Patents

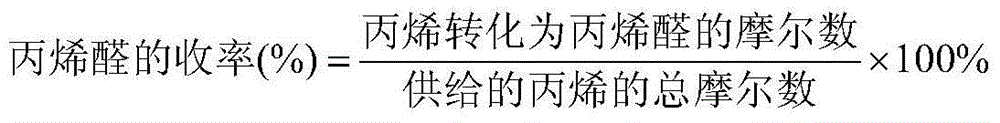

Literature

112 results about "Lanthanum aluminate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lanthanum aluminate is an inorganic compound with the formula LaAlO₃, often abbreviated as LAO. It is an optically transparent ceramic oxide with a distorted perovskite structure.

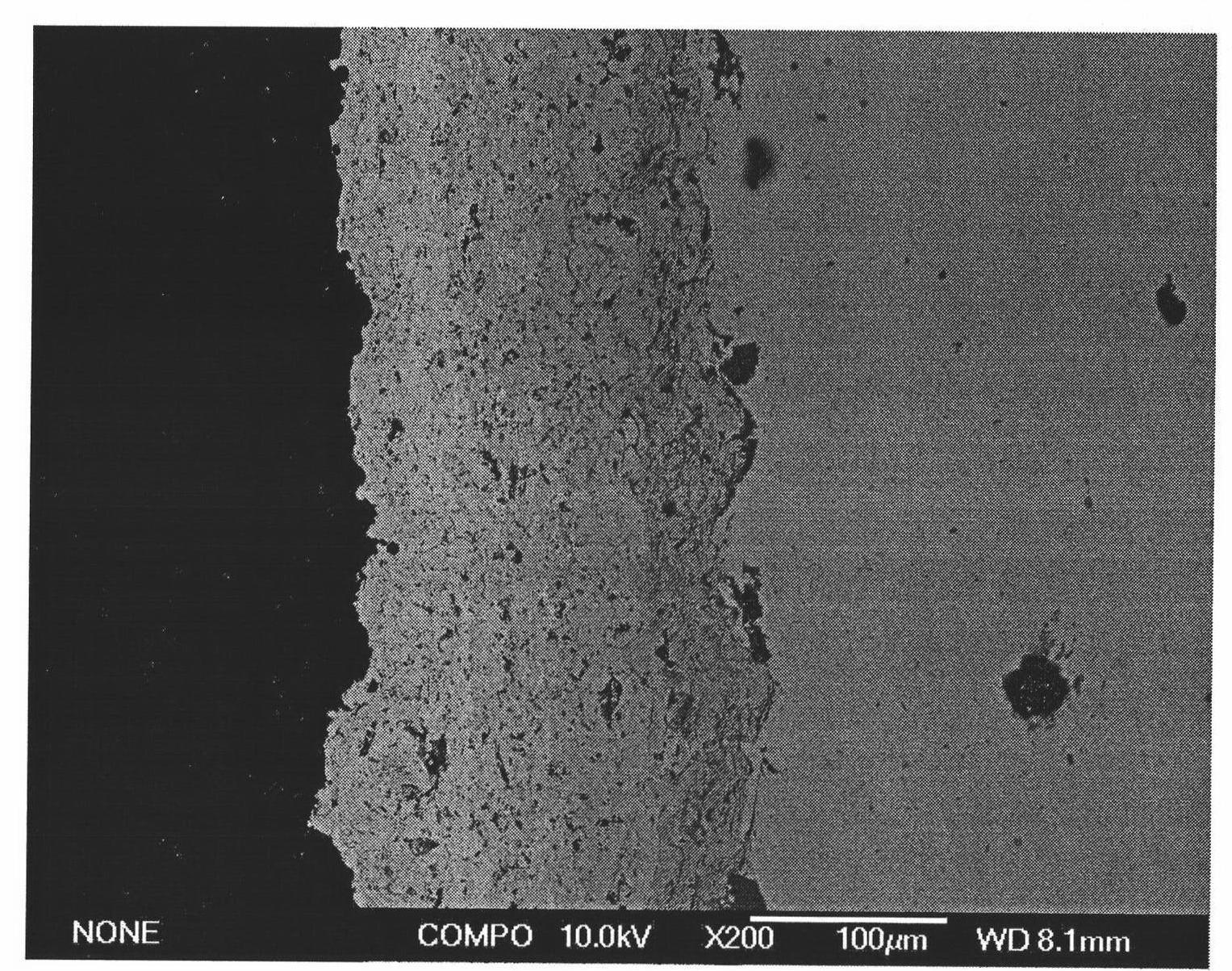

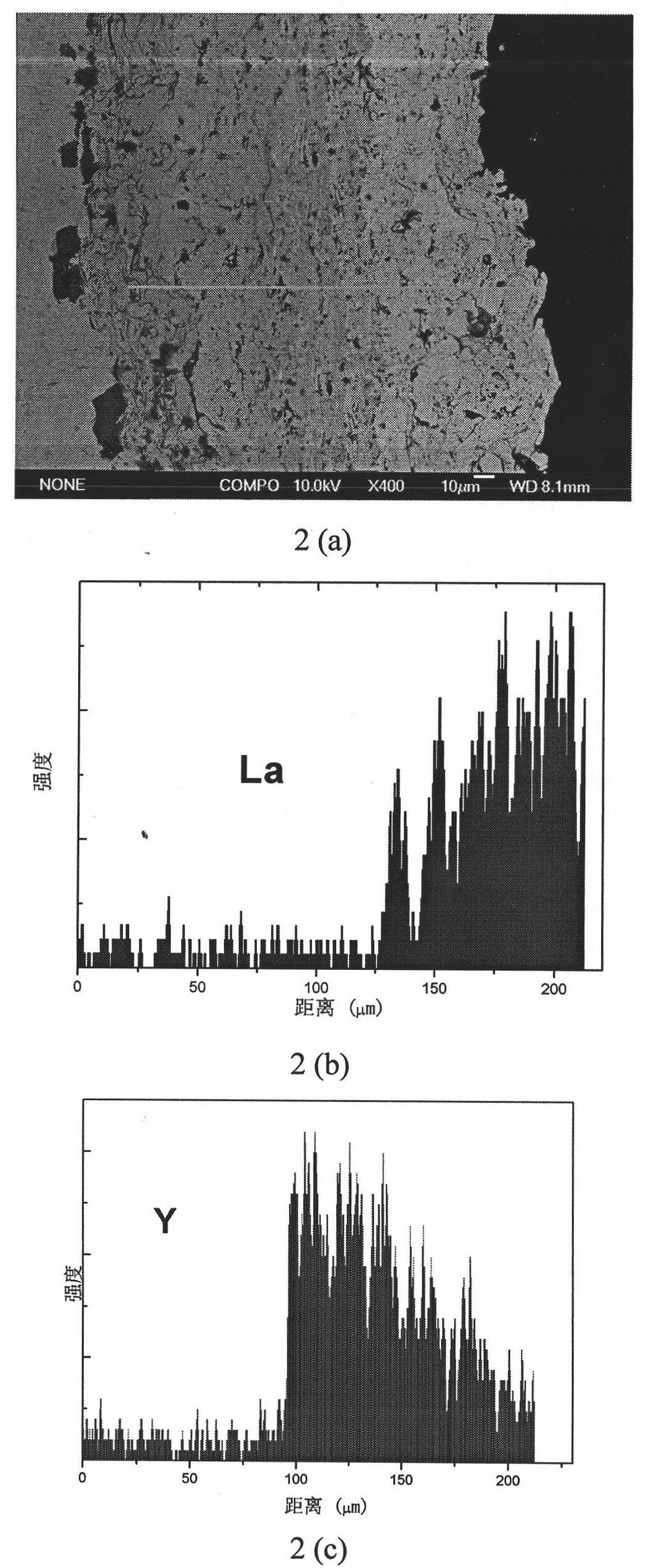

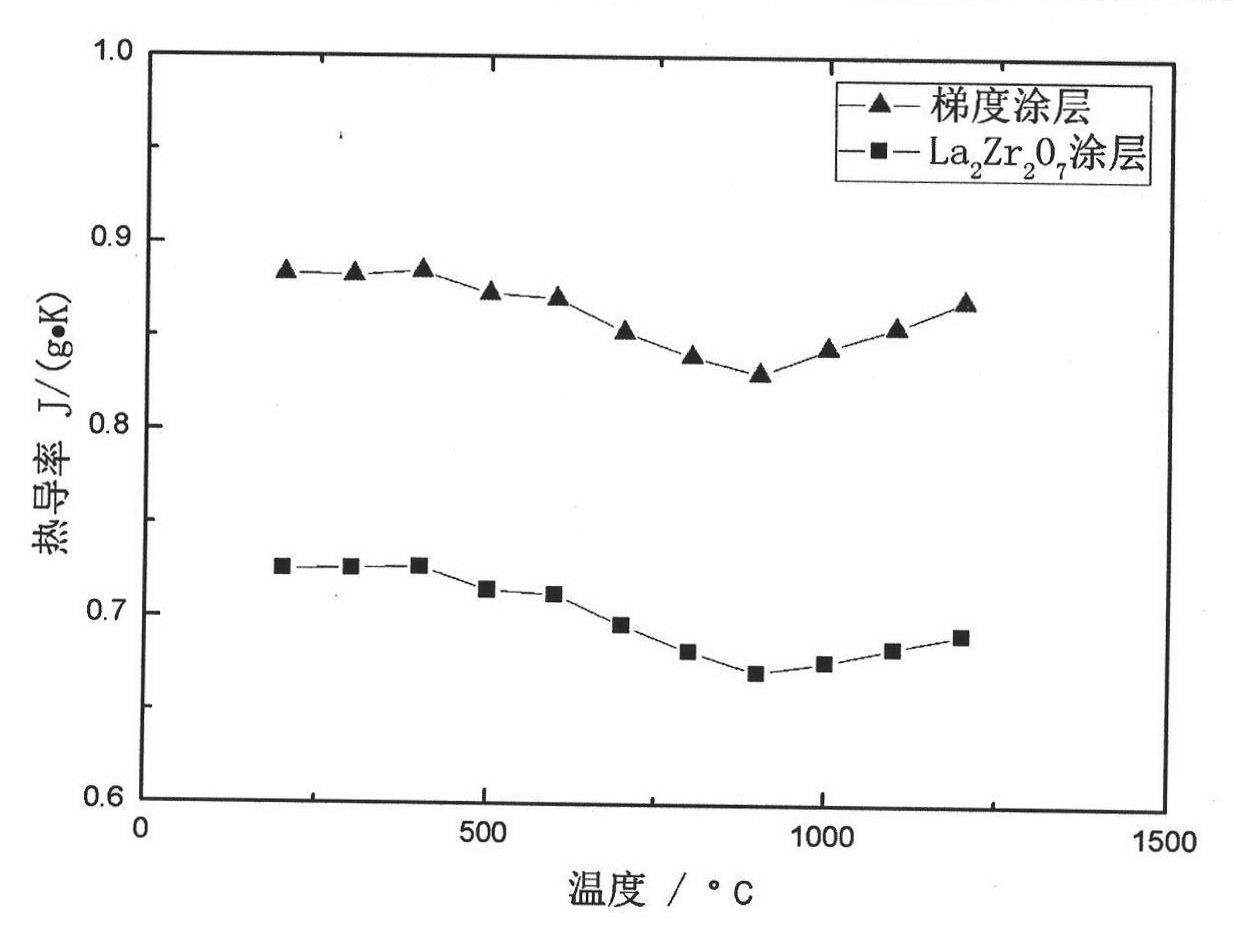

Thermal protection coating with component gradient change and preparation method

InactiveCN101768380AReduce heat stress concentrationImprove thermal shock resistanceMolten spray coatingRare-earth elementLanthanum aluminate

The invention belongs to the field of inorganic materials, particularly relates to a thermal protection coating with component gradient change and a preparation method. The thermal protection coating comprises two components of M1 and M2, wherein the M1 is selected from one of YSZ, lanthanum aluminate, mulite or BSAS, the M2 is selected from one of Ln2Zr2O7, Ln2Ce2O7, Ln2SiO5, Ln2Si2O7 or MoSi2, and Ln is selected from rare earth elements the atom coefficients of which are 57-71, Y or Sc. The thermal protection coating has the characteristics of good coating compactness, high bonding strength with a substrate, low thermal conductivity and the like and has favorable thermal shock resistance.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

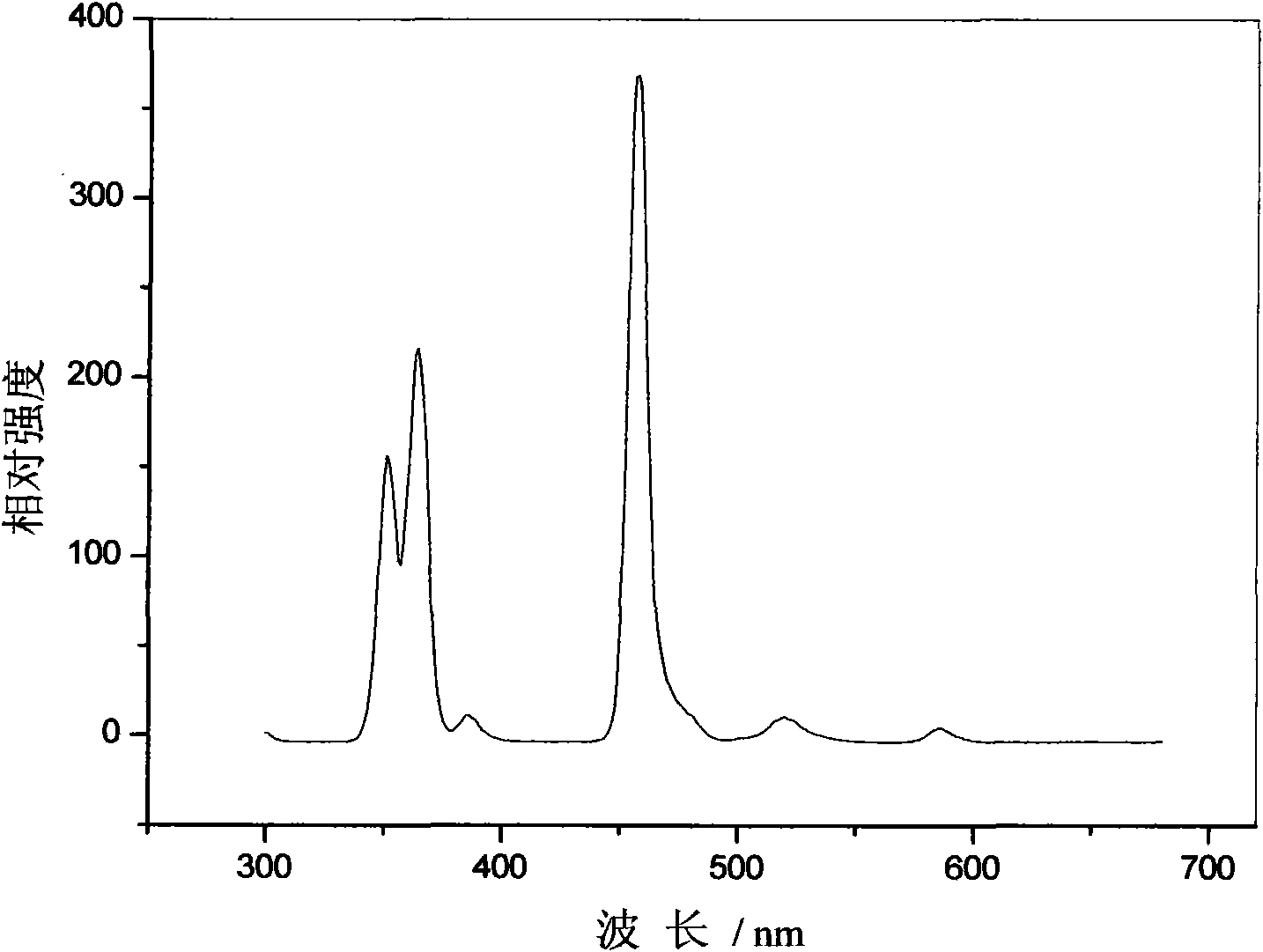

Metal nano particle-doped rare earth lanthanum aluminate light-emitting material and preparation method thereof

InactiveCN101899308AImprove stabilityImprove luminosityLuminescent compositionsRare earthLanthanum aluminate

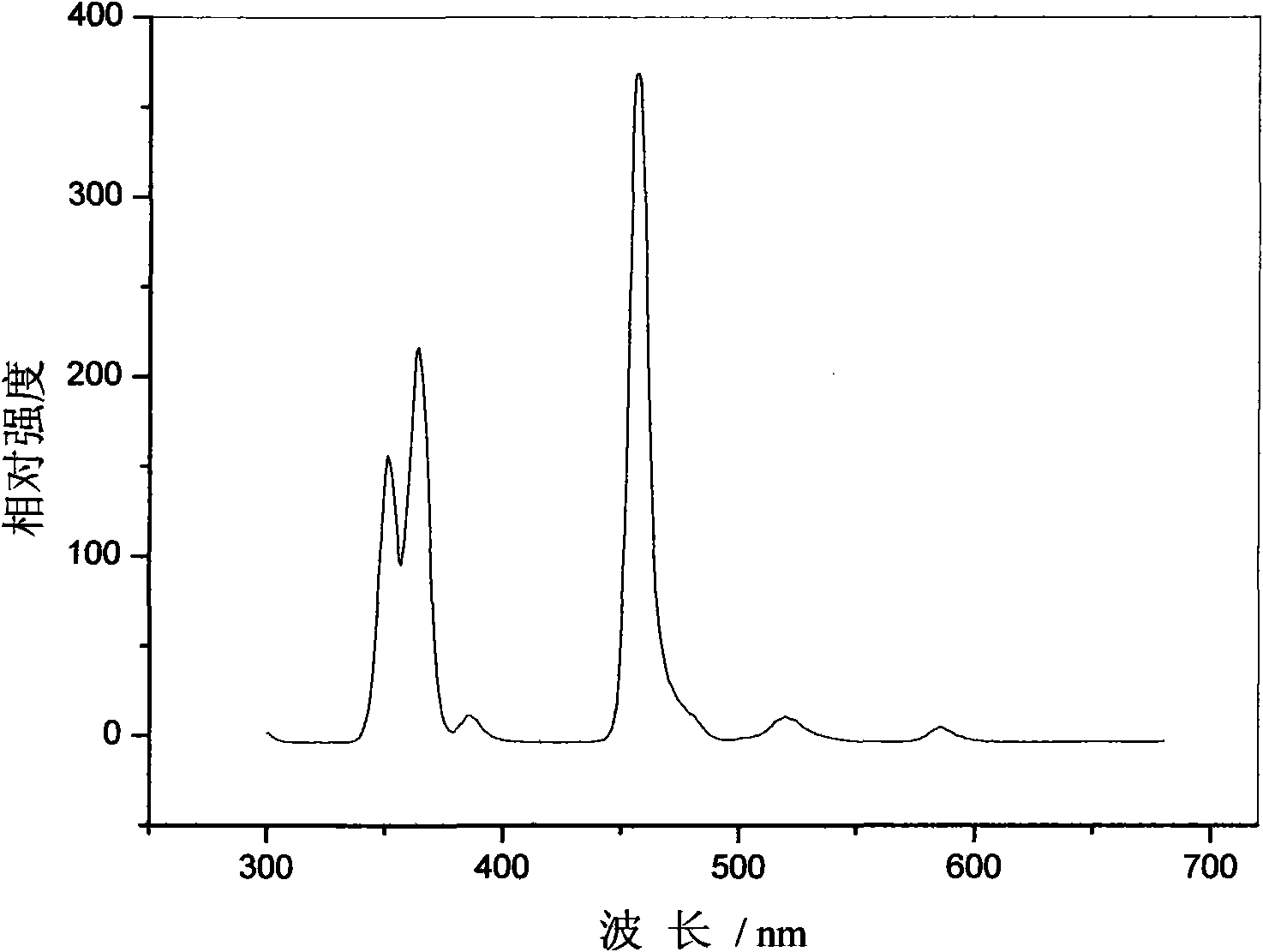

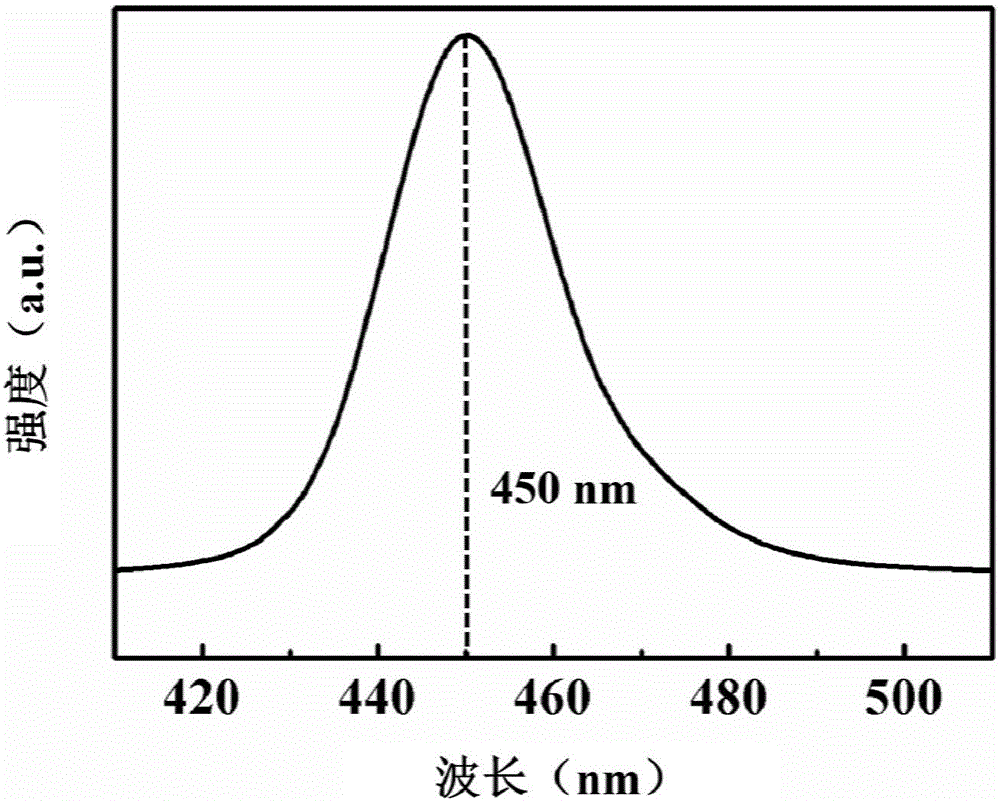

The invention discloses a metal nano particle-doped rare earth lanthanum aluminate light-emitting material, which belongs to the field of preparation of rare earth lanthanum aluminate light-emitting materials. The material has the chemical general formula of La1-x AlO3:Lnx@My, wherein @ is a cladding, and M is a metal nano particle and is selected from at least one of Ag, Au, Pt, Pd and Cu; and Ln is rare earth metal and is selected from one of Tm, Sm and Tb or a mixture of Sm and Tb, x is more than zero and smaller than or equal to 0.2, and y is a molar ratio of M and Al and is more than zero and smaller than or equal to 1*10<-2>. The invention also discloses a preparation method of the meal nano particle-doped rare earth lanthanum aluminate light-emitting material. The rare earth lanthanum aluminate light-emitting material prepared by doping the metal nano particle has the advantages of high stability and better light-emitting performance. The preparation method of the invention has simple process, low equipment requirement, no pollution and easy control and is suitable for industrialized production.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Nonvolatile semiconductor memory element and manufacturing method thereof

InactiveUS20090057750A1TransistorSemiconductor/solid-state device manufacturingOptoelectronicsLanthanum aluminate

