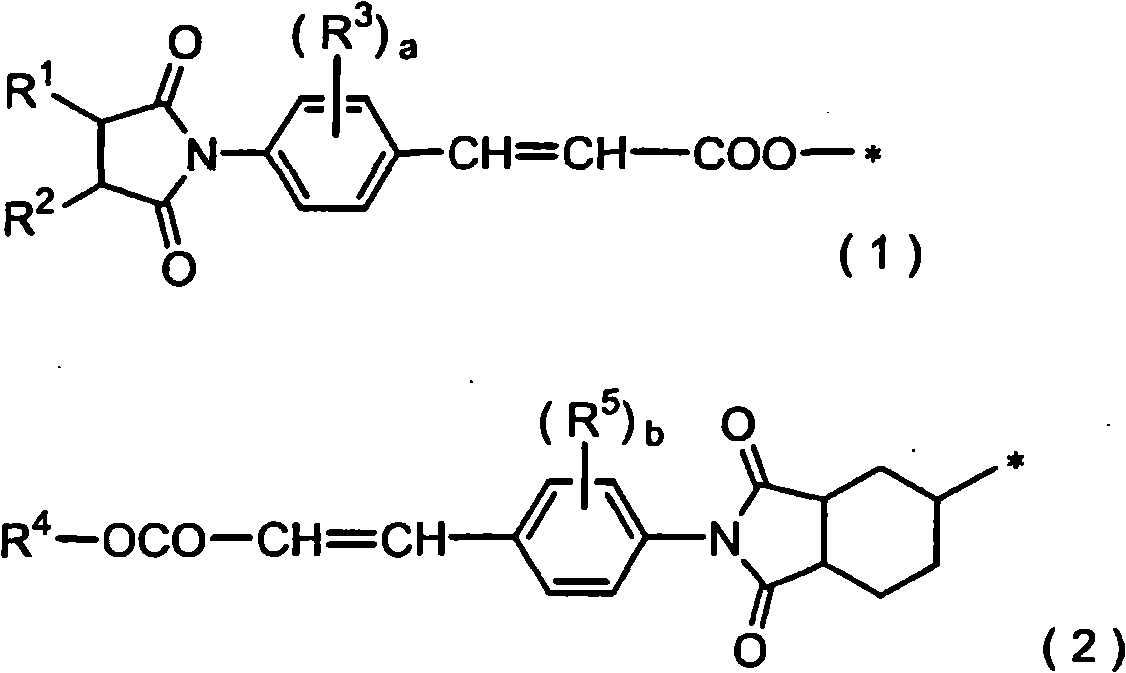

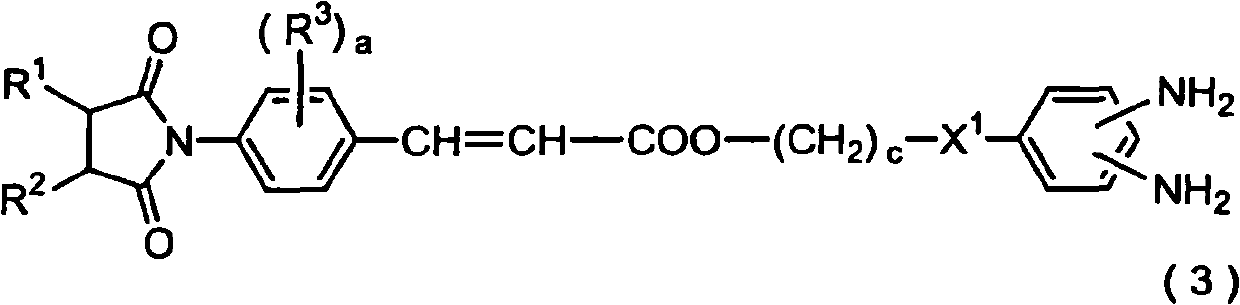

A liquid crystal aligning agent containing at least one polymer selected from the group consisting of polyamic acids, polyimides, and polyamic acid esters, said polymer having a group represented by general formula (1) or (2). In general formula (1), R1 and R2 are each independently hydrogen or a monovalent organic group, or R1 and R2 may be bonded to each other to form a ring; R3 is fluoro or cyano; a is an integer of 0 to 4; and * is a free valency, while in general formula (2), R4 is C1-40 alkyl or a C3-40 monovalent organic group containing an alicyclic group, with the proviso that the hydrogen atoms of the alkyl may be partially or completely replaced by fluorine atoms; R5 is fluoro or cyano; b is an integer of 0 to 4; and * is a free valency.

Owner:JSR CORPORATIOON

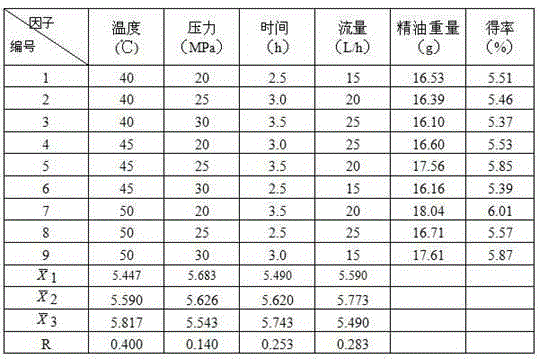

Method for extracting radix saussureae lappae essential oil by supercritical carbon dioxide

InactiveCN102978005AImprove extraction efficiencyEasy to handleEssential-oils/perfumesFreeze-dryingEconomic benefits

The invention discloses a method for extracting radix saussureae lappae essential oil by supercritical carbon dioxide, comprising the following steps of: firstly, freezing and drying radix saussureae lappae until the weight percentage of water is less than 10%; slicing and crushing to obtain radix saussureae lappae powder; and extracting the radix saussureae lappae powder for 30-240 minutes under the conditions that the temperature is 40-55 DEG C, the extraction pressure is 10-30 MPa and the CO2 flow is 5-25 L / h to obtain the radix saussureae lappae essential oil. By adopting the method for extracting the radix saussureae lappae essential oil, the extraction efficiency is high, the heat decomposition of essential oil components is not caused and the yield is higher than 6.04%. Compared with the traditional method, the method has the advantages that the production efficiency is greatly improved, the production period is shortened, the product yield is high and the economic benefit is obvious; and no environmental pollution is caused and the method is convenient for manual control and industrial production.

