Patents

Literature

45results about How to "Resistant to thermal shock" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

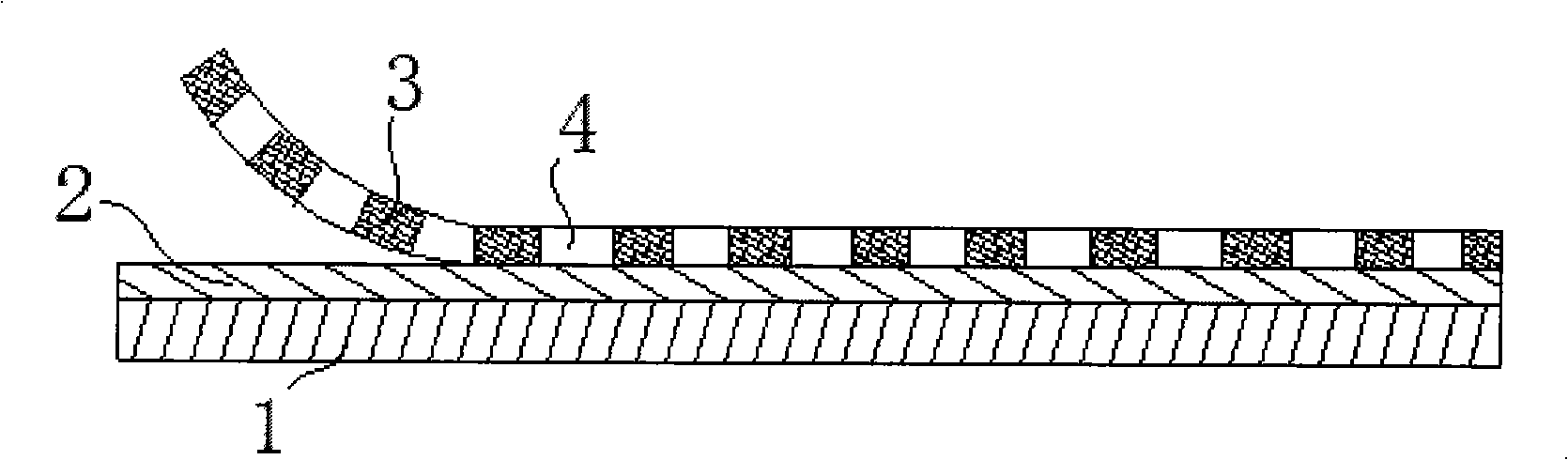

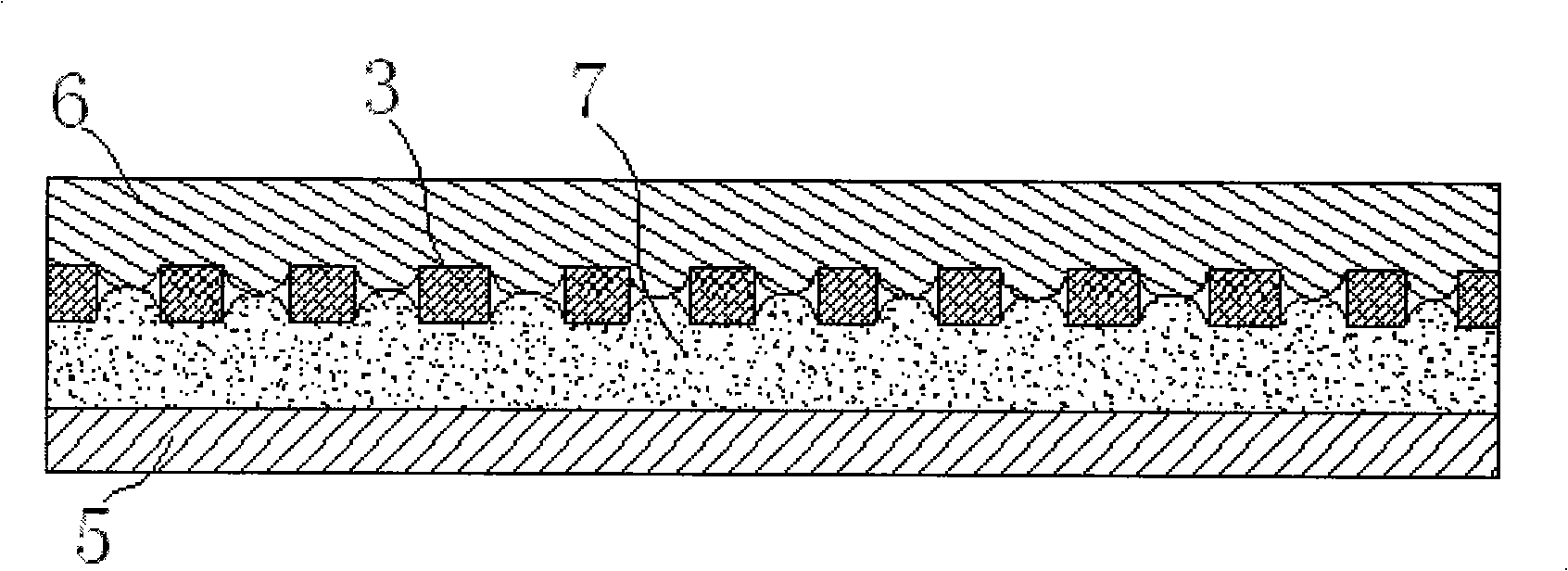

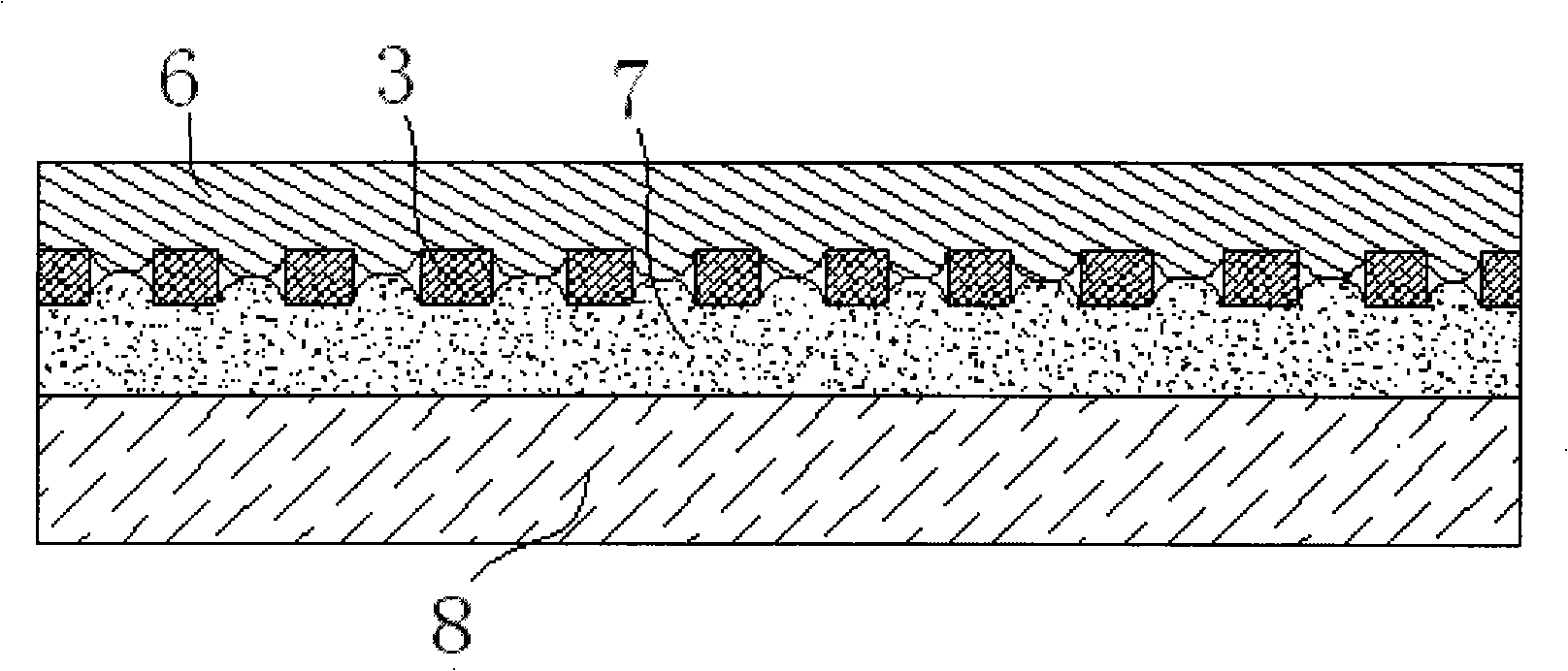

Ultra-thin shielding film and circuit board capable of changing circuit impedance, and method for preparing same

ActiveCN101448362AReduce thicknessStrong enoughPrinted circuit detailsMagnetic/electric field screeningAnisotropic conductive adhesiveMetal foil

