Metal nano particle-doped rare earth lanthanum aluminate light-emitting material and preparation method thereof

A technology of metal nanoparticles and luminescent materials, which is applied to the preparation of rare earth lanthanum aluminate luminescent materials and the field of rare earth lanthanum aluminate luminescent materials doped with metal nanoparticles, can solve the problem of low luminous efficiency and the like, and achieve simple process and luminescent performance. Good and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

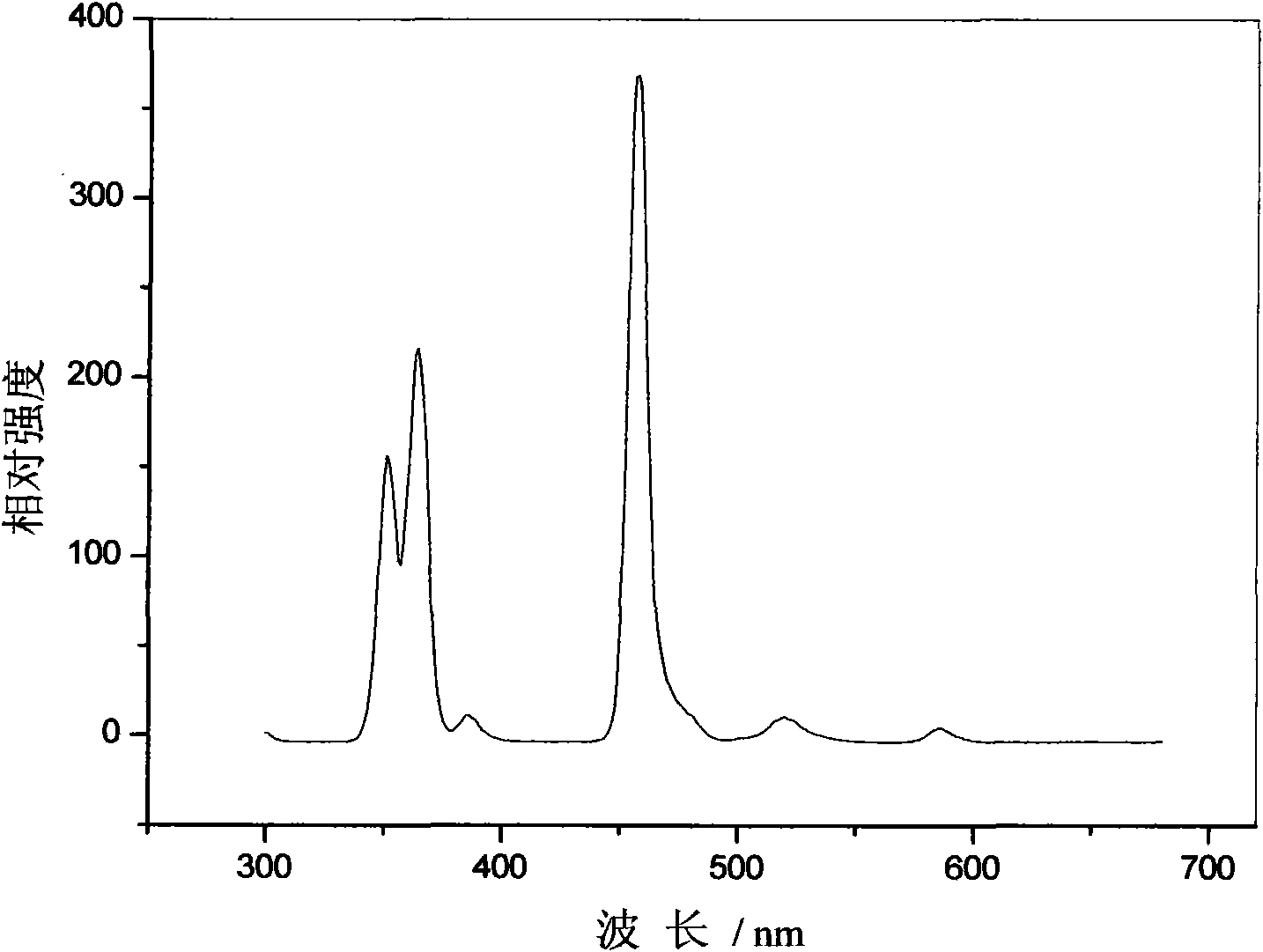

Image

Examples

preparation example Construction

[0016] The present invention also provides a preparation method of rare earth lanthanum aluminate luminescent material doped with metal nanoparticles, comprising the following steps:

[0017] S1. Add the solution of M to the solution dissolved in polyvinylpyrrolidone, treat the surface of M for 12-24h, and then add Al 3+ Stir the solution and surfactant, then slowly add the precipitant under stirring, react in a water bath at 0-100°C and stir for 1.5-5h, let it stand for aging, then filter to remove the precipitate, wash and dry, and dry the The precipitate of Al 2 o 3 @M powder; wherein, @ is coating, M is metal nanoparticles, at least one selected from Ag, Au, Pt, Pd, Cu;