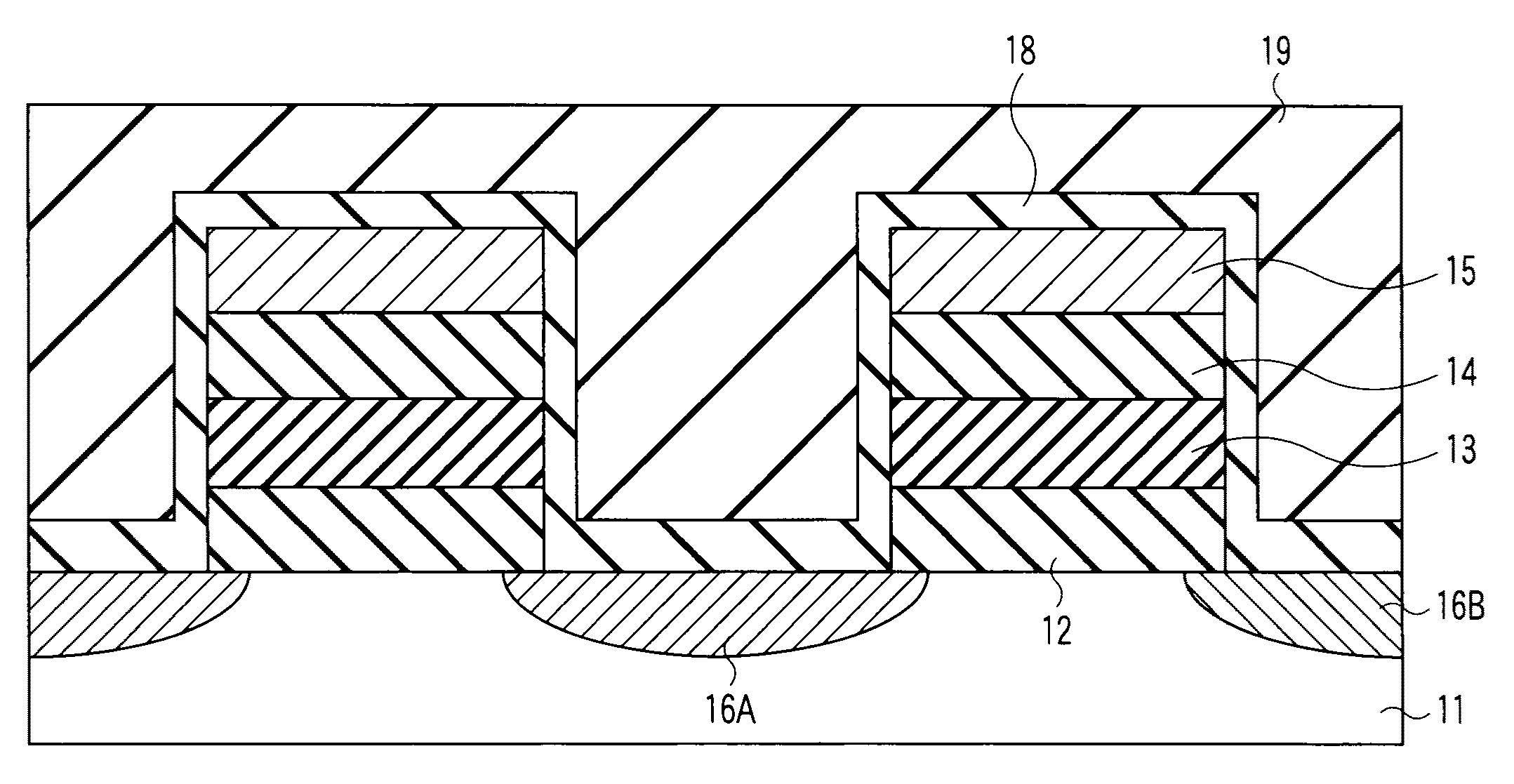

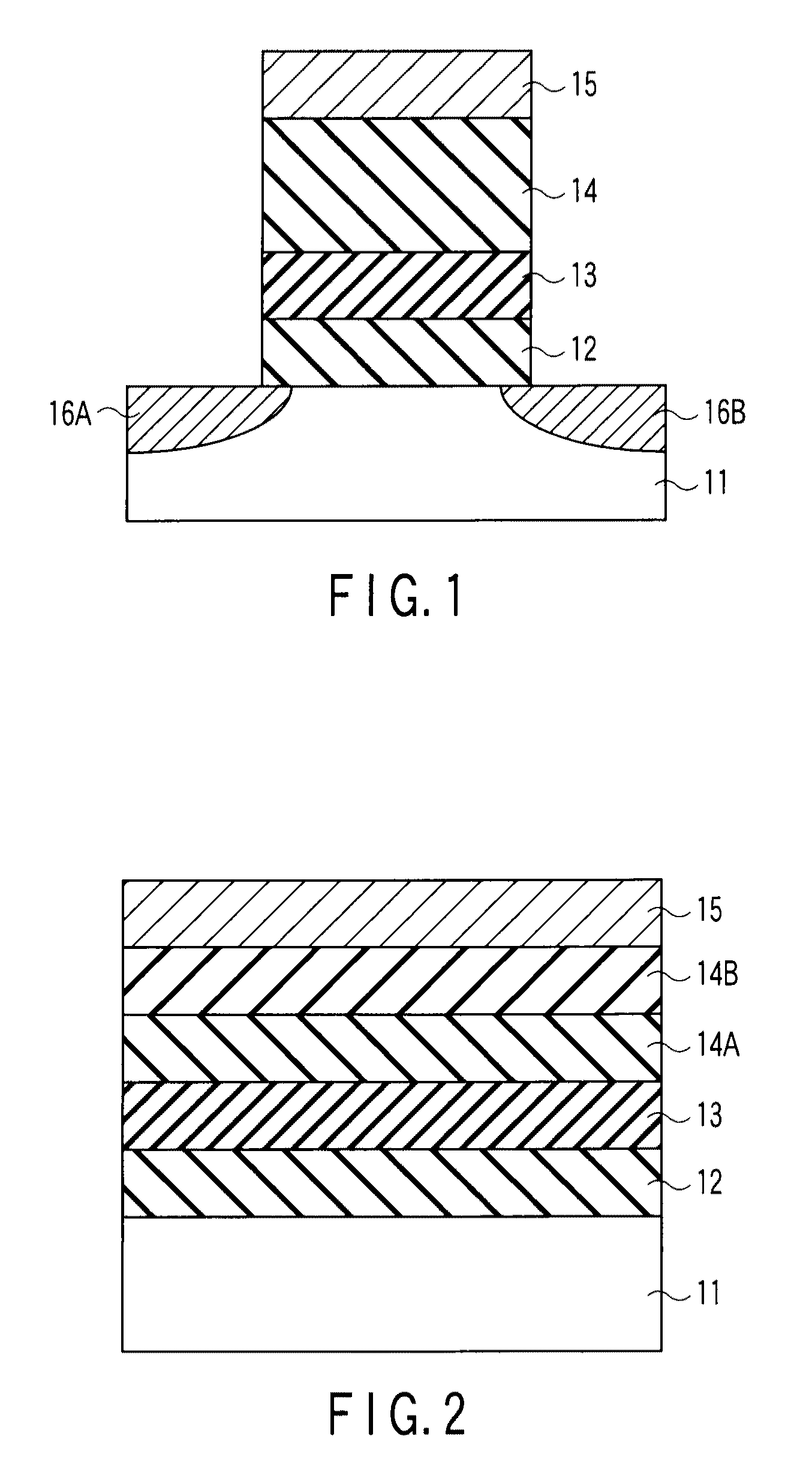

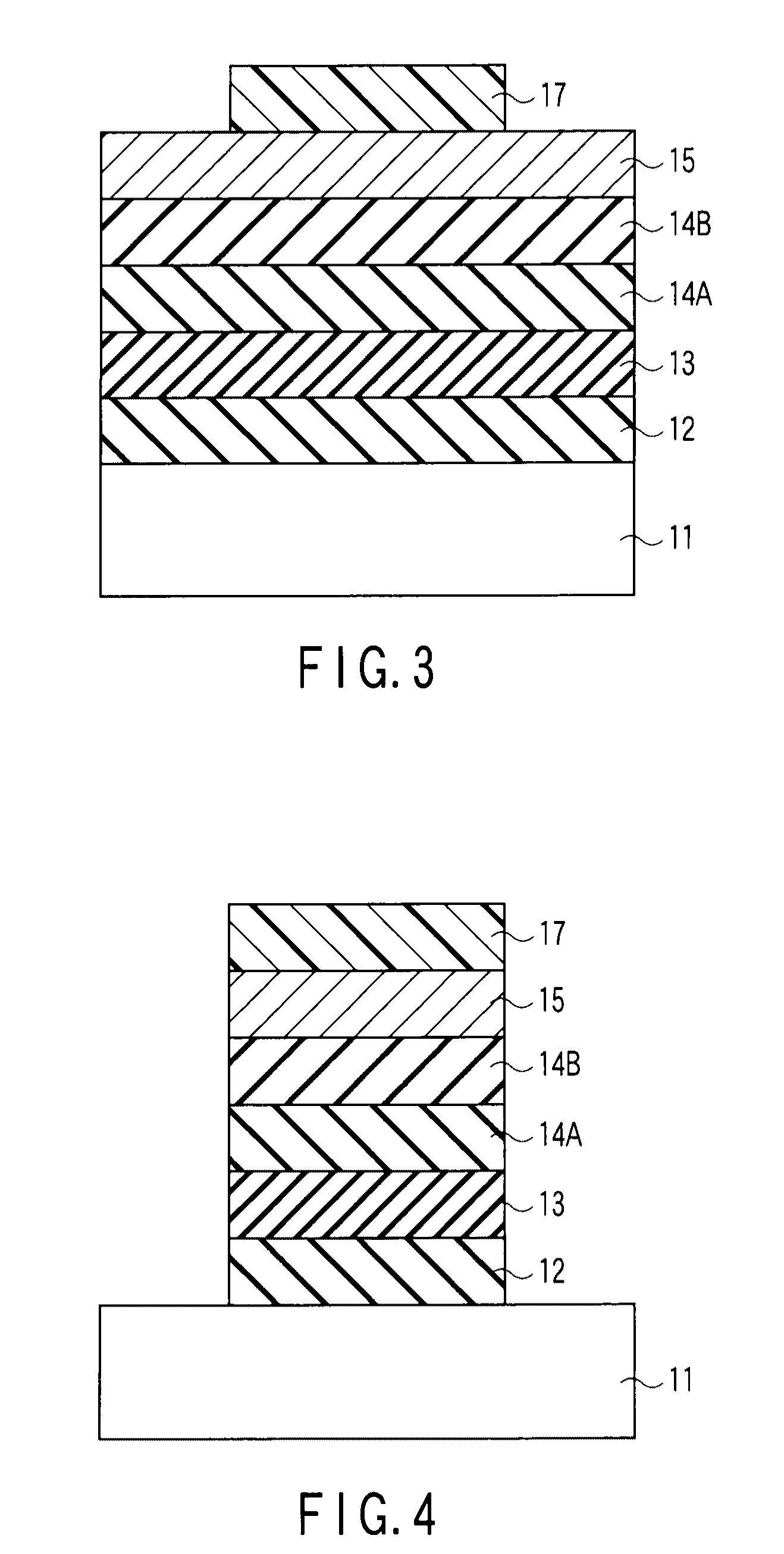

A nonvolatile semiconductor memory element includes a semiconductor substrate, a source region and a drain region which are provided separately in the semiconductor substrate, a tunnel insulating layer which is provided between the source region and the drain region on the semiconductor substrate, a charge storage layer which is provided on the tunnel insulating layer, a block insulating layer which is provided on the charge storage layer and includes a crystallized lanthanum aluminate layer, and a control gate electrode which is provided on the block insulating layer.

