Patents

Literature

72results about How to "Ease of light" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

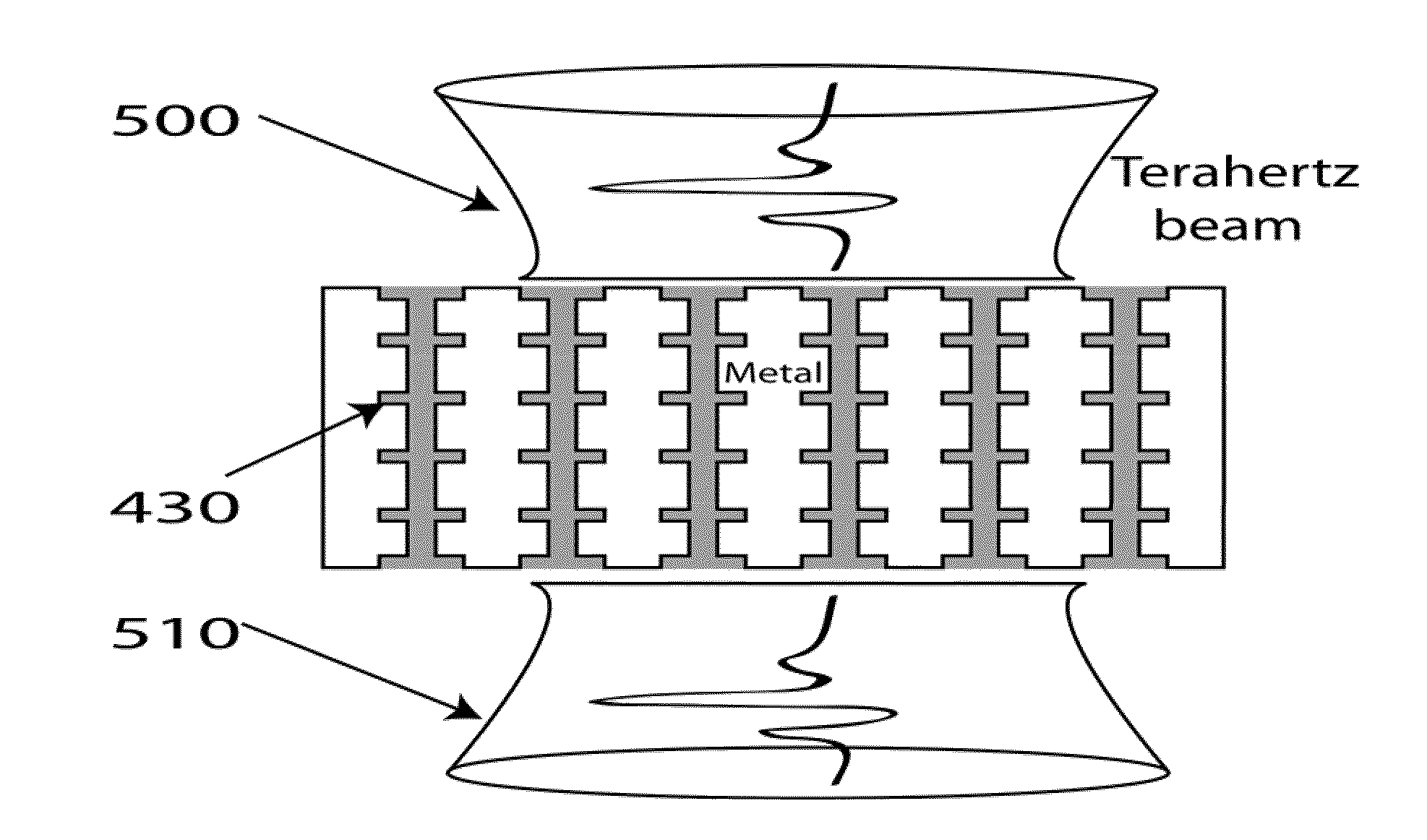

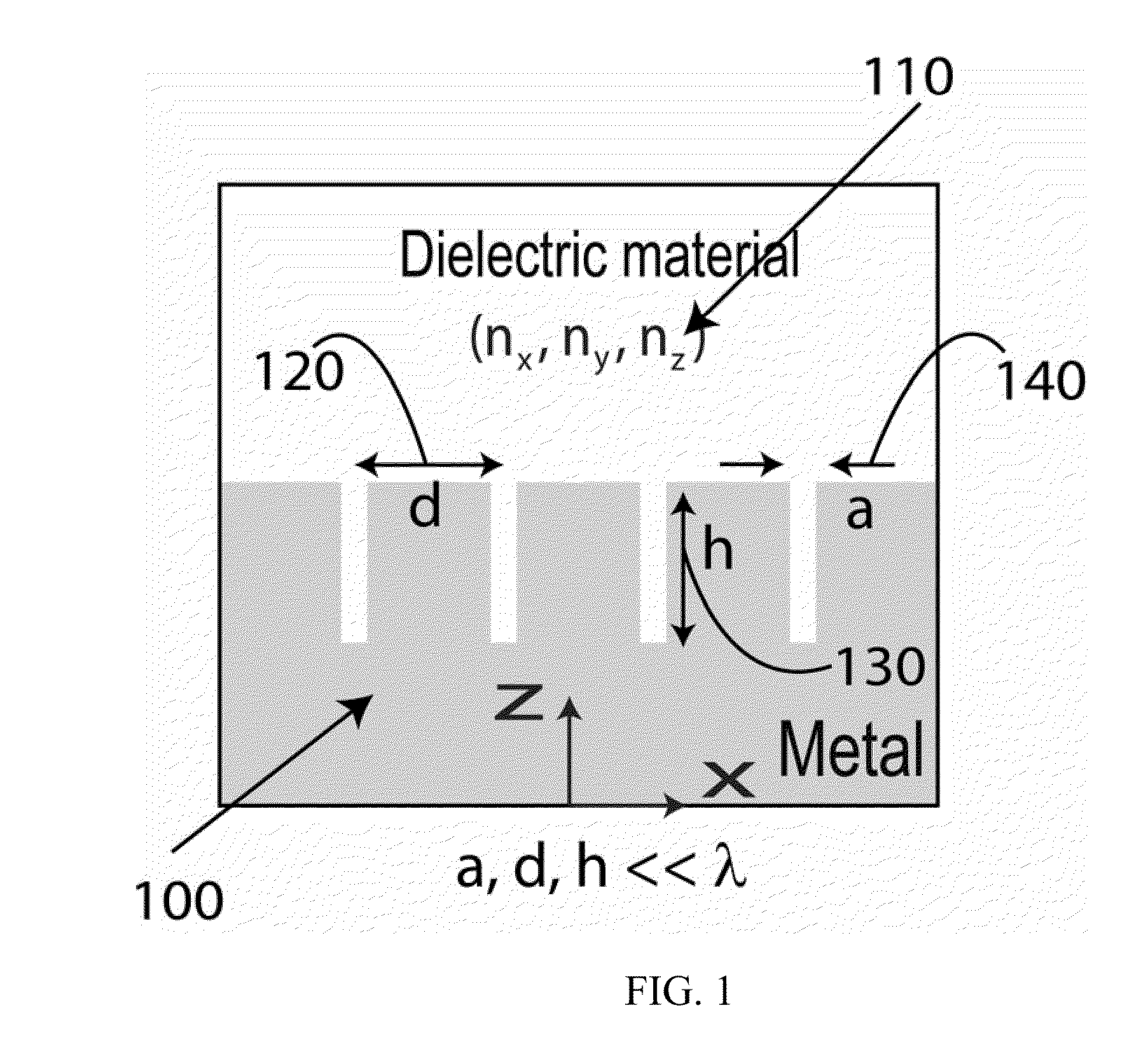

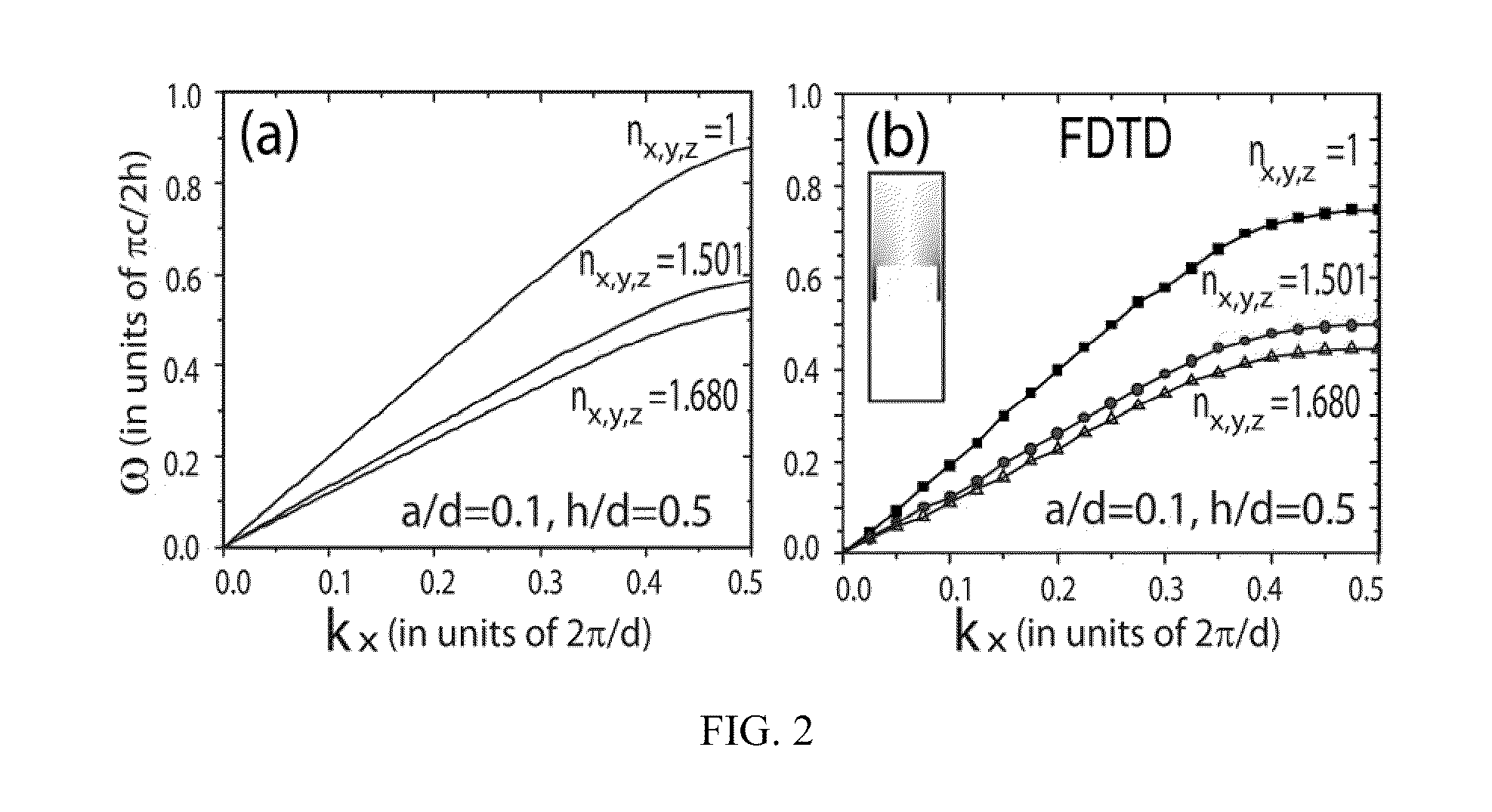

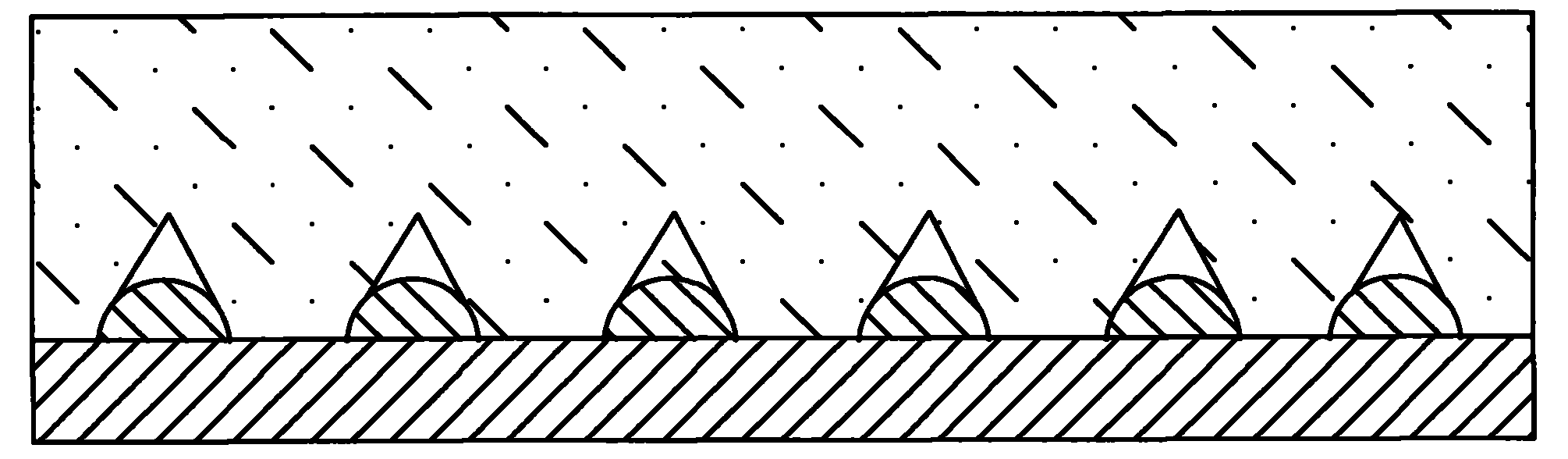

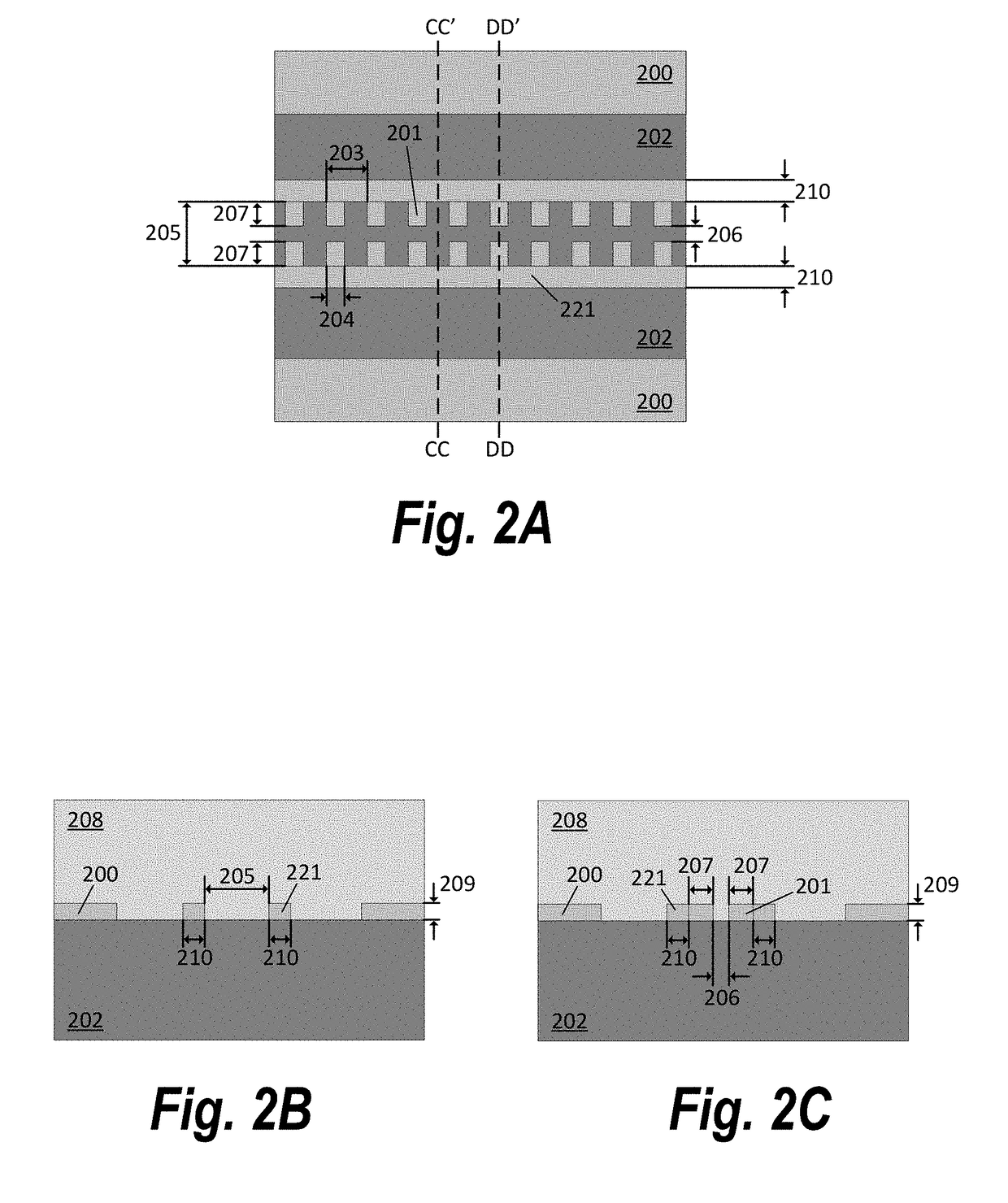

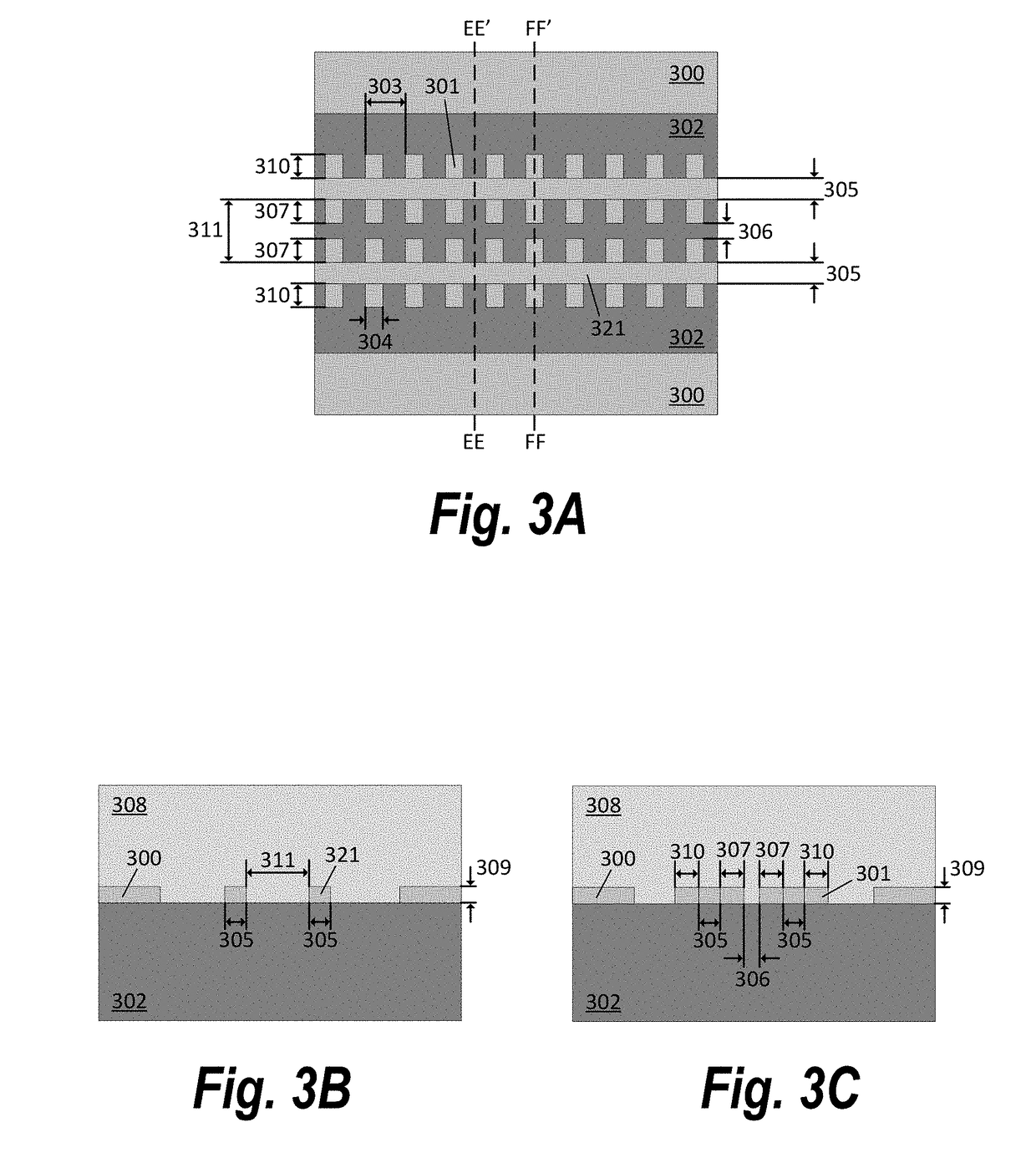

Dynamic Terahertz Switch Using Periodic Corrugated Structures

InactiveUS20120019901A1Ease of lightOptical light guidesNon-linear opticsManufacturing technologyElectrical conductor

A subwavelength terahertz (THz) switch using an artificially designed conductor metamaterial is discussed in this invention. Theoretically, slow-light EM wave propagating at THz speed imitates the strongly localized surface plasmon modes and henceforth is called Spoof Surface Plasmon Polariton (SSPP) mode in this invention. The SSPP mode of slow-light EM propagation can be easily tailored by changing the refractive index of the dielectric materials inside the metallic gap structure engineered as a periodic array of grooves. Thus, the incorporation of electro-optical material which has birefringence such as a nematic liquid crystal (N-LC) or multiple-refractive indices into the metallic gap leads to a highly compact and efficient terahertz switch being controlled by a low-voltage signal. The optimal design of the SSPP switch enabled by this novel method shows many interesting properties including 1) strong subwavelength localization; 2) relatively high extinction (On / Off switching) ratio; and 3) small damping attenuation. The THz dynamic switches can be used to construct linear switches, Y junction switches and Mach-Zehnder interferometers by using micromachining and other fabrication techniques.

Owner:MAZUMDER PINAKI

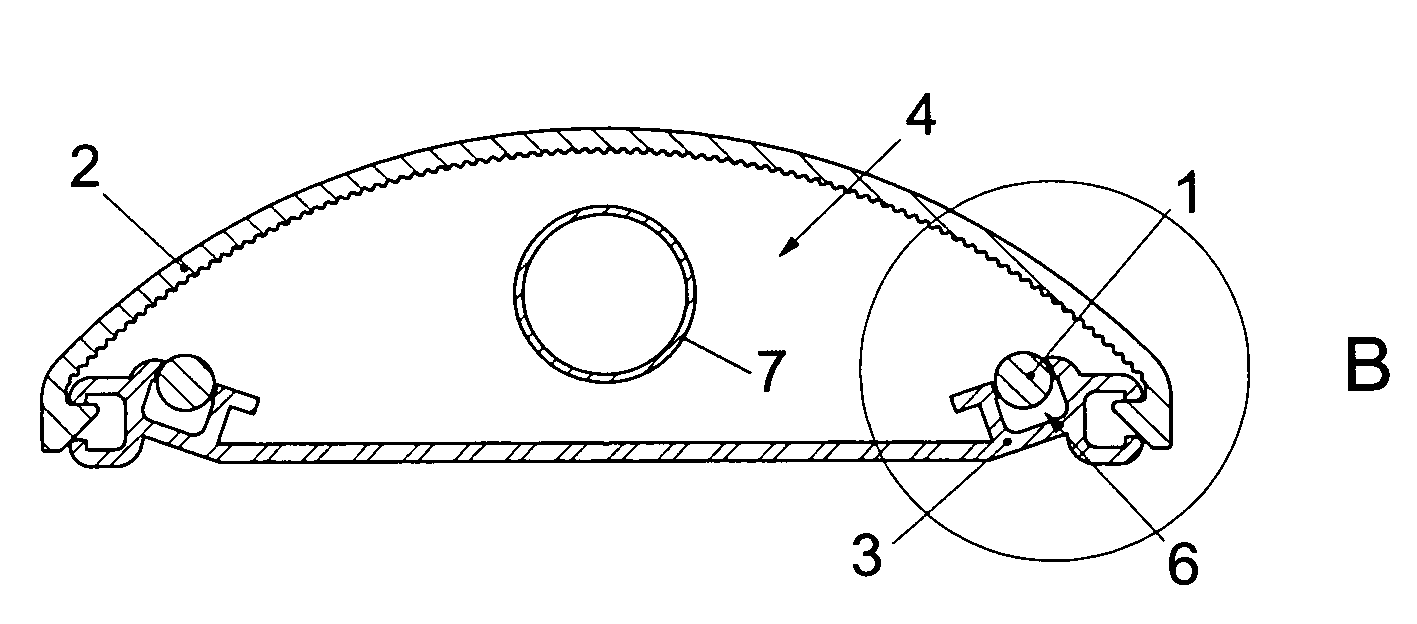

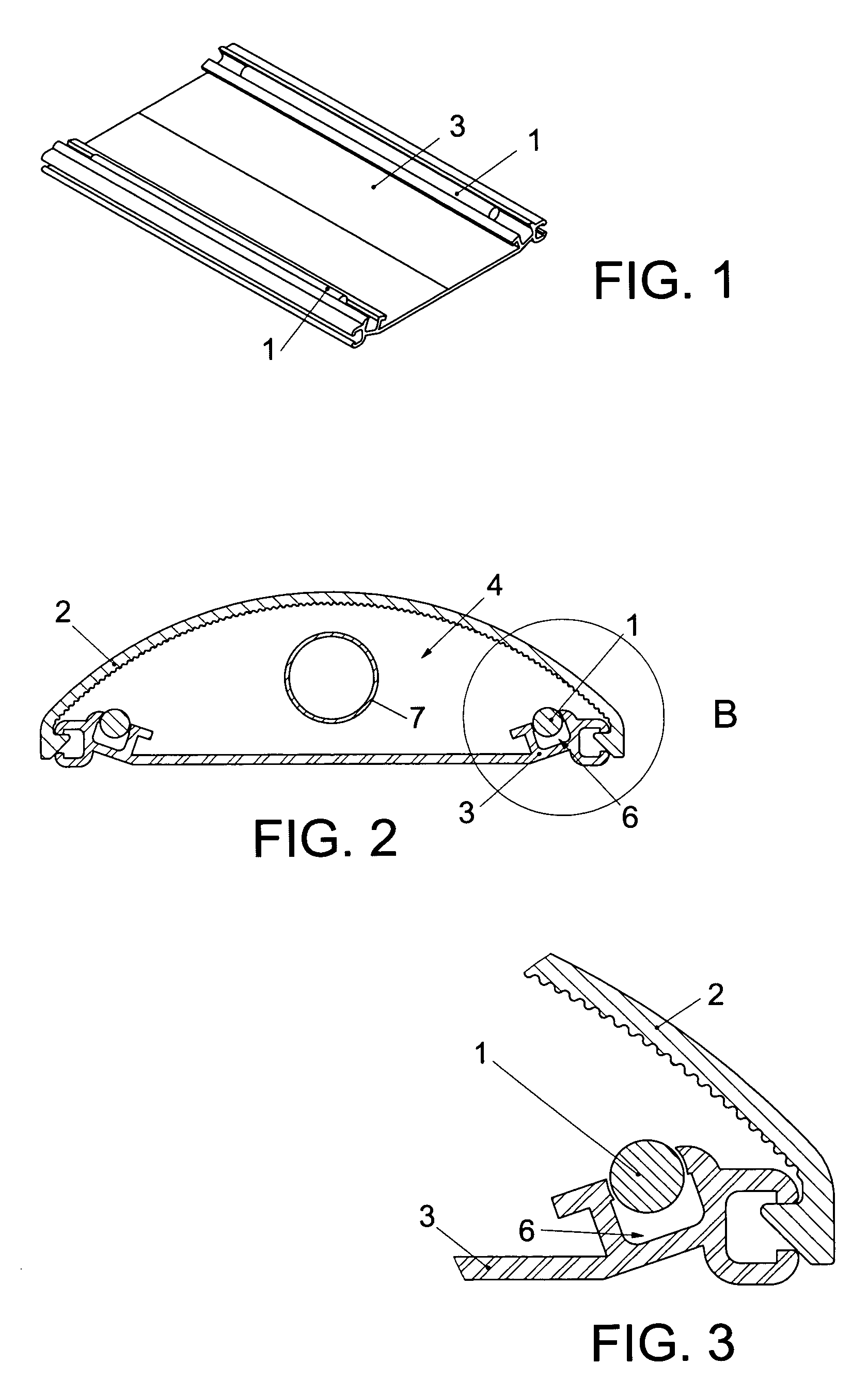

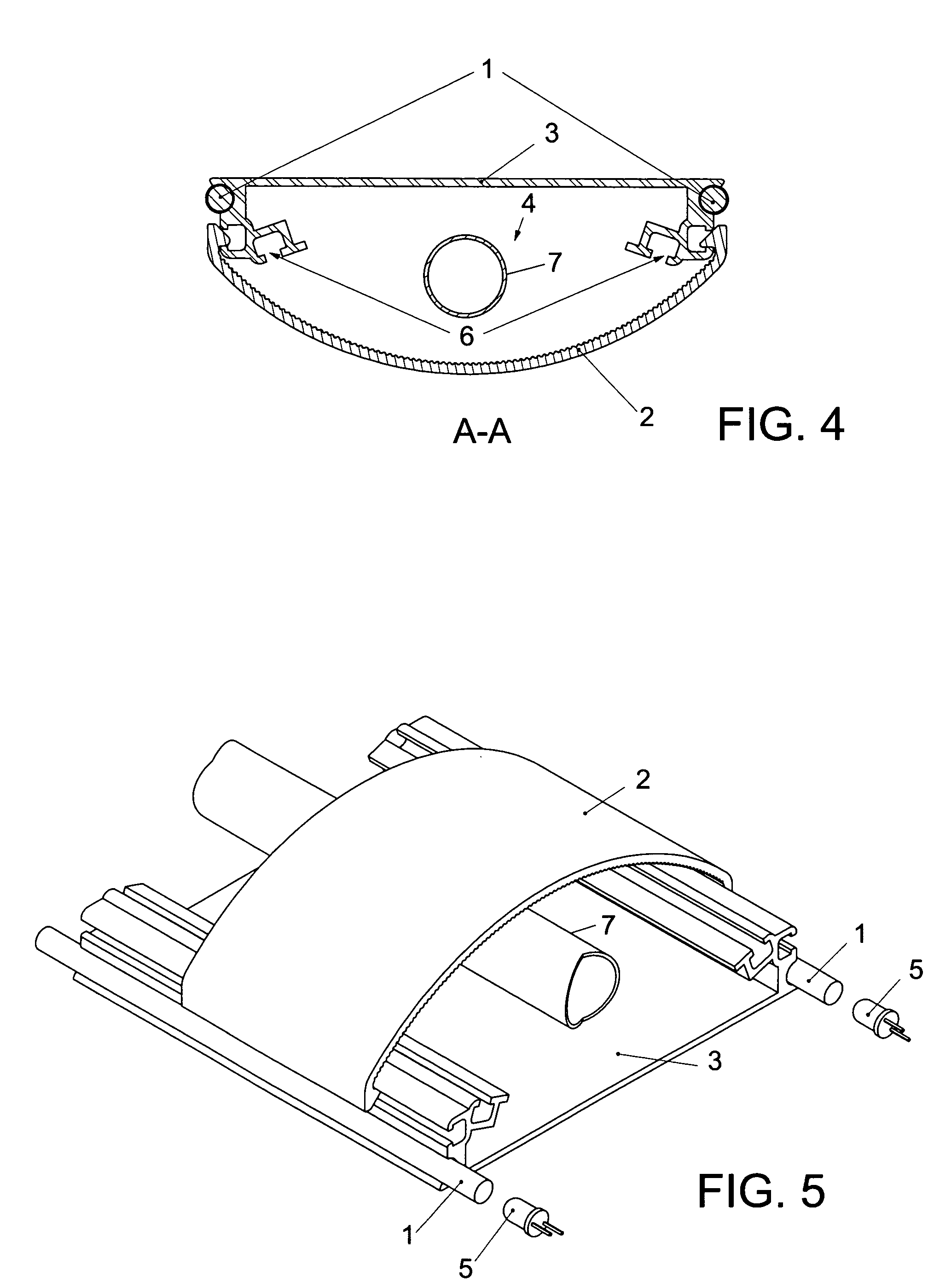

Arrangement in connection with a lighting fixture, and a lighting fixture

InactiveUS7090375B2Ease of lightPleasant for passengers' eyesGeneral lightingLight source combinationsEffect lightDimmer

The arrangement in connection with a lighting fixture, and a lighting fixture, the arrangement comprising a first light source which is arranged in connection with the lighting fixture structure. The arrangement further comprises one or more second light sources and an optic guide, which comprises a first end, a second end and a guide portion between them; is arranged to transmit light over the guide portion between the first end and the second end; and is arranged in connection with a lighting fixture to provide dimmer lighting compared with the lighting provided with the first source, whereby one or more second light sources is / are arranged in connection with one end or both ends of the optic guide and to function as the light source of the optic guide.