[0018] S2, according to La 1-x AlO 3 :Ln x @M y The stoichiometric ratio of each element in the formula provides the raw material of La, the raw material of Ln and the above-mentioned Al 2 o 3 @M powder, grind and mix evenly, heat up to 1200 ℃ ~ 1500 ℃ for reduction reaction in reducing atmosphere...

Embodiment 1

[0023] La doped with platinum (Pt) nanoparticles prepared by a solid-state method 0.995 A1O 3 :Sm 0.005 @Pt 5×10 -3

[0024] At room temperature, weigh 0.30 g of polyvinylpyrrolidone (PVP) and dissolve it in 6 mL of deionized water, and add a concentration of 1 × 10 -2 mol / L platinum metal nanoparticle solution 4mL, and stirred for 18h, followed by adding 8mL of A1C1 with a concentration of 1mol / L while stirring 3 solution and 5mL isopropanol, stir well and slowly add 40mL NH with a concentration of 2mol / L dropwise 4 HCO 3 Solution, stirred and reacted for 5 hours, then aged for a certain period of time, repeated several times of filtration, washing, and then dried, and the dried precipitate was heat-treated at 500°C for 8 hours to obtain A1 2 o 3 @Pt 5×10 -3 of powder.

[0025] Weigh 1.1388g of La 2 (CO 3 ) 3 , 0.2549g of A1 2 o 3 @Pt 5×10 -3 and 0.0060g of Sm 2 (CO 3 ) 3 , placed in an agate mortar and ground until well mixed, then transferred the powder...