Owner:KK TOSHIBA

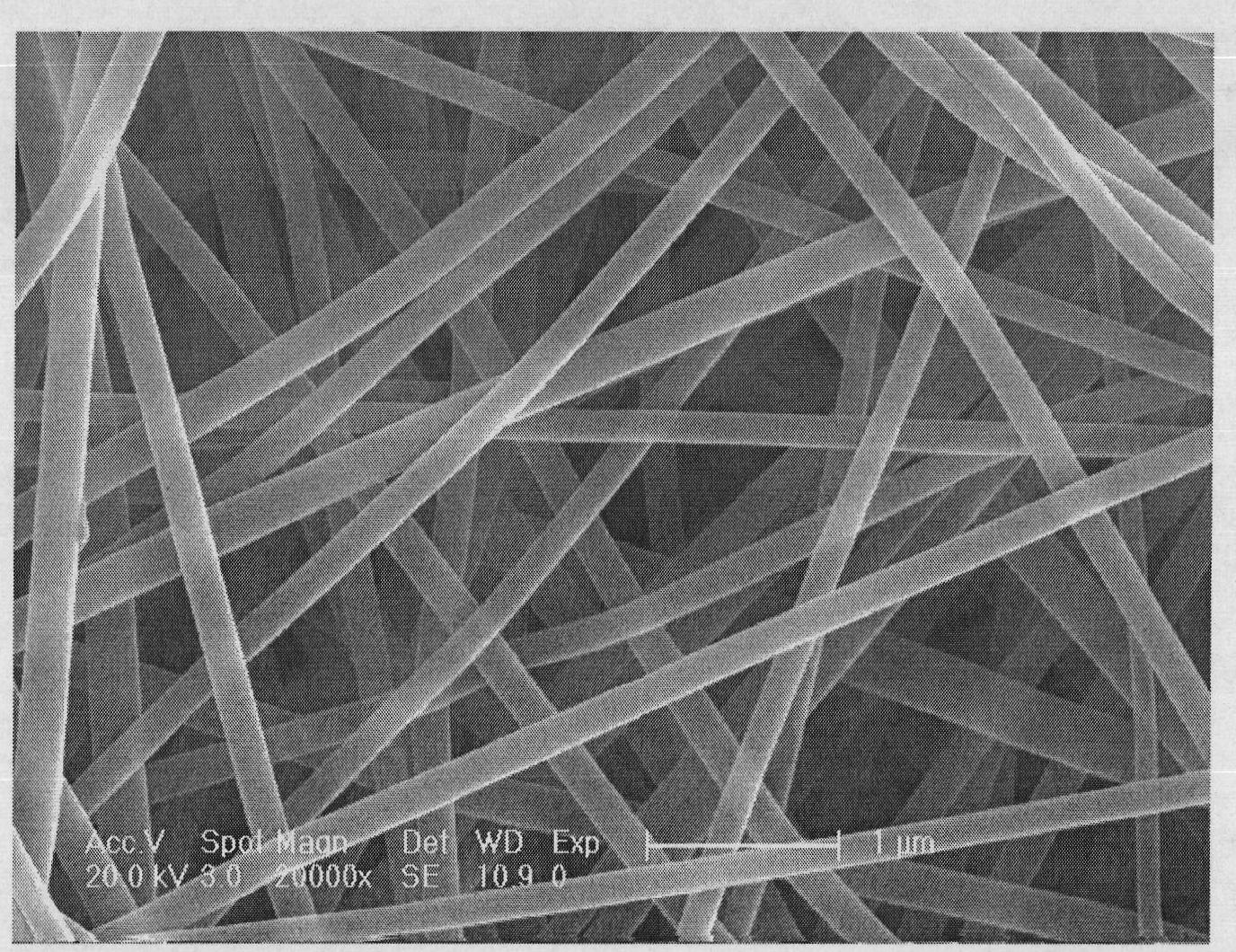

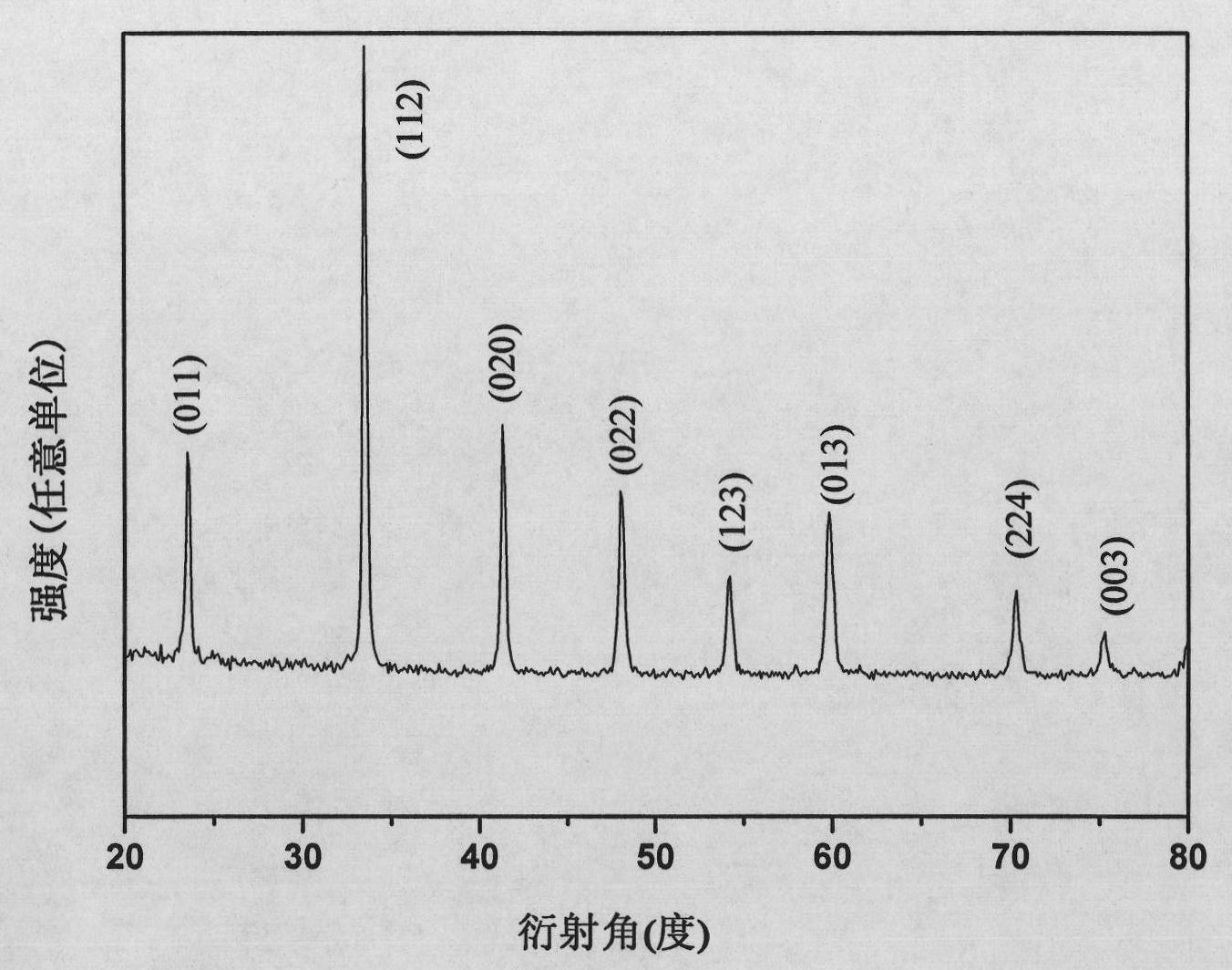

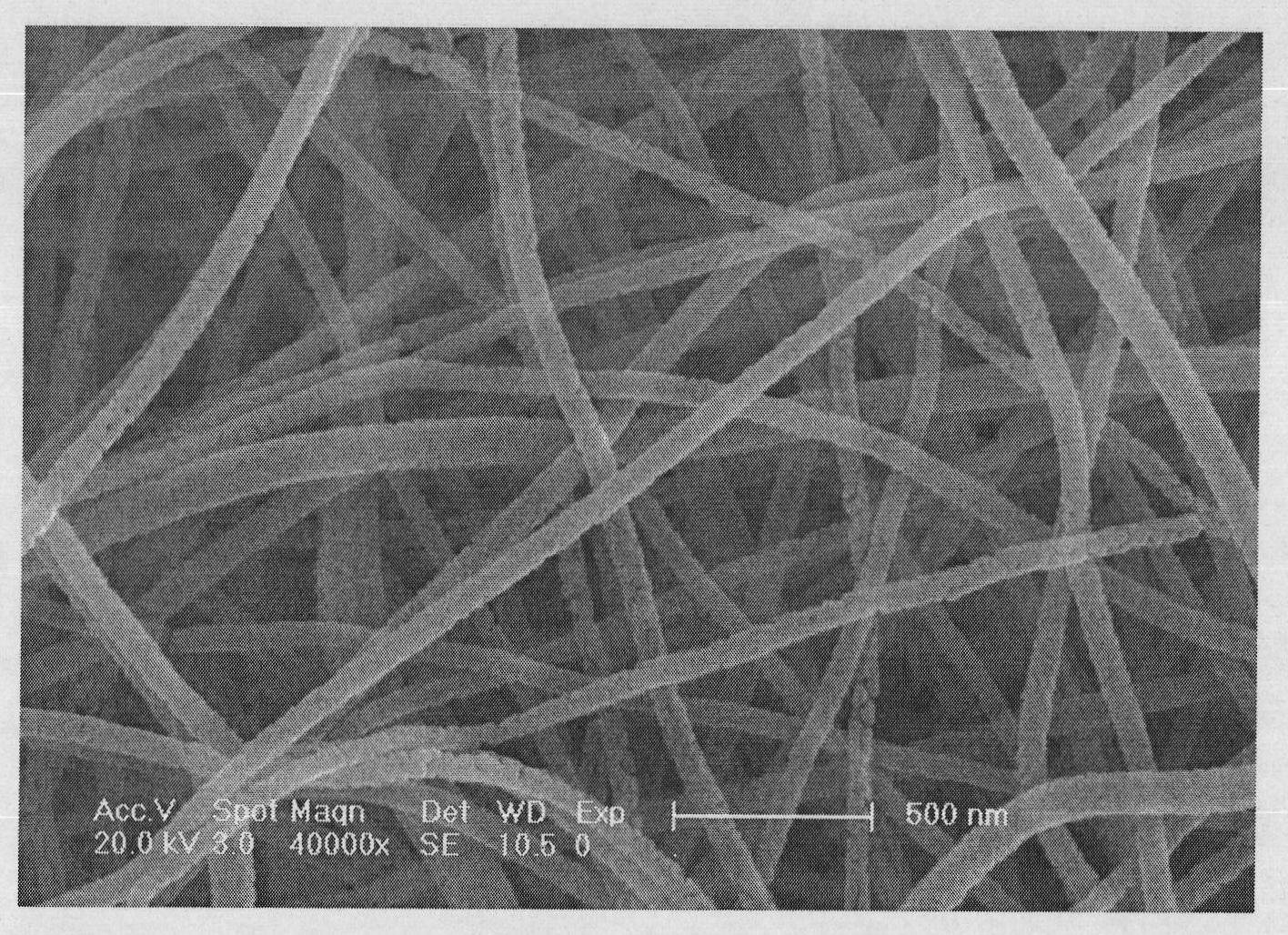

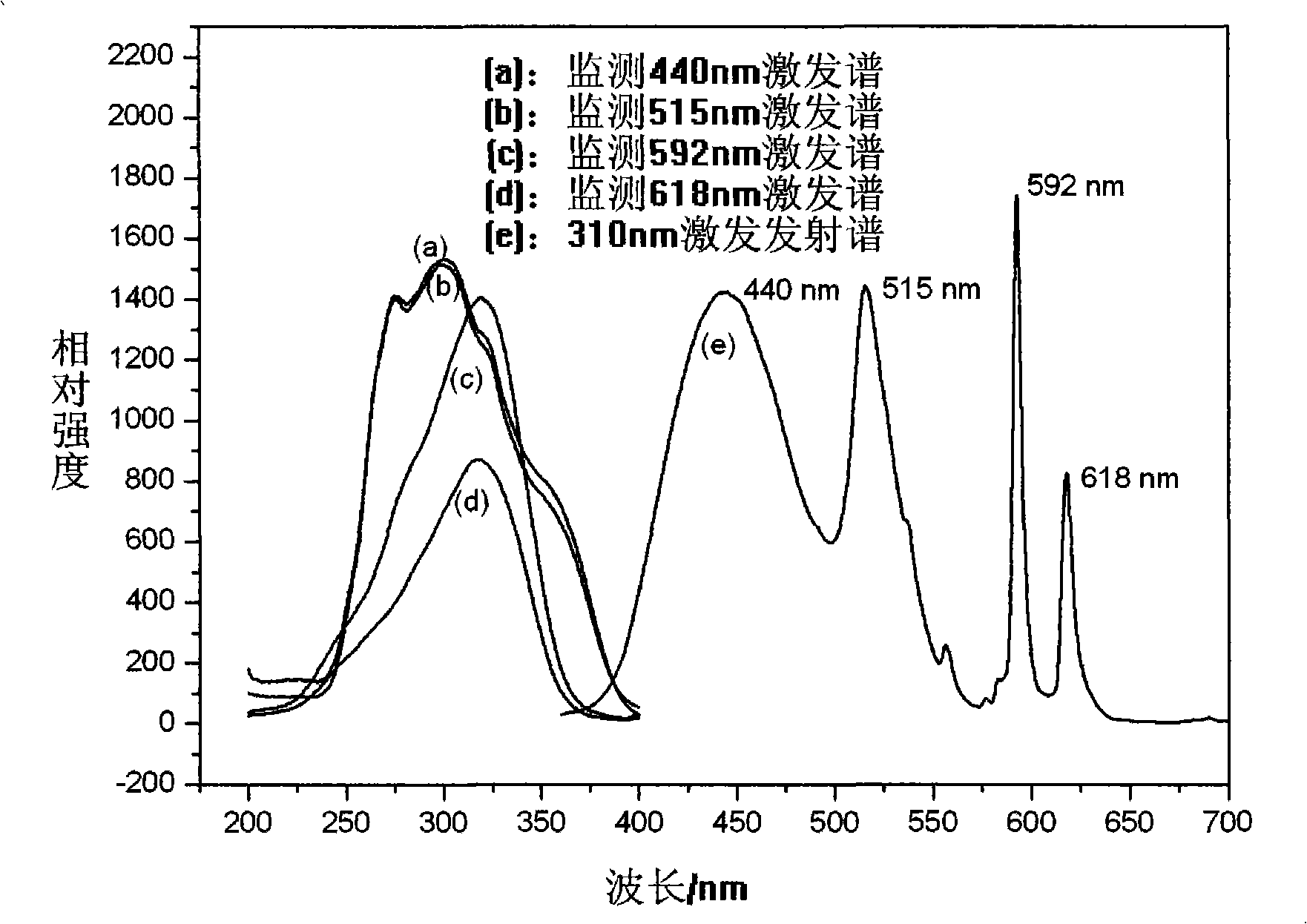

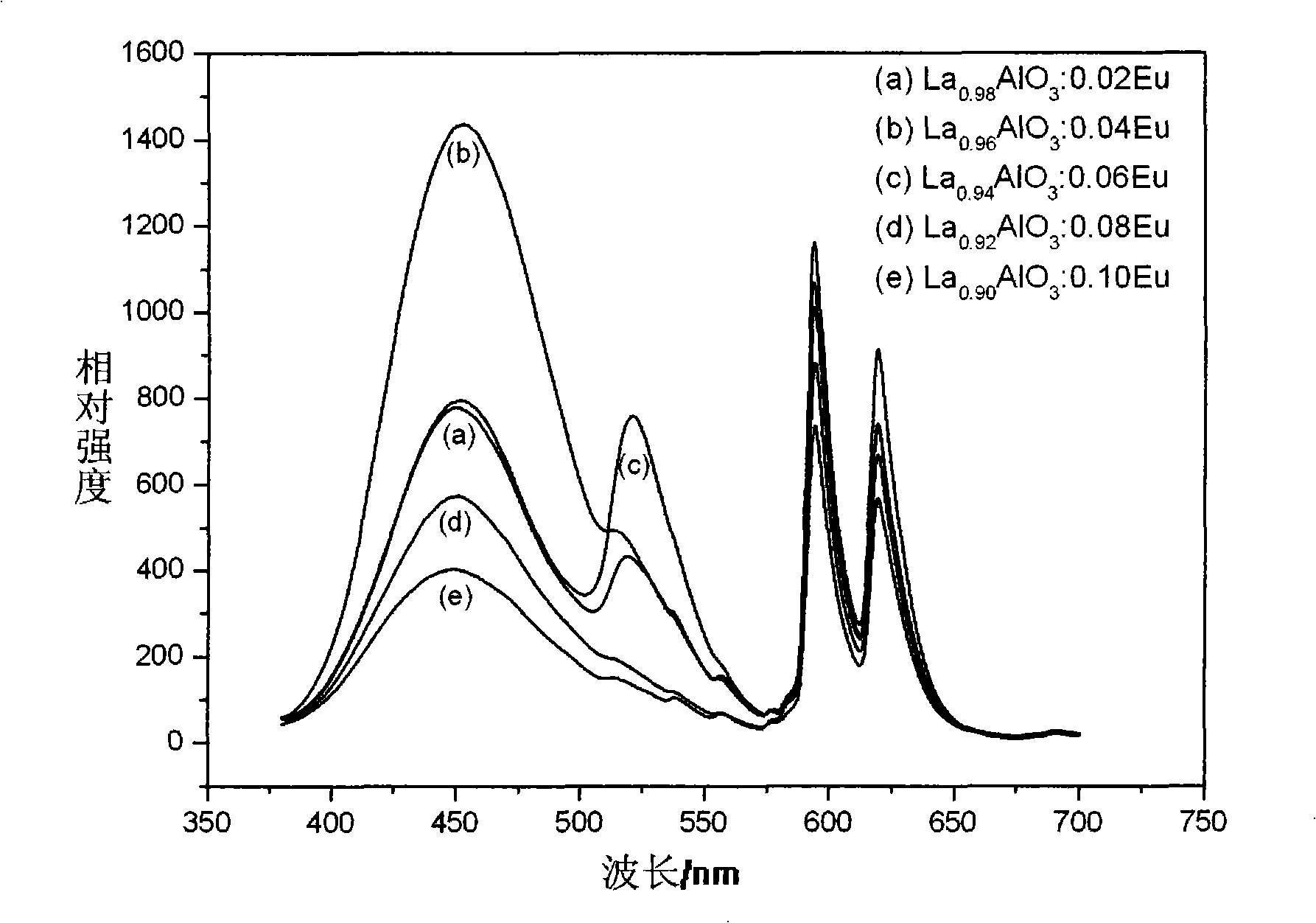

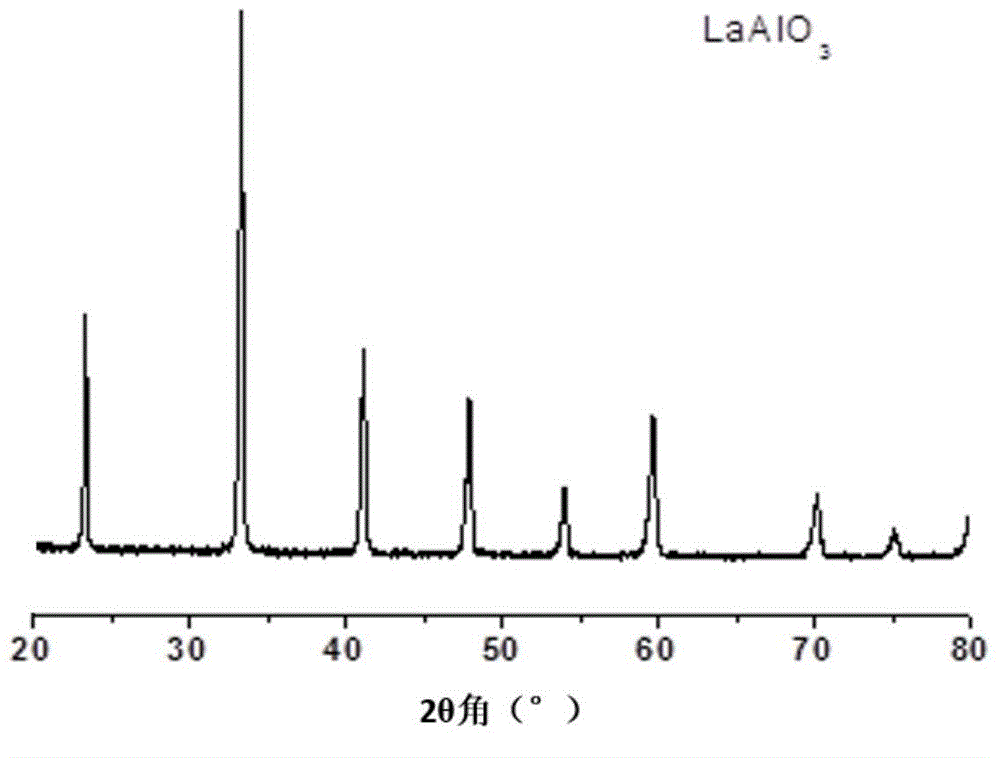

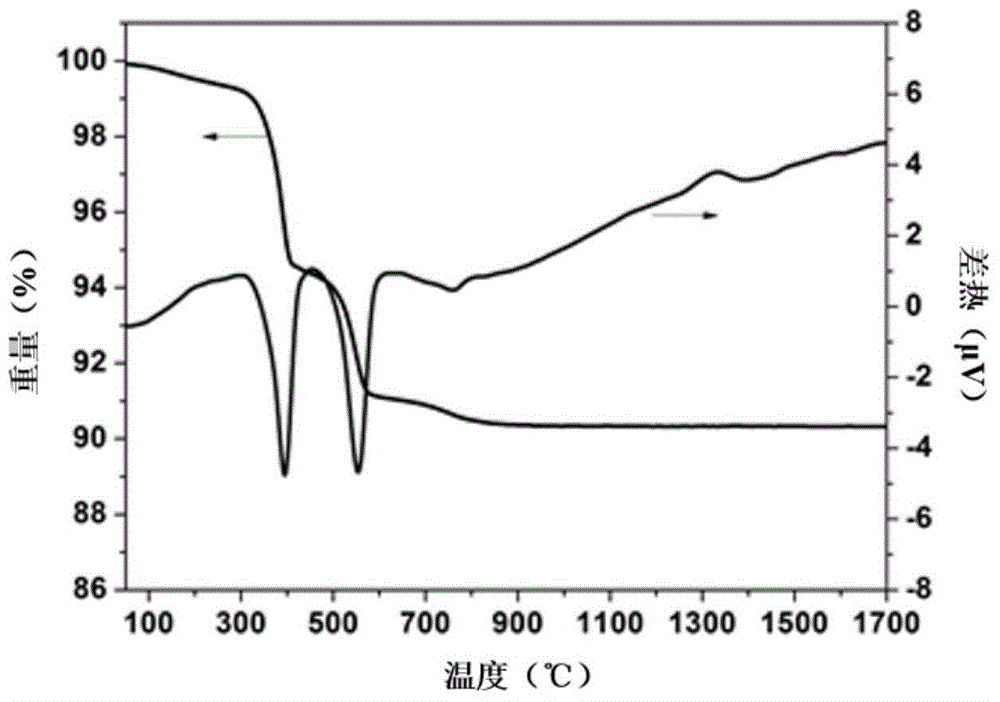

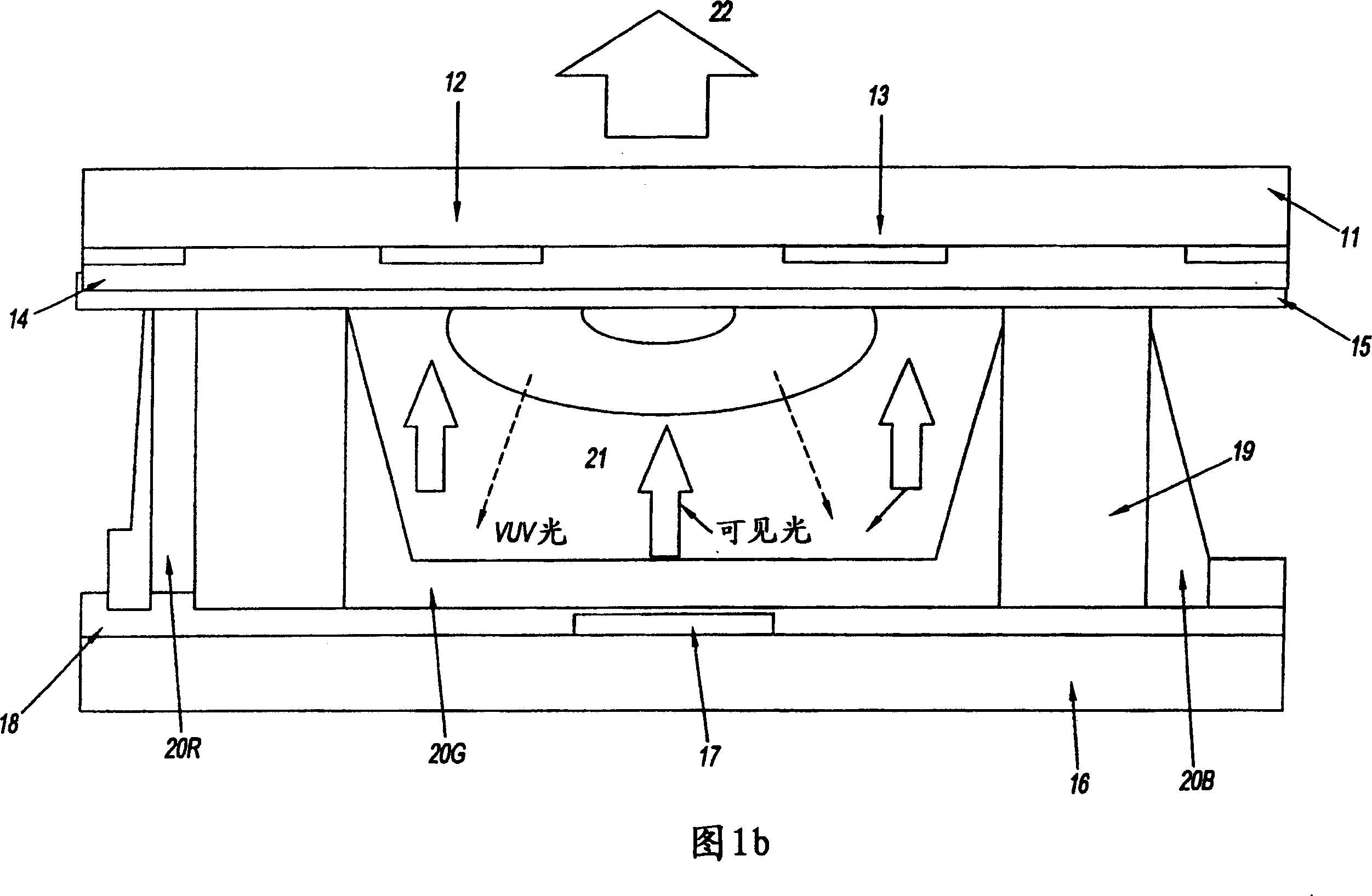

Polycrystalline nano-fiber with europium ion doped with lanthanum aluminate and preparation method thereof

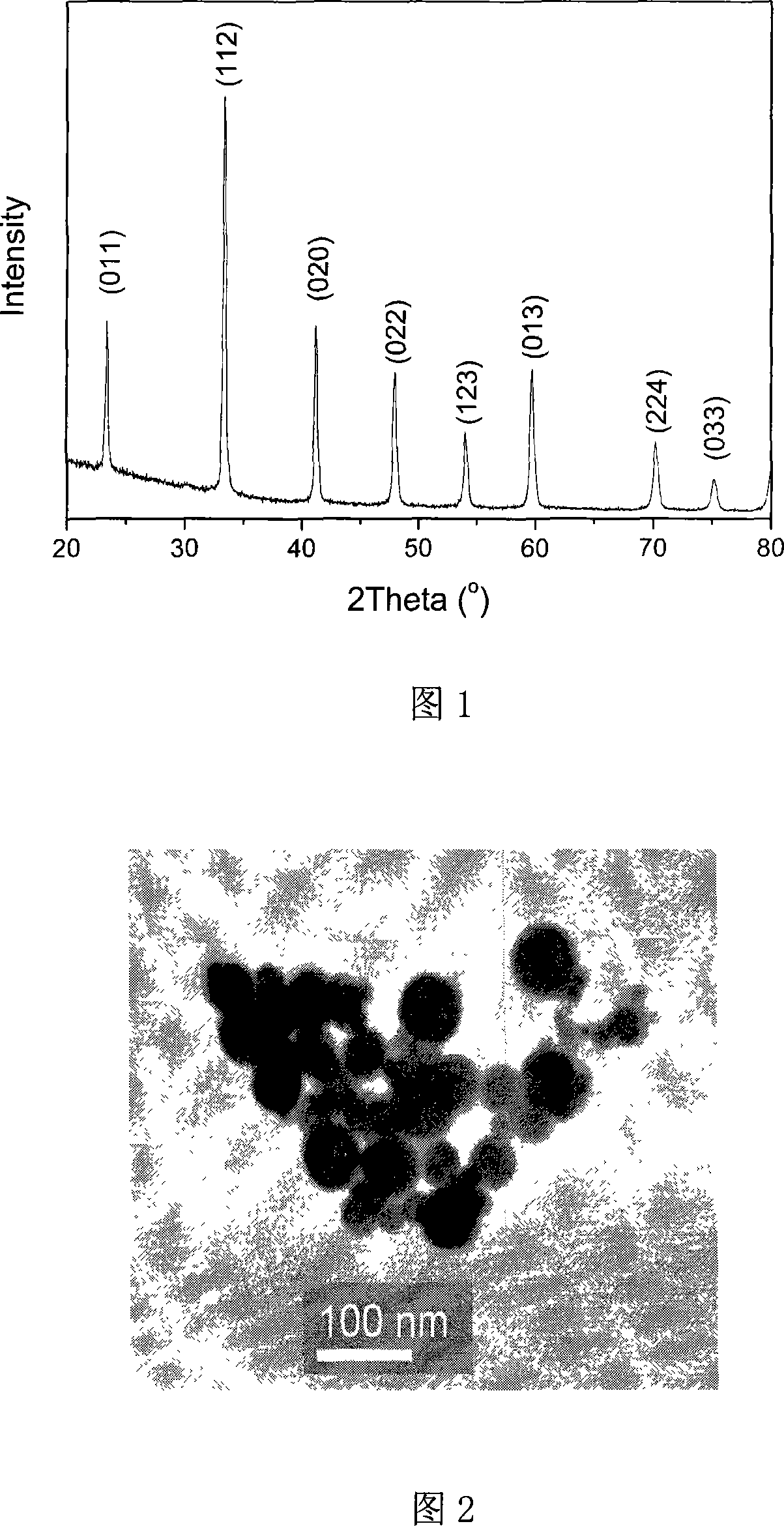

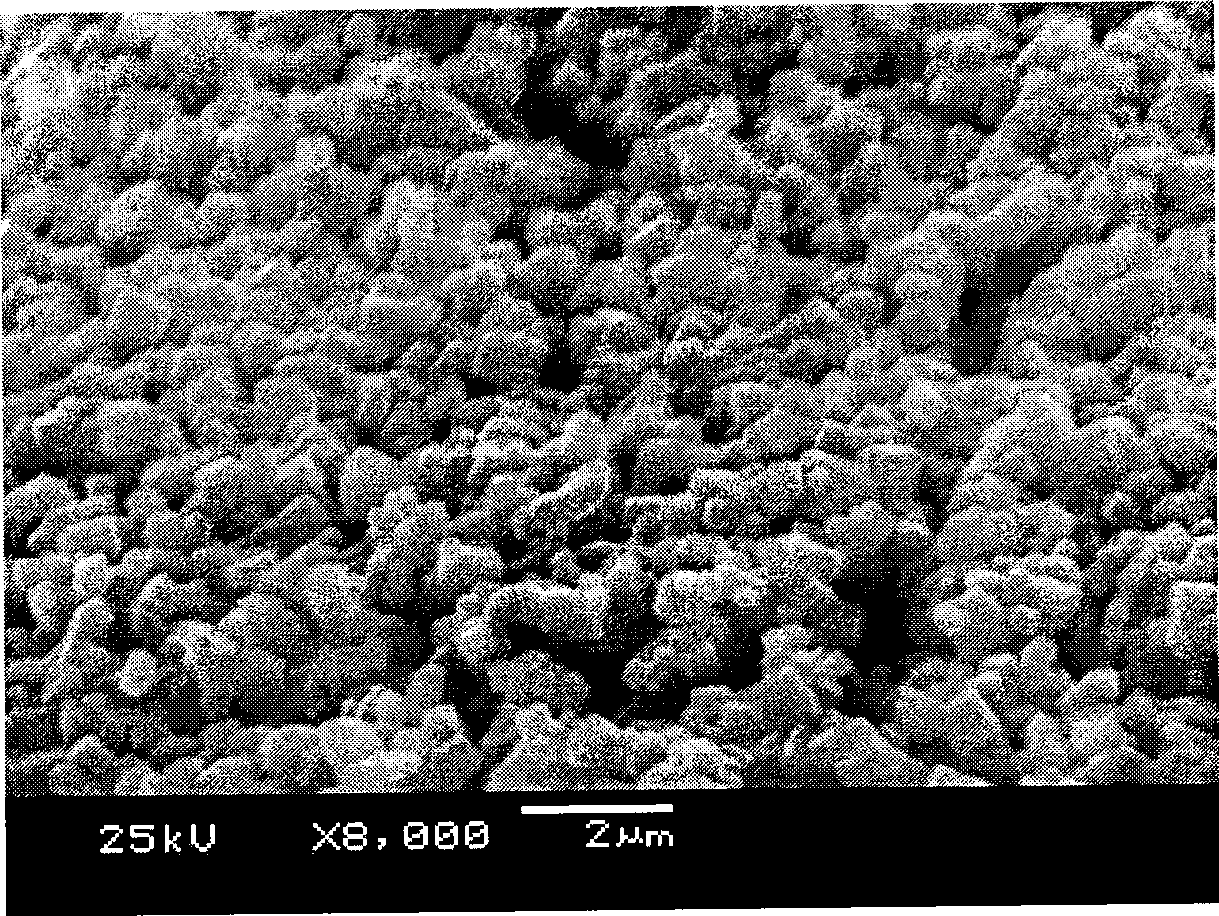

The invention relates to polycrystalline nano-fiber with europium ion doped with lanthanum aluminate and a preparation method thereof, which belongs to the technical field of nano-material preparation. The invention comprises three steps of: (1) preparation of spinning solution; dissolving lanthanum nitrate, europium nitrate, aluminium nitrate and PVP in DMF to form the spinning solution. (2) preparing PVP / metal nitrate composite nano-fiber with the electrospinning technology, 17-20kV of voltage , 16-20 cm of solidification distance , room temperature in 18-28 degrees C., and 40-50 percent of relative humidity. (3) preparing La1-xEuxAlO3 (x = 0-0.1) nano-fiber: heat-processing the PVP / metal nitrate composite nano-fiber to obtain La1-xEuxAlO3 (x = 0-0.1) polycrystalline nano-fiber; the nano-fiber is composed of nano-particles, has the diameter of 75-100 nm and the length of more than 300 Mum, has good crystallinity, and belongs to the rhombohedral crystal system.

Owner:CHANGCHUN UNIV OF SCI & TECH

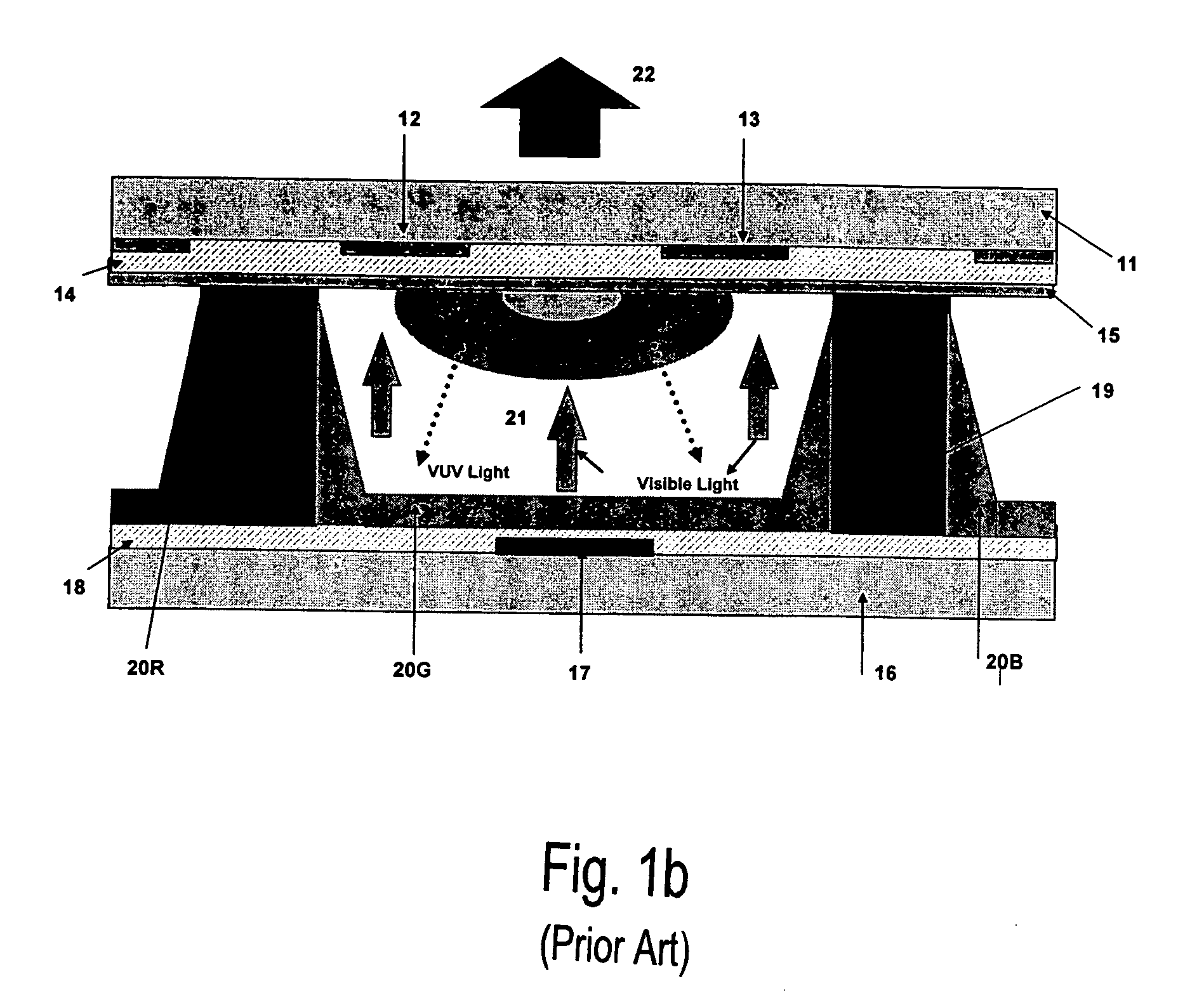

Single-substrate single-doping lanthanum aluminate full-color adjustable fluorinite and production method thereof

InactiveCN101402860AAdjust color coordinatesColor temperature adjustableGas discharge lamp usageRare earth metal compoundsGreen-lightFluorescent lamp

The invention provides a full-color phosphor of a single substrate single mixed lanthanum aluminate base with adjustable colors as well as a manufacture method. The invention belongs to the technical fields of photoelectric materials and apparatuses. The chemical formula of the phosphor is La1-aAlO3:Eua,Li<+>b, wherein, accounted by molal quantity, a is equal to or more than 0.02 and equal to or less than 0.2; b is equal to or more than 0.00 and equal to or less than 0.4; under the excitation of lights with wavelengths of 250nm to 400nm, the phosphor can simultaneously have three emission areas which include the blue lights the emission wavelengths of which are 440nm, the green lights the emission wavelengths of which are 515nm and the red lights the emission wavelengths of which are 592 and 618nm for composing the white light. The manufacture process is as follows: the weighed materials are dissolved into alcohol for forming serum and manufactured into powder through ultrasonic surging and drying; then the mixed gas of N2 and H2 is used as the reduction atmosphere for obtaining the phosphor under high temperature ignition. The spectrum characteristics of the phosphor can be effectively adjusted through adjusting the preparation technical conditions which include the ignition time, the ignition temperature, the reduction atmosphere and the adding concentration of a charge compensation agent of Li<+>. The full-color phosphor can be used for the white light apparatuses of a white light LED, a fluorescent lamp, and the like.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

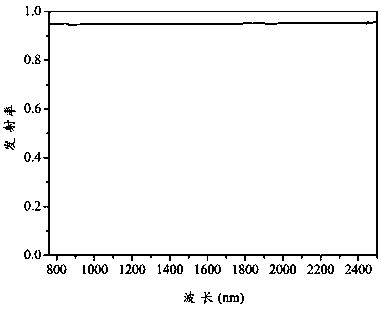

Infrared energy-saving coating material and applications thereof

InactiveCN104987763AHigh infrared emissivityStable serviceChemical industryCoatingsCore componentLanthanum

The present invention provides an infrared energy-saving coating material and applications thereof, and belongs to the technical field of infrared energy-saving materials, wherein a high-emissivity infrared energy-saving material is adopted as a core component, and a dispersant accounting for 3-5% of the mass of the infrared energy-saving coating material, a liquid binder accounting for 10-50% of the mass of the infrared energy-saving coating material, and a stabilizer accounting for 2-5% of the mass of the infrared energy-saving coating material are added to prepare the infrared energy-saving coating material, wherein the high-emissivity infrared energy-saving material adopts lanthanum aluminate of the perovskite structure as a main phase, 0.01-0.25 mole of second main group element ions is doped at the lanthanum site, and 0.02-0.5 mole of transition metal element ions is doped at the aluminum site. According to the present invention, the highest emissivity of the prepared infrared energy-saving coating material can achieve 0.95, and the prepared infrared energy-saving coating material has good high temperature stability, and has great application potential in the high temperature thermal industry furnace kiln energy saving field.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

High-emissivity infrared energy-saving material and applications thereof

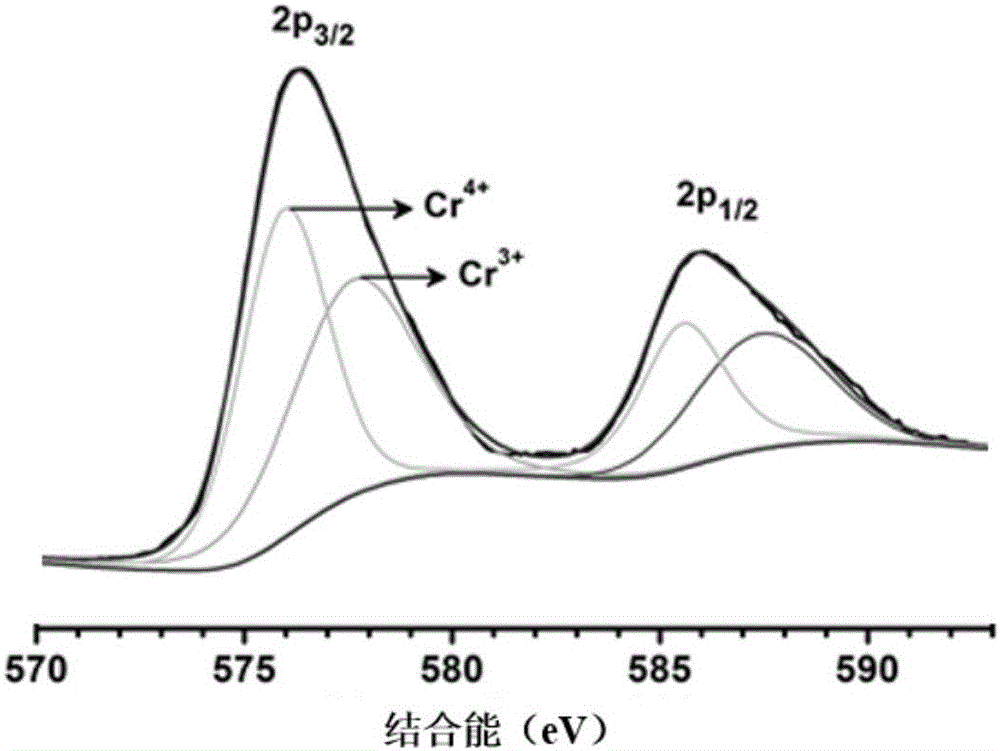

InactiveCN104987057AHigh emissivityLong-term stable serviceLuminescent compositionsManganese oxideLanthanum

The present invention provides a high-emissivity infrared energy-saving material and applications thereof, and belongs to the technical field of infrared energy-saving materials. According to the high-emissivity infrared energy-saving material, lanthanum aluminate of the perovskite structure is adopted as a main phase, 0.01-0.25 mole of second main group element ions is doped at the unit mole lanthanum site, and 0.02-0.5 mole of transition metal element ions is doped at the unit mole aluminum site; and the high-emissivity infrared energy-saving material is prepared from a lanthanum compound, an aluminum compound, a dopant I and a dopant II, wherein the lanthanum compound is lanthanum oxide, the aluminum compound is aluminum oxide, the dopant I is a mixture comprising one or a plurality of materials selected from magnesium oxide, calcium oxide, strontium oxide and barium oxide, and the dopant II is a mixture comprising one or a plurality of materials selected from chromium oxide, manganese oxide, iron oxide and nickel oxide. According to the present invention, the emissivity of the prepared high-emissivity infrared energy-saving material can be up to 0.95, and the prepared high-emissivity infrared energy-saving material has good high temperature stability.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

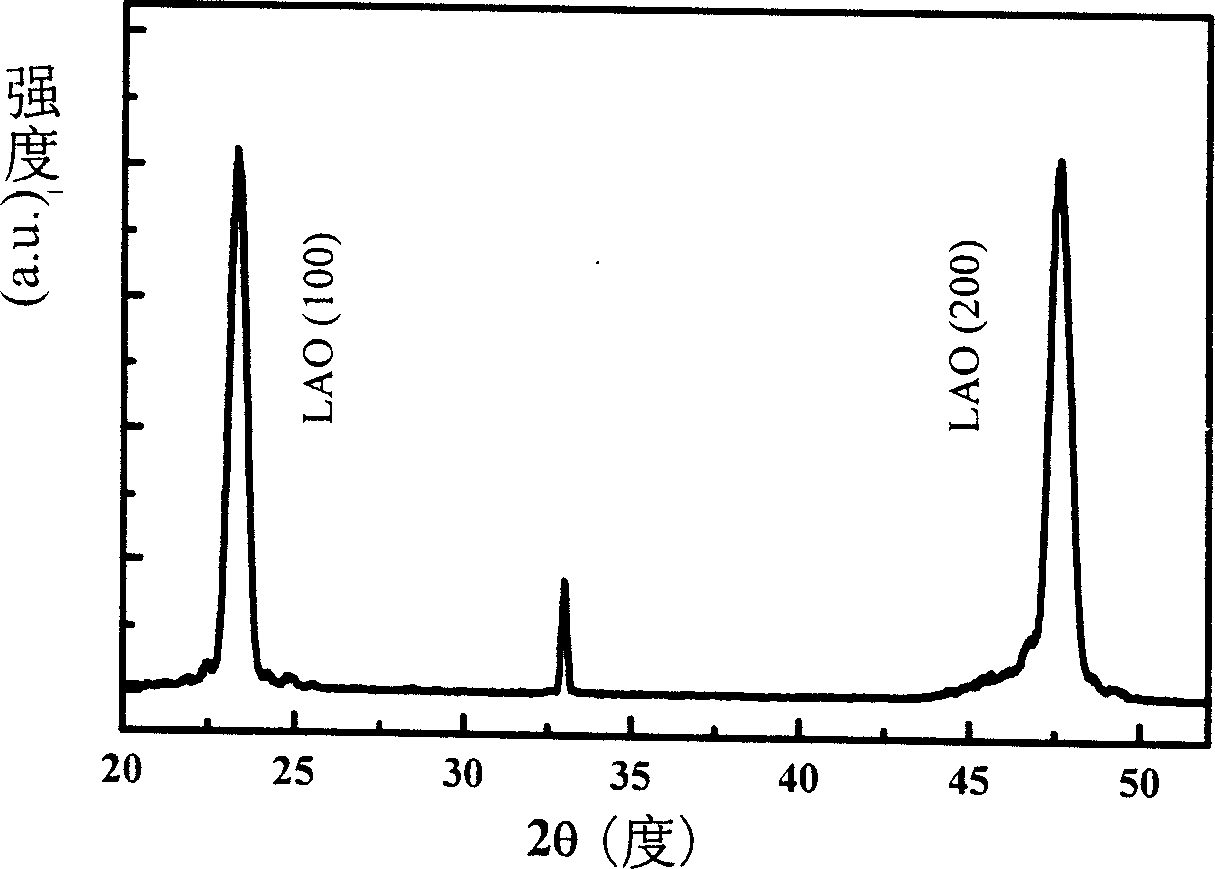

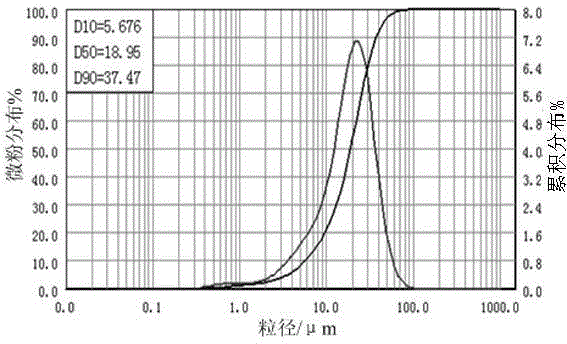

Method for preparing nano aluminate lanthanum powder

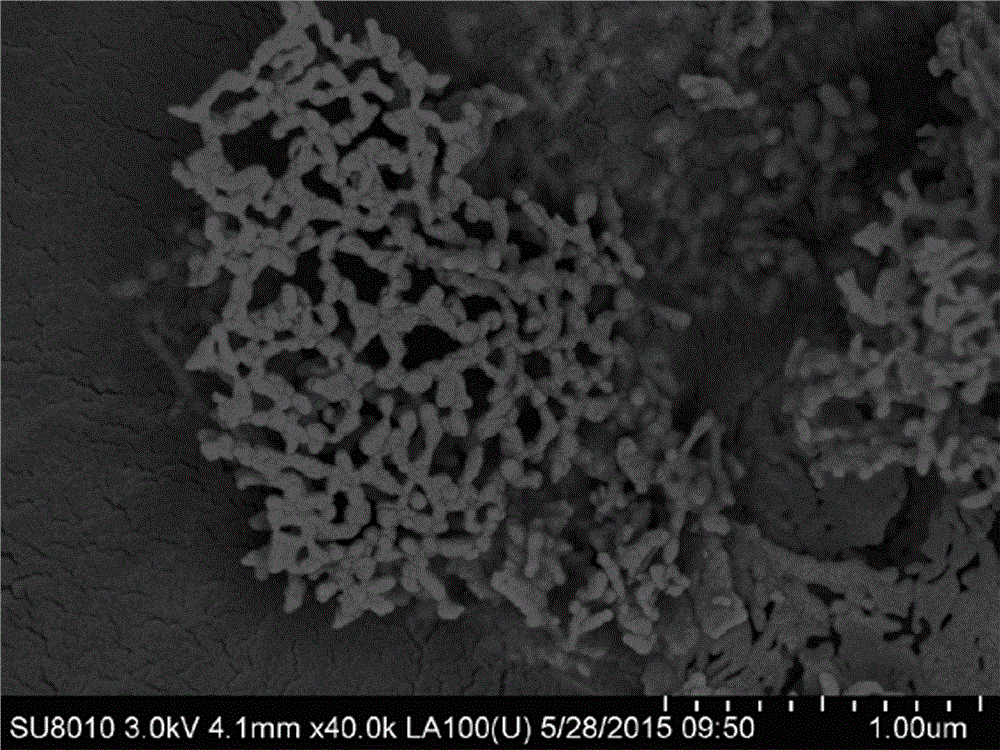

InactiveCN101157474AReunion slightRegular shapeRare earth metal compoundsAluminium oxides/hydroxidesAluminatePtru catalyst

The invention relates to a method for preparing nanometer lanthanum aluminate powders. The method comprises the following steps: mixing and stirring microemulsion with the composite of Span80 and Tween80 as the surfactant, with n-butanol as the assistant surfactant and respectively with water solution of lanthanum nitrate and aluminum nitrate and ammonia water as the aqueous phase; after separation, washing and drying, incinerating the product at 750-1000 DEG C to obtain globular lanthanum aluminate powders with high purity, light agglomeration and particle diameter range of 20-60mm. The method of the invention solves problems of the traditional nanometer lanthanum aluminate powder preparing method, including high temperature, large lanthanum aluminate powder size, morphological irregularity and serious agglomeration. The product can be used as key materials for microwave devices such as wave filters, harmonic oscillators, superconductive films, etc., and can also be applied as the catalyst for oxidative coupling of methane as well as hydrogenization and hydrogenolysis of hydrocarbons.

