Mo-S/NF hydrogen evolution material, and preparation method and application thereof

A hydrogen evolution reaction and hydrogen evolution technology, applied in the field of hydrogen energy, can solve problems such as insufficient performance, and achieve the effects of low cost, improved hydrogen evolution performance, and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Ammonium tetrathiomolybdate 0.5mmol

[0032] Thiourea 0.5mmol

[0033] Deionized water 10mL

[0034] The hydrogen evolution material is prepared by the preparation method of the following steps:

[0035] Dissolve 0.5 mmol of ammonium tetrathiomolybdate and 0.5 mmol of thiourea in 10 mL of deionized water, and sonicate in an ultrasonic oscillator for 5 min until stirred and dissolved. After seeing that there are no solid particles in the solution, transfer it to a high-pressure reactor, put in 8mm×8mm×1mm nickel foam, and heat it in water at 180°C for 12h. The Mo-S / NF was taken out and treated, put into a resistance furnace, fed with nitrogen, and calcined at a temperature of 300°C for 2 hours to finally obtain the Mo-S / NF hydrogen evolution material.

Embodiment 2

[0041] Ammonium tetrathiomolybdate 0.5mmol

[0042] Thiourea 1.0mmol

[0043] Deionized water 10mL

[0044] The hydrogen evolution material is prepared by the preparation method of the following steps:

[0045] Dissolve 0.5 mmol of ammonium tetrathiomolybdate and 1.0 mmol of thiourea in 10 mL of deionized water, and sonicate in an ultrasonic oscillator for 5 min until stirred and dissolved. After seeing that there are no solid particles in the solution, transfer it to a high-pressure reactor, put in 8mm×8mm×1mm nickel foam, and heat it in water at 180°C for 12h. The Mo-S / NF was taken out and treated, put into a resistance furnace, fed with nitrogen, and calcined at a temperature of 400°C for 2 hours to finally obtain the Mo-S / NF hydrogen evolution material.

Embodiment 3

[0051] Ammonium tetrathiomolybdate 0.5mmol

[0052] Thiourea 2.5mmol

[0053] Deionized water 10mL

[0054] The hydrogen evolution material is prepared by the preparation method of the following steps:

[0055] Dissolve 0.5 mmol of ammonium tetrathiomolybdate and 2.5 mmol of thiourea in 10 mL of deionized water, and sonicate in an ultrasonic oscillator for 5 minutes until stirred and dissolved. After seeing that there are no solid particles in the solution, transfer it to a high-pressure reactor, put in 8mm×8mm×1mm nickel foam, and heat it in water at 180°C for 12h. The Mo-S / NF was taken out and treated, put into a resistance furnace, fed with nitrogen, and calcined at a temperature of 400°C for 2 hours to finally obtain the Mo-S / NF hydrogen evolution material.