Owner:重庆市日用化学工业研究所有限责任公司

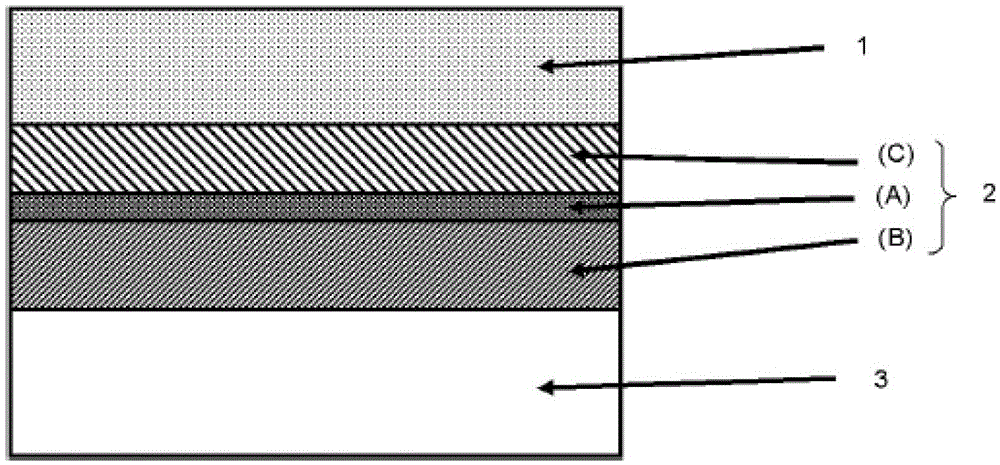

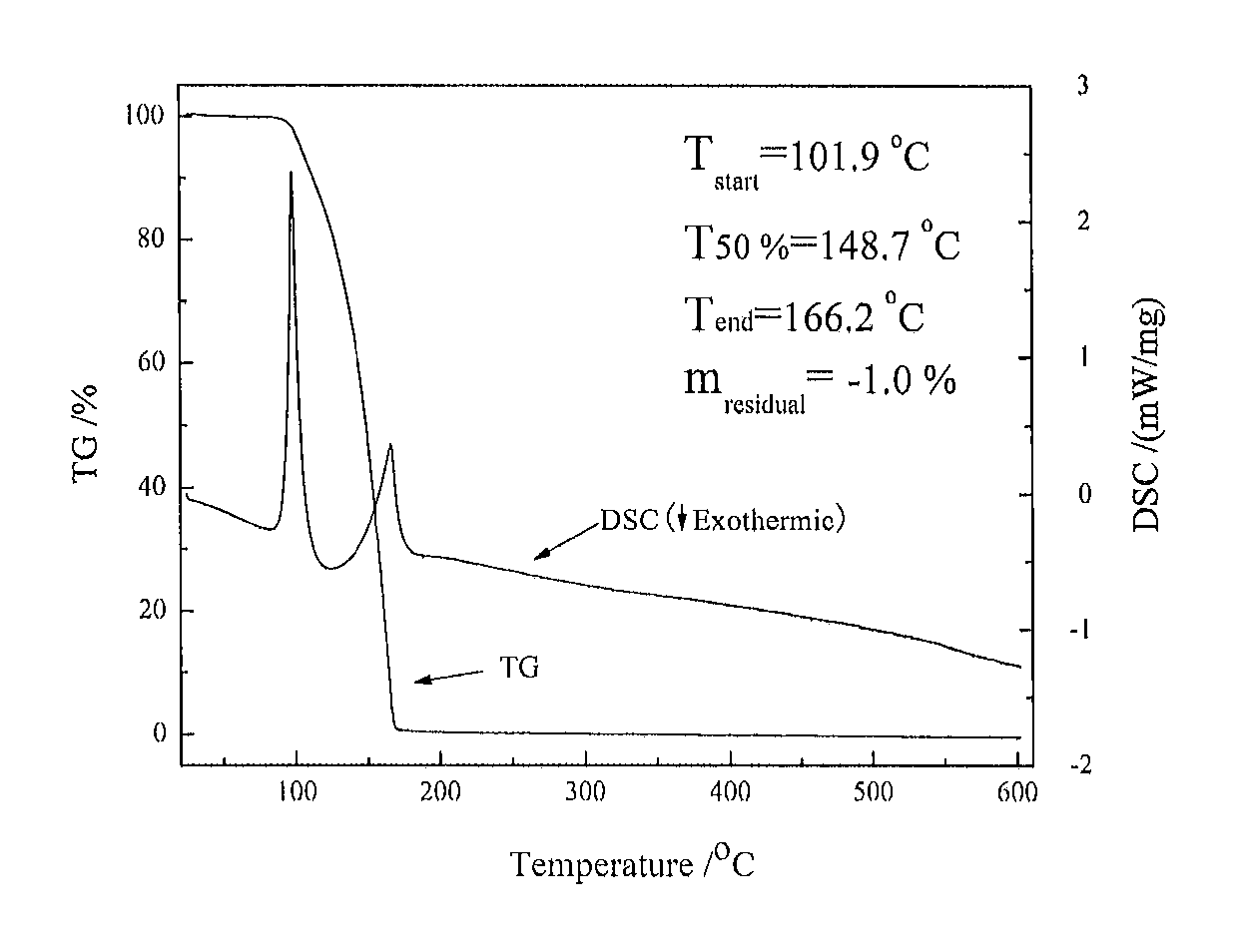

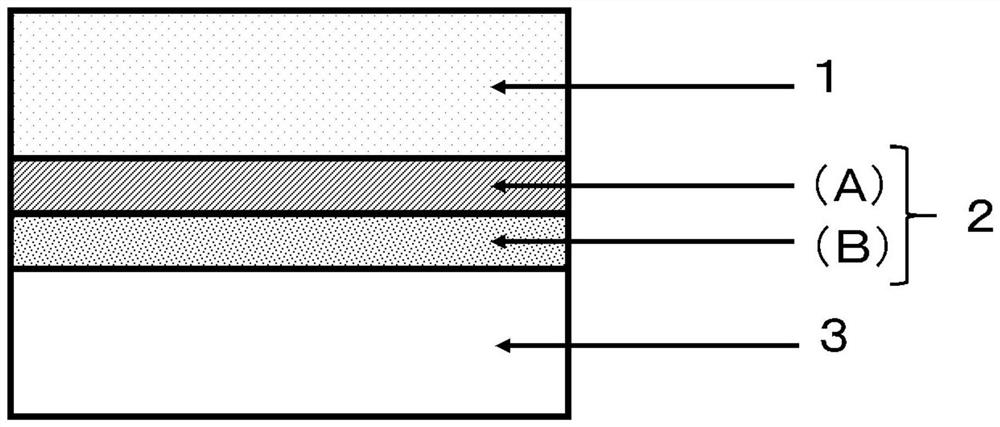

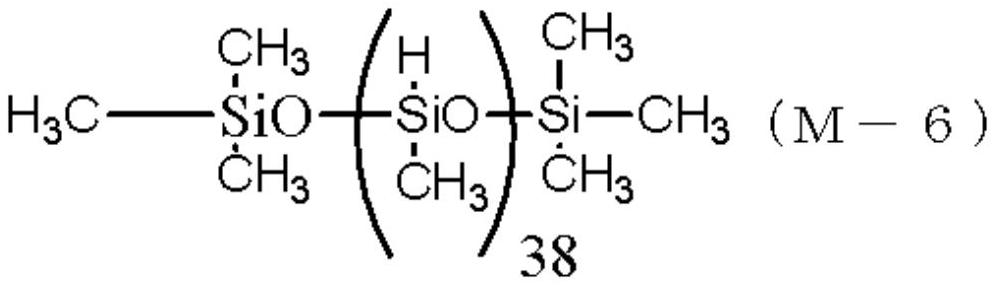

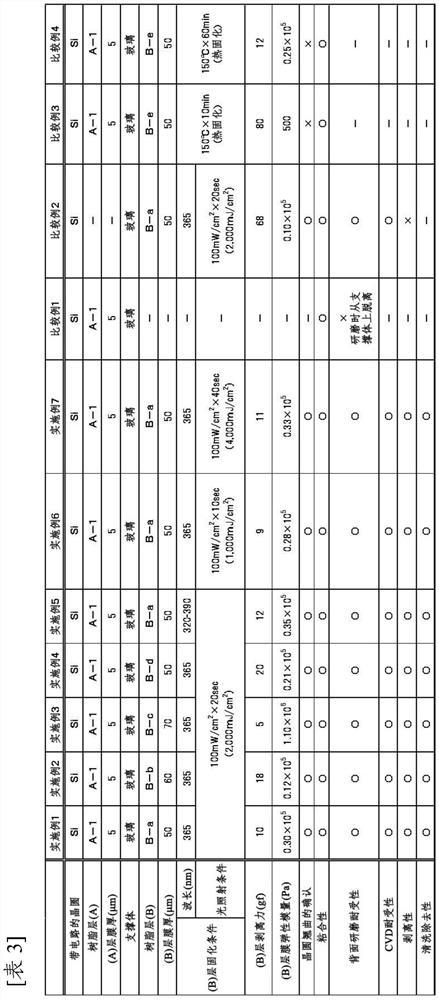

Wafer processing laminate, temporary adhesive material for wafer processing, and method for manufacturing thin wafer

