Spiral Mo2C catalyst with ultralow platinum loading capacity, and preparation method and application thereof

A helical and catalyst technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as performance and stability gaps, achieve improved hydrogen evolution performance, reduce platinum loading, The effect of the simple process of the preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

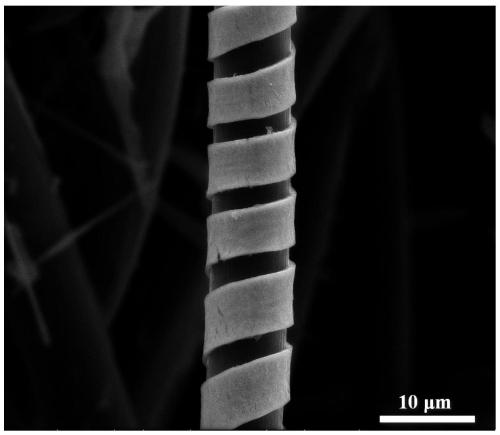

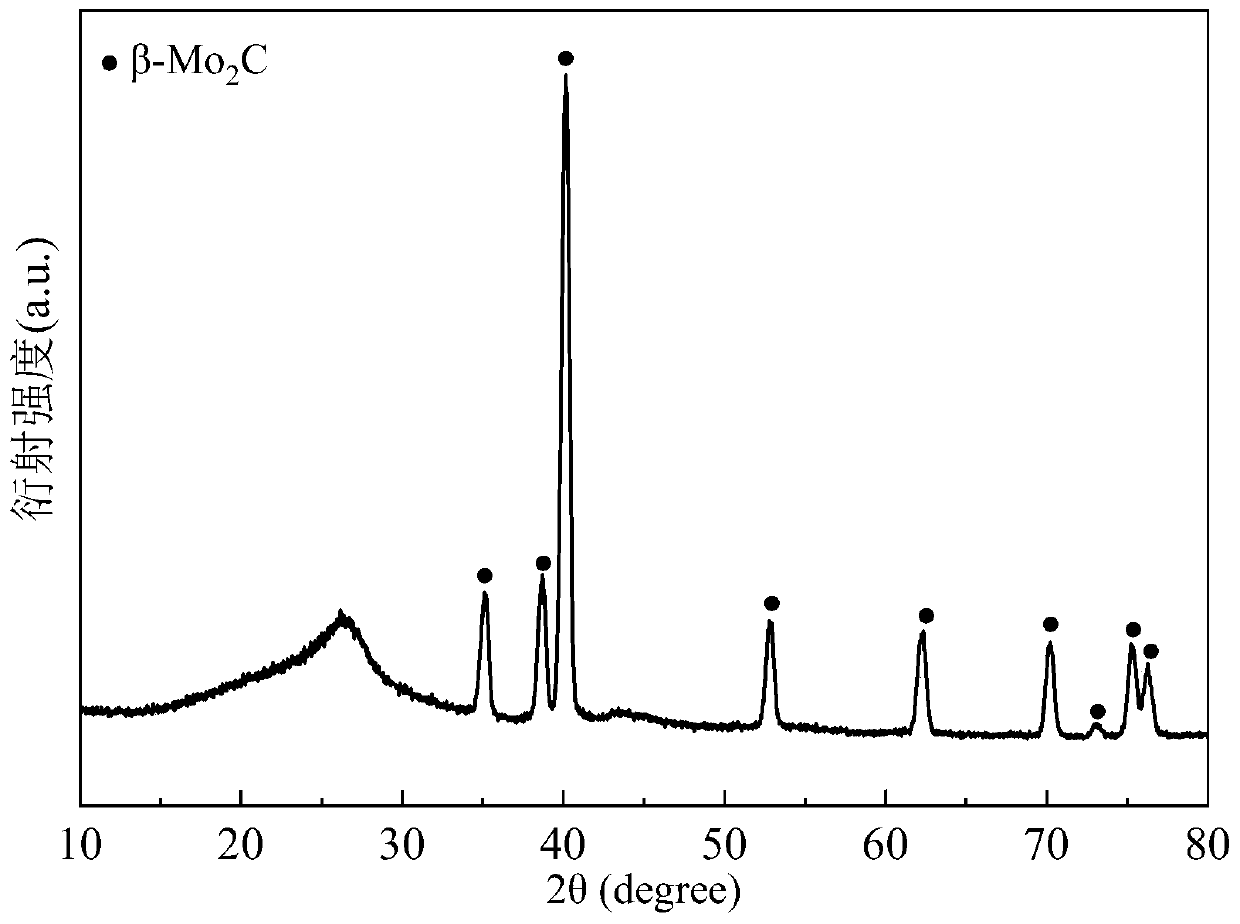

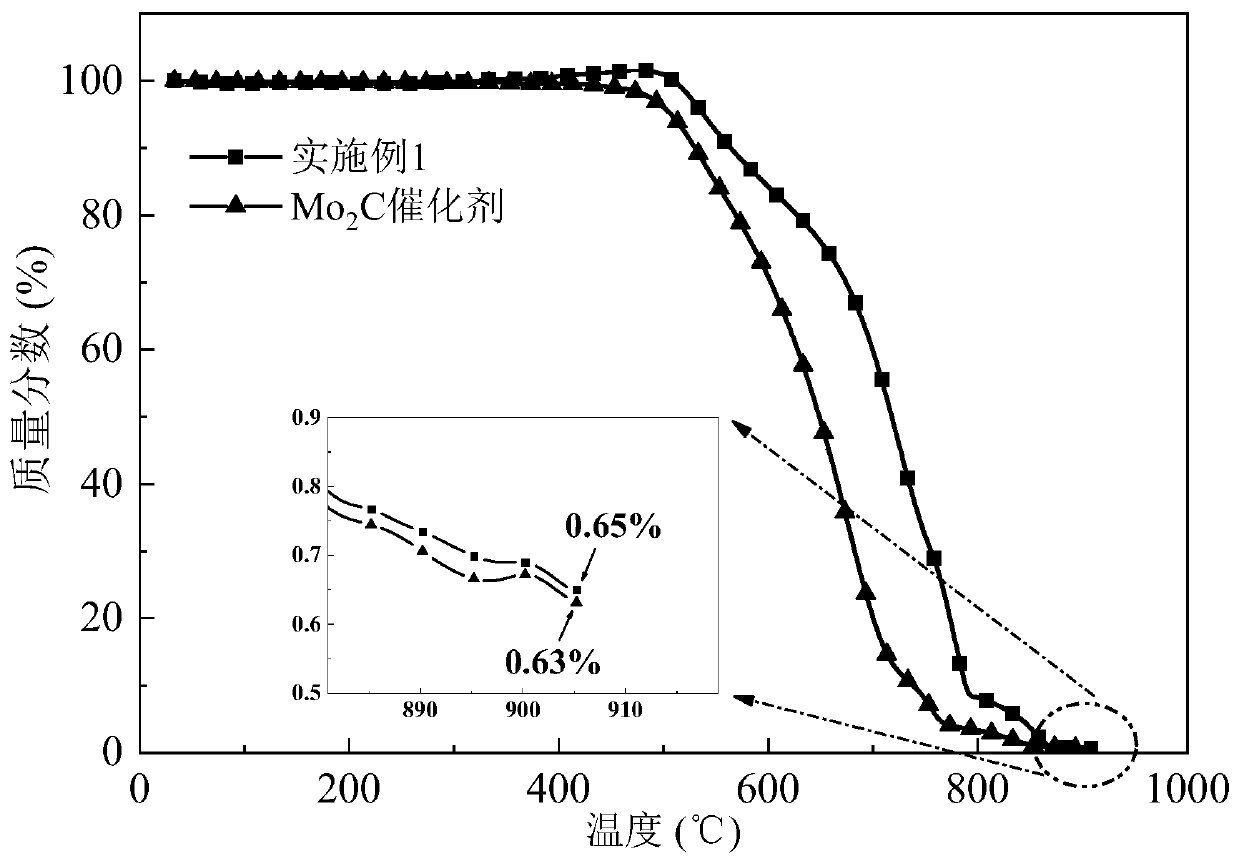

[0053] This example provides a helical ultra-low platinum loading Mo that can be applied to electrolytic water hydrogen evolution reaction. 2 C catalyst, its preparation method is as follows.

[0054] (1) The purchased carbon cloth material is cut into a size of 1.0cm×2.0cm. Ultrasonic cleaning with 95% ethanol and deionized water, respectively, and drying for later use.

[0055] (2) Measure 150mL of ammonium molybdate solution with concentration of 10mmol / L as electrolyte, fix carbon cloth as working electrode with polytetrafluoroethylene electrode clip, immerse in ammonium molybdate electrolyte, carbon rod as counter electrode, Constitute a double-electrode electrolytic cell, adopt the method of constant current cathodic electrodeposition, at 4mA / cm 2 Under the current density, the electrodeposition time is 30min, and then the working electrode is washed with deionized water and dried to obtain the helical MoO 2 Precursor.

[0056] (3) The helical MoO prepared in step (2...

Embodiment 2

[0064] A helical ultra-low platinum loading Mo for hydrogen evolution reaction in water electrolysis 2 C catalyst, its preparation method is as follows.

[0065] (1) The carbon cloth material is cut into a size of 1.0cm×2.0cm. Ultrasonic cleaning with 95% ethanol and deionized water, respectively, and drying for later use.