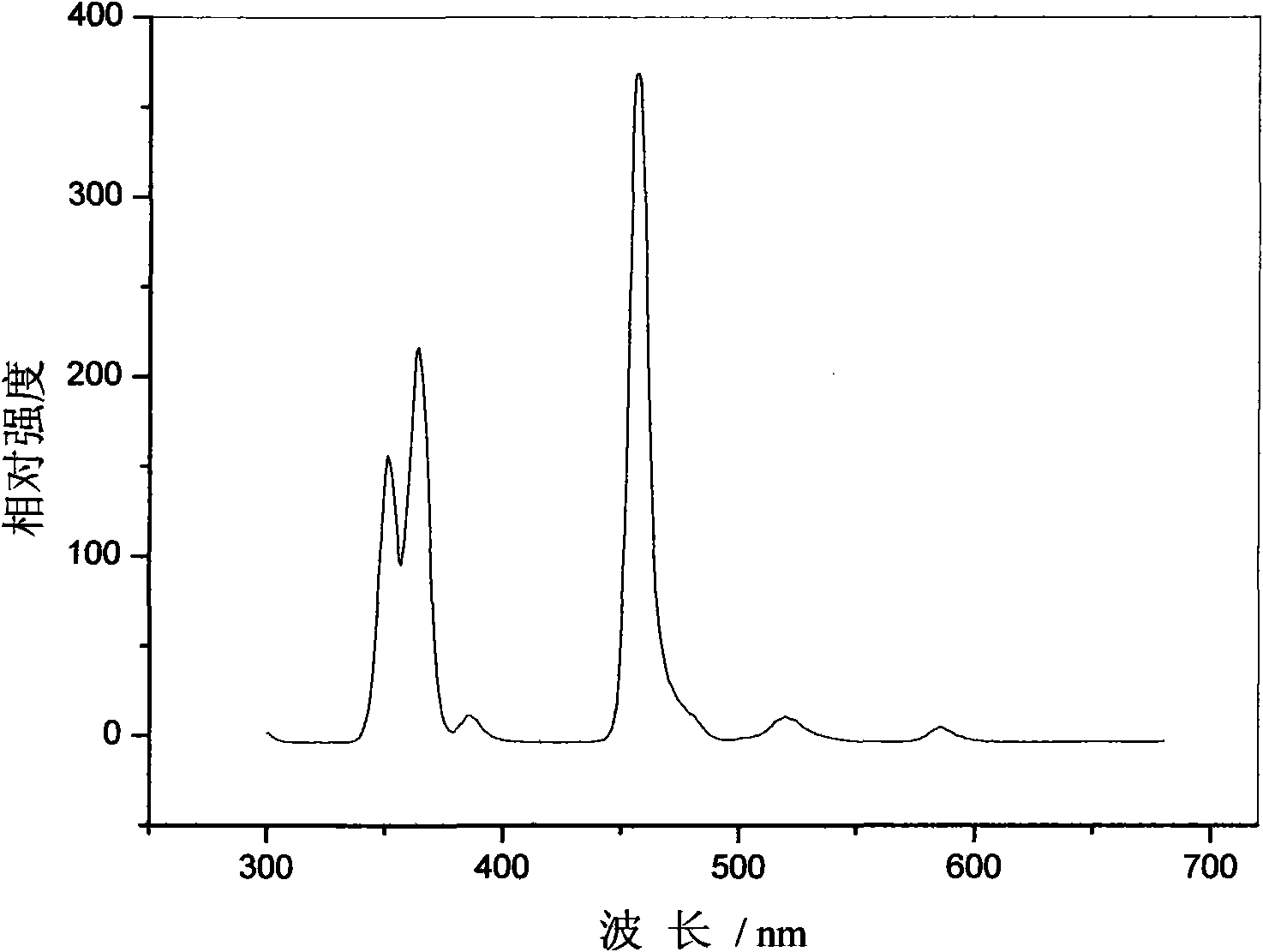

Embodiment 2

[0027] La doped with Au nanoparticles prepared by a solid-state method 0.97 A1O 3 :Tb 0.03 @Au 1×10 -2

[0028] At room temperature, weigh 0.15g of polyvinylpyrrolidone and dissolve it in 4mL of deionized water, dissolve it, and then add it at a concentration of 1×10 -2 mol / L Au metal nanoparticle solution 6mL, stirred for 12h, then added 6mL Al(NO 3 ) 3 solution and 5% (volume percent, V / V, the same below) polyethylene glycol 2000 (PEG2000) aqueous solution 10mL, and then slowly drop 20mL concentration of 2mol / L (NH 4 ) 2 CO 3 solution, stirred and reacted for 4 hours, then aged for a certain period of time, repeated several times of filtration, washing, and then dried, and heat-treated the dried precipitate at 1000°C for 1.5 hours to obtain Al 2 o 3 @Au 1×10 -2 of powder.

[0029] Then weigh 1.1895g of LaCl 3 , 0.2549g Al 2 o 3 @Au 1×10 -2 and 0.0398g of TbCl 3 , put it in an agate mortar and grind until it is evenly mixed, then transfer the powder to a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com