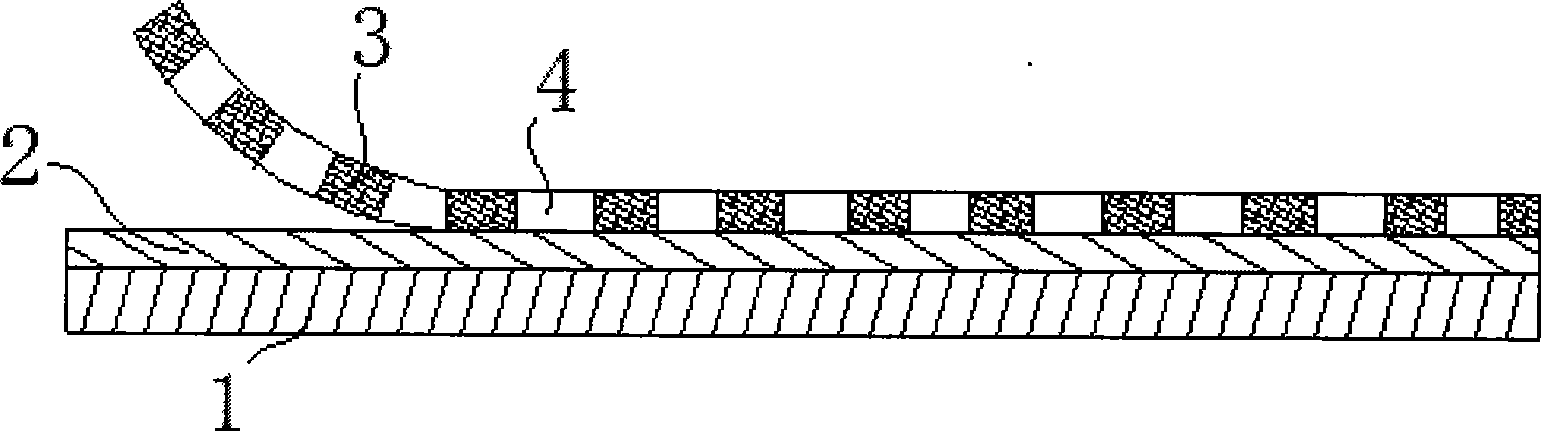

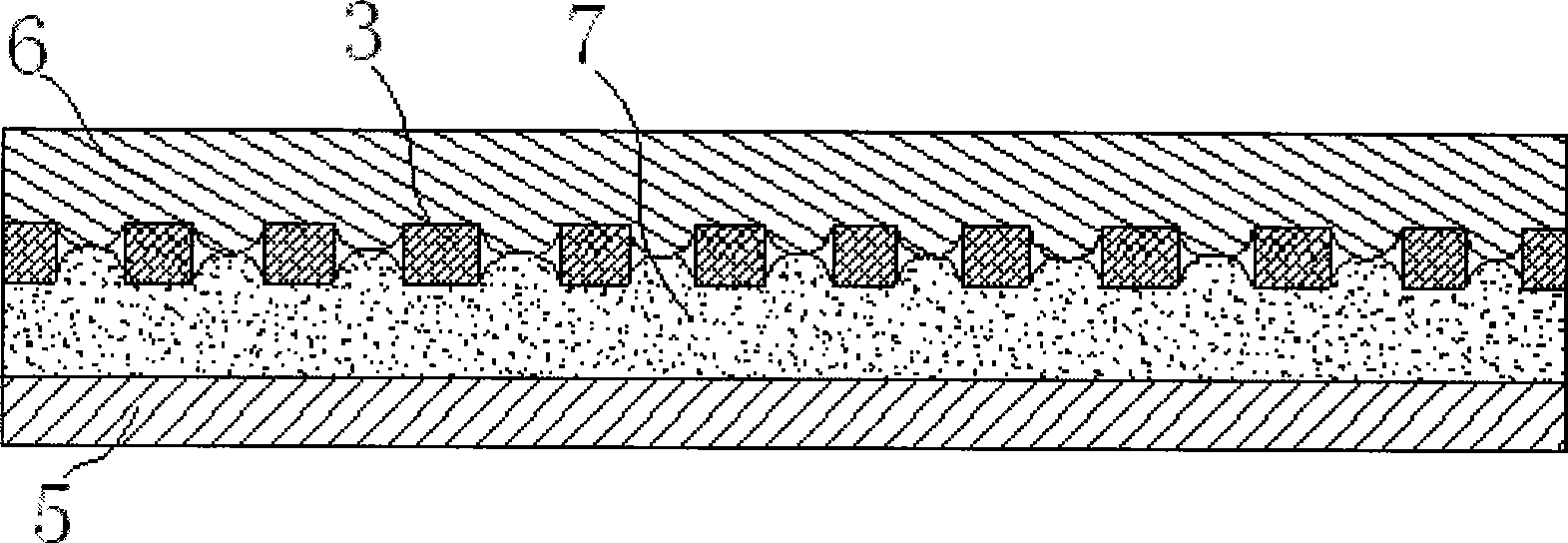

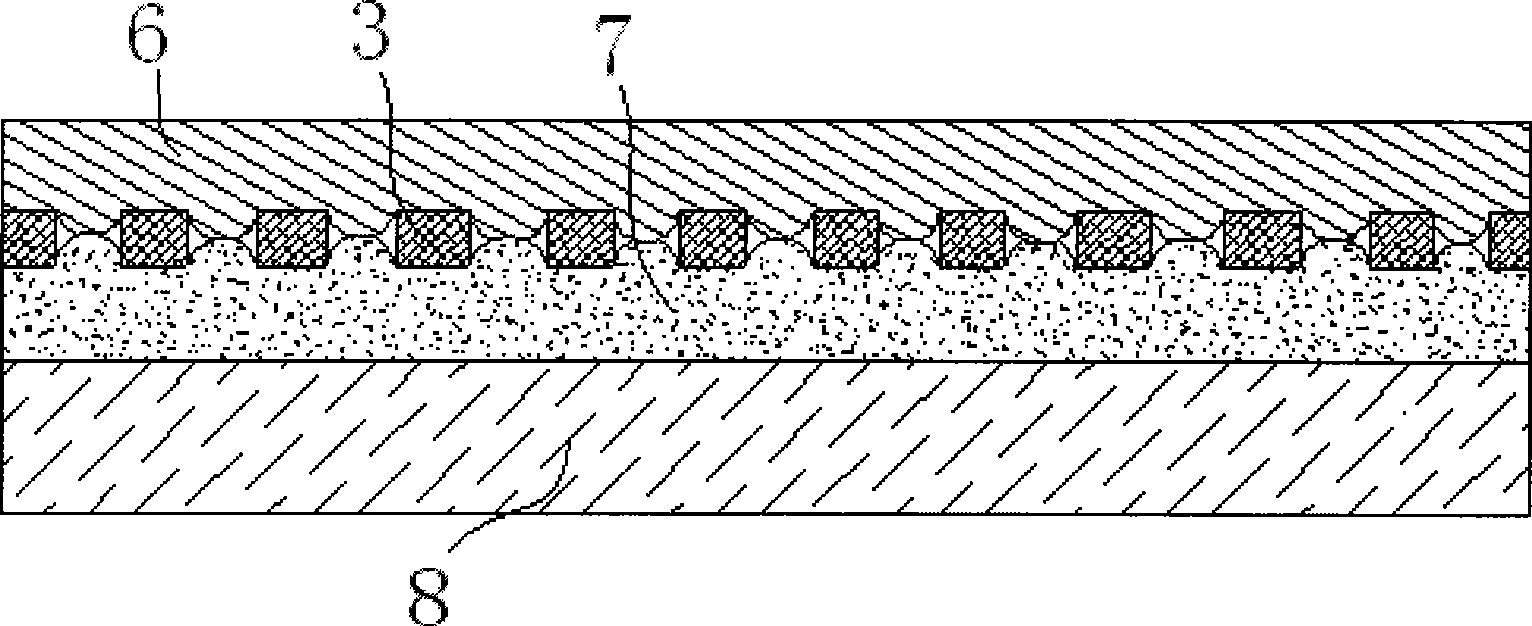

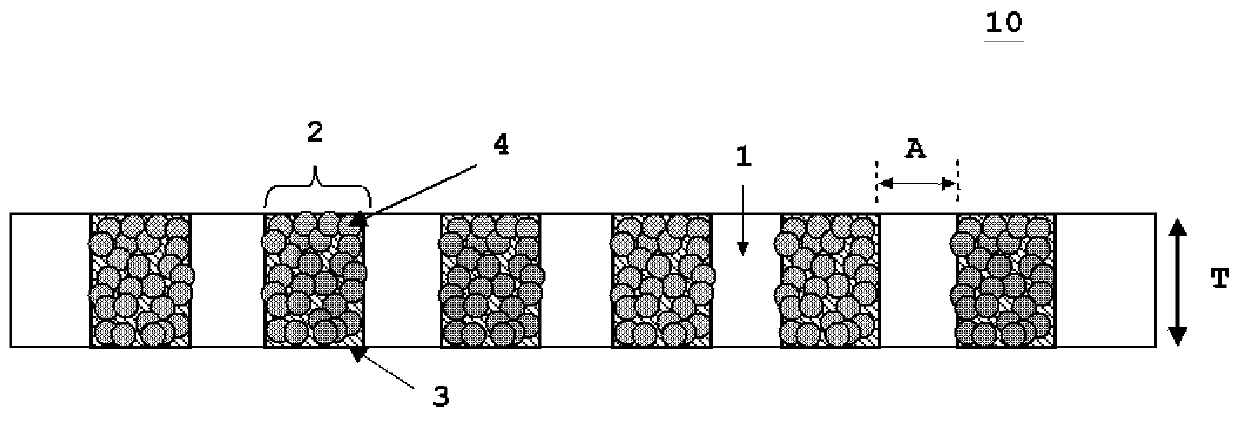

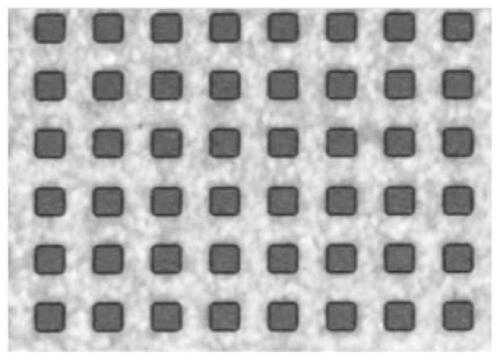

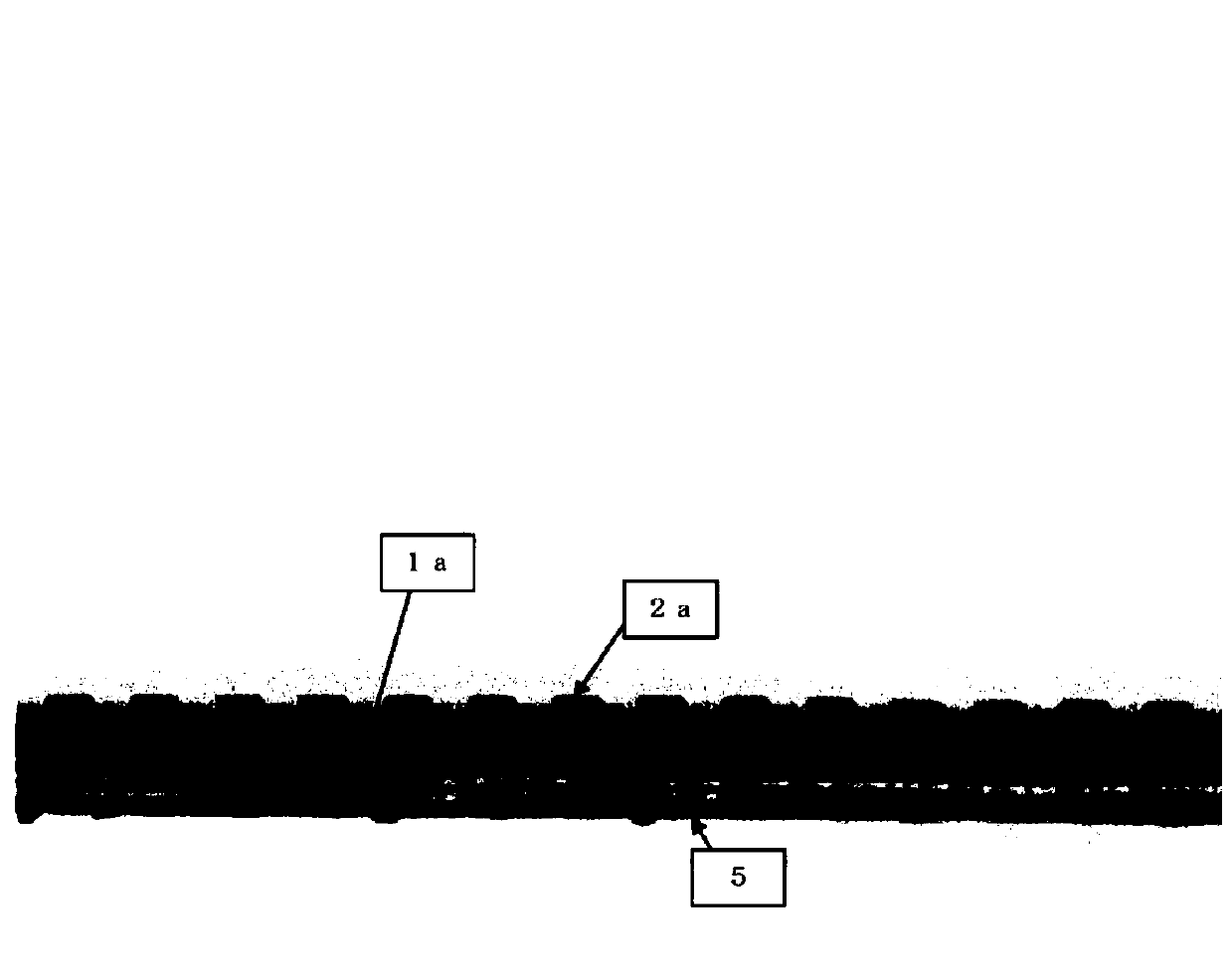

The invention provides an ultra-thin shielding film and a circuit board capable of changing circuit impedance, and a method for preparing same. The shielding film capable of changing the circuit impedance consists of an insulated coverage film layer, a metal foil layer, an anisotropic conductive adhesive layer and a protective release film layer; the metal foil layer is provided with meshes according to the impedance requirement design of the product and is arranged between the insulated coverage film layer and the anisotropic conductive adhesive layer; the surface of the anisotropic conductive adhesive layer is covered by the protective release film. The invention has the advantages that the ultra-thin layer of metal foil with a certain mesh dimension which is completely connected together is provided; the metal foil layer and the insulated layer have extremely high peeling strength, can durably bear heat impact and can be used for the multi-time pressing process of a soft / hard combination board; meanwhile, the thickness of a dielectric layer can be reduced and the aim of controlling the impedance can be achieved. Furthermore, the cost is low, the bending performance is excellent and the processing is easy.

Owner:GUANGZHOU FANGBANG ELECTRONICS

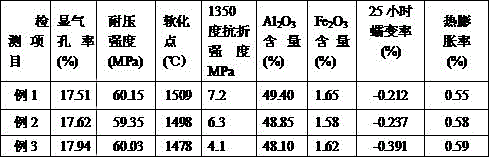

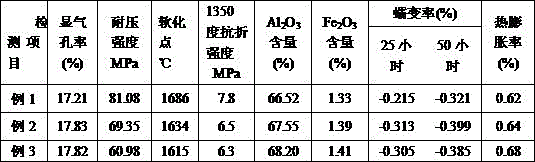

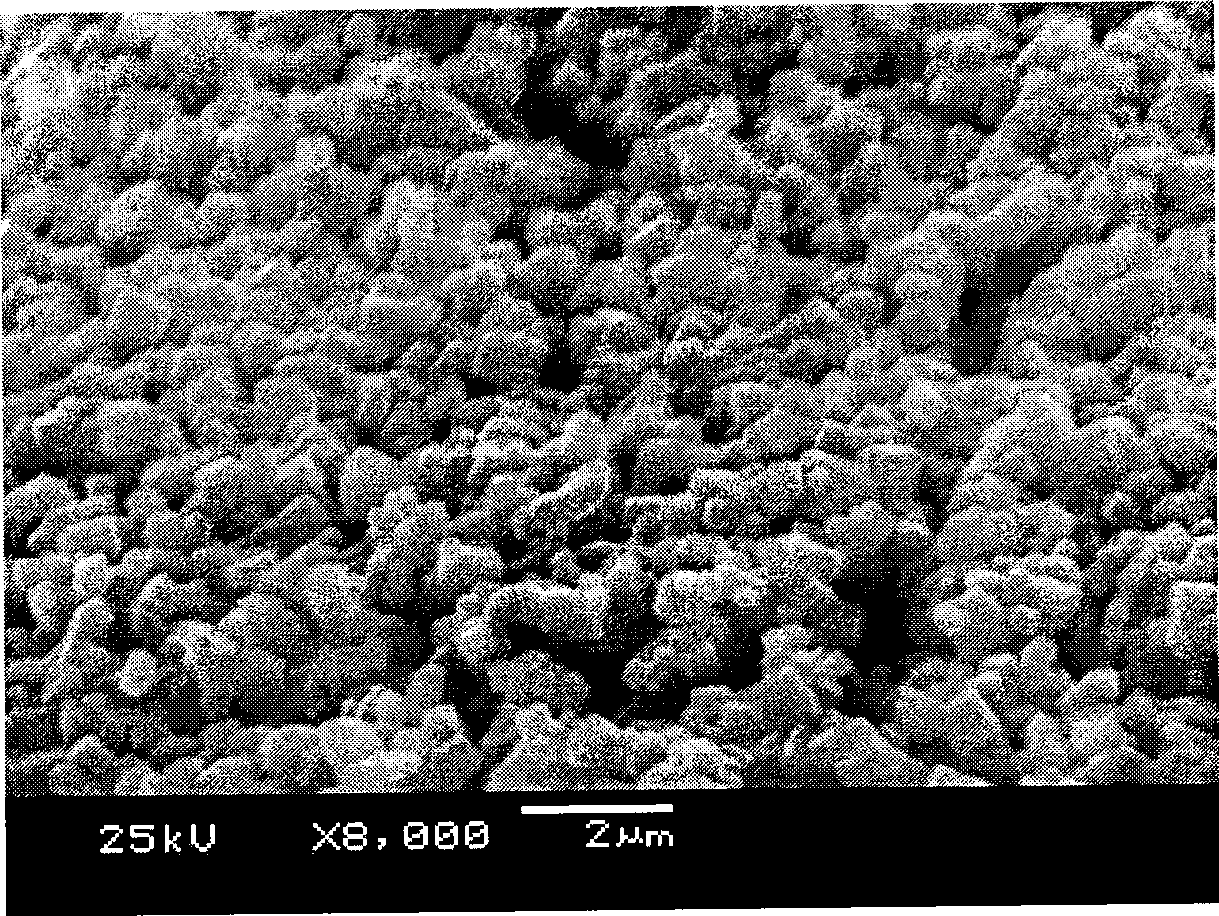

Preparation of high-temperature floamed ceramic

InactiveCN101323538AWide operating temperature rangeGuaranteed chemical stabilityCeramicwarePorosityContinuous use

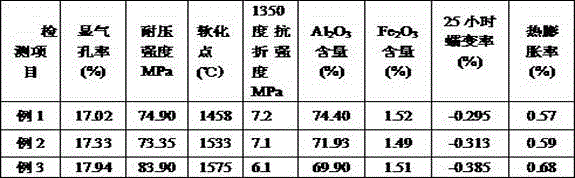

The invention provides a preparation method of a high temperature foam ceramics, which is characterized in that: zirconium diboride-aluminum oxide composite ceramic powder is prepared into ceramic slurry, polyurethane foaming plastic with certain bore diameter and porosity is soaked into the ceramic slurry so that the ceramic slurry evenly adheres to the surface of the pores of the polyurethane foaming plastic to form a ceramic slurry layer, which are then prepared into a polyurethane foaming plastic ceramic blank, and then are subjected to drying, degreasing and sintering, and the high temperature foam ceramics is prepared. The invention adjusts the high temperature resisting performance of the high temperature foam ceramics prepared by adjusting the ratio of zirconium diboride and aluminum oxide, therefore, the high temperature foam ceramics can resist high temperature and greatly expand working temperature scope; the high temperature foam ceramics prepared by the method can resist high temperature and keep chemical stability under high temperature condition; therefore, in high temperature working environment, the high temperature foam ceramics can be used repeatedly or continuously for the performances of thermal-shock resistance, oxidation resistance, molten steel erosion resistance, and the like, when being used in the filtration of molten steel, showing good performance.

Owner:SHANDONG UNIV OF TECH

Preparation method of charcoal material surface coating for resisting high temperature oxidation

The present invention is preparation process of high temperature oxidation resisting coating on the surface of carbon material. The preparation process includes the steps of: cleaning and stoving the surface of the carbon material, compounding slurring with silica powder, boron powder, water and adhesive in certain weight proportion, coating the slurry onto the surface of the carbon material through soaking, spraying or brushing to form slurry layer of 200-240 micron thickness, drying, heating in vacuum resistive furnace first at 400-500 deg.c for 10-20 min and then at 1420-1500 deg.c for 20-30 min, and cooling to obtain high temperature oxidation resisting ceramic coating. The present invention has simple technological process, high production efficiency, good repeatability and low production cost and is suitable for industrial production.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

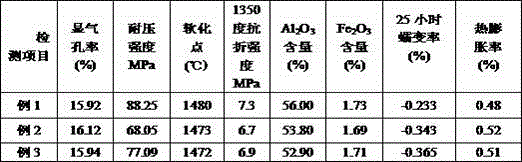

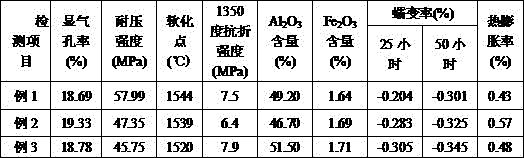

Bauxite composite refractory brick and preparation method and application thereof

The invention provides a bauxite composite refractory brick which comprises a main material and an additive, wherein the main material comprises the following raw materials by the mass percentage: 20%-35% of large bauxite clinker particles, 15%-30% of small bauxite clinker particles, 5%-15% of a combined clay fine powder, 15%-30% of a fine bauxite clinker powder, and 5%-20% of an andalusite micro-powder; the mass of the additive is 4.5%-5.5% of the mass of the main material. The invention also provides a preparation method and application of the bauxite composite refractory brick. The bauxite composite refractory brick is reasonable in composition collocation, good in thermal shock property, relatively good in thermal stability and relatively high in refractoriness under load, so as to improve the service life of a carbon roasting furnace using the bauxite composite refractory brick for constructing a flue wall.