Owner:重庆工学院

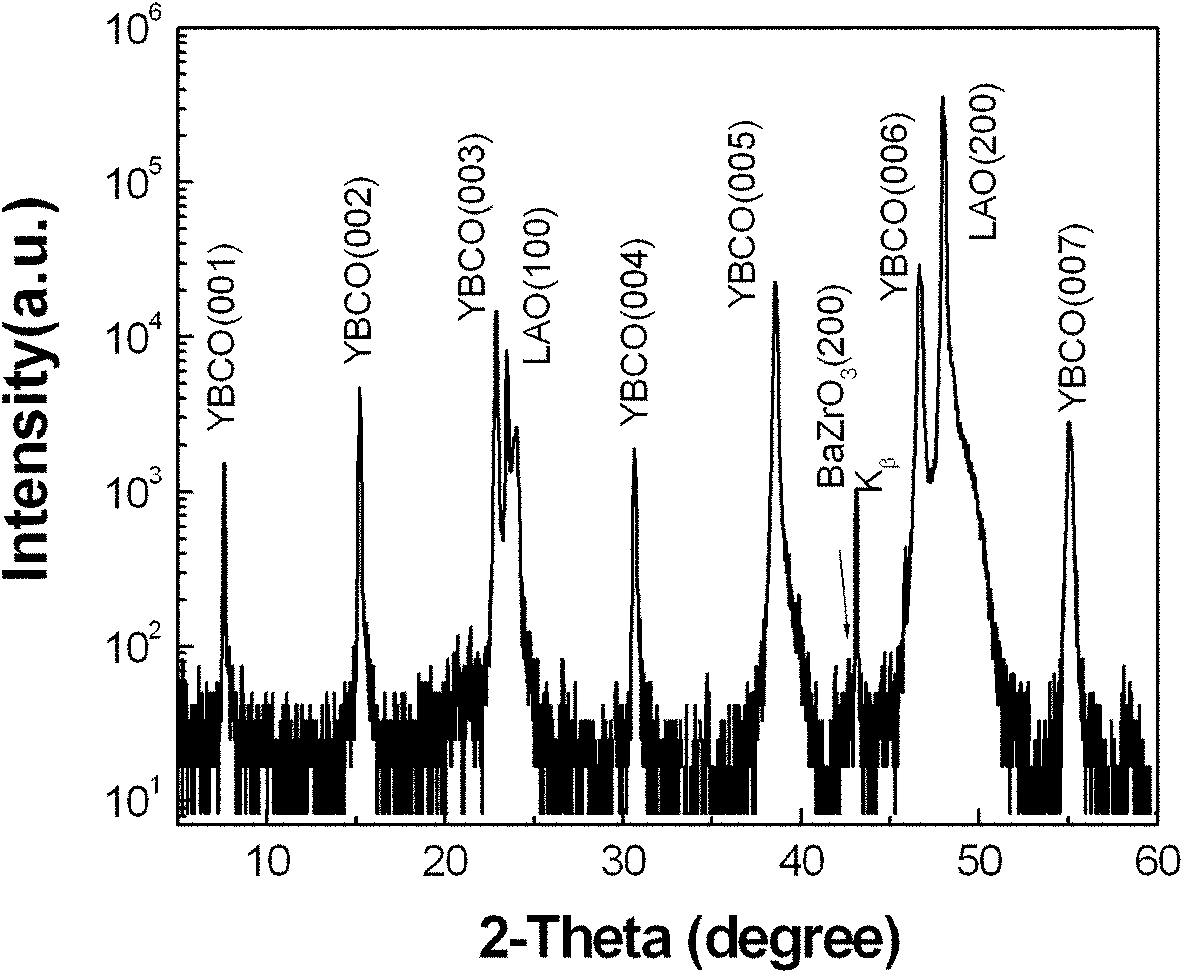

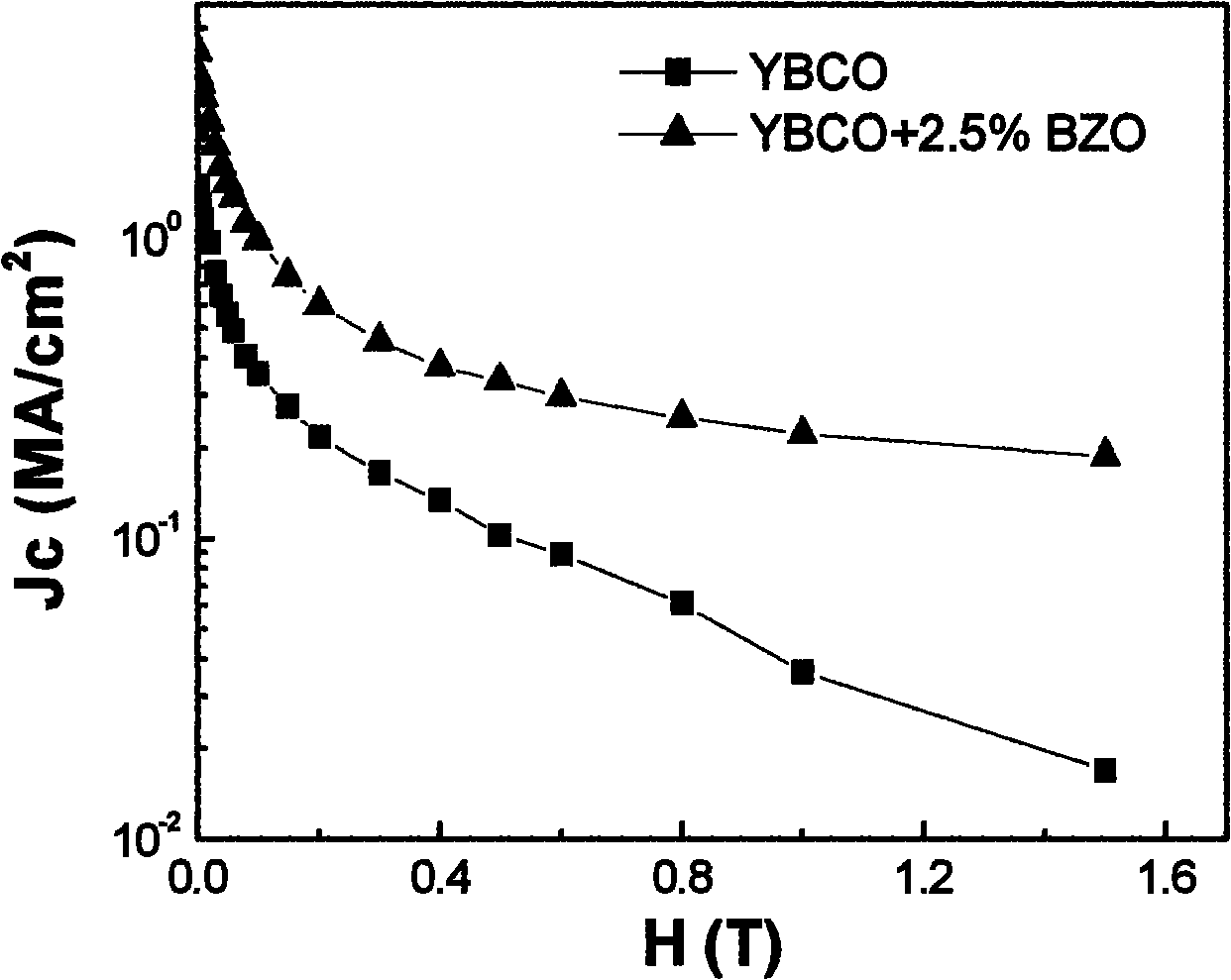

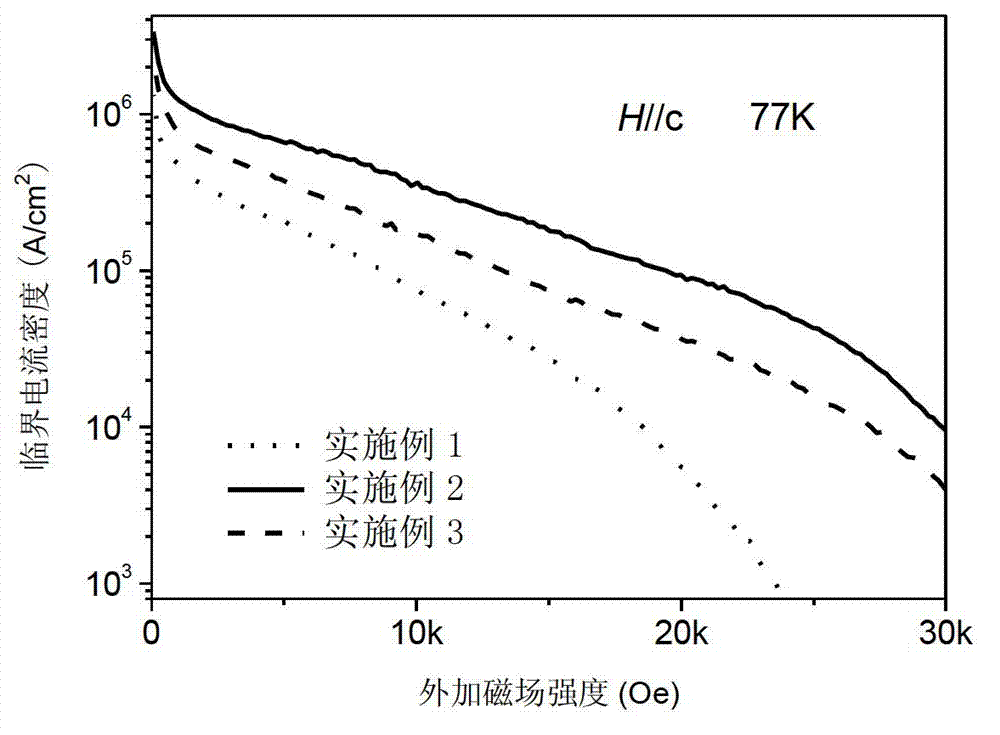

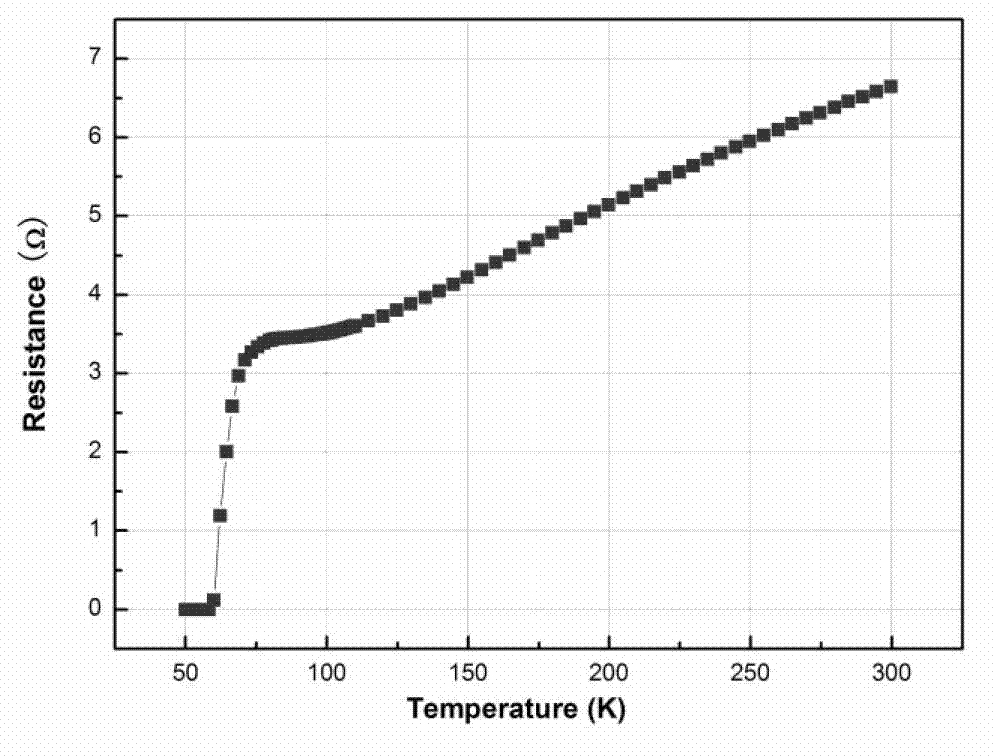

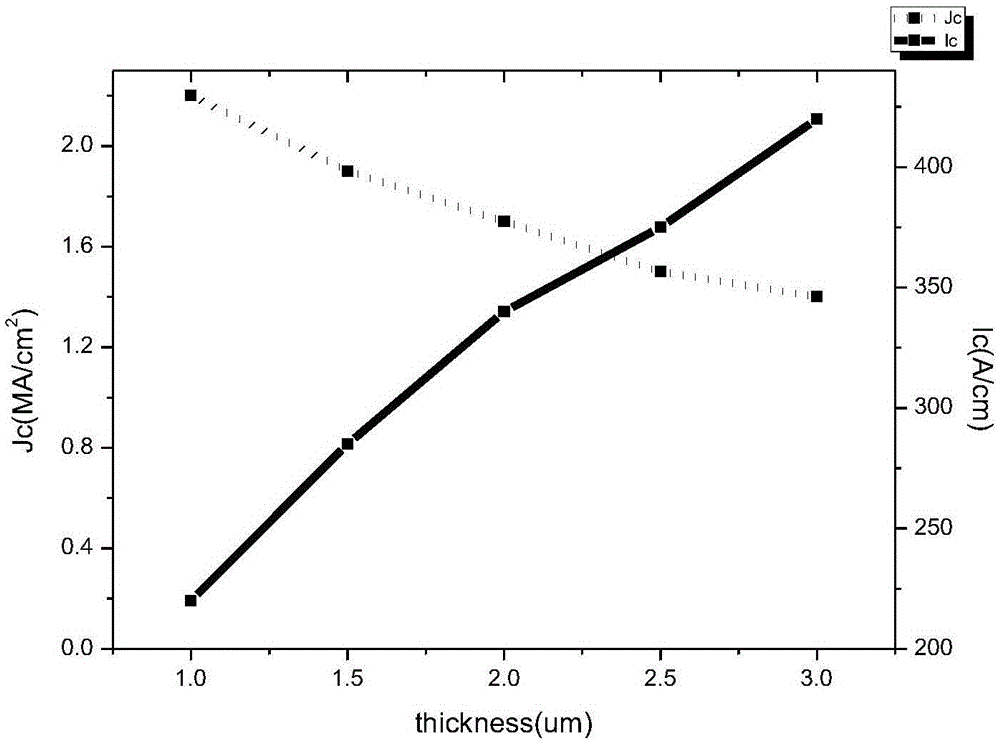

Second-phase nanoparticle doped YBCO (yttrium barium copper oxide) film and preparation method thereof

ActiveCN102142300AEvenly dispersedJc performance improvementSuperconductors/hyperconductorsSuperconductor devicesYttrium barium copper oxideSingle crystal substrate

The invention discloses a second-phase nanoparticle doped YBCO (yttrium barium copper oxide) film and a preparation method thereof. The film is composed of the following compositions in percentage by mass: 0.1-5% of second-phase nanoparticles and the balance of YBCO, wherein the second-phase nanoparticle is BaZrO3, BaHfO3 or Y2BaCuO5. The method for preparing the film comprises the following steps: 1, preparing a second-phase nanoparticle doped YBCO precursor solution; 2, uniformly coating the second-phase nanoparticle doped YBCO precursor solution on a lanthanum aluminate single crystal substrate; 3, carrying out low temperature pyrolysis on the obtained product; 4, carrying out high temperature crystallization and oxygen diffusion processing on the object obtained in the step 3 so as to obtain the second-phase nanoparticle doped YBCO film. The preparation method disclosed by the invention is easy to operate, simple in experimental facility, low in cost, and capability of satisfying the requirements of industrial production. Compared with a pure YBCO film, the Jc performance of the prepared second-phase nanoparticle doped YBCO film is obviously improved under a magnetic field.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

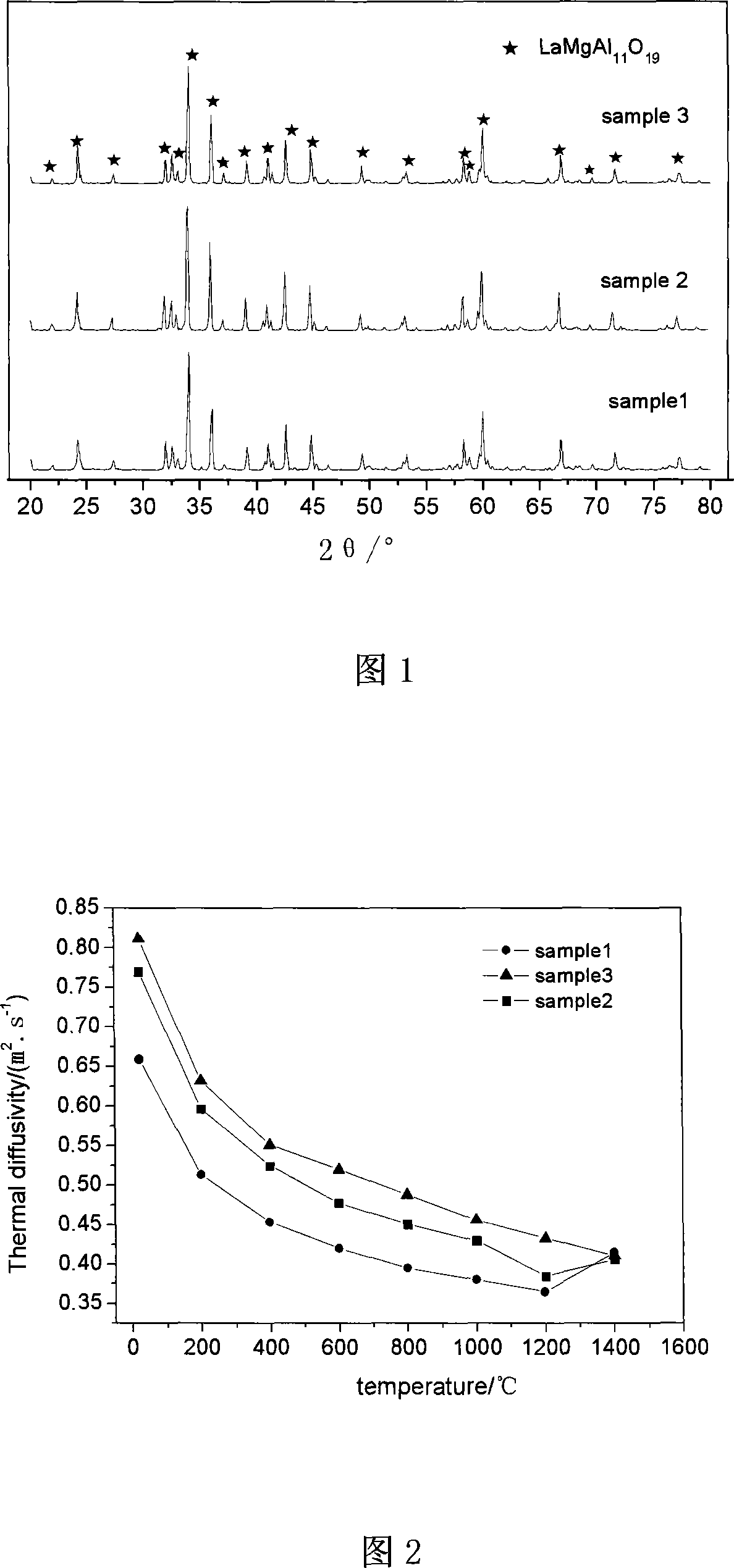

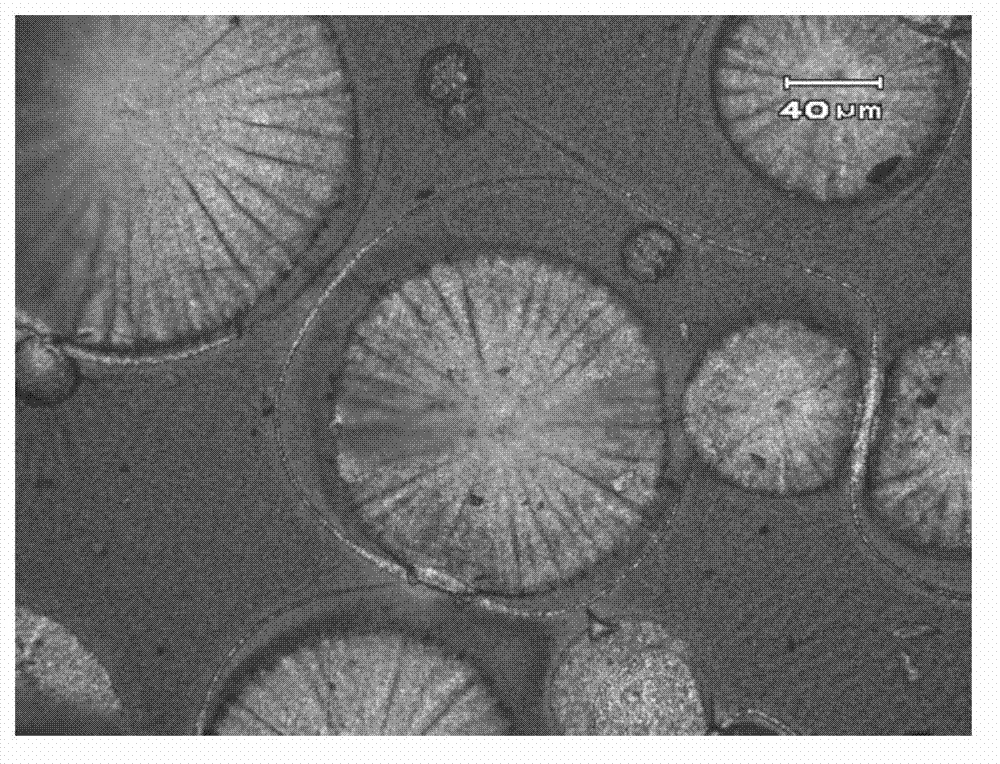

Method for preparing magnesium-based lanthanum aluminate thermal barrier coating

The invention relates to a preparation method of a magnesium-based lanthanum aluminate thermal barrier coating material, belonging to the field of materials. The characteristics are: according to the stoichiometric ratio of LaMgAl11O19, the ingredients are prepared. The preparation method: 1) Wet ball milling in a polyurethane ball mill tank with alumina balls as the grinding body, drying, and compression molding; 2) The molded body is pre-fired in a high-temperature furnace , to obtain a calcined block; 3) pulverizing the above calcined block, adding MgO fine powder to the pulverized calcined raw material; putting it into a polyurethane ball mill tank and carrying out wet ball milling with alumina balls to obtain a ceramic slurry; 4) drying the above ceramic slurry in a drying oven, granulating, and forming the granulated raw material by isostatic pressing; sintering the formed green body at 1550-1700° C. for 6-24 hours to obtain a high-purity magnesium-based lanthanum aluminate ceramic material; The ceramic material can be used as a target material for preparing a thermal barrier coating by the EB-PVD method.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

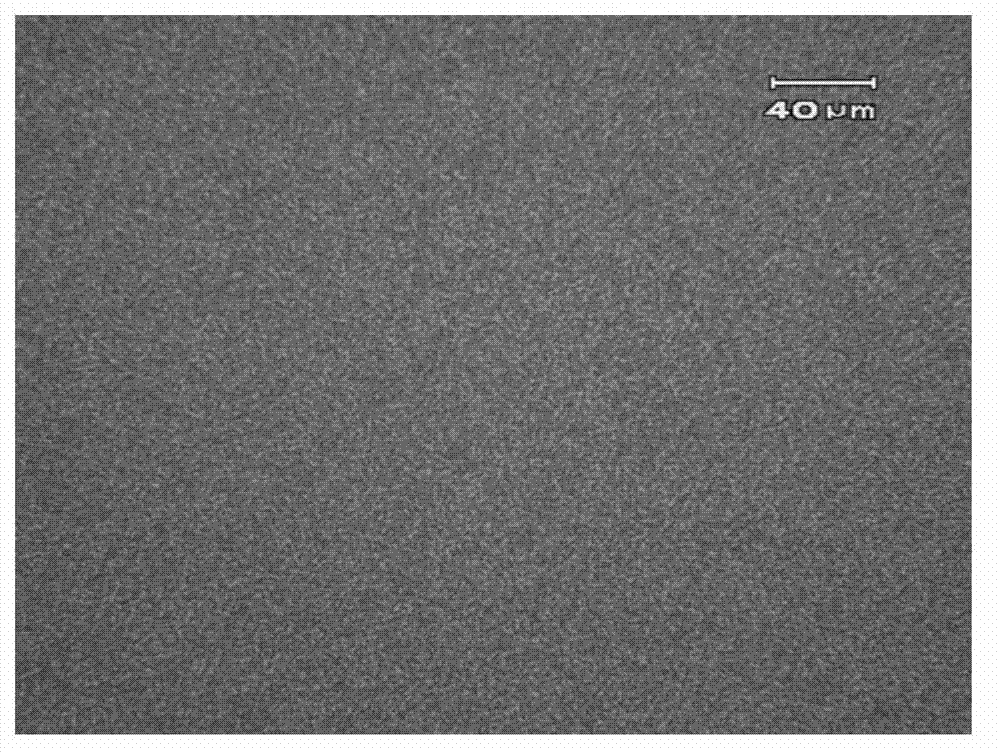

Preparation method of yttrium-barium-copper-oxidize superconducting film

The invention discloses a preparation method of a yttrium-barium-copper-oxidize superconducting film. The method comprises the following steps: preparing a yttrium-barium-copper-oxidize sol without fluorine into a yttrium-barium-copper-oxidize gel film on a monocrystal lanthanum aluminate substrate; after drying the obtained gel film, sequentially carrying out overheating treatment, crystallization treatment and oxygen permeating treatment on the gel film; and cooling the gel film, thereby obtaining the yttrium-barium-copper-oxidize superconducting film. According to the method, carbon dioxide is led into a low-temperature heat treatment process to control the conversion of a barium-contained phase, so that a reversible reaction, namely (Ba(OH)2+CO2=BaCO3+H2O is always performed in the direction at which barium carbonate is generated, so that the problem of rough surface of the yttrium-barium-copper-oxidize superconducting film due to the fact that barium hydroxide is molten at a high temperature is solved. In addition, water vapor is led into a high-temperature heat treatment process, so that the reversible reaction is performed in the direction at which the barium hydroxide is generated, so that the barium carbonate is completely converted into the barium hydroxide; and the barium hydroxide can further react with yttrium oxide and copper oxide to generate a yttrium-barium-copper-oxidize phase, and therefore, the yttrium-barium-copper-oxidize film with the good surface quality and the excellent superconducting performance is obtained.