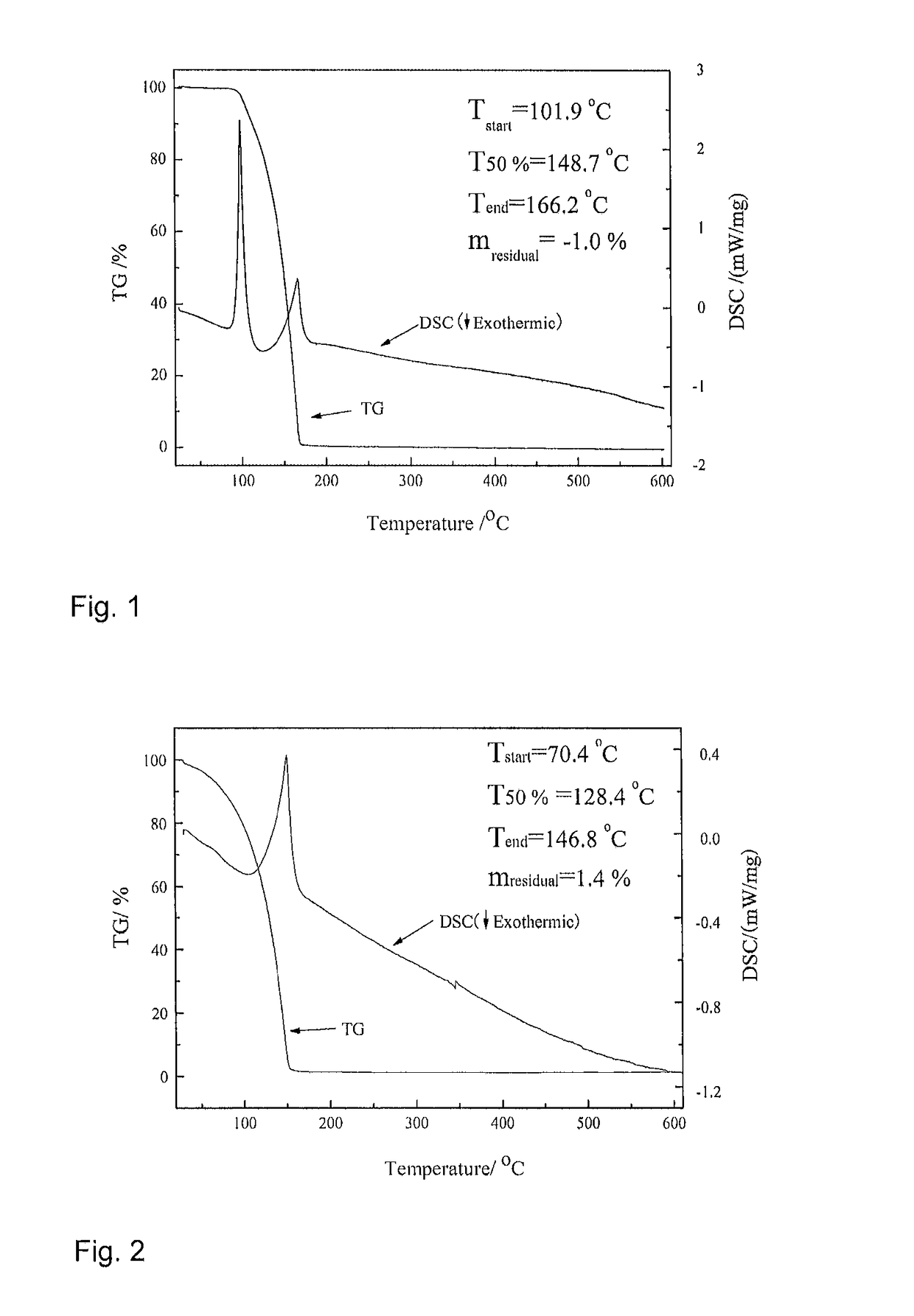

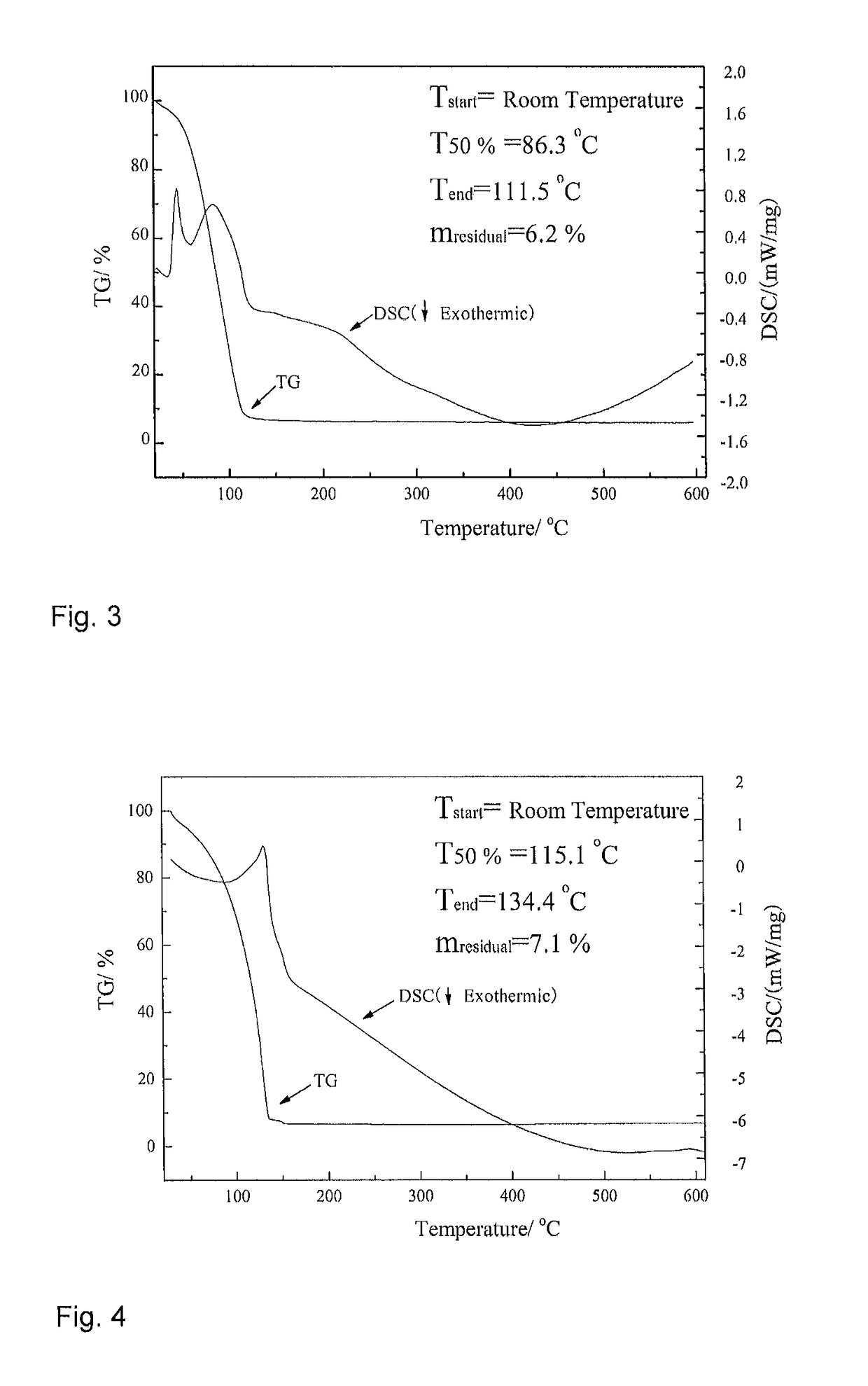

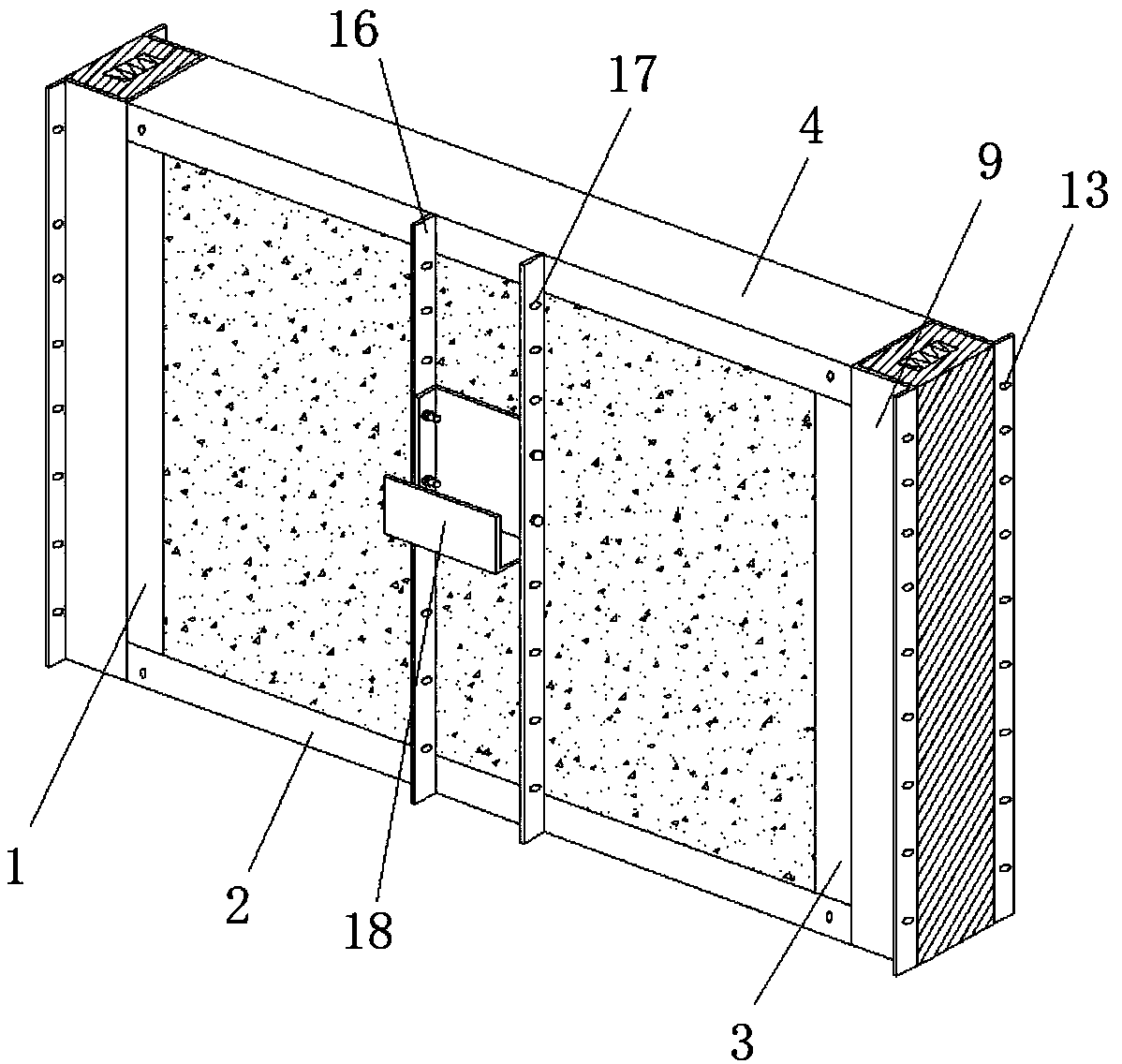

ActiveCN105733498ANo thermal decompositionImprove enduranceLayered productsSolid-state devicesWaferingThermosetting polymer

