Method and product of coating nanocrystalline thin film based on plasma atomic layer deposition

A technology of atomic layer deposition and plasma, which is applied in the direction of liquid-coating devices, coatings, gaseous chemical plating, etc., can solve the problem of loss of luminous performance and achieve the effect of facilitating mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

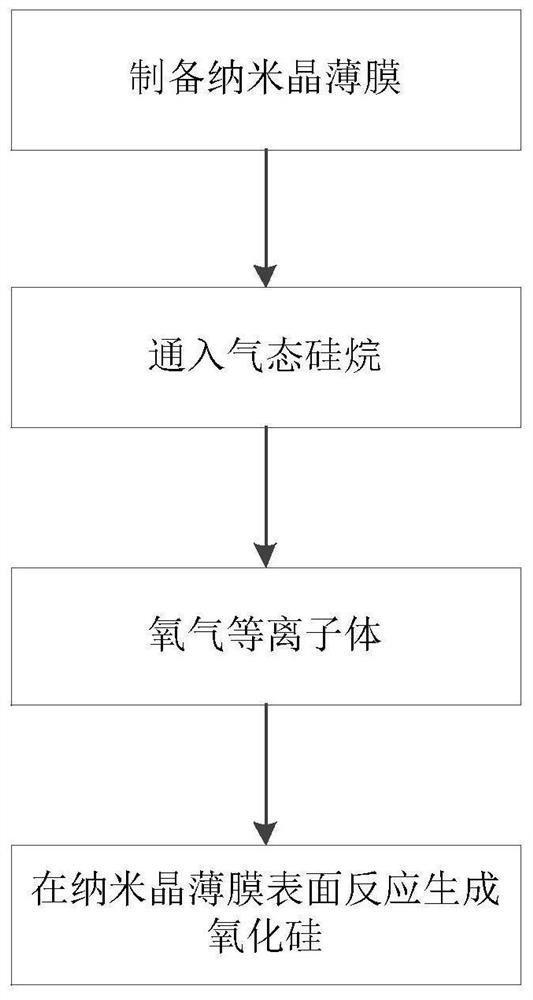

[0027] A method for coating a nanocrystalline film based on plasma atomic layer deposition, the preparation method mainly includes the following steps:

[0028] Step 1. Preparation of nanocrystalline colloid

[0029] Mix oleylamine, oleic acid, and lead bromide according to the ratio of mass fraction of 12-18:7-10:1-4, and heat to 150°C-180°C under an inert atmosphere until a completely dissolved precursor is formed; Immediately inject a certain proportion of cesium stearate-octadecene mixed solution into the precursor, the mass ratio of cesium stearate to octadecene in the mixed solution is 1~3:10~15, and the reaction is 5s~ After 10s, place the whole in an ice-water mixture to cool and stop the reaction; then, centrifuge and purify the reaction product quantum dot colloid and add n-hexane solution. The mass ratio of quantum dot colloid to n-hexane solution is 0.5-1:10-15. Formation of nanocrystalline colloids.

[0030] Step 2, preparing a nanocrystalline thin film.

[003...

Embodiment 1

[0041] (a1) Mix oleylamine solution, oleic acid solution, and lead bromide powder to form a mixed solution, and heat to 150° C. under an inert atmosphere to fully dissolve the mixed solution to obtain a precursor solution. In the precursor solution, oleylamine, oil The ratio of acid and lead bromide mass fraction is 12:7:1;

[0042] (a2) Add cesium stearate-octadecene mixed solution in the precursor solution, react for 5s, obtain the quantum dot colloid with this, centrifugally purify the quantum dot colloid, then add n-hexane solution, form nanocrystalline colloid with this, Wherein, the cesium stearate-octadecene mixed solution is a mixed solution formed by mixing cesium stearate and octadecene according to a mass ratio of 1:10, and the mass ratio of quantum dot colloid and n-hexane solution is 0.5:10;

[0043] (a3) The nanocrystalline colloid obtained in step (a2) is spin-coated on the carrier, and the desired nanocrystalline film is obtained after curing, wherein the rotat...

Embodiment 2

[0048] (a1) Mix oleylamine solution, oleic acid solution, and lead bromide powder to form a mixed solution, and heat to 180° C. under an inert atmosphere to fully dissolve the mixed solution to obtain a precursor solution. In the precursor solution, oleylamine, oil The ratio of acid and lead bromide mass fraction is 18:10:4;

[0049] (a2) Add cesium stearate-octadecene mixed solution to the precursor solution, and react for 10s to obtain the quantum dot colloid, then centrifugally purify the quantum dot colloid, and then add n-hexane solution to form nanocrystalline colloid, Wherein, the cesium stearate-octadecene mixed solution is a mixed solution formed by mixing cesium stearate and octadecene according to a mass ratio of 3:15, and the mass ratio of quantum dot colloid and n-hexane solution is 1:15;

[0050] (a3) The nanocrystalline colloid obtained in step (a2) is spin-coated on the carrier, and the desired nanocrystalline film is obtained after curing, wherein the rotation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com