Quantum dot-wrapped phase-change paraffin microcapsule, LED device, and preparation methods of phase-change paraffin microcapsule and LED device

A technology of LED devices and phase-change paraffin, applied in chemical instruments and methods, semiconductor devices, electrical components, etc., can solve the problems of hindered development of quantum dots, narrow emission peaks, strong light, strong thermal instability, etc., and achieve weakened saturation The degree of absorption, increasing the surface area, reducing the effect of demanding standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

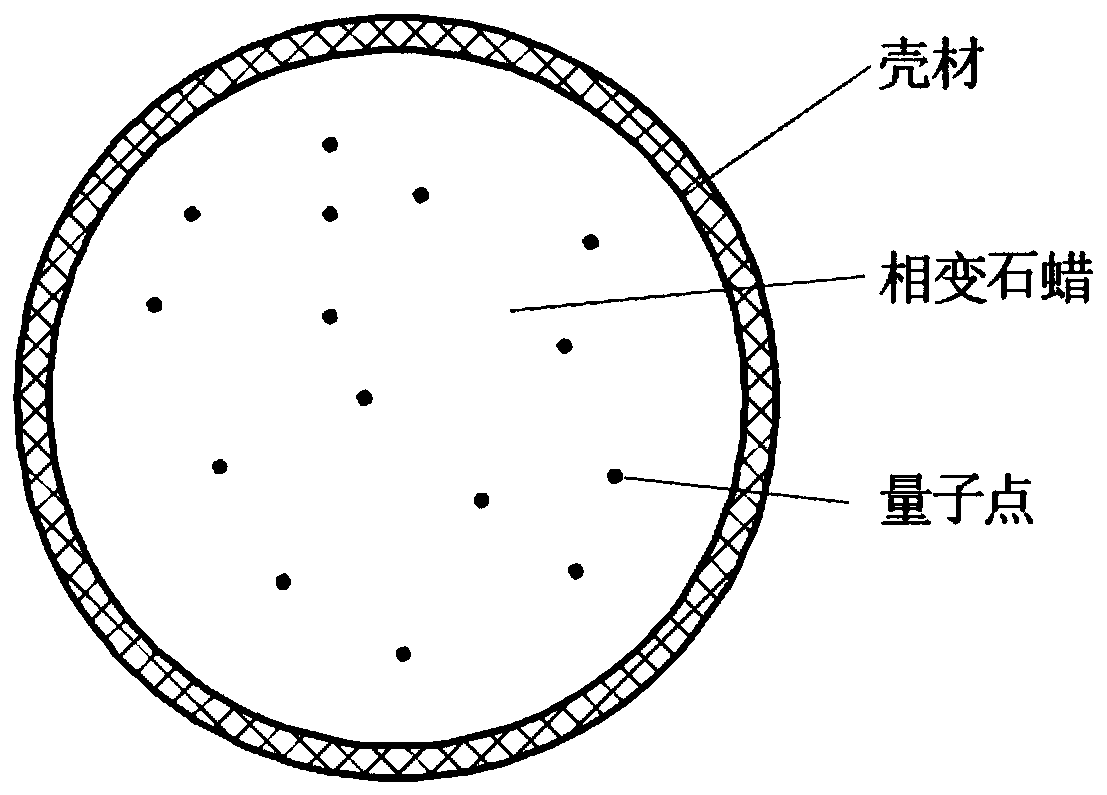

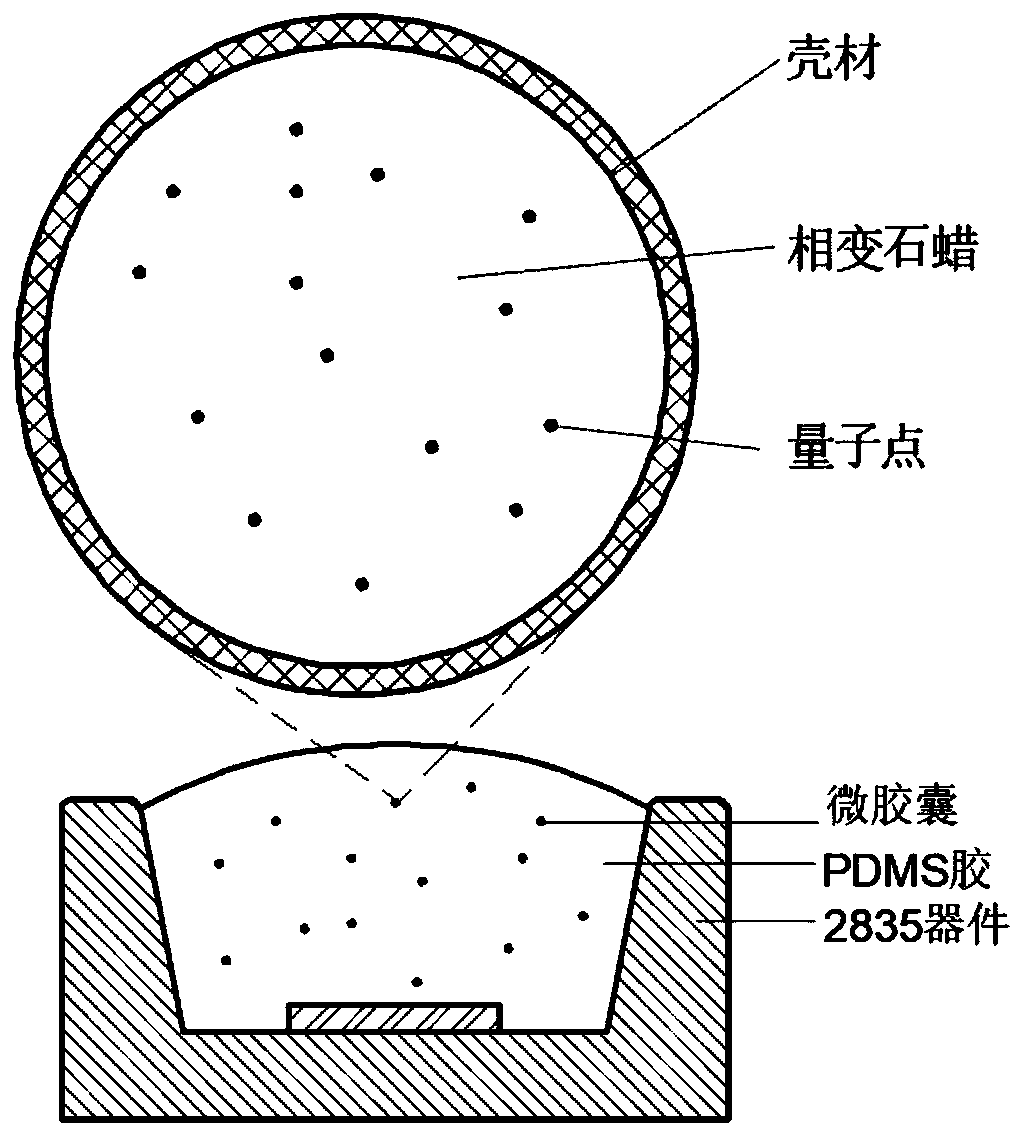

[0041] A method for preparing phase-change paraffin microcapsules wrapped with quantum dots, comprising the steps of:

[0042] (1) Add methyl methacrylate (MMA), methacrylic acid (MAA), and dicyclohexyl peroxycarbonate (DCPD) as an initiator into a flask, stir magnetically at 62-65°C, and carry out 60- 80min prepolymerization reaction;

[0043] (2) Heat the phase-change paraffin to 6°C higher than its phase-transition temperature to melt, add quantum dots and use shear dispersion to stir evenly at a speed of 7-10KRPM for 10-20min;