Owner:XIAN UNIV OF TECH

Epitaxial growing lanthanum aluminate film material on silicon substrate and preparation method

InactiveCN1725444AImprove crystal structureGood compatibilityPolycrystalline material growthSemiconductor/solid-state device manufacturingHydrofluoric acidLanthanum aluminate

This invention relates to a method for epitaxial growing LaAlO3 film material and its preparation method, which takes type n or p silicon chip as the substrate to epitaxial grow a La a AlO film material layer on it directly. The preparation method includes: taking out cleaned silicon chip from hydrofluoric acid solution directly and putting it into the sample-feeding chamber or epitaxial chamber of an epitaxial device, applying two steps for the epitaxial growth: growing LaAlO3 material directly on the silicon substrate or taking LaALo3 grown on the silicon plate as the buffer layer then to grow YBCO, BaTiO3, LaMnO3, SrTiO3 and its doped BaTiO3, LaMnO3, SrTiO3 CaTi oxide films and multi-layer film.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

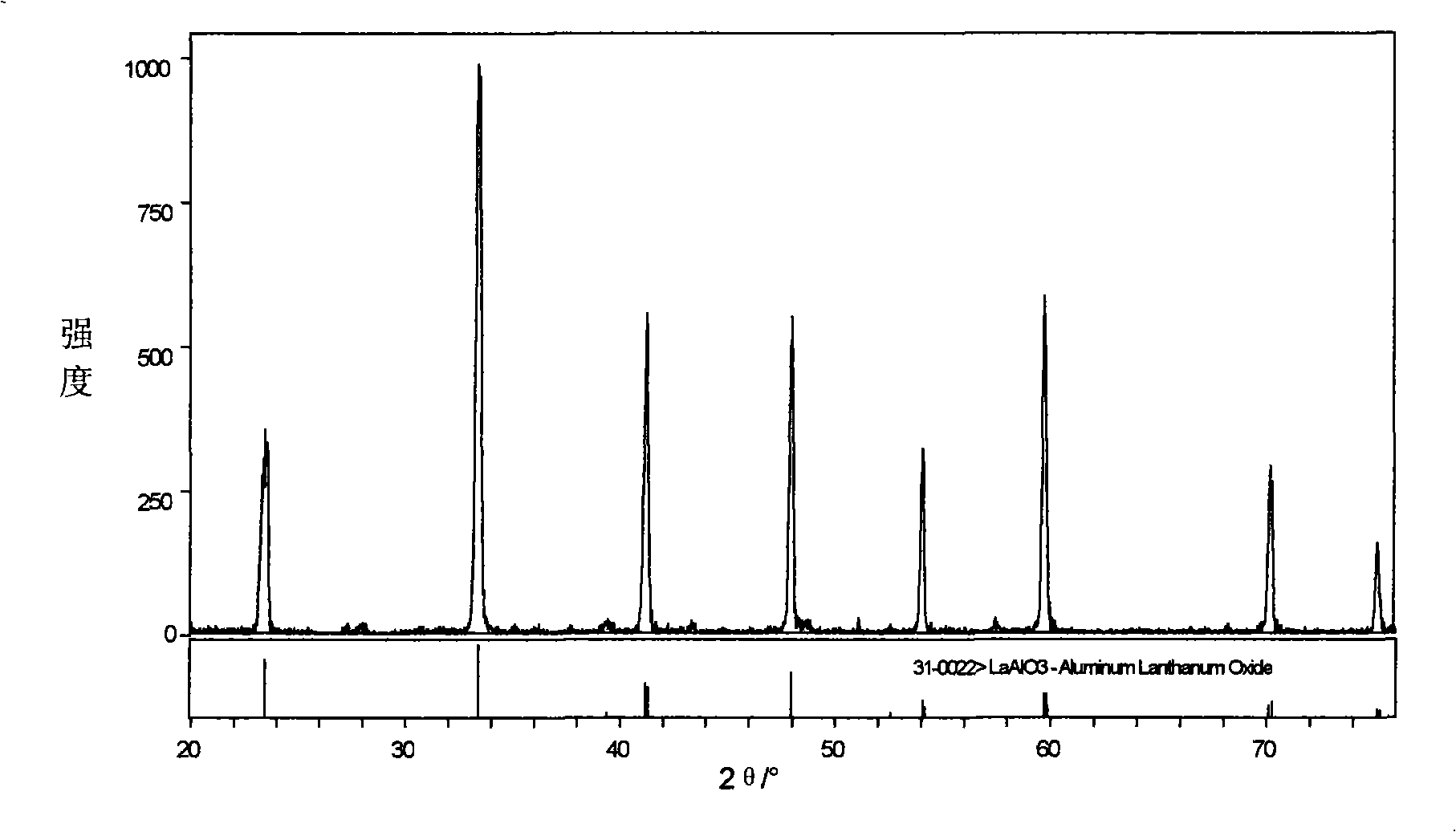

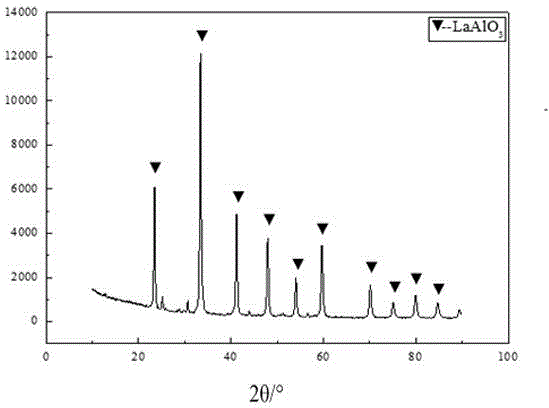

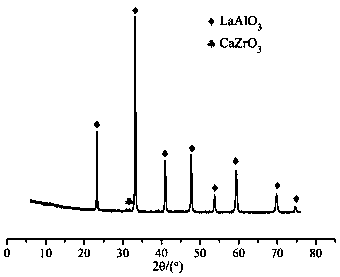

Method for preparing lanthanum aluminate/lanthanum chromate by spraying pyrolysis

ActiveCN104876254AProcess parameter control is simpleSimplify structural complexityChromates/bichromatesRare earth metal compoundsAluminium chlorideSlag

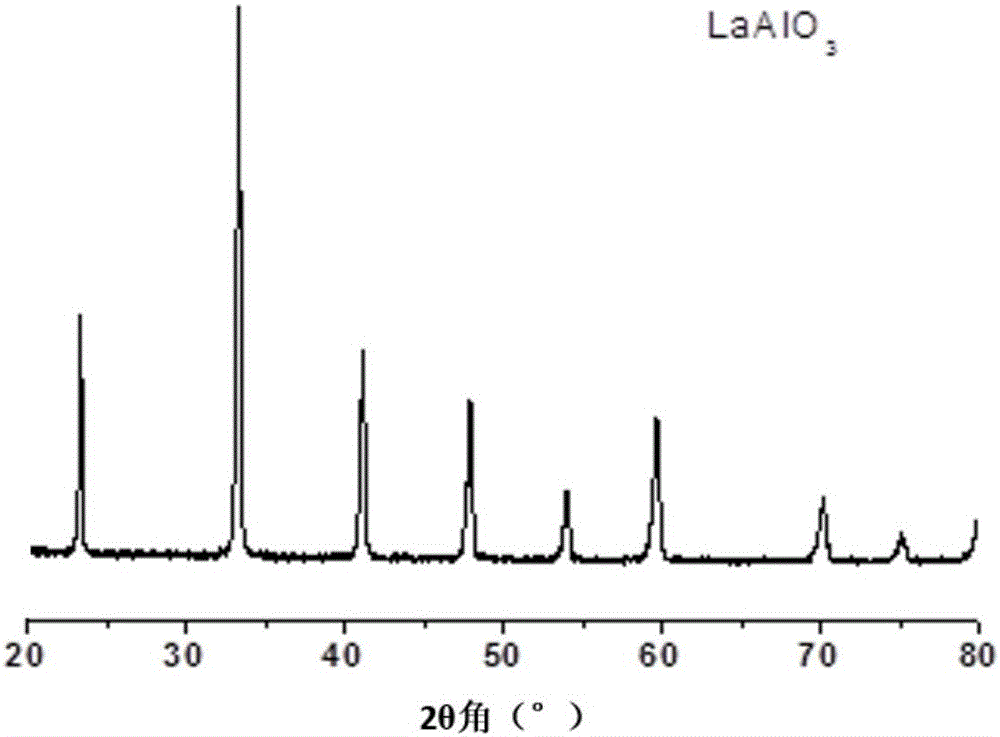

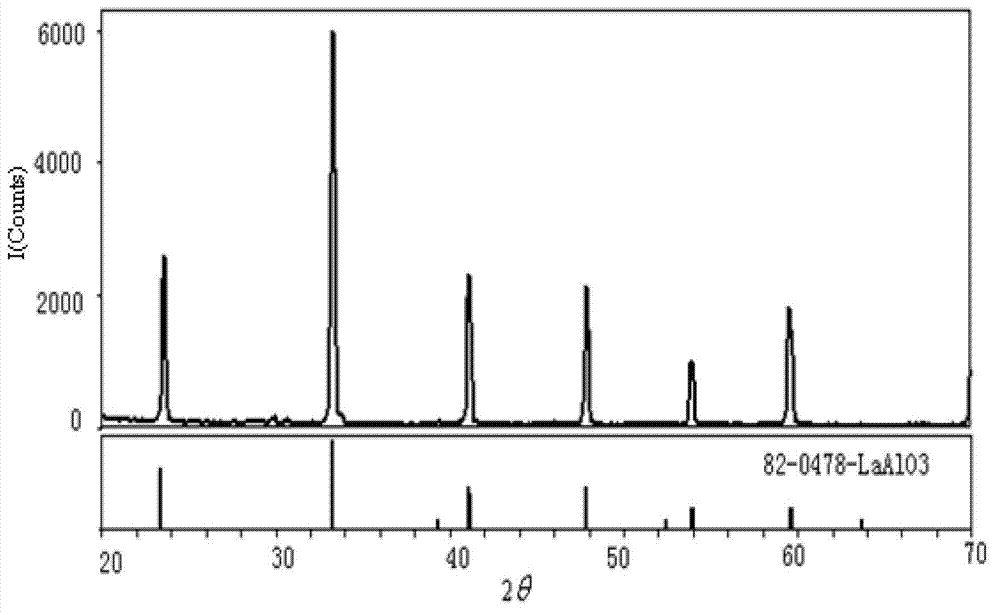

The invention discloses a method for preparing lanthanum aluminate / lanthanum chromate by spraying pyrolysis and belongs to the technical field of materials. The method comprises the following steps: (1) dissolving lanthanum chloride and aluminium chloride or chromium chloride to prepare solution; (2) adopting air as carrier gas, spraying the solution into a roasting furnace to carry out spraying pyrolysis and obtaining roasting slag; (3) calcining the roasting slag to obtain the lanthanum aluminate or the lanthanum chromate. The method disclosed by the invention has the advantages that the reaction temperature and the reaction time for producing the lanthanum aluminate are reduced; and proved by analysis results of X-ray diffraction of a product secondarily roasted, the crystal form of the product is an inclined and square hexahedron, so that the defects such as high reaction temperature of a solid-phase synthesis method and non-uniform particle size and distribution and irregular shape of the product are effectively avoided.

Owner:NORTHEASTERN UNIV

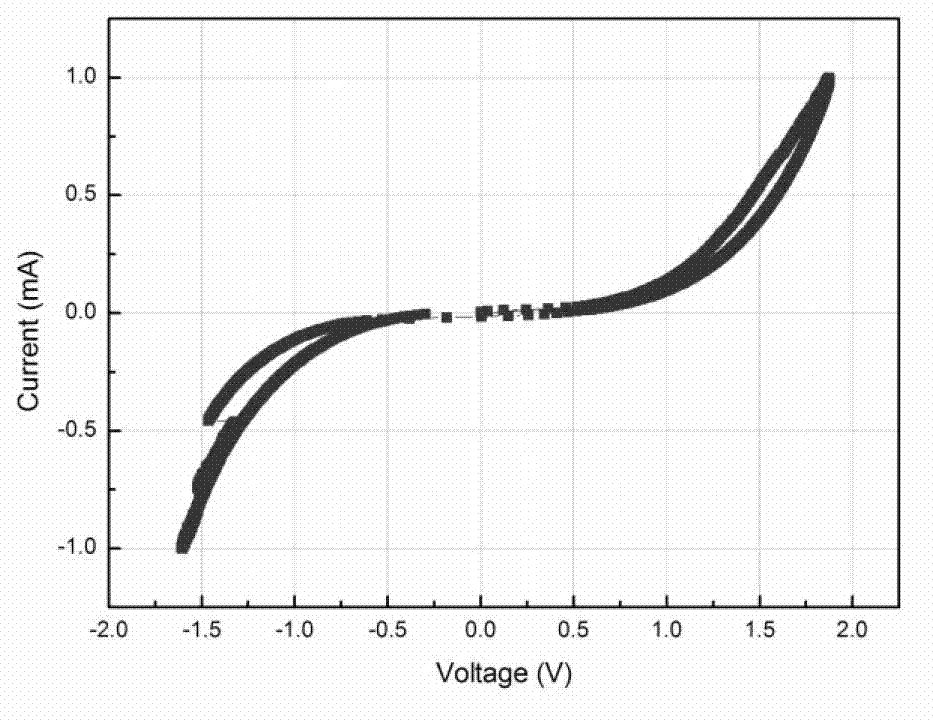

Zirconium oxide resistance memorizer film preparation method and test method of resistance change property of zirconium oxide resistance memorizer film

InactiveCN103094477ASimple processLow costElectrical apparatusResistance/reactance/impedenceSputteringYttrium barium copper oxide

The invention discloses a zirconium oxide resistance memorizer film preparation method. The method comprises a first step of enabling zirconium oxide colloidal sol to serve as precursor solution, a second step of enabling a yttrium barium copper oxide superconducting film of a lanthanum aluminate single crystal substrate to serve as a substrate pulling zirconium oxide film, a third step of producing a zirconium oxide gel film on a superconducting electrode by adopting of a dipping and pulling method, a fourth step of carrying out annealing treatment for the zirconium oxide gel film and natural cooling of the zirconium oxide gel film and a fifth step of carrying out upper current conducting cap sputtering for the zirconium oxide gel film to obtain a zirconium oxide resistance memorizer film. The invention further discloses a test method of the resistance change property of the zirconium oxide resistance memorizer film prepared by means of the preparation method, the zirconium oxide resistance memorizer film is connected by adopting of a four-lead method, leads are connected with a test point through metal indium, the zirconium oxide resistance memorizer film is fixed on a sample platform and then is placed in a material comprehensive physical property measuring device and a volt-ampere characteristic curve test is carried out on the zirconium oxide resistance memorizer film. The zirconium oxide resistance memorizer film preparation method is simple in craft, low in equipment price and low in cost. The zirconium oxide resistance memorizer film of the resistance change property is environment-friendly, low in cost and easy to operate.

Owner:XIAN UNIV OF TECH

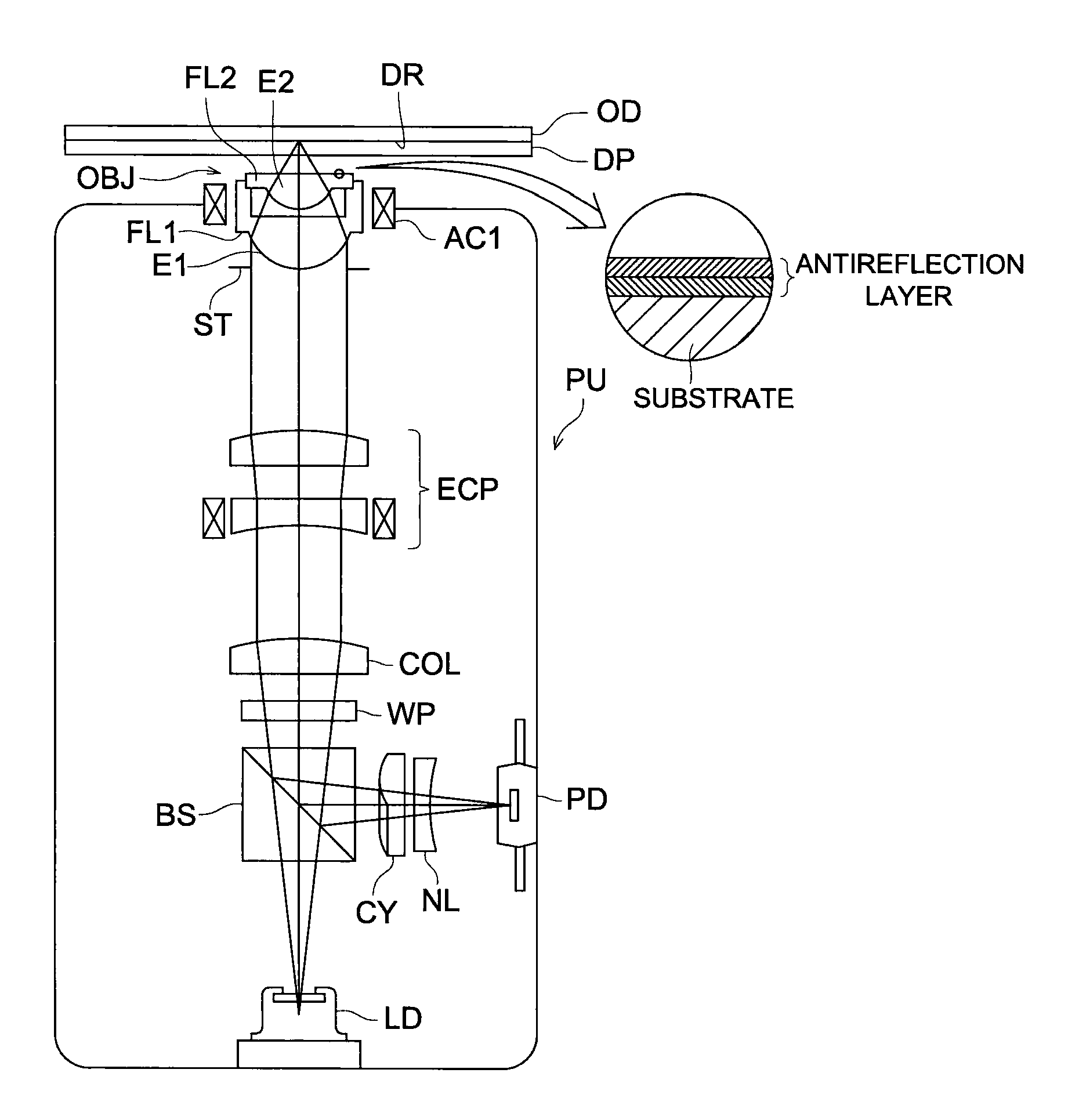

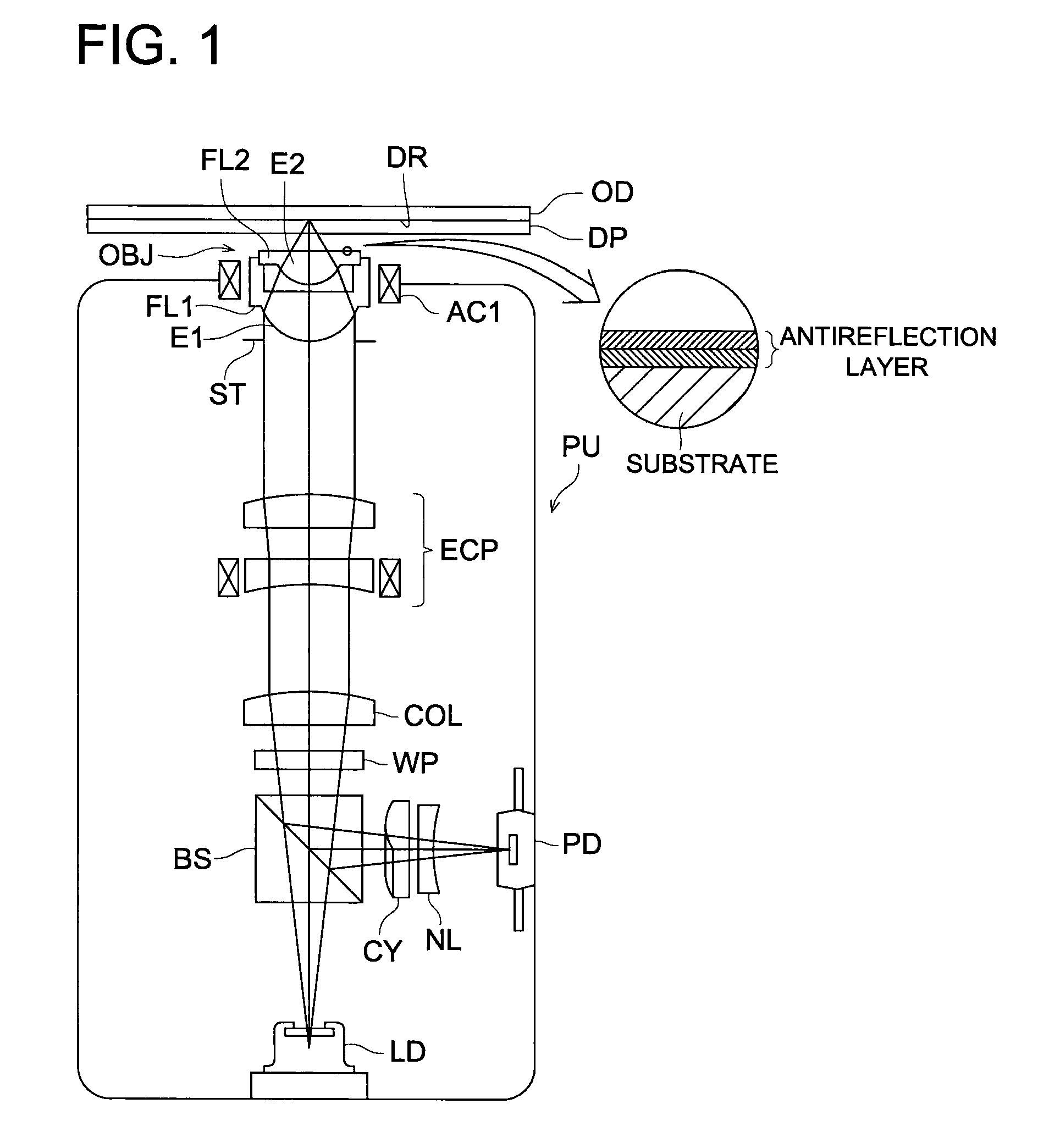

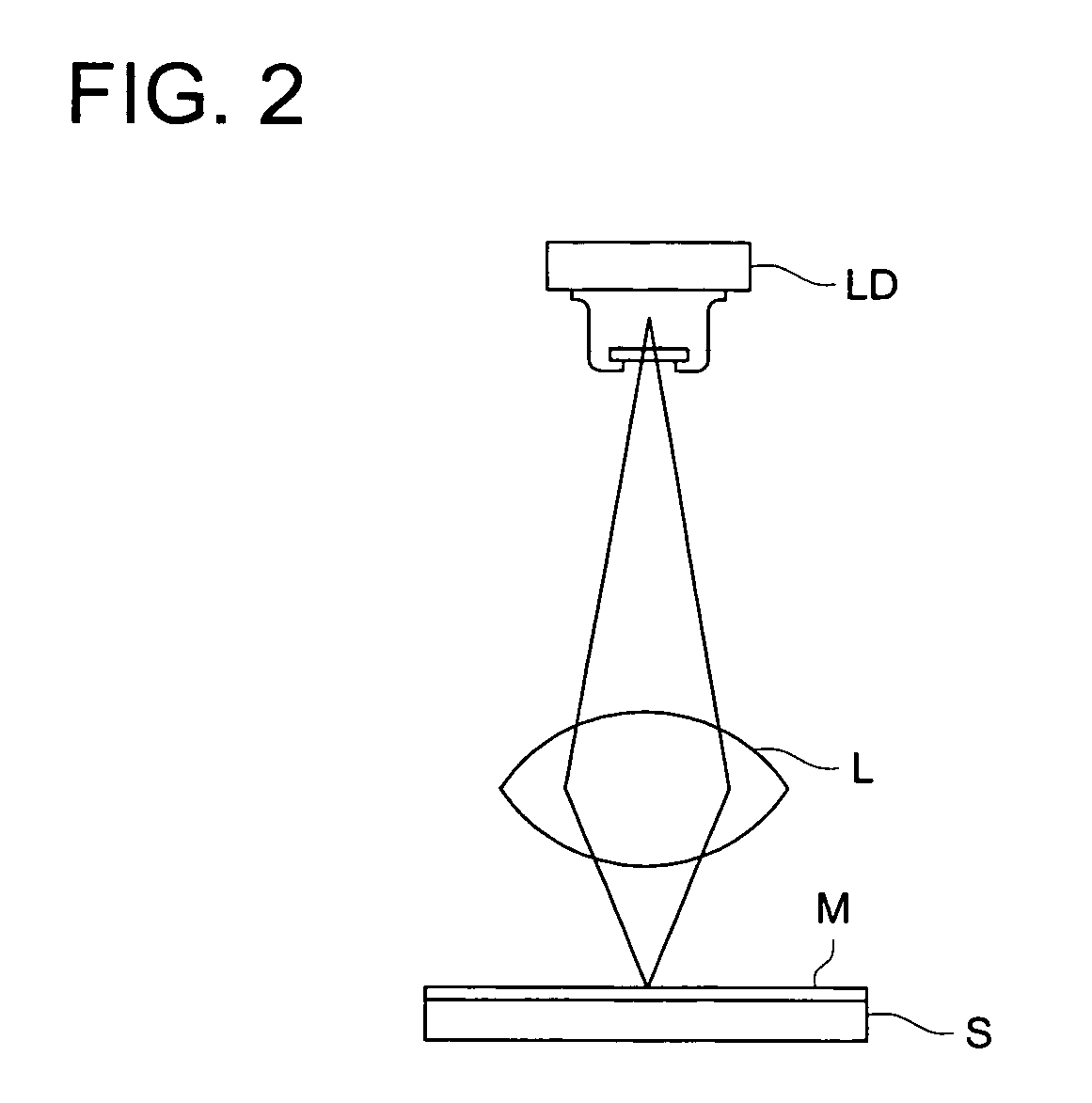

Optical element and optical pickup apparatus

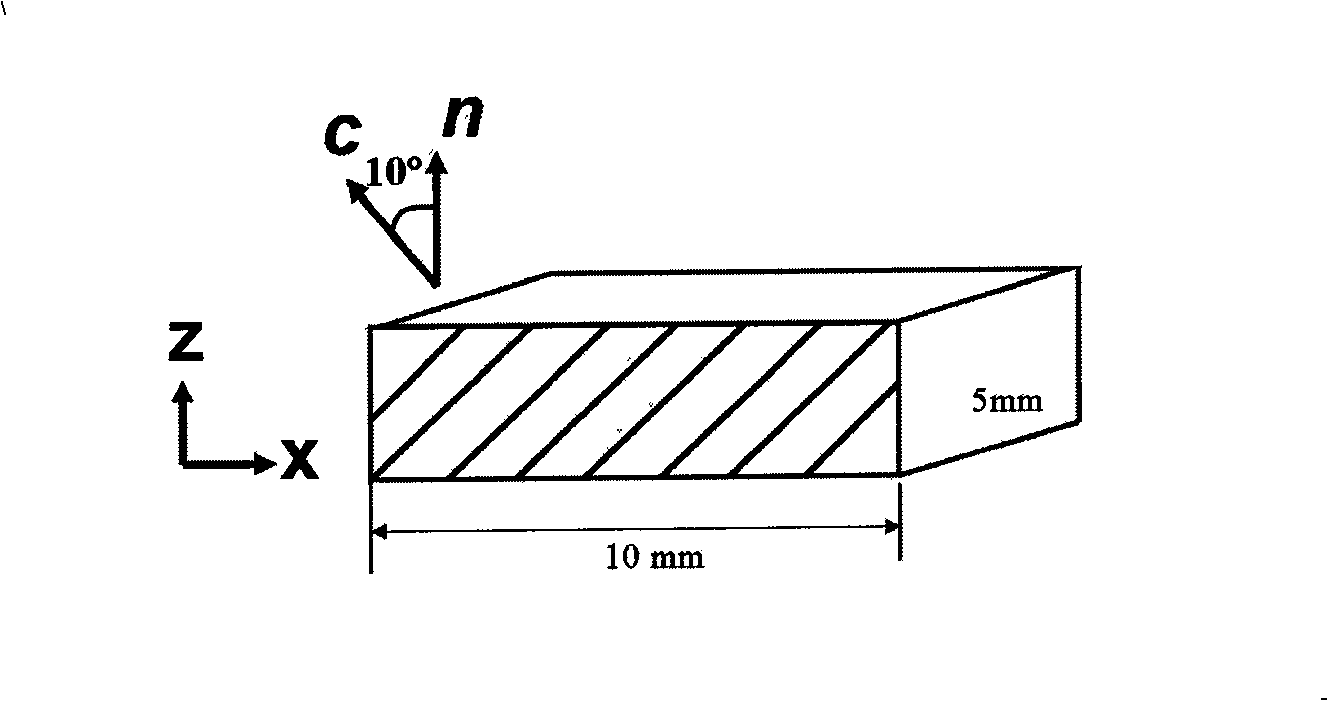

InactiveUS7715302B2Avoid degradationImprove the heating effectLaser using scattering effectsSynthetic resin layered productsOptical pickupRefractive index

