Novel composite conductive ceramic and method for producing the same

A composite conductive and new technology, applied in the field of materials, can solve the problems of non-adjustable, high conductive temperature, high sintering temperature, etc., and achieve the effect of adjustable resistivity, easy industrialization, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Weigh 1.0196g (0.01mol) Al 2 o 3 and 4.5780g (0.01mol) La 2 (CO 3 ) 3 , Grinding and mixing with an agate mortar to obtain a precursor. Put the above precursors in a muffle furnace for sintering at 1000°C for 6 hours, then grind a little to get LaAlO3 powder.

[0020] Take 0.0063g (2.94×10 -5 mol)LaAlO 3 With 0.4503g (0.00305mol) SrCO 3 , 0.2436g (0.00305mol) TiO 2 After fully grinding and mixing in an agate mortar for 3 hours, use a tablet machine to press into a disc under a pressure of 10 MPa, put the disc in a muffle furnace, and sinter at 1200 ° C for 6 h under the protection of carbon.

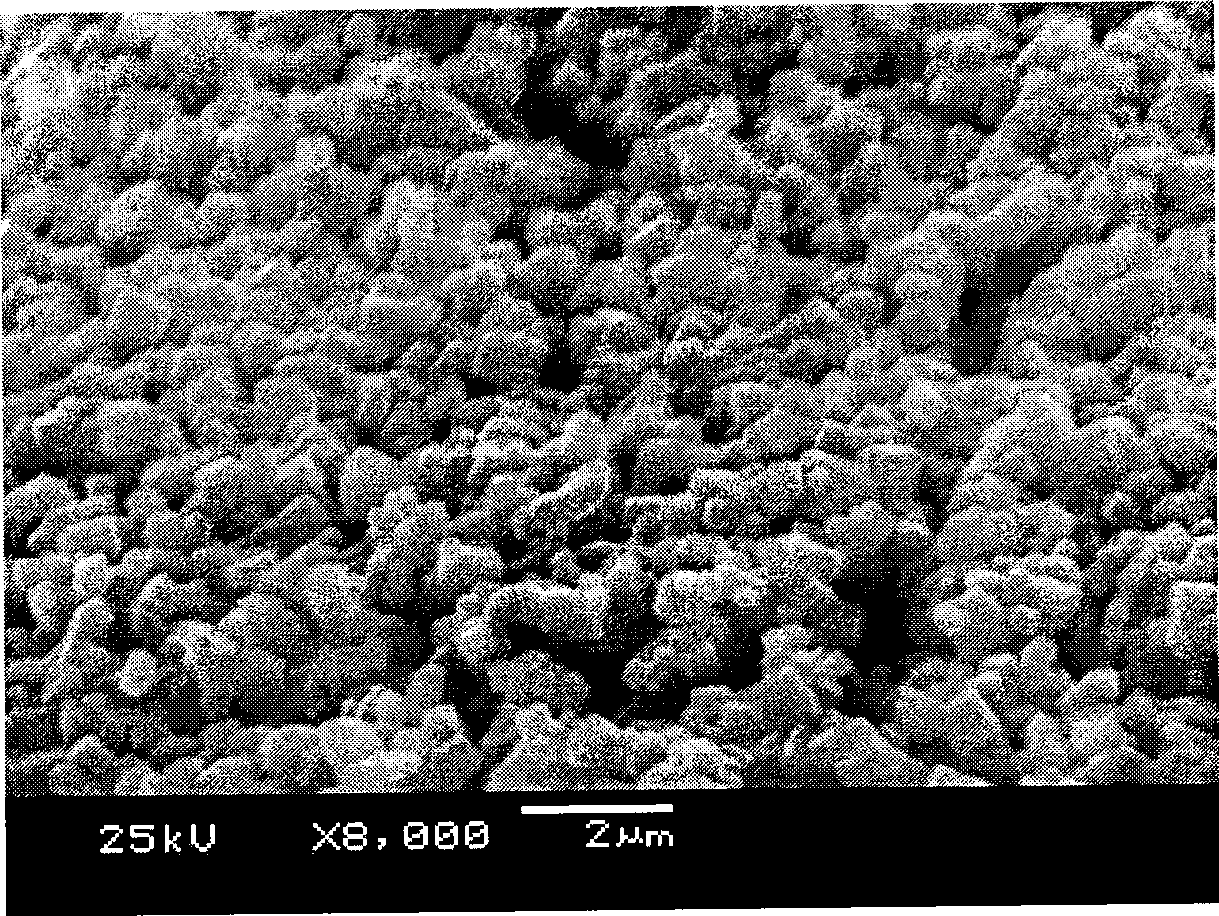

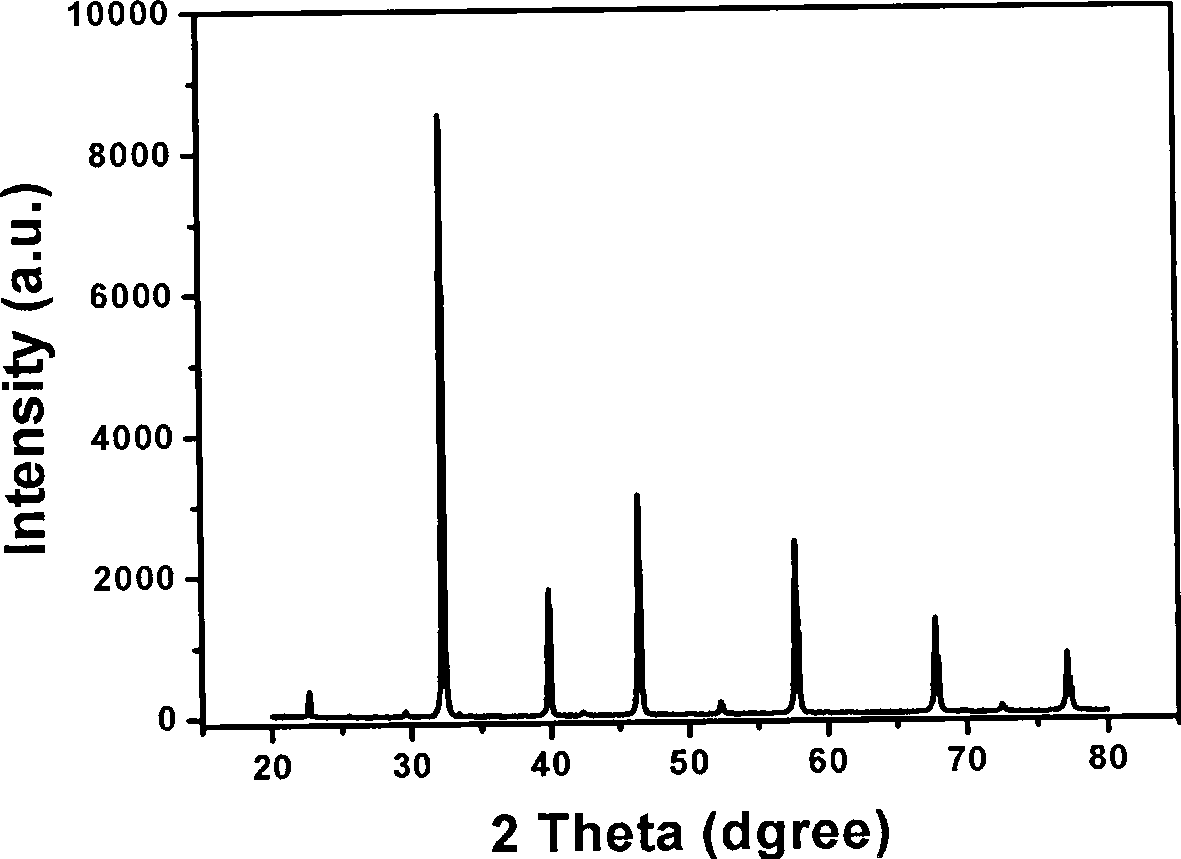

[0021] The resulting product is determined by energy dispersive X-ray spectroscopy, and its composition formula is 0.009LaAlO 3 : 0.991SrTiO 3 (molar ratio), the average particle size is 1um. Its conductivity is 4.62×10 -4 S m -1 , SEM image and XRD pattern such as figure 1 with figure 2 shown. The obtained product was soaked in 1M hydrochloric acid for 2 hours, a...

Embodiment 2