Owner:济源市金峰耐火材料有限公司

Ultra-thin shielding film and circuit board capable of changing circuit impedance, and method for preparing same

ActiveCN101448362BReduce thicknessStrong enoughMagnetic/electric field screeningPrinted circuit detailsAnisotropic conductive adhesiveMetal foil

The invention provides an ultra-thin shielding film and a circuit board capable of changing circuit impedance, and a method for preparing same. The shielding film capable of changing the circuit impedance consists of an insulated coverage film layer, a metal foil layer, an anisotropic conductive adhesive layer and a protective release film layer; the metal foil layer is provided with meshes according to the impedance requirement design of the product and is arranged between the insulated coverage film layer and the anisotropic conductive adhesive layer; the surface of the anisotropic conductive adhesive layer is covered by the protective release film. The invention has the advantages that the ultra-thin layer of metal foil with a certain mesh dimension which is completely connected together is provided; the metal foil layer and the insulated layer have extremely high peeling strength, can durably bear heat impact and can be used for the multi-time pressing process of a soft / hard combination board; meanwhile, the thickness of a dielectric layer can be reduced and the aim of controlling the impedance can be achieved. Furthermore, the cost is low, the bending performance is excellent and the processing is easy.

Owner:GUANGZHOU FANGBANG ELECTRONICS

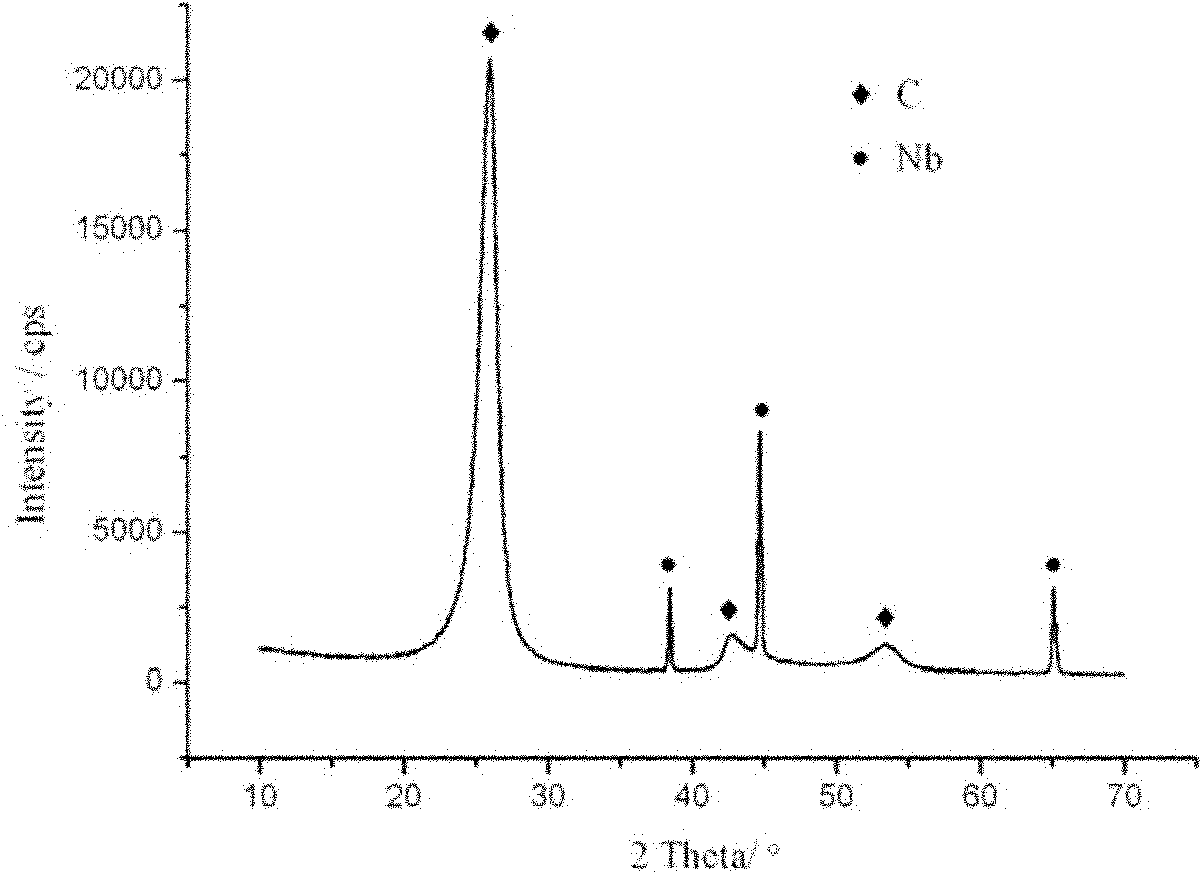

Method for preparing anti-oxidation Nb coating on surface of carbon material

InactiveCN102127737AImprove compactnessImprove uniformityVacuum evaporation coatingSputtering coatingOxidation resistantGraphite

The invention provides a method for preparing an anti-oxidation Nb coating on the surface of a carbon material. In the method, ultrahigh vacuum multifunctional magnetron sputtering coating equipment is adopted, metal Nb with the purity of 99.9 percent is taken as a target, 99.99 volume percent high-purity argon is taken as sputtering gas, and the anti-oxidation Nb coating is prepared on the surface of a graphite material through direct current magnetron sputtering. The anti-oxidation Nb coating prepared by the method has high compactness and uniformity, thermal shock resistance and high high-temperature oxidation resistance; the thickness of the coating is convenient to control by adjusting a magnetron sputtering process parameter, and the coating is convenient to prepare on a large scale; the temperature rise of a base material is low when the coating is prepared, and the components of the coating are uniform and stable; and the process is relatively simple and high in repeatability.

Owner:SHAANXI UNIV OF SCI & TECH

Method for coating silicon carbide on carbon material

ActiveCN101423422AThickness is easy to controlPrevent peelingElectrical resistance and conductanceAdhesive

The invention discloses a method for coating silicon carbide on a carbon material, which comprises the following steps: silicon powder, acetone, an additive and an adhesive are mixed and ultrasonically dispersed for 3 to 5 minutes to obtain a steady suspension. The carbon material covering Si can be obtained by performing the electrophoretic deposition of the Si on the surface of the carbon material and taking the carbon material as an electrode. The carbon material is dried at a temperature of between 100 and 150 DEG C and is heated and sintered in an electrical resistance furnace. The heating temperature is between 1,000 and 1,500 DEG C, and the SiC coating of the carbon material can be prepared after the thermal insulation is performed for 20 to 60 minutes. The method has the advantages of relatively simple technical process, good repetitiveness, and quick deposition process, and the obtained coating has controllable thickness and is uniform.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