Owner:KONICA MINOLTA OPTO

High-emissivity infrared energy-saving material preparation method

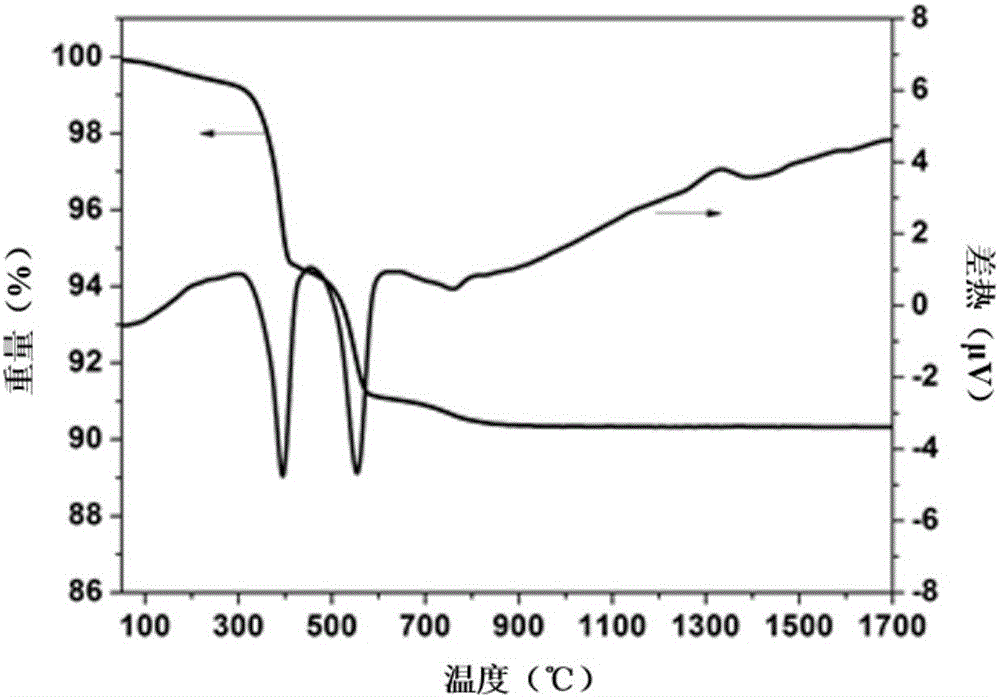

The present invention provides a high-emissivity infrared energy-saving material preparation method, and belongs to the technical field of infrared energy-saving materials. According to the prepared high-emissivity infrared energy-saving material, lanthanum aluminum oxide of the perovskite structure is adopted as the main phase, 0.01-0.25 mole of second main group element ions are doped at the lanthanum position, 0.02-0.5 mole of transition metal element ions are doped at the aluminum position, and the infrared emissivity of the material is 0.80-0.95. The preparation method is a high-temperature solid-phase reaction method, a flame spraying method or liquid-phase synthesis method. Mainly the material of the present invention has the following advantages that the highest emissivity of the infrared energy-saving material achieves 0.95, and the material has a good high temperature stability and has great application potential in the high temperature thermal furnace kiln energy saving field.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Method for preparing lanthanum aluminate powder efficiently

InactiveCN103112881ASmall granularityIncrease contact areaMaterial nanotechnologyRare earth metal compoundsAluminium hydroxideLanthanum hydroxide

The invention relates to a method for preparing lanthanum aluminate powder efficiently. The method comprises the following steps: (1) adding water into lanthanum oxide, wherein the mass of the added water is 1-20 times more than that of the lanthanum oxide, stirring, controlling the material temperature to be 30-250 DEG C and keeping warm for 1-8 hours, thus obtaining lanthanum hydroxide by the hydrothermal method; (2) adding aluminum hydroxide into a system of lanthanum hydroxide obtained by the hydrothermal method and water, wherein the mole ratio of the aluminum hydroxide to the lanthanum oxide is 2:1, using the water as medium, fully mixing the aluminum hydroxide with the lanthanum hydroxide by stirring, and filtering after stirring for 1-10 minutes; and (3) keeping the mixture of the aluminum hydroxide and the lanthanum hydroxide at the temperature of 1000-1400 DEG C for 1-5 hours, and thereby obtaining the lanthanum aluminate powder. The method for preparing lanthanum aluminate powder efficiently has the advantages that (a) the preparation technology is environment-friendly; and (b) the preparation efficiency is high. The aluminum hydroxide and the lanthanum hydroxide are fully mixed and the mixture is easy to filter, the calcination temperature is low, and the combining time is short. The method for preparing lanthanum aluminate powder efficiently is suitable for preparing lanthanum aluminate powder in large scales.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

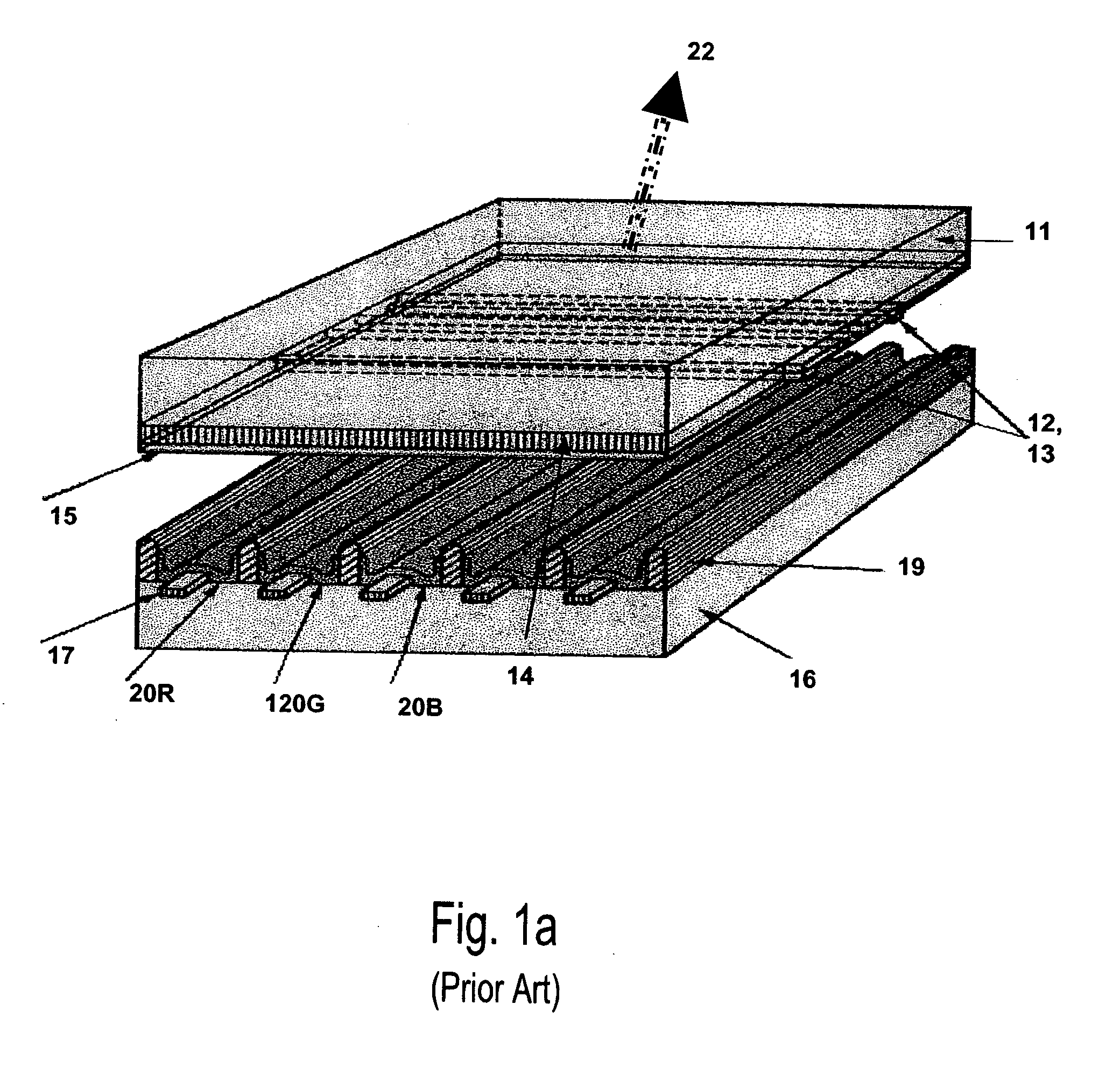

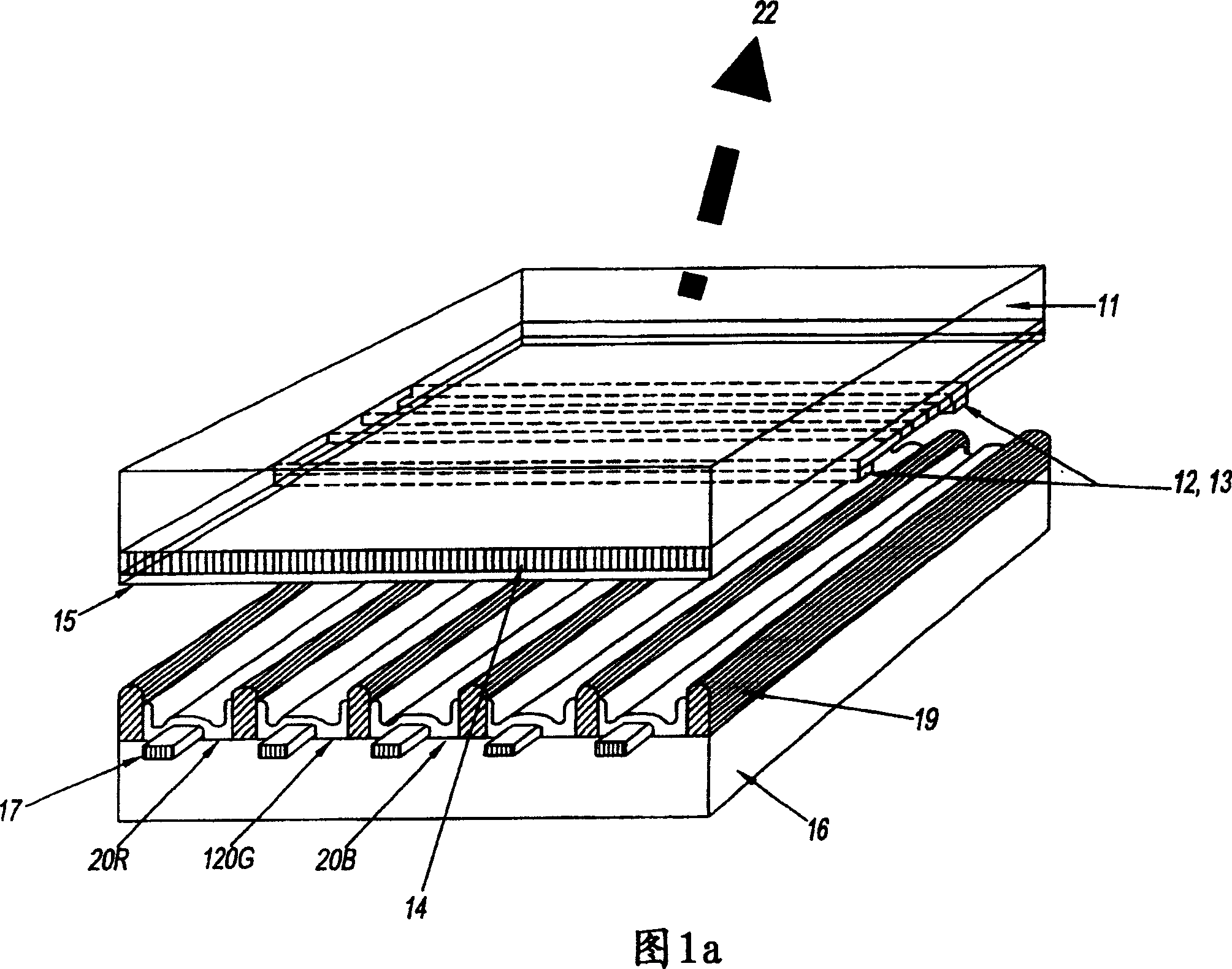

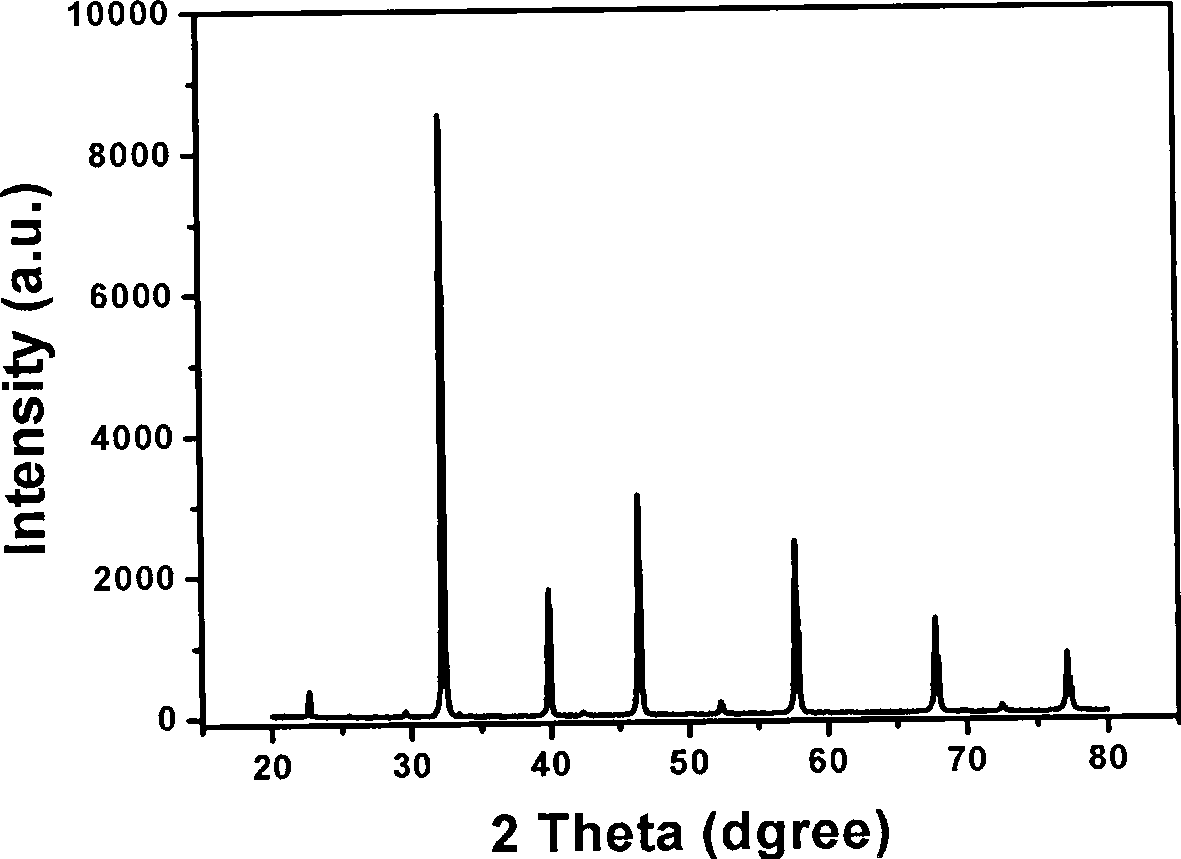

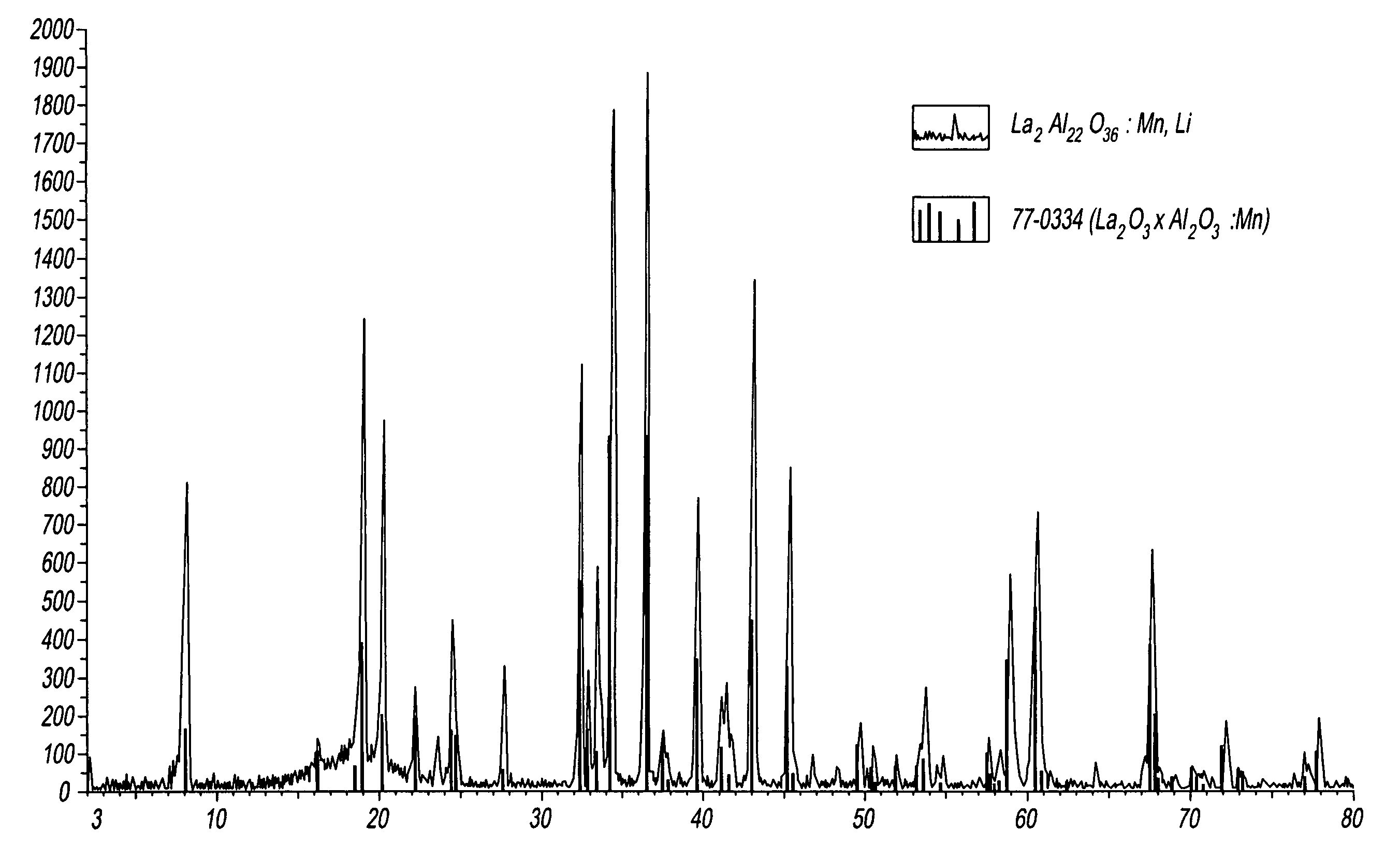

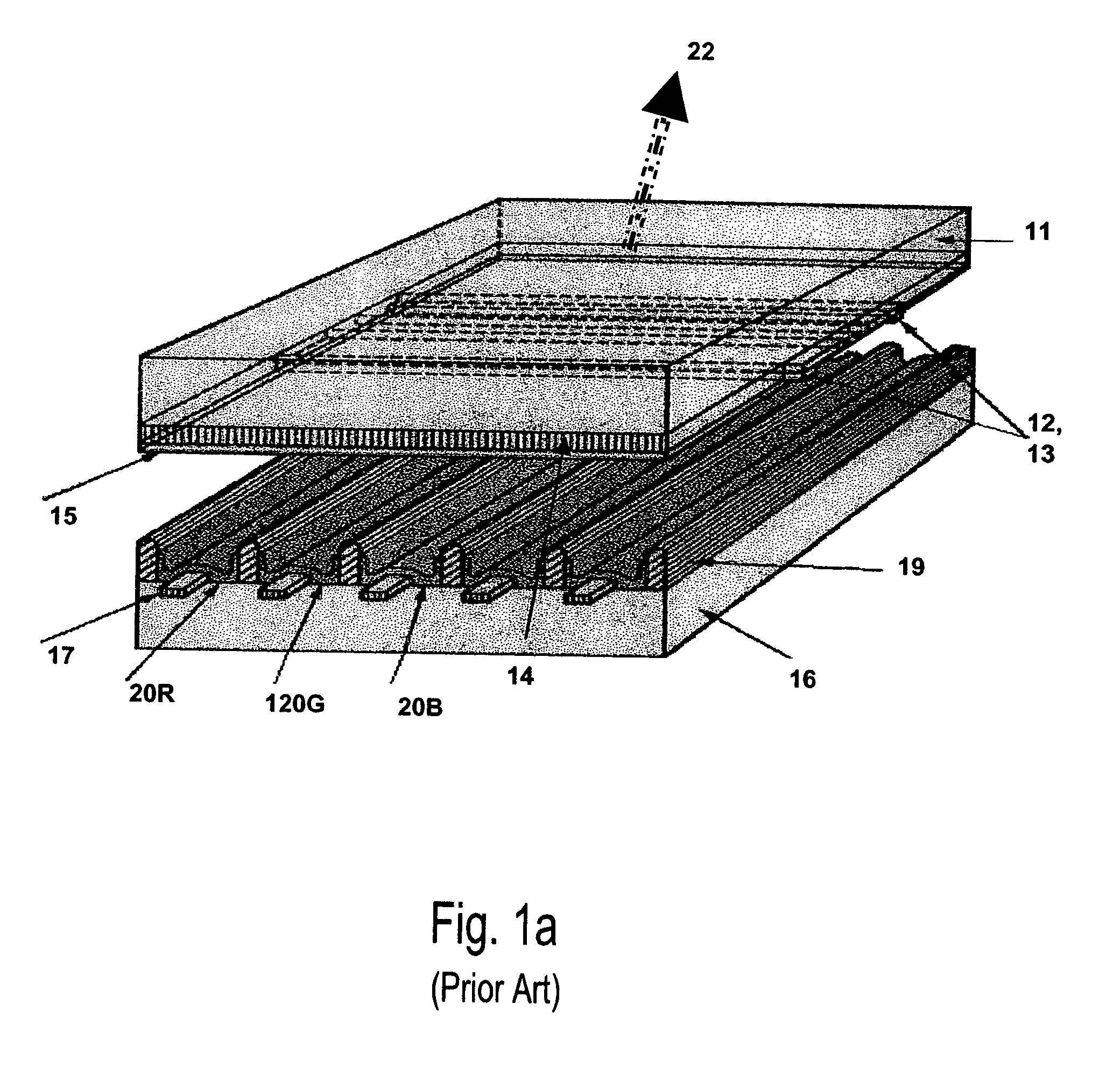

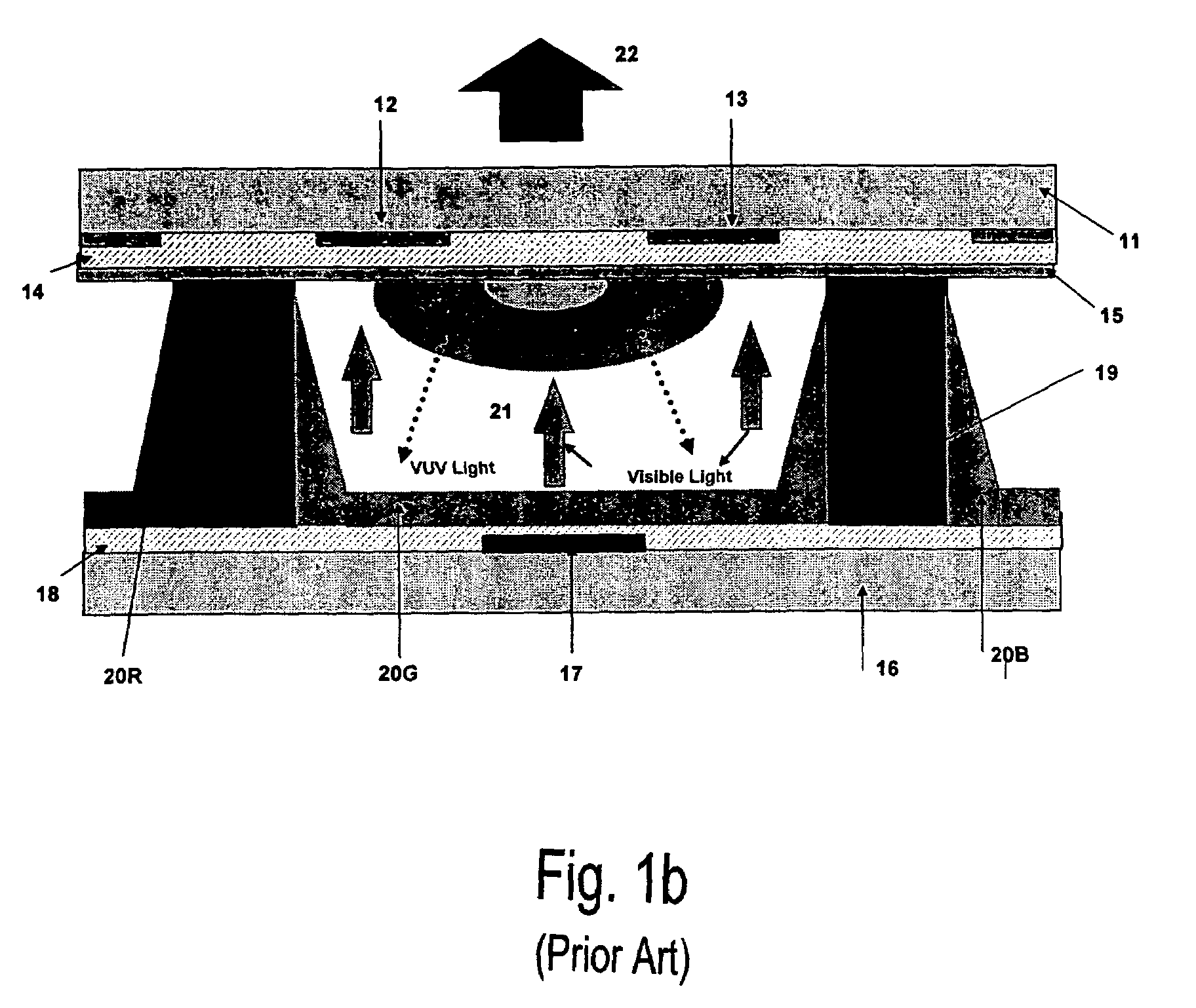

Green emitting phosphor material and plasma display panel using the same

InactiveUS20050194570A1Minimize cross contaminationImpurities increaseOptical filtersAlternating current plasma display panelsManganeseFlat panel display

A green emitting lanthanum aluminate phosphors activated with manganese and alkali halide for plasma display panels (PDP) having an empirical formula: La2-x-yB22O36:Mnx.Ay wherein: A=Li, Na or K; B═Al or Al+Ga; and 0.01≦x≦0.1 and 0.01≦y≦0.1 is provided. The phosphor has a band emission in green region, peaking at 515 nm when excited by 147 and 173 nm radiation from Xenon gas mixture, a uniform particle size distribution (0.01 to 10 microns), which is a size distribution appropriate for thin phosphor screens required for a variety of flat panel display and lamp applications. They exhibit high brightness, good color saturation, good stability and shorter persistence under VUV excitation.