Owner:TEKNOWARE

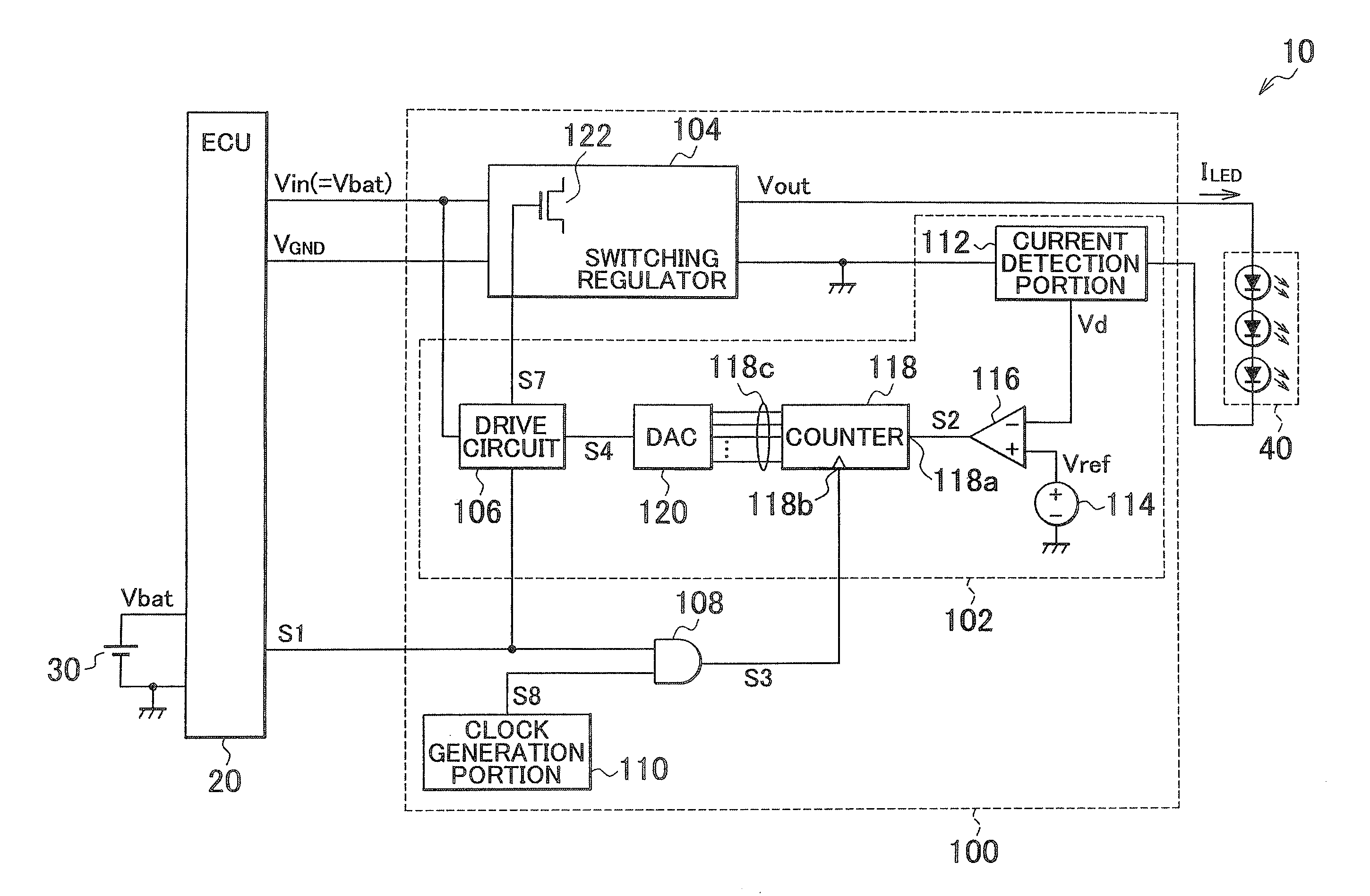

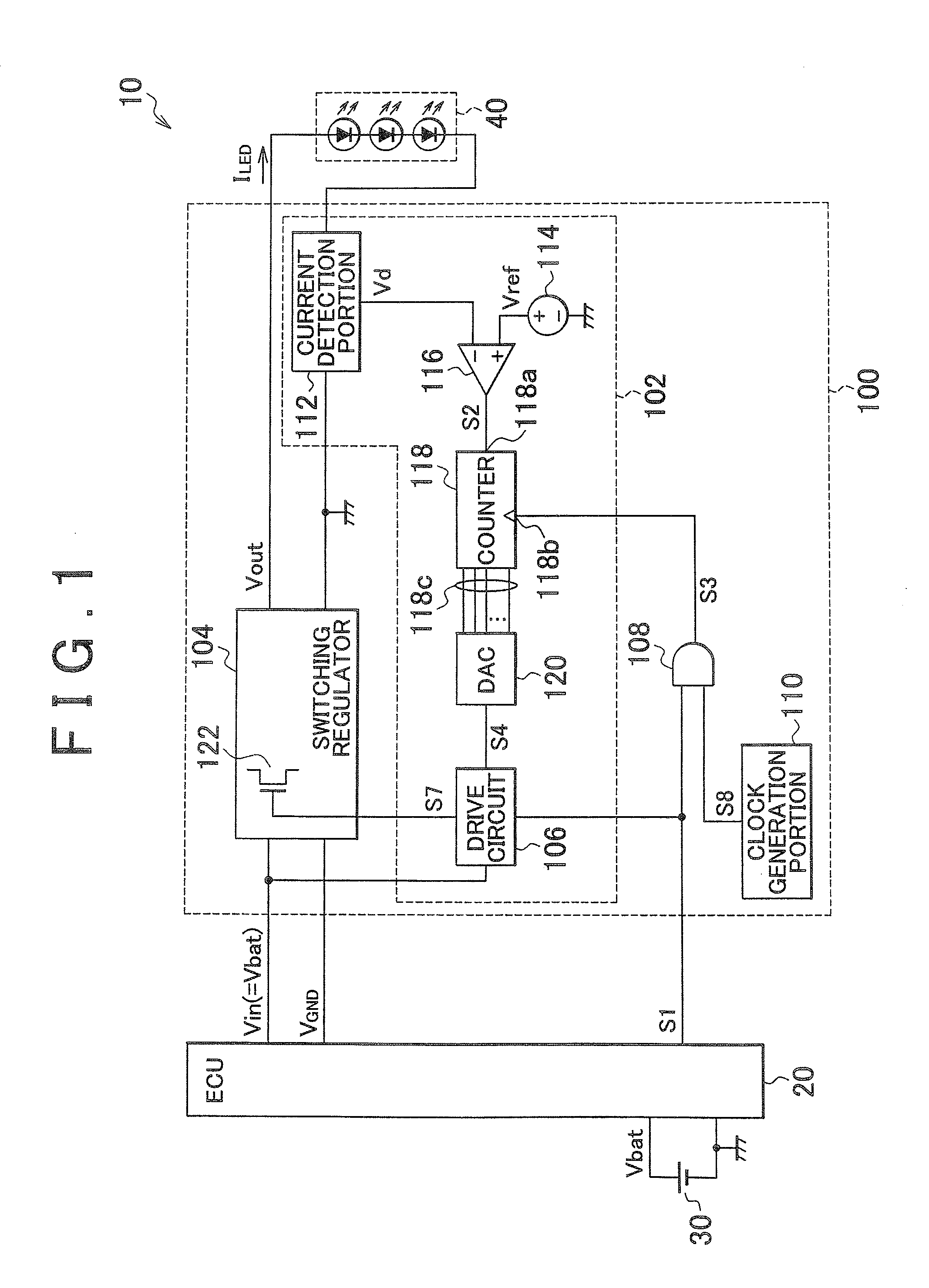

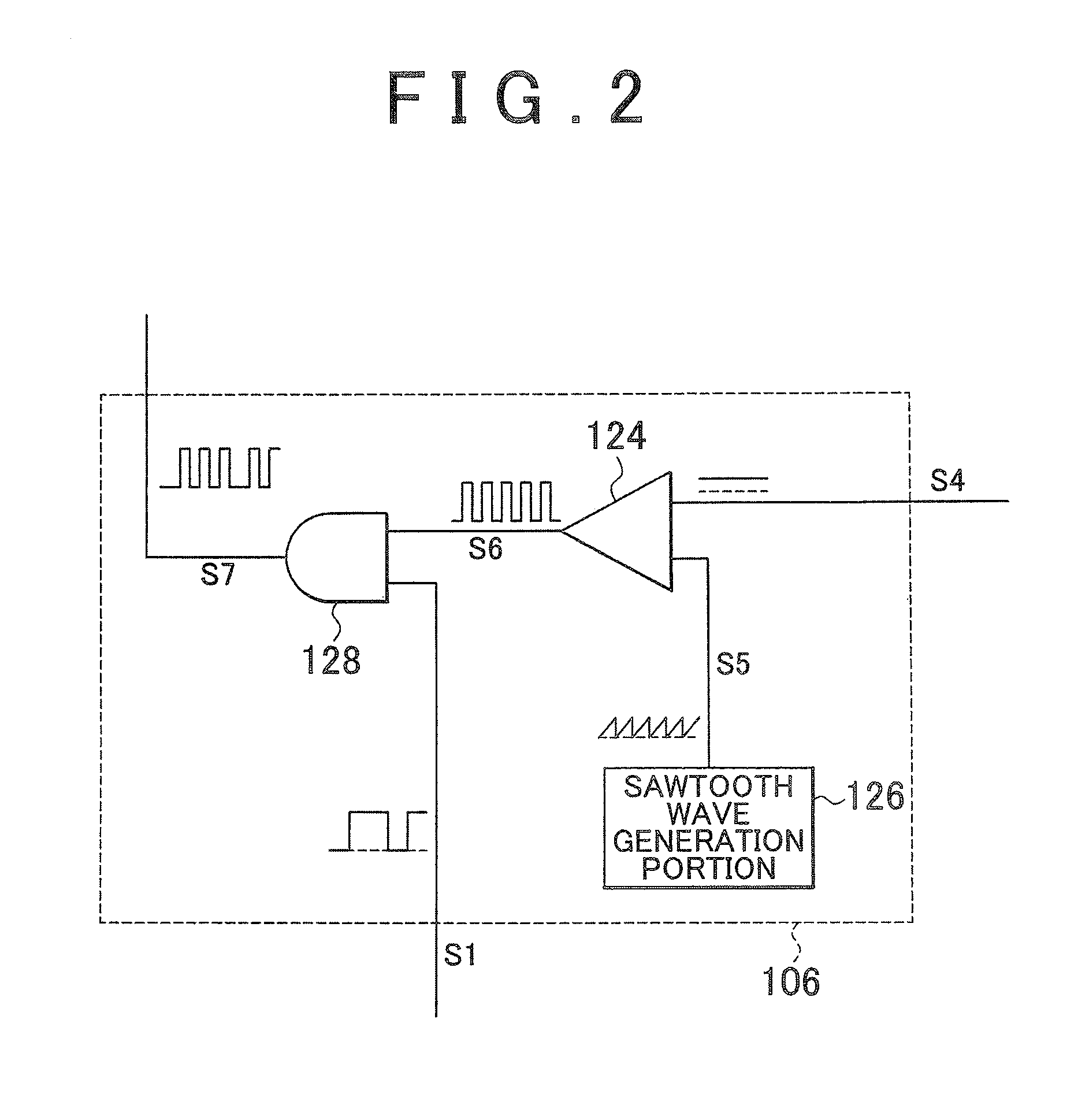

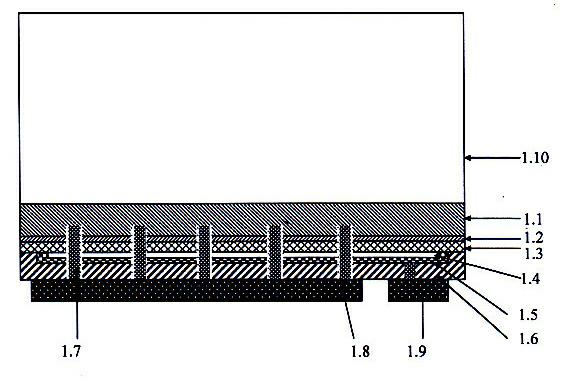

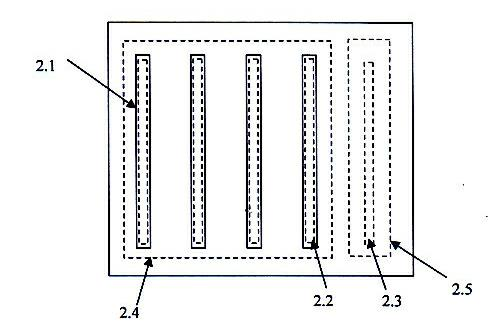

Semiconductor light source lighting circuit

ActiveUS20120286687A1Reduce circuit sizeEase of lightElectrical apparatusElectroluminescent light sourcesDriving currentEffect light

A semiconductor light source lighting circuit includes a switching regulator that produces a drive current ILED with a switching element, and a control circuit that controls turning on and off of the switching element so that the magnitude of the drive current ILED approaches a target value. The control circuit includes an error comparator that compares the drive current ILED and the target value, an up / down counter that performs a counting operation, in which the control digital value is incremented or decremented based on the result of the comparison, a D / A converter that converts the control digital value into an analog duty ratio setting signal S4, and a drive circuit that controls the turning on and off of the switching element based on the signal S4. The up / down counter stops the counting operation when the switching regulator is brought into the inactive state.

Owner:KOITO MFG CO LTD

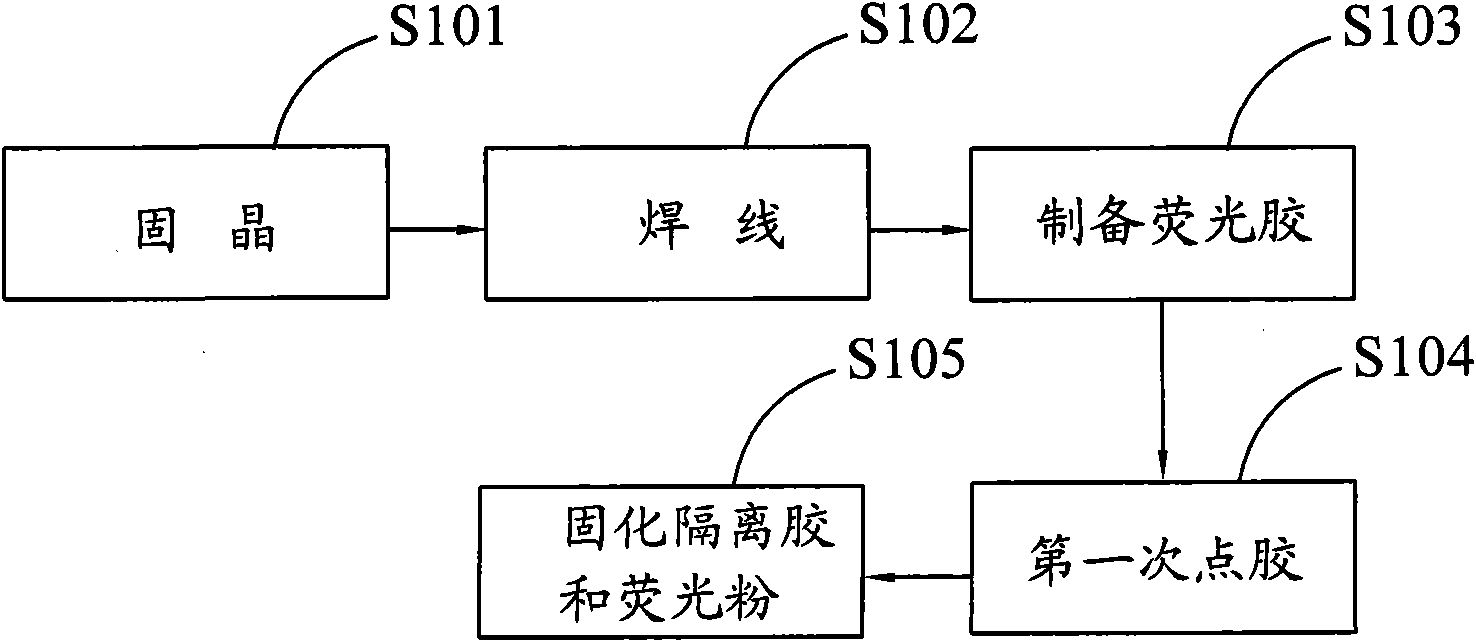

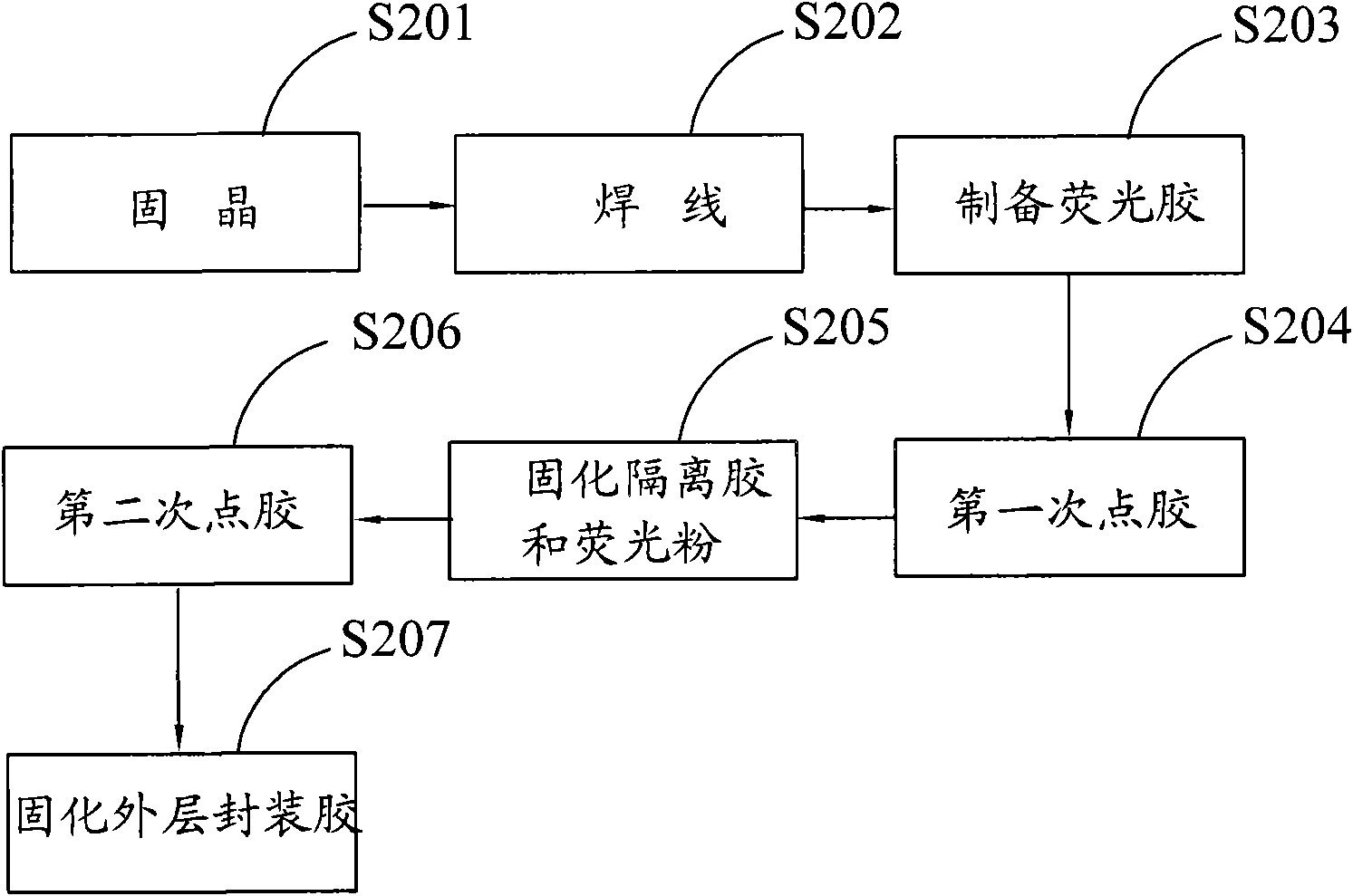

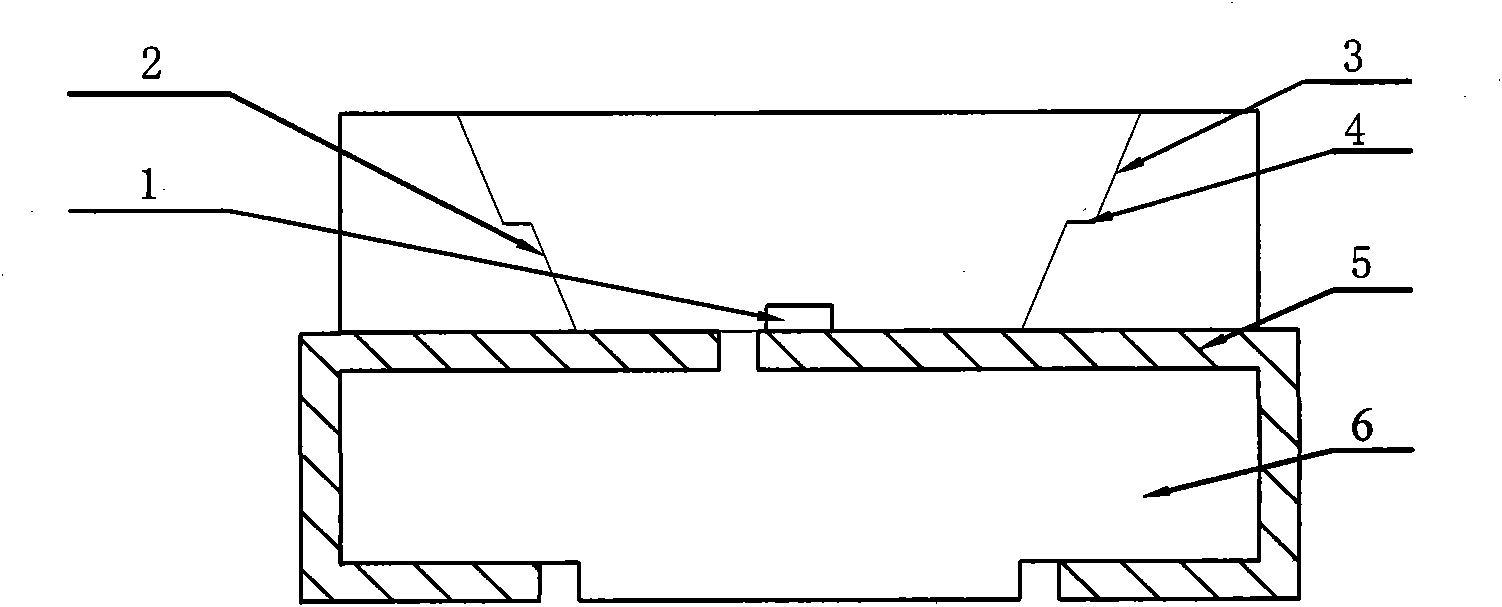

LED encapsulation method and LED encapsulation structure encapsulated with same

InactiveCN101916806AReduce interface light lossAvoid low excitation efficiencySolid-state devicesSemiconductor devicesFluorescenceEngineering

The invention is suitable for LED encapsulation field and provides an LED encapsulation method and an LED encapsulation structure encapsulated with the same. The method comprises the following steps of: die bonding: fixing an LED chip on a lead frame of an LED bracket; wire bonding: electrically connecting the LED chip and the lead frame via a bonding wire; preparation of fluorescent glue: evenly mixing insulation glue and phosphor powder to prepare the fluorescent glue; glue dispensation for the first time: dispensing the fluorescent glue into a reflection cup so as to cover the LED chip; and solidification of the phosphor powder and the insulation glue: inverting the LED bracket subjected to the first glue dispensation and baking so as to form a crescent phosphor powder layer far away from the LED chip. The invention employs an anti-deposition encapsulation technology to perform LED encapsulation, thereby solving the problem that the over-high temperature caused by long-term contact between the phosphor powder and the chip influences the luminous efficiency, reducing the light loss caused by scattering and interface light loss, and improving the extraction efficiency of the LED.

Owner:SHENZHEN REFOND OPTOELECTRONICS

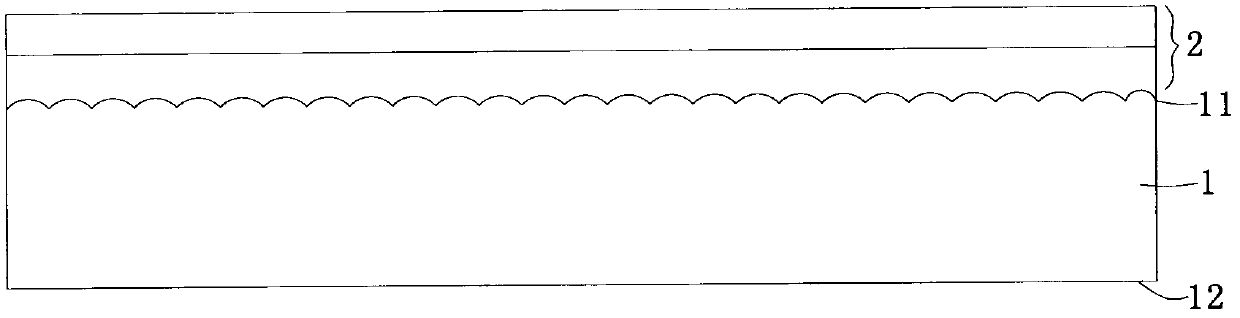

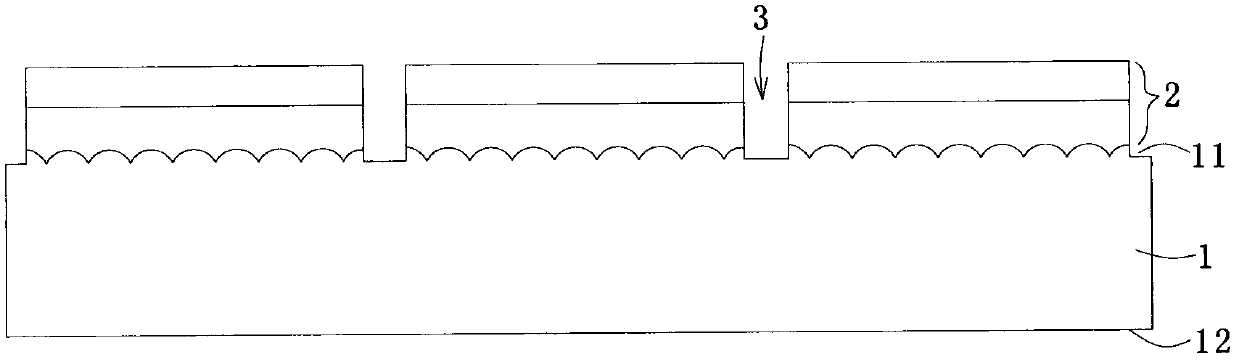

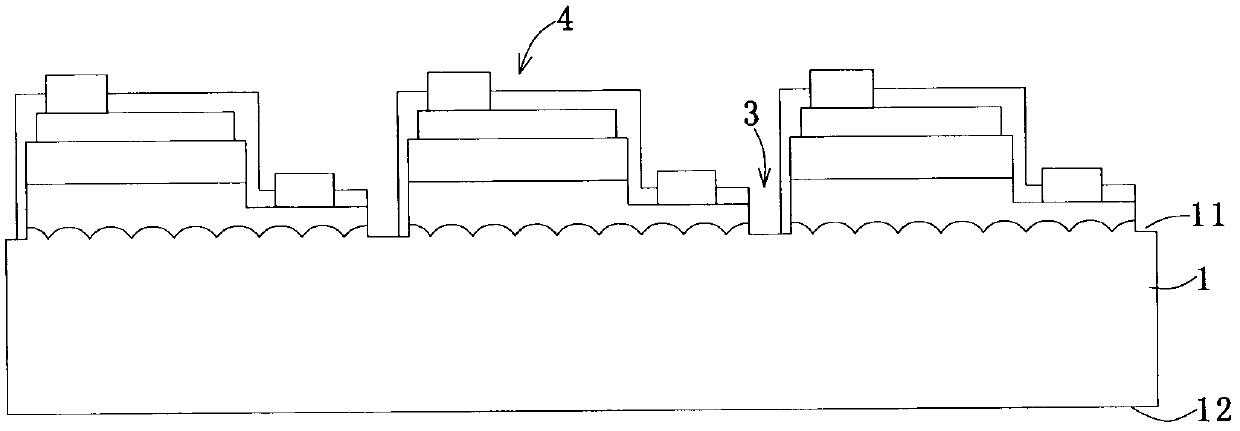

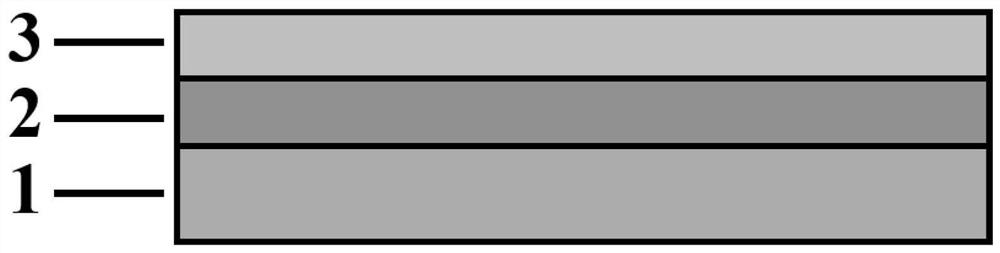

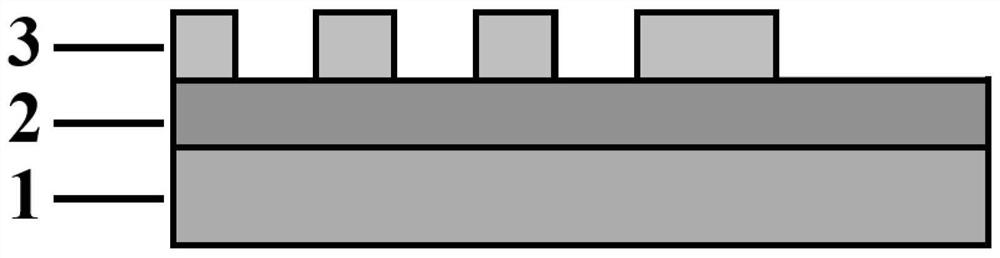

Production method for sapphire pattern substrate

InactiveCN101814426ALow refractive indexReduce hardnessSemiconductor/solid-state device manufacturingRefractive indexPhotoresist

The invention discloses a production method for a sapphire pattern substrate, comprising the following particular steps of (1) depositing a layer of thin film on the upper surface of a sapphire which has a low refractive index material and 1AA-999AA thickness; (2) preparing a mask pattern on the thin film with photoresistance; (3) transferring the pattern masked with photoresist to the thin film through etching to obtain a protuberance with the 1AA-999AA thickness, wherein the lower substrate of the pattern of the protuberance has a width of 0.5-3 mu m and a gap of 0.5-3 mu m; and (4) cleaning the sapphire to remove the residual photoresistance. The invention has the advantages that PSS cost can be greatly reduced and total reflection angles are increased for light, thereby being more favorable for emergent light, improving emergent light efficiency, being favor of laser peeling and increasing excellent rate of the finished product LED chip.

