Azabiphenyl organic compound, display panel and display device

A technology for display panels and organic layers, applied in organic chemistry, electric solid devices, semiconductor devices, etc., can solve the problems of intermolecular close packing, high refractive index, and luminous efficiency, etc., and achieve high vitrification. Effect of transition temperature, improvement of luminous efficiency, and improvement of light extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

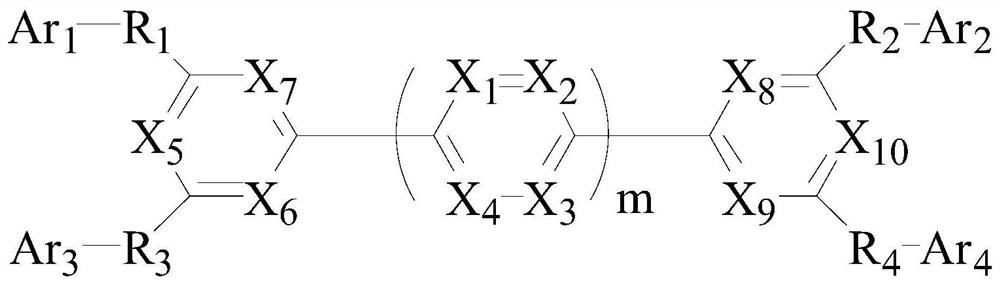

[0036] According to one embodiment of the present invention, the azabiphenyl organic compound is selected from any one of the following structures:

[0037]

[0038] According to one embodiment of the present invention, in the chemical formula I, X 1 -X 4 One of the nitrogen atoms, or, X 1 -X 4 Two of them are nitrogen atoms.

[0039] According to one embodiment of the present invention, in the chemical formula I, X 1 and x 3 are the same atoms, or, X 2 and x 4 are the same atoms.

[0040] According to one embodiment of the present invention, in the chemical formula I, R 1 , R 2 , R 3 , R 4 are the same substituents. This symmetrical structure achieves better refractive index and transmittance.

[0041] According to one embodiment of the present invention, in the chemical formula I, Ar 1 、Ar 2 、Ar 3 、Ar 4 are the same substituents. This symmetrical structure achieves better refractive index and transmittance.

[0042] According to one embodiment of the pr...

Embodiment 1

[0084] The synthetic route of compound CP2:

[0085]

[0086] In a 250ml three-necked flask, under the protection of nitrogen, in 150ml DMF, sequentially add raw material intermediate M1 (0.025mol), intermediate M5 (0.012mol) and palladium acetate (0.0003mol), mix and stir, and then add K 3 PO 4 (0.045mol) aqueous solution, reflux reaction at a temperature of 130°C for 10h. Naturally cool to room temperature, after the reaction is over, add 100mL deionized water, then drop a few drops of 2M HCl, extract with dichloromethane, collect the organic phase, and wash with anhydrous Na 2 SO 4 Dry processing. The dried solution was filtered, and the solvent was removed by a rotary evaporator to obtain a crude product. The crude product was purified by silica gel column chromatography, and finally purified to obtain the product CP2.

[0087] Compound CP2 elemental analysis result (molecular formula C 53 h 33 N 5 ): Theoretical values: C, 86.04; H, 4.50; N, 9.47. Test values:...

Embodiment 2

[0089] The synthetic route of compound CP4:

[0090]

[0091] In a 250ml three-necked flask, under the protection of nitrogen, in 150ml DMF, sequentially add raw material intermediate M1 (0.025mol), intermediate M5 (0.012mol) and palladium acetate (0.0003mol), mix and stir, and then add K 3 PO 4 (0.045mol) aqueous solution, reflux reaction at a temperature of 130°C for 10h. Naturally cool to room temperature, after the reaction is over, add 100mL deionized water, then drop a few drops of 2M HCl, extract with dichloromethane, collect the organic phase, and wash with anhydrous Na 2 SO 4 Dry processing. The dried solution was filtered, and the solvent was removed by a rotary evaporator to obtain a crude product. The crude product was purified by silica gel column chromatography, and finally purified to obtain the product CP4.

[0092] Compound CP4 element analysis result (molecular formula C 49 h 29 N 9 ): Theoretical: C, 79.12; H, 3.93; N, 16.95. Test values: C, 79.1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com