Iron-nickel layered double metal hydroxide/foam nickel composite material and preparation method and application thereof

A layered bimetallic, hydroxide technology, applied in the field of composite materials, can solve the problems of scarcity of resources, high price, difficult to apply in a wide range, etc., and achieve the effects of low price, simple steps, and easy widespread promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

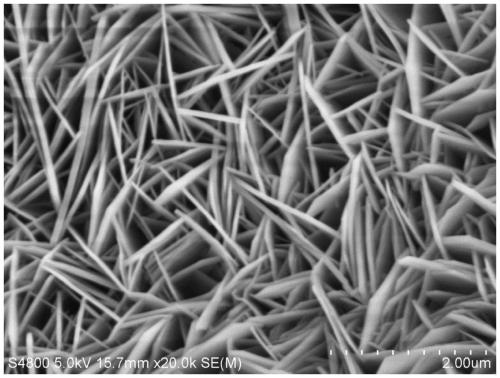

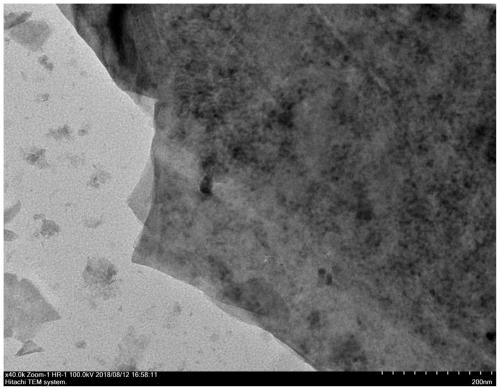

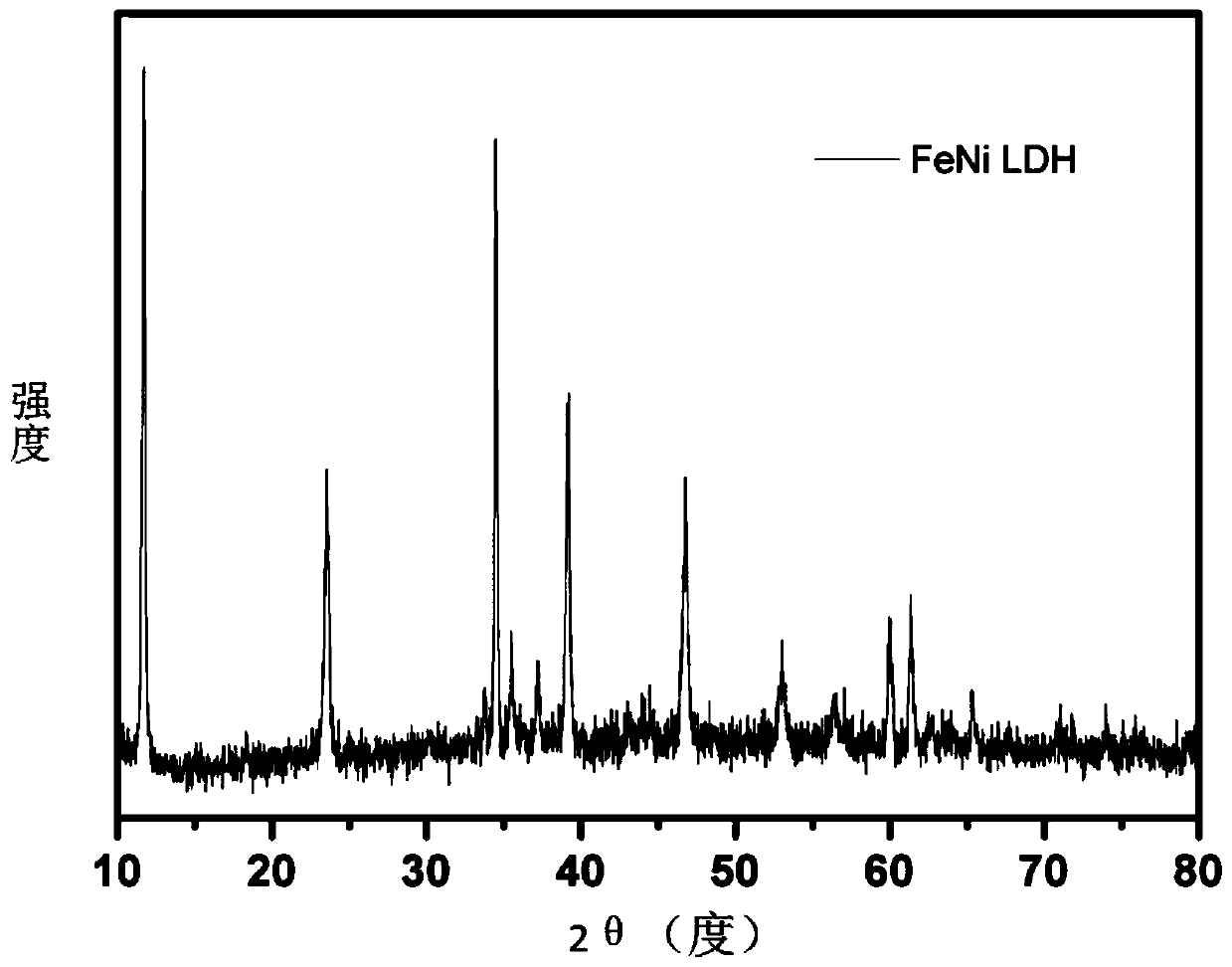

[0021] The invention provides a method for preparing an iron-nickel layered double hydroxide / foam nickel composite material, comprising:

[0022] 1) In the presence of a solvent, the iron source, ammonium fluoride, urea and nickel foam are subjected to a solvothermal reaction to obtain a reaction product A;

[0023] 2) In the presence of a solvent, the nickel source, ammonium fluoride, urea, and reaction product A are subjected to a solvothermal reaction to prepare an iron-nickel layered double hydroxide / foam nickel composite material.

[0024] In step 1) of the above-mentioned preparation method, the consumption of each material can be selected in a wide range, but in order to further improve the overpotential, stability and Catalytic performance, preferably, in step 1), the amount ratio of iron source, ammonium fluoride, urea and nickel foam is 0.75mmol: 1-8mmol: 2-18mmo: 1cm×1cm-2.5cm×4cm, the foam The thickness of nickel is 1.5mm.