Owner:NANCHANG UNIV

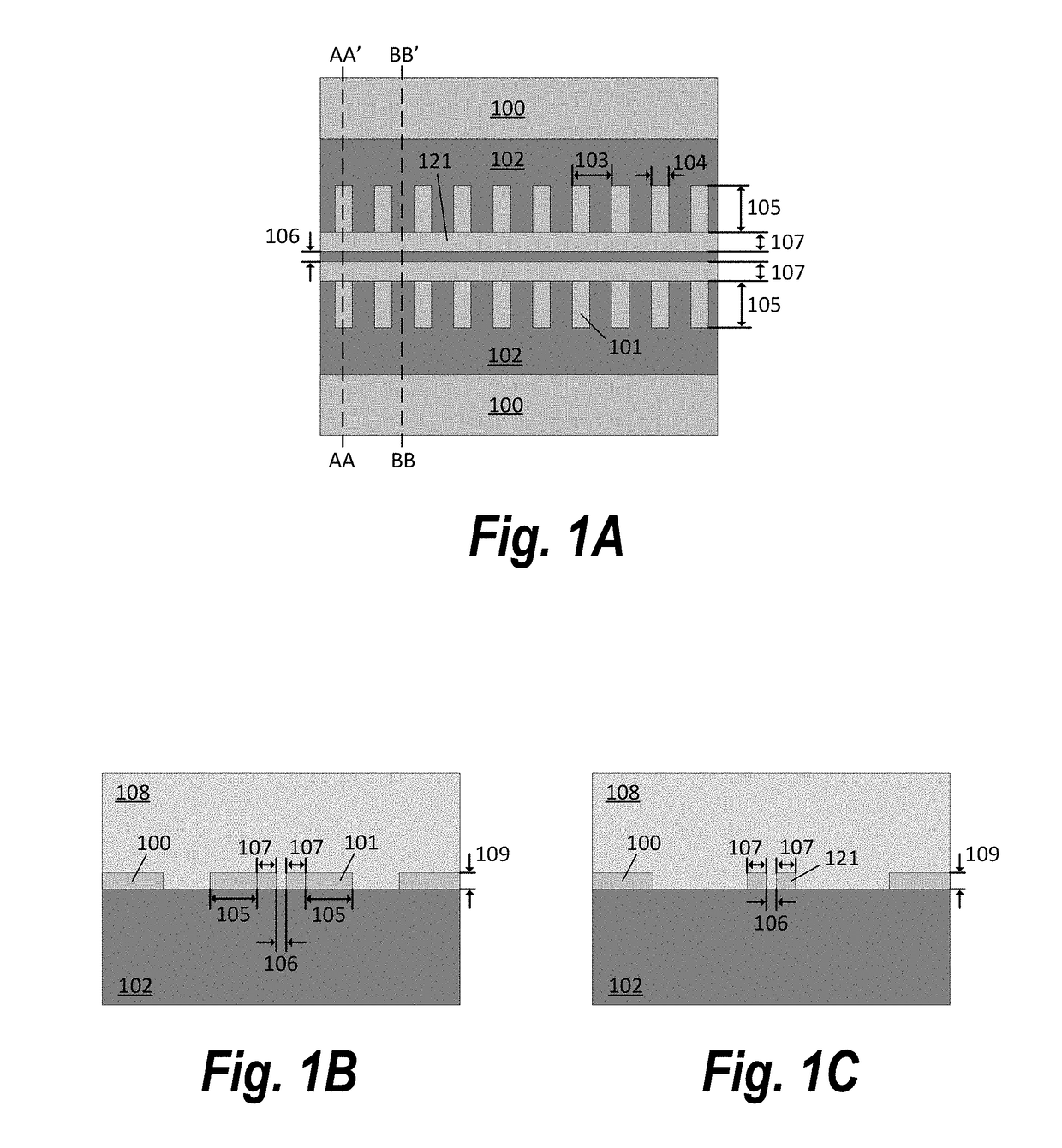

Slot Waveguide with Structural Modulation

ActiveUS20190067830A1Reduced propagation lossLarge mode overlapIndividually energised antenna arraysElectromagnetic transmittersSlot-waveguideElectrical and Electronics engineering

Owner:OMEGA OPTICS

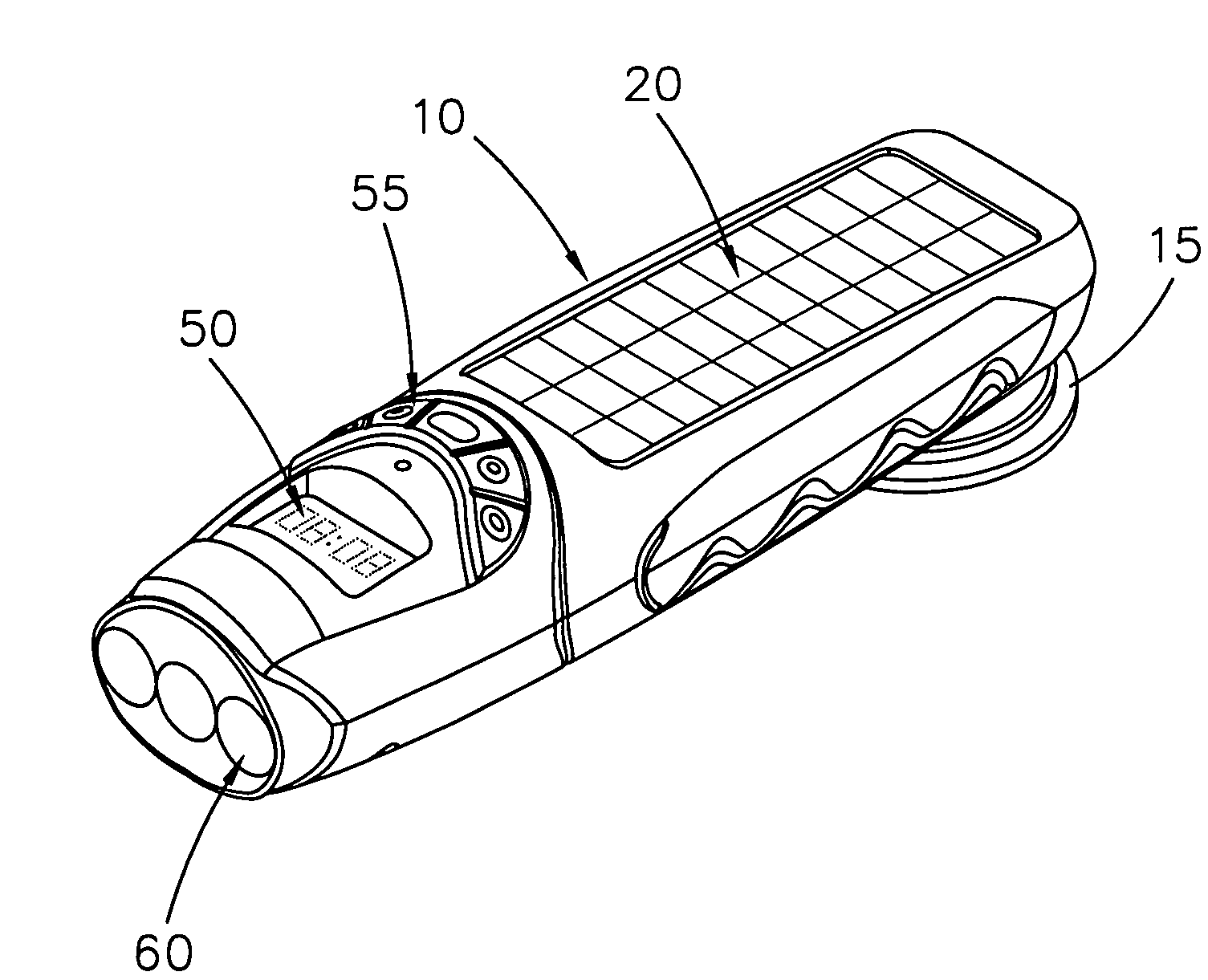

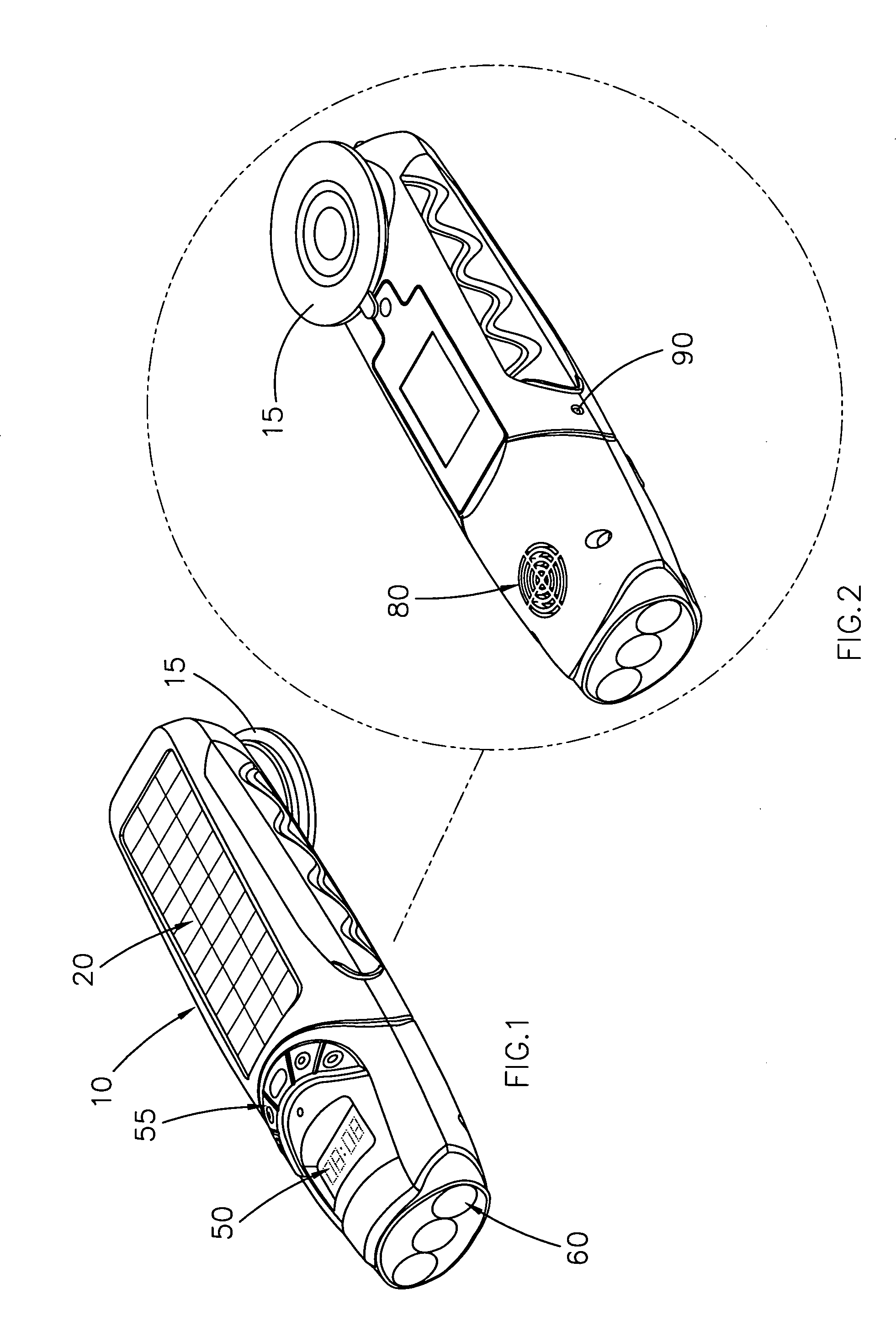

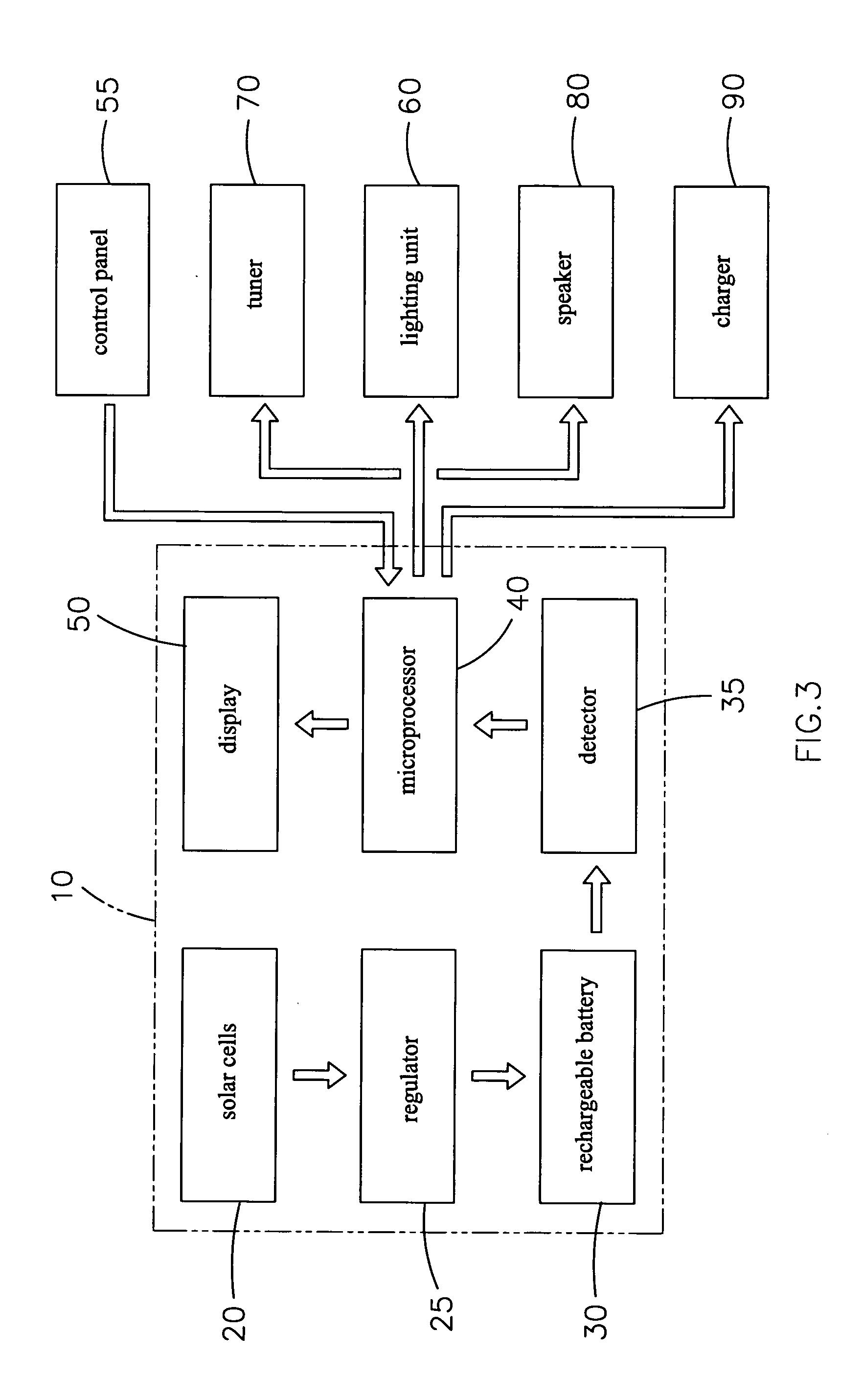

Intelligent solar electric torch

InactiveUS20080106891A1Ease of lightBatteries circuit arrangementsLighting support devicesElectricityElectrical battery

A solar electric torch includes at least one solar cell made of amorphous silicon and provided thereon for converting light into electricity, a rechargeable battery installed therein for receiving the electricity from the solar cell and storing the same, a regulator arranged between the solar cell and the rechargeable battery for stabilizing the recharging and avoiding the transfer of the electricity to the solar cell from the rechargeable battery, a detector connected to the rechargeable battery for detecting the amount of the electricity stored in the rechargeable battery and a rate of the recharging, a microprocessor connected to the detector, a display mounted thereon and connected to the microprocessor for showing the amount of the electricity and the recharging rate and a lighting unit mounted thereon and connected to the microprocessor for illuminating.

Owner:LEE IN OK

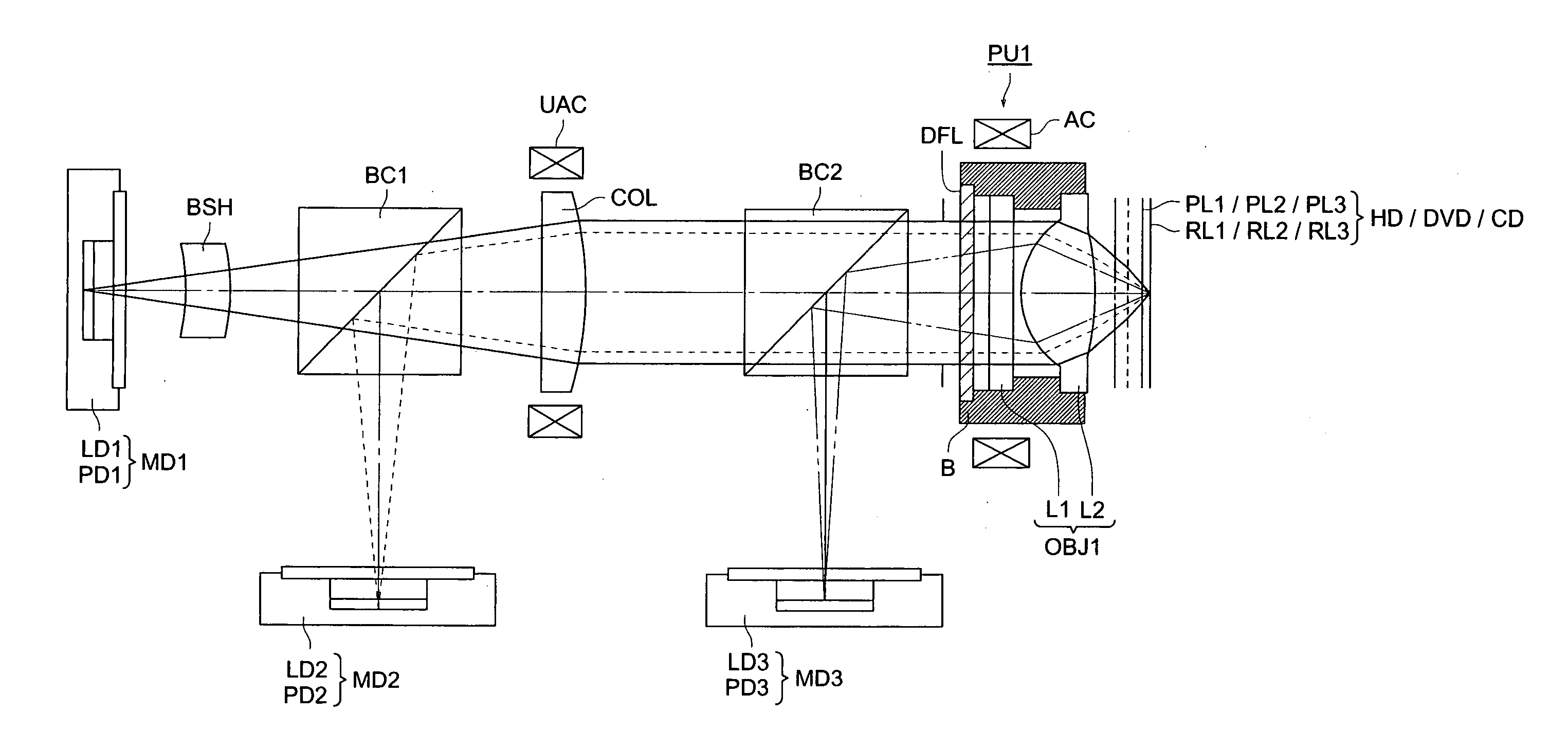

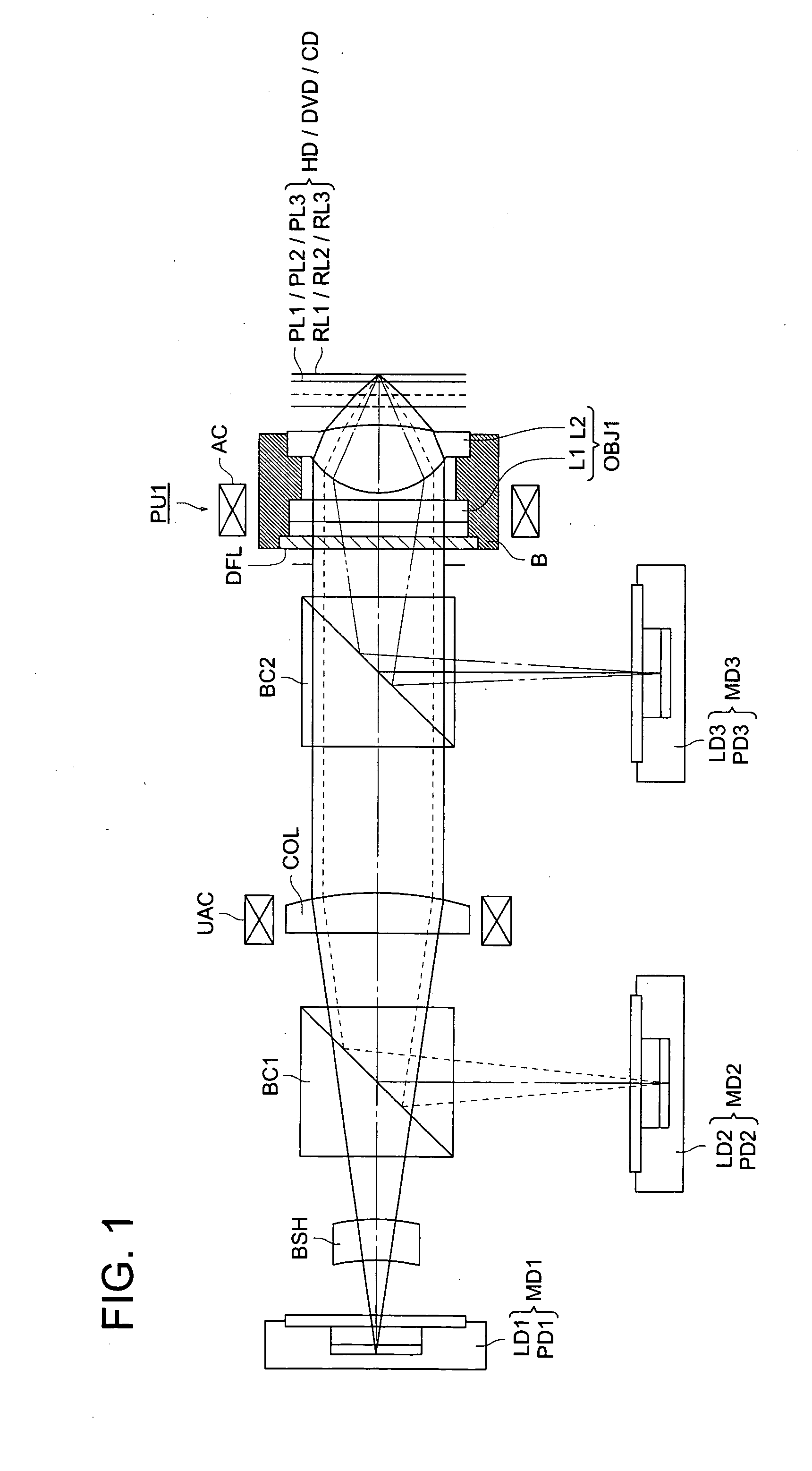

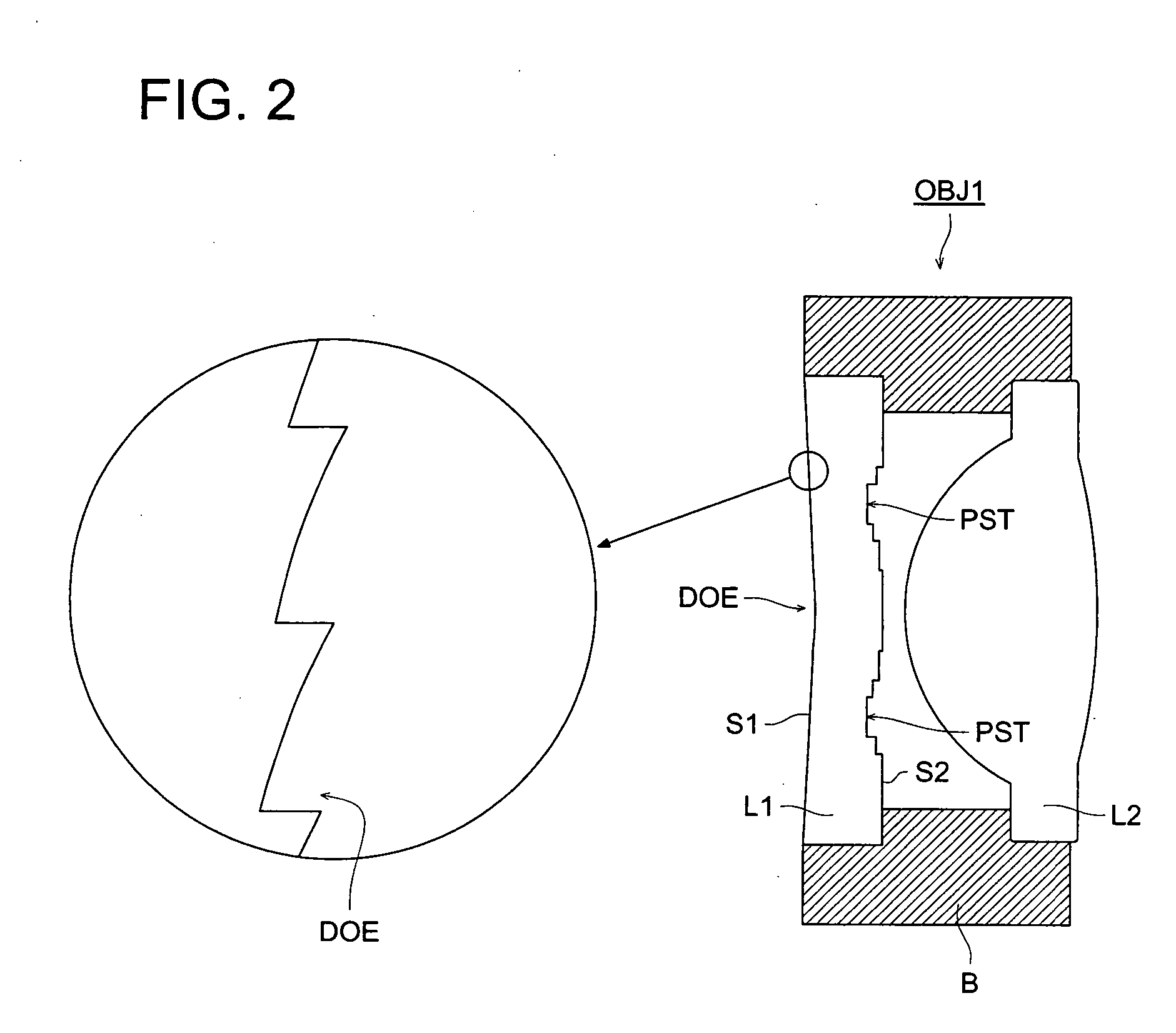

Optical element, optical pickup device and optical information recording and reproducing apparatus

InactiveUS20050094536A1Increase productionReduce manufacturing costOptical beam sourcesRecord information storageOptical pickupLight flux

An optical element for use in an optical pickup device to conduct reproducing and / or recording information for a first disk including a protective substrate by the use of a first light flux emitted from a first light source and to conduct reproducing and / or recording information for a second disk including a protective substrate by the use of a second light flux emitted from a first light source, the optical element includes: an optical surface on which a first phase structure is formed to have a function to correct a spherical aberration; an optical surface on which a second phase structure is formed such that when the wavelength of the first light flux changes, the second phase structure generates a spherical aberration in a direction reverse to the direction of a spherical aberration generated by the first phase structure.

Owner:KONICA MINOLTA OPTO

Gallium nitride based light emitting diode and manufacturing method thereof

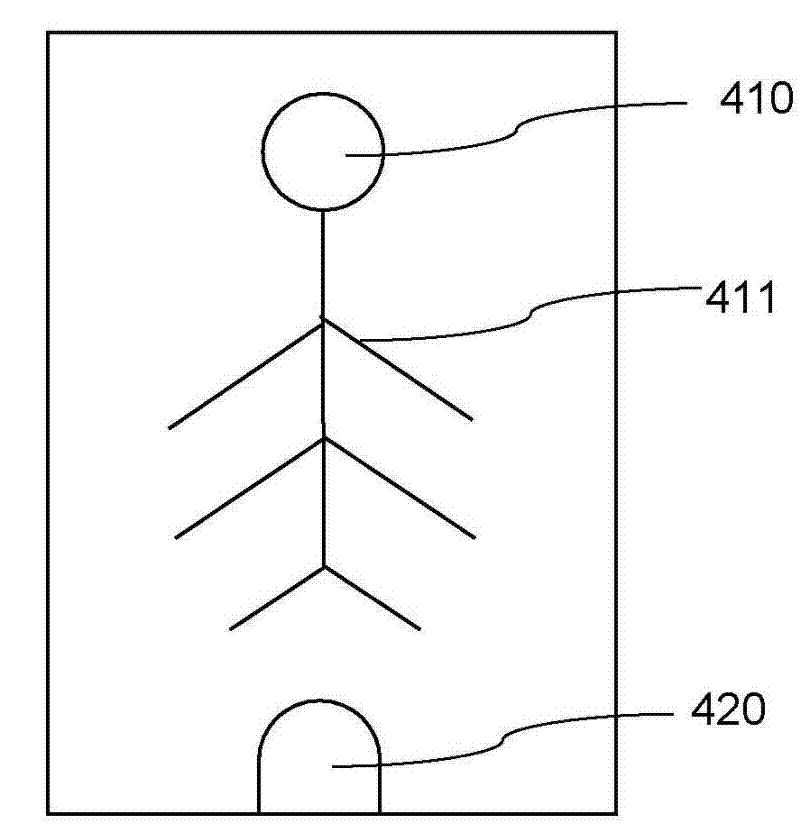

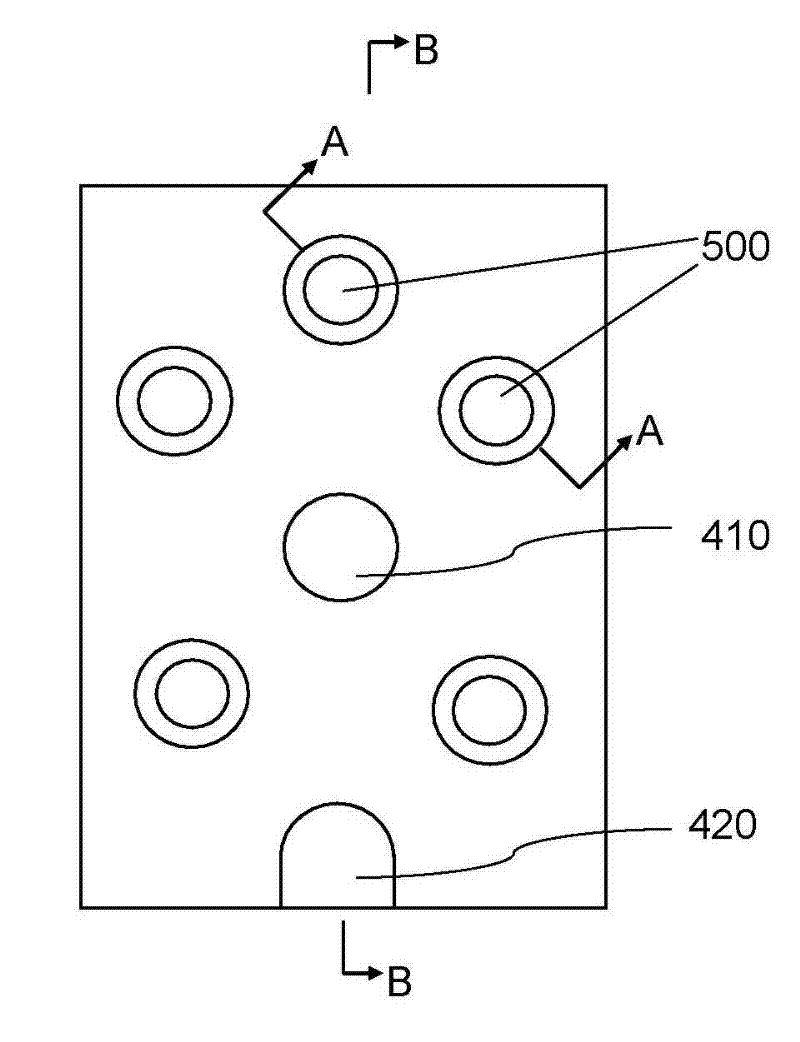

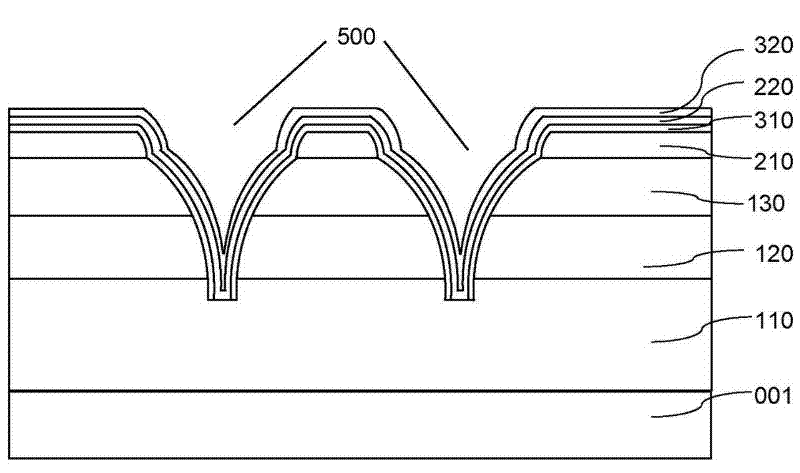

InactiveCN102420279AImprove luminous efficiencyIncrease the number of holesSemiconductor devicesGallium nitrideElectrically conductive

The invention discloses a gallium nitride based light emitting diode and a manufacturing method thereof. In the invention, a double-layer transparent conducting layer structure is designed, a first transparent extension layer is formed on a p type semiconductor layer, a p electrode is provided at a center area of an epitaxial structure layer, peripheral of the p electrode is provided with a hole structure, and a second transparent extension layer is formed in the hole structure and is connected with an n electrode to form an equipotential surface. After current is injected from the p electrode, the current diffuses to a whole light emitting surface through the first transparent extension layer and flows to an n type layer through the p type semiconductor layer, and since the second transparent extension layer and the n electrode are in a same electric potential, the current diffuses to the second transparent extension layer to reach the n electrode finally. According to the gallium nitride based light emitting diode and the manufacturing method, in a process that the current flows to the n electrode from the p electrode, the current is uniformly distributed on an epitaxial luminescent layer, a current flow through path of a P layer is shorter, simultaneously, structure of partial light emitting surface is changed, and luminescence efficiency is effectively raised.