PUM

| Property | Measurement | Unit |

|---|---|---|

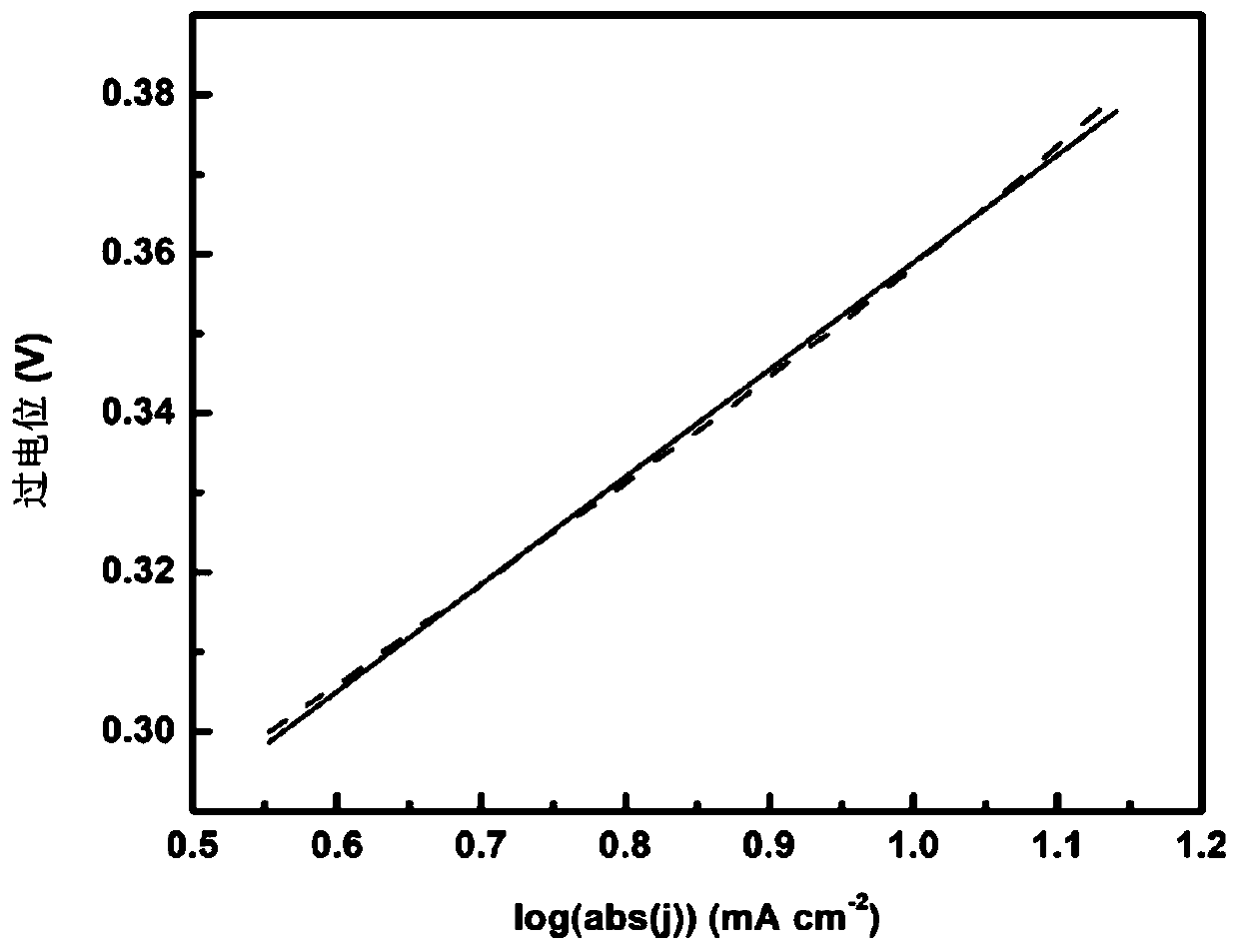

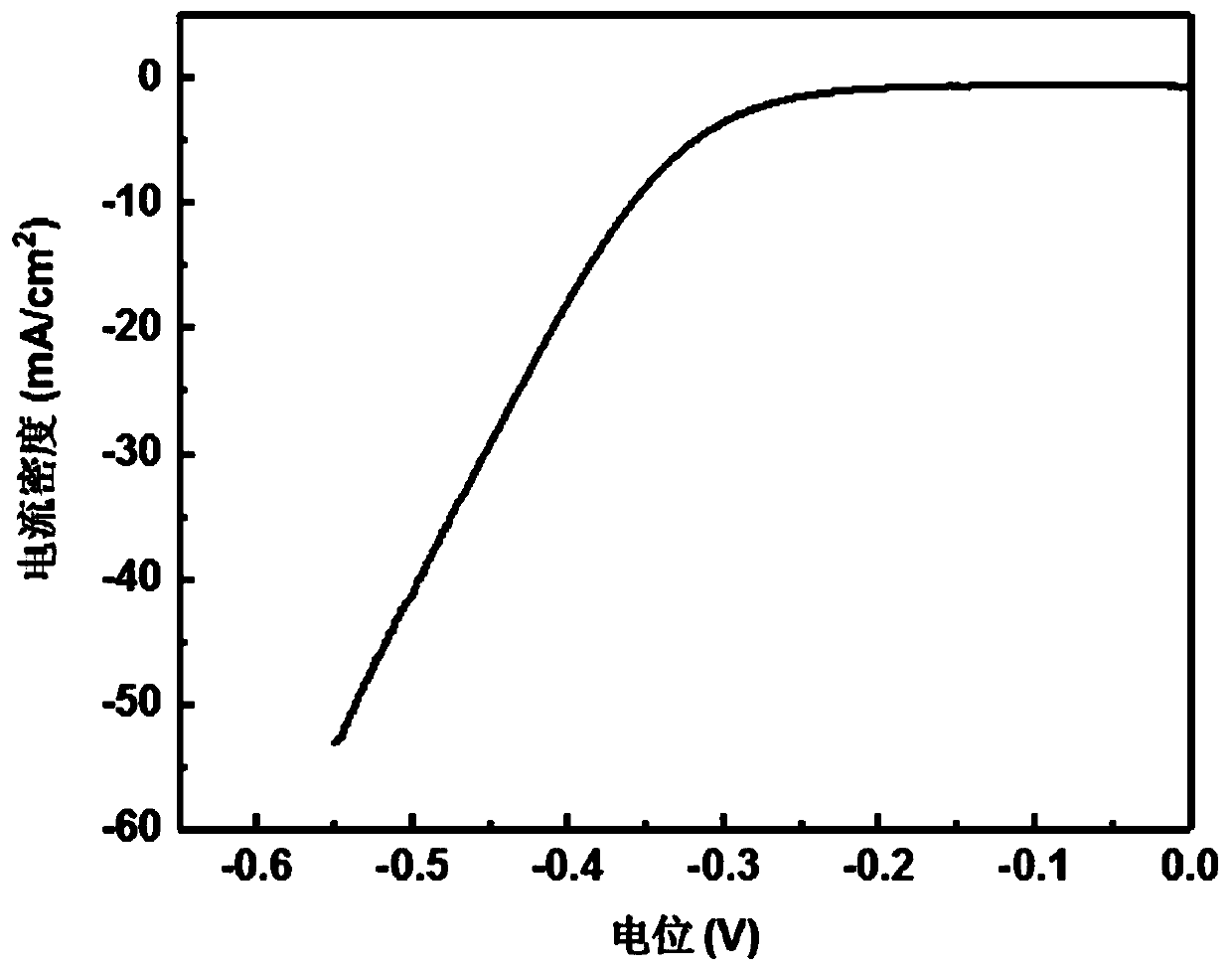

| electric potential / voltage | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com