Owner:SHIN ETSU CHEM CO LTD

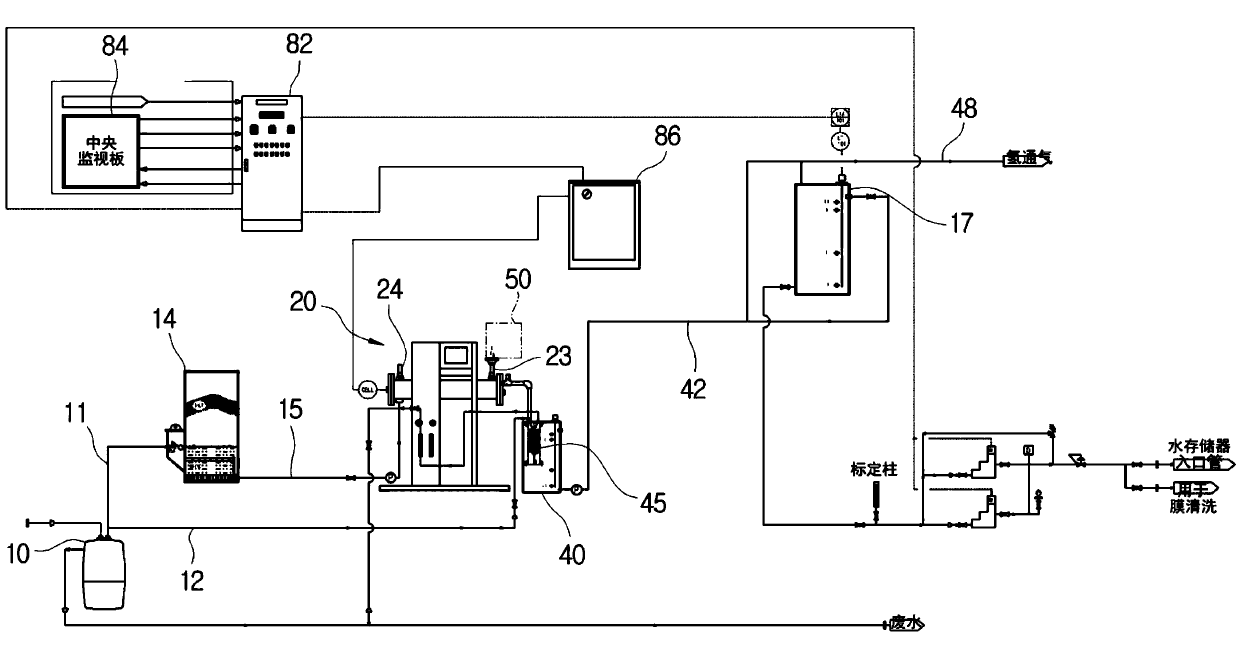

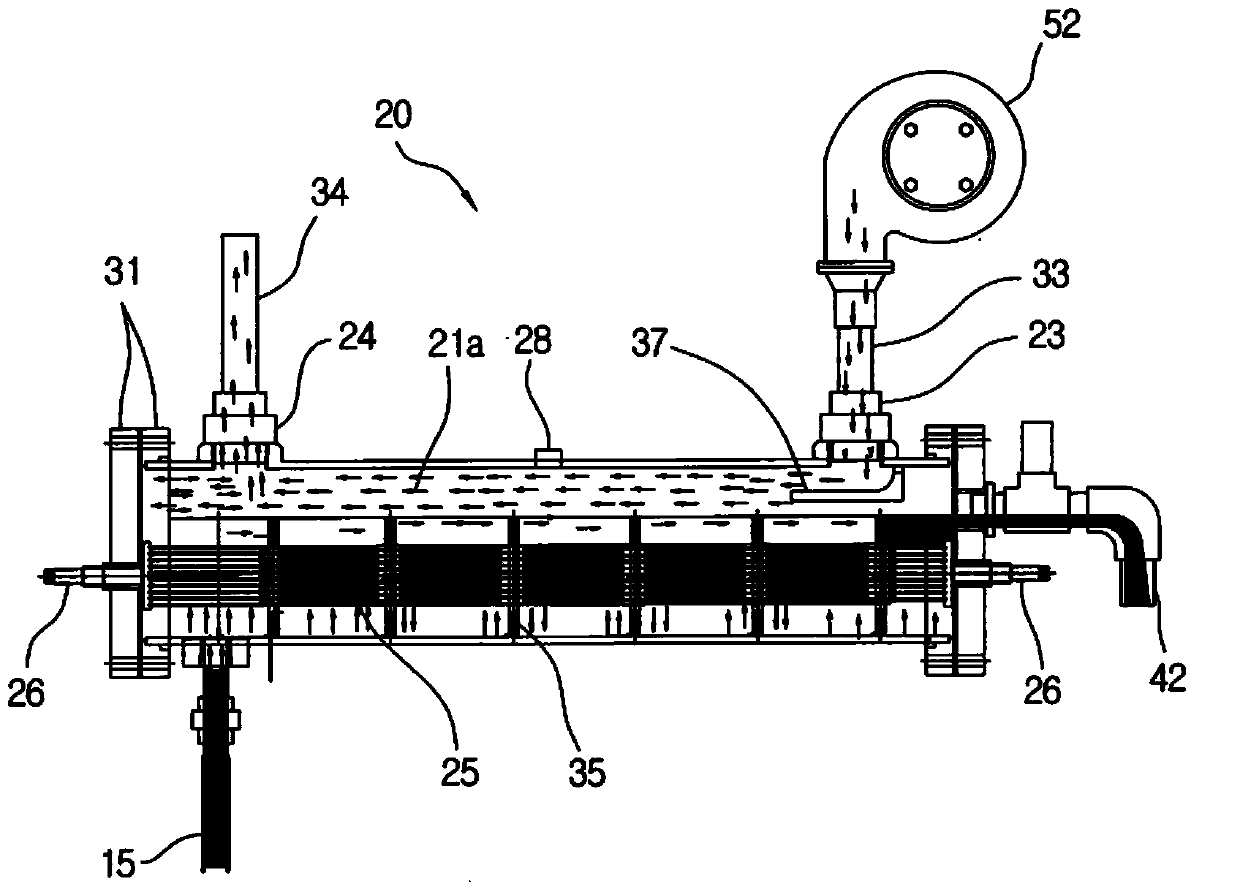

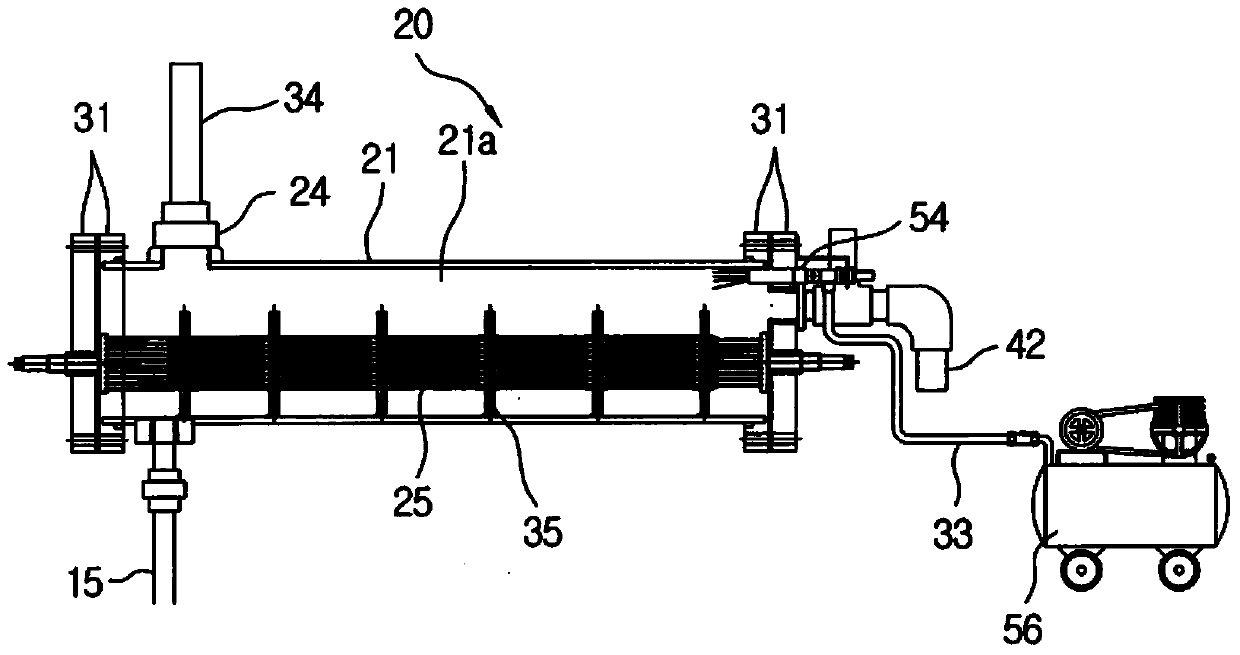

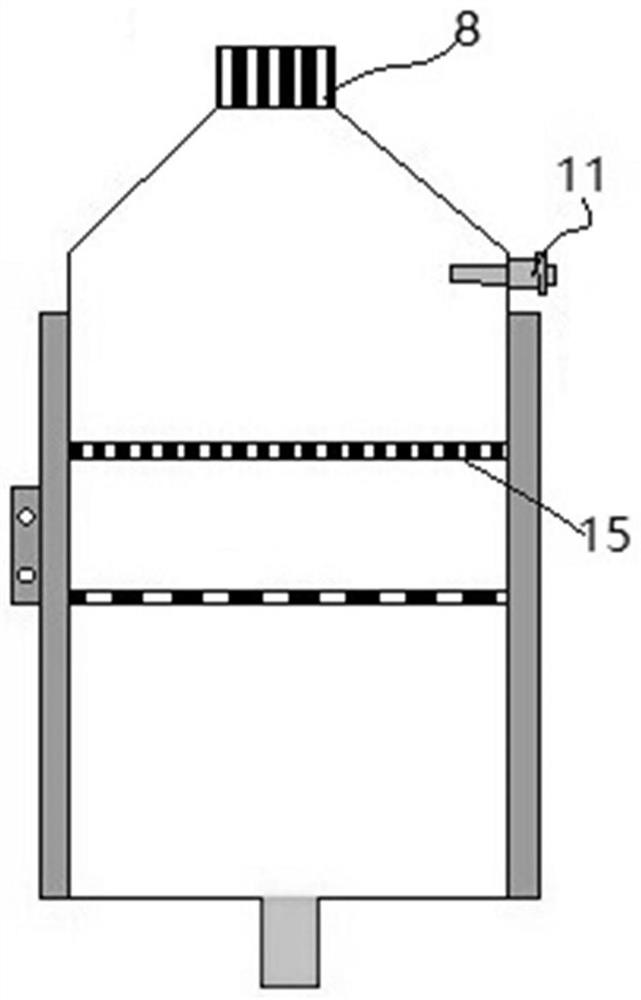

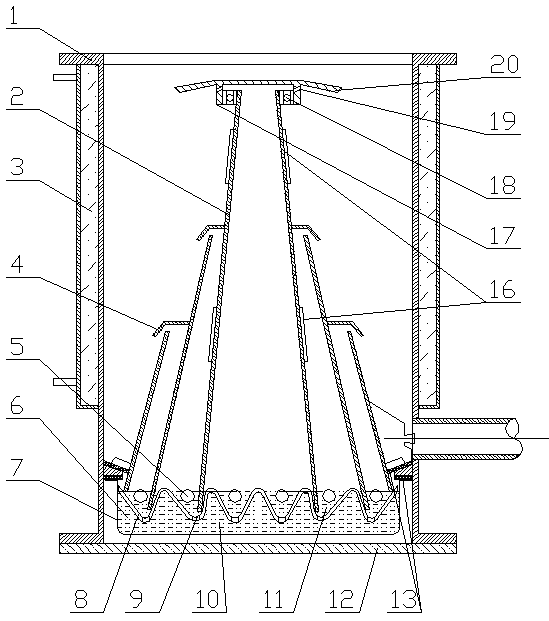

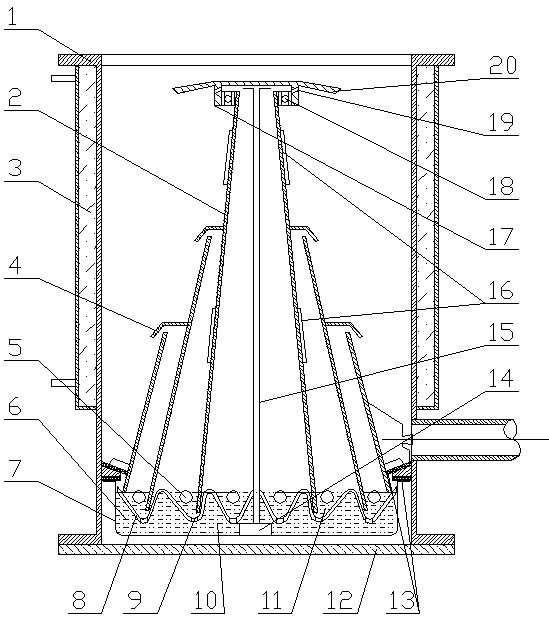

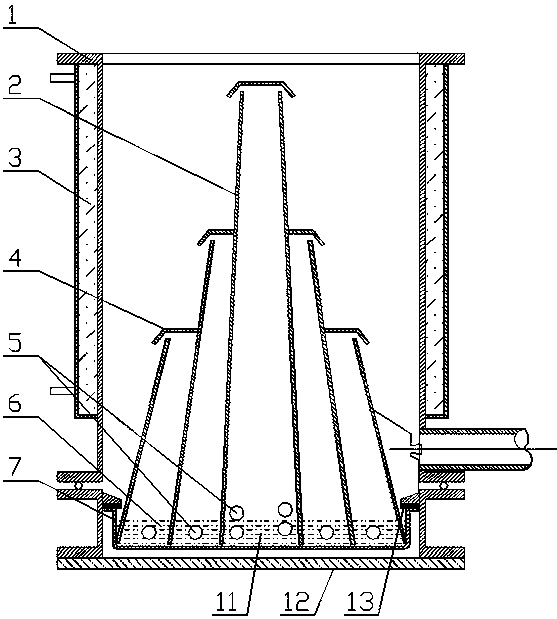

Open-cell type apparatus for preparing sodium hypochlorite

ActiveCN103380087ASuppress generationReduce hardnessCellsWater treatment parameter controlHigh concentrationElectrolysis

Provided is an open cell-type apparatus for producing sodium hypochlorite based on electrolysis using soft water and salt. The apparatus includes: a sodium hypochlorite generator including a plurality of electrode plates supported by a support, a flow channel for air flow provided above the support and the electrode plates, and an air intake hole and an air exhaust hole which communicate with the flow channel; a cooling unit for lowering a temperature of the flow channel; and a controller for controlling operation of the cooling unit by detecting a temperature of the sodium hypochlorite generator. The apparatus constantly maintains an optimum temperature of the sodium hypochlorite generator in order to produce sodium hypochlorite of a high concentration with high efficiency.