Owner:XIAMEN SANAN OPTOELECTRONICS TECH CO LTD

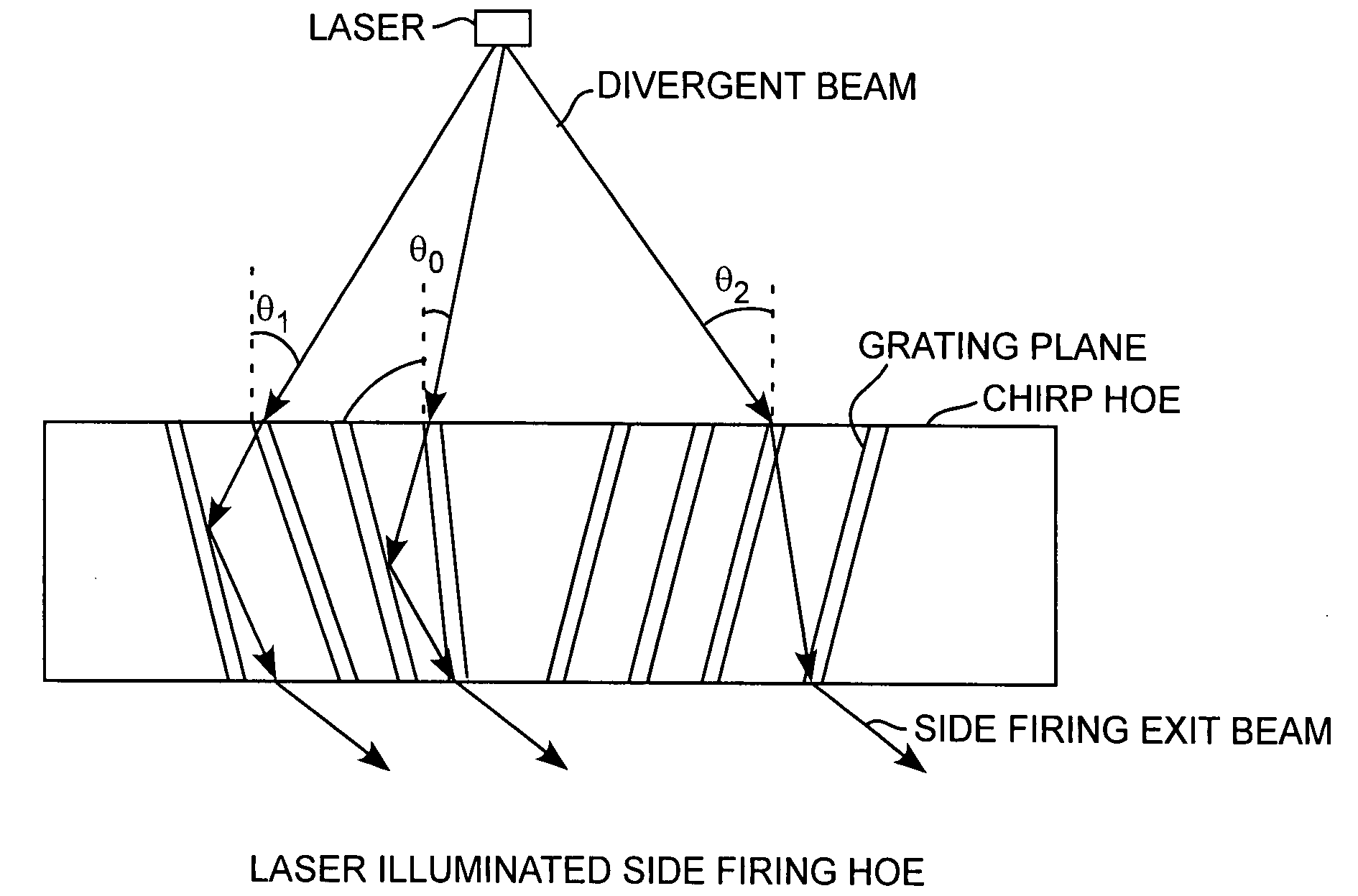

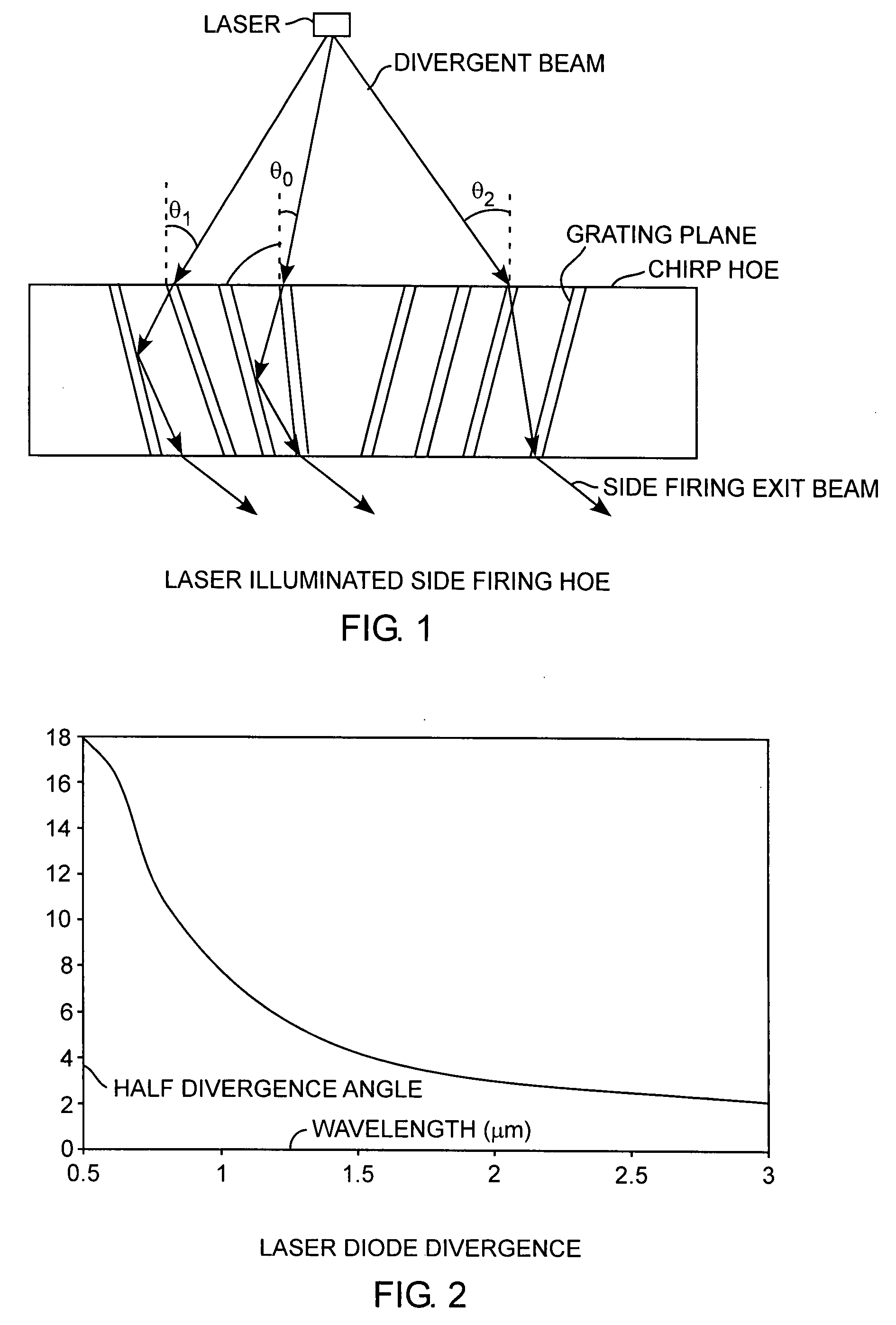

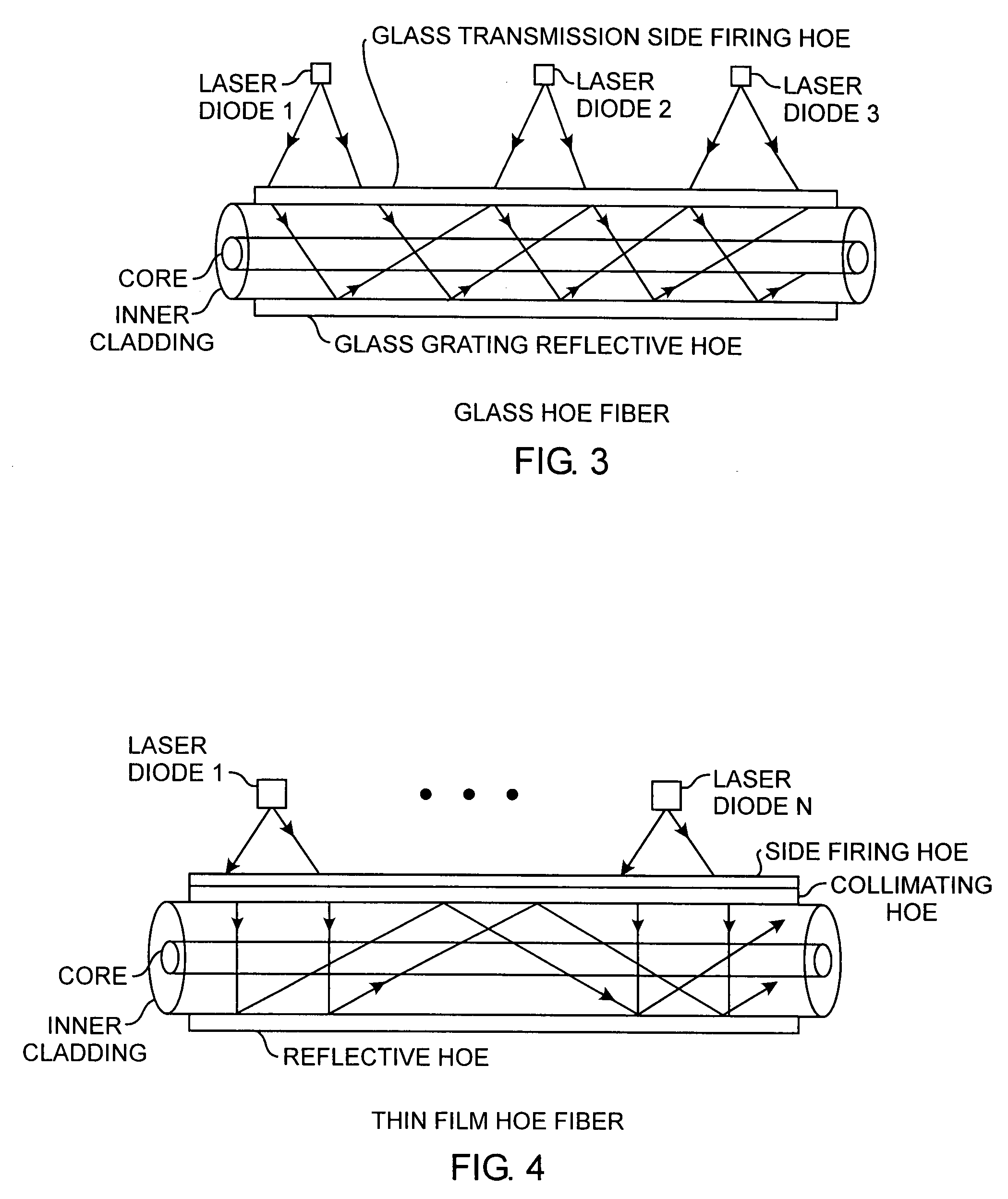

High power optical fiber laser array holographic coupler manufacturing method

InactiveUS20090086298A1Ease of lightEase of mechanical couplingCoupling light guidesSubstrate with hologramGratingLaser array

A chirped grating is made in a thin film layer or a glass layer for producing a holographic optical element within the layer well suited for use as an optical coupler for coupling side fired laser light into optical fibers for laser light pumping of optical fibers with the grating made in the layer by generating interference fringes burned into the layer with interference fringes created from interfering a reference laser beam with a plurality of convergent laser beams from respective lenses of an array of lenses.

Owner:THE AEROSPACE CORPORATION

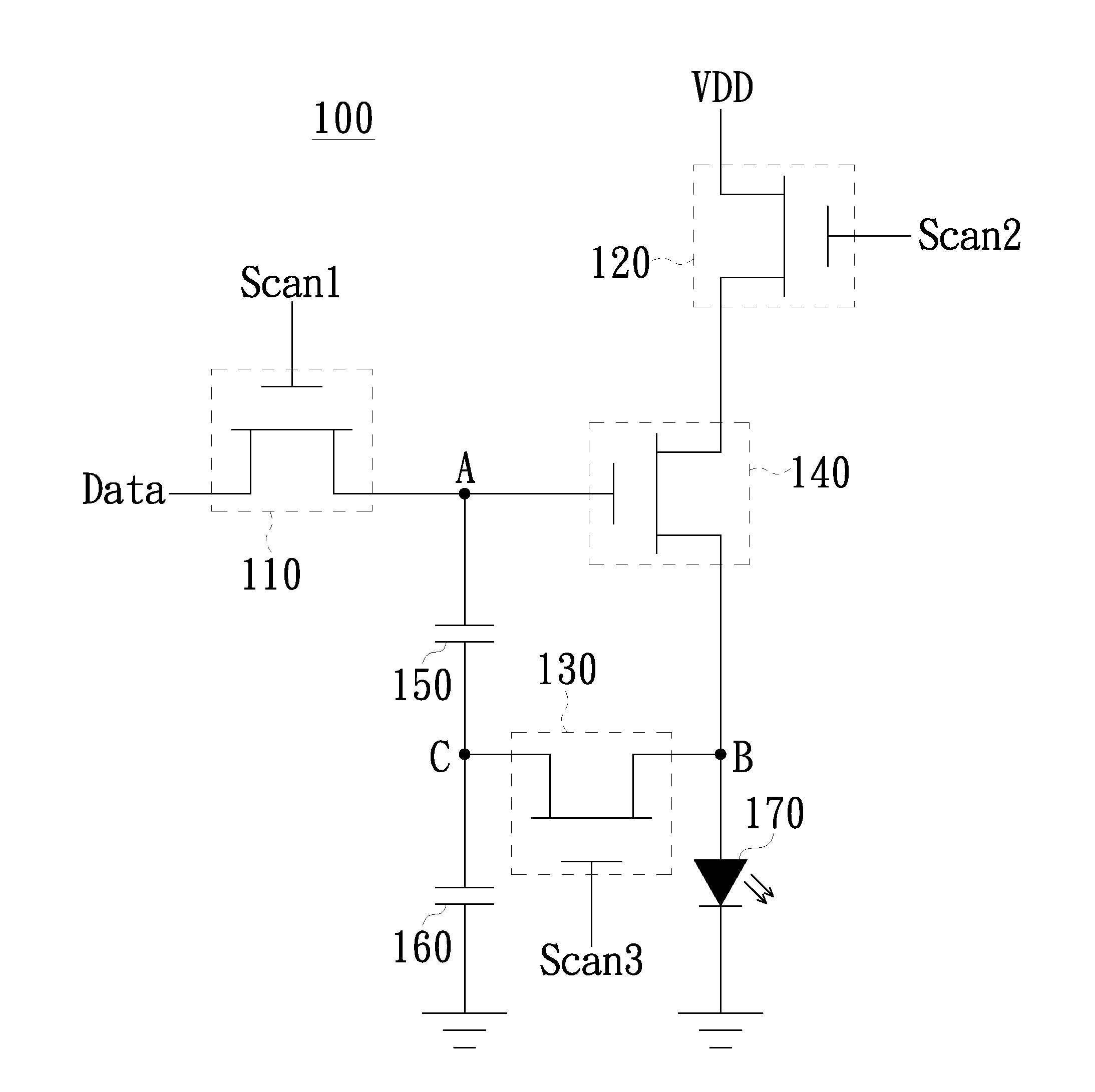

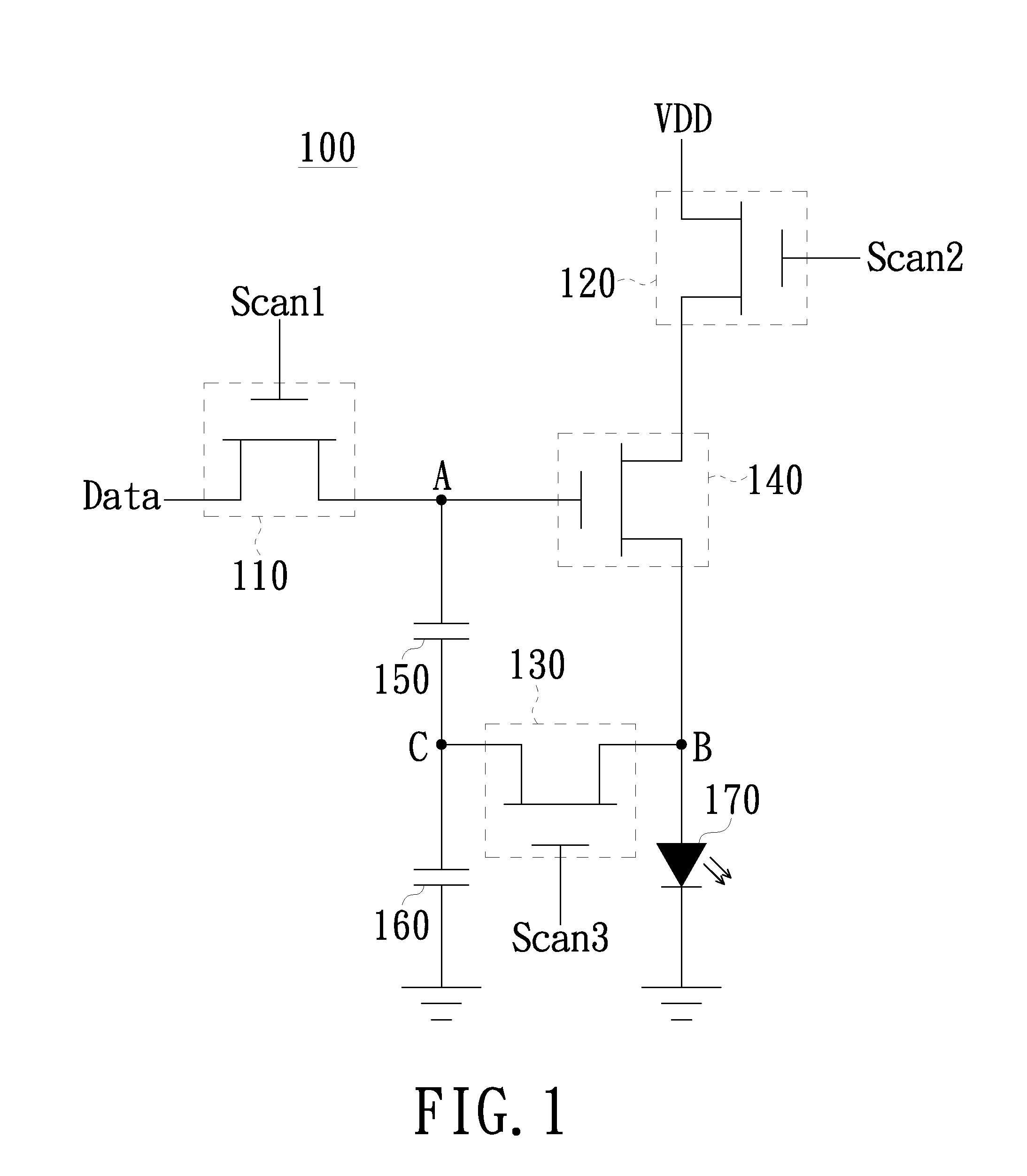

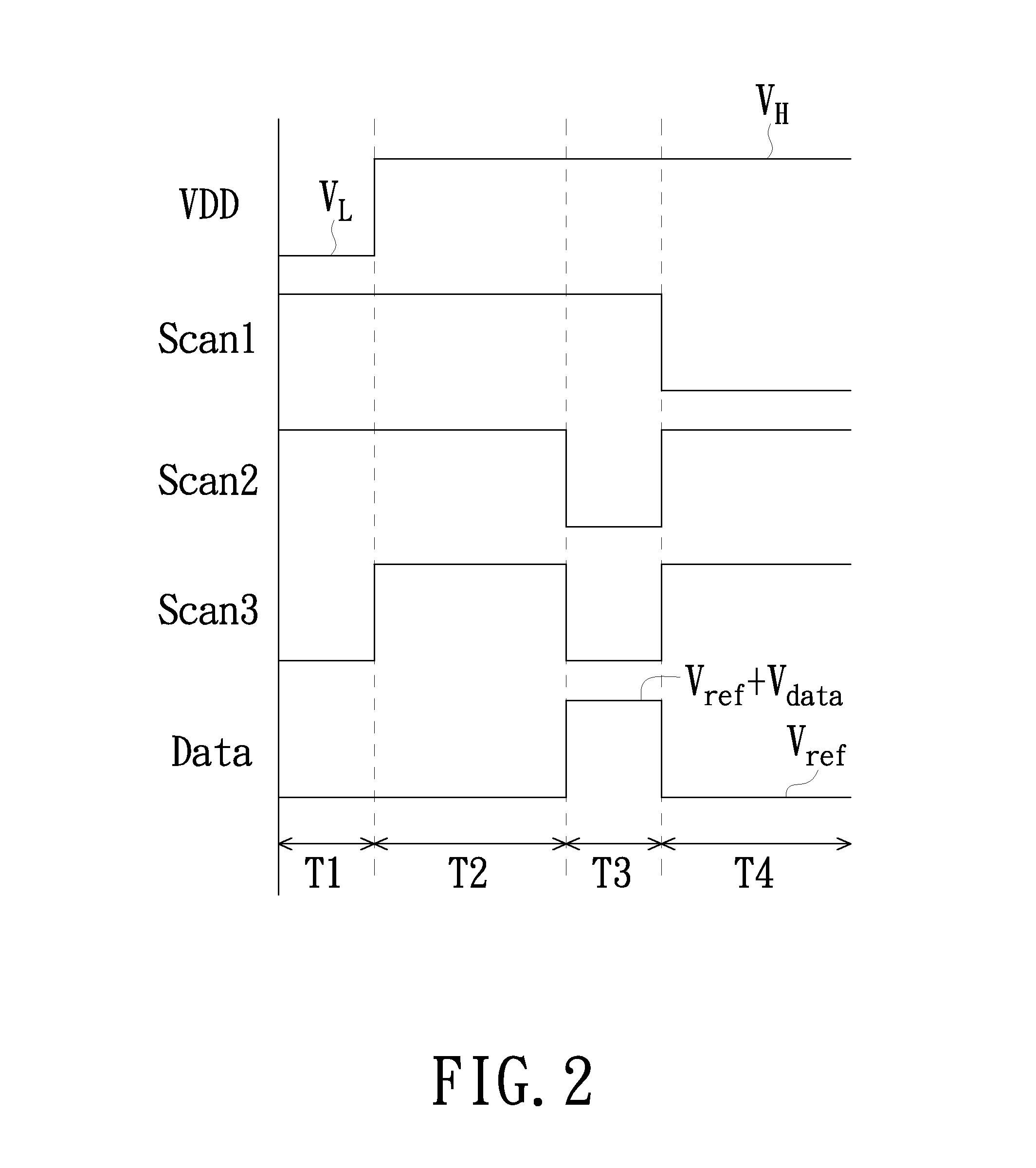

Pixel circuit

InactiveUS20170053595A1Effectively compensating variationPrevent dimmingStatic indicating devicesScan lineHemt circuits

A pixel circuit includes first to third switches, a transistor, a light emitting diode, and first and second capacitors. The first switch has its control end coupled to a first scan line and its first end for receiving a data signal. The second switch has its control end coupled to a second scan line and its third end for receiving a power supply voltage. The transistor has its control end coupled to the second end and its fifth end coupled to the fourth end. The third switch has its control end coupled to a third scan line and its eighth end coupled to the sixth end. the light emitting diode has its anode and cathode coupled to the eighth end and a reference voltage level, respectively. The first and second capacitors are coupled between the second end and seventh end and between the seventh end and reference voltage level, respectively.

Owner:FLEXTERRA INC

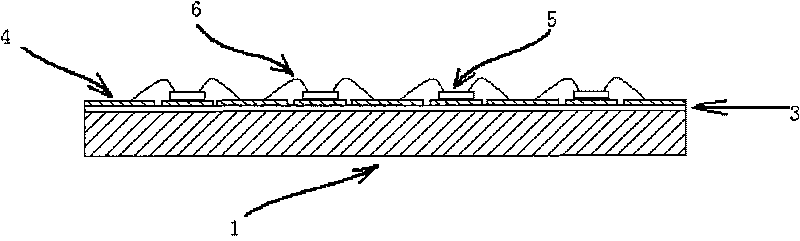

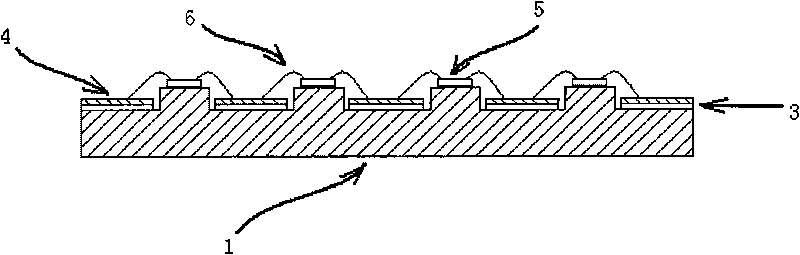

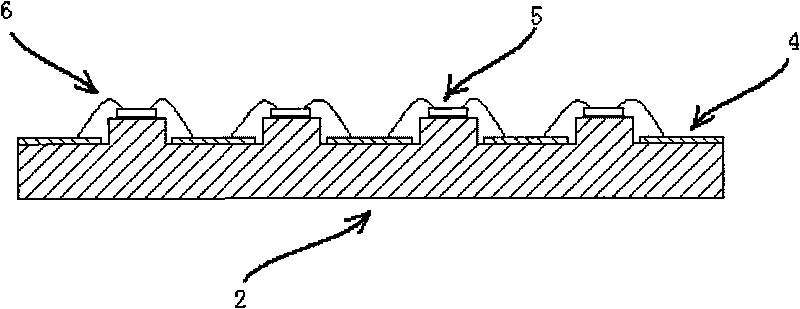

Packaging substrate structure for LED and production method thereof

InactiveCN101752354AEase of lightImprove light color distributionSemiconductor/solid-state device detailsSolid-state devicesHeat conductingEngineering

The invention discloses a packaging substrate structure for an LED and a production method thereof. An LED substrate of the invention is characterized in that a boss with the specific size, shape and height is formed on a die bonding or eutectic position of a common LED substrate; and the boss is directly connected with the substrate. The substrate outside the boss is paved with a circuit connection layer. An LED chip is bonded on the boss in a die bonding or eutectic mode. Compared with the common metal PCB, the LED substrate on the boss position reduces an insulating material layer with bad heat-conducting property so that the heat generated by the high-power LED chip can be better dissipated through the substrate from the bottom. The boss structure increases the utilization of the emitted light on the lateral surface of the LED chip, improves the light-extraction efficiency, reduces the influence of the reflector cup, increases the light emergent angle, and greatly improves the light color distribution of the LED.