[0023] Weigh 1.0196g (0.01mol) Al 2 o 3 , 3.2582g (0.01mol) La 2 o 3 , use an agate mortar to grind and mix the precursor, put the above precursor in a muffle furnace for sintering at 1000°C for 6 hours, and then grind it a little to get LaAlO 3 Powder.

[0024] Take 0.0063g (2.94×10 -5 mol)LaAlO 3 With 0.4503g (0.00305mol) SrCO 3 , 0.2436g (0.00305mol) TiO 2 After fully grinding and mixing in an agate mortar for 3 hours, use a tablet machine to press into a disc under a pressure of 10MPa, put the disc in a tube furnace, and inject H 2 Sintering at 1200°C for 6h under the same conditions.

[0025] The resulting product is determined by energy dispersive X-ray spectroscopy, and its composition formula is 0.009LaAlO 3 : 0.991SrTiO 3 (molar ratio), the average particle size is 1um. Its conductivity is 5.72×10 -4 S m -1 .

Embodiment 3

[0027] Weigh 1.0196g (0.01mol) Al 2 o 3 , 4.5780g (0.01mol) La 2 (CO 3 ) 3 , use an agate mortar to grind and mix the precursor, put the above precursor in a muffle furnace for sintering at 1000°C for 6 hours, and then grind it a little to get LaAlO 3 Powder.

[0028] Take 0.0063g (2.94×10 -5 mol)LaAlO 3 With 0.4503g (0.00305mol) SrCO 3 , 0.2436g (0.00305mol) TiO 2 After fully grinding and mixing in an agate mortar for 3 hours, use a tablet machine to press into a disc under a pressure of 10 MPa, put the disc in a muffle furnace, and sinter in air at 1200 ° C for 6 h.

[0029] The resulting product is determined by energy dispersive X-ray spectroscopy, and its composition formula is 0.009LaAlO 3 : 0.991SrTiO 3 , the average particle size is 1um. Its conductivity is 9.53×10 -6 S m -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com