Low temperature preparation method for hydrogen evolution cathode material and application thereof

A hydrogen evolution cathode and cathode active material technology, applied in the direction of electrodes, cells, electrolysis process, etc., can solve the problems of increasing technical difficulty and non-repeatability, reaction speed is difficult to form particles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The invention provides a low-temperature preparation method of a hydrogen-evolution cathode material. The method comprises the following steps: performing surface treatment on an active metal; performing a constant temperature treatment on a precursor reaction solution of a prepared cathode active material at a temperature of minus 20°C to 0°C ; Place the surface-treated active metal in the precursor reaction solution of the cathode active material, and perform agitation and immersion plating at a temperature of minus 20°C to 0°C; and take out the active metal and rinse and dry it for hydrogen evolution cathode material.

[0024] The inventor's design thinking is: use the precursor reaction solution of the cathode active material as the plating solution, and use active metals such as copper as the substrate to directly dip-plate precious metals such as platinum on the surface under low temperature conditions (-20°C to 0°C). , different from the reference (CN 1483539A) i...

Embodiment 1

[0043] First, cut a copper sheet with a purity of 99.9% into 3×3 cm, soak it in 2M sodium carbonate solution for 30 minutes to remove surface oil, take it out and rinse it with deionized water, and then soak it in 1M sulfuric acid solution for 30 minutes to remove surface oxidation layer, removed, rinsed with deionized water, and blown dry with nitrogen. Prepare 100ml of 10mg / L ethanol solution of chloroplatinic acid, and place it in a DHJF-8002 low-temperature (constant temperature) stirring reaction bath, control the temperature, and make the temperature reach minus 15°C. After that, place the cleaned copper sheet in a chloroplatinic acid solution at a temperature of minus 15° C. and stir for immersion plating for 2 hours. Finally, the dipped samples were taken out, rinsed with deionized water, and dried with nitrogen gas for later use.

Embodiment 2

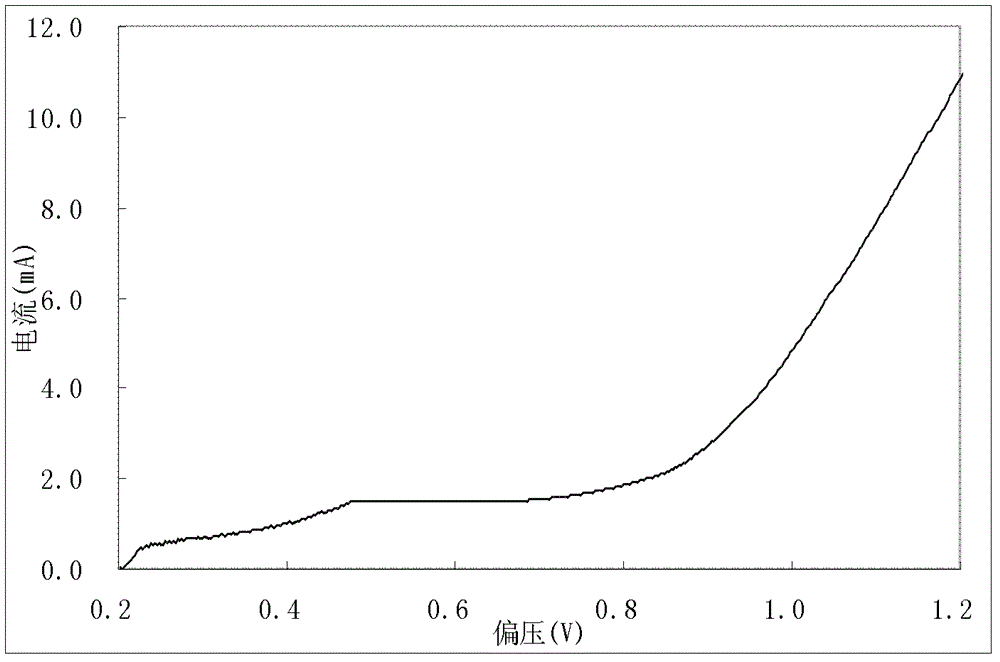

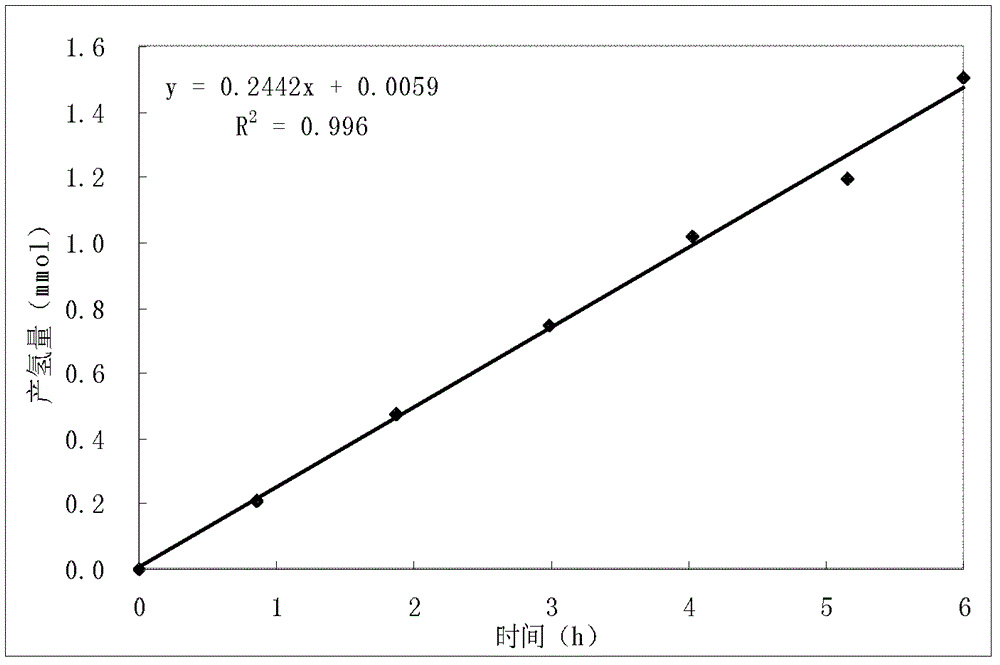

[0050] First, cut a copper sheet with a purity of 99.9% into 3×3 cm, soak it in 2M sodium carbonate solution for 30 minutes to remove surface oil, take it out and rinse it with deionized water, and then soak it in 1M sulfuric acid solution for 30 minutes to remove surface oxidation layer, removed, rinsed with deionized water, and blown dry with nitrogen. Prepare 100ml of 10mg / L ethanol solution of chloroplatinic acid, and place it in a DHJF-8002 low-temperature (constant temperature) stirring reaction bath, control the temperature, and make the temperature reach minus 20°C. After that, place the cleaned copper sheet in a chloroplatinic acid solution at a temperature of minus 20° C. and stir for immersion plating for 2 hours. Finally, the dipped samples were taken out, rinsed with deionized water, and dried with nitrogen gas for later use. Test results: The current density at 1.2V bias is 1.04mA / cm 2 , the hydrogen production rate per unit area under 1.2V bias is 0.023mmol / hc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com