Owner:SUN YAT SEN UNIV

Semiconductor light-emitting device provided with transparent organic supporting base plate and preparation method for semiconductor light-emitting device

InactiveCN102324458ALow costOvercome the disadvantage of high manufacturing costSemiconductor devicesPhysical chemistrySemiconductor

Owner:南昌硅基半导体科技有限公司

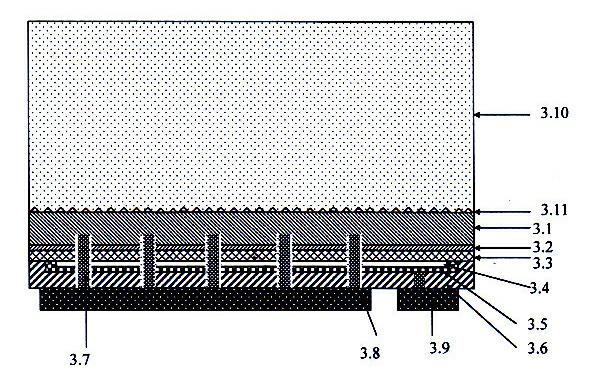

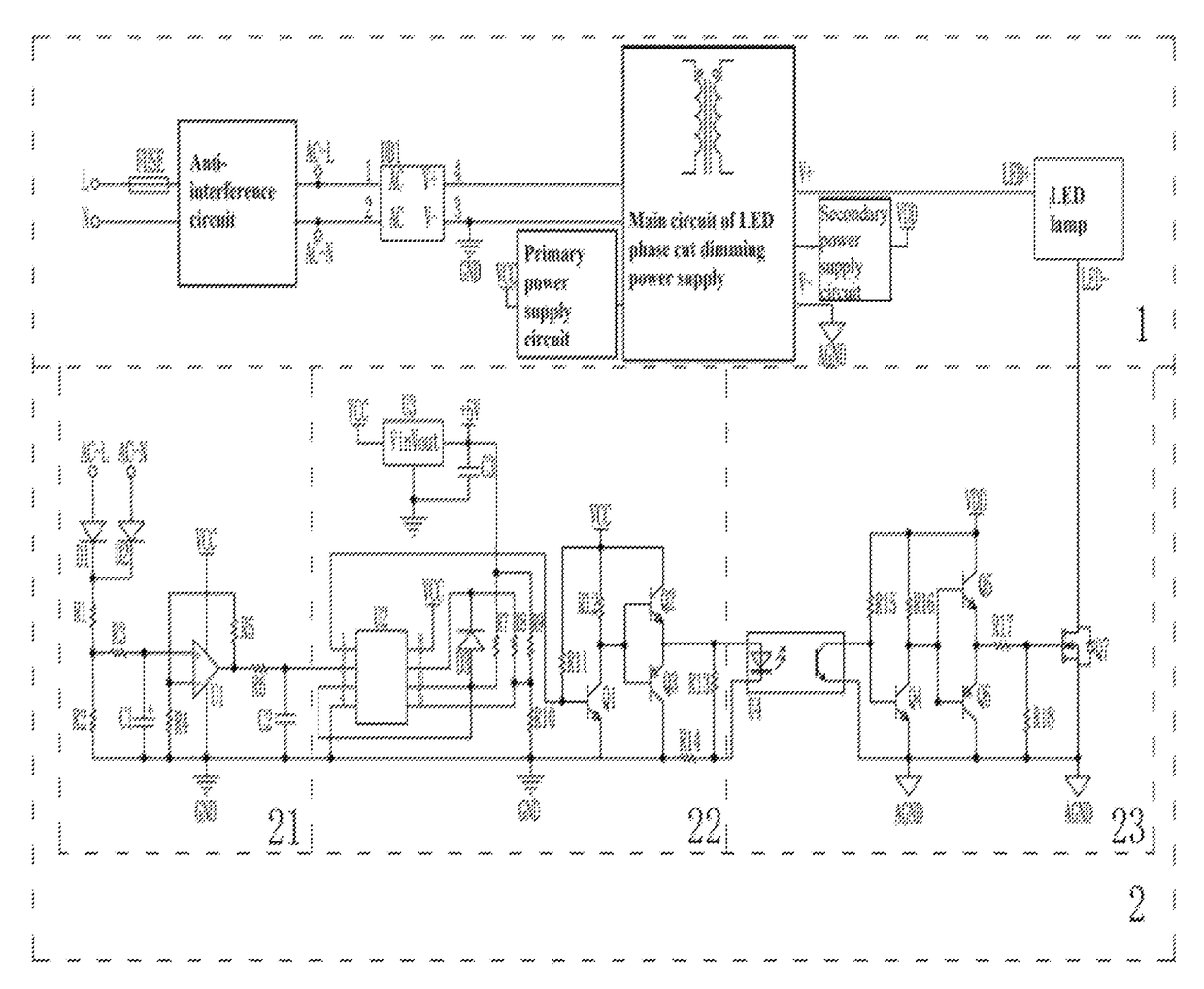

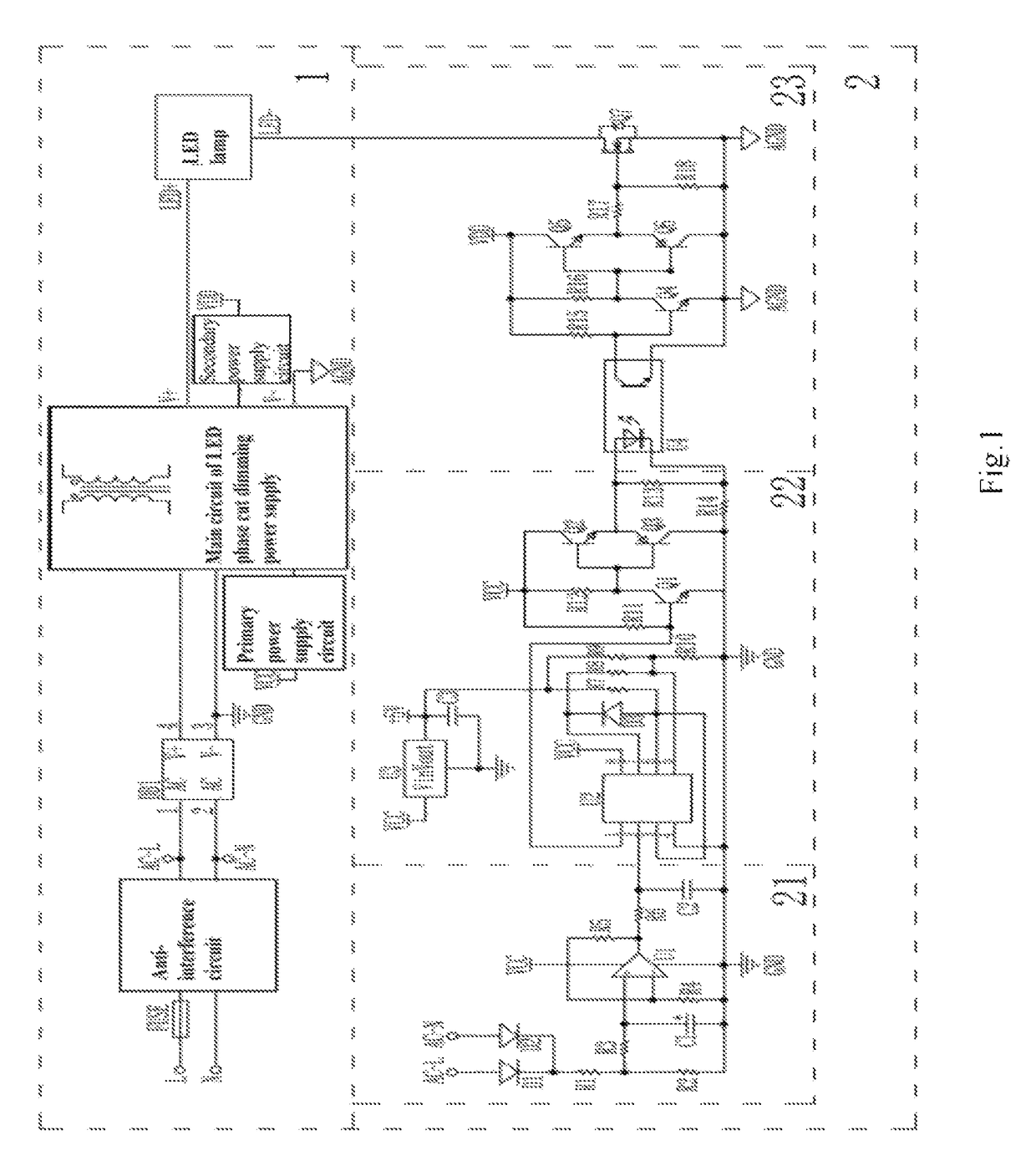

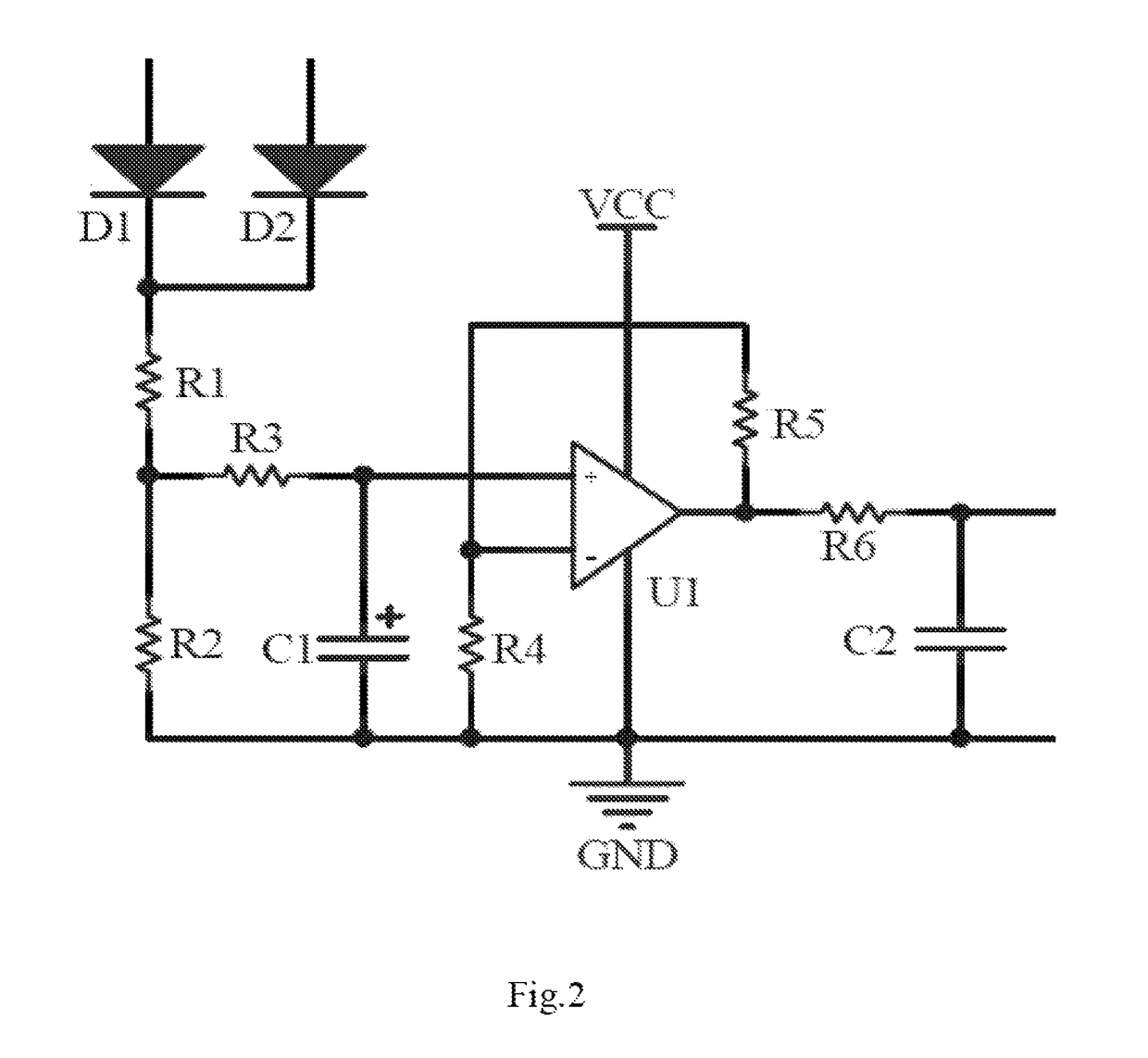

Kind of pulse width dimming control circuit for LED phase cut dimming power supply

ActiveUS9609713B1Improve compatibilityEliminate signal distortionElectrical apparatusElectroluminescent light sourcesDimmerField-effect transistor

The invention discloses a kind of pulse width dimming control circuit for LED phase cut dimming power supply, which comprises LED phase cut dimming power supply circuit and pulse width dimming control circuit. The pulse width dimming control circuit is composed of voltage sampling amplification circuit, signal conversion circuit, photoelectric coupler and pulse width PWM control circuit. The signal input terminal of the voltage sampling amplification circuit is connected to the live wire L and the null line N after passing through the anti-interference circuit for voltage sampling. The output control part of the pulse width PWM control circuit consists of a field-effect transistor, the drain electrode of which connects to LED lamp. The Invention is a kind of pulse width dimming control circuit for LED phase cut dimming power supply, which has no restriction on load power and has strong compatibility with phase cut dimmer, wide dimming range.

Owner:ZHUHAI SHENGCHANG ELECTRONICS CO LTD

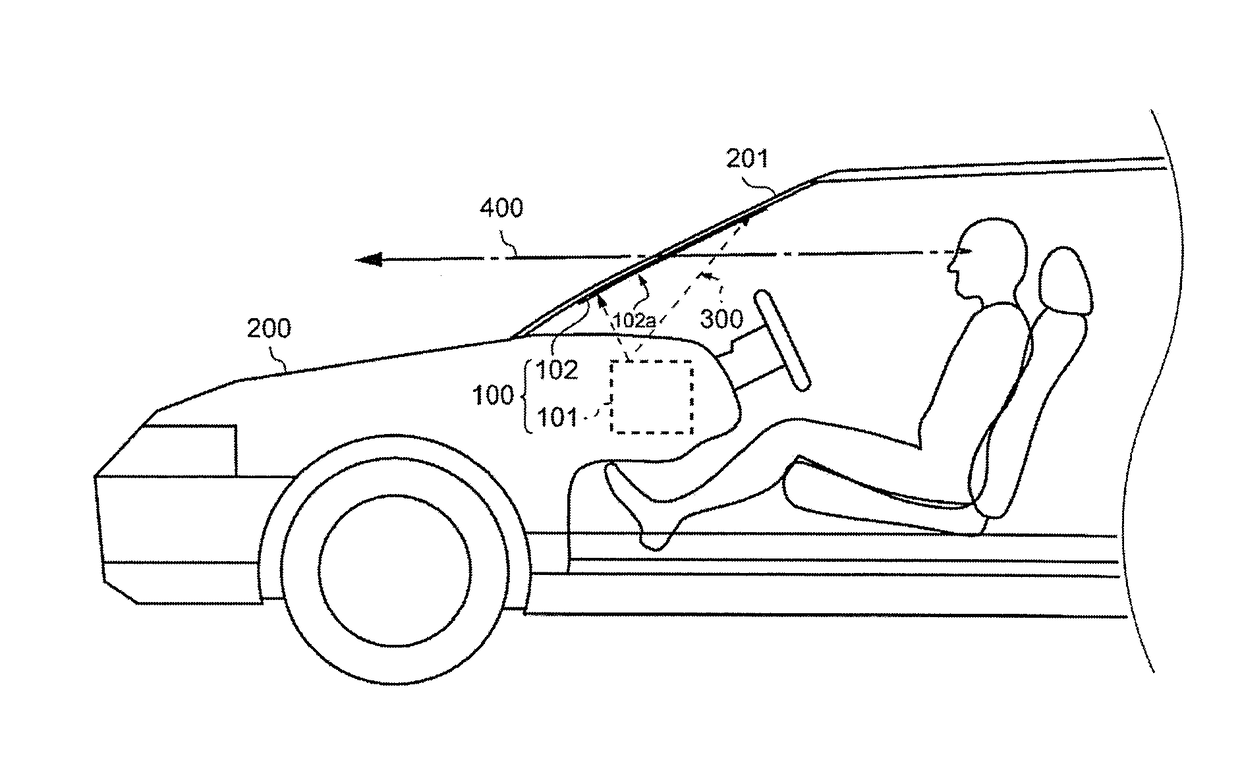

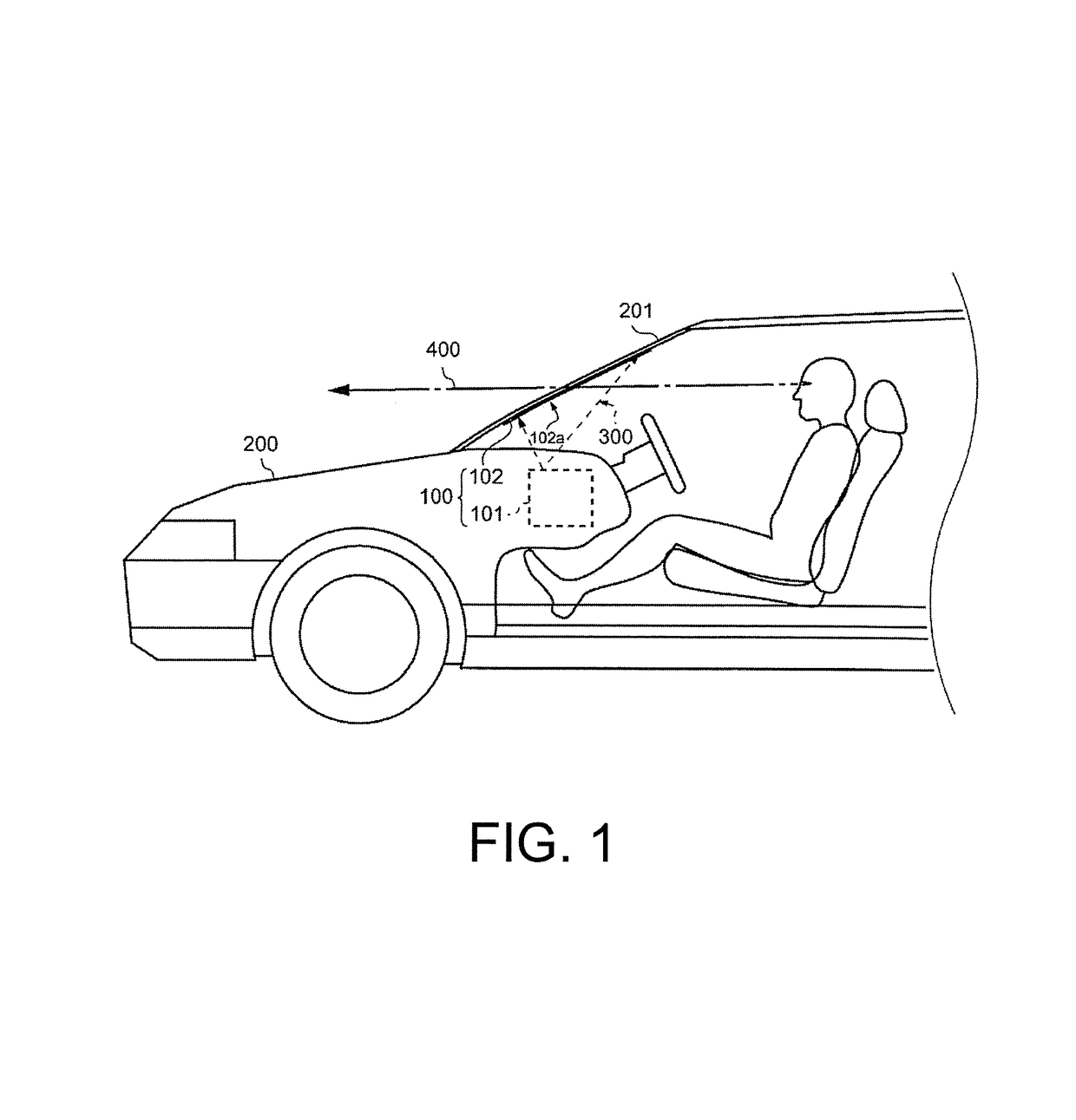

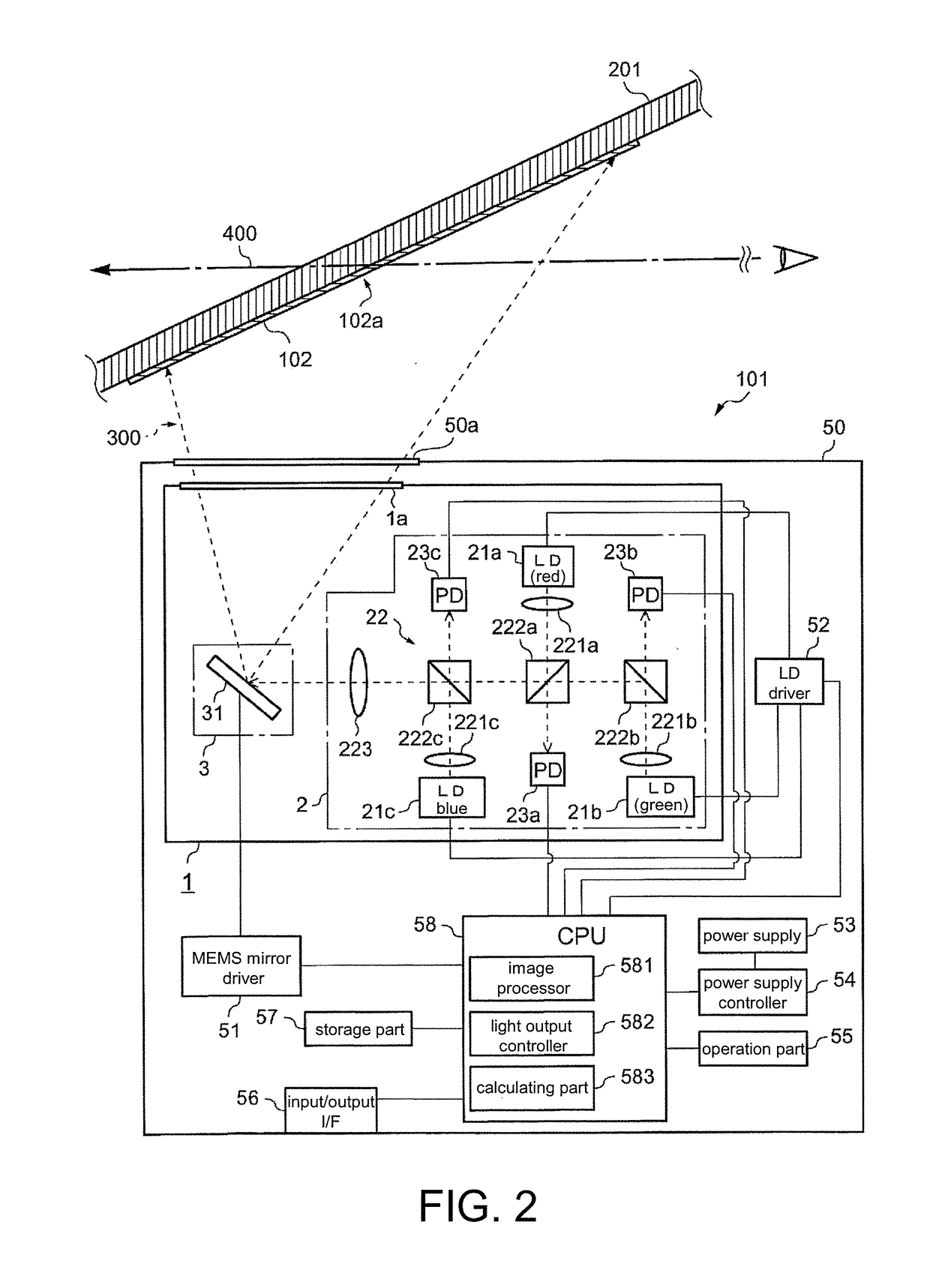

Projection device

ActiveUS20170099469A1Suppressing and preventing problemLight colorProjectorsSemiconductor laser optical deviceLaser lightLight emission

A projection device is provided, which is capable of suppressing or preventing problems that result from a light emission delay of a light source. The projection device includes a plurality of light sources respectively emitting a laser light; a scanning part enabling the laser light to scan; and a controller controlling an output of the laser light. In a scanning range including a first scanning range and a second scanning range, the controller controls such that the output has a first light amount in the first scanning range and has a second light amount which is greater than the first light amount in the second scanning range.

Owner:FUNAI ELECTRIC CO LTD

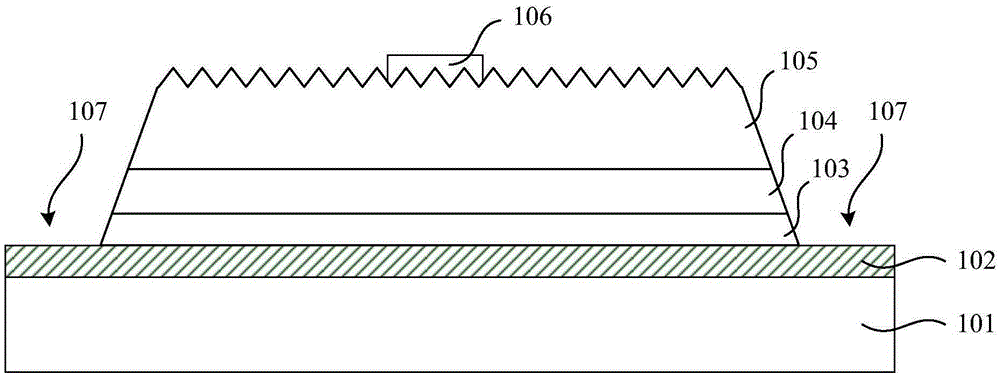

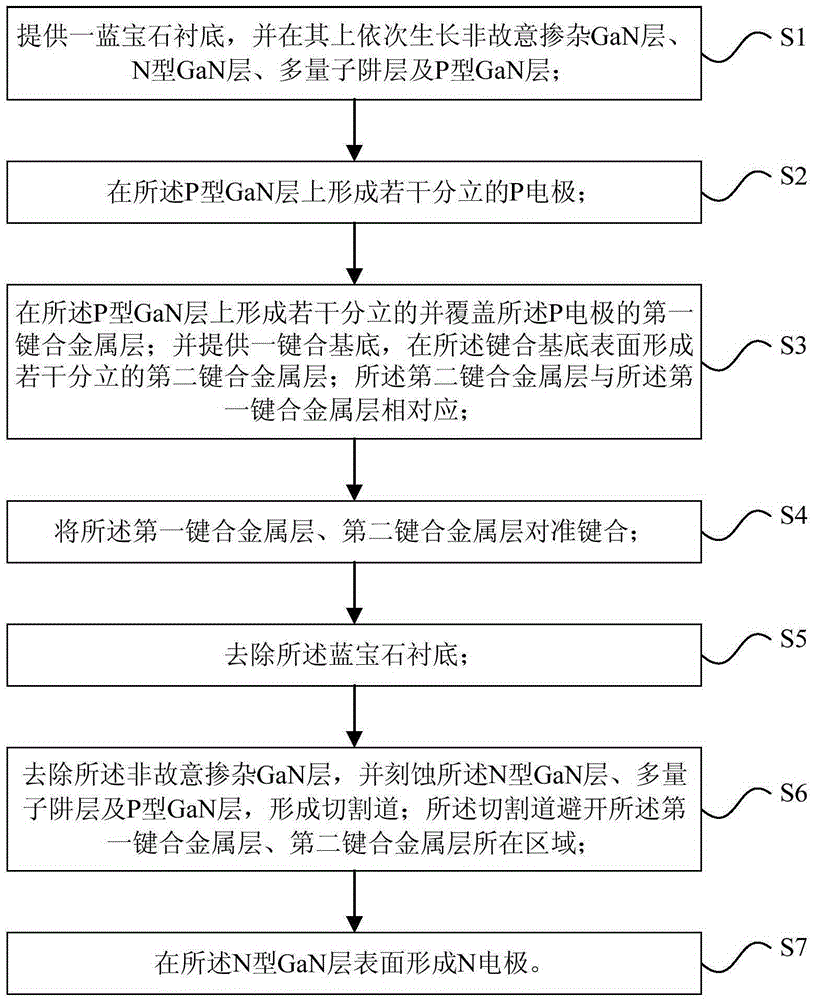

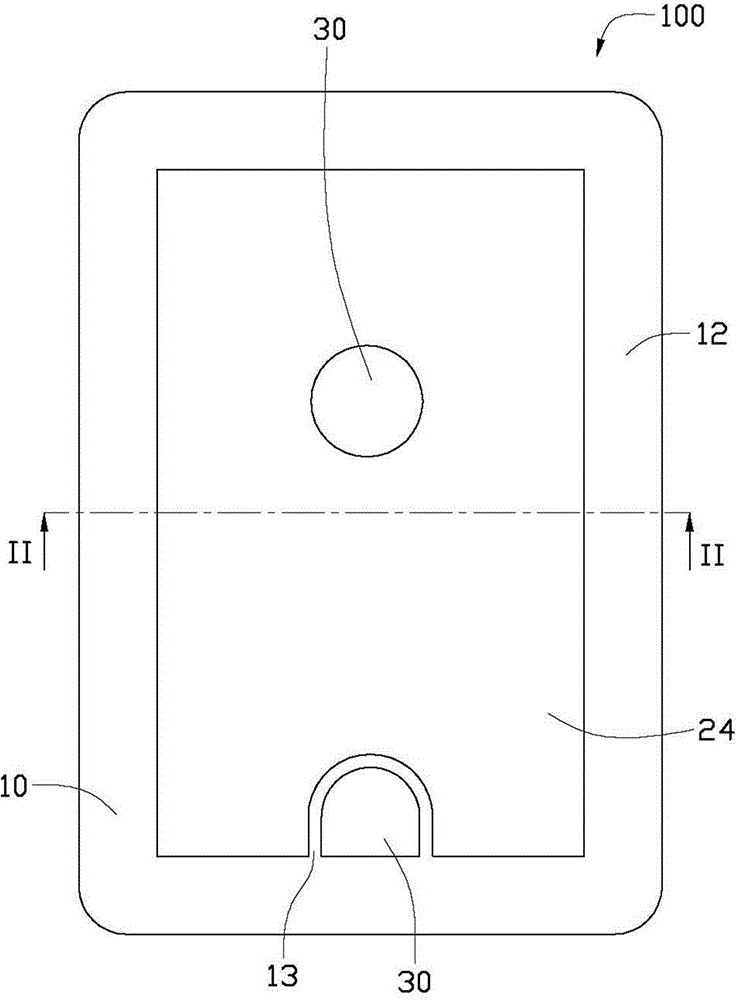

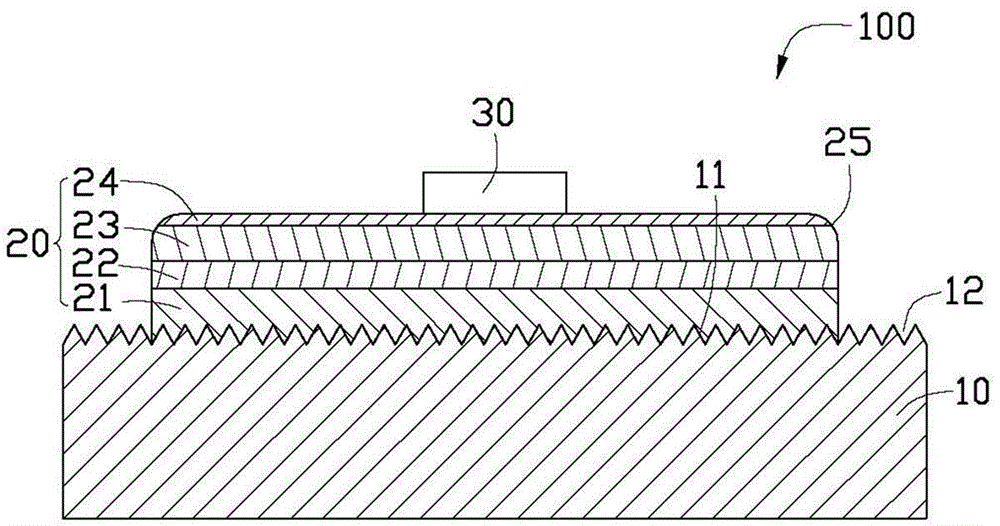

LED vertical chip structure and manufacturing method thereof

ActiveCN106711291APrevent metal splashReduce the risk of electric leakageSemiconductor devicesEngineeringQuantum well

The invention provides an LED vertical chip structure and a manufacturing method thereof. The method comprises the following steps of S1, providing a sapphire substrate and growing an unintentionally-doped GaN layer, an N-type GaN layer, a multi-quantum well layer and a P-type GaN layer successively on the substrate; S2, forming several discrete P electrodes; S3, forming several discrete first bonding metal layers which cover the P electrodes; and providing a bonding substrate and forming several discrete second bonding metal layers on a surface of the bonding substrate; S4, carrying out alignment bonding on the first bonding metal layers and the second bonding metal layers; S5, removing the sapphire substrate; S6, removing the unintentionally-doped GaN layer, and using a dry method etching technology to form a cutting channel, wherein the cutting channel avoids an area where the bonding metal layers are located; and S7, forming an N electrode. In the invention, a graphical bonding structure (formed by several discrete bonding metal layers) is adopted so that a metal splashing problem generated when ICP etches the cutting channel is effectively avoided; and a chip electric leakage risk is reduced so that chip reliability is effectively increased.

