A kind of nano-ceramic coating that can be cured at room temperature and its preparation method

A nano-ceramic, room temperature curing technology, used in fireproof coatings, coatings and other directions, can solve the problems of cumbersome preparation process, inability to cure, and high construction requirements, and achieve the effect of expanding the application field and scope, improving the service cycle, and simple construction requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

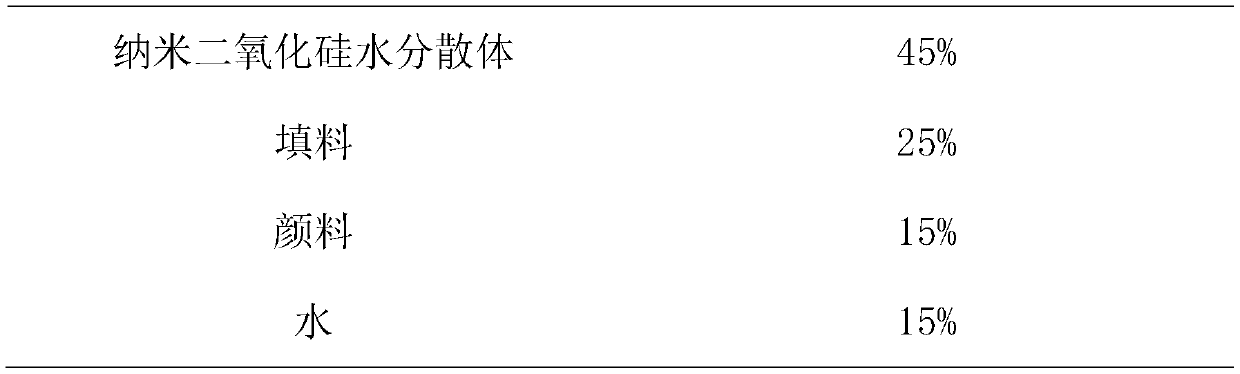

[0042] Material ratio of component A

[0043]

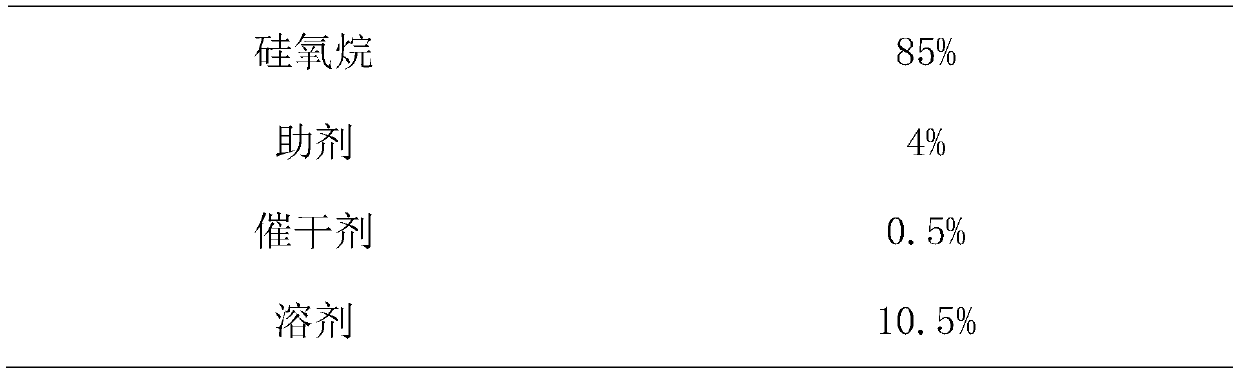

[0044] Material ratio of component B

[0045]

Embodiment 1

[0046] The preparation method of the nano-ceramic coating in Example 1: adding fillers, pigments and water to the nano-silica aqueous dispersion, stirring evenly at a low speed, and then grinding on a sand mill until the material is discharged below 25 μm, to obtain A component;

[0047] Add additives, driers and solvents into the siloxane, stir well to obtain component B;

[0048] Mix components A and B uniformly in proportion to obtain a multi-purpose ceramic coating.

example 2

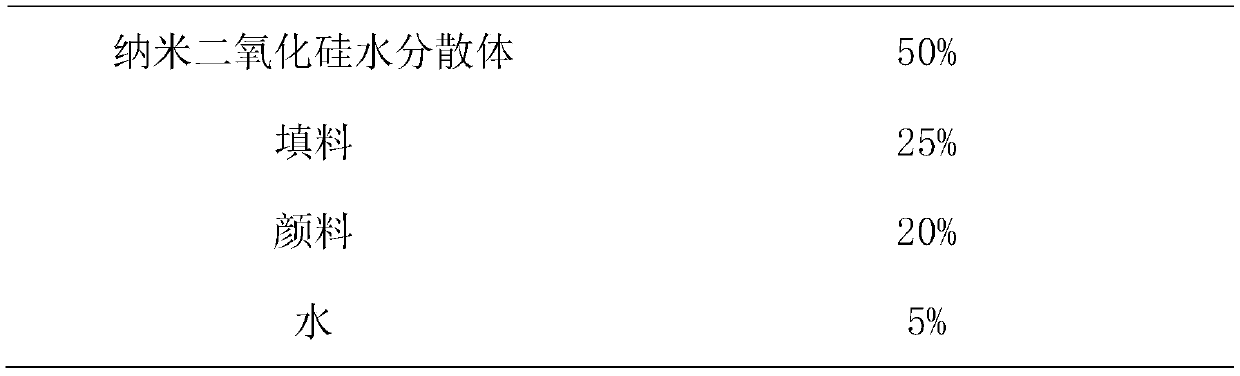

[0050] Material ratio of component A

[0051]

[0052] Material ratio of component B

[0053]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com