Owner:金庆洙 +2

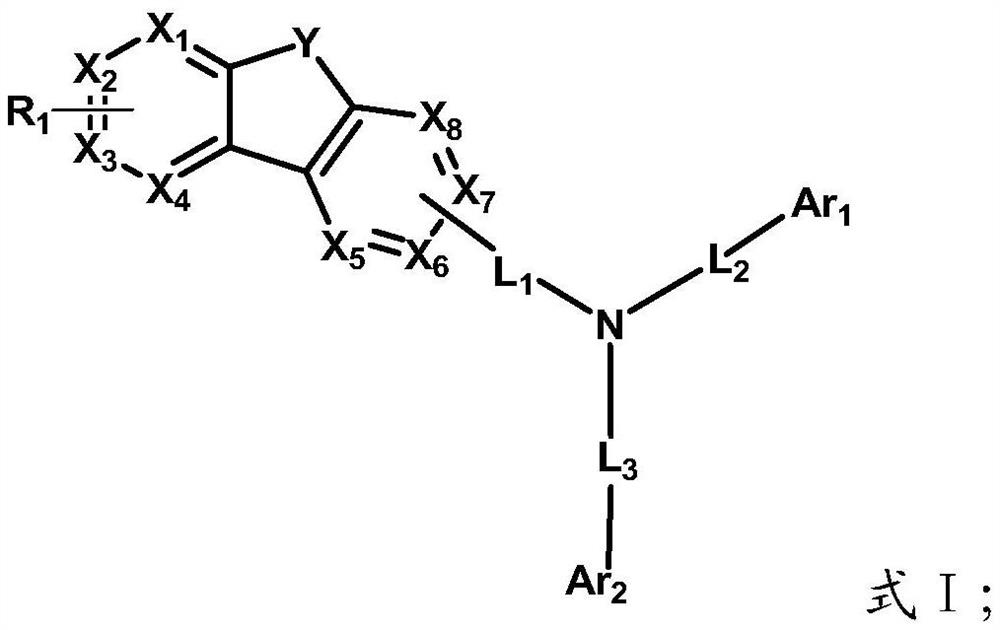

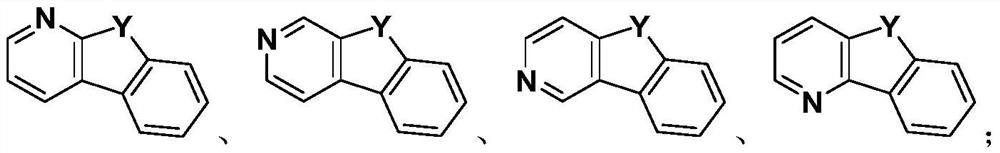

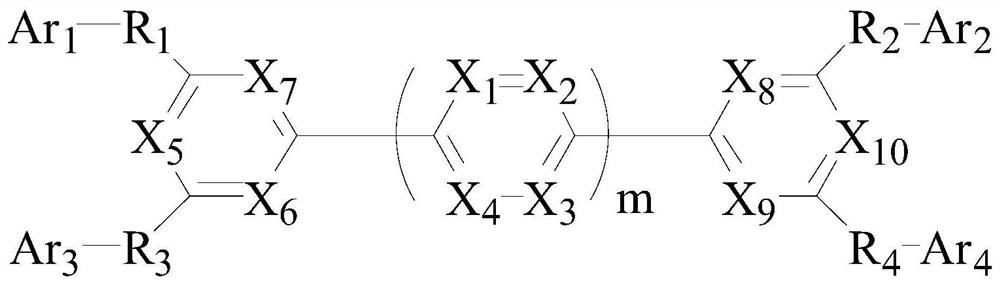

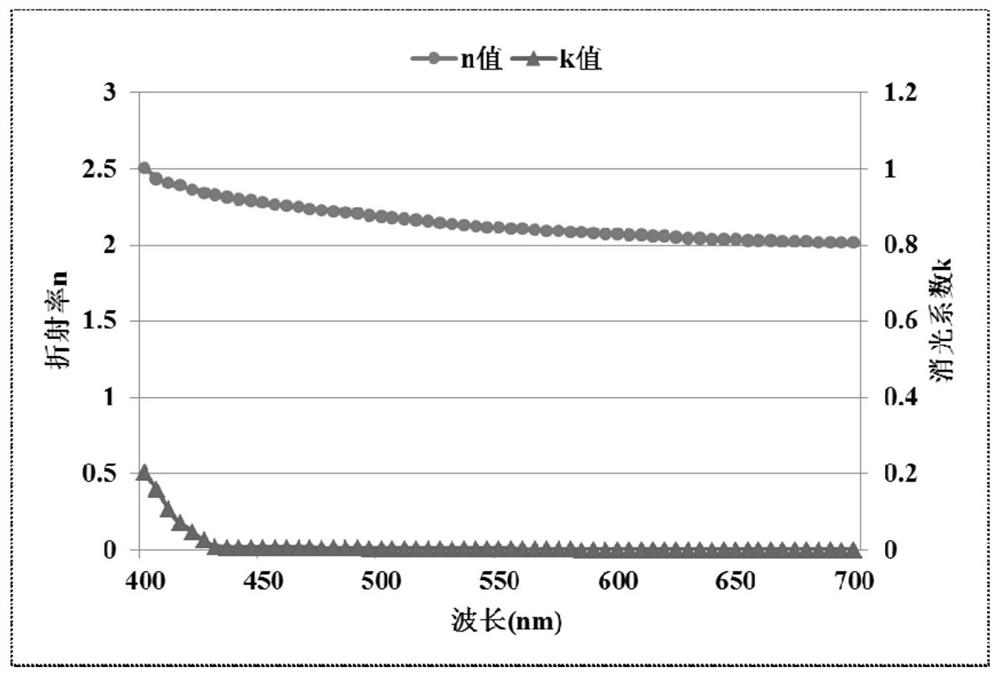

Heterocyclic compound containing heteroatom substituted fluorene and application thereof in photoelectric device

PendingCN114106001AImprove stabilityIncreased durabilityOrganic chemistrySolid-state devicesRefractive indexHeteroatom

The invention provides a heterocyclic compound containing heteroatom substituted fluorene. The heterocyclic compound has a structure as shown in a formula I in the specification. The fluorene group is subjected to specific heteroatom substitution, and the prepared heterocyclic compound has the following advantages that (1) the refractive index is high, and the light extraction efficiency is high; (2) absorption is not realized in wavelength regions of blue, green and red, and the color purity is not reduced; (3) the difference in refractive index measured in each wavelength region of blue, green, and red is small; (4) the glass transition temperature is high, the decomposition temperature is high, and the material can be evaporated but cannot be thermally decomposed; and (5) a film prepared from the material is high in stability, excellent in durability and long in service life.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

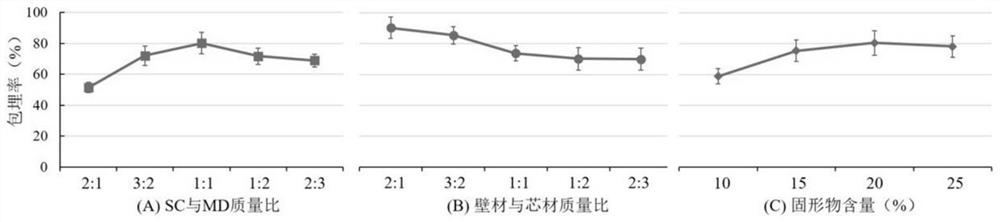

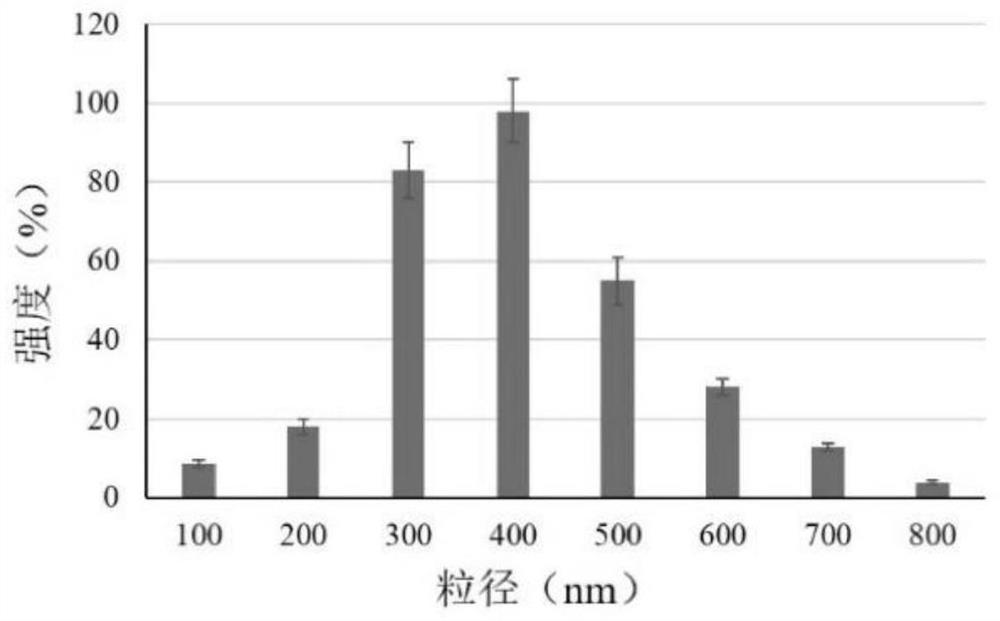

Peony seed oil microcapsule and preparation method thereof

PendingCN114468298AImprove oxidation stabilityImprove thermal stabilityLipidic food ingredientsFood shapingBiotechnologySodium Caseinate

The invention discloses a peony seed oil microcapsule and a preparation method thereof. The peony seed oil microcapsule provided by the invention is prepared from the following substances in mass ratio: a core material: peony seed oil; the wall material comprises a wall material A and a wall material B; the wall material A is maltodextrin; the wall material B is selected from one of soybean protein isolate, whey protein isolate and sodium caseinate; the mass ratio of the wall material B to the wall material A is (2: 1)-(1: 2); the mass ratio of the wall material to the core material is (2: 1)-(1: 2). The invention also provides a preparation method of the peony seed oil microcapsule. The peony seed oil is embedded through the composite wall material, and the preparation process conditions of the peony seed oil microcapsule are optimized by utilizing an orthogonal experiment on the basis of a single factor experiment, so that the optimal embedding conditions are obtained. After the peony seed oil is subjected to microencapsulation, nutritional ingredients of the peony seed oil can be effectively reserved, and oxidation can be delayed to a great extent.

Owner:山东四季园牡丹生物科技有限公司

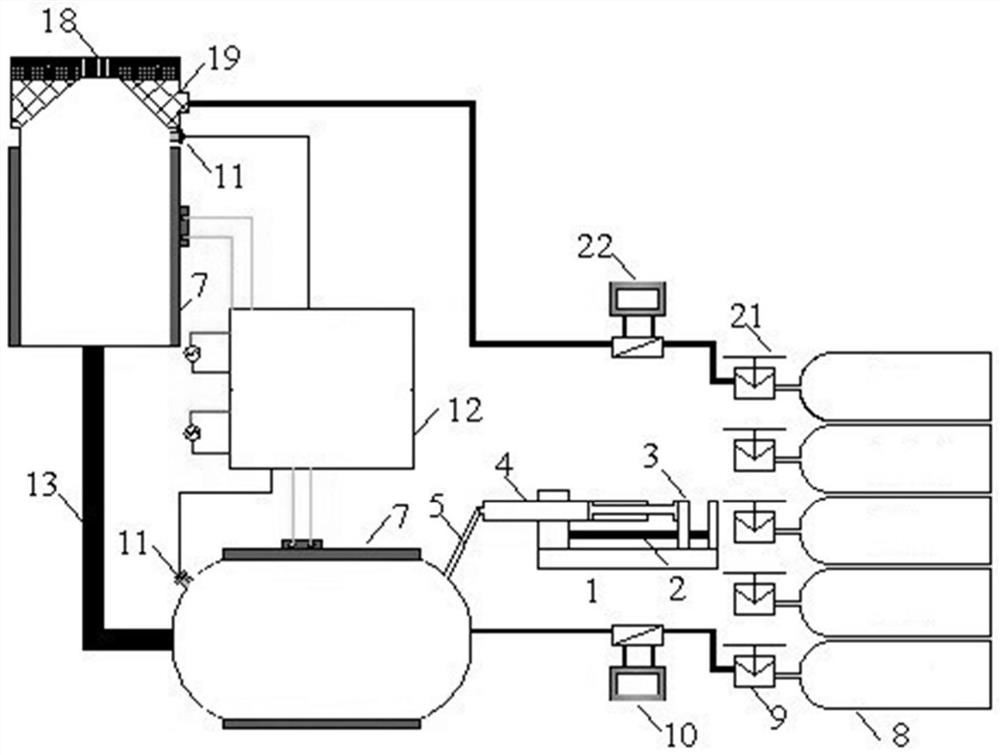

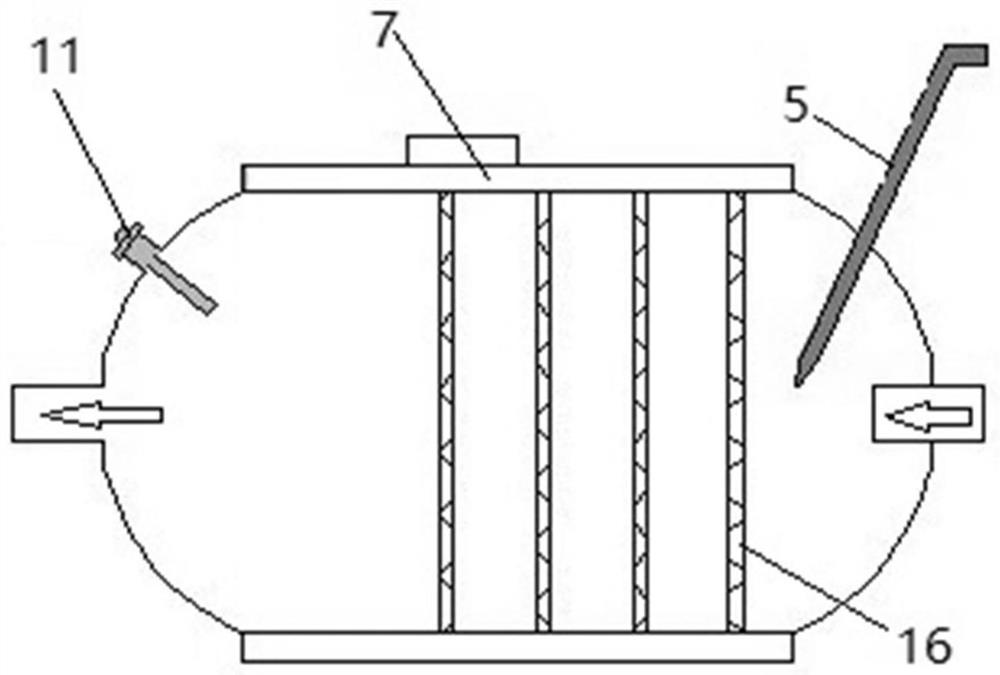

Liquid fuel combustion flame-adjusting burner device

PendingCN112815307ALow costReduce difficultyBurnersFuel supply regulationGas cylinderEquivalence ratio

The invention discloses a liquid fuel combustion flame-adjusting burner device which is characterized in that liquid fuel enters an evaporator premixing evaporation tank body through a liquid conveying pipe by a fuel supply device, and the fuel supply amount is controlled; the premixed gas flow of a gas cylinder group entering the evaporator premixing evaporation tank body is controlled by a premixed gas flow valve; all components in the fuel are vaporized by adjusting the heating temperature, and the fuel in the premixed gas is not condensed before combustion; a co-flow device and a co-flow gas flow valve are used for controlling co-flow gas so as to eliminate the influence of ambient air on combustion flames; and laminar flow and turbulent flow premixed gas combustion flames with different equivalence ratios are realized by adopting a burner outlet structure and fuel flow as well as selective matching of premixed gas types and flow. According to the liquid fuel combustion flame-adjusting burner device provided by the invention, evaporation mixing of multi-component fuel and accurate control of the premixed equivalence ratio are realized, so that the cost of the liquid burner and the difficulty of liquid fuel evaporation mixing control are greatly reduced.