Owner:ENRAYTEK OPTOELECTRONICS

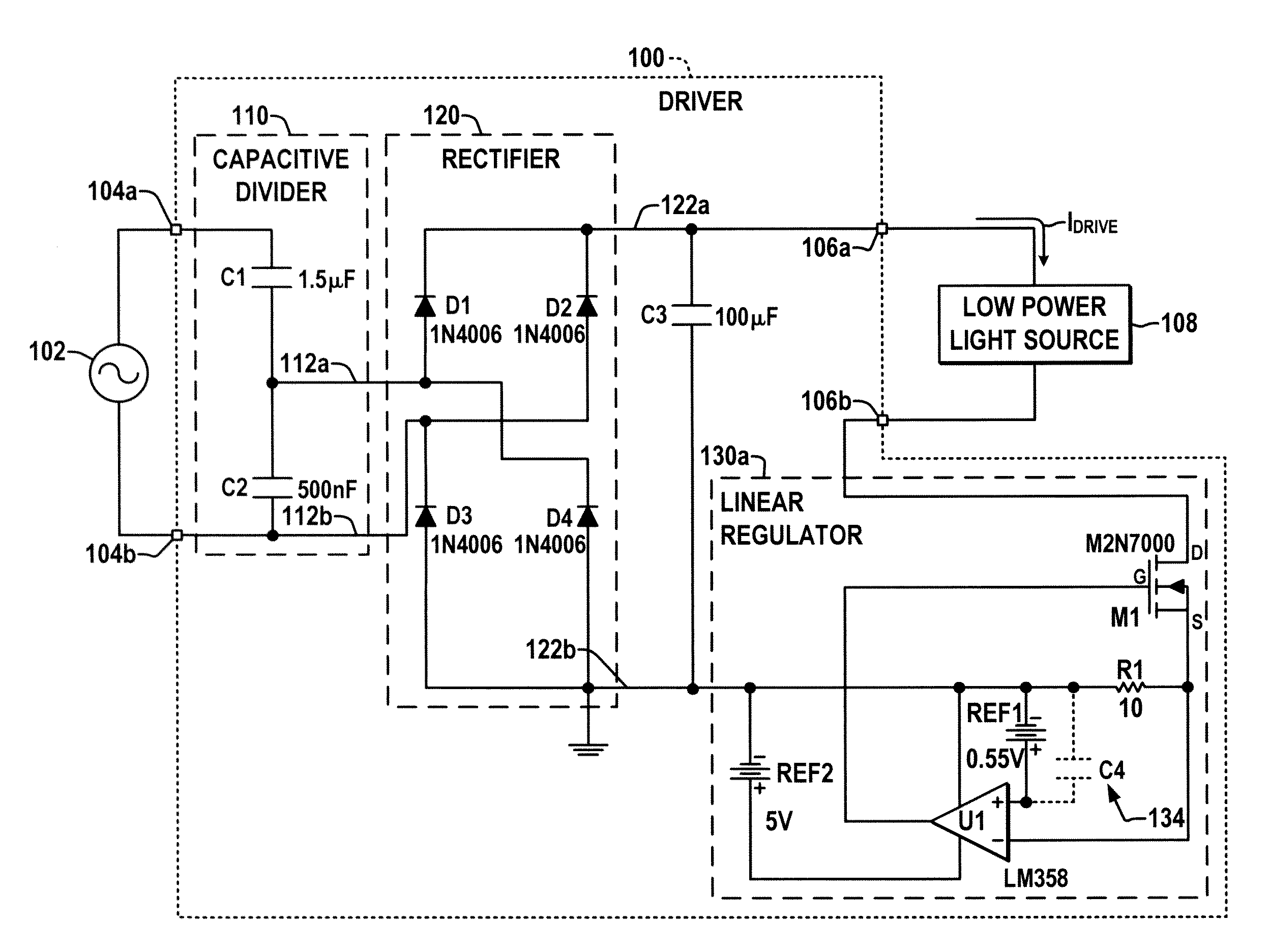

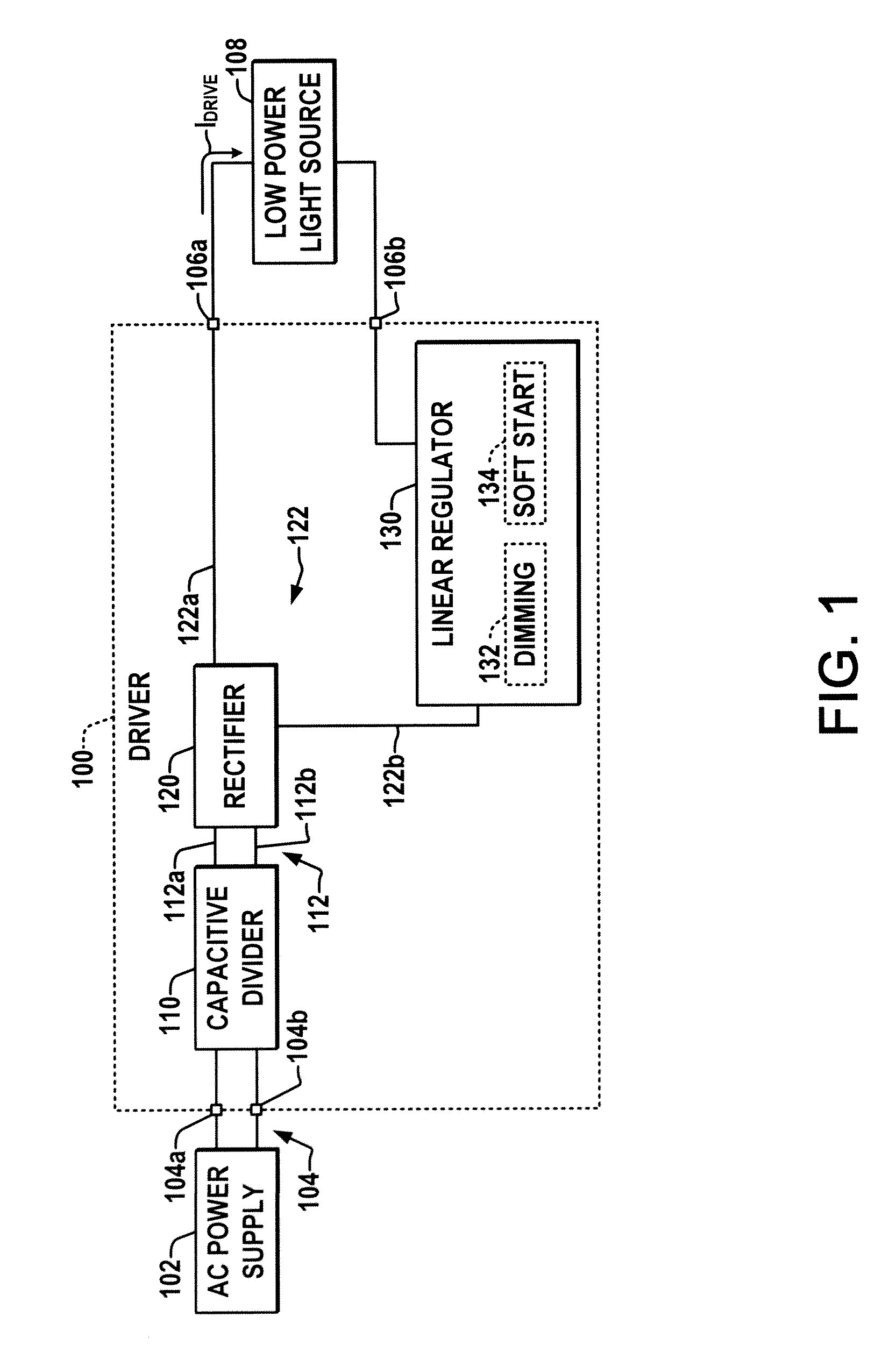

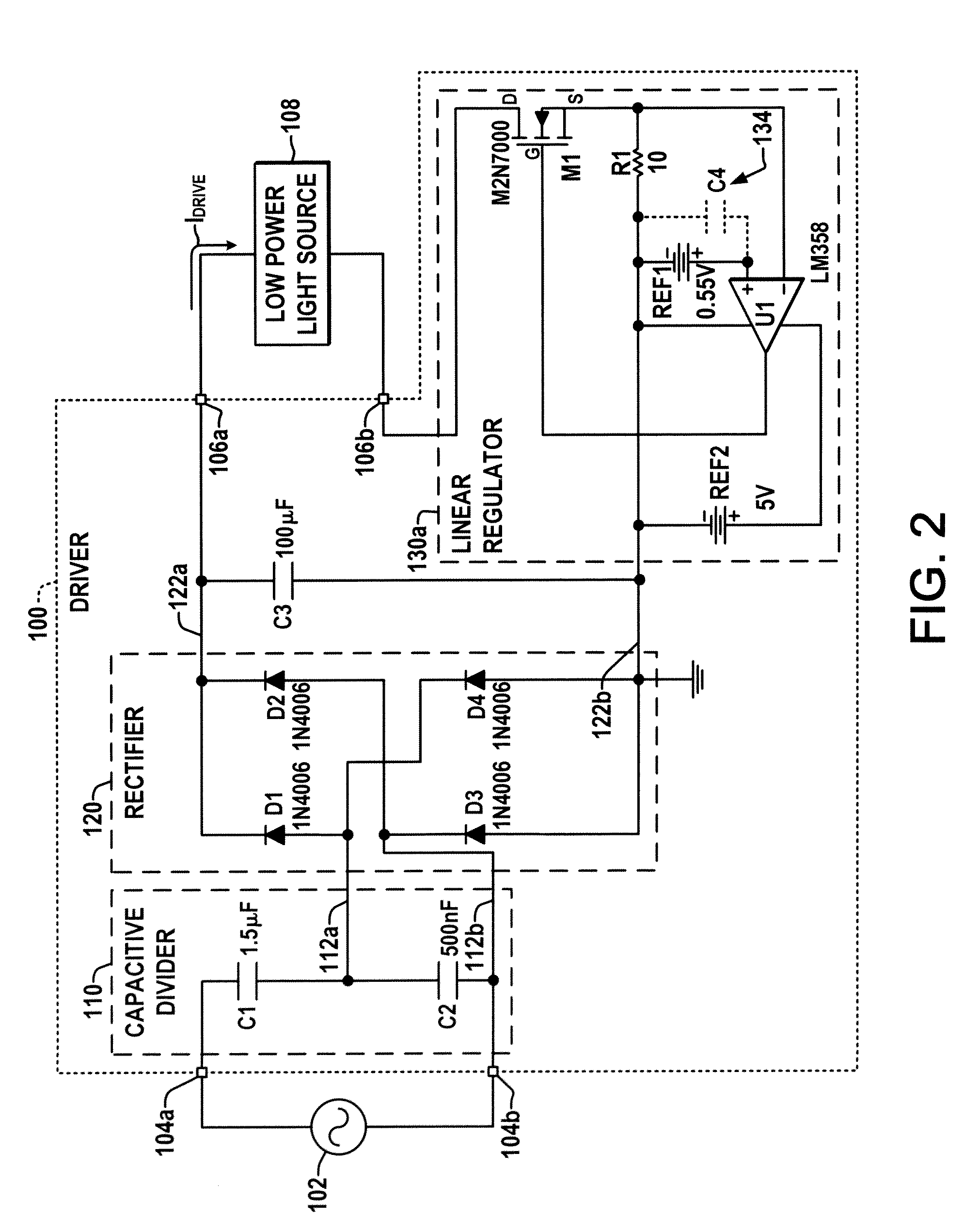

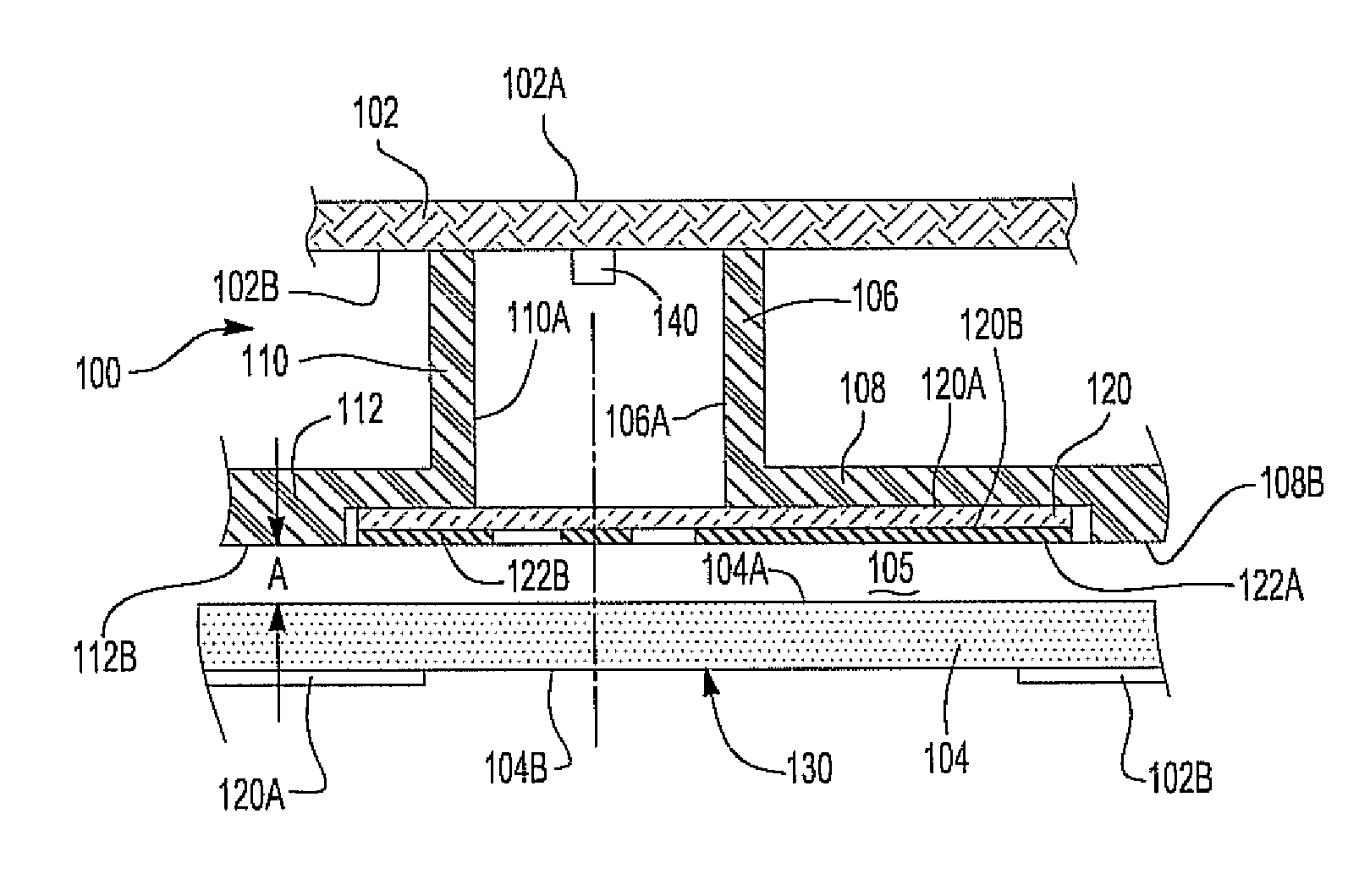

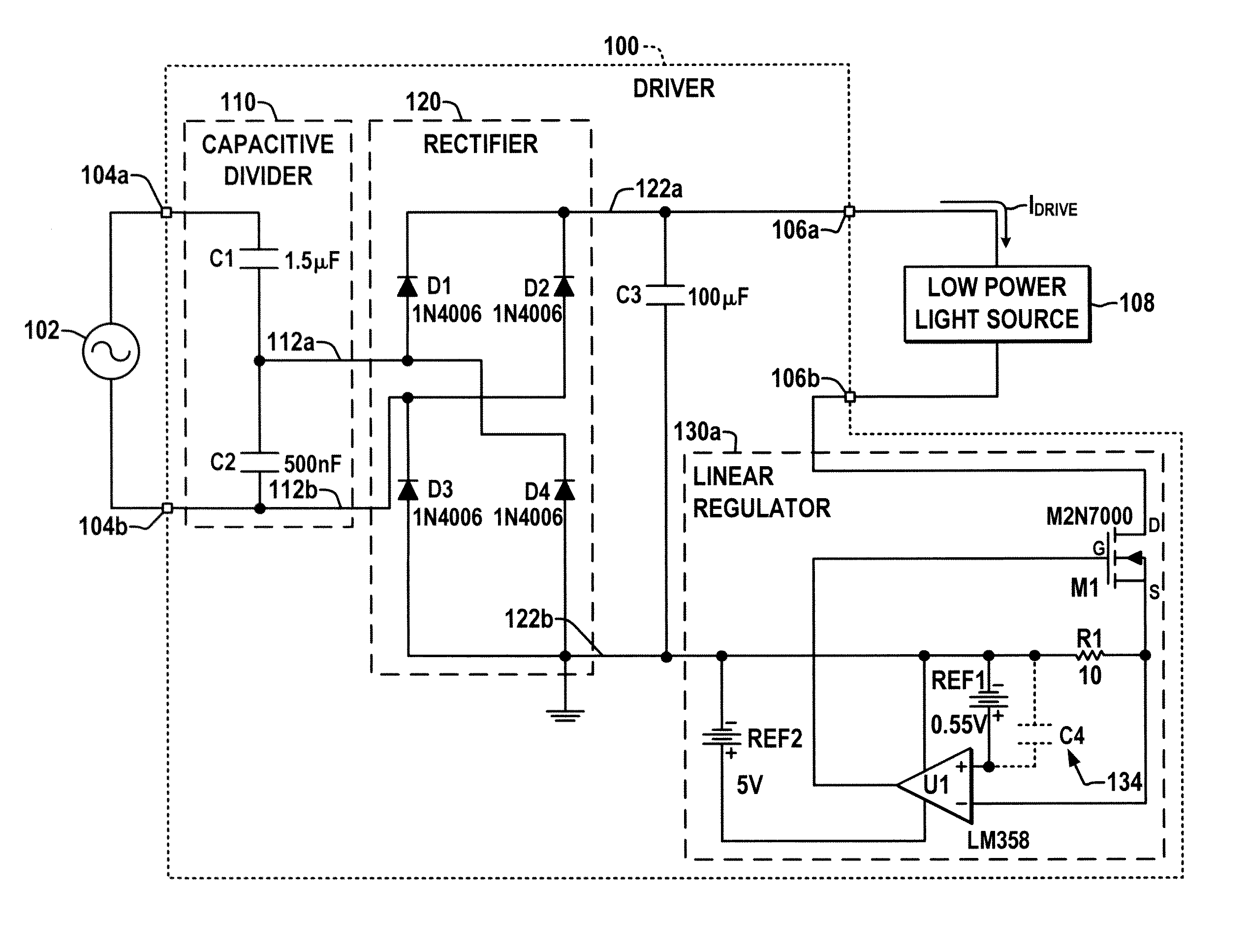

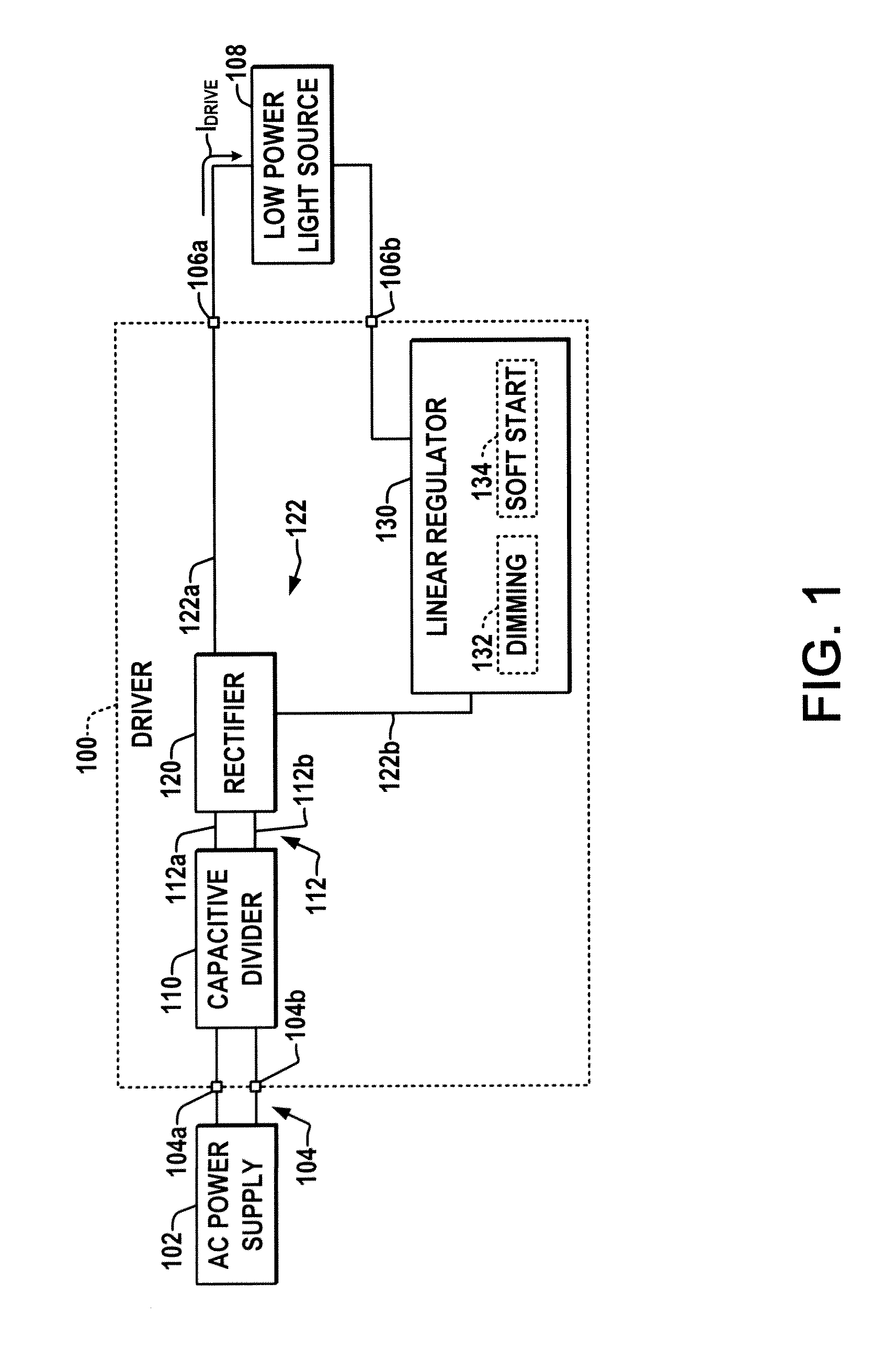

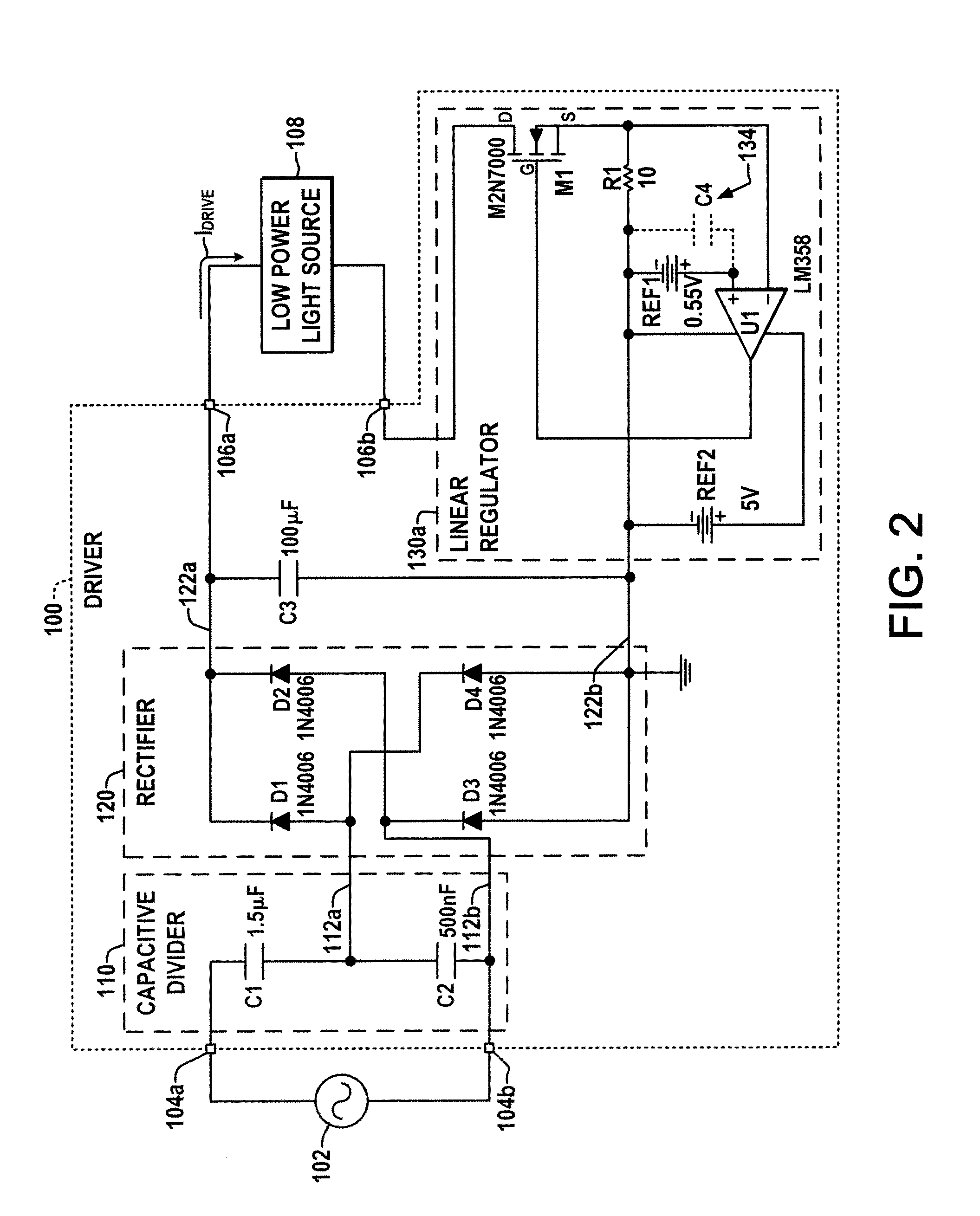

High efficiency low power capacitor charged DC driver

ActiveUS20110089867A1Facilitate efficiencyEmission be avoidAc-dc conversion without reversalElectroluminescent light sourcesCapacitanceLight source

A high efficiency low power DC driver apparatus is presented for powering a light source, with a capacitive divider circuit receiving an AC input and providing a divided AC output, a rectifier provide a DC output below ten watts, output terminals coupleable to one or more light sources, and a linear regulator coupled in series with the light source to regulate a drive current flowing through the series circuit.

Owner:SAVANT TECH LLC

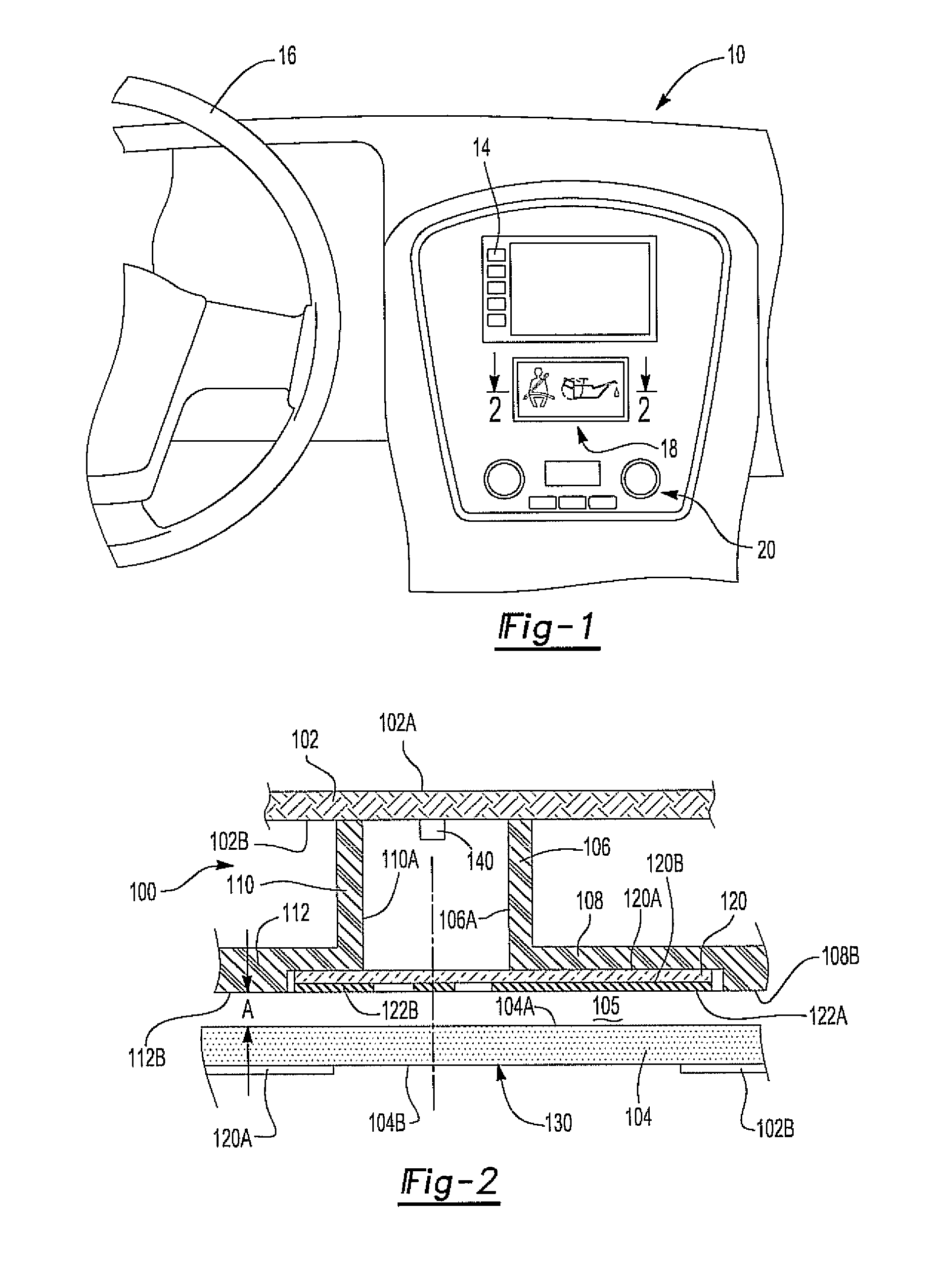

Illuminated indicator display

InactiveUS20120281423A1Ease of lightInstrument arrangements/adaptationsOptical signallingMobile vehicleDashboard

The present invention provides for an illuminated indicator display apparatus for use in an automotive vehicle display or dashboard. The illuminated indicator includes a light source, at least one baffle disposed adjacent the light source, a first panel disposed opposite the light source and connected to the at least one baffle, and a second panel spaced apart at a predetermined distance and positioned parallel to the first panel. The first panel or the second panel further including printed or painted graphics (such as low fuel indicator, seatbelt warning, etc.) viewable to the operator of an automotive vehicle. The baffle is made of an opaque material operable to block light from the light source. The second panel is tinted dark operable only to allow a portion of the light from a light source to pass through the second panel thereby further dimming the light able to pass through the second panel.

Owner:TOYOTA MOTOR ENGINEERING & MANUFACTURING NORTH AMERICA

High efficiency low power capacitor charged DC driver

ActiveUS7960922B2Easy to operateAvoid excessive EMI or RFI emissionsAc-dc conversion without reversalElectroluminescent light sourcesCapacitanceDriving current

A high efficiency low power DC driver apparatus is presented for powering a light source, with a capacitive divider circuit receiving an AC input and providing a divided AC output, a rectifier provide a DC output below ten watts, output terminals coupleable to one or more light sources, and a linear regulator coupled in series with the light source to regulate a drive current flowing through the series circuit.