Owner:PANASONIC CORP

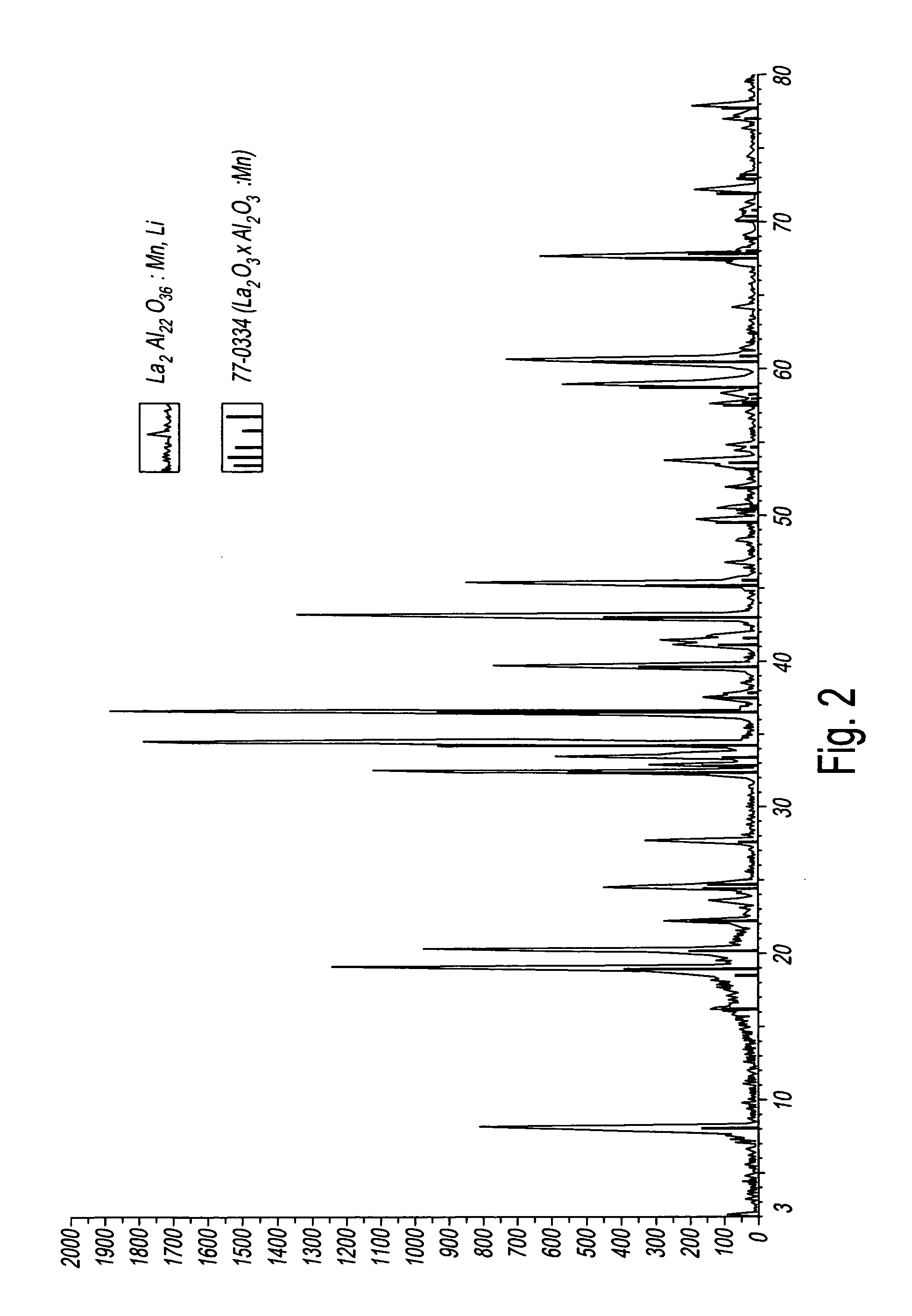

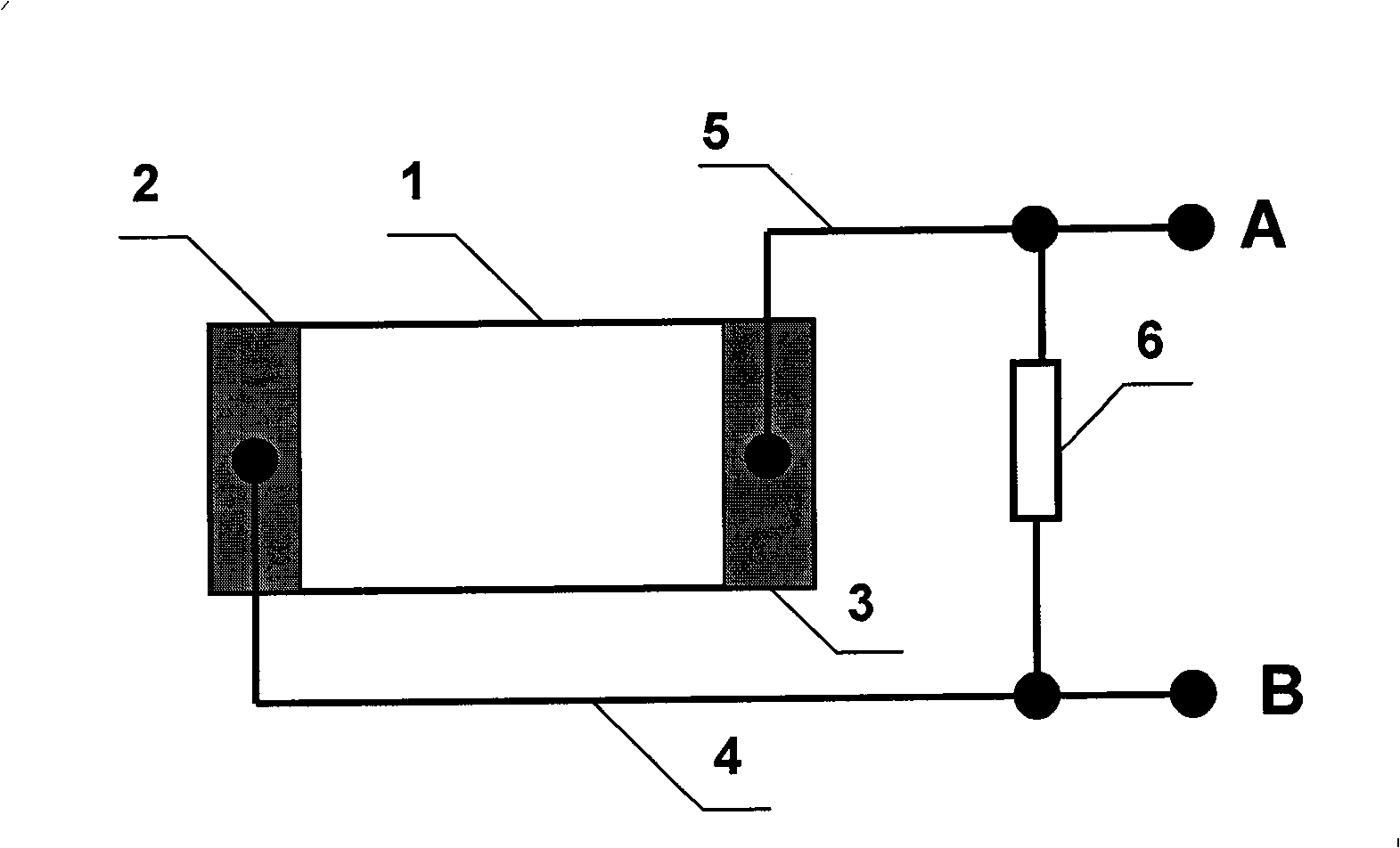

Photodetector

The invention provides a light detector, comprising a light sensor, a first electrode and a second electrode which are connected with the light sensor, and a first electrode lead and a second electrode lead; the ends of the first electrode lead and the second electrode lead are respectively connected with the first electrode and the second electrode and the other ends thereof are used as output terminals; light response material of the light sensor is strontium lanthanum aluminate single wafer, strontium lanthanum aluminate mono-crystalline film or strontium lanthanum aluminate polycrystalline film; the mono-crystalline film or the polycrystalline film is prepared on a substrate. The light detector of the invention can quickly respond to a laser pulse of ns pulse width under the ultraviolet band, with the width of generated voltage pulse of less than 2 ns and full width of pulse of only a plurality of ns.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

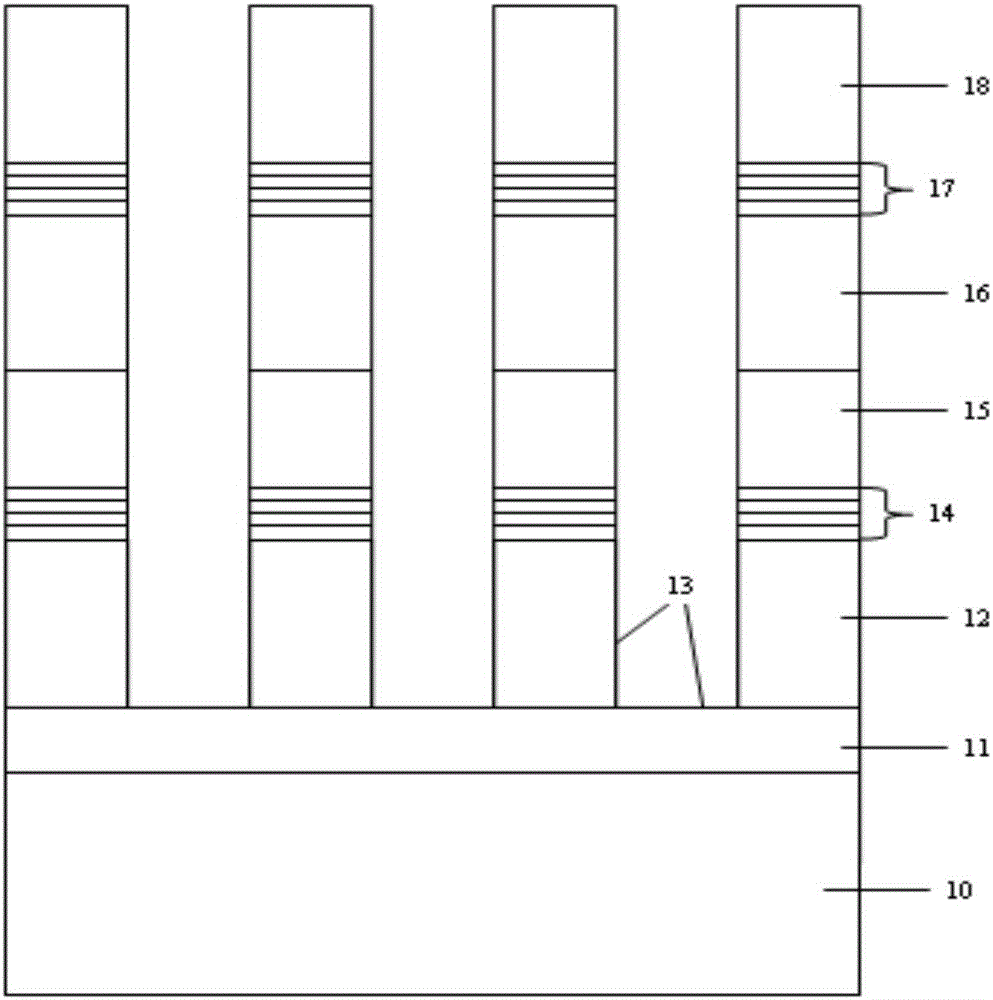

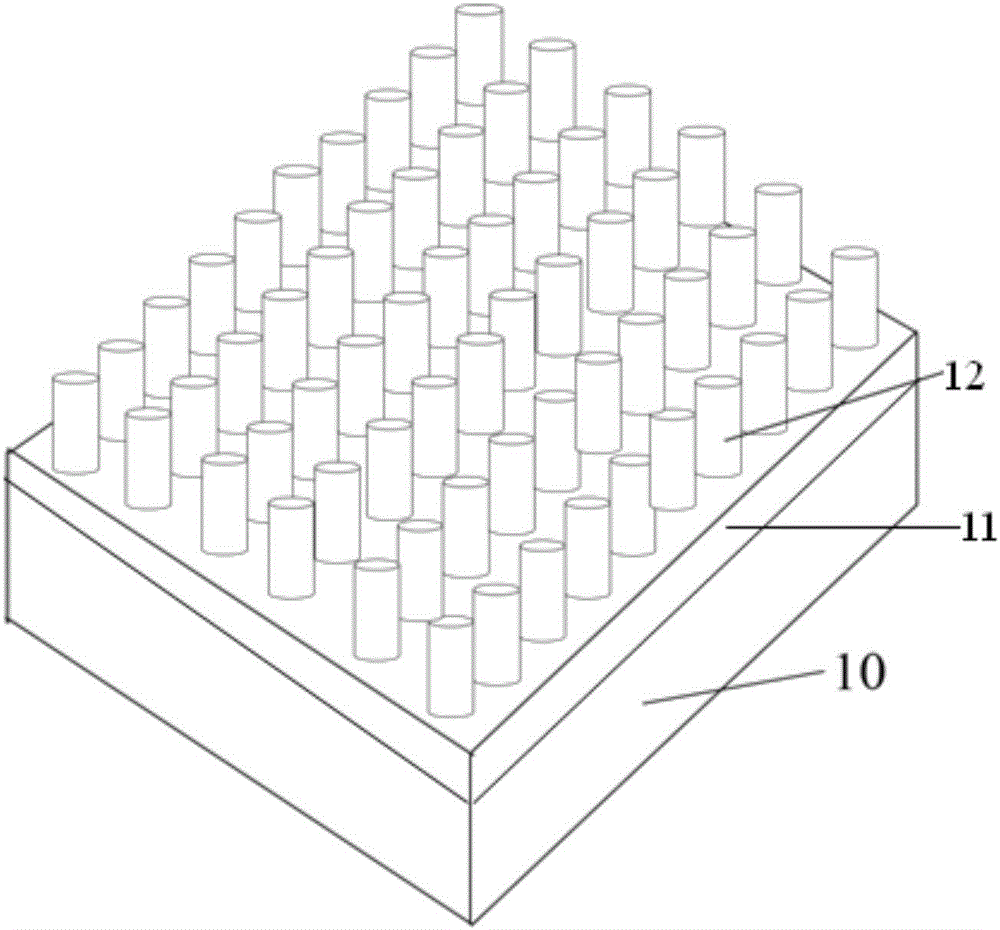

Nano-pillar LED grown on strontium tantalum lanthanum aluminate substrate and preparation method thereof

The invention belongs to the technical field of nano-pillar LED preparation, and discloses a nano-pillar LED grown on a strontium tantalum lanthanum aluminate substrate and a preparation method thereof. The nano-pillar LED grown on a strontium tantalum lanthanum aluminate substrate comprises a strontium tantalum lanthanum aluminate substrate, an AlN nucleation layer grown on the strontium tantalum lanthanum aluminate substrate, a GaN nano-pillar template grown on the AlN nucleation layer, an AlN / GaN super lattice layer grown on the GaN nano-pillar template, a non-doped GaN layer grown on the AlN / GaN super lattice layer, an n-type doped GaN layer grown on the non-doped GaN layer, an InGaN / GaN quantum well grown on the n-type doped GaN layer, and a p-type doped GaN layer grown on the InGaN / GaN quantum well. The substrate material is of low cost. A nano-pillar array prepared is size-controllable and of uniform orientation. The obtained nano-pillar LED has low defect density and excellent electrical and optical properties.

Owner:SOUTH CHINA UNIV OF TECH

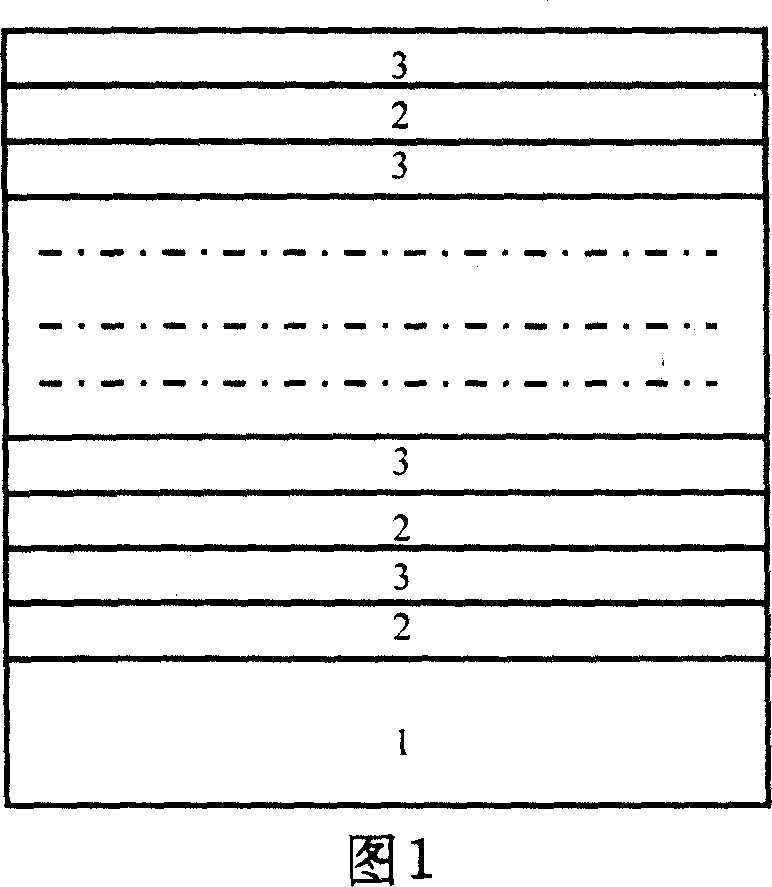

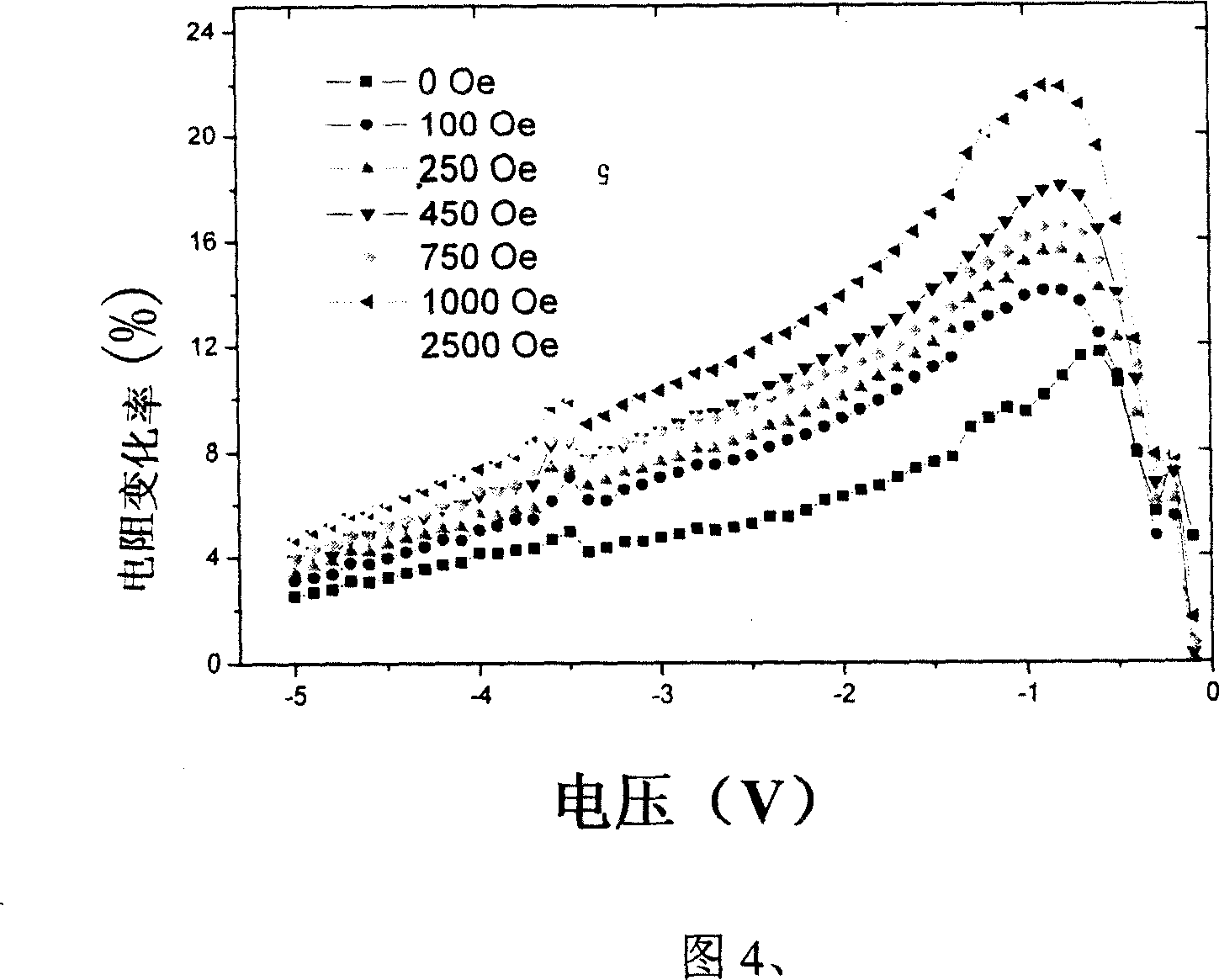

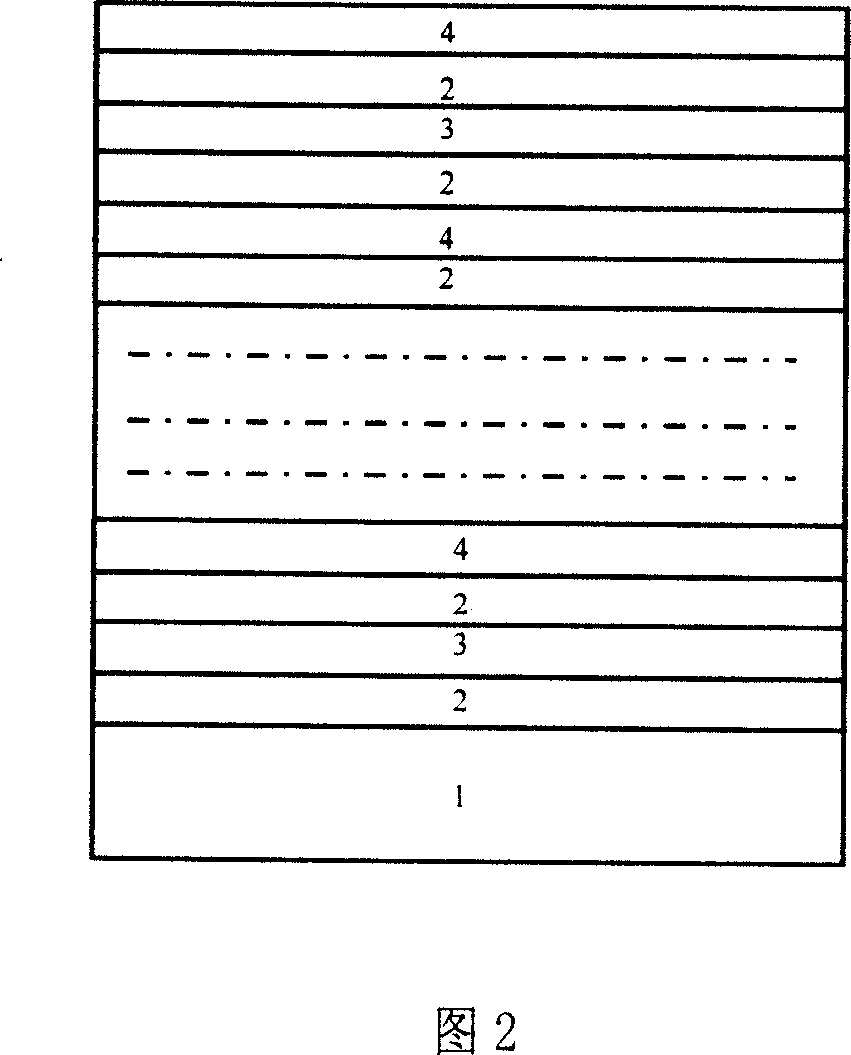

Heterojunction material with magnetoresistance characteristics

InactiveCN1992366AHas giant magnetoresistanceHigh sensitivity in low fieldMagnetic-field-controlled resistorsGalvano-magnetic material selectionHeterojunctionStrontium titanate

This invention relates to a new heterojunction material with magnetoelectric resistance property, including the doped manganese oxide layer generated in the substrate, and the auxiliary layer generated on the said doped manganese oxide layer; the doped manganese oxide layer is generated on the auxiliary layer, and the auxiliary layer is generated on the doped manganese oxide layer, which in turn stacking; preparing the two materials heterojunction magnetoelectric resistance material. Also, the doped manganese oxides can periodically and alternately stack with the three materials of strontium titanate and lanthanum aluminum, or strontium titanate and barium titanate, or barium titanate and lanthanum aluminate, to prepare the multilayer membrane of the three materials and the magnetoelectric resistance heterojunction material of superlattice structure, in which the doped manganese oxide layers thickness being 0.8nm~5mum, the auxiliary layer thickness being 0.8nm~5mum. The said heterojunction material has low-field high sensitivity magnetoelectric resistance property, and 30% greater magnetoelectric resistance changing rate even at room temperature and it has very wide applications in the magnet recording, the magnetic header and the sensors.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

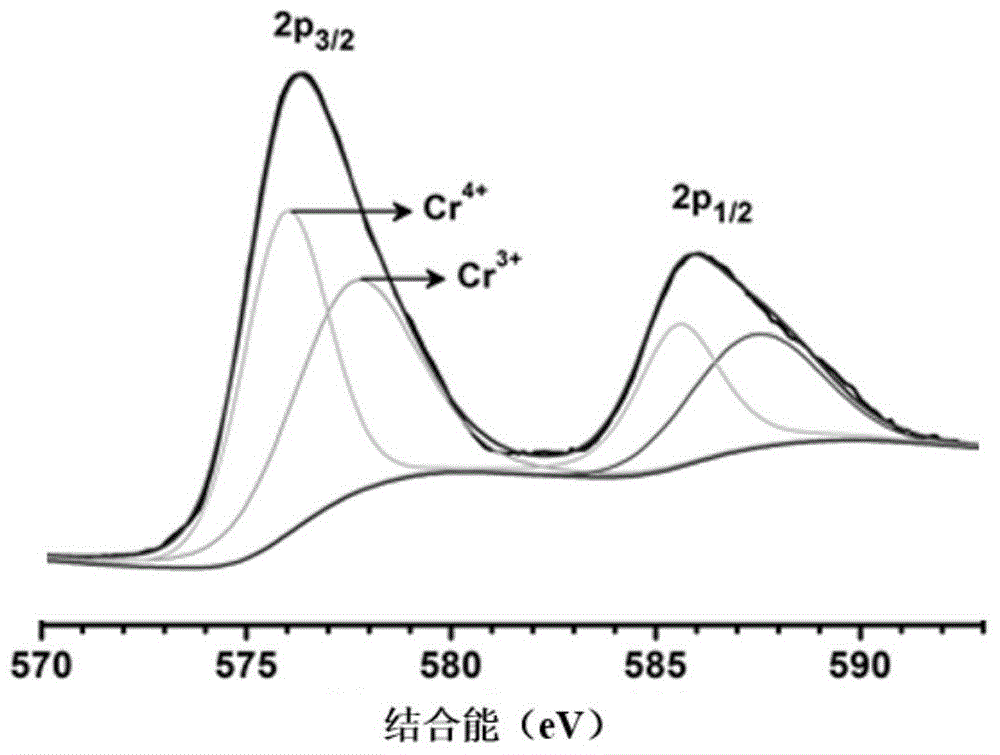

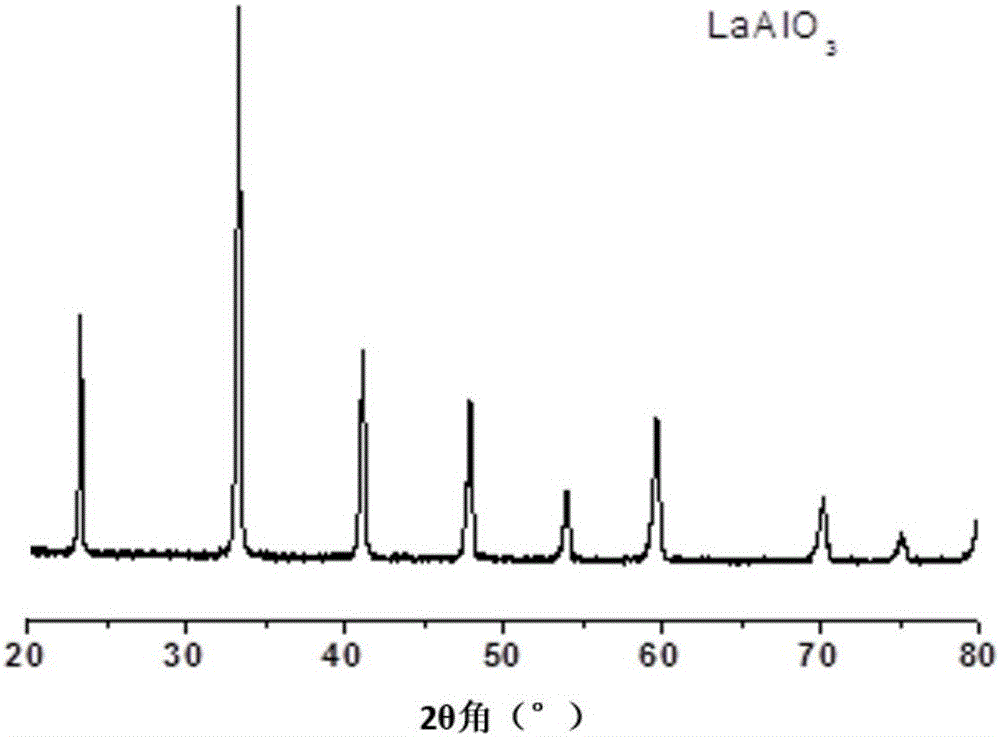

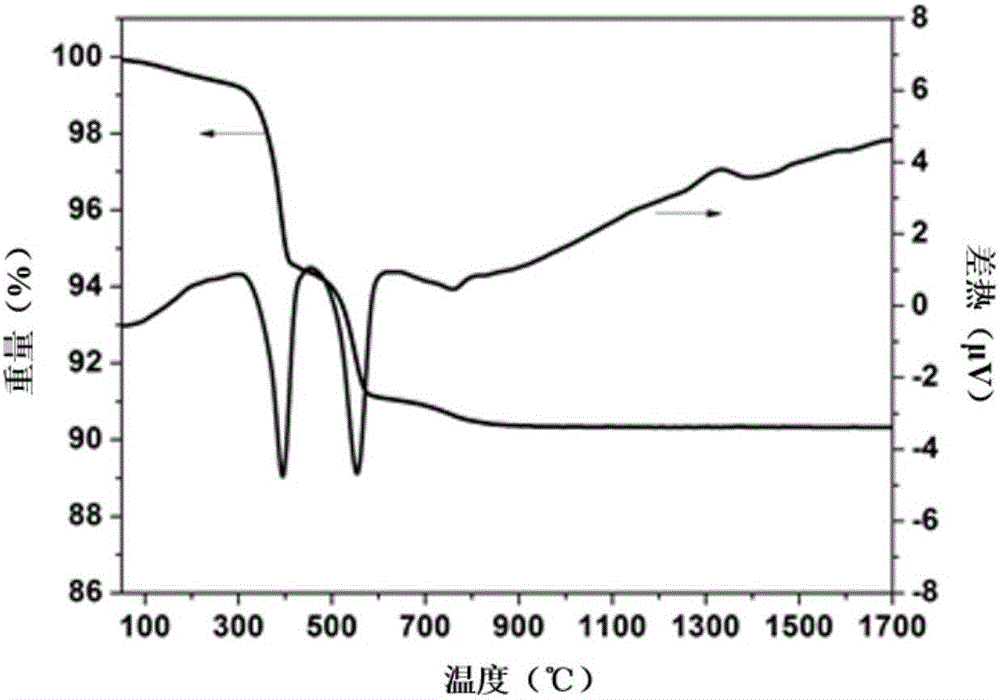

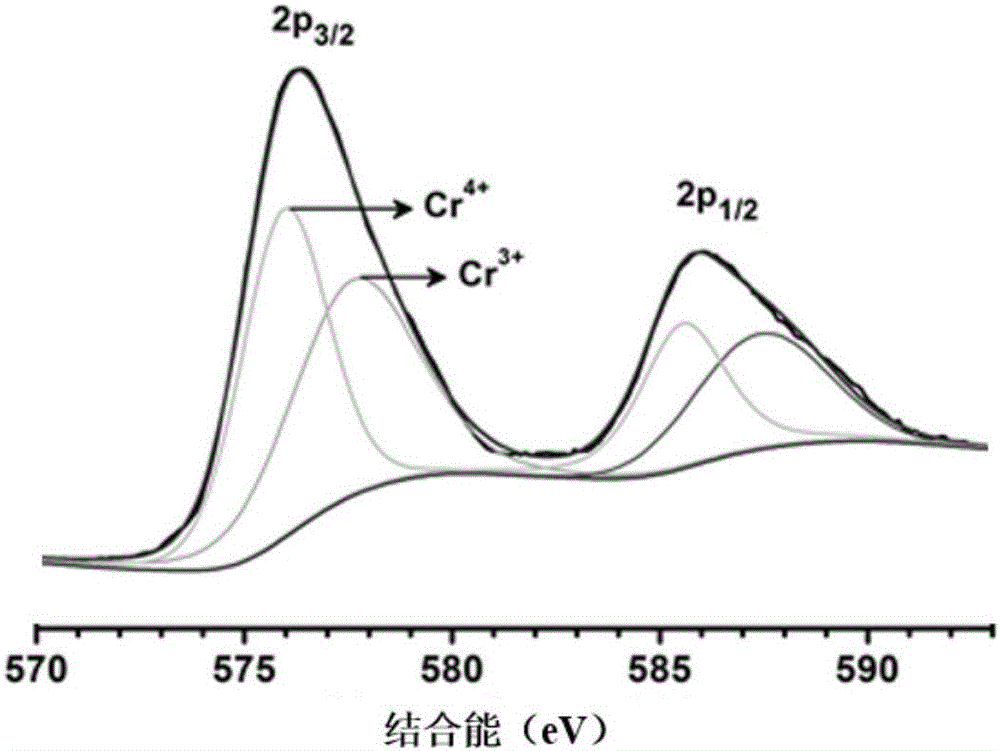

High-emissivity infrared energy-saving material and preparation method thereof

The invention belongs to the technical field of infrared energy conservation, and relates to a high-emissivity infrared energy-saving material and a preparation method thereof. The high-emissivity infrared energy-saving material takes lanthanum aluminate with a perovskite structure as a main phase, and raw materials of the high-emissivity infrared energy-saving material comprise lanthanum oxide, aluminum oxide, a doping agent I and a doping agent II, which are used for preparing the lanthanum aluminate main phase; wherein the doping agent I is calcium oxide, and the doping agent II is chromiumoxide; 0.1-0.2 mol of calcium ions are doped at the lanthanum site per unit mol, and 0.1-0.2 mol of chromium ions are doped at the aluminum site per unit mol; the raw materials of the high-emissivityinfrared energy-saving material also comprise zirconium oxide; wherein the zirconium oxide and calcium oxide are subjected to a solid-phase reaction to generate second main-phase calcium zirconate, generation of a low-melting-phase (CaLa) Al3O7 is inhibited or reduced through the solid-phase reaction, and zirconium ions subjected to the solid-phase reaction with calcium ions in calcium oxide areprovided by zirconium oxide. The material has the characteristics of high emissivity, high temperature resistance, high stability and high compatibility.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

