High-emissivity infrared energy-saving material and preparation method thereof

A high-emissivity, energy-saving material technology, applied in the field of infrared energy-saving, can solve the problems of affecting stability, losing the properties of nano-materials, crystal growth, etc., and achieving the effect of high structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

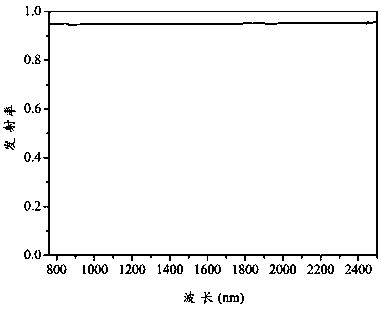

[0022] Embodiment 1: lanthanum oxide, calcium oxide, aluminum oxide, chromium oxide and zirconium oxide are carried out batching and ball milling according to the molar ratio La:Ca:Al:Cr:Zr=0.84:0.2:0.8:0.2:0.04, after drying at 1200 ℃ in an air atmosphere for 120 min, and then the pre-fired powder was ground and pressed and calcined in an air atmosphere at 1600 ℃ for 120 min, and finally a high-emissivity infrared energy-saving material was prepared. The emissivity of the high-emissivity infrared energy-saving material is 0.95.

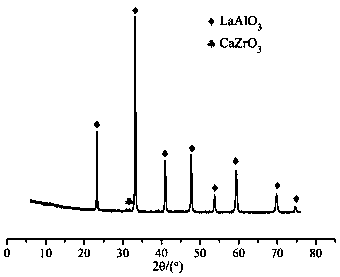

[0023] From figure 1 It can be seen that in this implementation case, the main crystal phase of the high-emissivity infrared energy-saving material is lanthanum aluminate, the secondary crystal phase is calcium zirconate, and no other impurity phases are found, indicating that most of the calcium and chromium ions have been solid-dissolved into the lanthanum aluminate The crystal lattice forms a lanthanum aluminate-based ceramic material co-doped wi...

Embodiment 2

[0025] Embodiment 2: lanthanum oxide, calcium oxide, aluminum oxide, chromium oxide and zirconium oxide are carried out batching and ball milling according to the molar ratio La:Ca:Al:Cr:Zr=0.82:0.2:0.8:0.2:0.02, after drying at 1200 ℃ in the air atmosphere for 120 min, and then the pre-fired powder was ground and pressed and calcined in the air atmosphere at 1600 ℃ for 120 min, and finally a high-emissivity infrared energy-saving material was prepared. The emissivity of the high-emissivity infrared energy-saving material is 0.93.

Embodiment 3

[0026] Embodiment 3: lanthanum oxide, calcium oxide, aluminum oxide, chromium oxide and zirconium oxide are carried out batching and ball milling according to the molar ratio La:Ca:Al:Cr:Zr=0.83:0.2:0.8:0.1:0.03, after drying at 1300 ℃ in an air atmosphere for 60 minutes, and then the pre-fired powder was ground and pressed and calcined in an air atmosphere at 1500 ℃ for 360 minutes, and finally a high-emissivity infrared energy-saving material was prepared. The emissivity of the high-emissivity infrared energy-saving material is 0.91.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com