Nano ceramic composite thin polypropylene multifunction fiber and preparing method

A nano-ceramic, fine-denier polypropylene technology, applied in rayon manufacturing, fiber chemical characteristics, textiles and papermaking, etc., can solve the problems of undiscovered, small cross-section of fine-denier fibers, loss of fiber texture and feel, etc., to improve the finished product. rate, improved conventional performance, enhanced chemical activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

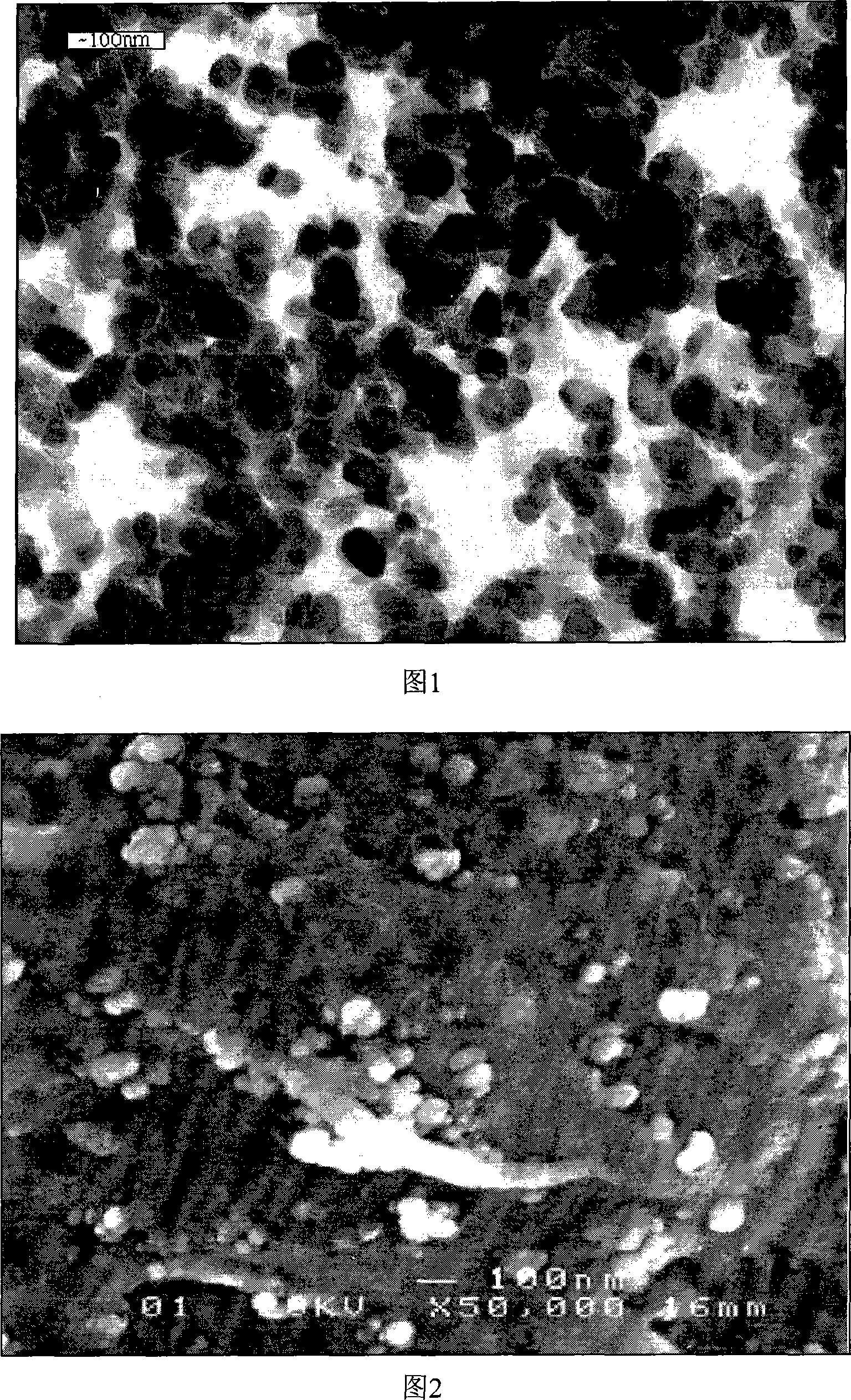

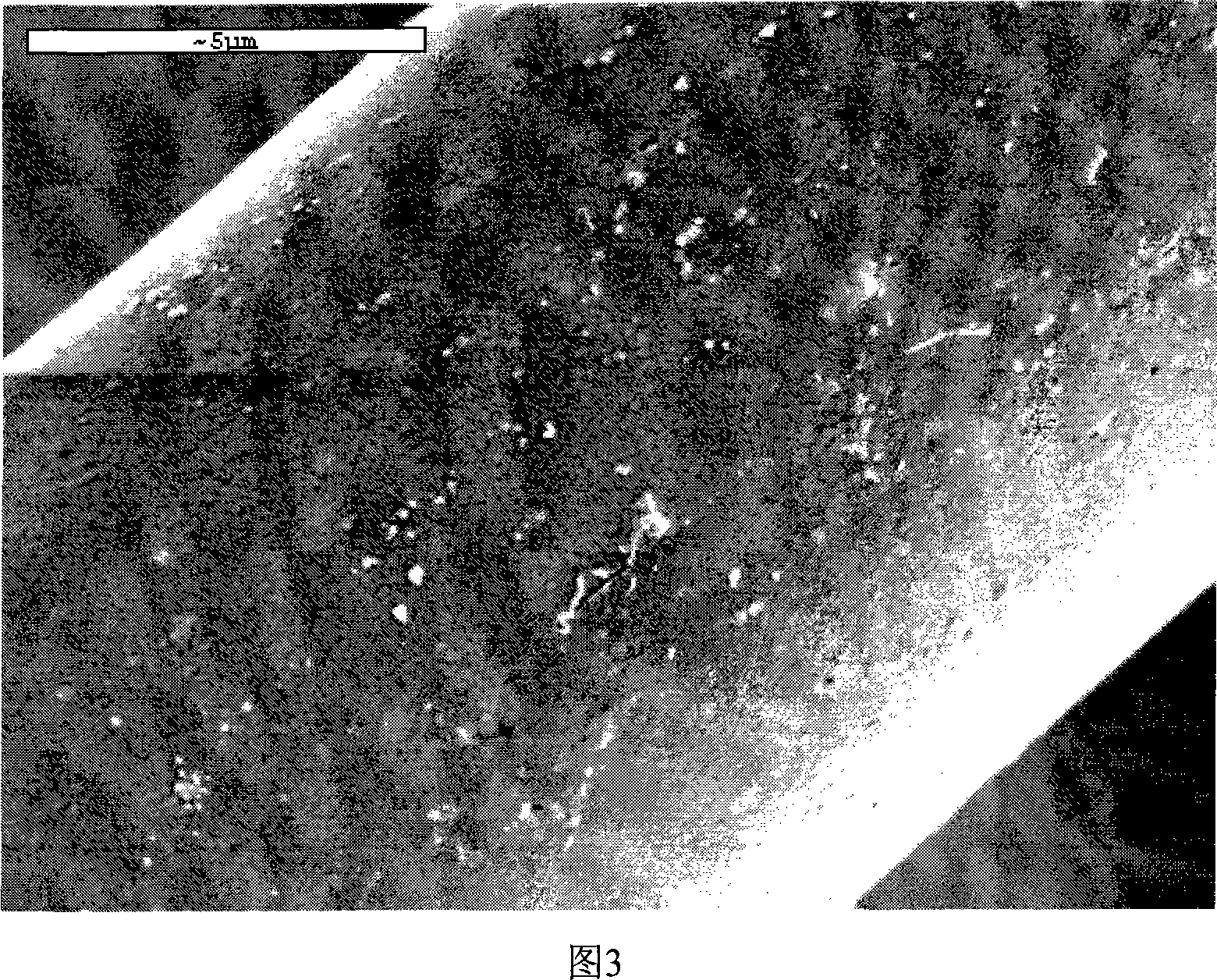

[0051] Nano-ceramic composite fine-denier polypropylene multifunctional fiber, the components contain 260 parts by weight of polypropylene, 30 parts of ZrO 2 and 9 parts polyethylene wax, of which ZrO 2 The particle size of the nano-ceramic powder is 20-80nm, and the melt index of polypropylene is 45g / 10min. First, weigh 30 parts of ZrO 2 Nano-ceramic powder, adding 2wt% potassium oleate sulfonate and water of ceramic powder weight, ball milling 30hr to obtain concentration is the nano-ceramic water dispersion slurry of 30wt%; Add 9 parts of polyethylene wax, 25 parts of powdered Polypropylene and No. 120 solvent oil, the amount of solvent oil and water are respectively 35wt% and 15 times of the weight of the ceramic powder, add the above ceramic slurry at 60-95°C and stir to form a water-oil two-phase mixed system, and then add Ceramic powder weight 2wt% rosin amine, through a chemical reaction, nano-ceramic particles are separated from the water phase and coated with polye...

Embodiment 2

