Zirconium oxide resistance memorizer film preparation method and test method of resistance change property of zirconium oxide resistance memorizer film

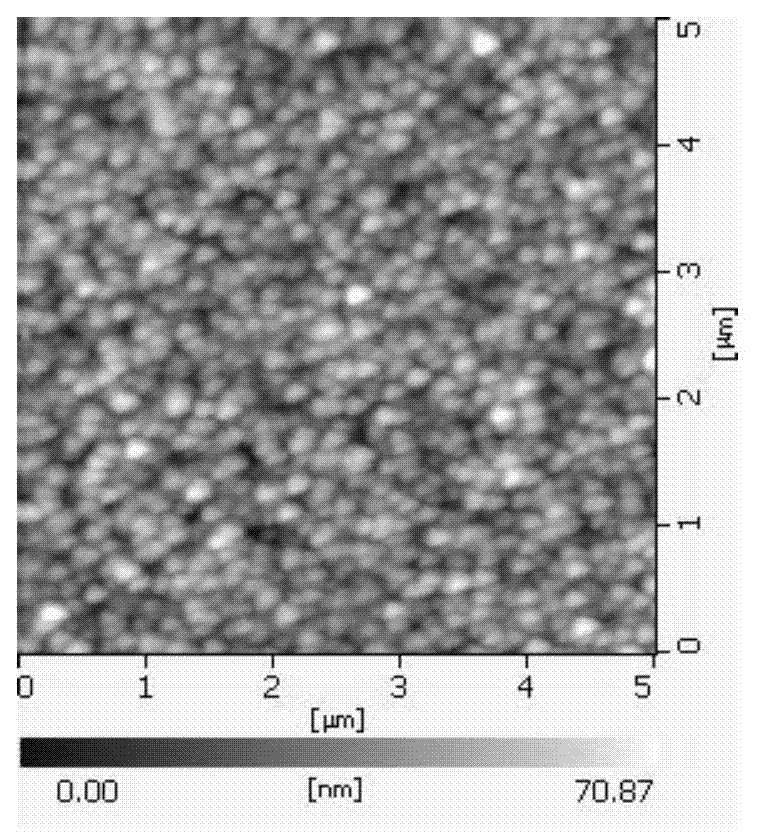

A resistance memory and thin film preparation technology, which is applied in the field of microelectronic materials, can solve the problems of expensive equipment and achieve the effect of low equipment, good film quality, and smooth and dense surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

