Lithium air battery ionic liquid electrolyte and air battery preparation method

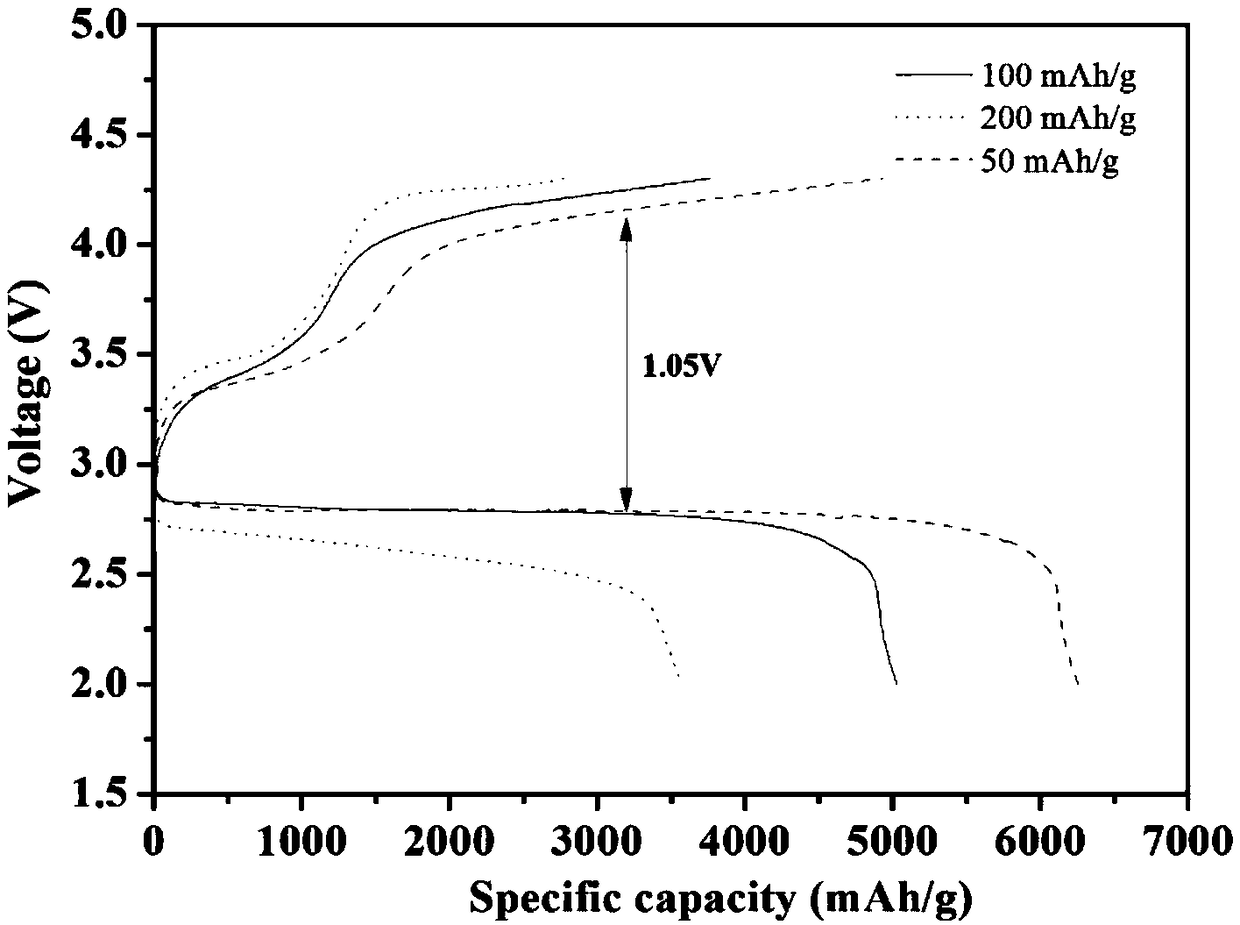

A lithium-air battery and ionic liquid technology, applied in the preparation of lithium-air battery ionic liquid electrolyte and air battery, electrolyte and air battery preparation, can solve problems such as battery performance degradation, achieve wide liquid temperature range, strong practicability, and improve Effects of specific capacity and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This example provides a preparation method for 1-ethyl-3-methylimidazolium tetrafluoroborate ionic liquid, which specifically includes:

