Eosin based metal-organic framework for hydrogen production driven by visible light and preparation method thereof

An organic framework and visible light technology, applied in the field of photocatalytic materials, can solve the problems of low visible light utilization rate, high price, toxicity, etc., and achieve the effect of excellent luminescence stability, low price and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

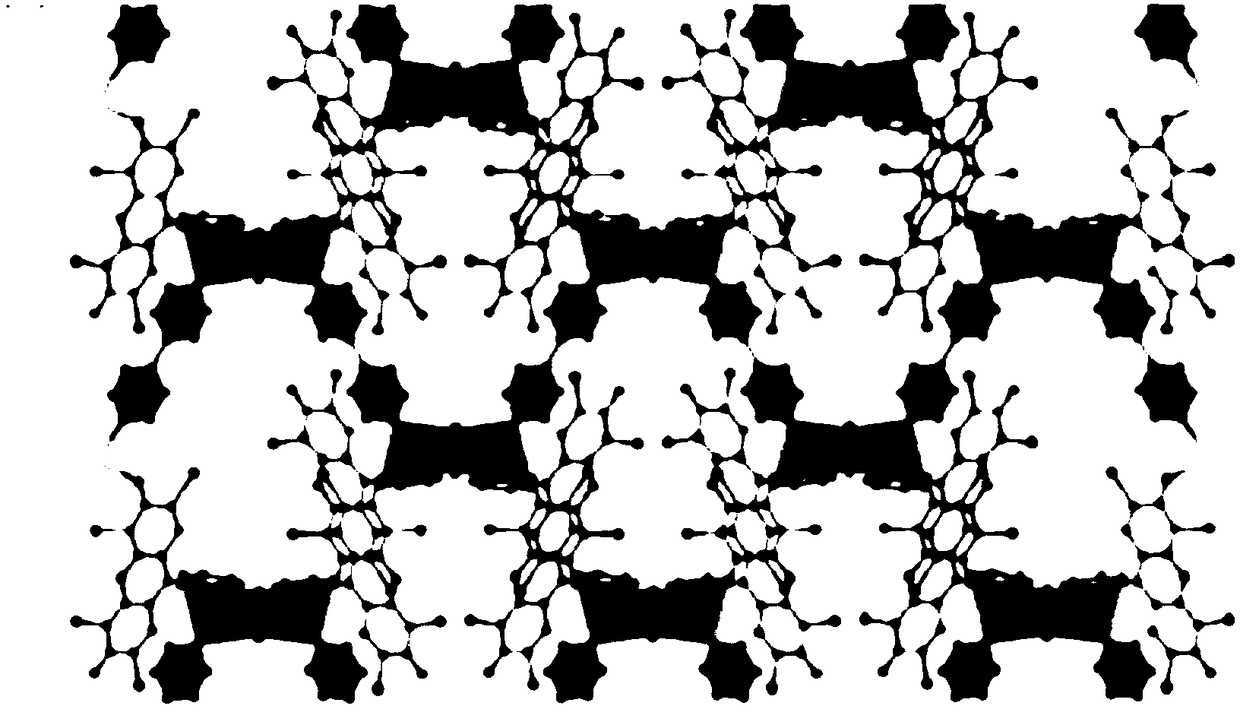

[0036] Weigh 18.7mg of eosin, 4.2mg of 4,4'-bipyridine and 10.8mg of Cd(NO 3 ) 2 4H 2 0, be placed in the glass sample vial of 10mL, add the mixed solvent of 5mL water and methanol (volume ratio is 1:1), then glass sample vial is placed in hydrothermal synthesis reactor, then hydrothermal synthesis reactor is placed In an electric blast drying oven at a constant temperature of 80°C, react for 24 hours. After the reaction, cool to obtain red blocky crystals, filter, wash, and dry at 100°C for 5 hours to obtain a metal-organic framework. Its crystal structure is as figure 1 It can be seen from the figure that the eosin unit is evenly distributed and has a large pore channel, which lays the foundation for the research on its photo-splitting water hydrogen production performance.