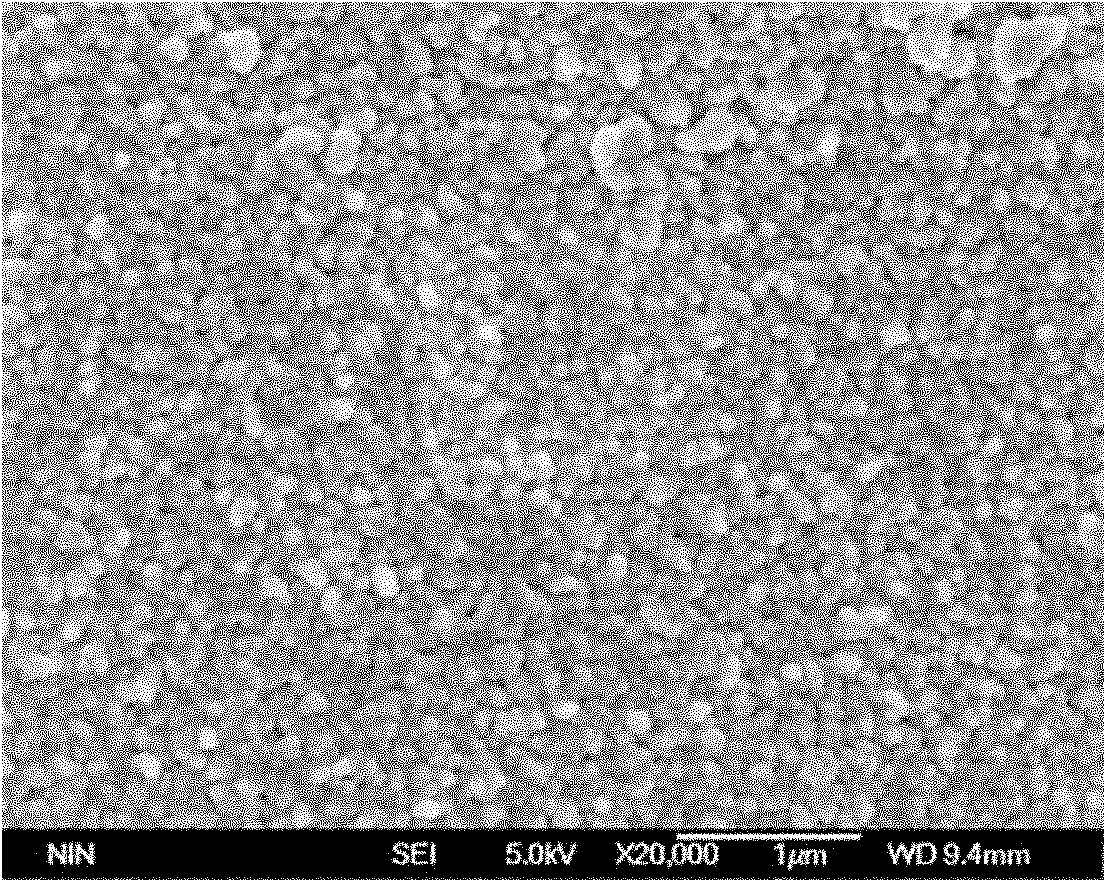

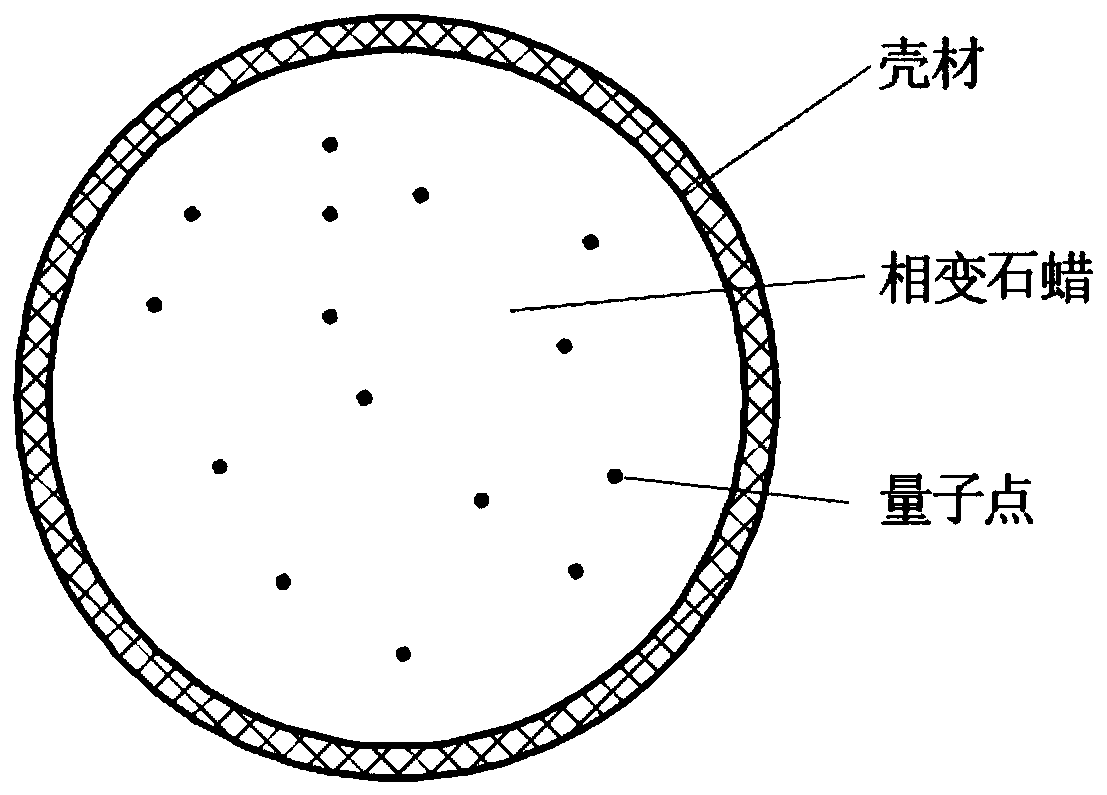

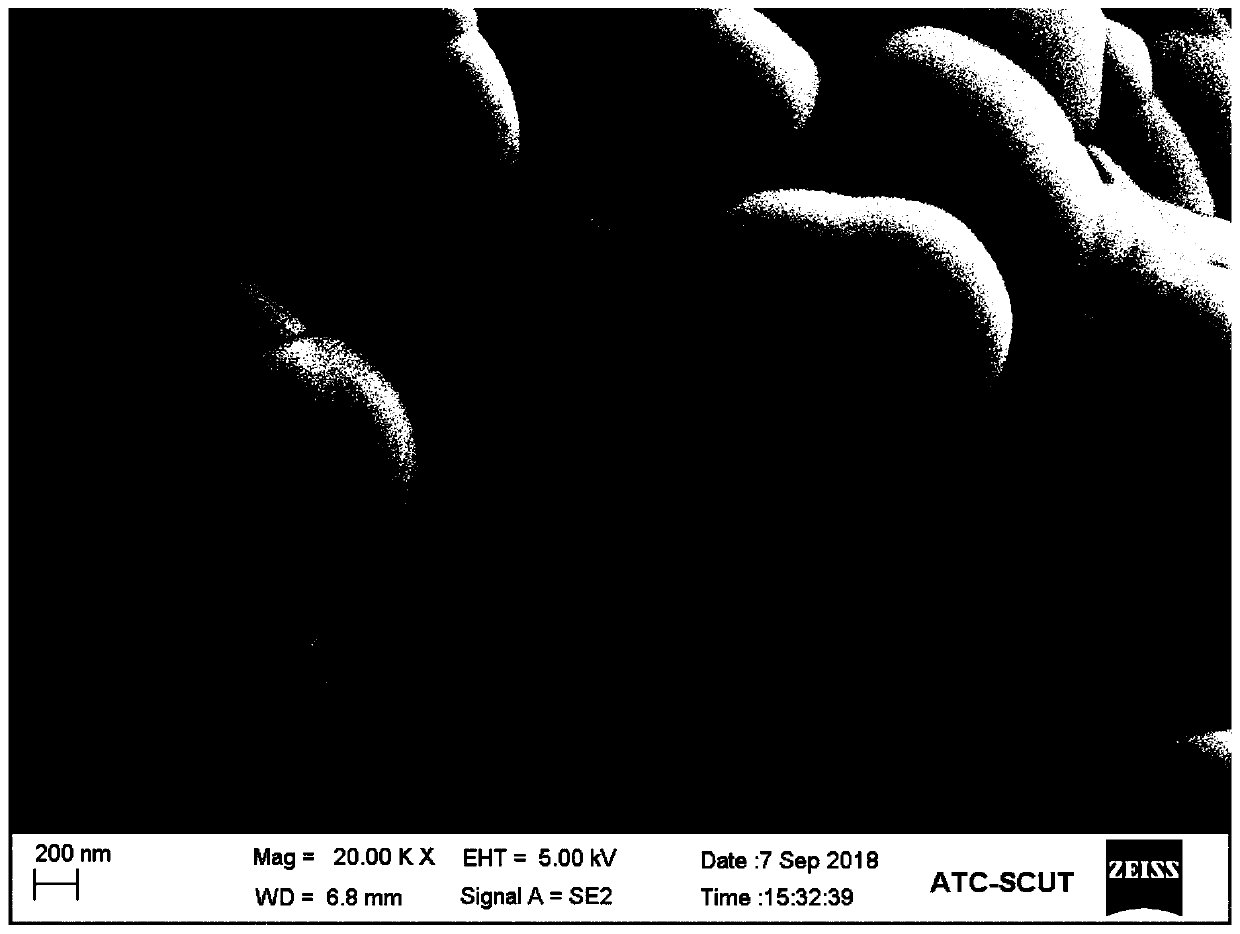

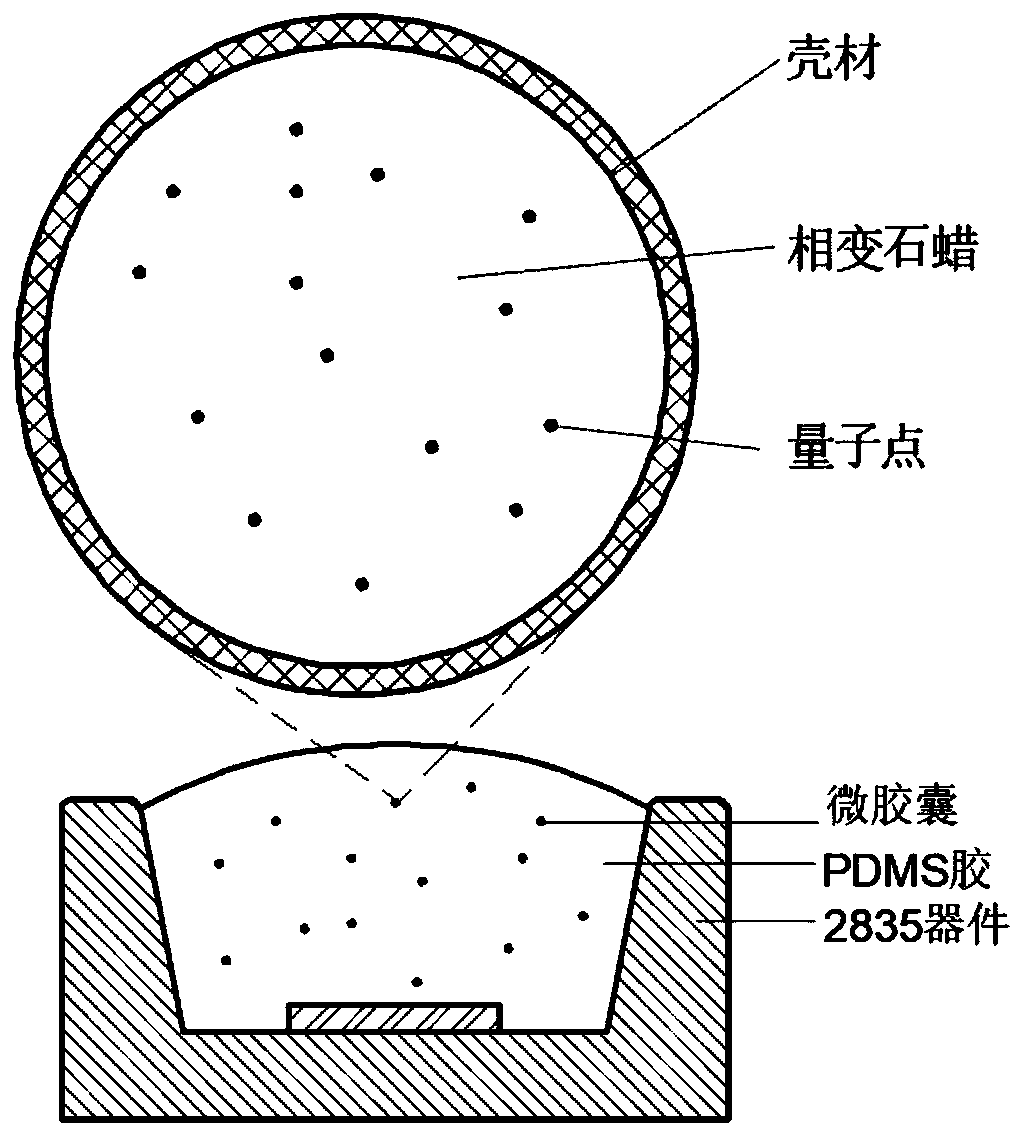

Quantum dot-wrapped phase-change paraffin microcapsule, LED device, and preparation methods of phase-change paraffin microcapsule and LED device

PendingCN110591688AStable light outputUniform light outputMaterial nanotechnologyHeat-exchange elementsParaffin waxMethacrylic acid copolymer

The invention belongs to the technical field of packaging preparation of light-emitting diode (LED) luminescent materials, and relates to a quantum dot wrapped phase-change paraffin microcapsule, an LED device and preparation methods of the phase-change paraffin microcapsule and the LED device. The quantum dot wrapped phase-change paraffin microcapsule comprises quantum dots, phase-change paraffinand methyl methacrylate-methacrylic acid copolymer shell material, wherein the quantum dots are dispersed and wrapped in the phase-change paraffin which is used as a spherical core of the microcapsule, and the methyl methacrylate-methacrylic acid copolymer outer shell coats the outer surface of the phase-change paraffin wax in a spherical shell shape. The LED device which contains the quantum dot-wrapped phase-change paraffin microcapsule comprises LED lamp beads and a colloid fluorescent coating, wherein the colloid fluorescent coating is doped with the quantum dot-wrapped phase-change paraffin microcapsule, and the colloid fluorescent coating coats light-emitting cup openings of the LED lamp beads. According to the invention, paraffin wax in a liquid state is encapsulated through microcapsules, so that the problem of insufficient scattering performance of quantum dots is solved by optimizing scattering; the surface area is increased through microencapsulation, and heat absorption iscarried out by phase change of the paraffin wax, so that the load of heat dissipation of LED is reduced.

Owner:SOUTH CHINA UNIV OF TECH

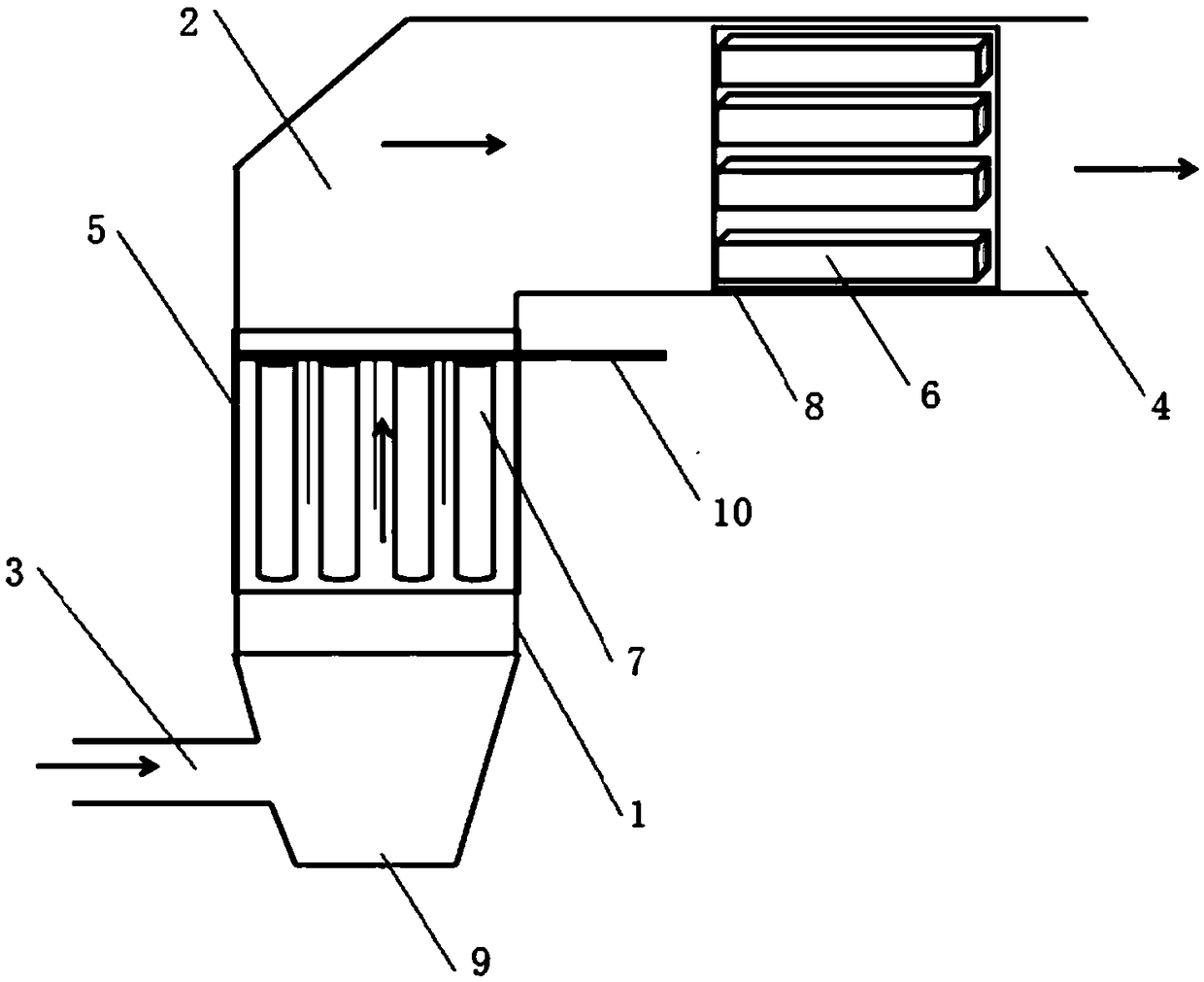

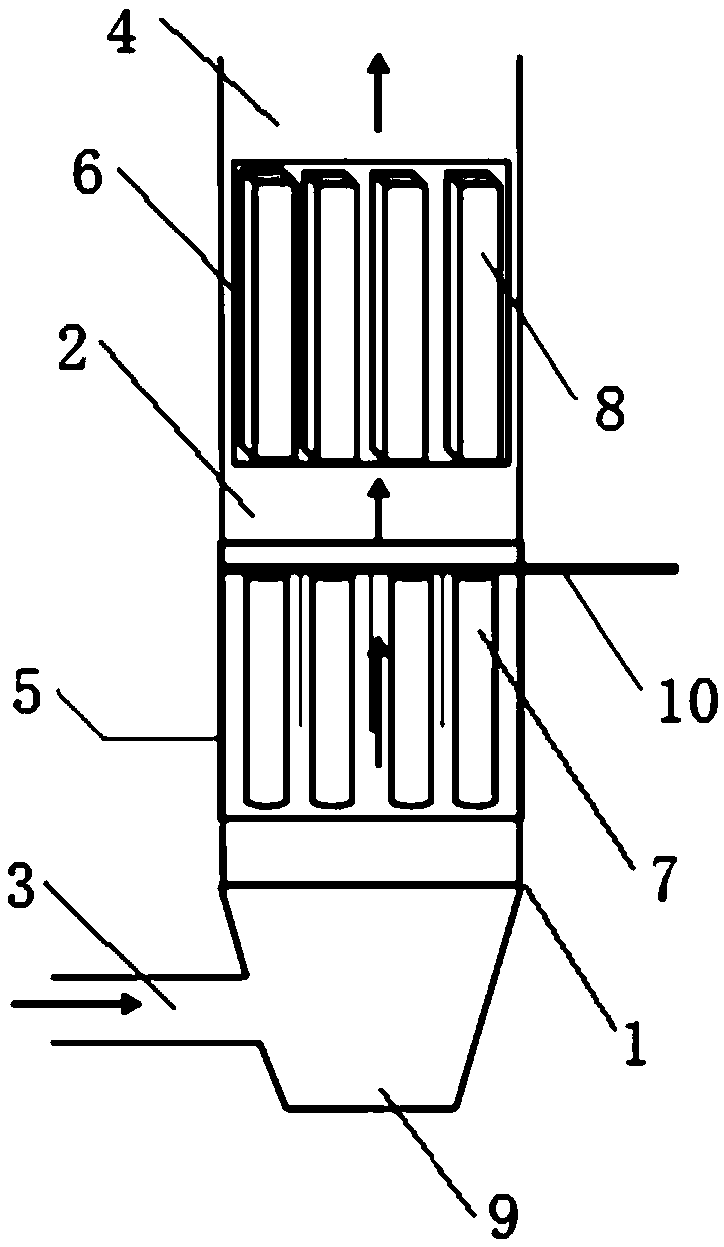

High-temperature flue gas dust removal and denitration integrated device and process thereof

InactiveCN108970396AHigh mechanical strengthLarge filter areaDispersed particle filtrationMetal fiberRare-earth element

The invention discloses a high-temperature flue gas dust removal and denitration integrated device which comprises a machine body, wherein a flue gas passage is formed inside the machine body; a fluegas inlet is formed at the lower part of the machine body; a flue gas outlet is formed at the upper part of the machine body and is conducted with the flue gas passage; a high-temperature dust removerand a SCR (Selective Catalytic Reduction) denitration reactor are sequentially mounted in a detachable mode in the machine body along a direction in which flue gas passes; the high-temperature dust remover comprises a plurality of filter cartridges regularly arranged and a dust purging collection assembly; the top end of each filter cartridge is open, and the bottom end of the filter cartridge issealed; each filter cartridge comprises at least one filter layer made of a metal fiber net; a plurality of ceramic honeycomb bodies regularly arranged are arranged in the SCR denitration reactor; each ceramic honeycomb body comprises a carrier and a catalyst distributed on the carrier; each catalyst is formed by V2O5 or rare earth elements or transition elements; each carrier adopts TiO2 or a molecular sieve or cordierite. The high-temperature dust remover and the SCR denitration reactor are mounted in a detachable mode; the filter cartridges made of the metal fiber nets are adopted; for each filter cartridge, the filtering area is not limited, filter pores are regularly arranged, and a through hole rate is high; the high-temperature flue gas dust removal and denitration integrated device is long in service life and has high-temperature resistance.