[0044] (3) Add molten phase-change paraffin and N,N-methylenebisacrylamide (MBA) as a crosslinking agent into the flask, and mix and react for 10-15 minutes;

[0045](4) Mix distilled water and polyvinyl alcohol (PVA) as a dispersant in a beaker, heat it in a water bath to 62-65°C, pour all the liquid in the flask into the beaker, and stir at a speed of 7-10KRPM by means of shear dispersion 3-5min, transfer the mixture in the beaker to the flask ...

Embodiment 1

[0055] (1) Add methyl methacrylate (MMA), methacrylic acid (MAA), and dicyclohexyl peroxycarbonate (DCPD) as an initiator into a three-necked flask, stir magnetically at 65°C, and perform 60min prepolymerization reaction;

[0056] (2) Heat 38# phase-change paraffin to 48°C to melt it, add CdSe-570 quantum dots and stir evenly for 15 minutes at 9KRPM by means of shear dispersion;

[0057] (3) Add molten phase-change paraffin and N,N-methylenebisacrylamide (MBA) into the above-mentioned three-necked flask, and mix and react for 15 minutes;

[0058] (4) Mix distilled water and polyvinyl alcohol (PVA) as a dispersant in a beaker, heat it in a water bath to 65°C, pour all the liquid in the above-mentioned three-necked flask into the beaker, and stir it by means of shear dispersion at 10KRPM for 3 -5min, transfer the mixture in the beaker to a three-necked flask and react at 75°C for 5h;