Owner:CHANGAN UNIV

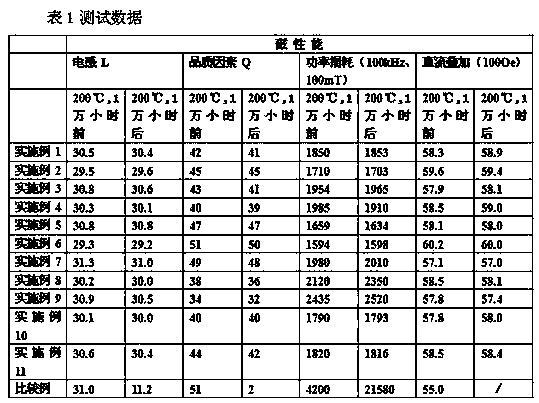

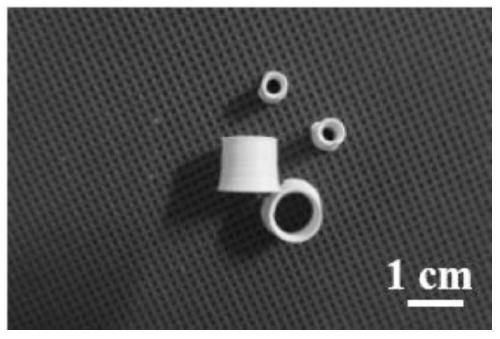

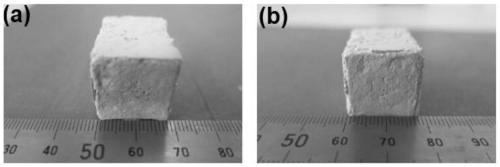

Preparation method of a low-loss heat-free aging iron powder core

ActiveCN103700460BImprove insulation performanceFully insulatedInorganic material magnetismCompression moldingIron powder

The invention discloses a method for preparing a low-loss heat-free aging iron powder core. By adding a high-temperature-resistant inorganic insulating agent and a high-temperature-resistant binder, in conjunction with a suitable insulating coating method, and through compression molding and high-temperature annealing processes, the The iron powder core magnetic core maintains the original magnetic properties at 200°C and 10,000 hours, and has no thermal aging phenomenon, which solves the thermal aging problem of ordinary iron powder cores. At the same time, the core loss is about 50% of ordinary iron powder cores. In the case of 100kHz and 100mT, the core loss is around 2000mw / cm3.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

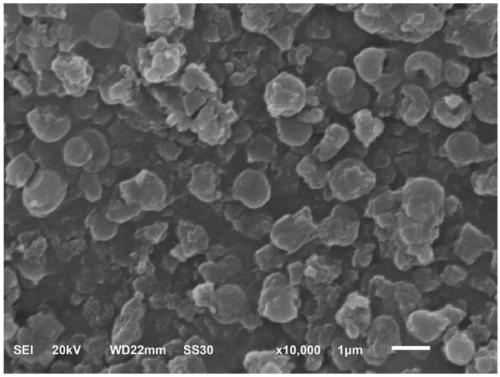

Dental ceramic material and preparation method and application thereof

InactiveCN110041066AGood biocompatibilityHigh solid contentAdditive manufacturing apparatusTissue regenerationBiocompatibility TestingSlurry

The invention provides a dental ceramic material and a preparation method and an application thereof, and belongs to the field of dental ceramic materials. The preparation method includes the following steps: mixing zirconia ceramic powder and an inorganic phosphate solution to obtain ceramic slurry; carrying out 3D printing or injection molding on the ceramic slurry to obtain ceramic body; and dehydrating and sintering the ceramic body in order to obtain the dental ceramic material. The dental ceramic material of the invention adopts the inorganic phosphate as a binder, does not undergo thermal decomposition under the condition of ensuring good bonding performance, changes from an amorphous phase to a crystalline phase when reaching phase transition temperature, which means the inorganicphosphate is converted into a corresponding crystalline phase during the sintering process, so as to further increase the solid content and compactness of bioceramic. In addition, in the invention, the zirconia ceramic powder has good biocompatibility and has lower size shrinkage compared with ceramic prepared by conventional organic binder ceramic slurry.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

Mother stock of polyvinyl carbon nanotube anti-static composite material and anti-static composite material based on mother stock

InactiveCN1303147CImprove antistatic performanceImprove mechanical propertiesHigh concentrationMasterbatch

The invention relates to an anti-static modified material with carbon nanotubes (CNTs) predominantly and a process which is a thermal oxidation treatment with acid together with a ball grinding surface treatment to CNTs and comprises: adding maleic anhydride grafted polyethylene, coupling agents and EPT rubber to prepare the high concentration masterbatch of CNTs / PE anti-static composite material by solution blending and melt blending methods, mixturing the said masterbatch with common PE in a finite proportion to melt blend and prill, then getting the final CNTs / PE anti-static composite material. The electrical surface resistivity and volume resistivity can reach the operating requirements of the anti-static material when the content of CNTs is only 0.3 wt % in the CNTs / PE anti-static composite material in the invention.

Owner:EAST CHINA UNIV OF SCI & TECH

The Method of Improving the Performance of Carbonized Wood by Silica Sol Impregnation Pretreatment

ActiveCN103240780BLow viscosityLow costWood treatment detailsPressure impregnationLoss rateVolumetric Mass Density

The invention relates to a method for improving a carbonized wood property by silica sol impregnation pretreatment. The method comprises the following steps of: placing wood in a treatment tank, carrying out the silica sol infusion pretreatment on the wood, and carrying out stacking and air dry on the treated wood; carrying out common kiln drying on the treated wood so as to enable the water content ratio of the wood to be reduced to be 12-18%, and then discharging the dried wood out of a kiln, placing the wood after drying in charring equipment for carrying out hot modification carbonizing treatment; and finally taking out the wood. The method provided by the invention has the advantages that silica sol is adopted to be used as modification liquid so as to carry out the impregnation pretreatment on the wood, the front drying is not needed, the manufacturing cost is low, the mass loss rate of preparative carbonized wood is reduced, and the equilibrium water content is reduced; and the dimensional stability. the density and the mechanical strength are improved, corrosion proof and weather resisting properties are improved, flame retardant and termite proof properties can be improved to a certain degree, and the method has the characteristics of being odorless, innoxious, safe and environment-friendly.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI

Diffusion pump

InactiveCN108691820AReduce the temperatureTemperature low to highMachines/enginesDiffusion pumpsControl systemEvaporation

A diffusion pump comprises a pump body, pump oil, a pump core, an evaporation system, a cooling system, an injection system and a control system. The evaporation system is mounted at the bottom of thepump body in a mode of suspension, or heat insulation or heat isolation, and adopts the heating mode of instant heating or floating instant heating to heat the pump oil in a heating area to enable the pump oil to be evaporated instantly into steam. Fixed spraying heads or rotating spraying heads are arranged at the top of a steam guiding pipe in the injection system, a set of nozzles which spraytowards the inclined lower portion is evenly arranged on the periphery of each fixed spraying head, and the steam is sprayed out from the nozzles to form a rotating circinate airflow swirl. A series of nozzles are arranged on the peripheries of the rotating spraying heads, and the rotating spraying heads can rotate at a high speed through counter-acting force generated when the nozzles spray the steam. Heating devices are mounted on the pump core or on the steam guiding pipe, thus the temperatures of the pump core and the steam can be increased, the speed rate and kinetic energy of steam spraying are increased, and quick starting of the diffusion pump can be achieved.

Owner:戴海玥

Aluminum precursors for thin-film deposition, preparation method and use thereof

InactiveUS20170327944A1Decrease in reactivityIncrease stabilityGroup 3/13 element organic compoundsChemical vapor deposition coatingDecompositionAluminium

Provided is an aluminum precursor for thin-film deposition having a structure of formula (I) or (II), wherein R.sub.1, R.sub.2, R.sub.3, R.sub.4, R.sub.5, R.sub.6, and R.sub.7 each independently represent a hydrogen atom, C.sub.1.about.C.sub.6 alkyl, halo-C.sub.1.about.C.sub.6 alkyl, C.sub.2.about.C.sub.5 alkenyl, halo-C.sub.2.about.C.sub.5 alkenyl, C.sub.3.about.C.sub.10 cycloalkyl, halo-C.sub.3.about.C.sub.10 cycloalkyl, C.sub.6.about.C.sub.10 aryl, halo-C.sub.6.about.C.sub.10 aryl or --Si(R.sub.0).sub.3, and wherein R.sub.0 is C.sub.1.about.C.sub.6 alkyl or halo-C.sub.1.about.C.sub.6 alkyl. According to the present invention, based on the interaction principle between molecules, aluminum precursors for thin-film deposition are provided, which have a good thermal stability, are not susceptible to decomposition and convenient for storage and transportation, have good volatility at a high temperature, and are excellent in film formation. ##STR00001##