Owner:SAVANT TECH LLC

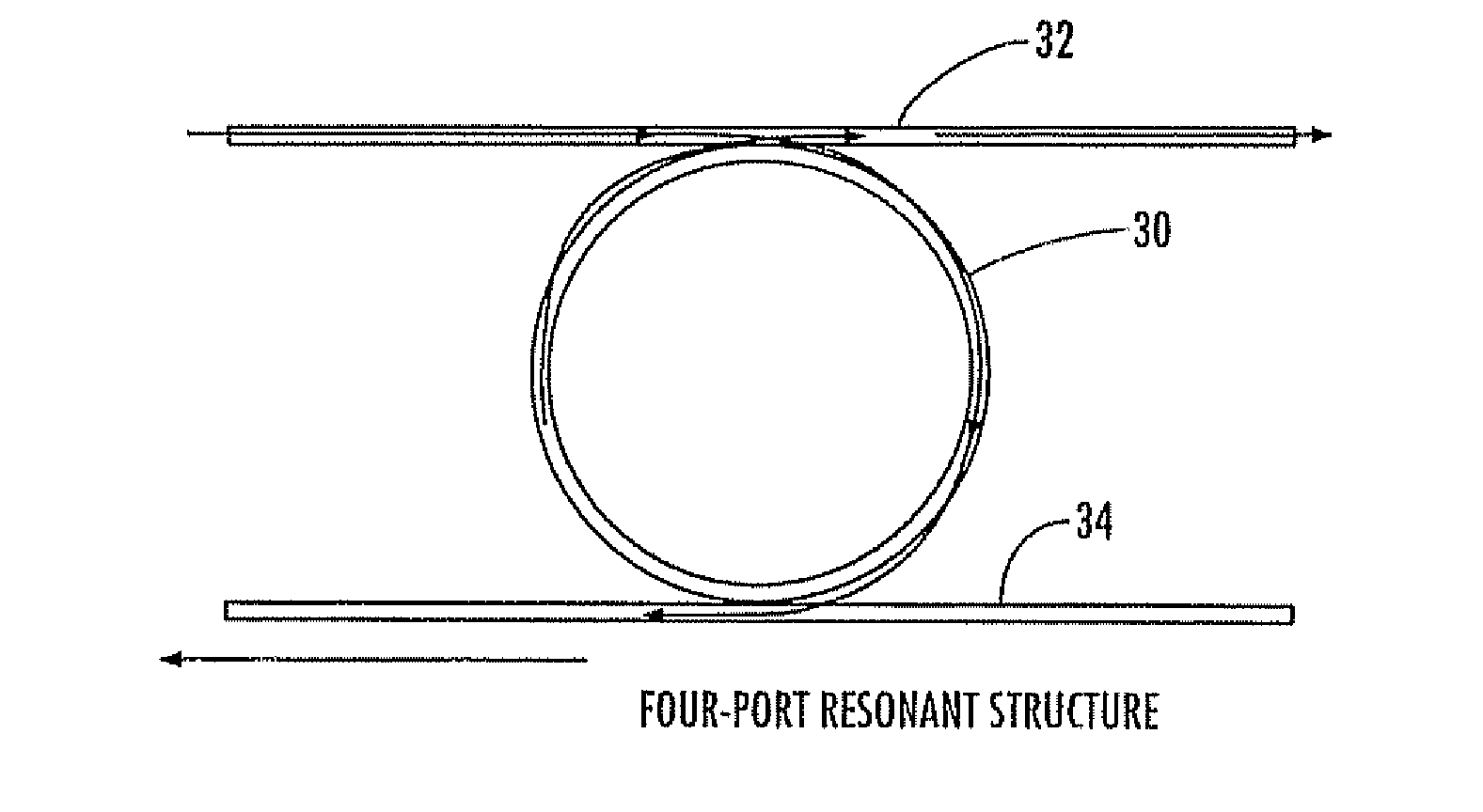

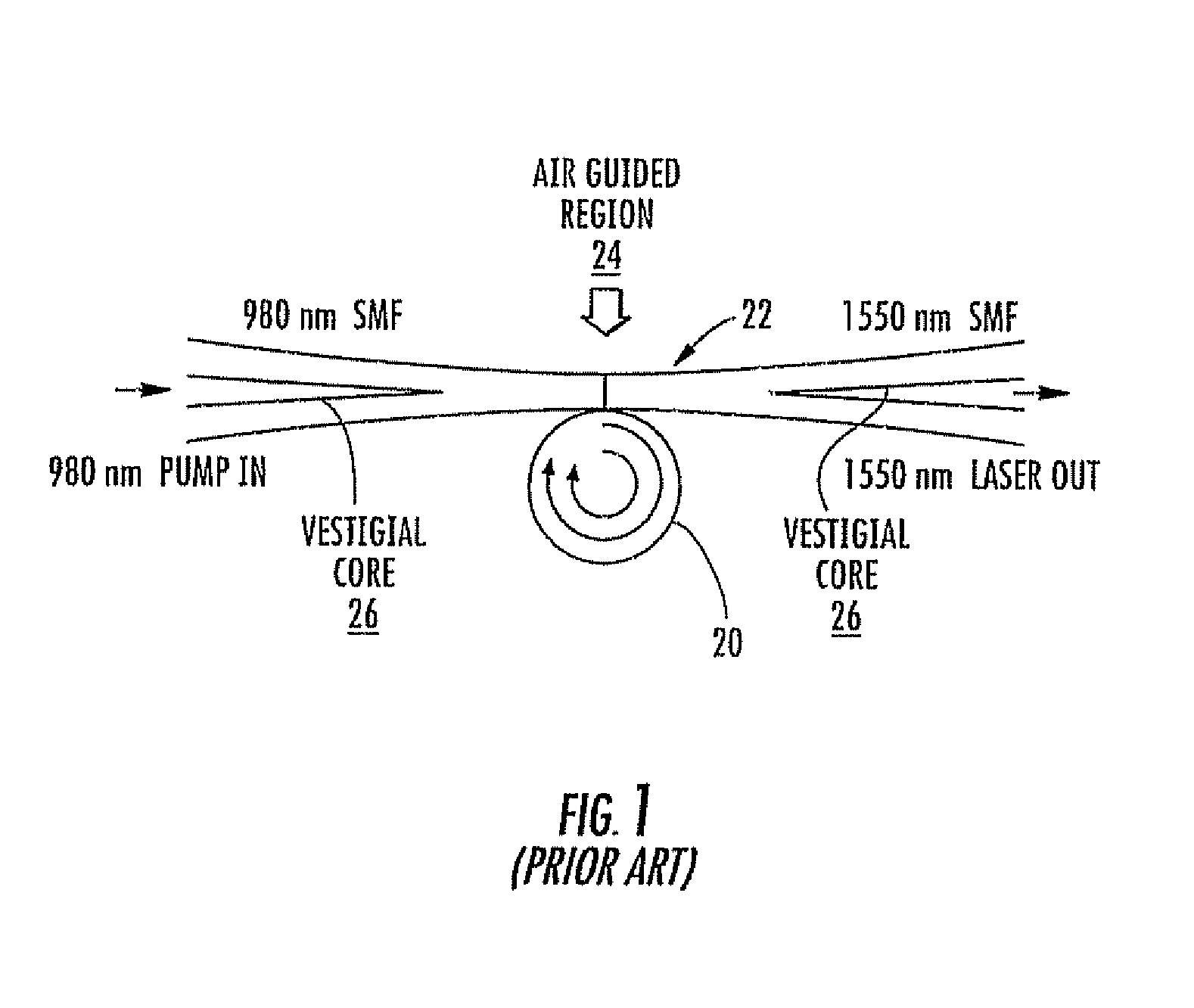

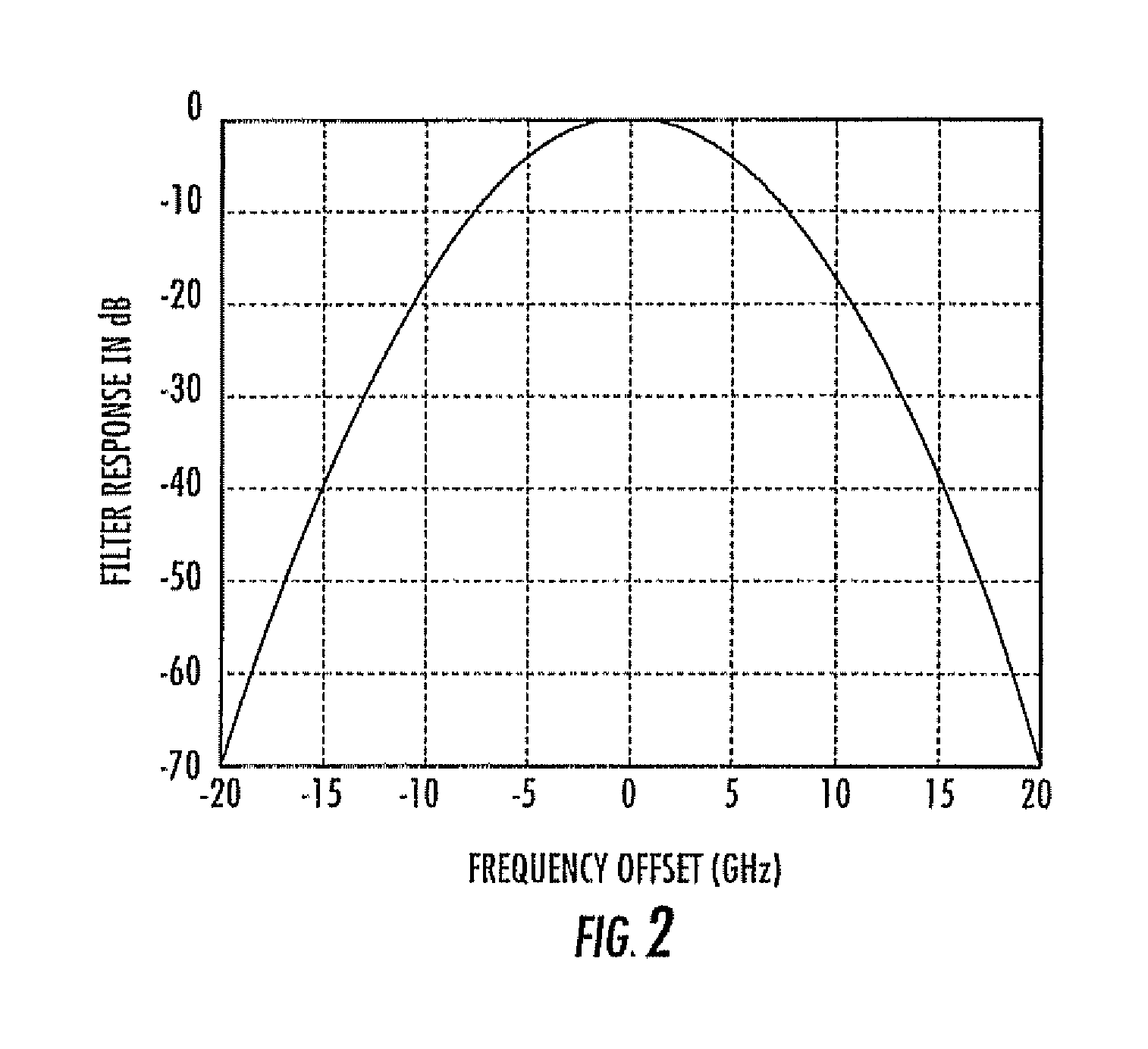

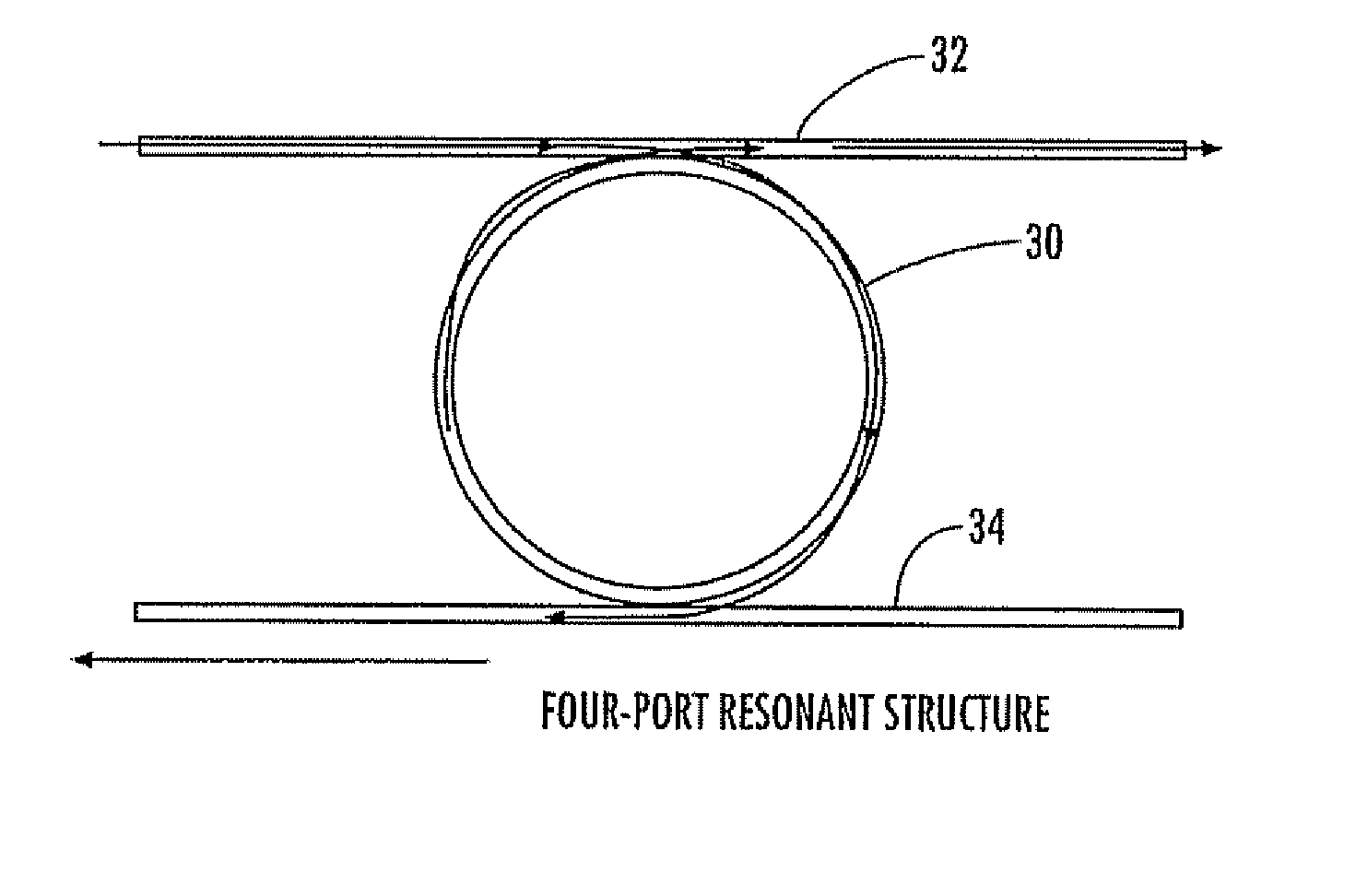

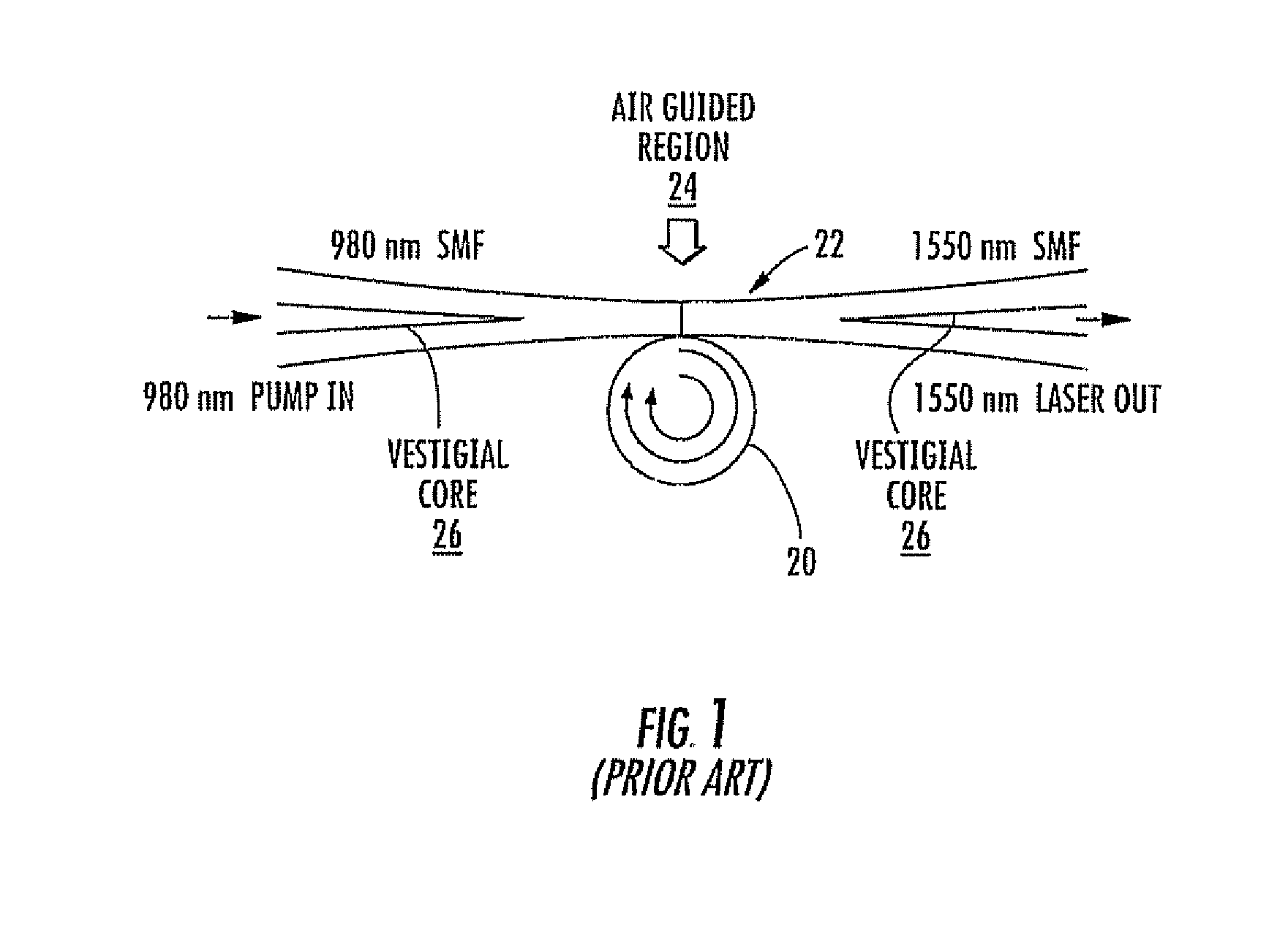

Spiral waveguide slow wave resonator structure

InactiveUS20060280407A1Ease of lightSimple preparation techniqueLaser detailsCoupling light guidesCouplingSlow light

An optical microresonator includes microcylinder and spiral resonant waveguide formed on the microcylinder that optically couples light from an optical source waveguide to the microcylinder and slows light propagating along the microcylinder. A coupling element, for example, a diffraction grating can be operative with the resonant waveguide structure and configured to meet a desired phase matching A second microcylinder having a spiral resonant waveguide formed thereon can be positioned adjacent to the spiral resonant waveguide formed on the first microcylinder for coupling therewith. The spiral resonant waveguides on first and second microcylinders can be configured for slowing light propagating along the microcylinder.

Owner:HARRIS CORP

Stealth cutting LED (light emitting diode) chip and manufacture method thereof

The invention discloses a stealth cutting LED (light emitting diode) chip, which comprises a substrate, a luminescence epitaxial layer and a reflection layer, wherein the luminescence epitaxial layer and the reflection layer are grown on the surface of the substrate; the luminescence epitaxial layer and the reflection layer are respectively positioned on two sides of the substrate; the substrate is provided with a first surface and a second surface opposite to the first surface; the luminescence epitaxial layer is formed on the first surface; the reflection layer is formed on the second surface; the reflection layer is a metal layer or an alloy layer; and the reflection layer is also attached with a total reflection membrane. The manufacture method for the stealth cutting LED chip comprises the following manufacture steps: forming the luminescence epitaxial layer on the first surface of the substrate; forming a channel favorable for the stealth cutting to penetrate through the substrate on the luminescence epitaxial layer; causing the luminescence epitaxial layer to form respectively independent luminescence chips of which the substrates are connected; forming the reflection layer on the second surface of the substrate; forming a modification layer in the substrate in a stealth cutting mode; applying external force to the substrate; dividing the substrate into the respectively independent luminescence chips of which the substrates are separated.

Owner:上海蓝宝光电材料有限公司 +1

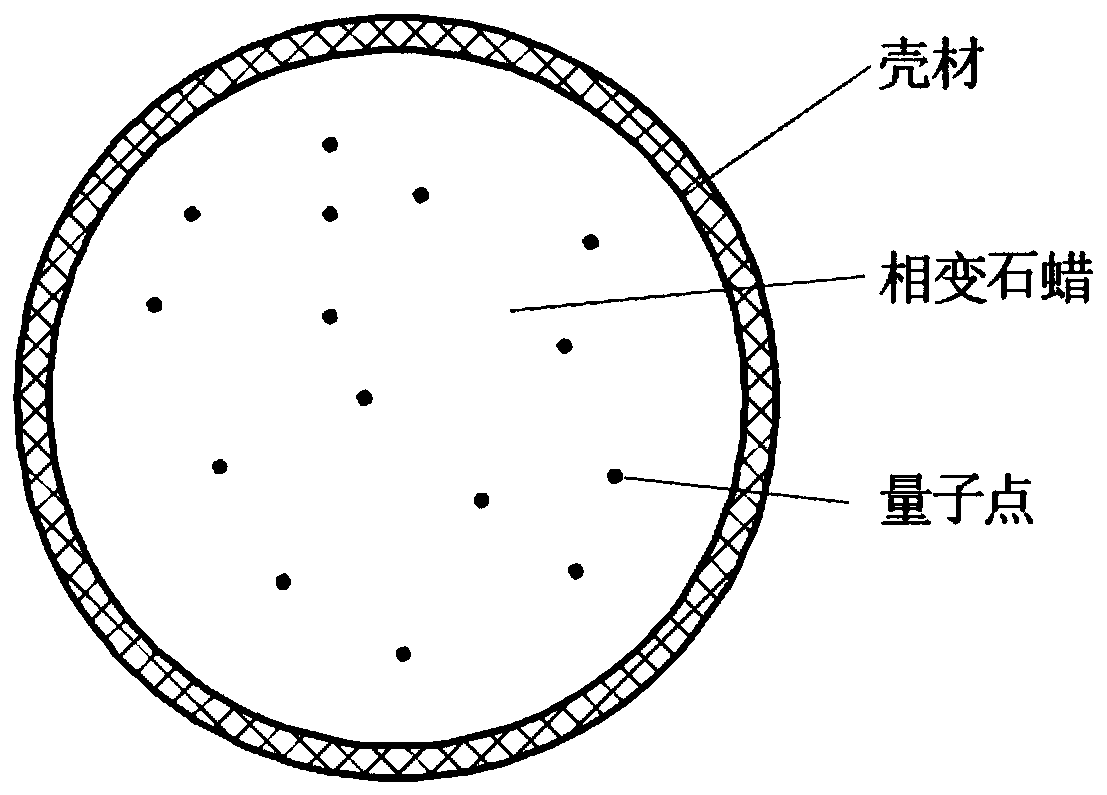

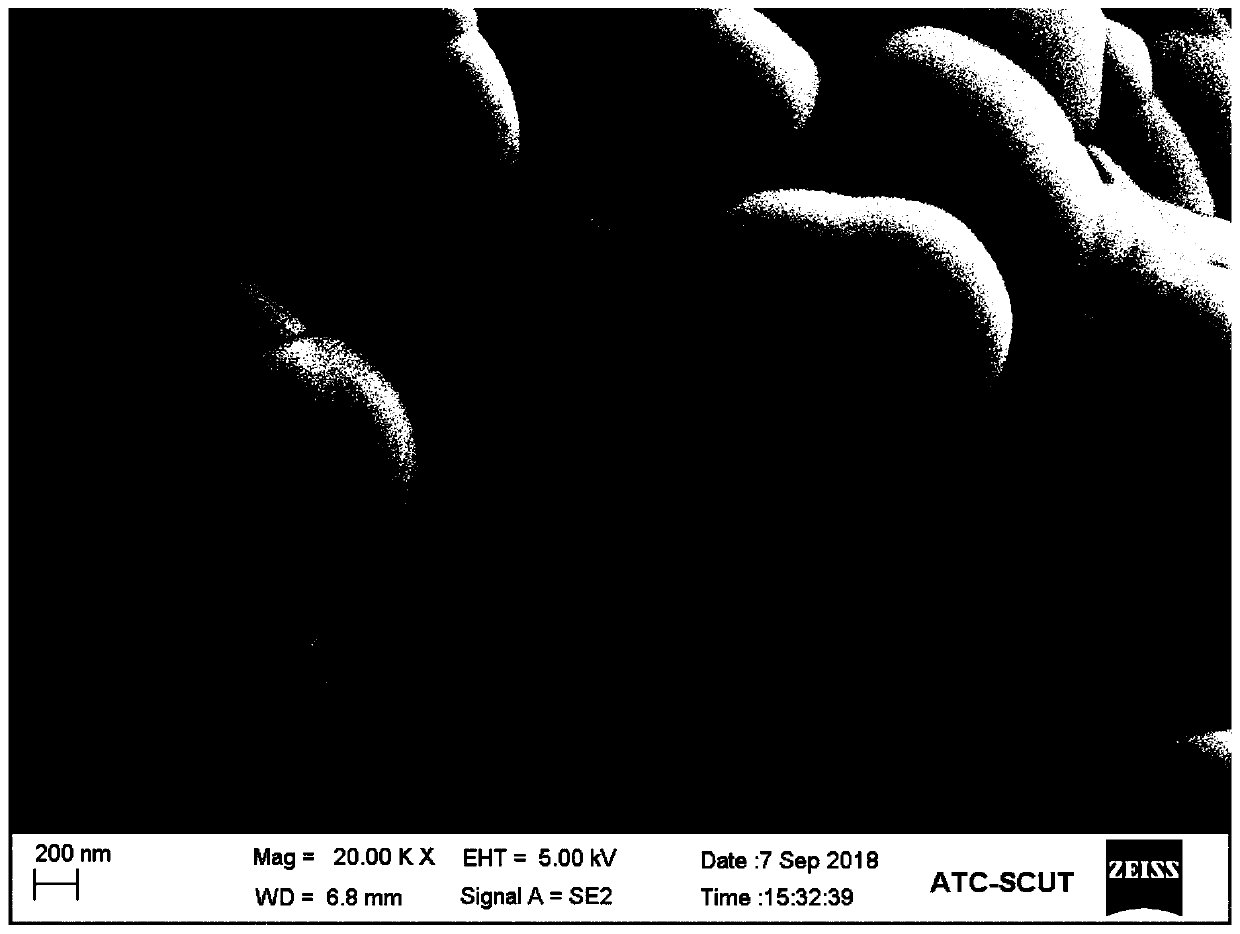

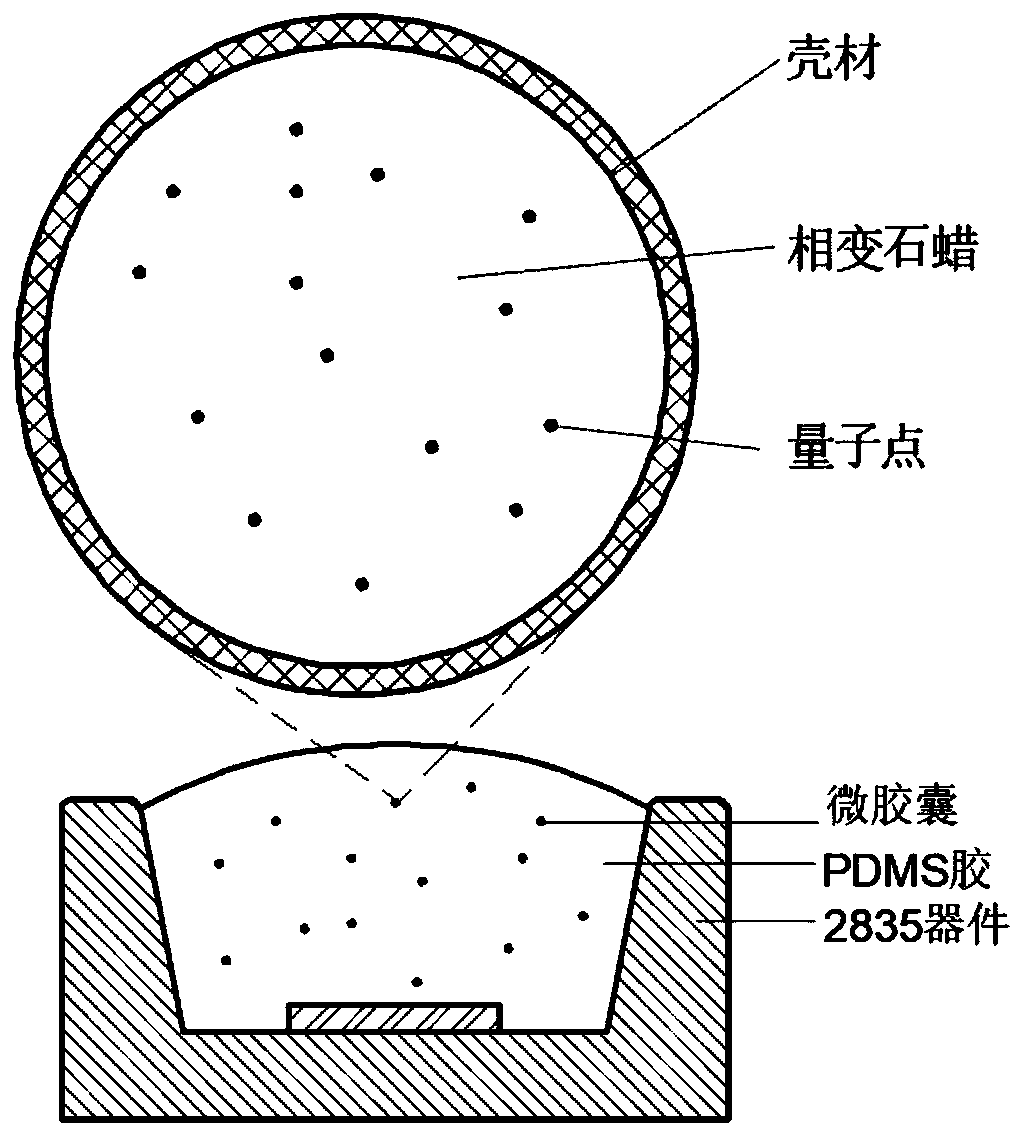

Quantum dot-wrapped phase-change paraffin microcapsule, LED device, and preparation methods of phase-change paraffin microcapsule and LED device

PendingCN110591688AStable light outputUniform light outputMaterial nanotechnologyHeat-exchange elementsParaffin waxMethacrylic acid copolymer

The invention belongs to the technical field of packaging preparation of light-emitting diode (LED) luminescent materials, and relates to a quantum dot wrapped phase-change paraffin microcapsule, an LED device and preparation methods of the phase-change paraffin microcapsule and the LED device. The quantum dot wrapped phase-change paraffin microcapsule comprises quantum dots, phase-change paraffinand methyl methacrylate-methacrylic acid copolymer shell material, wherein the quantum dots are dispersed and wrapped in the phase-change paraffin which is used as a spherical core of the microcapsule, and the methyl methacrylate-methacrylic acid copolymer outer shell coats the outer surface of the phase-change paraffin wax in a spherical shell shape. The LED device which contains the quantum dot-wrapped phase-change paraffin microcapsule comprises LED lamp beads and a colloid fluorescent coating, wherein the colloid fluorescent coating is doped with the quantum dot-wrapped phase-change paraffin microcapsule, and the colloid fluorescent coating coats light-emitting cup openings of the LED lamp beads. According to the invention, paraffin wax in a liquid state is encapsulated through microcapsules, so that the problem of insufficient scattering performance of quantum dots is solved by optimizing scattering; the surface area is increased through microencapsulation, and heat absorption iscarried out by phase change of the paraffin wax, so that the load of heat dissipation of LED is reduced.