Owner:ZHEJIANG ZHENENG CATALYST TECH CO LTD

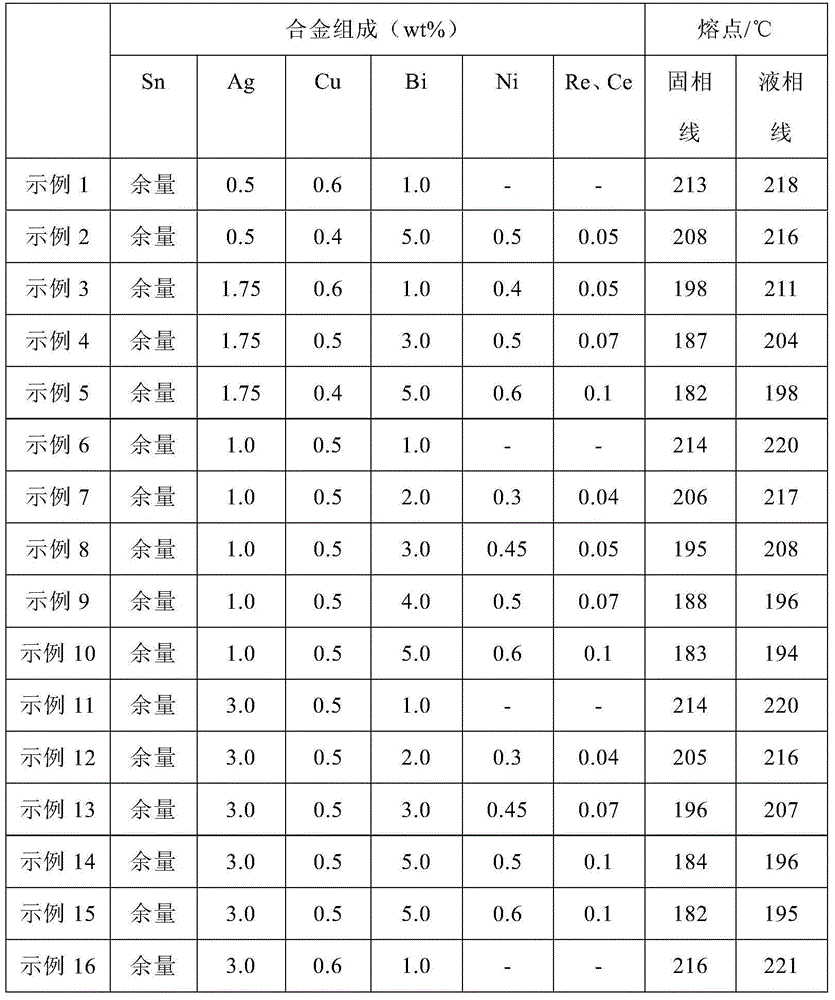

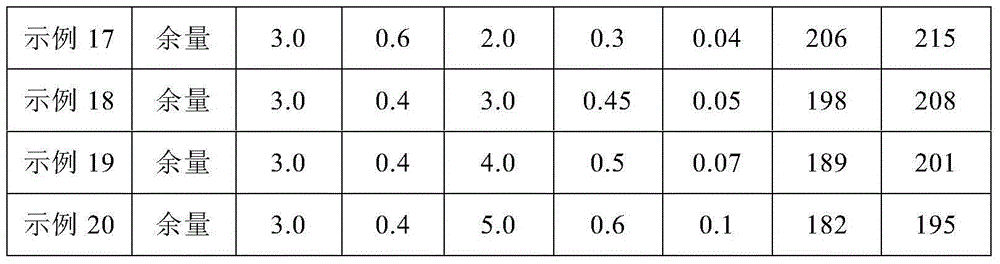

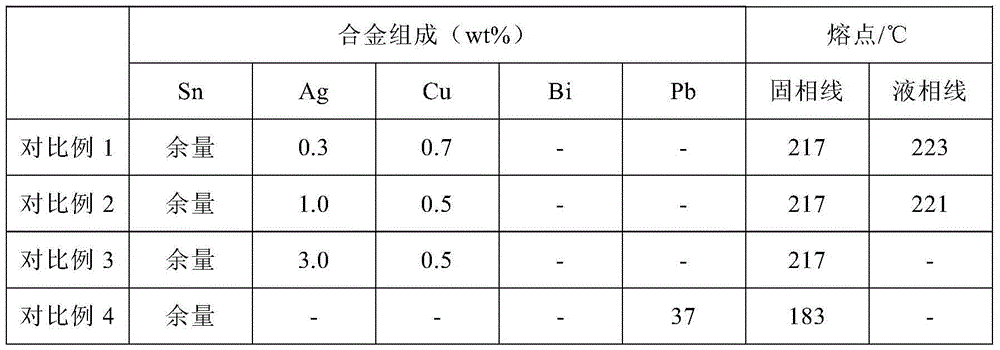

Novel low-melting-point lead-free solder

InactiveCN104439751AReduce difficultyLow melting pointWelding/cutting media/materialsSoldering mediaChemical compositionMetallurgy

The invention discloses novel low-melting-point lead-free solder. The chemical material of the novel low-melting-point lead-free solder comprises, by mass, 0.3-3.5% of Ag, 0.3-.7% of Cu, 0.8-6.0% of Bi, 0.1-0.6% of Ni, 0.01-0.15% of rare earth metal, and the balance Sn. The novel low-melting-point lead-free solder is low in cost and has wet property, welding spot reliability, spreading property and heat shock resistance and other excellent performance. Above all, the novel low-melting-point lead-free solder is low in melting point, the difficulty of reflow soldering can be reduced, the novel low-melting-point lead-free solder is particularly suitable for the development tendency of light, thin, short and minimized electronic products currently, and energy conservation, emission reduction and energy consumption reduction are facilitated.

Owner:YIK SHING TAT INDUSTRIALCO LTD +1

Heat-resistance stainless steel exhaust pipe and manufacturing method thereof

InactiveCN101949474AEasy to processGuaranteed high temperature performanceFoundry mouldsProcess efficiency improvementHeat resistanceManganese

The invention discloses a heat-resistance stainless steel exhaust pipe and a manufacturing method thereof. According to a formula, the heat-resistance stainless steel exhaust pipe comprises the following components in part by mass: 11.42 to 38.66 parts of low-carbon steel, 0 to 70 parts of material remelted steel, 0.3 to 0.8 part of electrolytic manganese, 0.4 to 0.7 part of ferrosilicon, 4.1 to 13.75 parts of electrolytic nickel, 13 to 43.5 parts of ferrochromium and 0.05 to 0.1 part of deoxidizer. The preparation method comprises the following steps of: performing shot blasting, preparing materials, smelting, pouring, filling molds, shaking out sand and the like. The heat-resistance stainless steel exhaust pipe overcomes a large number of defects in the prior art, and has the advantages of high product size precision, durability, low deformation rate, simple preparation process and high yield.

Owner:西峡飞龙特种铸造有限公司

Low-creep high-rcasting refractory brick and preparation method and application thereof

InactiveCN106187241AResistant to thermal shockImprove thermal shock resistanceBrickThermal stability

The invention provides a low-creep high-rcasting refractory brick. The low-creep high-rcasting refractory brick comprises a main material and an additive, the main material is mainly prepared from, by mass, 20%-40% of flint clay large particles, 20%-35% of flint clay small particles, 15%-25% of flint clay fine powder, 5%-15% of bonding clay fine powder and 5%-15% of bauxite clinker micro powder. The mass of the additive accounts for 4.5%-5.5% that of the main material. The invention further provides a preparation method and application of the low-creep high-rcasting refractory brick. The low-creep high-rcasting refractory brick is reasonable in component matching and has the thermal shock property, good thermal stability and high refractoriness under load, and therefore the service life of a carbon calcinatory with a flame path wall built by the low-creep high-rcasting refractory brick is prolonged.

Owner:济源市金峰耐火材料有限公司

Method for making gradient silicon carbide coating by electrophoresis codeposition

InactiveCN101565848ASimple processGood repeatabilityElectrolytic coatingsElectrophoresisOxidation resistant

The invention discloses a method for making gradient silicon carbide coating by electrophoresis codeposition, which includes the following steps: by ultrasonic processing, suspending liquid A is prepared by silica powder, carbon soot, caking agent polyvinyl butyral, acetone and additive n-butylamine which are mixed according to the mass proportion of 2-16:20:15:100:1; by ultrasonic processing, suspending liquid B is prepared by silica powder, carbon soot, polyvinyl butyral, acetone and n-butylamine which are mixed according to the mass proportion of 16-30:20:15:100:1; by ultrasonic processing, suspending liquid C is prepared by silica powder, carbon soot, polyvinyl butyral, acetone and n-butylamine which are mixed according to the mass proportion of 15-40:10:15:100:1; by ultrasonic processing, suspending liquid D is prepared by silica powder, carbon soot, polyvinyl butyral, acetone and n-butylamine which are mixed according to the mass proportion of 40-70:10:15:100:1; with graphite material as the anode, under a constant potential mode the suspending liquids above are deposited, dried, heated to be between 1200 DEG C and 1600 DGE C, and preserved at the temperature for 20 to 60 minutes. The invention has the advantages of simple process, good thermal-shock resistance and oxidation resistance, controllable coating thickness and uniform coating.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Mullite composite refractory brick and preparation method and application thereof

The invention provides a mullite composite refractory brick which comprises a main material and an additive; the main material comprises the following raw materials by the mass percentage: 5%-15% of large bauxite clinker particles, 15%-30% of large mullite particles, 10%-20% of small sillimanite particles, 10%-30% of small mullite particles, 5%-15% of a kaolin micro-powder, and 15%-35% of a fine mullite powder; the mass of the additive is 4.5%-5.5% of the mass of the main material. The invention also provides a preparation method and an application of the mullite composite refractory brick. The mullite composite refractory brick is reasonable in composition collocation, has the advantages of good thermal shock property, relatively good thermal stability, and relatively high refractoriness under load, so as to improve the service life of a carbon roasting furnace using the bauxite composite refractory brick for constructing a flue wall.

Owner:济源市金峰耐火材料有限公司

Low-creep fire brick, and preparation method and application thereof

The invention provides a low-creep fire brick. The low-creep fire brick is prepared from a main material and an additive, wherein the main material is prepared from the following raw materials in percentage by mass: 20 to 40 percent of large flint clay particles, 20 to 30 percent of small sillimanite particles, 15 to 40 percent of binding clay fine powder and 5 to 15 percent of bauxite clinker micro powder; the mass of the additive is 4.5 to 5.5 percent of that of the main material. The invention also provides a preparation method and application of the low-creep fire brick. The low-creep fire brick provided by the invention is reasonable in component matching and has good thermal-shock property, better thermal stability and higher refractoriness under load, so that the service life of a carbon roasting furnace with a flue wall built by using the low-creep fire brick is increased.

Owner:济源市金峰耐火材料有限公司

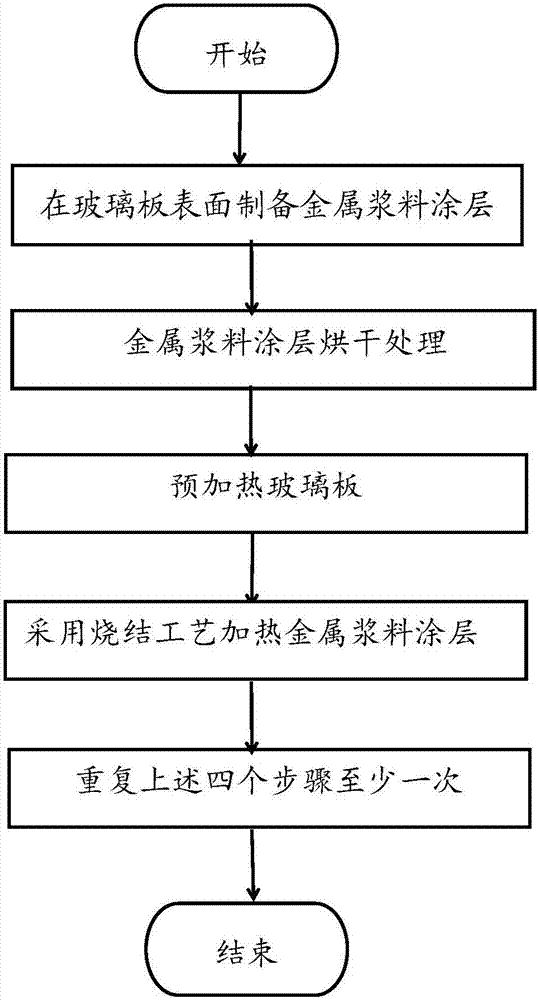

Method for preparing metallized layer for vacuum glass metal sealing

The invention discloses a method for preparing a metallized layer for vacuum glass metal sealing. The method comprises the following steps: 1, preparing a metal slurry coating on the surface of a to-be-sealed area at the periphery of a glass plate; 2, drying the metal slurry coating; 3, preheating the glass plate to the temperature of 200-350 DEG C, and maintaining the temperature in a set time period; 4, heating the metal slurry coating by adopting a sintering process, and enabling the metal slurry coating to be consolidated onto the glass plate so as to form a metallized layer; and 5, repeating the steps 1-4 at least one time, and completing the preparation of the metallized layer for vacuum glass metal sealing. The problems that the strength of a sealed edge is low and the gas tightness is poor when the vacuum glass is sealed by a metal brazing process are solved, the strength and gas tightness of the vacuum glass sealed edge can be obviously improved, and the yield and service life of vacuum glass production are further improved.

Owner:LUOYANG LANDGLASS TECH CO LTD

Flint-clay composite refractory brick as well as preparation method and application thereof

The invention provides a flint-clay composite refractory brick, which is prepared from a main material and an additive, wherein the main material comprises the following raw materials in percentage by mass: 6 to 12 percent of bauxite clinker large particle, 7 to 28 percent of flint clay large particle, 15 to 27 percent of andalusite small particle, 5 to 10 percent of flint clay small particle, 15 to 27 percent of andalusite fine powder, 5 to 10 percent of flint clay fine powder and 5 to 14 percent of kaolin micro powder; the mass of the additive is 4.5 to 5.5 percent of that of the main material. The invention also provides a preparation method and application of the flint-clay composite refractory brick. The flint-clay composite refractory brick is reasonable in the matching of components, and further has favorable heat shock resistance, better heat stability and higher refractoriness under load, so as to improve the service life of a carbon roasting furnace of which the flue wall is built by applying the flint-clay composite refractory brick.

Owner:济源市金峰耐火材料有限公司

Novel composite conductive ceramic and method for producing the same

InactiveCN101429021ACorrosion resistanceHigh temperature resistantStrontium titanium oxideNumerical range

The invention relates to the field of materials, in particular to a conducting ceramic material, and discloses a novel composite conducting ceramic and a method for preparing the same. The constitution formula of the novel composite conducting ceramic is xLaAlO3:(1-x)SrTiO3, wherein x is a mole number of which the numerical range is between 0.001 and 0.015. The method for preparing the composite conducting ceramic comprises the following steps: grinding and mixing a strontium titanate substrate raw material with lanthanum aluminate evenly; tabletting the mixture at a pressure of between 8 and 12 MPa; and baking the mixture at a temperature of between 1,200 and 1,400 DEG C for 4 to 8 hours. The mol ratio of the strontium element in the strontium titanate matrix raw material to the lanthanum aluminate is (1-x) to x, wherein x is between 0.001 and 0.015. The new novel composite conducting ceramic has the performances of electrical conductivity, corrosion resistance, high temperature resistance, high strength, innocuity, thermal conductivity and the like, and is applicable to sensors, electric heating warming, industrial heating, drying and conductive ceramic for shielding electromagnetic waves for construction.

