Organic compound, display panel and display device

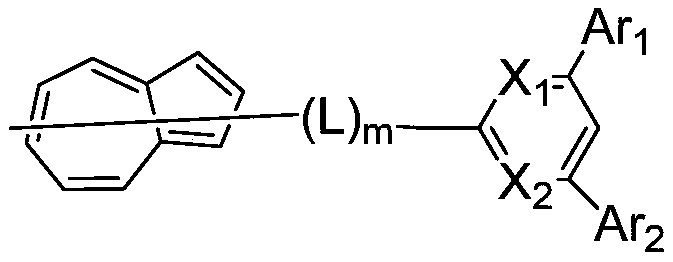

An organic compound and display panel technology, applied in the field of display panels and display devices, organic compounds, can solve problems such as the inability to solve luminous efficiency and chromaticity at the same time, the inability to achieve close packing between molecules, and the inability to meet the requirements of high refractive index, etc. , to save the preparation cost, the preparation method is simple, and the effect of alleviating the angle dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079]

[0080]

[0081] (1) In a 250ml round bottom flask, compound 1-1 (15mmol), diethyl malonate (35mmol) and sodium ethoxide (15mmol) were added to dry ethanol (100ml), under nitrogen atmosphere, temperature React at 78°C for 12 hours, add the obtained intermediate mixed solution into water, then filter through a pad of diatomaceous earth, extract the filtrate with dichloromethane, then wash with water, and dry with anhydrous magnesium sulfate, filter and evaporate , the crude product was purified by silica gel column chromatography to obtain the intermediate compound 1-2.

[0082] (2) In a 250ml round bottom flask, add compound 1-2 (15mmol), diethylphenylamine (15mol) to dry POCl 3 (100ml), under nitrogen atmosphere, the temperature is 6.0 hours under the condition of 120 ℃, and the obtained intermediate mixed solution is added in water, then filtered through a diatomaceous earth pad, and the filtrate is extracted with dichloromethane, then washed with water, and A...

Embodiment 2

[0087]

[0088] (1) In a 250ml round bottom flask, compound 13-1 (15mmol), diethyl malonate (35mmol) and sodium ethoxide (15mmol) were added to dry ethanol (100ml), under nitrogen atmosphere, temperature React at 78°C for 12 hours, add the obtained intermediate mixed solution into water, then filter through a pad of diatomaceous earth, extract the filtrate with dichloromethane, then wash with water, and dry with anhydrous magnesium sulfate, filter and evaporate , the crude product was purified by silica gel column chromatography to obtain the intermediate compound 13-2.

[0089] (2) In a 250ml round bottom flask, add compound 13-2 (15mmol), diethylphenylamine (15mol) to dry POCl 3(100ml), under nitrogen atmosphere, the temperature is 6.0 hours under the condition of 120 ℃, and the obtained intermediate mixed solution is added in water, then filtered through a diatomaceous earth pad, and the filtrate is extracted with dichloromethane, then washed with water, and After dryin...

Embodiment 3

[0095]

[0096] (1) In a 250ml round bottom flask, compound 14-5 (20mmol), compound 14-4 (10mmol) and Pd(PPh 3 ) 4 (0.3mmol) was added to a mixture of toluene (30ml) / ethanol (20ml) and potassium carbonate (12mmol) aqueous solution (10ml), and the reaction was refluxed under nitrogen atmosphere for 12h. The resulting mixture was cooled to room temperature, added to water, and filtered through a pad of celite. The filtrate was extracted with dichloromethane, washed with water, and dried over anhydrous magnesium sulfate. After filtration and evaporation, the crude The product yielded the final product compound P14.

[0097] 1 H NMR (400MHz, CDCl 3 )δ8.50-8.31 (m, 2H), 8.20 (s, 2H), 7.91-7.39 (m, 18H), 7.54 (d, J = 8.4Hz, 4H), 7.28 (s, 1H), 7.23-7.00 (m,3H);

[0098] Characterization results: elemental analysis results of compound P14 (molecular formula C 48 h 30 N 2 ): theoretical value: C, 90.85; H, 4.73; N, 4.42. Test values: C, 90.85; H, 4.73; N, 4.42. ESI-MS (m / z...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com