Forming method of bulk acoustic wave resonance device

A resonant device, bulk acoustic wave technology, applied in the direction of impedance network, electrical components, etc., to achieve the effect of avoiding process technology, reducing production cost, and improving Q value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] As mentioned in the background art, the bulk acoustic wave resonance device formed in the prior art still has many problems. The following will be described in detail with reference to the accompanying drawings.

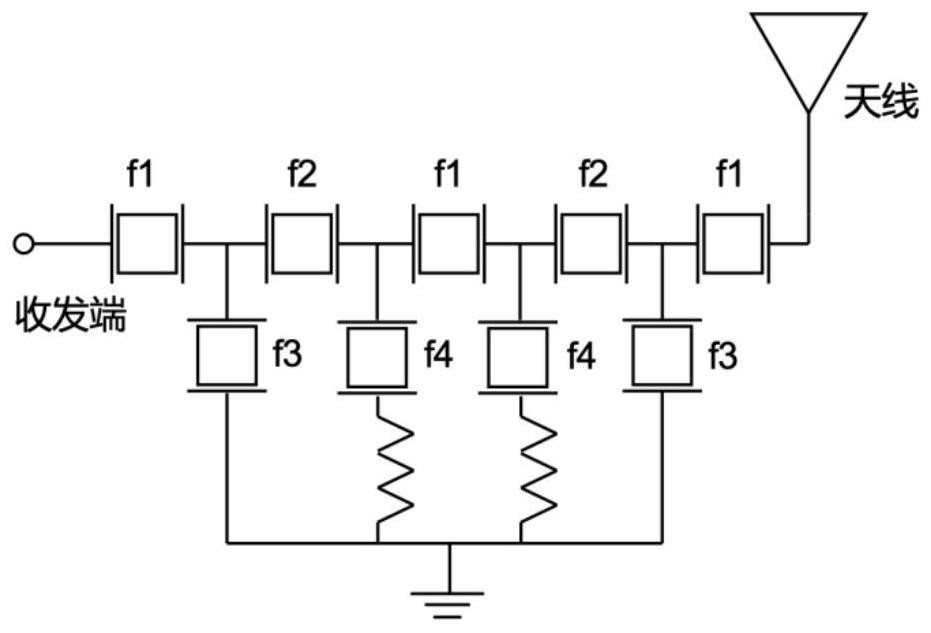

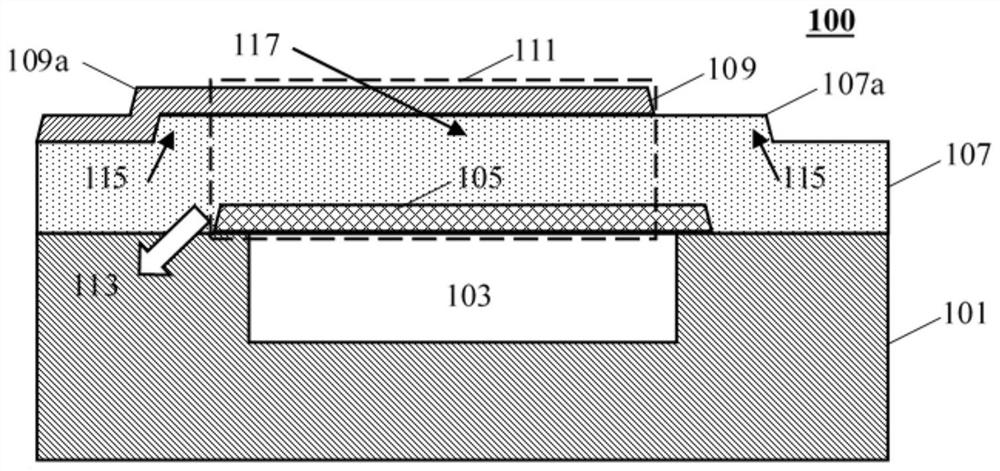

[0039] figure 1 is a schematic diagram of a bulk acoustic wave filter circuit; figure 2 It is a schematic diagram of the structure of a thin film bulk acoustic wave resonator.

[0040] Please refer to figure 1 , a bulk acoustic wave filter circuit, including a ladder circuit composed of a plurality of bulk acoustic wave resonators, wherein f1, f2, f3, f4 respectively represent four different frequencies. In each bulk acoustic wave resonator, the metal electrodes on both sides of the piezoelectric layer of the resonator generate alternating positive and negative voltages, and the piezoelectric layer generates acoustic waves through alternating positive and negative voltages, and the acoustic waves in the resonator propagate in a direction perpendicular to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com