Lithium ion battery electrolyte and lithium ion battery containing the same

A lithium-ion battery and electrolyte technology, applied in secondary batteries, circuits, electrical components, etc., can solve hidden dangers, high and low temperature safety issues, and achieve the effects of preventing expansion, wide liquid temperature range, and reducing gas volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment is used to illustrate the electrolyte provided by the present invention.

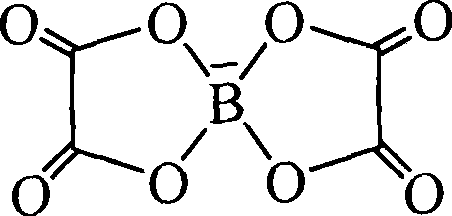

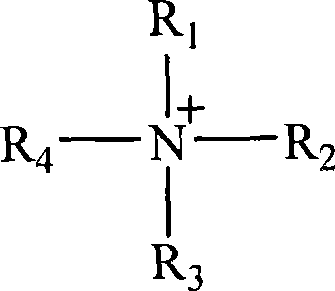

[0042] (1) Preparation of ionic liquid

[0043] Under the protection of nitrogen, using 30 ml of acetonitrile as the solvent, 20.4 g of N-methylpiperidine and 28.2 g of bromobutane were refluxed at 70°C for 4 hours, filtered, and vacuum dried at 50°C for 5 hours to obtain N- Methyl-N-butylpiperidine bromide. Take 30.0 g of the prepared N-methyl-N-butylpiperidine bromide and 24.6 g of lithium bisoxalate borate to react for 3 hours at room temperature. After liquid separation, evaporation of the solvent, vacuum drying at 90°C for 10 hours to obtain N -Methyl-N-butylpiperidine bisoxalic acid borate (PP14BOB).

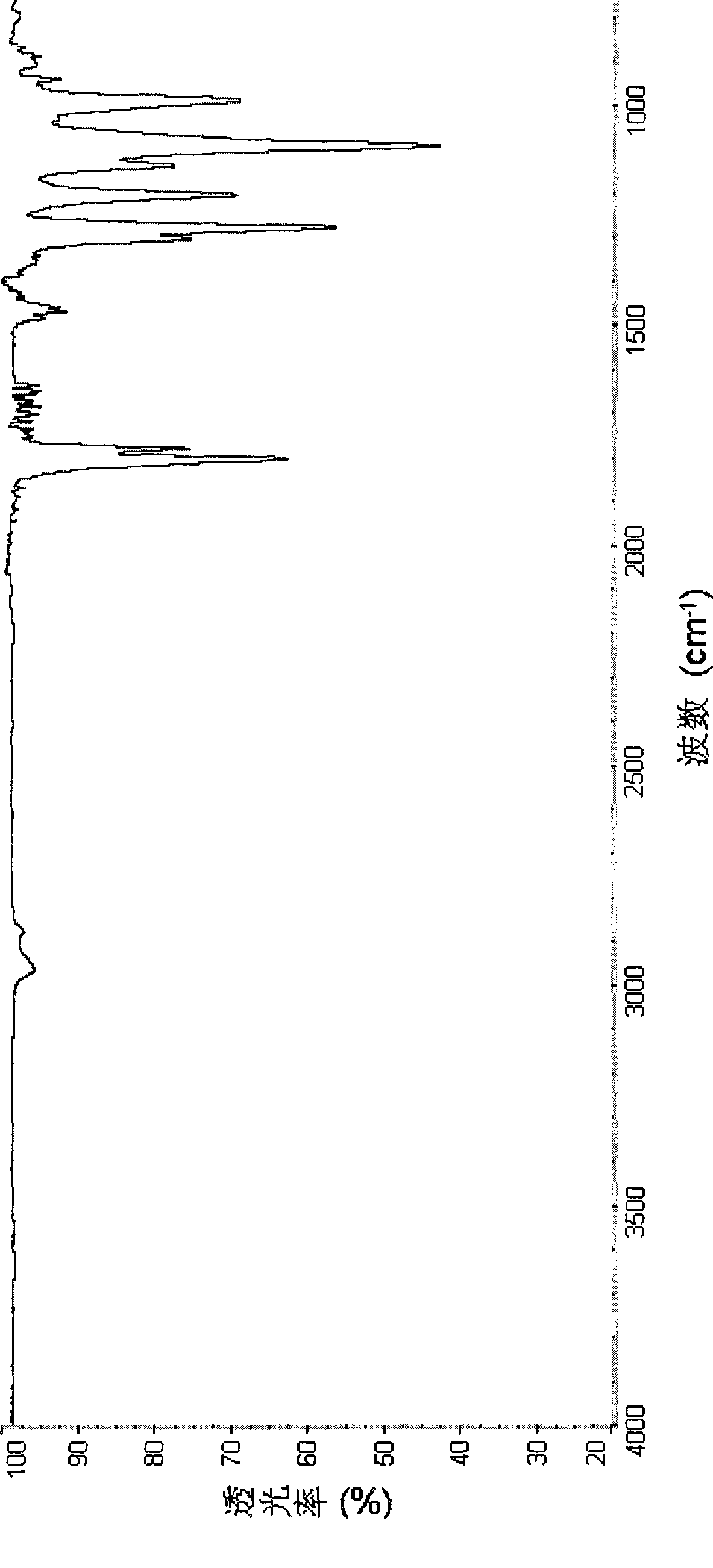

[0044] After the obtained ionic liquid is separated and purified by silica gel column chromatography, it is stored in a glove box. figure 1 Is the FTIR diagram of PP14BOB obtained, where the wave number is 1275cm -1 The peak of is the stretching vibration peak of the B-O single bo...

Embodiment 2

[0048] This embodiment is used to illustrate the electrolyte provided by the present invention.

[0049] (1) Preparation of ionic liquid

[0050] Prepare N-methyl-N-propylpyrrole bisoxalic acid borate (Py13BOB) according to the same method as in Example 1 step (1), except that 17.5 g of N-methylpyrrole is used instead of 20.4 Grams of N-methylpiperidine, 25.3 grams of bromopropane instead of 28.2 grams of bromobutane.

[0051] (2) Preparation of electrolyte

[0052] At room temperature, in a glove box, mix Py13BOB, propylene carbonate, and ethyl methyl carbonate in a weight ratio of 30:35:35, and then add LiPF to it 6 The electrolyte is formulated into an electrolyte solution with a concentration of 0.6 mol / liter. The prepared electrolyte sample is referred to as A2.

Embodiment 3

[0054] This embodiment is used to illustrate the electrolyte provided by the present invention.

[0055] (1) Preparation of ionic liquid

[0056] Prepare trimethylpropylammonium bisoxalic acid borate (N1113BOB) according to the same method as in Example 1 step (1), except that 12.1 g of trimethylamine is used instead of 20.4 g of N-methylpiperidine Pyridine, 25.3 grams of bromopropane instead of 28.2 grams of bromobutane.

[0057] (2) Preparation of electrolyte

[0058] At room temperature, in a glove box, mix N1113BOB, propylene carbonate, and ethyl methyl carbonate at a weight ratio of 50:25:25, and then add LiPF to it 6 The electrolyte is formulated into an electrolyte solution with a concentration of 1.5 mol / liter. The prepared electrolyte sample is referred to as A3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com