[0025] In step 1) of above-mentioned p...

Embodiment 1

[0036] 1) Mix 0.3030g ferric nitrate nonahydrate (0.75mmol), 0.1666g ammonium fluoride (4.49mmol), 0.54g urea (9mmol), and 30mL deionized water in a beaker to obtain a uniform solution.

[0037] 2) Transfer the above-mentioned homogeneous solution to a stainless steel reaction kettle with a polytetrafluoroethylene jacket and add nickel foam (2cm×3cm), place it directly in an oven at 120°C, and react at 120°C for 12h until the reaction time is over Afterwards, it was naturally cooled to 25° C. to obtain the reaction product A1.

[0038] 3) Mix 0.0218g nickel nitrate hexahydrate (0.075mmol), 0.01666g ammonium fluoride (0.449mmol), 0.054g urea (0.9mmol), and 30mL deionized water in a beaker to obtain a uniform solution.

[0039]4) Transfer the above-mentioned homogeneous solution to a stainless steel reaction kettle with a polytetrafluoroethylene jacket and add the above-mentioned reaction product A1, directly place it in an oven at 120°C, and react at 120°C for 12 hours. After t...

Embodiment 2

[0041] Carry out according to the method of embodiment 1, difference is, in steps 1) and 2), ammonium fluoride 1mmol, urea 2mmol, nickel foam 1cm×1cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com