Owner:JIANGNAN UNIV +1

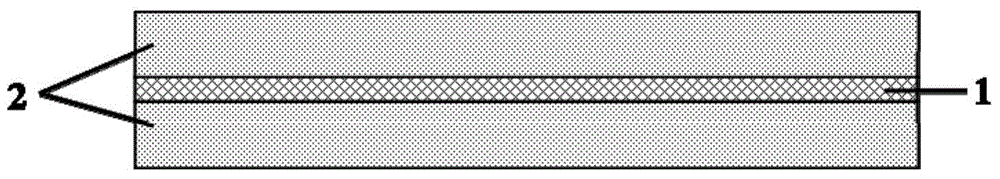

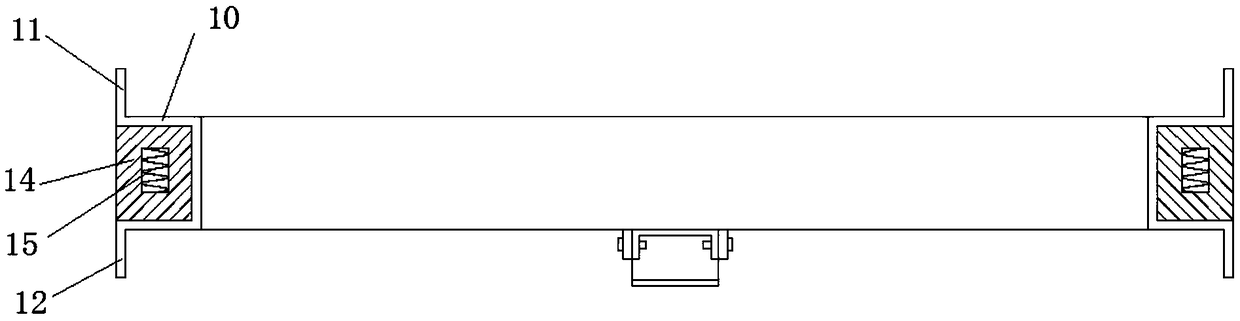

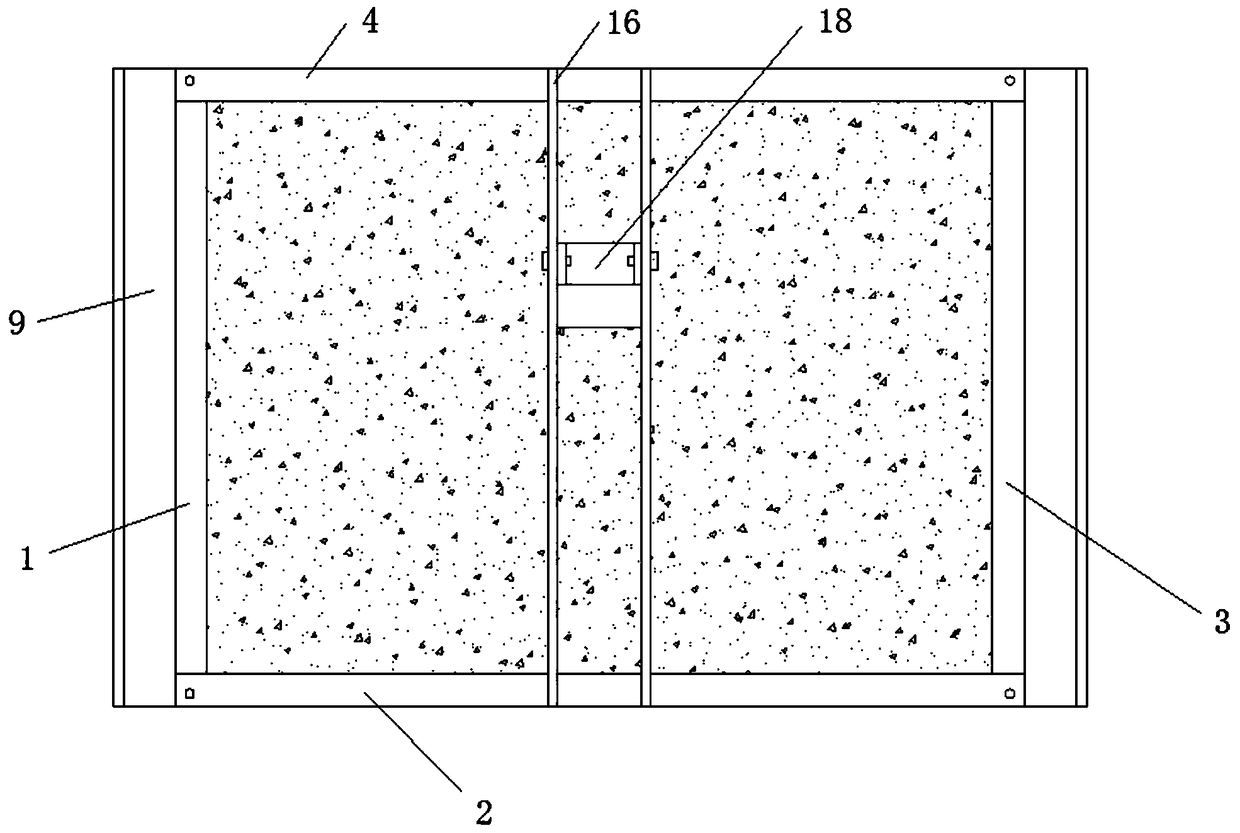

Light steel frame-foamed concrete-steel wire mesh composite wall and connecting method thereof

The invention provides a light steel frame-foamed concrete-steel wire mesh composite wall and a connecting method thereof. The light steel frame-foamed concrete-steel wire mesh composite wall comprises four cold-formed thin-walled C-shaped channel steel, namely the first channel steel, the second channel steel, the third channel steel, and the fourth channel steel; the first channel steel, the second channel steel, the third channel steel and the fourth channel steelsuccessivelyintersect vertically end to end to surround a light steel frame, steel wire meshes are welded to the inner surfaces of flanges on the same sides of the first channel steel, the second channel steel, the third channel steel and the fourth channel steel, foamed concrete building blocks are symmetrically arranged in alight steel frame cavity, a brace is arranged between the two foamed concrete building blocks, a gap of the light steel frame is filled with self-compacted concrete, and connecting parts are arrangedon the surfaces of the first channel steel and the third channel steel correspondingly. The light steel frame-foamed concrete-steel wire mesh composite wall has good integrity and strength, meanwhilehas good functions of buffering and damping, and has a good vibration isolation effect when encountering high external vibration.

Owner:SHENYANG JIANZHU UNIVERSITY

Polypropylene coarse fiber for concrete and method for preparing same

ActiveCN101337781BReduce or eliminate thermo-oxidative agingImprove anti-aging propertiesWater bathsPolymer science

Owner:JIANGSU SOBUTE NEW MATERIALS

High-efficiency reinforced halogen-free flame retardant functional masterbatch for polyoxymethylene direct injection molding and preparation method thereof

ActiveCN109535642BSolve the technical problem of mismatching processing temperatureAvoid damagePolyoxymethyleneMasterbatch

The invention belongs to the technical field of plastic modification and processing, and in particular relates to a high-efficiency enhanced halogen-free flame-retardant functional masterbatch and a preparation method thereof which can be directly applied to injection molding of polyoxymethylene products; the functional masterbatch is composed of A and B two It is composed of two kinds of masterbatches. The mass percentage of A masterbatch is as follows: glass fiber 50.0~70.0 wt.%, high flow polyoxymethylene 22.0~40.0 wt.%, polyoxyethylene 5.0~7.0 wt.%, polytetrafluoroethylene Powder 1.0~3.0 wt.%, Antioxidant 0.1~0.3 wt.%. Compared with the traditional plastic functional masterbatch, the functional masterbatch prepared by the present invention avoids the processing of polyoxymethylene in the enhanced halogen-free flame retardant modification system. During the process, the decomposition of the flame retardant and the matrix resin is caused by the mutual shear friction and heat generation between the glass fiber and the flame retardant, and at the same time solves the problem of mutual loss of modification performance caused by the mismatch of the processing temperature of the above two modification systems. Significantly enhanced the modification efficiency of both.

Owner:江苏万纳普新材料科技有限公司

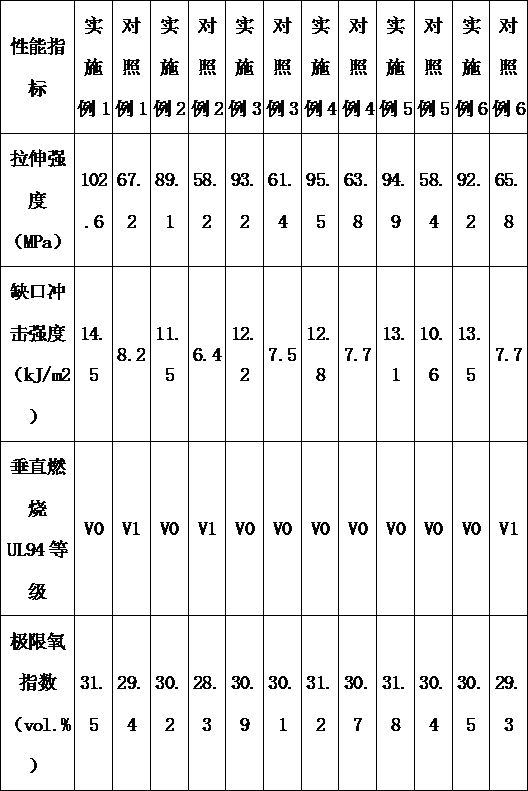

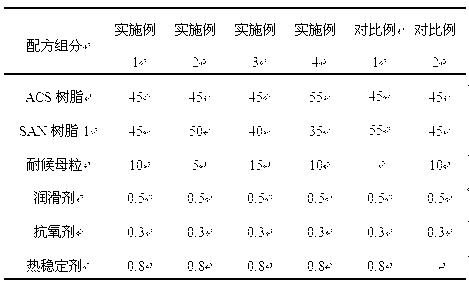

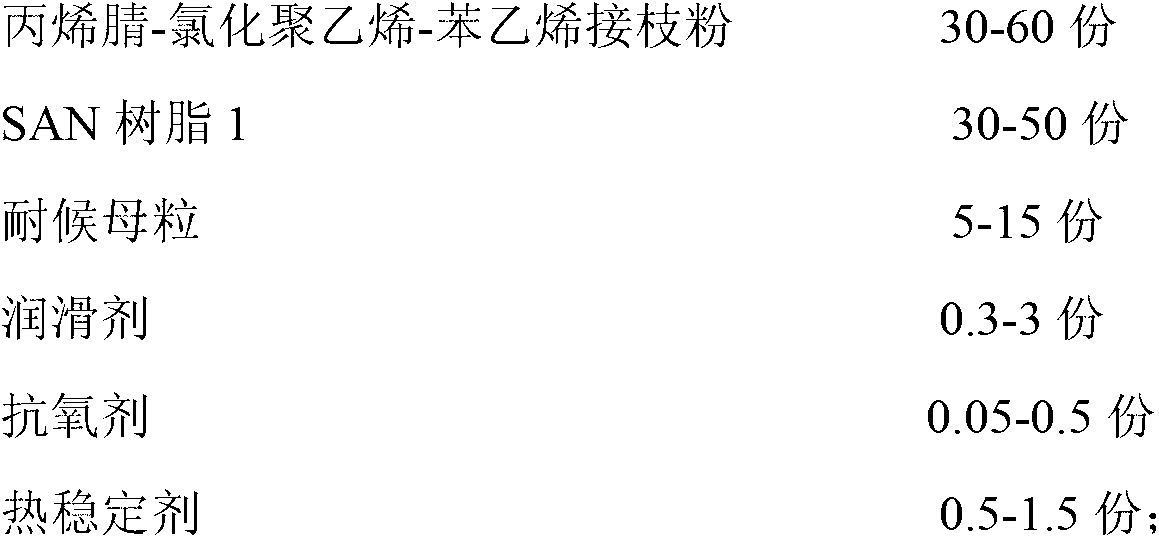

Acrylonitrile-chlorinated polyethylene-styrene resin composition and preparation method of acrylonitrile-chlorinated polyethylene-styrene resin composition

The invention discloses an acrylonitrile-chlorinated polyethylene-styrene resin composition and a preparation method of the acrylonitrile-chlorinated polyethylene-styrene resin composition. The composition comprises the following components in part by weight: 30 to 60 parts of acrylonitrile-chlorinated polyethylene-styrene grafting powder, 30 to 50 parts of SAN resin 1, 5 to 15 parts of weather resistance master batch, 0.3 to 3 parts of lubricant, 0.05 to 0.5 part of antioxidant and 0.5 to 1.5 parts of heat stabilizer. The composition is prepared by stirring and mixing the components except for the weather resistance master batch, adding the mixture from a main feed inlet of a double screw extrusion machine, adding the weather resistance master batch from a side feed inlet of the double screw extrusion machine and carrying out extrusion and granulation to obtain a sample. The obtained composition has excellent weather resistance, high low-temperature impact property and good antistatic property, size stability and processing property and is particularly suitable for the field of electrons, electrical appliances, communication, instruments, building materials, decorative materials,automobile parts and the like with high requirements on weather resistance, impact resistance and surface antistatic property.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Green ecological zero energy consumption integration house