[0066] (2) Measure 100 mL of ammonium molybdate solution with a concentration of 10 mmol / L as the electrolyte, fix the carbon cloth as a working electrode with a polytetrafluoroethylene electrode clip, immerse it in the ammonium molybdate electrolyte, and use the carbon rod as the counter electrode, Constitute a double-electrode electrolytic cell, adopt the method of constant current cathodic electrodeposition, at 6mA / cm 2 Under the current density, the electrodeposition time is 30min, and then the working electrode is washed and dried with deionized water to obtain helical MoO 2 Precursor.

[0067] (3) The helical MoO prepared in step 2) 2 Put the pr...

Embodiment 3

[0073] A helical ultra-low platinum loading Mo for hydrogen evolution reaction in water electrolysis 2 C catalyst, its preparation method is as follows.

[0074] (1) The carbon cloth material is cut into a size of 1.0cm×2.0cm. Ultrasonic cleaning with 95% ethanol and deionized water, respectively, and drying for later use.

[0075] (2) Measure 150 mL of ammonium molybdate solution with a concentration of 5 mmol / L as the electrolyte, fix the carbon cloth with a polytetrafluoroethylene electrode clip as the working electrode, immerse it in the ammonium molybdate electrolyte, and use the carbon paper as the counter electrode , constituting a double-electrode electrolytic cell, using constant current cathodic electrodeposition, at 4mA / cm 2 Under the current density, the electrodeposition time is 20min, and then the working electrode is washed and dried with deionized water to obtain helical MoO 2 Precursor.

[0076] (3) The helical MoO prepared in step (2) 2 Put the precursor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com