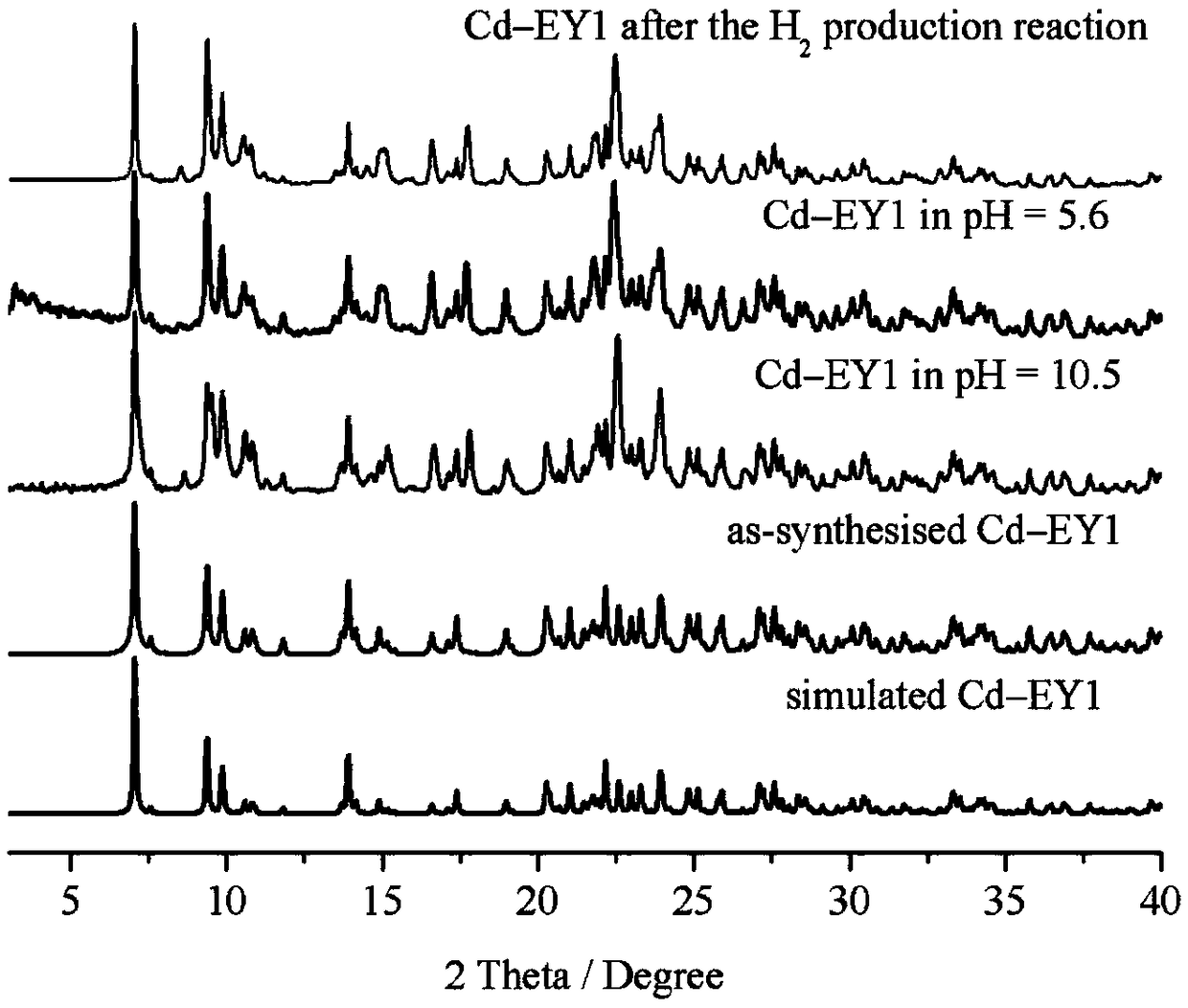

[0037] Stability testing of materials

[0038] Weigh 2 parts of the material Cd-EY in Example 1, add them to the aqueous solutions with pH values of 5.6 and 10.5 respectively, stir for 24 hours, f...

Embodiment 2

[0046] Weigh 18.7mg of eosin, 4.2mg of 4,4'-bipyridine and 12.5mg of Cd(NO 3 ) 2 4H 2 0, be placed in the glass sample vial of 10mL, add the mixed solvent of 7mL water and methanol (volume ratio is 1:1), then glass sample vial is placed in the hydrothermal synthesis reactor, then the hydrothermal synthesis reactor is placed In an electric blast drying oven at a constant temperature of 75°C, react for 24 hours. After the reaction, cool to obtain red blocky crystals, filter, wash, and dry at 90°C for 6 hours to obtain a metal-organic framework.

Embodiment 3

[0048] Weigh 22.4mg of eosin, 4.2mg of 4,4'-bipyridine and 10.8mg of Cd(NO 3 ) 2 4H 2 0, be placed in the glass sample vial of 10mL, add the mixed solvent of 10mL water and methanol (volume ratio is 1:1), then glass sample vial is placed in hydrothermal synthesis reactor, then hydrothermal synthesis reactor is placed In an electric blast drying oven at a constant temperature of 75°C, react for 26 hours. After the reaction, cool to obtain red blocky crystals, filter, wash, and dry at 100°C for 6 hours to obtain a metal-organic framework.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com