InactiveCN101457594BIncrease heatIncrease gas productionWallsSolar heat devicesLiving roomCollector device

Owner:赵民忠

An insulating, heat-conducting, ablation-resistant adhesive and its application in lightning protection

ActiveCN104789175BAvoid failureImprove lightning protectionNon-macromolecular adhesive additivesSynthetic resin layered productsAdhesiveThermal insulation

The invention belongs to the technical field of lightning protection, and relates to an insulating, heat-conducting, ablation-resistant adhesive and its application in lightning protection. The adhesive is mainly prepared from the following raw materials: 20-100% but not including 100% of a mixture of high temperature resistant resin and curing agent, and 0-80% but not including 0% of insulating, heat-conducting and ablation-resistant inorganic filler. After curing, the electrical conductivity of the adhesive is in the range of 10‑8‑10‑20S / m, the DC breakdown voltage in air is in the range of 30‑300kV / mm, and the thermal conductivity is in the range of 0.2‑3.0W / (m· Within the range of K), the ablation resistance temperature is as high as 3000°C. When the insulating, heat-conducting and ablation-resistant adhesive of a certain thickness (30‑250 μm) is used to paste the conductive film on the surface of the continuous carbon fiber laminated composite material part, it can prevent the conduction of the current to the continuous carbon fiber laminated composite material part and improve the conductive film. lightning protection.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

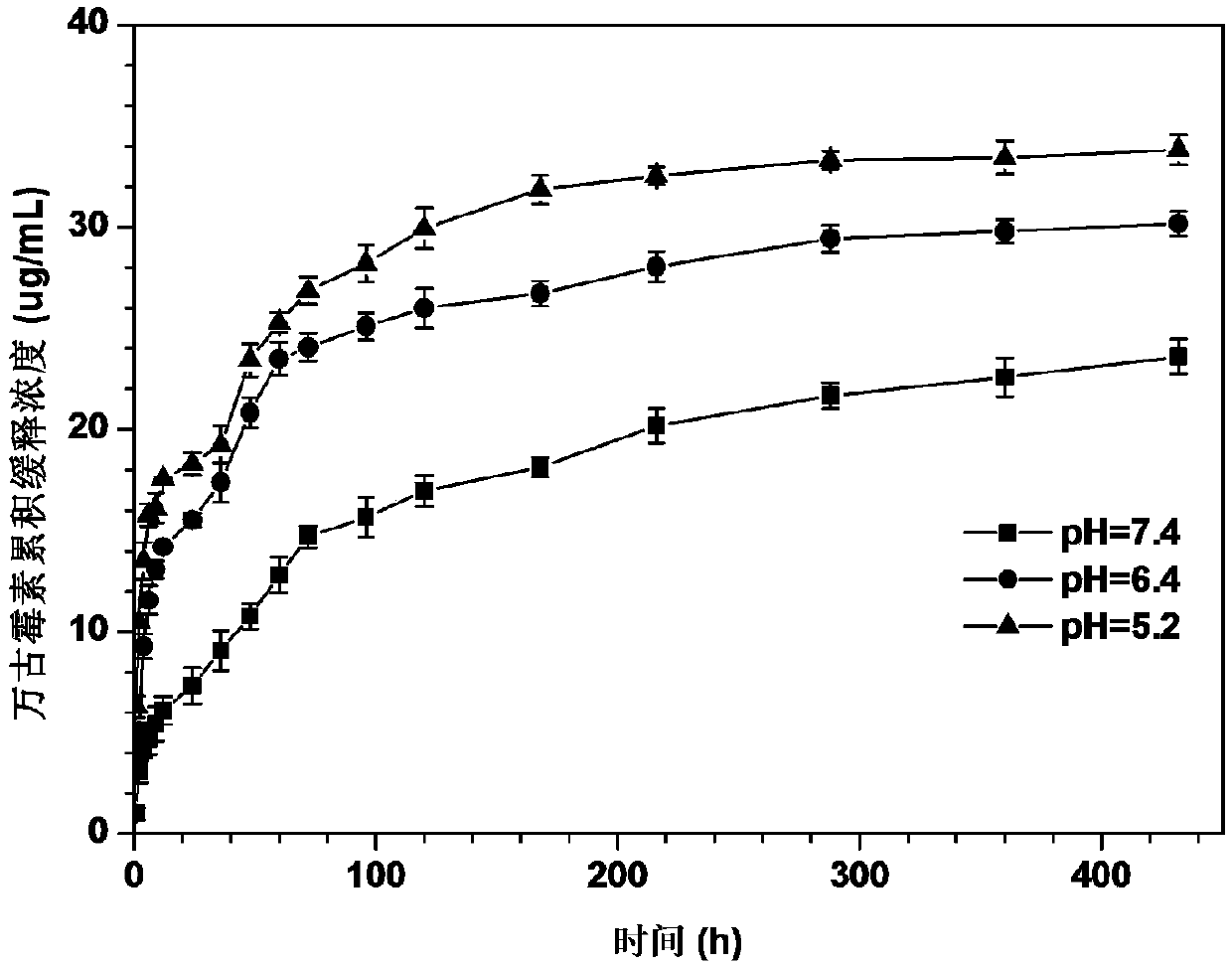

A kind of preparation method of nano-microspheres of pH response sustained-release vancomycin

ActiveCN106674425BNo generationNo thermal decompositionAntibacterial agentsSaccharide peptide ingredientsNitrogen gasEthyl fumarate

The invention discloses a preparation method for a nanoparticle capable of releasing vancomycin by responding to pH. The method comprises the following steps of: dissolving template molecule vancomycin, functional monomer hydroxyethyl methylacrylate and 2-(diethylamino) ethyl methacrylate in deionized water and uniformly stirring, thereby acquiring a mixed solution; dissolving a cross-linking agent and a photoinitiator in ethyl alcohol and then dripping into the mixed solution under a stirring state, and then acquiring the reaction mixture after stirring; pouring the reaction mixture into a three-neck flask and standing by for 1-3h at 4 DEG C; introducing nitrogen into the flask so as to discharge air in the flask; putting the flask to an environment at 15-35 DEG C, performing UV-irradiation in the wavelength of 365nm on the flask and continuously mechanical stirring for 0.5-1.5h, thereby acquiring the nanoparticle carrying the vancomycin. The preparation method disclosed by the invention is simple and easy; the resource consumption is less; a method for triggering precipitation polymerization by ultraviolet rays is economic and environment-friendly; the vancomycin is prevented from thermal decomposition under high temperature; the prepared nanoparticle is high in drug loading capacity; the release of the vancomycin can be effectively controlled.

Owner:HUBEI UNIV

Wafer processing body, temporary adhesive material for wafer processing, and method

PendingCN114521211ANo thermal decompositionNo flowSolid-state devicesSemiconductor/solid-state device manufacturingWaferMechanical engineering

The present invention is a temporary bonding material for wafer processing, which is used for temporarily bonding a wafer having a circuit surface on the front surface and a back surface to a support, and which is characterized by being provided with a composite temporary bonding material layer having an at least two-layer structure having a first temporary bonding layer and a second temporary bonding layer, the first temporary adhesive layer can be adhered to the surface of the wafer in a peelable manner and is composed of a thermoplastic resin layer (A), and the second temporary adhesive layer is laminated on the first temporary adhesive layer and is composed of a photocuring siloxane polymer layer (B). Thus, the present invention provides a film which improves wafer warpage during thermal bonding, has good peelability and cleaning removability, can be formed on a substrate having a large step difference with a uniform film thickness, has high adaptability to processes such as a TSV formation process, has excellent resistance to a thermal process, and can be formed on a substrate having a large step difference. The present invention relates to a wafer processed body, a temporary adhesive material for wafer processing, and a method for manufacturing a thin wafer using the same, wherein the productivity of the thin wafer can be improved.

Owner:SHIN ETSU CHEM IND CO LTD

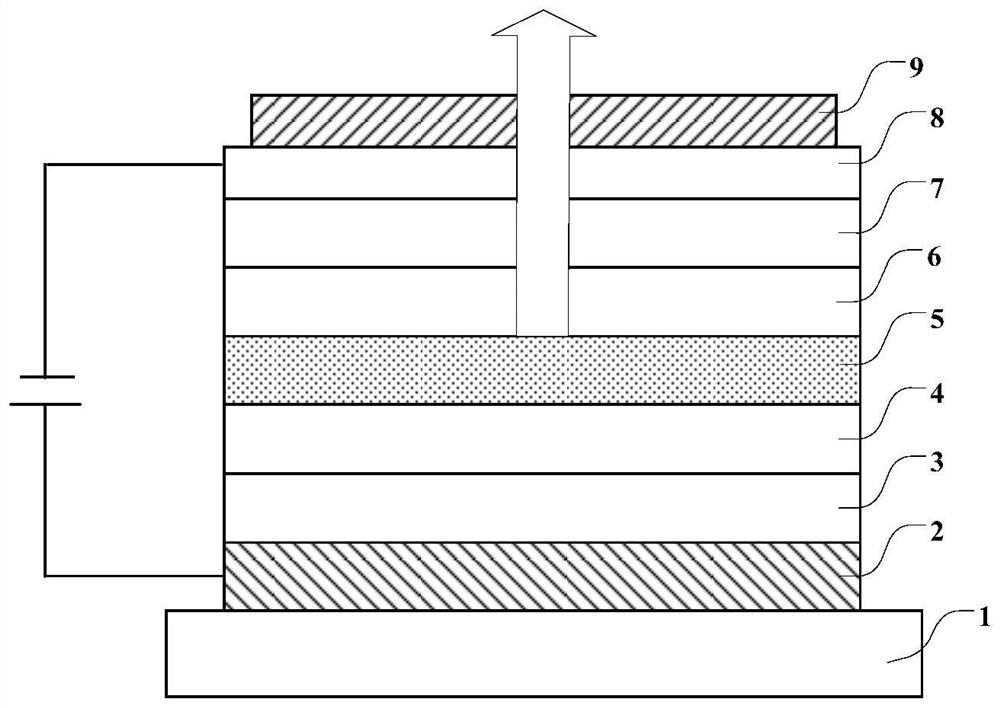

Azabiphenyl organic compound, display panel and display device

ActiveCN109265445BNot corroded by water and oxygenImprove light extraction efficiencyOrganic chemistrySolid-state devicesOrganic light emitting deviceDisplay device

The present application relates to the field of organic electroluminescent materials, in particular to a novel azabiphenyl organic compound, a display panel and a display device. The azabiphenyl organic compound has the structure shown below: the compound of the present invention can be applied to the capping layer, hole transport layer, electron transport layer and light-emitting layer of organic light-emitting devices, which can improve the performance of top-emitting organic photoelectric devices. Light extraction efficiency and luminous efficiency (especially the most effective for blue light pixels), alleviate the angle dependence of OLED device light emission (most effective for red / green light pixels), and effectively block water and oxygen in the external environment to protect the OLED display panel Not corroded by water and oxygen.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com