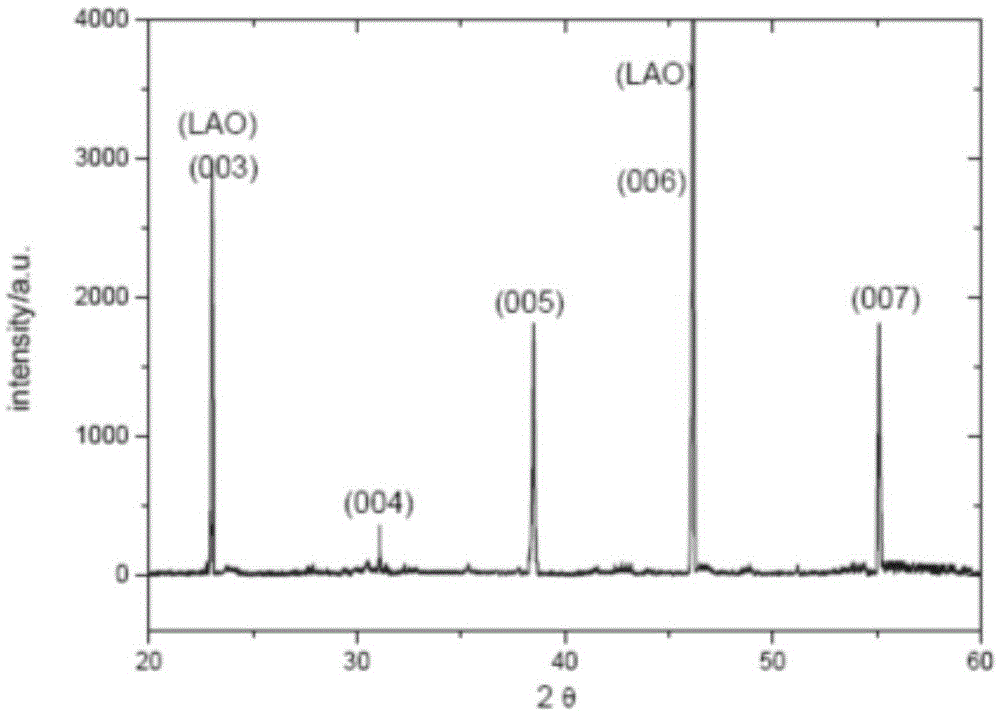

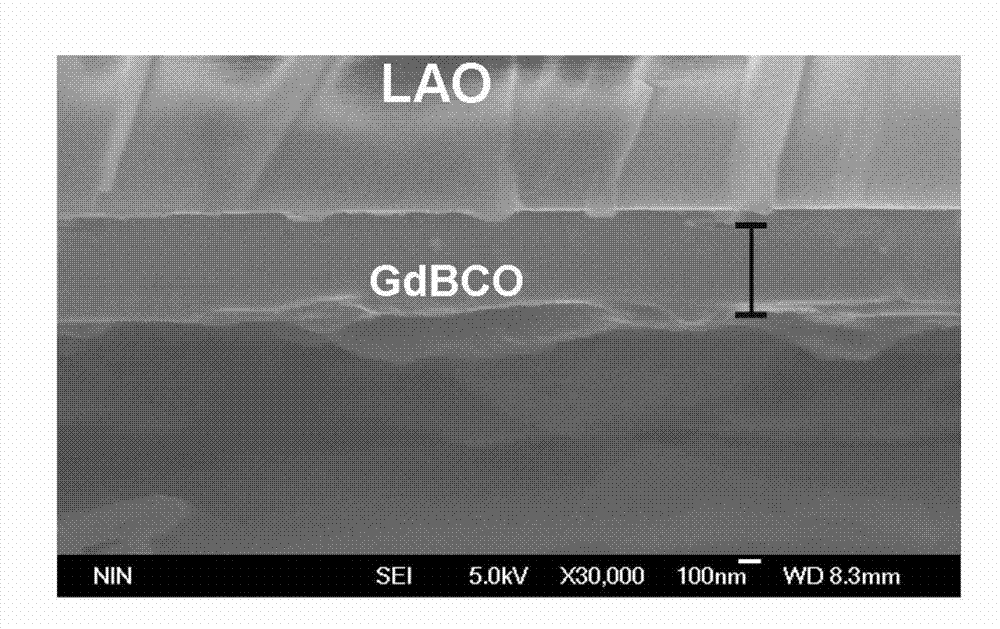

Growing method of Y<1-x>RE<x>BCO superconducting layer of coated conductor through magnetron sputtering method

InactiveCN105525267AOvercome the thickness effectIncrease growth rateSuperconductors/hyperconductorsVacuum evaporation coatingFilm coatingFilm-coated tablet

The invention provides a growing method of a Y<1-x>RE<x>BCO superconducting layer of a coated conductor and particularly relates to a method for preparing the Y<1-x>RE<x>BCO superconducting layer on a lanthanum aluminum oxide (LAO) substrate through a magnetron sputtering method. The thickness effect of a YBCO superconducting layer is overcome effectively, and the superconducting current-carrying capability is improved. Firstly, a Y<1-x>RE<x>BCO magnetron sputtering target is prepared by partially replacing Y with Sm or Gd; then a reaction chamber is vacuumized until the vacuum degree is smaller than or equal to 5*10<-4> Pa, and the LAO substrate is heated to 600-700 DEG C; after 20-30 minutes, the chamber is filled with argon and oxygen, air pressure is stabilized at 30-60 Pa, the ratio of the oxygen to the argon is 1:2-1:3, and sputtering is started by taking Y<1-x>RE<x>BCO as the target. After sputtering is completed, the temperature is decreased to 400-450 DEG C, the chamber is filled with oxygen until the air pressure is maintained at 700-750 mbar, and annealing treatment is carried out for 40-80 minutes. After film coating is completed, the temperature is decreased to the room temperature, and the Y<1-x>RE<x>BCO superconducting layer growing on the LAO substrate is obtained. By means of the method, the coated conductor with the thickness of the Y<1-x>RE<x>BCO superconducting layer reaching 3 microns can be produced.

Owner:NANJING UNIV OF POSTS & TELECOMM

Growing method of lanthanum aluminate crystal

ActiveCN101280459AEasy to operateReduce manufacturing costPolycrystalline material growthFrom frozen solutionsFurnace temperatureRefractive index

The invention provides a bridgman growth method for the growth of lanthanum aluminate LaAlO3 crystals, which includes the following steps. (1) The Al2O3 and the La2O3 are taken as the raw materials in which the quantity ratio is in accordance with the chemical composition of LaAlO3, mixed and pressed. (2) The crucible loaded with the raw material briquetting is moved inside a vacuum decline furnace. The temperature is increased to 10-2-10-4Pa through the vacuum pumping. The insert protection gas is charged when the furnace temperature is increased to 1500 to 1700 DEG C, and then the temperature in continuously increased to 2100 to 2300 DEG C. (3) The raw materials and the top of the seed crystals are in melting so that the inoculation growth can be achieved. The temperature gradient of solid-liquid interface for the crystal growth is within a framework of 25 to 85 DEG C / cm, and the crucible decline rate is between 0.2 to 10 mm / h. (4) After the crystal growth is completed, the furnace temperature is reduced to a room temperature with the speed of 30 to 100 DEG C / h. The obtained lanthanum aluminate crystals have excellent crystal properties, low dielectric constant and dielectric loss as well as medium refractive index.

Owner:苏州晶生新材料有限公司

Stable green fluorescence powder and plasma displaying panel using the same

The invention relates to a kind of lanthanum aluminate phosphor of alkaline manganese metal halide activation which is used for a plasma display panel (PDP) with green emission, and its mixture preparing. The phosphor has following formula: Ln (2-x-y) B22O36: Mnx.Ay, in which: Ln is selected from: La, Y, Gd, Tb, and their combinations of lanthanide metal, in which, La: 0.57 <= La <= 1. 782, and Y: 0 <= Y <= 0.19, and Gd: 0.198 <= Gd <= 0.95, and Tb: 0 <= Tb <= 0.19. A is selected from Li, Na, K, and their combinations. B is selected from Al and the combination of Al and Ga, in which, 0.01 <= x <= 0.1, and 0.01 <= y <= 0.1. When the phosphors are excited by the radiation of 147nm and 173nm of different composition of xenon gas mixture, the phosphors has energy band emission in the green region, and it reachs the peak at 515nm.

Owner:PANASONIC CORP

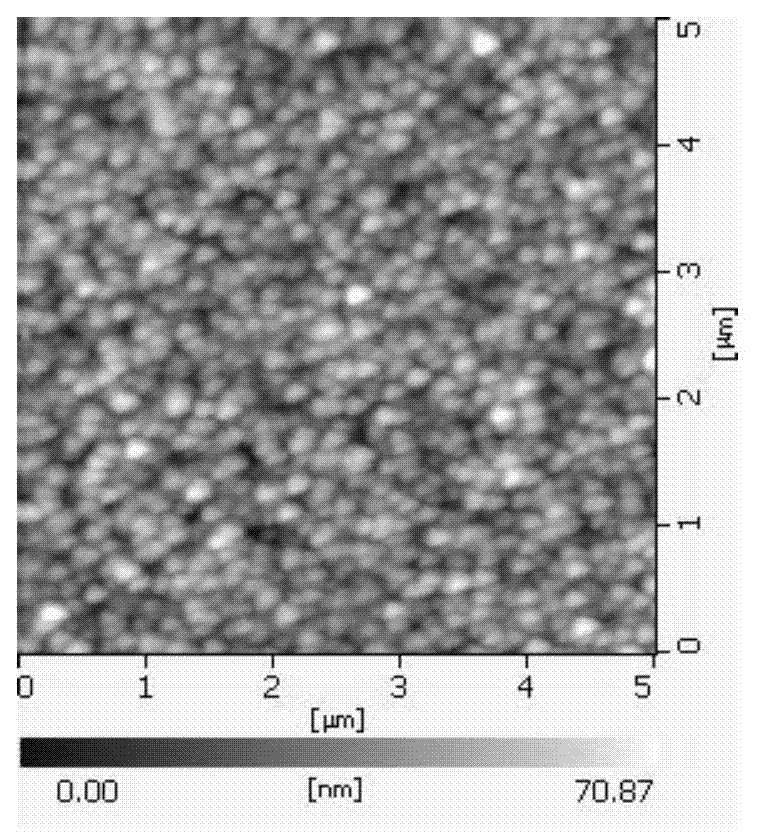

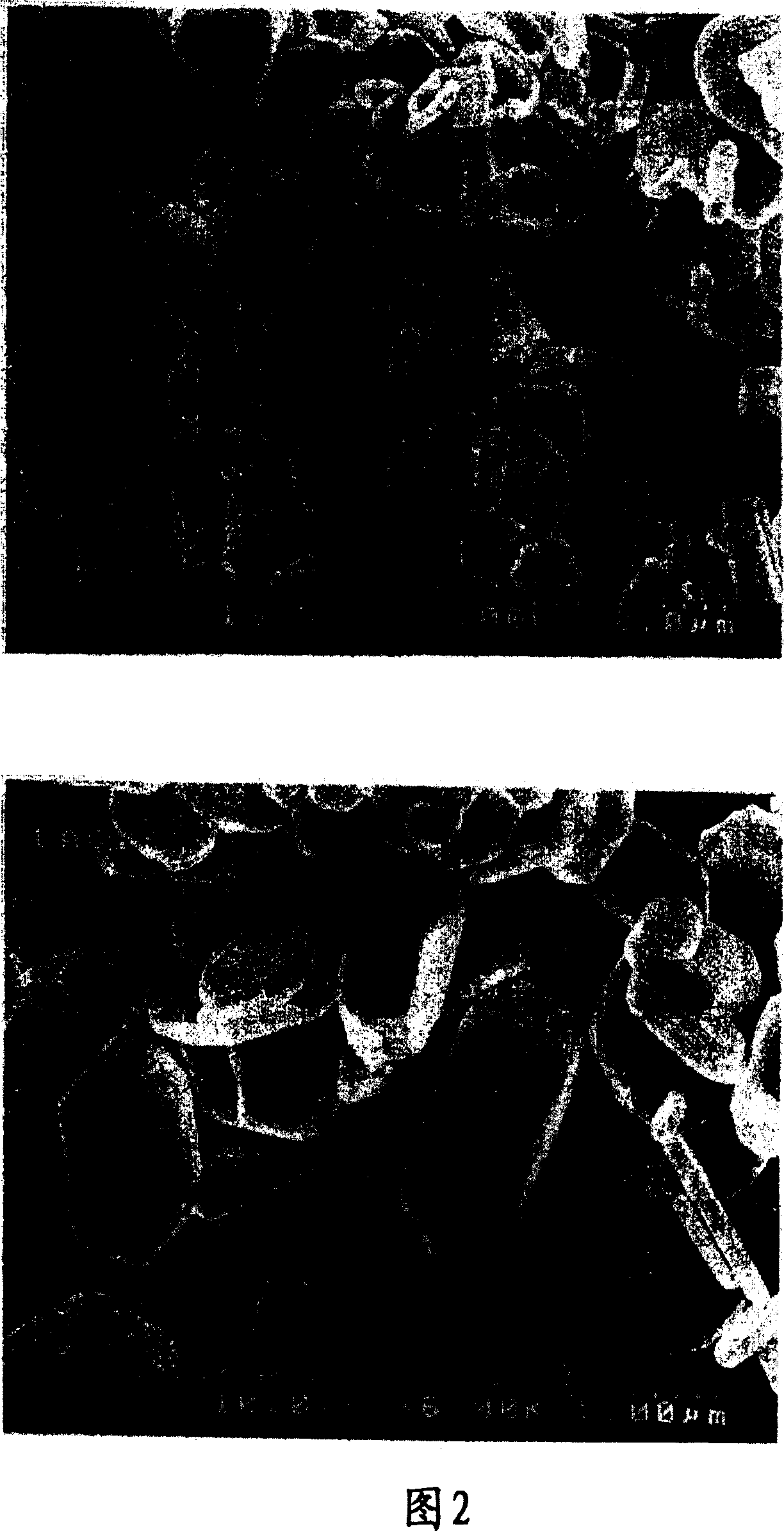

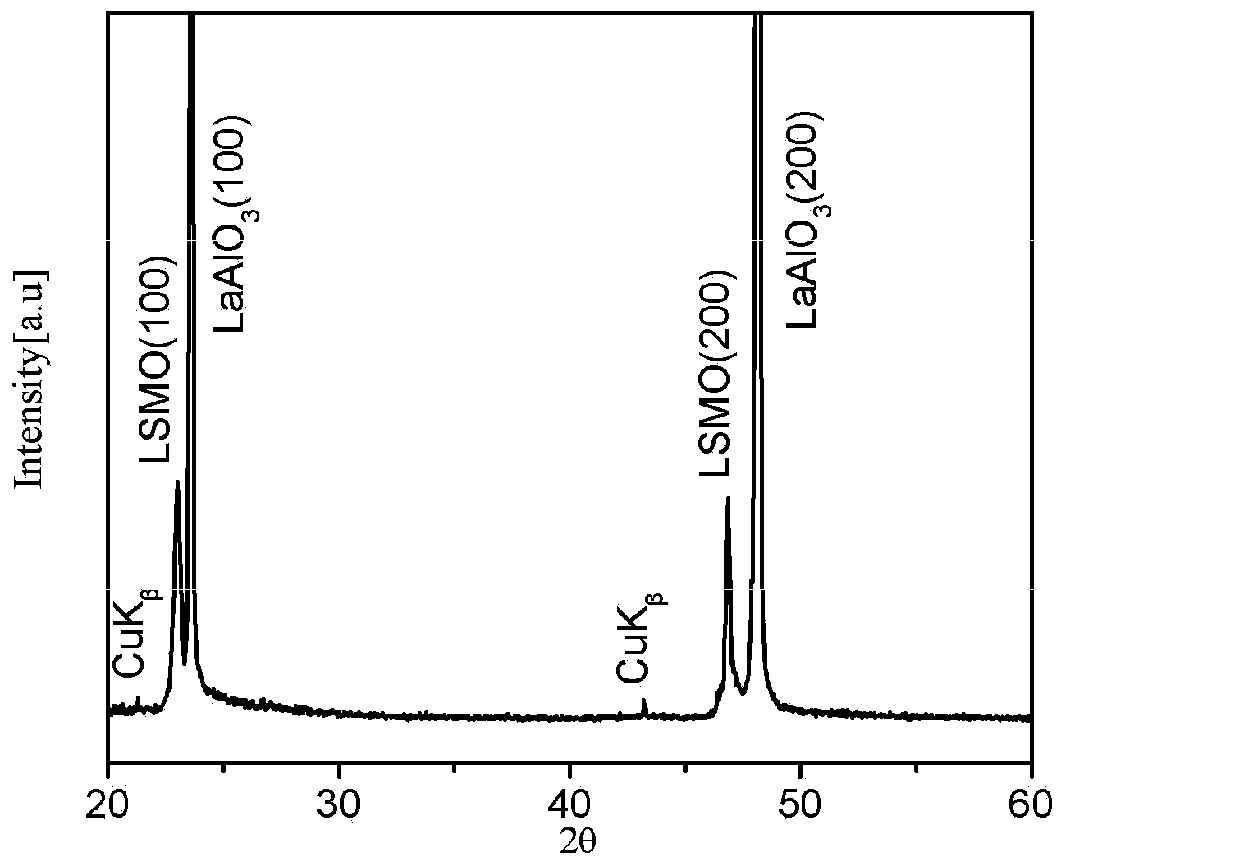

Preparation method of high temperature superconducting coated conductor La0.7Sr0.3MnO3 buffer layer thin film

ActiveCN103515026ADecompose fullyAvoid formingCable/conductor manufactureElectrical conductorThermal insulation

The invention discloses a preparation method of a high temperature superconducting coated conductor La0.7Sr0.3MnO3 buffer layer thin film. The preparation method mainly comprises the steps of a, lanthanum nitrate, strontium nitrate and manganese nitrate are dissolved in N, N-dimethyl formamide to form an anhydrous solution, wherein the number ratio of lanthanum ions, strontium ions and manganese ions is 7:3:10; b, polyvinylpyrrolidone K30 is added into the anhydrous solution of step a to form colloid; c, the colloid prepared by step b is coated on a lanthanum aluminum oxide substrate, and then drying in an infrared drying box is carried out; and d, a substrate plate which is dried by step c is placed in a tube type furnace, undergoes thermal insulation at the temperature of 160 to 220 DEG C, is slowly heated to the temperature of 500 to 540 DEG C for thermal insulation, and finally undergoes annealing at the temperature of 830 to 870 DEG C. According to the method, a good LSMO thin film with a smooth surface can extends and grows on the lanthanum aluminum oxide (LaAlO3) substrate; and the method has the advantages of low preparation cost and less environment pollution, and is suitable for mass production.

Owner:四川中创登峰科技有限公司

Propylene selective oxidation catalyst and preparation method thereof

ActiveCN104646012AOrganic compound preparationOxygen compounds preparation by hydrocarbon oxidationActive componentActive phase

The invention relates to a multi-metal oxide catalyst which contains following elements: molybdenum, bismuth, iron, nickel, cobalt and copper. The catalyst is represented as following general formula (I): Mo<a'>Bi<b'>Fe<c'>Ni<d'>Co<e'>Cu<f>Si<h>AB<j>O<y>. The catalyst also contains a magnesium lanthanum aluminate oxide. The catalyst is used in a selective oxidation reaction of olefin. The active components, the molybdenum and the like, are not liable to loss due to sublimation and an active phase is not liable to cause phase transformation. The catalyst is high in reaction activity and selectivity and is long in service life.

Owner:PETROCHINA CO LTD

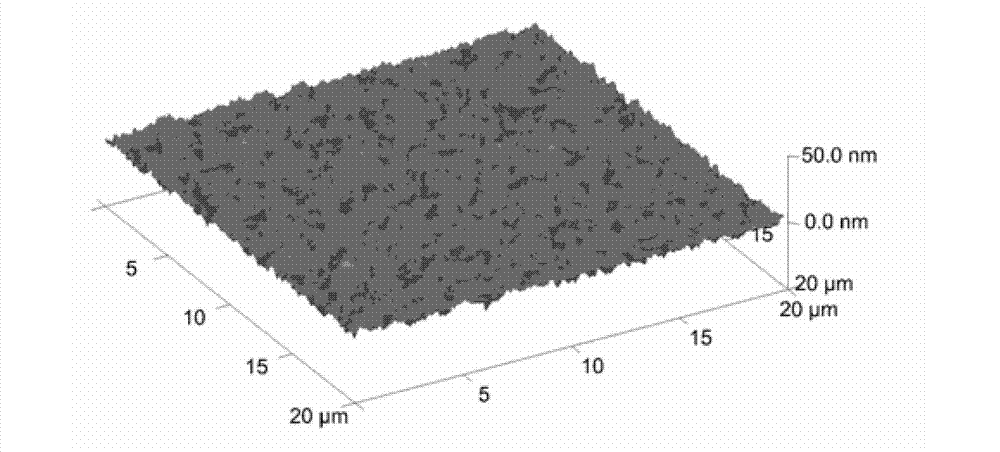

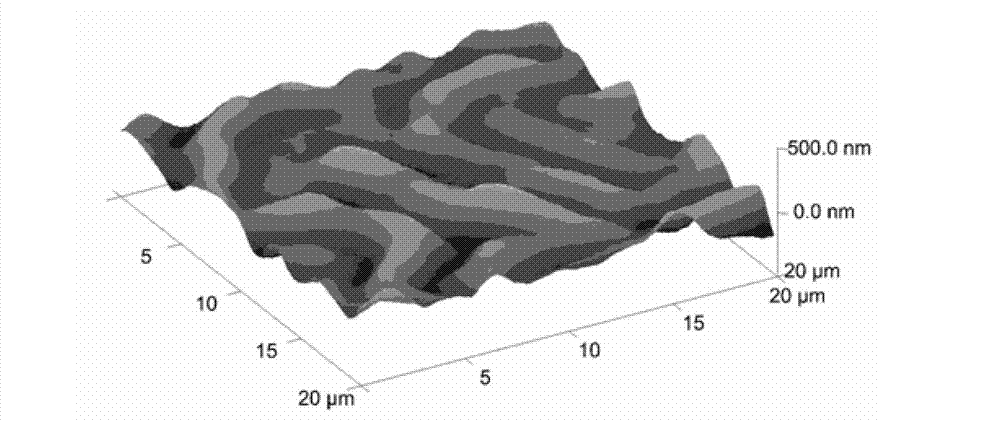

Preparation method of gadolinium-barium-copper-oxygen compact film

The invention discloses a preparation method of a gadolinium-barium-copper-oxygen compact film. The preparation method comprises the following steps of: dissolving gadolinium trifluoroacetate, barium trifluoroacetate and copper trifluoroacetate in methanol to obtain a first trifluoroacetate precursor solution; adding a chelating agent and the first trifluoroacetate precursor solution into an agitator, agitating and reacting to form a complex, and fixing the volume of the complex in a methanol and propanoic acid mixed solution to obtain a second trifluoroacetate precursor solution; uniformly coating the second trifluoroacetate precursor solution on a lanthanum aluminate monocrystalline substrate by adopting a spin-coating method, and then, placing the lanthanum aluminate monocrystalline substrate coated with a coating layer in a thermal decomposition furnace to carry out thermal decomposition to obtain a precursor film with a smooth surface; and placing the precursor film in a tube furnace to carry out crystallization treatment, dropping a temperature in the tube furnace to the temperature of oxygen diffusion treatment after the crystallization treatment to carry out the oxygen diffusion treatment, and cooling along with the furnace to obtain the gadolinium-barium-copper-oxygen compact film. The preparation method is simple in process and reasonable in design, and further, is easy to operate, and the gadolinium-barium-copper-oxygen compact film prepared by adopting the preparation method has the smooth surface, is flat and compact, and is excellent in performance.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Novel composite conductive ceramic and method for producing the same

InactiveCN101429021ACorrosion resistanceHigh temperature resistantStrontium titanium oxideNumerical range

The invention relates to the field of materials, in particular to a conducting ceramic material, and discloses a novel composite conducting ceramic and a method for preparing the same. The constitution formula of the novel composite conducting ceramic is xLaAlO3:(1-x)SrTiO3, wherein x is a mole number of which the numerical range is between 0.001 and 0.015. The method for preparing the composite conducting ceramic comprises the following steps: grinding and mixing a strontium titanate substrate raw material with lanthanum aluminate evenly; tabletting the mixture at a pressure of between 8 and 12 MPa; and baking the mixture at a temperature of between 1,200 and 1,400 DEG C for 4 to 8 hours. The mol ratio of the strontium element in the strontium titanate matrix raw material to the lanthanum aluminate is (1-x) to x, wherein x is between 0.001 and 0.015. The new novel composite conducting ceramic has the performances of electrical conductivity, corrosion resistance, high temperature resistance, high strength, innocuity, thermal conductivity and the like, and is applicable to sensors, electric heating warming, industrial heating, drying and conductive ceramic for shielding electromagnetic waves for construction.

Owner:SHANGHAI NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com