Owner:SHANGHAI NORMAL UNIVERSITY

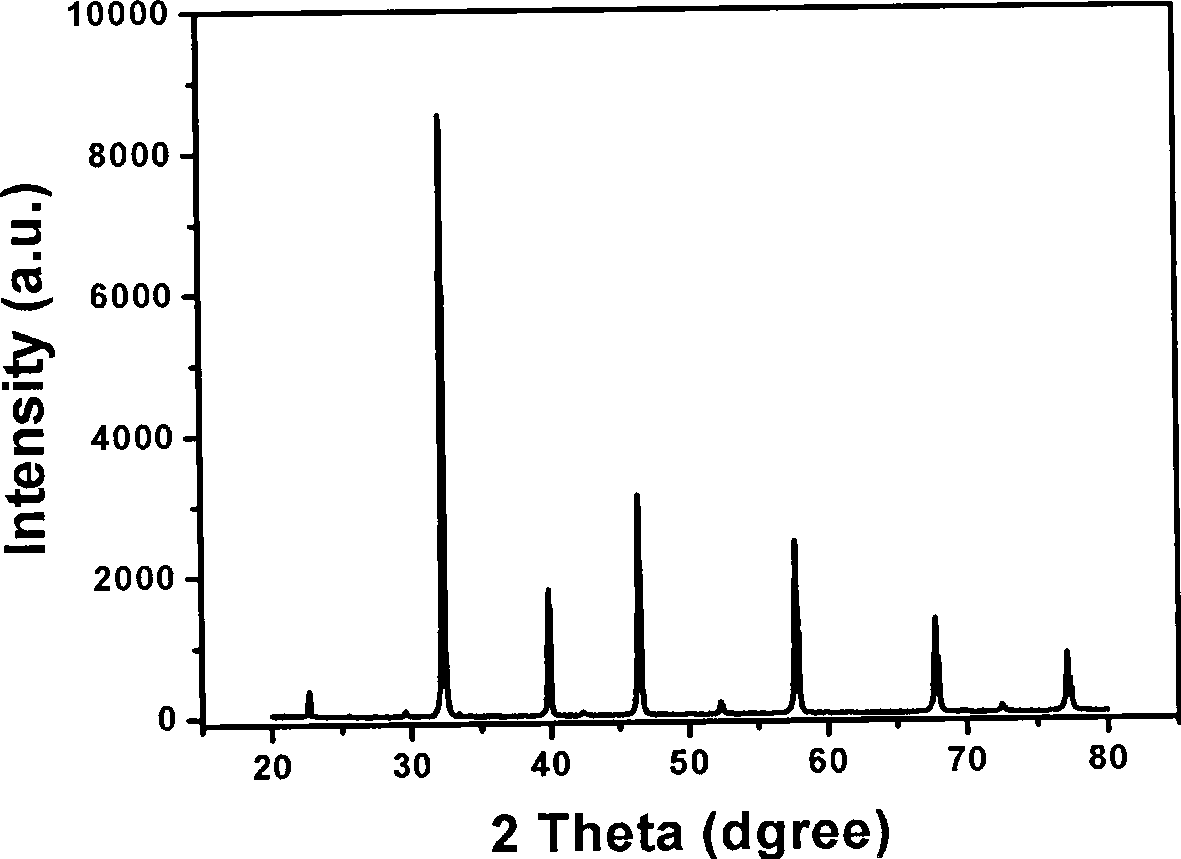

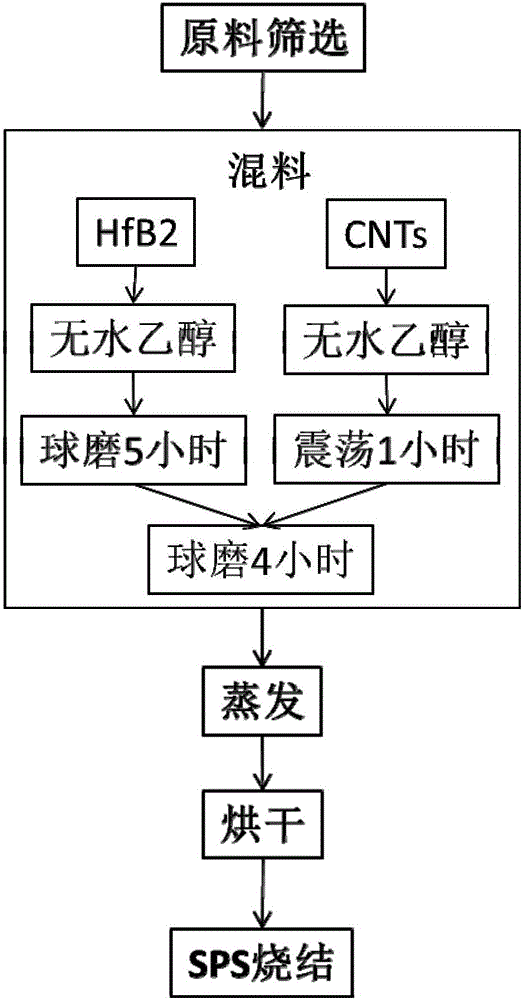

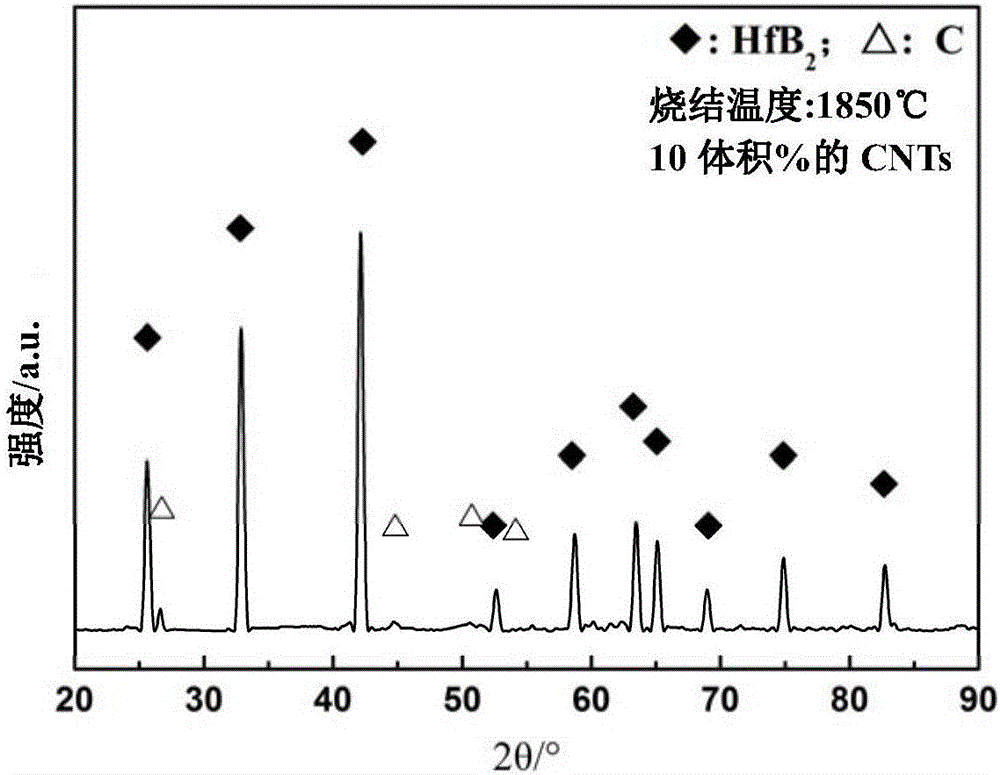

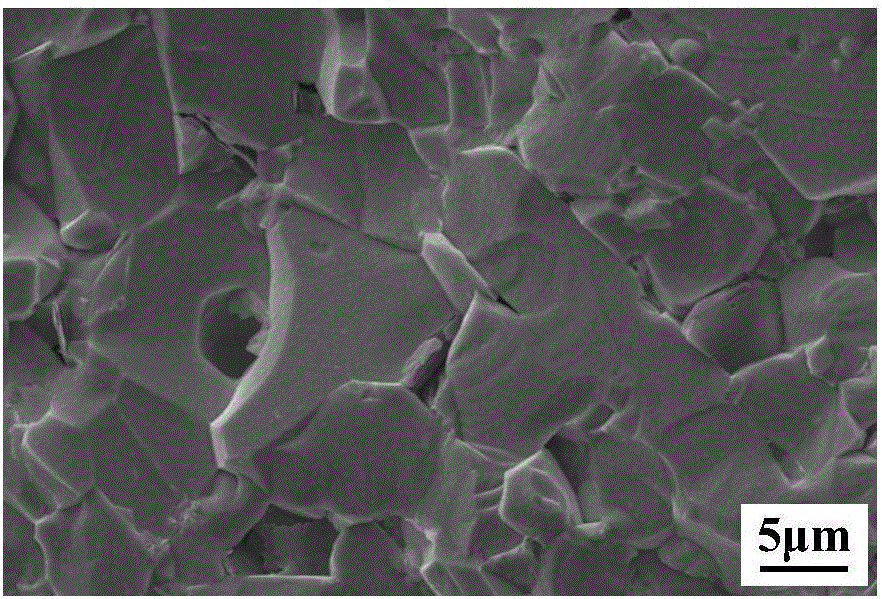

Carbon nanotube toughened hafnium diboride super-high-temperature ceramic composite material and preparing method thereof

InactiveCN106518085AImprove fracture toughnessImprove thermal shock resistanceCeramic compositeCarbon nanotube

Owner:HARBIN INST OF TECH

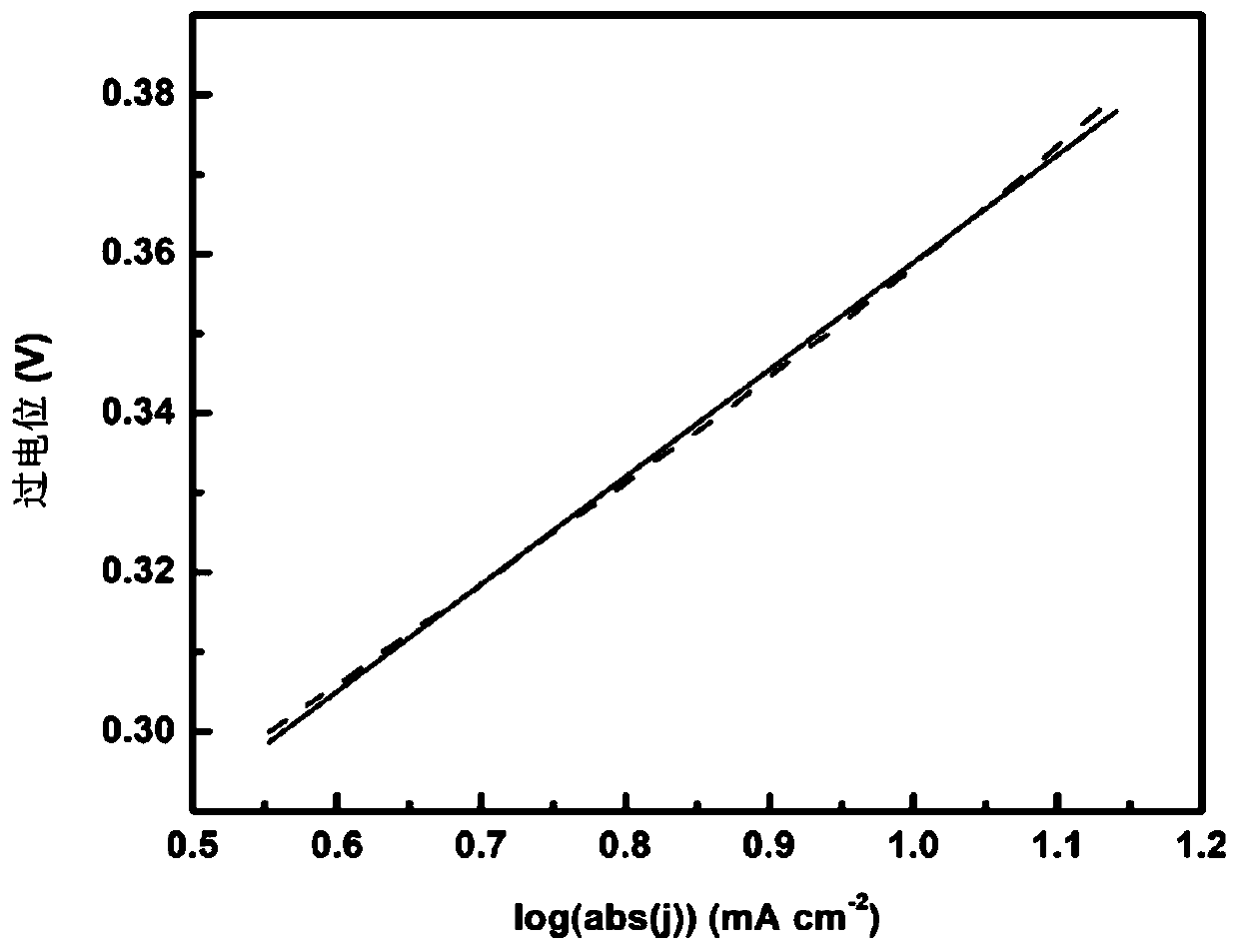

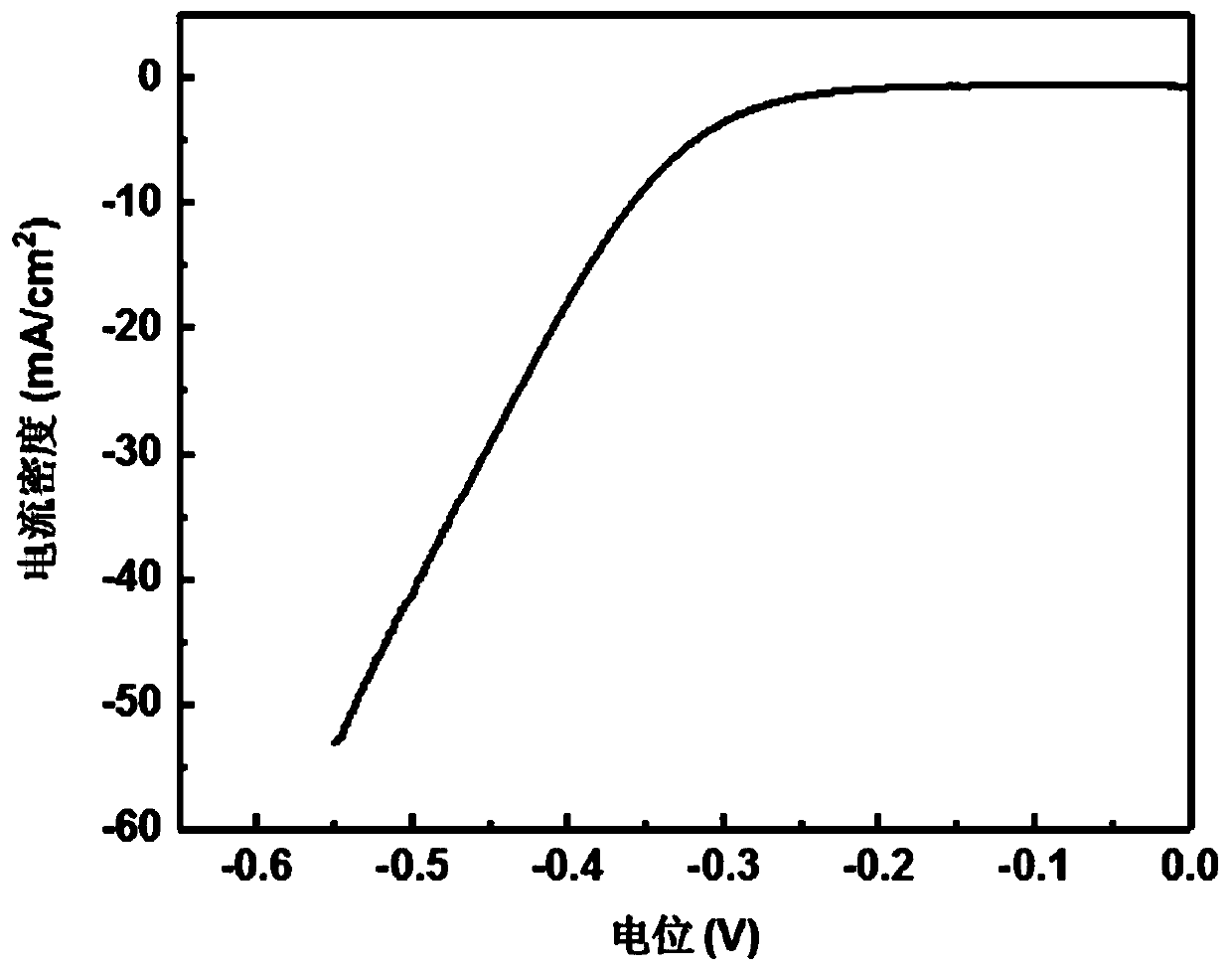

Mo-S/NF hydrogen evolution material, and preparation method and application thereof

InactiveCN111359636AImprove hydrogen evolution performanceImprove adsorption capacityPhysical/chemical process catalystsElectrodesThioureaThio-

The invention relates to a Mo-S / NF hydrogen evolution material, and a preparation method and an application thereof. The preparation method comprises the following steps: 1, mixing ammonium tetrathiomolybdate, thiourea and water, and carrying out ultrasonic dispersion to obtain a mixed solution; 2) adding the mixed solution into a reaction kettle, putting foamed nickel as a carrier into the reaction kettle, and performing a hydrothermal reaction to obtain Mo-S / NF; and 3) calcining the Mo-S / NF under an oxygen-free condition to obtain the Mo-S / NF hydrogen evolution material. The hydrogen evolution material is applied to an electrocatalytic hydrogen evolution reaction. Compared with like materials in the prior art, the Mo-S / NF hydrogen evolution material prepared in the invention is low in raw material cost, simple in preparation mode and good in hydrogen evolution effect in an alkaline solution, and is expected to face industrial development.