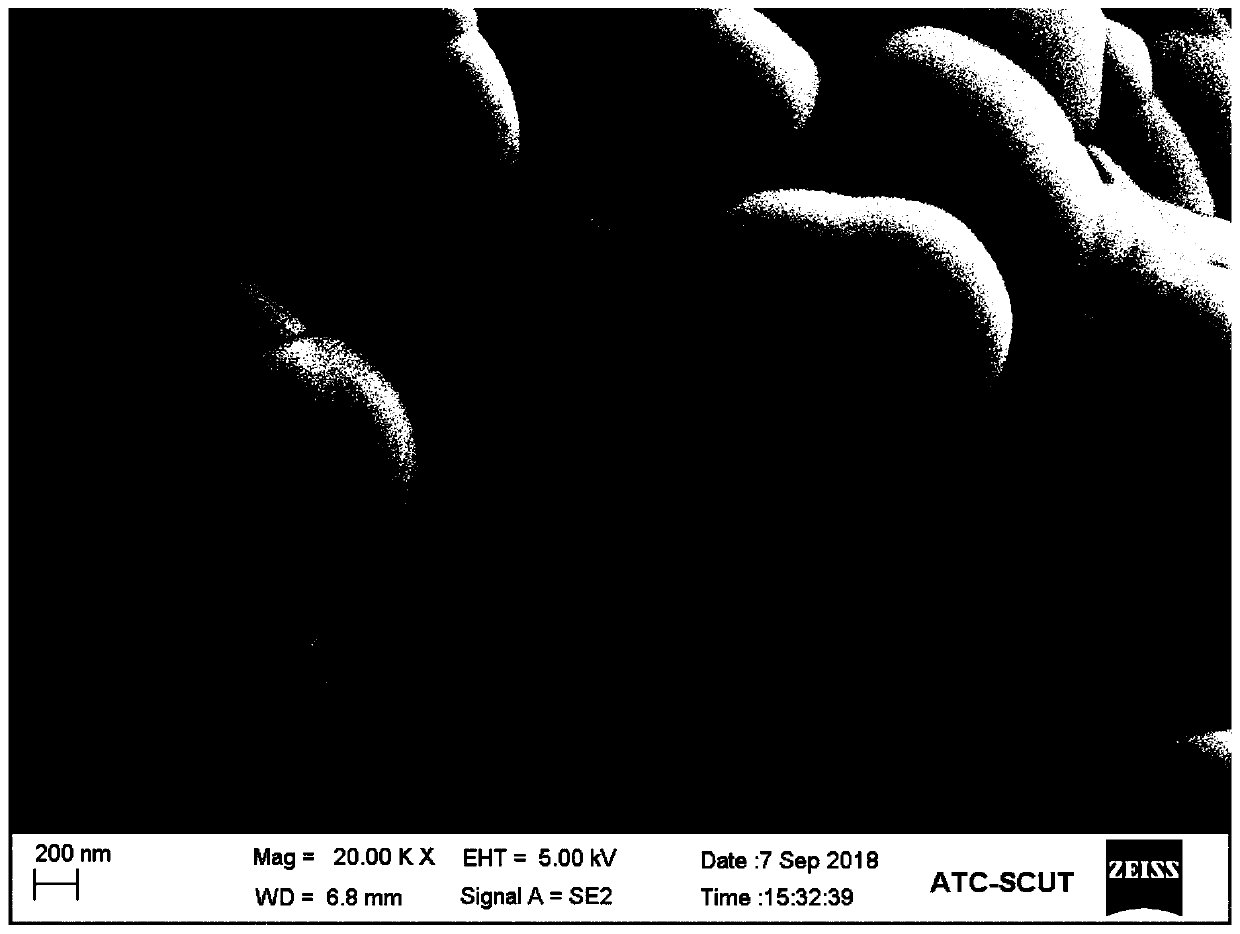

[0059] (5) Filter the prepared mixed slurry, wash with 50°C distilled water, and dry the res...

Embodiment 2

[0065] (1) Add methyl methacrylate (MMA), methacrylic acid (MAA), and dicyclohexyl peroxycarbonate (DCPD) as an initiator into a three-necked flask, stir magnetically at 62°C, and perform 70min prepolymerization reaction;

[0066] (2) Heat 45# phase-change paraffin to 54°C to melt it, add CdSe-525 quantum dots and stir evenly for 10 minutes at 7KRPM by means of shear dispersion;

[0067] (3) Add molten phase-change paraffin and N,N-methylenebisacrylamide (MBA) into the above-mentioned three-necked flask, and mix and react for 10 minutes;

[0068] (4) Mix distilled water and polyvinyl alcohol (PVA) as a dispersant in a beaker, heat it in a water bath to 63°C, pour all the liquid in the above-mentioned three-necked flask into the beaker, and stir for 4 minutes at 7KRPM by means of shear dispersion , transfer the mixture in the beaker to a three-necked flask and react at 74°C for 4h;

[0069] (5) Filter the prepared mixed slurry, wash with distilled water at 54° C., and dry the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com