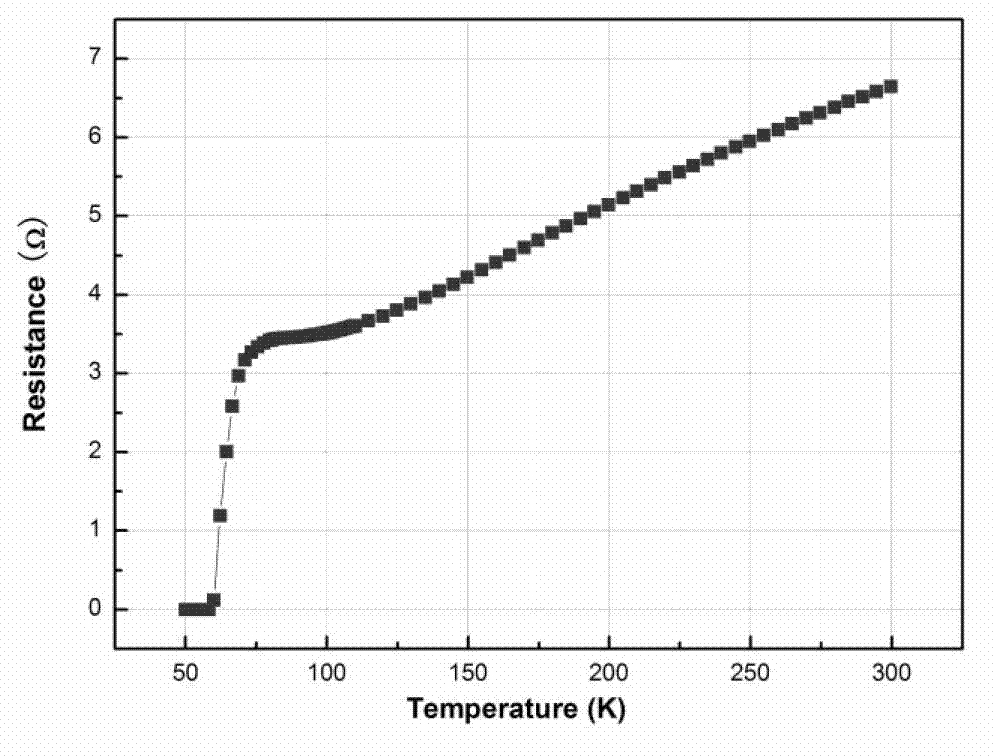

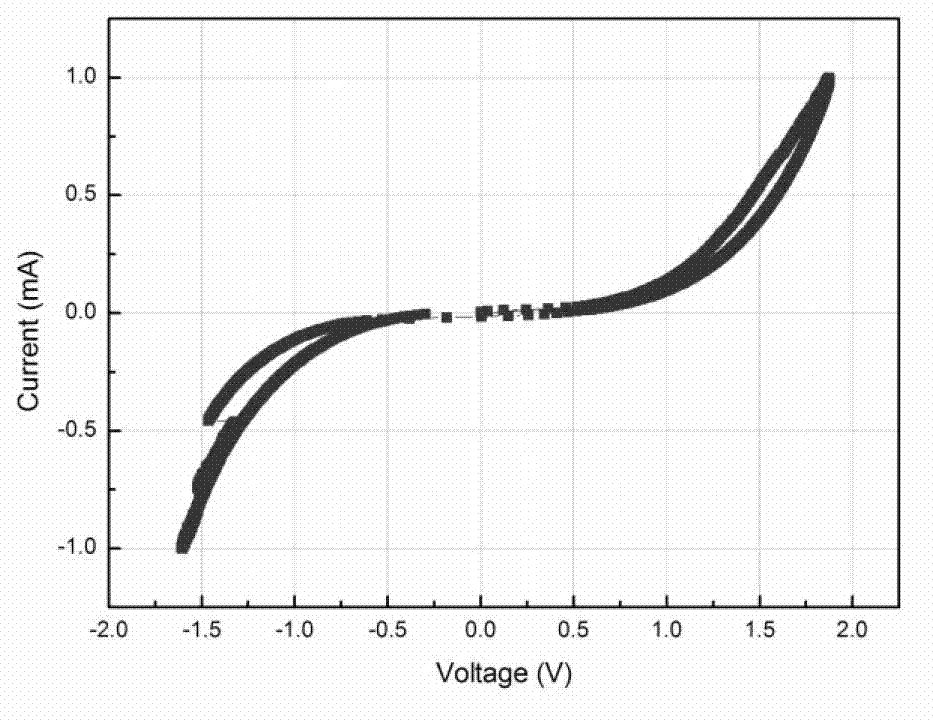

[0033] The method for testing the resistance switching characteristics of the zirconia resistance memory film prepared by the above preparation method, the specific steps are as follows:

[0034] Step 1. Connect the zirconia resistance memory film with four wires. The wires are gold wires with a purity of 99.9%. The wires are connected to the test points with metal indium. Two of the wires are connected to the platinum layer of the top electrode. Independent, the other two leads are connected to the bottom electrode yttrium barium copper oxide superconducting film, which is separated and independent;

[0035] Step 2, fix the zirconia resistance memory film connected with four leads on the sample stage, and then put it into the material comprehensive physical property measuring instrument for the Voltage-Current characteristic curve (Voltage-Current) test, in which the material comprehensive physical property measuring instrument Set it to the electrical performance test, that ...

Embodiment 1

[0039] Step 1, in the glove box that relative humidity is not greater than 40%RH, zirconium n-butoxide, acetylacetone and dehydrated alcohol are mixed with the mol ratio of 1:1:40, then mixed solution is stirred on magnetic stirrer 2h to The solution was clarified, and then it was sealed and aged for 24 hours to obtain the zirconia sol.

[0040] Step 2, at room temperature, use the zirconia sol prepared in step 1 as the precursor solution, use the yttrium barium copper oxide superconducting film of the lanthanum aluminate single crystal substrate as the substrate to pull the zirconia film, and then use the dipping and pulling method A zirconia gel film was prepared on a superconducting electrode by a film pulling machine, and then placed in the air to dry naturally for 10 minutes;

[0041] Step 3, annealing the zirconia gel film prepared in step 2 in an annealing furnace at 500°C, the annealing treatment is carried out in the atmosphere, the annealing time is 20min, after the ...

Embodiment 2

[0049] Step 1, in a glove box with a relative humidity not greater than 40%RH, zirconium n-butoxide, acetylacetone and absolute ethanol are mixed with a molar ratio of 1:1:45, and then the mixed solution is stirred on a magnetic stirrer for 1.5h After the solution is clarified, it is sealed and aged for 20 hours to obtain the zirconia sol.

[0050] Step 2, at room temperature, use the zirconia sol prepared in step 1 as the precursor solution, use the yttrium barium copper oxide superconducting film of the lanthanum aluminate single crystal substrate as the substrate to pull the zirconia film, and then use the dipping and pulling method A zirconia gel film was prepared on a superconducting electrode by a film pulling machine, and then placed in the air to dry naturally for 8 minutes;

[0051] Step 3, annealing the zirconia gel film prepared in step 2 in an annealing furnace at 500°C, the annealing treatment is carried out in the atmosphere, the annealing treatment time is 15min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com