Owner:SHANGHAI INST OF TECH

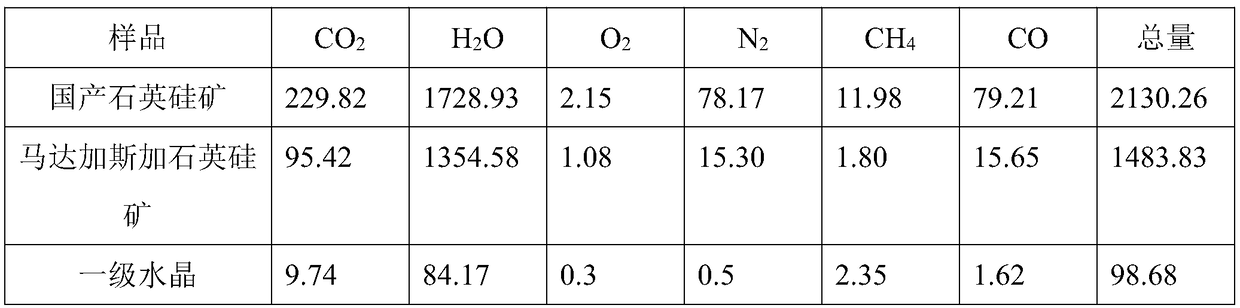

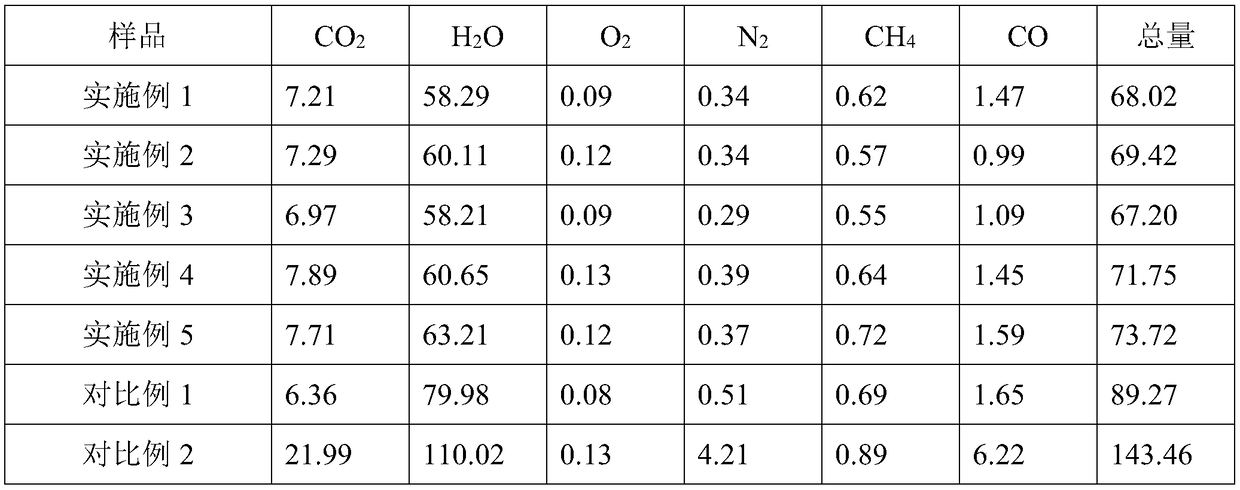

Ultra-pure color-spot-free high-end fully-transparent quartz material and preparation method and application thereof

The invention discloses an ultra-pure color-spot-free high-end fully-transparent quartz material and a preparation method and application thereof. Domestic quartz silicon ores are subjected to purification treatment through the processing steps of concentration of quartz silicon ores, water quenching, aqua regia impurity removing, esterification, floatation, magnetic separation, high-temperature vacuum treatment, ultrasonic purification and the like, and the ultra-pure quartz material for preparing color-spot-free high-end fully-transparent quartz glass ingots can be obtained. According to theultra-pure color-spot-free high-end fully-transparent quartz material and the preparation method and the application thereof, by combining the requirement for industrial production scales, the technological conditions for microwave processing and production of the ultra-pure color-spot high-end fully-transparent quartz material are further improved; particularly for the source of ultra-pure quartz raw materials in China, the production technological conditions for producing the ultra-pure quartz raw materials by the domestic quartz silicon ores are truly provided, the production technologicalconditions are mature and reasonable and have a stable technical effect, and technological supports are provided for scale production of the ultra-pure quartz glass ingots, and truly lowering of theproduction cost of the ultra-pure quartz glass ingots.

Owner:HUNAN UNIV OF TECH

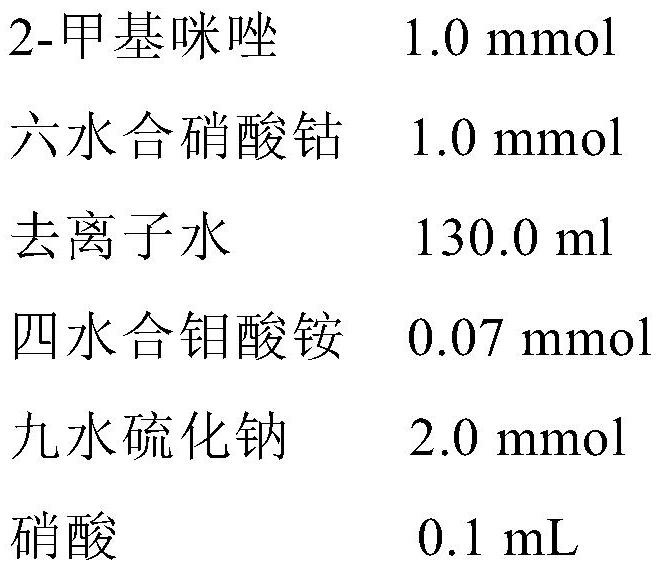

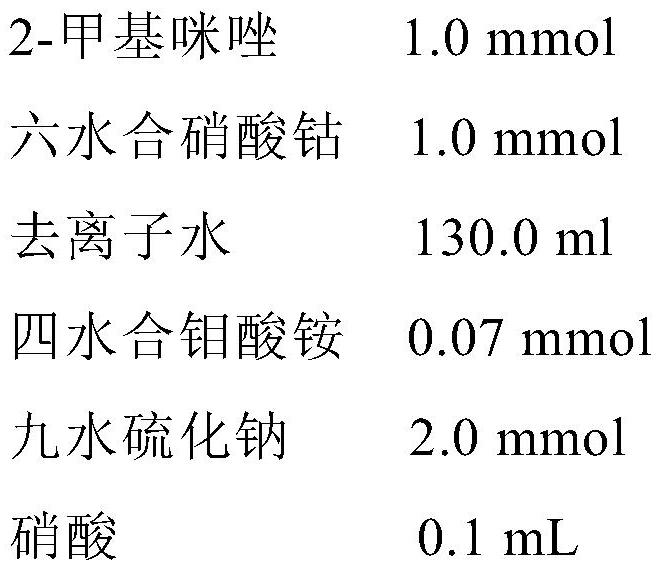

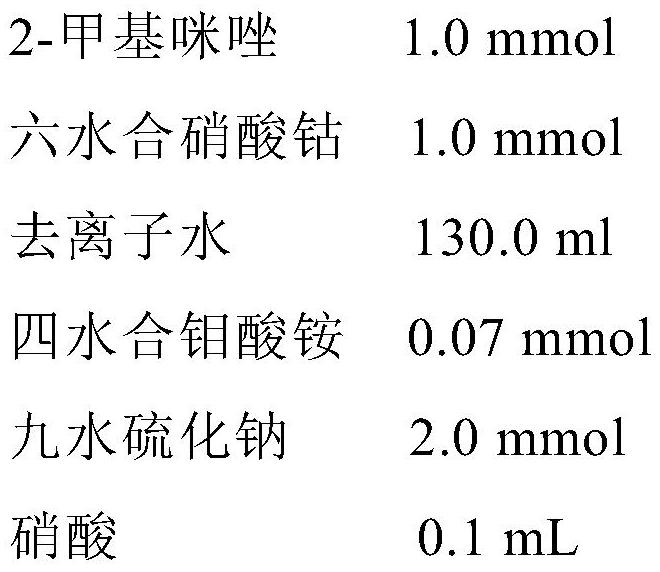

Molybdenum sulfide-coated cobalt-MOF/NF hydrogen evolution material, in-situ synthesis method and application

ActiveCN113249753AGood hydrogen evolution effectLow costElectrodesHydration reactionSODIUM SULFIDE NONAHYDRATE

The invention relates to a molybdenum sulfide-coated cobalt-MOF / NF hydrogen evolution material, an in-situ synthesis method and application. The method comprises the following steps: preparing a mixed aqueous solution A of 2-methylimidazole and cobalt nitrate hexahydrate; putting a foam liquid into the mixed aqueous solution A prepared in the step S1, and conducting standing and soaking to obtain Co-MOF / NF; mixing ammonium molybdate hydrate, sodium sulfide nonahydrate and deionized water to obtain a mixed solution B; and transferring the Co-MOF / NF into the mixed solution B, and carrying out a constant potential electrodeposition reaction to obtain MoS2-coated Co-MOF / NF. Compared with the prior art, the preparation method has the advantages that the flaky Co-MOF is self-loaded on the NF, so that the specific surface area of the material is increased, the contact area of the material and water is increased, hydrogen is easier to prepare, meanwhile, the nano structure of the material is improved, and the hydrogen evolution performance and stability of the material are improved.

Owner:SHANGHAI INST OF TECH

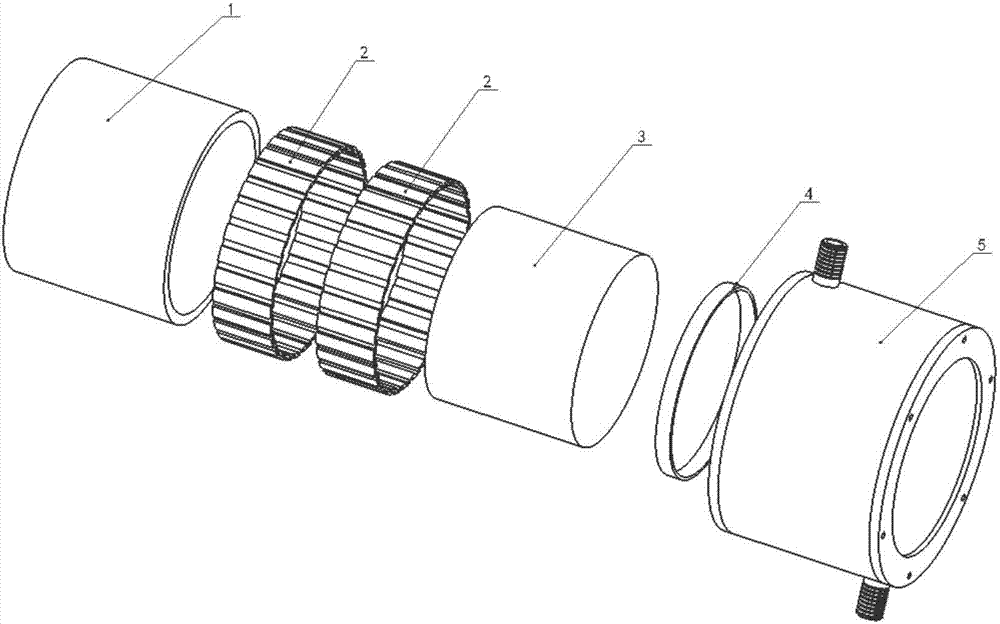

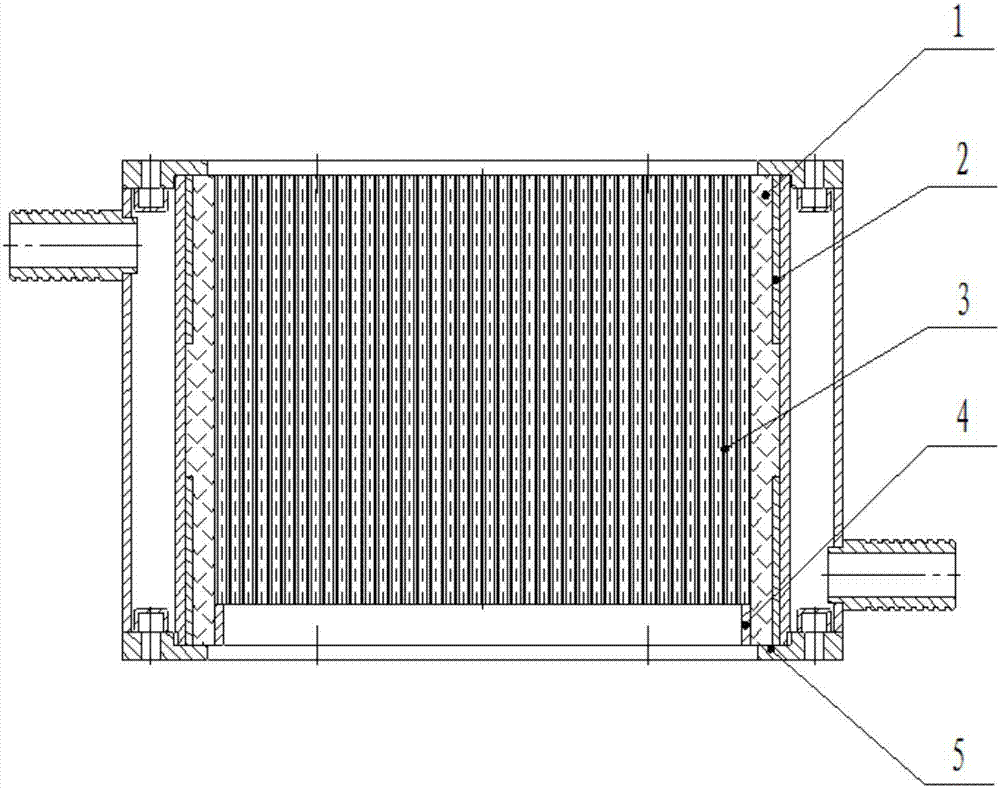

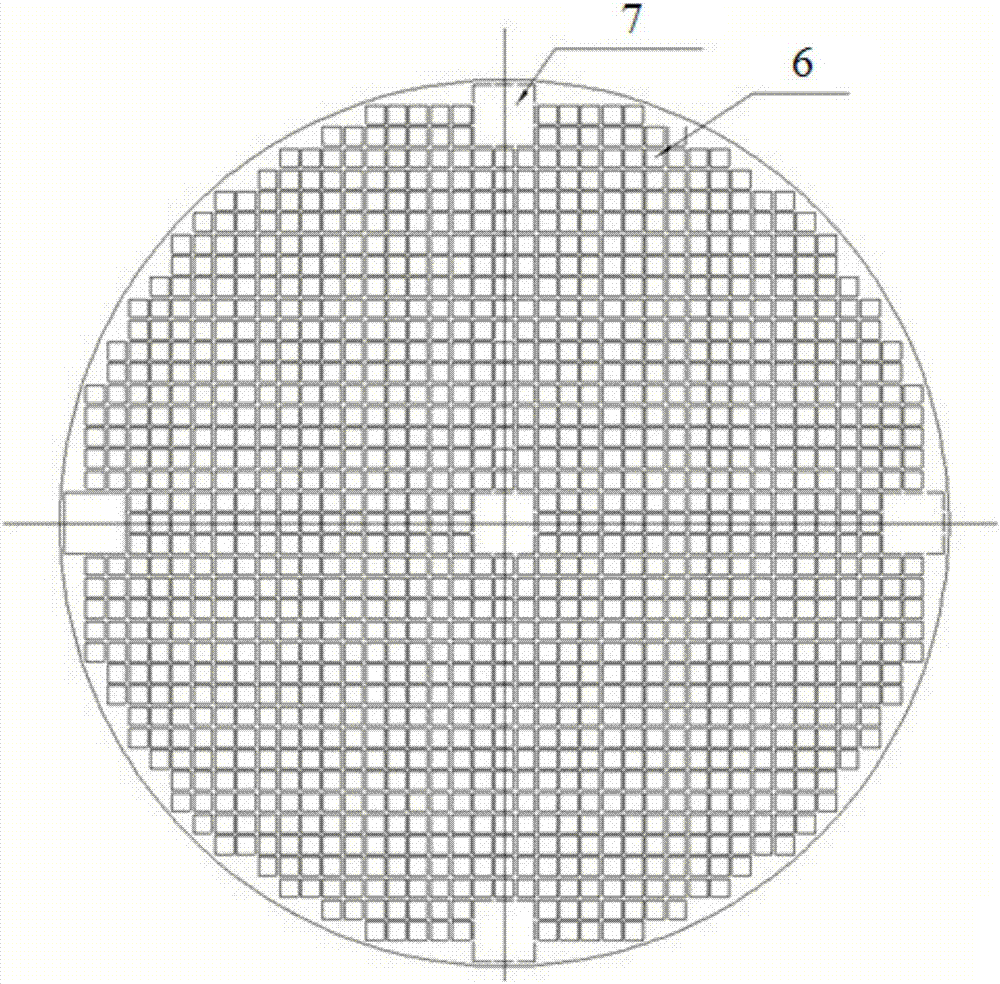

Tail gas catalyst of flameproof diesel engine for mining

PendingCN107237671AIncrease the area of actionReduce cloggingExhaust apparatusSilencing apparatusDieselingEngineering