[0053] Nano-ceramic composite fine-denier polypropylene multifunctional fiber, the components contain 270 parts by weight of polypropylene, 10 parts of ZrO 2 , 15 parts of TiO 2 and 12 parts of polyethylene wax, of which ZrO 2 、TiO 2 The particle size of the nano-ceramic powder is 10-60nm, and the melting index of polypropylene is 35g / 10min. Weigh ZrO according to the composition requirements of ceramic powder 2 、TiO 2 Nano-ceramic powder, adding 6wt% sodium cocoa oleate sulfonate and water of ceramic powder weight, ball milling 30hr respectively to obtain concentration is the nano-ceramic water dispersion slurry of 30wt% and 4wt%; Add 3 parts and 9 parts respectively in water Part polyethylene wax, 20 parts and 30 parts of powdered polypropylene and No. 100 solvent naphtha, the consumption of solvent naphtha and water are respectively 30wt% and 80wt%, 4 times and 10 times of ceramic powder weight, through the same as embodiment 1 Reaction, coating treatment process, resp...

Embodiment 3

[0055] Nano-ceramic composite fine-denier polypropylene multifunctional fiber, the weight components are 255 parts of polypropylene, 10 parts of ZrO 2 And 2 parts of ZrC, 2 parts of polyethylene wax, of which ZrO 2 , The particle size of ZrC nano-ceramic powder is 20-60nm, and the melt index of polypropylene is 55g / 10min. Weigh ZrO according to the composition requirements of ceramic powder 2 , ZrC nano-ceramic powder mixed into water, adding 3wt% potassium ethyl oleate sulfonate and water of the ceramic powder weight, ball milling for 36hr to obtain a concentration of 20wt% nano-ceramic water-dispersed slurry; adding 2 parts of polyethylene wax in water and No. 120 solvent naphtha, the consumption of solvent naphtha and water is respectively 35wt% and 10 times of ceramic powder weight, with the same technological process as embodiment 1, through the aqueous phase wet dispersion treatment of ceramic powder and organic coating treatment two Process, made of dry granular ZrO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com