[0031] Step 1: Measure 100-500mL of N-methylimidazole with a mass fraction of 99-99.5% in a 2000-3000mL flask, and continuously pass in argon protection. In an argon environment, heat the water bath to 30°C. Under rapid stirring, add bromoethane drop by drop with a constant pressure separatory funnel, wherein the volume ratio of bromoethane added to N-methylimidazole is 2-1.5:1; the mixture is refluxed at 30°C for 8-10 hours , until the reactant completely turned into a light yellow viscous liquid, cooled to room temperature to obtain the crude product;

[0032] Step 2: wash the crude product described in step 1 with ethyl acetate for 3 to 5 times, and the consumption of ethyl acetate is 30 to 100 mL; then put it into a vacuum oven at 70 to 100° C. pure crude product;

[0033] Step 3: Add the crude product described in step 2 into a...

Embodiment 2

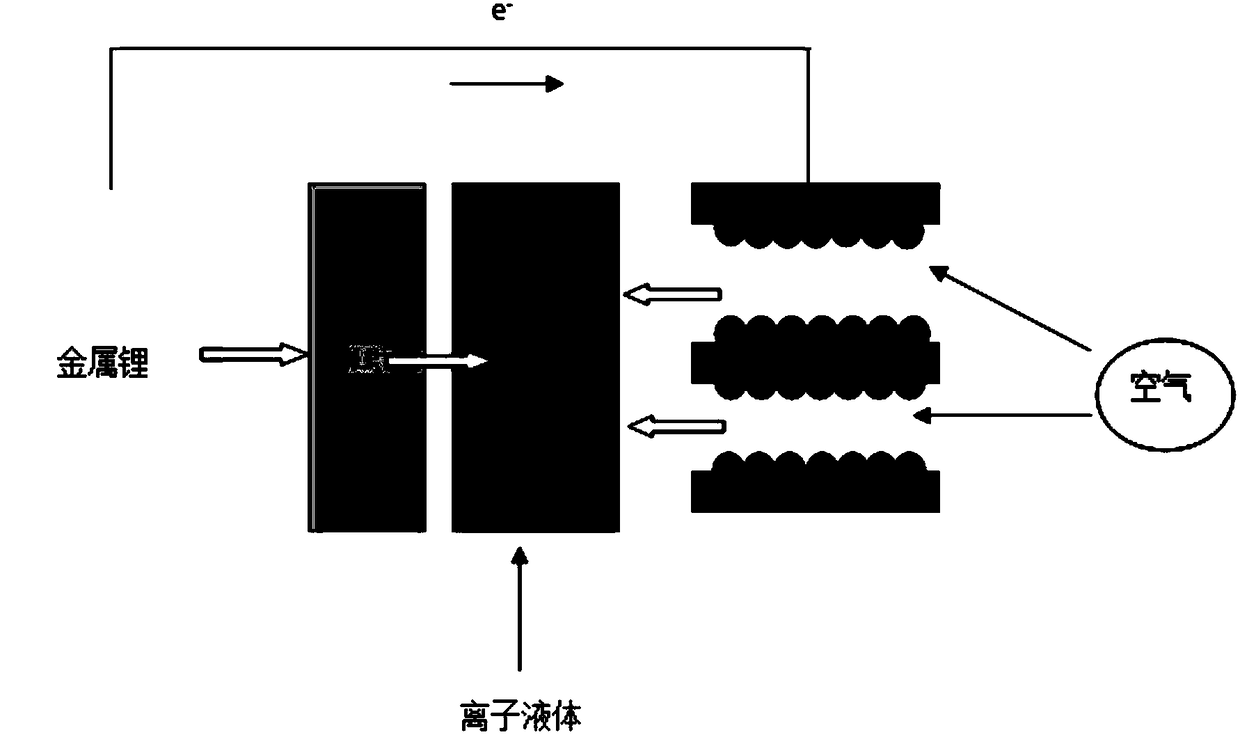

[0037] The assembly of embodiment 2 lithium-air batteries

[0038] The ionic liquid electrolyte prepared in Example 1 was placed between the lithium negative electrode and the air electrode of the lithium-air battery in a glove box, and assembled into a lithium-air battery by sealing the casing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com