The invention relates to a tail gas catalyst of a flameproof diesel engine for mining. The tail gas catalyst comprises a water jacket shell body. The tail gas catalyst is characterized in that the water jacket shell body is internally provided with a catalyzing unit, a plurality of direct-through small airways and by-pass big airways are arranged on the catalyzing unit in the axial direction, and the inner surfaces of the direct-through small airways and the by-pass big airways are evenly coated with precious metal catalyzing layers. According to the tail gas catalyst of the flameproof diesel engine for mining, the tail gas catalyst can be fully compatible with the flameproof diesel engine for mining without affecting the normal using of the original machine, and the tail gas catalyst of the flameproof diesel engine for mining has the characteristics of being good in heat stability, good in catalyzing quality, high in structural strength, resistant to thermal shock and the like.

Owner:无锡双翼汽车环保科技有限公司

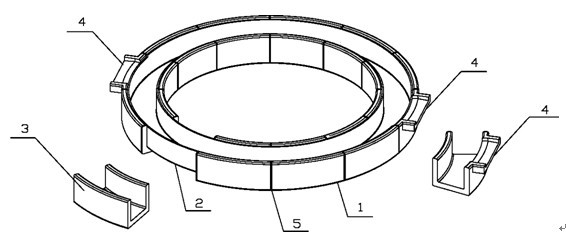

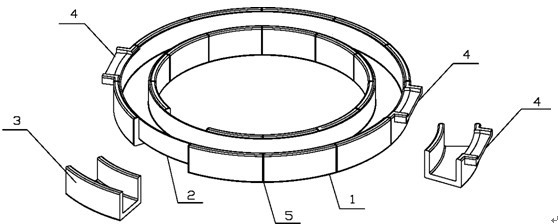

Water seal device suitable for high-temperature and high-thermal environment of dry quenching coke furnace

ActiveCN102618301AHigh temperature resistantResistant to thermal shockCoke quenchingSocial benefitsBrick

The invention relates to a water seal device suitable for a high-temperature and high-thermal environment of a dry quenching coke furnace, and belongs to the technical field of coke furnaces. The water seal device is used for sealing a red coke loading opening of the dry quenching coke furnace. According to the technical scheme, the water seal device consists of a permanent fire-resistant outer tank and a stainless steel inner tank, wherein according to the permanent fire-resistant outer tank, arc-shaped tank bricks and arc-shaped tank bricks with overflow weirs are bonded and built by using refractory mortar to form an annular tank; the stainless steel inner tank is manufactured by punching or welding a thin heat-resisting stainless steel plate to form an annular tank; the stainless steel inner tank is embedded into the permanent fire-resistant outer tank; the outer wall of the stainless steel inner tank is in close fit with the inner wall of the permanent fire-resistant outer tank; and the stainless steel inner tank is connected with the permanent fire-resistant outer tank in a detachable mode without connecting pieces. The water seal device has the characteristics of high-temperature resistance, thermal impact resistance performance, long service life and good sealing effect; and the damaged permanent fire-resistant outer tank can be coated and repaired simply by using the refractory mortar, and the stainless steel inner tank can be easy to replace, so that the construction process is safe and simple, and the water seal device has high practical value and obvious economic and social benefits.

Owner:HEBEI IRON AND STEEL

Anisotropic film and method for manufacturing anisotropic film

PendingCN111205788AMiniaturizationAchieve thinningNon-insulated conductorsNon-conductive material with dispersed conductive materialPolymer scienceElectrical connection

Owner:SHIN ETSU CHEM CO LTD

Preparation method of charcoal material surface coating for resisting high temperature oxidation

The present invention is preparation process of high temperature oxidation resisting coating on the surface of carbon material. The preparation process includes the steps of: cleaning and stoving the surface of the carbon material, compounding slurring with silica powder, boron powder, water and adhesive in certain weight proportion, coating the slurry onto the surface of the carbon material through soaking, spraying or brushing to form slurry layer of 200-240 micron thickness, drying, heating in vacuum resistive furnace first at 400-500 deg.c for 10-20 min and then at 1420-1500 deg.c for 20-30 min, and cooling to obtain high temperature oxidation resisting ceramic coating. The present invention has simple technological process, high production efficiency, good repeatability and low production cost and is suitable for industrial production.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Method for making gradient silicon carbide coating by electrophoresis codeposition

InactiveCN101565848BPrevent peelingFacilitates chemical bondingElectrolytic coatingsElectrophoresisOxidation resistant

The invention discloses a method for making gradient silicon carbide coating by electrophoresis codeposition, which includes the following steps: by ultrasonic processing, suspending liquid A is prepared by silica powder, carbon soot, caking agent polyvinyl butyral, acetone and additive n-butylamine which are mixed according to the mass proportion of 2-16:20:15:100:1; by ultrasonic processing, suspending liquid B is prepared by silica powder, carbon soot, polyvinyl butyral, acetone and n-butylamine which are mixed according to the mass proportion of 16-30:20:15:100:1; by ultrasonic processing,suspending liquid C is prepared by silica powder, carbon soot, polyvinyl butyral, acetone and n-butylamine which are mixed according to the mass proportion of 15-40:10:15:100:1; by ultrasonic processing, suspending liquid D is prepared by silica powder, carbon soot, polyvinyl butyral, acetone and n-butylamine which are mixed according to the mass proportion of 40-70:10:15:100:1; with graphite material as the anode, under a constant potential mode the suspending liquids above are deposited, dried, heated to be between 1200 DEG C and 1600 DGE C, and preserved at the temperature for 20 to 60 minutes. The invention has the advantages of simple process, good thermal-shock resistance and oxidation resistance, controllable coating thickness and uniform coating.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

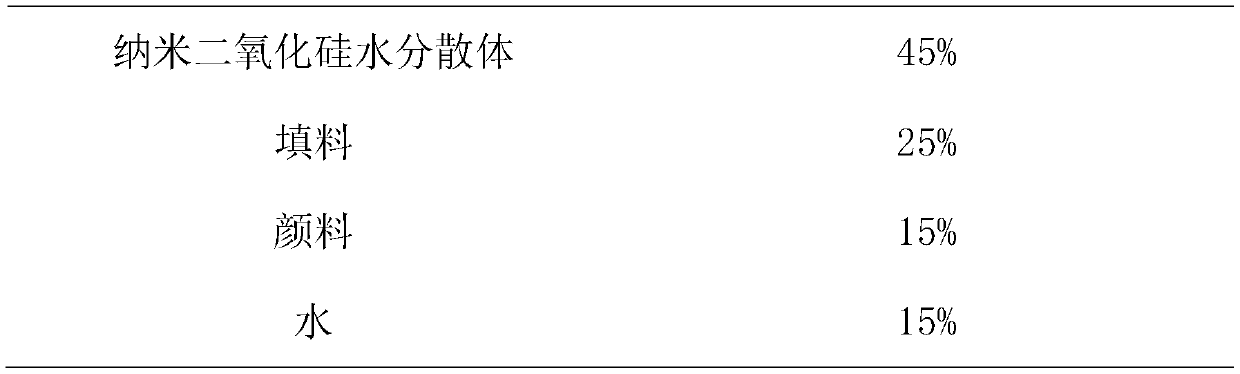

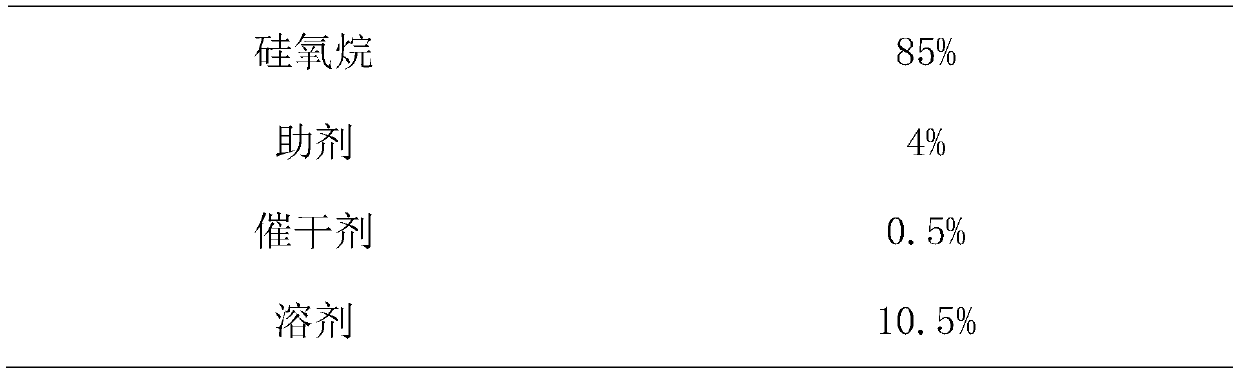

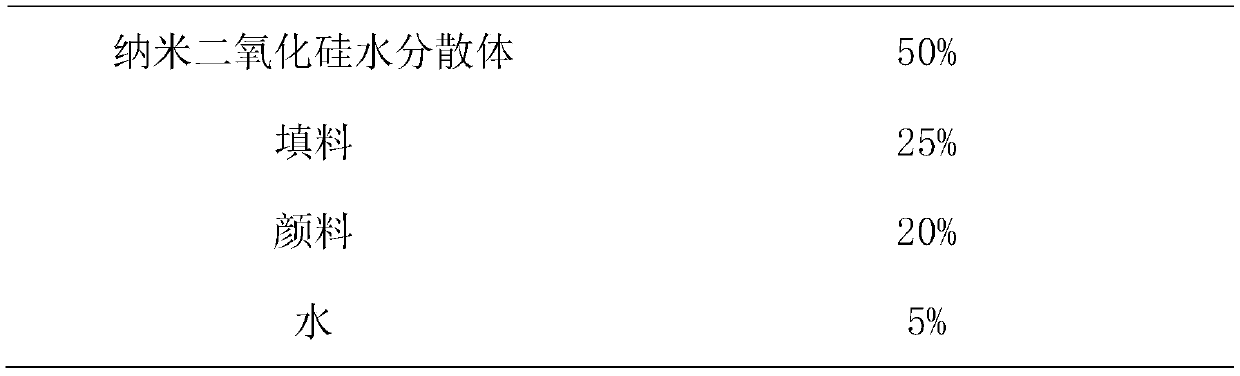

A kind of nano-ceramic coating that can be cured at room temperature and its preparation method

ActiveCN106977983BFlame retardantResistant to thermal shockFireproof paintsCeramic coatingNanoceramic

The invention discloses a nano ceramic coating capable of being cured at a normal temperature. The nano ceramic coating comprises a component A consisting of silicon sol, pigments, filler and water, and a component B consisting of siloxane, an aid, a drier and a solvent. The nano ceramic coating can be cured at the normal temperature, so that the application range is enlarged. In addition, the invention also discloses a preparation method of the nano ceramic coating capable of being cured at the normal temperature. The preparation method comprises the following steps: step 1, weighing the silicon sol, pigments, filler and water according to a corresponding ratio, mixing, stirring an obtained mixture, grinding the uniformly stirred mixture to powder with fineness of not higher than 25 micrometers, and adopting the powder as the component A; weighing the siloxane, aid, drier and solvent according to a corresponding ratio, mixing, uniformly stirring an obtained mixture, and adopting the mixture as the component B; and step 3, sufficiently mixing the component A and the component B according to a ratio, and generating the nano ceramic coating.

Owner:河北精涂科技有限公司

Turbocharger shell and preparation method thereof

ActiveCN101949311BEasy to operateResistant to thermal shockMachines/enginesEngine componentsMaterials preparationMold filling

The invention relates to a turbocharger shell and a preparation method thereof. According to a formula, the turbocharger shell is prepared from the following components in part by weight: 28 to 30 parts of pig iron, 3 to 8 parts of low-carbon steel, 32.53 to 45.2 parts of recirculated iron, 0.3 to 0.4 part of electrolytic manganese, 3.4 to 4.12 parts of No.75 ferrosilicon, 17.4 to 21.2 parts of electrolytic nickel, 1.4 to 1.95 parts of ferrochromium, 0.5 to 0.8 part of nickel magnesium nodulant and 0.8 to 1.0 part of inoculant. The preparation method comprises the following steps of: shot blasting, material preparation, smelting, nodulizing, pouring and mold-filling, shakeout and the like, wherein during mold-filling, pouring is performed after two external mold cores are closed, a set ofexternal mold core cavity is adopted for each product, the product is inoculated by a stream inoculation device, and the inoculant enters the cavity along molten iron. The product prepared according to the formula and the preparation method has the advantages of high dimensional accuracy, durability, stable size of castings and low deformation rate.

Owner:西峡县众德汽车部件有限公司

Method for melting metal by domestic microwave oven

InactiveCN101424483AWith high temperature insulation effectAvoid passingCrucible furnacesFiberMicrowave oven

The invention relates to a method for melting metal by a household microwave oven, and belongs to the technical field of melting metal. The method comprises the following steps: using cerium oxide as a stabilizing agent and using a zircite ceramic crucible containing 5 to 20 percent of cerous phosphate as a container, insulating heat around the crucible by a porzite fiber material, placing a silicon carbide ring between the crucible and the porzite fiber, putting a block shaped metal into the crucible, heating the metal by microwave in the microwave oven, taking out the silicon carbide ring after the metal is heated for 10 to 20 minutes, and continuously heating the metal. The method can melt metal with the melting point below 1,500 DEG C; and the melted metal does not adhere to the wall surface of the crucible, impurities are not introduced into the metal, and the temperature on the inner wall of a cavity of the microwave oven is lower than 100 DEG C. The method can be used for quickly melting small pieces of metal in the fields such as assaying, purifying, reclaiming and precisely casting the metal, and the like.

Owner:刘梦夏

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com