Owner:SOUTH CHINA UNIV OF TECH

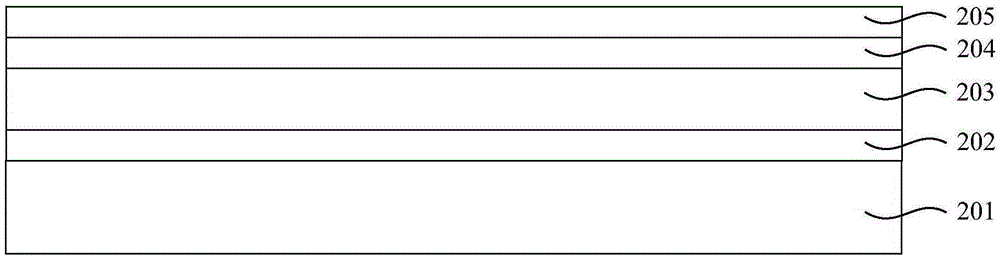

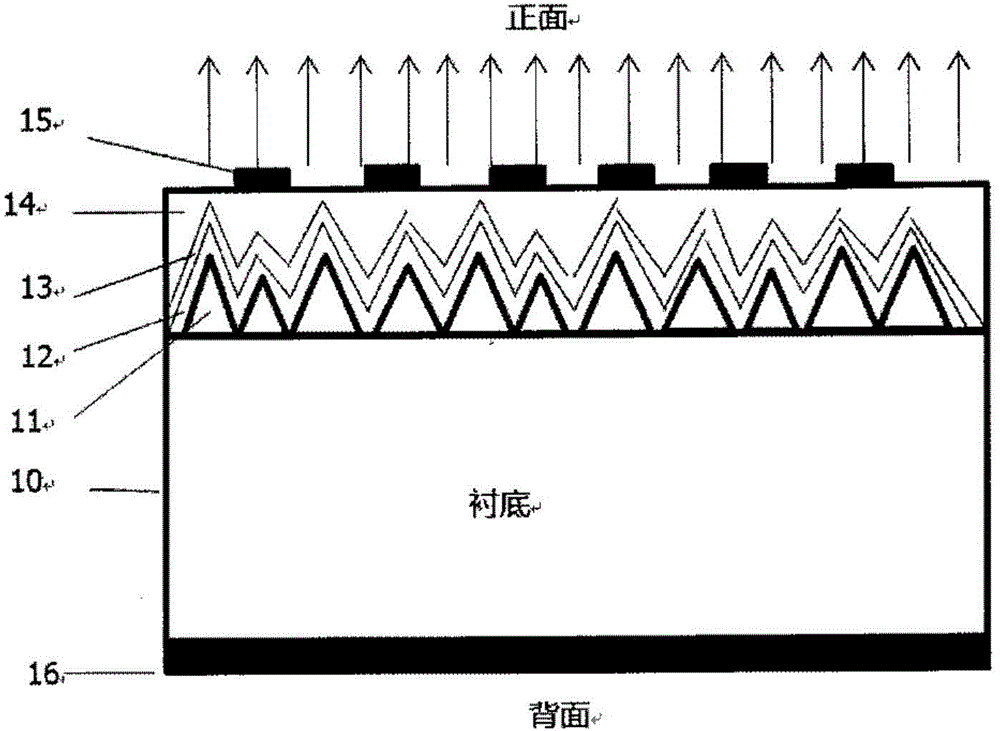

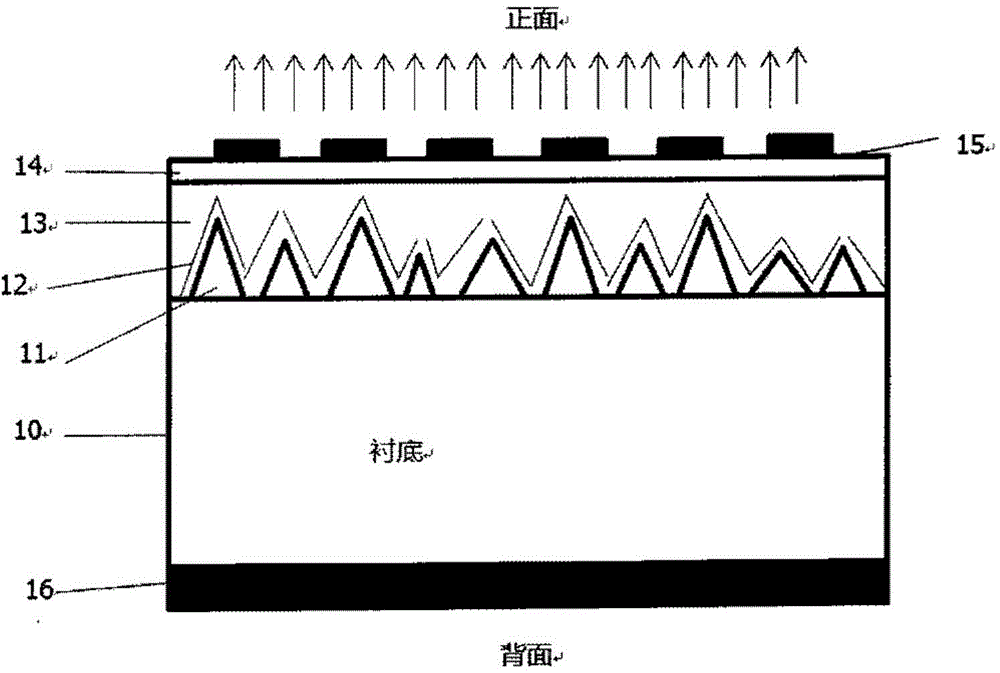

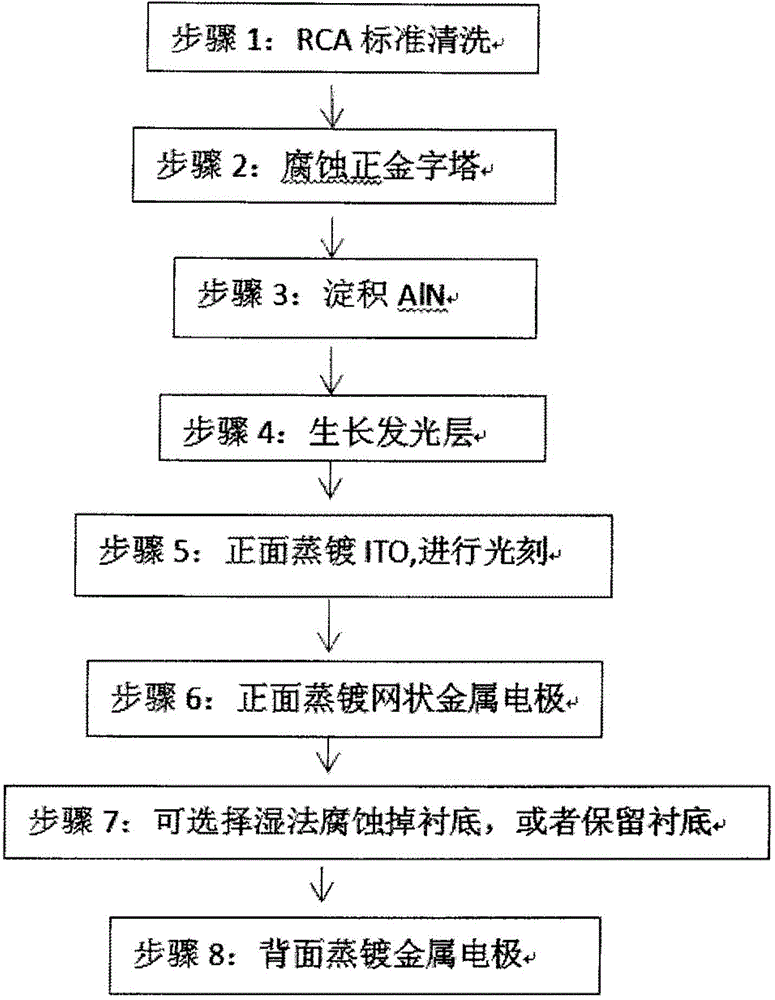

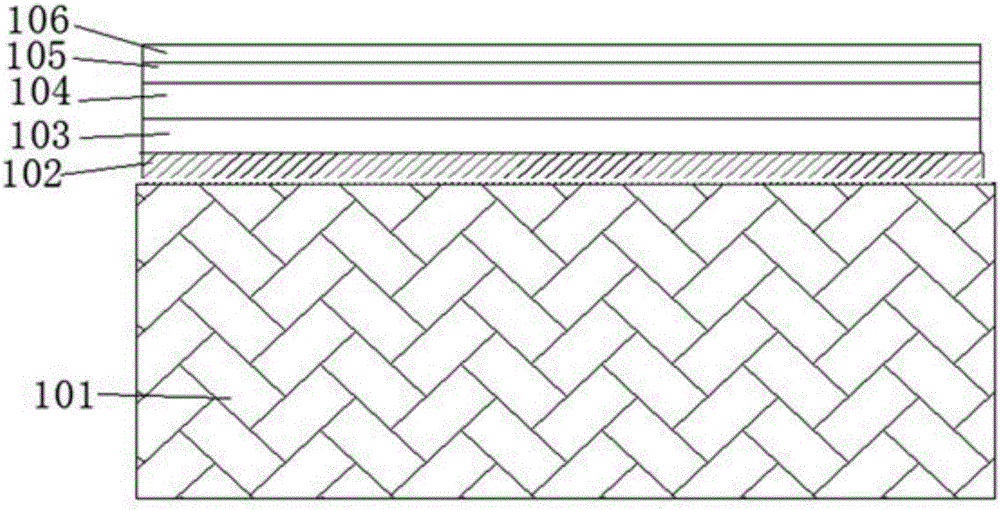

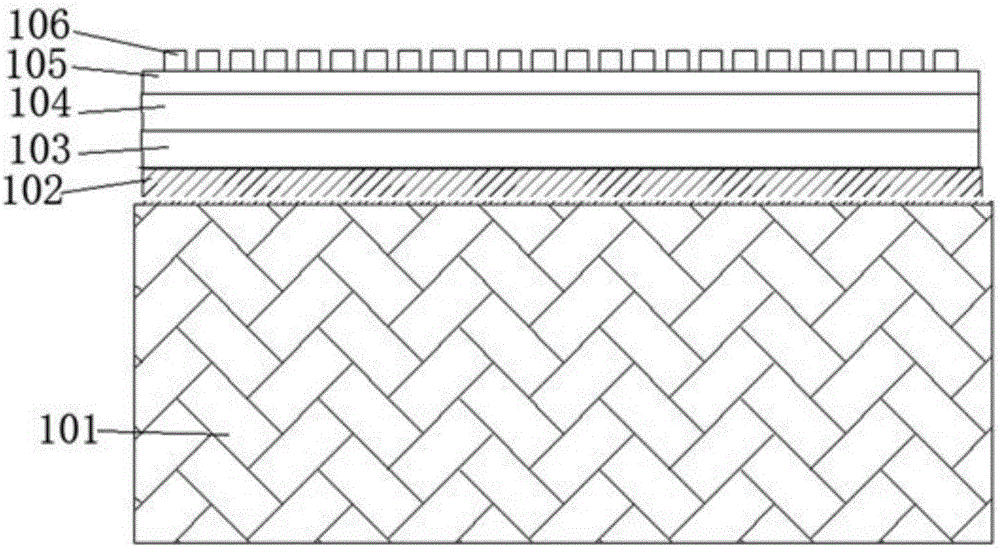

Silicon-based GaN luminescent device based on crystalline silicon photovoltaic technology and preparation method of silicon-based GaN luminescent device

InactiveCN104638081ASimple processReduce manufacturing costSemiconductor devicesEpitaxial materialP type silicon

The invention discloses a silicon-based GaN luminescent device based on a crystalline silicon photovoltaic technology. The silicon-based GaN luminescent device comprises a substrate for N-type or P-type silicon (100), a randomly distributed forward pyramid structure manufactured on the substrate, a buffering reflection layer which is manufactured on the surface of the forward pyramid structure and is made of high-temperature AlN or low-temperature AlN, a luminous layer which is manufactured on the buffering reflection layer, a transparent conductive oxide layer which is manufactured on the luminous layer, an upper electrode layer which is manufactured on the transparent conductive oxide layer and is in meshed distribution, and a lower electrode layer manufactured on the back surface of the substrate, wherein the surface of the luminous layer is parallel to the surface of the forward pyramid structure or parallel to the surface of the substrate; the surface of the transparent conductive oxide layer is a plane. According to the silicon-based GaN luminescent device, stress on an epitaxial material can be effectively released, so that high-quality luminous LED (light emitting diode) which is provided with epitaxial GaN and is low in manufacturing cost and high in efficiency can be obtained.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

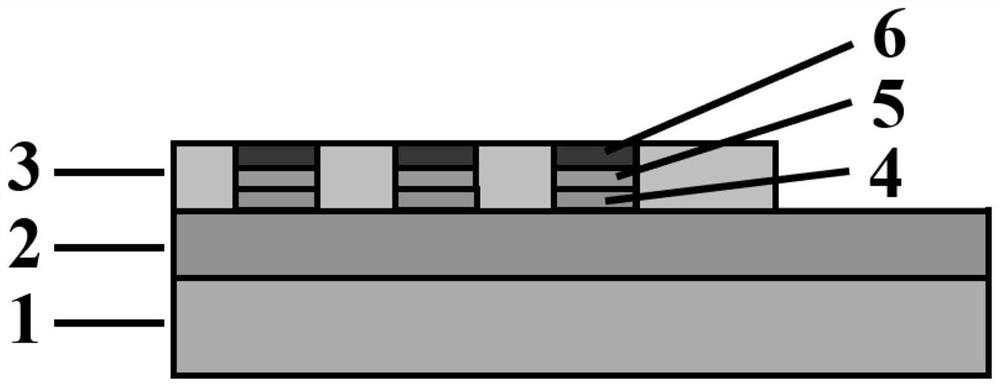

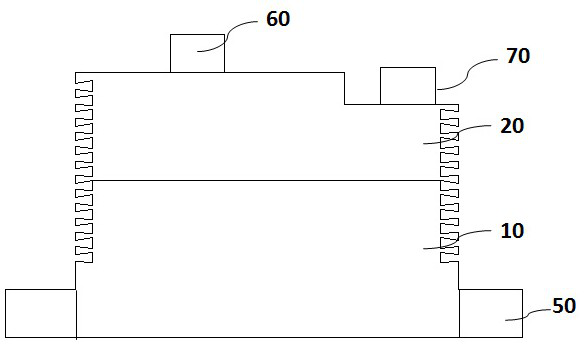

Micro-LED chip with epitaxial growth in selected area and preparation method of Micro-LED chip

InactiveCN111864024AImprove photoelectric performanceAvoid surface damageSolid-state devicesIdentification meansEngineeringDielectric layer

The invention discloses an epitaxial growth Micro-LED chip in a selected area and a preparation method of the epitaxial growth Micro-LED chip. The chip of a flip chip structure comprises a substrate,an n-GaN layer, an insulating dielectric layer and an ITO transparent conductive layer sequentially arranged from top to bottom. The insulating dielectric layer is provided with a chip epitaxial layerarray penetrating through the insulating dielectric layer, the n-GaN layer is exposed at the edge of one side of the insulating dielectric layer to form a mesa structure, the surface of the insulating dielectric layer is provided with an n electrode, the surface of the ITO transparent conductive layer is provided with a p electrode, and the p electrode and the n electrode are fixedly connected with a target substrate. In the preparation process, selective etching is carried out on the insulating dielectric layer to obtain a micropore array, and an epitaxial layer structure of the Micro-LED chip grows in micropores. According to the method, surface damage caused in the dry etching process of the epitaxial structure of the Micro-LED chip can be avoided, the Micro-LEDs are isolated from oneanother through the insulating dielectric layers, crosstalk can be prevented, and the display effect is improved.

Owner:WUHAN UNIV

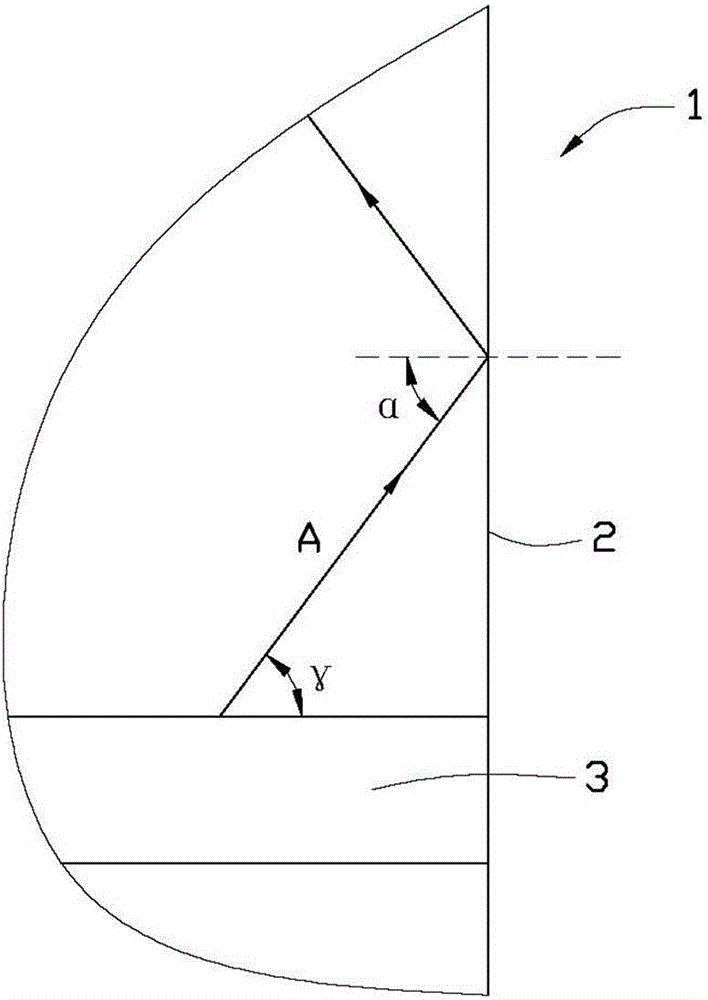

Light emitting diode crystalline grain

InactiveCN103066177AImprove luminous efficiencyReduce the angle of incidenceSemiconductor devicesElectrical conductorDiode

A light emitting diode crystalline grain comprises a substrate and an epitaxial layer which is formed on the substrate. The substrate comprises an upper surface. The epitaxial layer comprises a first semiconductor layer close to the substrate, a second semiconductor layer far away from the substrate, and an active layer arranged between the first semiconductor layer and the second semiconductor layer. The edge of the top, far away from the substrate, of the epitaxial layer is provided with an arc angle or a slant chamfer, and therefore light can be emitted from the side face of the epitaxial layer favorably, and luminous efficiency of the light emitting diode crystalline grain is improved.

Owner:ZHANJING TECH SHENZHEN +1

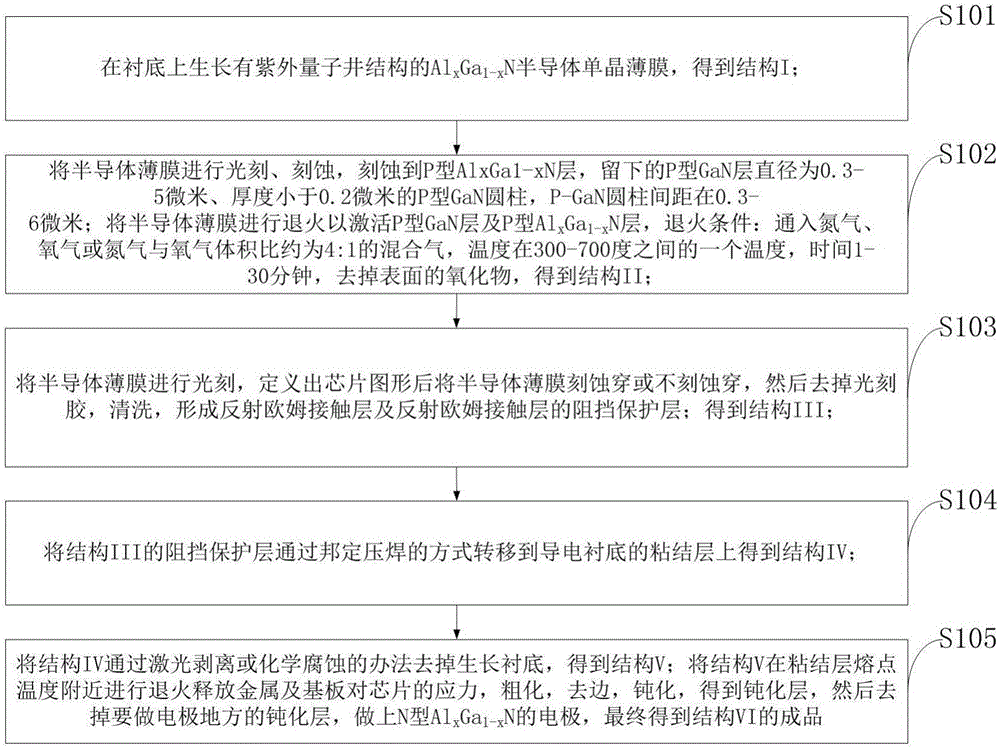

Manufacturing method for short wave UV LED chip having high reflection ohmic contact electrode

InactiveCN106025020AReduce areaImprove light extraction efficiencySemiconductor devicesEtchingUltraviolet lights

The invention discloses a manufacturing method for a short wave UV LED chip having a high reflection ohmic contact electrode. According to the method, an AlxGa1-xN semiconductor monocrystalline film having an UV quantum well structure grows on a substrate, a structure I is acquired, and the x is greater than or equal to 0 and is smaller than or equal to 1; photoetching and etching of the semiconductor film are carried out, etching is carried out to an AlxGa1-xN layer, P-type GaN layer cylinders are acquired, P-type GaN cylinder intervals are in a range of 0.3-6 micrometer, a chip pattern is defined through photoetching of the semiconductor film, and penetration-through etching or non-penetration-through etching is carried out; a high reflection ohmic contact layer and a blocking layer are made, the chip is transferred onto a conductive substrate through a mode of bonding or electroplating or a mixed bonding and electroplating mode, an UV LED device is finally manufactured. Relatively good reflection ohmic contact is formed at P-type GaN and P-type AlxGa1-xN layers of the UV LED through employing Ni / Al, Pt / Al, Pd / Al and so on metal lamination layers having relatively high reflectivity for UV light, and ultraviolet light emitting efficiency is improved.

Owner:MINNAN NORMAL UNIV +1

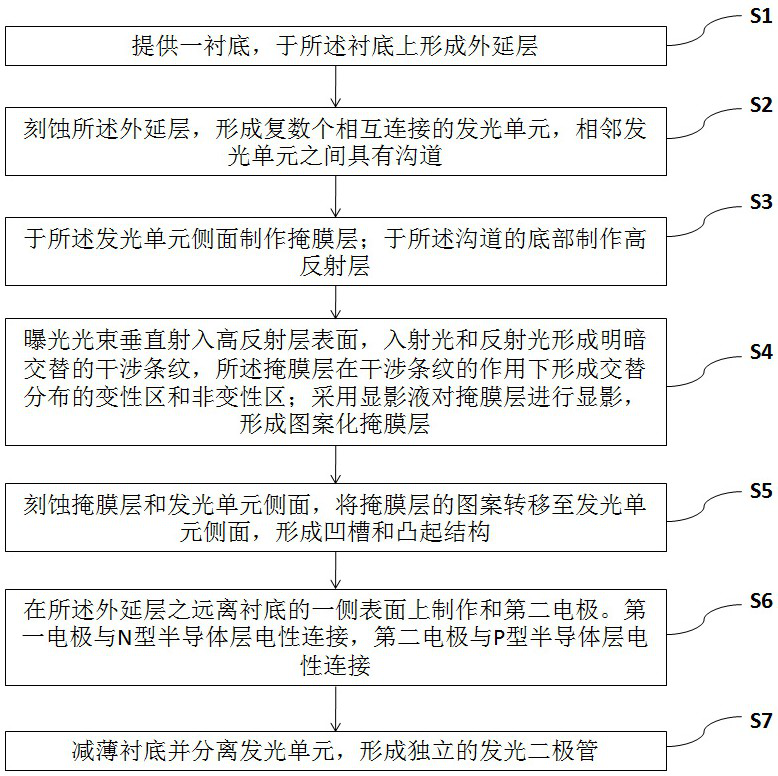

Light emitting diode and manufacturing method thereof

ActiveCN112447893ASolve difficult problems that are not easily exposedChange pathSolid-state devicesSemiconductor devicesReflective layerLight-emitting diode

The invention belongs to the field of semiconductors, and particularly relates to a light emitting diode and a manufacturing method thereof. A channel is etched between adjacent light emitting units,a high-reflection layer is manufactured at the bottom of the channel, interference fringes are generated through the high-reflection layer, and the side surface of the light emitting diode is exposedby adopting the interference fringes; therefore, the groove and the protruding structure are formed on the side face of the light-emitting diode, the width of the bottom of the groove is larger than that of the opening, the silicon dioxide layer is arranged on the surface of the protruding structure, and light-emitting efficiency of the light-emitting diode can be further improved.

Owner:ANHUI SANAN OPTOELECTRONICS CO LTD

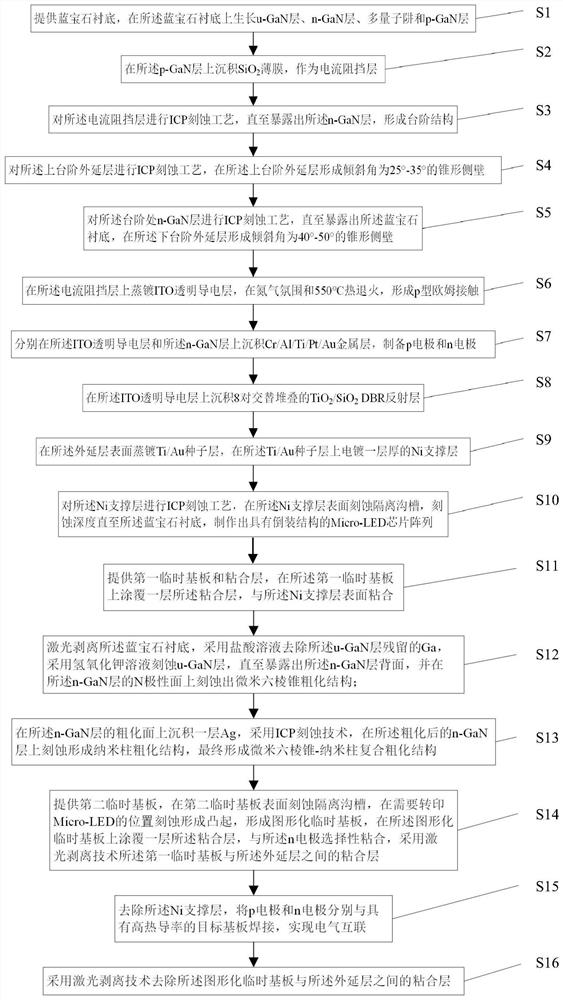

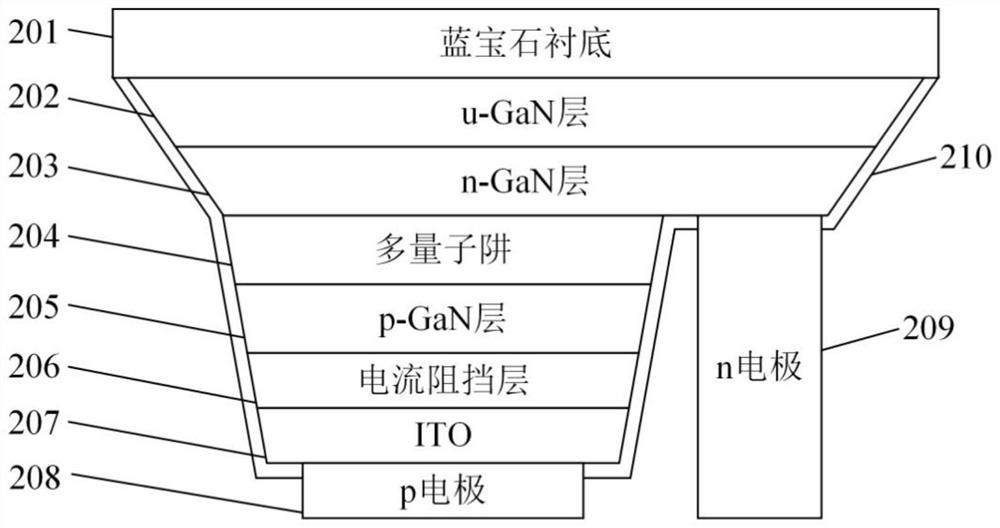

Thin film flip structure Micro-LED chip transferred by adhesive layer, and preparation method thereof

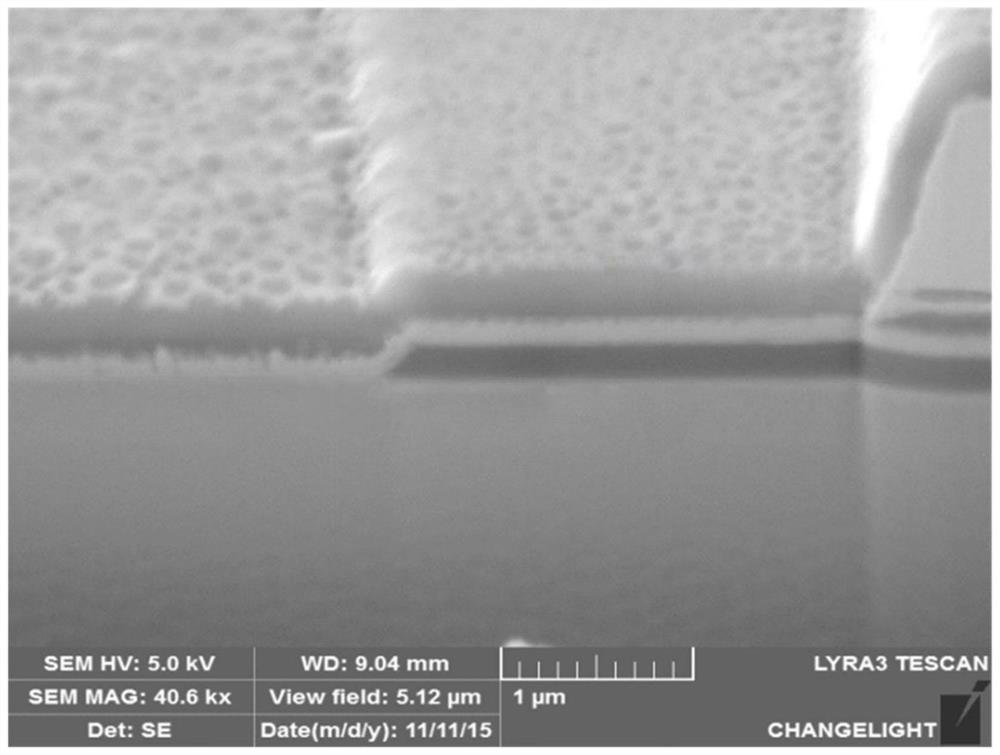

ActiveCN112018223AImprove light extraction efficiencyImprove photoelectric performanceSemiconductor devicesNanopillarThin membrane

The invention provides a thin film flip structure Micro-LED chip transferred by an adhesive layer, and a preparation method thereof. The light extraction efficiency of the chip can be effectively improved. The preparation method comprises the following steps: growing an epitaxial layer on a substrate; depositing a current blocking layer; etching to form a frustum-shaped first frustum-shaped epitaxial layer and a frustum-shaped second frustum-shaped epitaxial layer; forming a p electrode and an n electrode; depositing a plurality of pairs of alternately stacked DBR reflecting layers; evaporating a Ti / Au seed layer on the surface of the epitaxial layer, and electroplating a thick Ni support layer on the seed layer; etching ane isolation groove to manufacture a chip array with a flip structure; etching a micron hexagonal pyramid coarsening structure on the N polar surface of the n-GaN layer; further etching to obtain a nanopillar coarsened structure; coating the graphical temporary substrate with a bonding layer, and selectively bonding with the surface of the n electrode; removing the Ni support layer, and respectively welding the p electrode and the n electrode to the target substrate; and removing the bonding layer to obtain the transferred chip.

Owner:JIANGXI ZHAO CHI SEMICON CO LTD

Light-emitting, radiating and wiring process of light-emitting diode (LED) outdoor product chip integrated package

InactiveCN102185051AImprove qualityIncrease productivitySolid-state devicesSemiconductor devicesPrinted circuit boardEngineering

The invention discloses a light-emitting, radiating and wiring process of light-emitting diode (LED) outdoor product chip integrated package. A light-emitting LED chip integrated package product can be manufactured by designing an LED chip printed circuit board (PCB) wiring board, designing an LED chip light-reflecting cup bracket, manufacturing a silver-plated bracket through a bracket die, loading the silver-plated bracket into the LED chip PCB wiring board, designing a light-reflecting cup according to needs of the product, performing injection molding on a PCB, the bracket and a rubber cup to form the PCB, the wiring plate, the bracket and the rubber cup into a whole through a light-reflecting cup rubber die, and performing LED crystal fixation, routing and spot gluing process steps. In a packaging process, new light-emitting, radiating and wiring process technologies are adopted; the light-emitting efficiency and the radiating property of the product are improved; the quality and the efficiency of the product are improved; and the requirement of mass production is better met.

Owner:深圳市格特隆光电股份有限公司

Spiral waveguide slow wave resonator structure

InactiveUS20060280406A1Ease of lightSimple preparation techniqueCoupling light guidesOptical waveguide light guideCouplingSlow light

An optical microresonator includes microcylinder and spiral resonant waveguide formed on the microcylinder that optically couples light from an optical source waveguide to the microcylinder and slows light propagating along the microcylinder. A coupling element, for example, a diffraction grating can be operative with the resonant waveguide structure and configured to meet a desired phase matching. A second microcylinder having a spiral resonant waveguide formed thereon can be positioned adjacent to the spiral resonant waveguide formed on the first microcylinder for coupling therewith. The spiral resonant waveguides on first and second microcylinders can be configured for slowing light propagating along the microcylinder.

Owner:HARRIS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com